Framework model for measuring dress, cutting dress and fitting finished dress

A framing and tailoring technology, applied in the field of clothing, can solve problems such as the complexity of the measurement process and measurement values, and lack of common standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

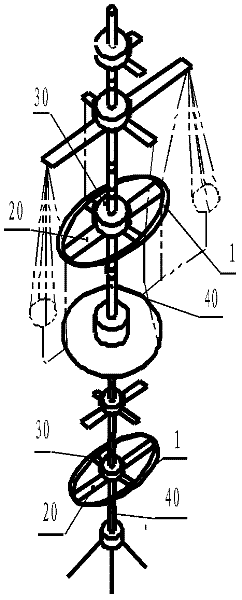

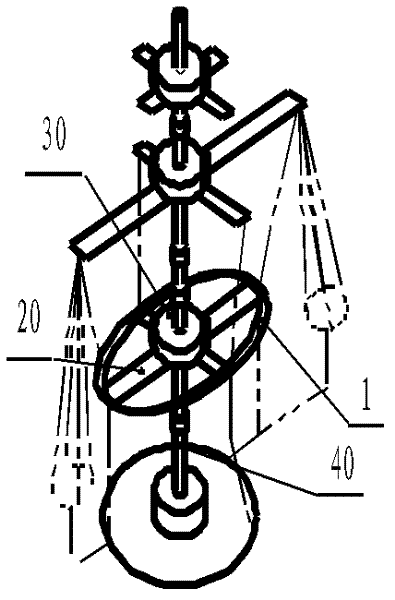

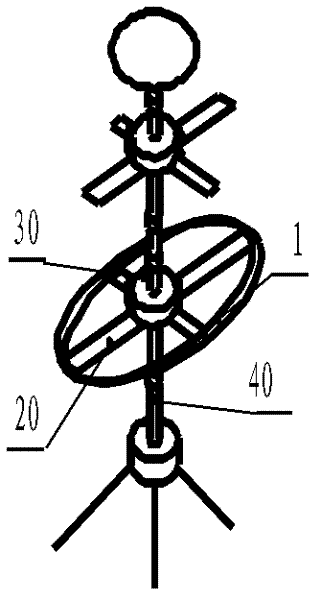

[0029] combine Figure 1 to Figure 8 , a framework mold for measuring, cutting and trying on ready-made garments, comprising an upper garment mold base and a lower garment mold base, the upper garment mold base and the lower garment mold base are combined by several groups of mold base components, the The formwork assembly includes a ruler sheet 1, a wide and thick ruler 20, a fixed seat 30, and a central riser 40. The ruler sheet 1 is connected to the wide and thick ruler 20, and the wide and thick ruler 20 is connected to the fixed seat 30. The fixed seat 30 is connected with the central standpipe 40; the ruler sheet 1 includes a ruler sheet body 2, and the ruler sheet body 2 is made of elastic material, and one end of the ruler sheet body 2 is provided with a head and tail connecting buckle 12, and the other end is provided with a The button hole ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com