Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "Simple cutting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

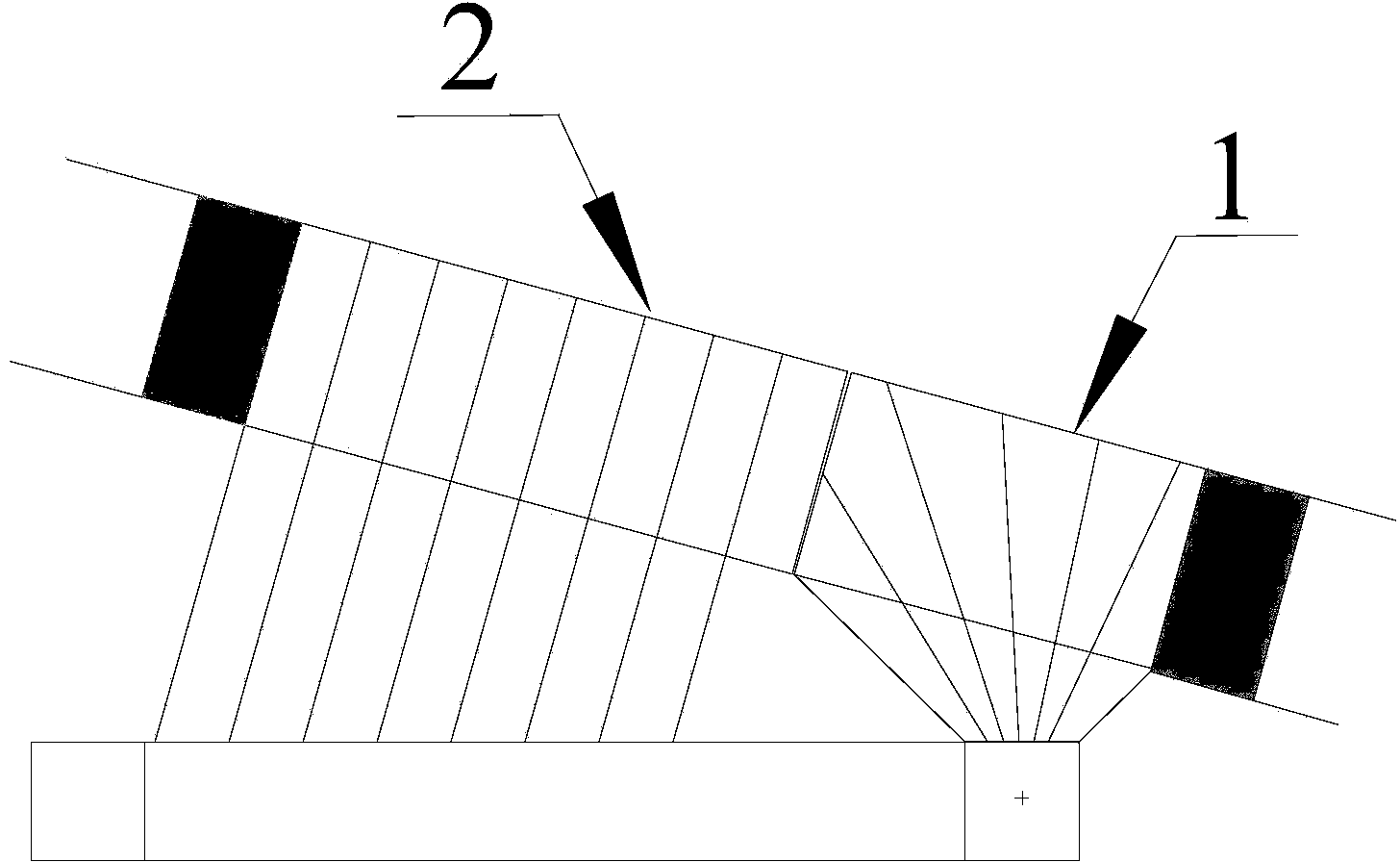

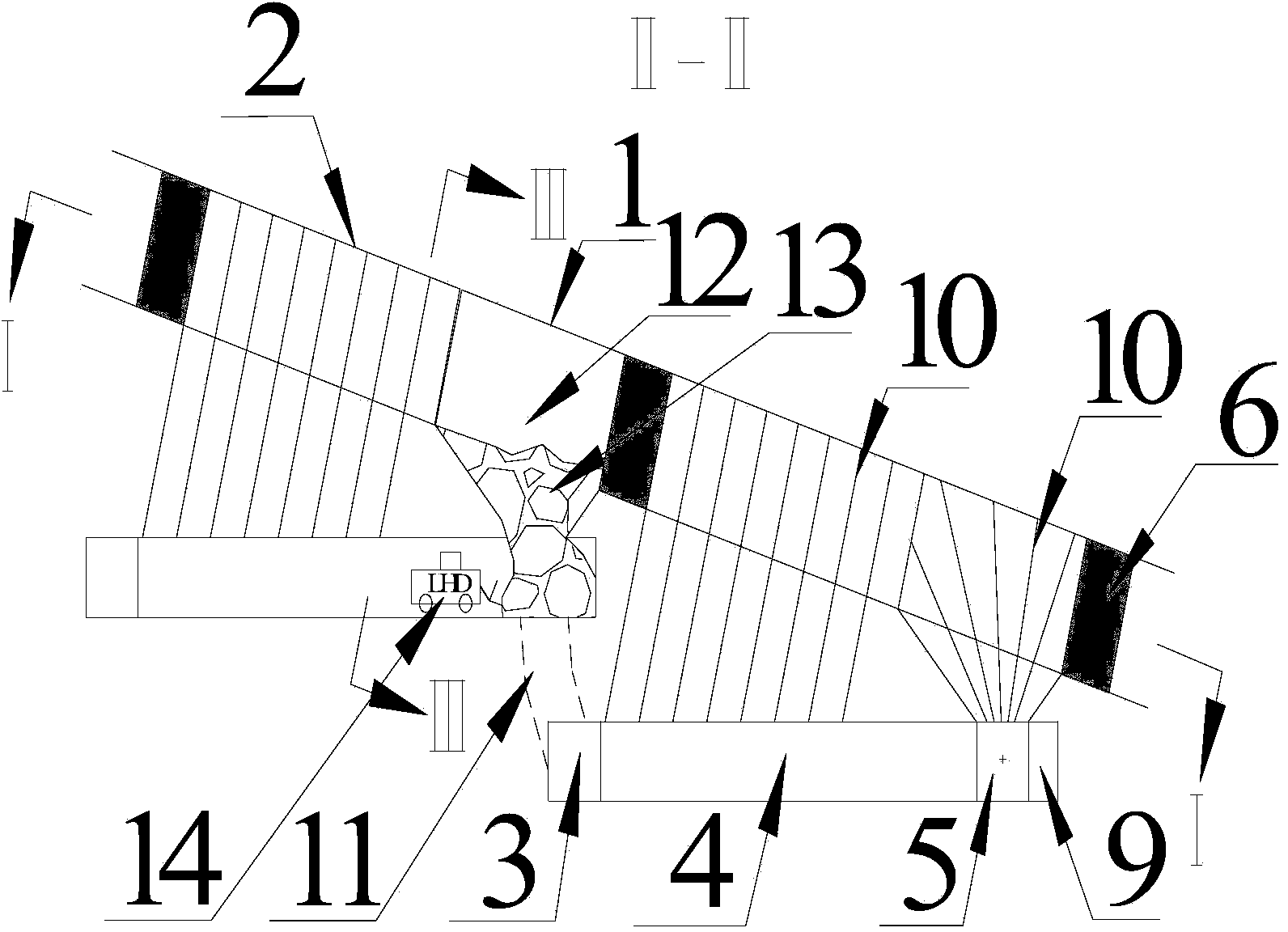

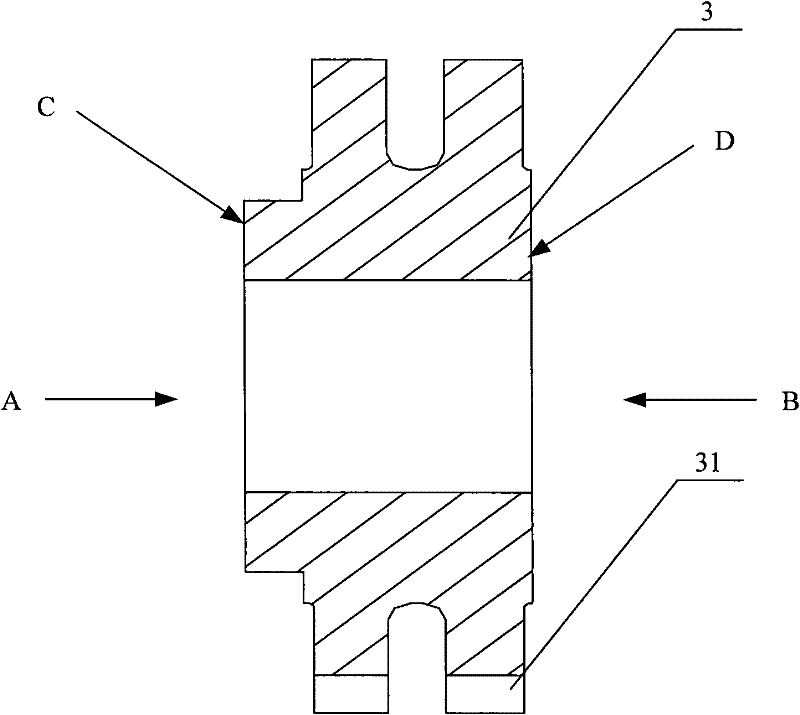

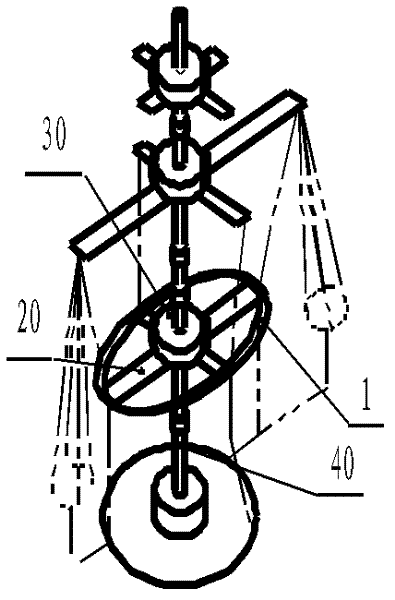

Novel mining method of gently-inclined thin and medium thickness ore bodies

InactiveCN103590831ARealize complementary advantagesJob safetyUnderground miningSurface miningWorkloadStoping

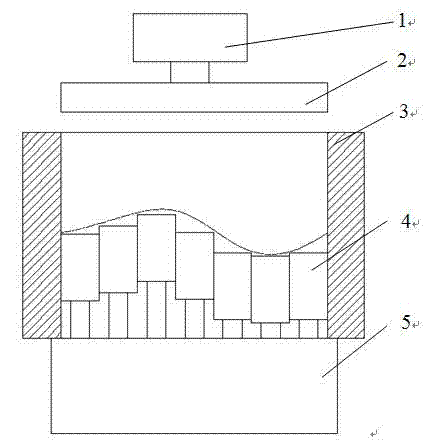

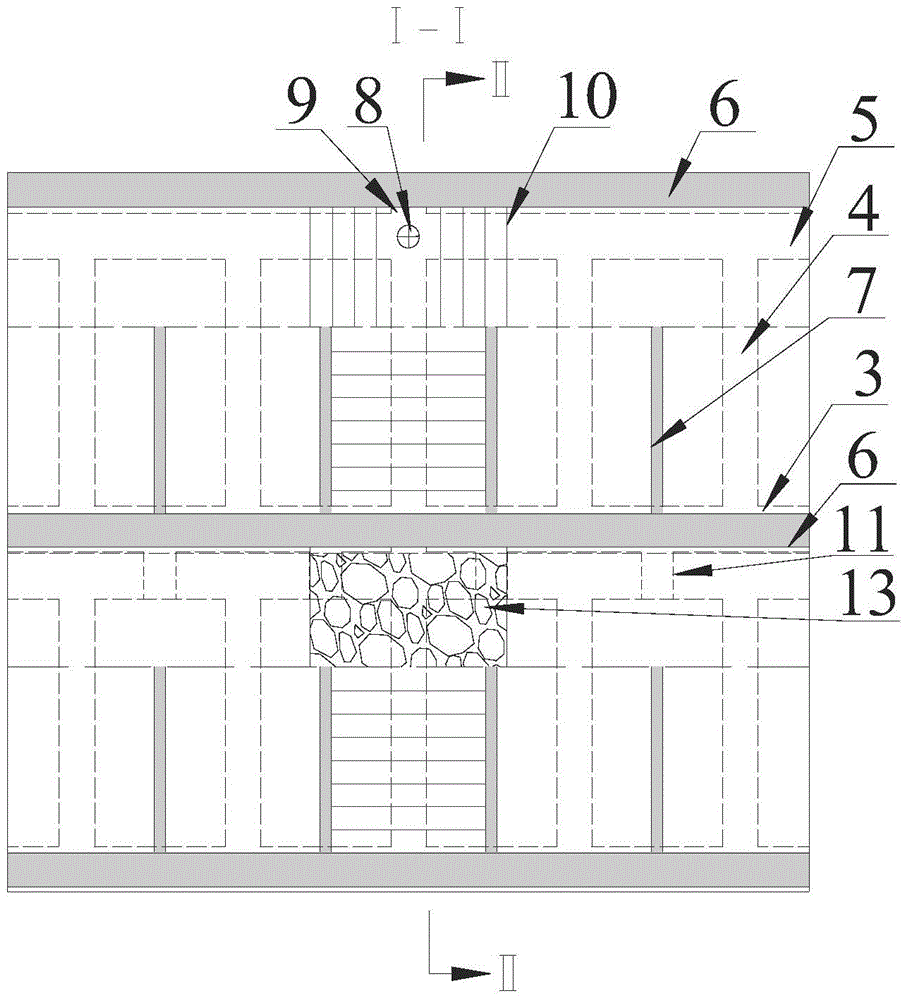

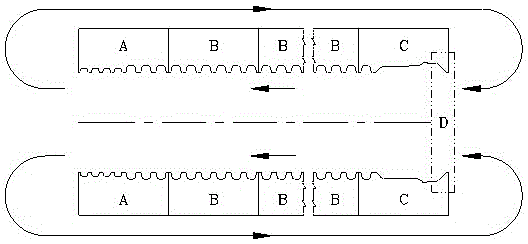

The invention discloses a novel mining method of gently-inclined thin and medium thickness ore bodies. According to the method, ore bodies in one stope are stoped by dividing the stope into two stope areas through steps: firstly, stoping is performed at the stope area (1) by using a pillarless sublevel caving method: the ore bodies are directly caved in single sublevel by using medium-length blastholes; a certain empty area formed after ore removal is used as a free surface for stoping of the stope area (2); then, the stoping is performed at the stope area (2) by using a blasting force carrying mining method; fan-shaped medium-length blastholes are arranged in a manner perpendicular to the ore body tendency, and are filled with powder according to sections, the decking parts are the parts from the lower disc boundaries of the ore bodies to the hole bottoms; the empty area formed during the stoping of the stope area (1) is used as a free surface for blasting row by row; ores in the stope area (2) are thrown in the empty area by using the blasting force. The method integrates the pillarless sublevel caving method and the blast force carrying mining method, so that the supporting difficulty and the workload are reduced, the operation is safer, the mining cost is low, and the labor productivity is high.

Owner:UNIV OF SCI & TECH BEIJING

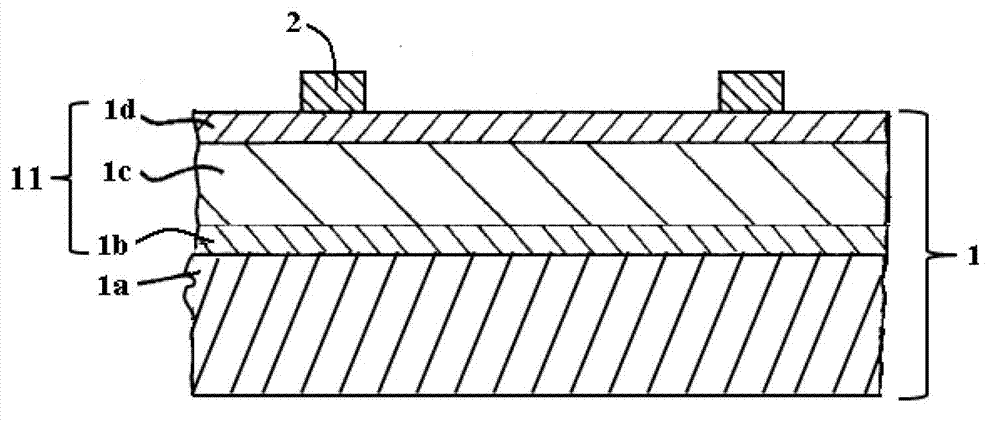

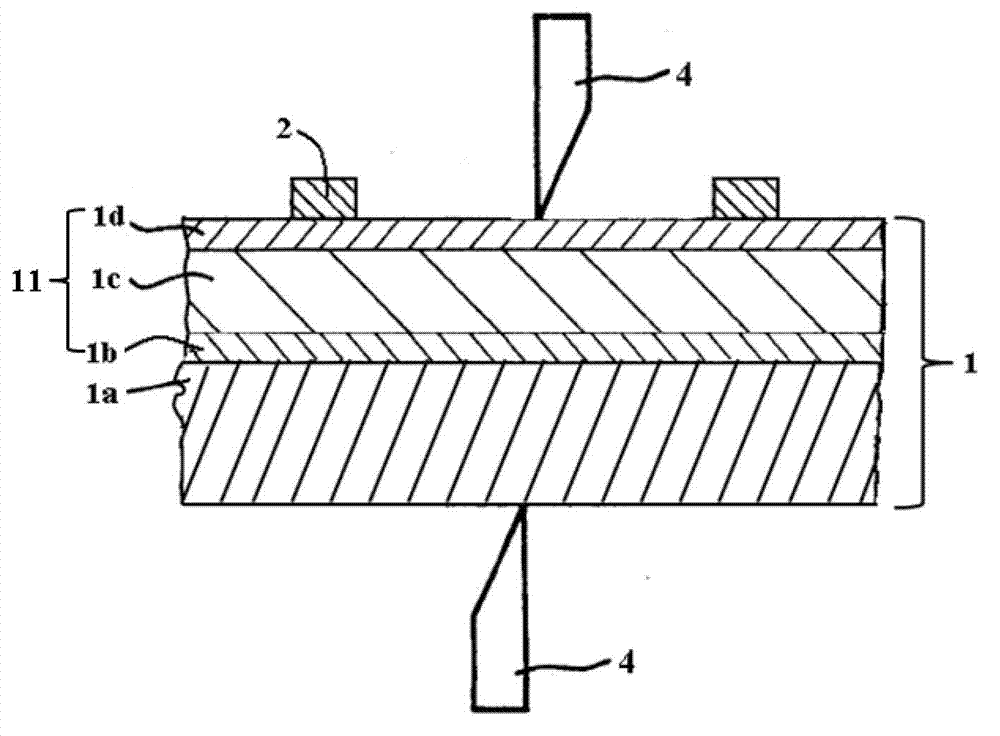

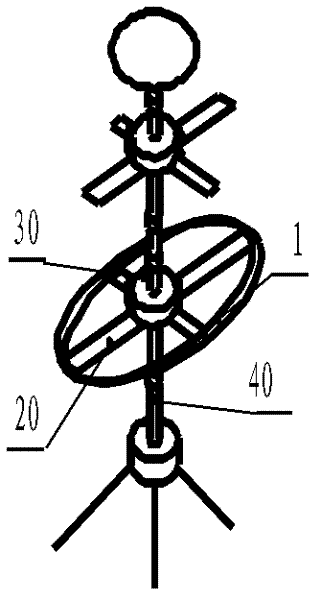

Cutting equipment and cutting method of flexible thin film solar cell

InactiveCN103050578AEliminate short circuitImprove compatibilityFinal product manufactureSemiconductor devicesControl systemMaterial consumption

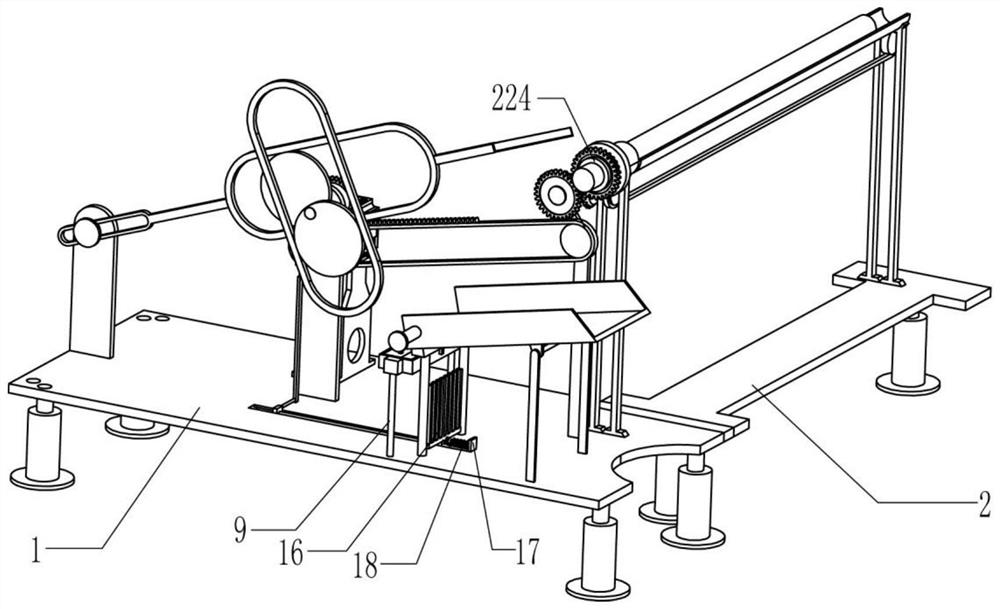

The invention discloses cutting equipment of a flexible thin film solar cell. The cutting equipment comprises an uncoiling mechanism, a conveying mechanism, a scoring mechanism, a cutting mechanism, a finished product coiling mechanism, a leftover coiling mechanism and a control system, wherein the control system is used for controlling the respective work of the uncoiling mechanism, the conveying mechanism, the scoring mechanism, the cutting mechanism, the finished product coiling mechanism and the leftover coiling mechanism. The invention also discloses a method for cutting the flexible thin film solar cell by the cutting equipment. The method comprises the following steps of uncoiling a cell to be cut, receiving and conveying the cell to be cut by the conveying mechanism, sequentially scoring and cutting the cell to be cut, coiling the obtained finished product by the finished product coiling mechanism, and coiling the cut leftovers by the leftover coiling mechanism. The cutting equipment and the cutting method have the advantages that the short-circuiting of the thin film solar cell caused by cutting can be thoroughly avoided by the cutting method; the automation degree is high, and the qualified rate of the flexible thin film solar cell and the production efficiency are improved; the material consumption amount is little, and the production cost is low; and the splitting process is simple, the equipment is simple, and the operation is convenient.

Owner:普尼太阳能(杭州)有限公司

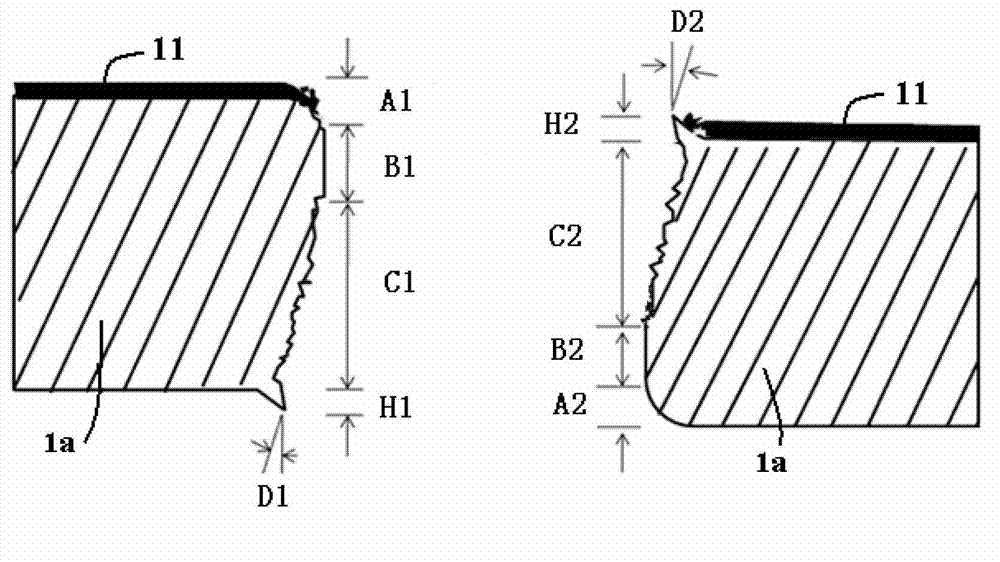

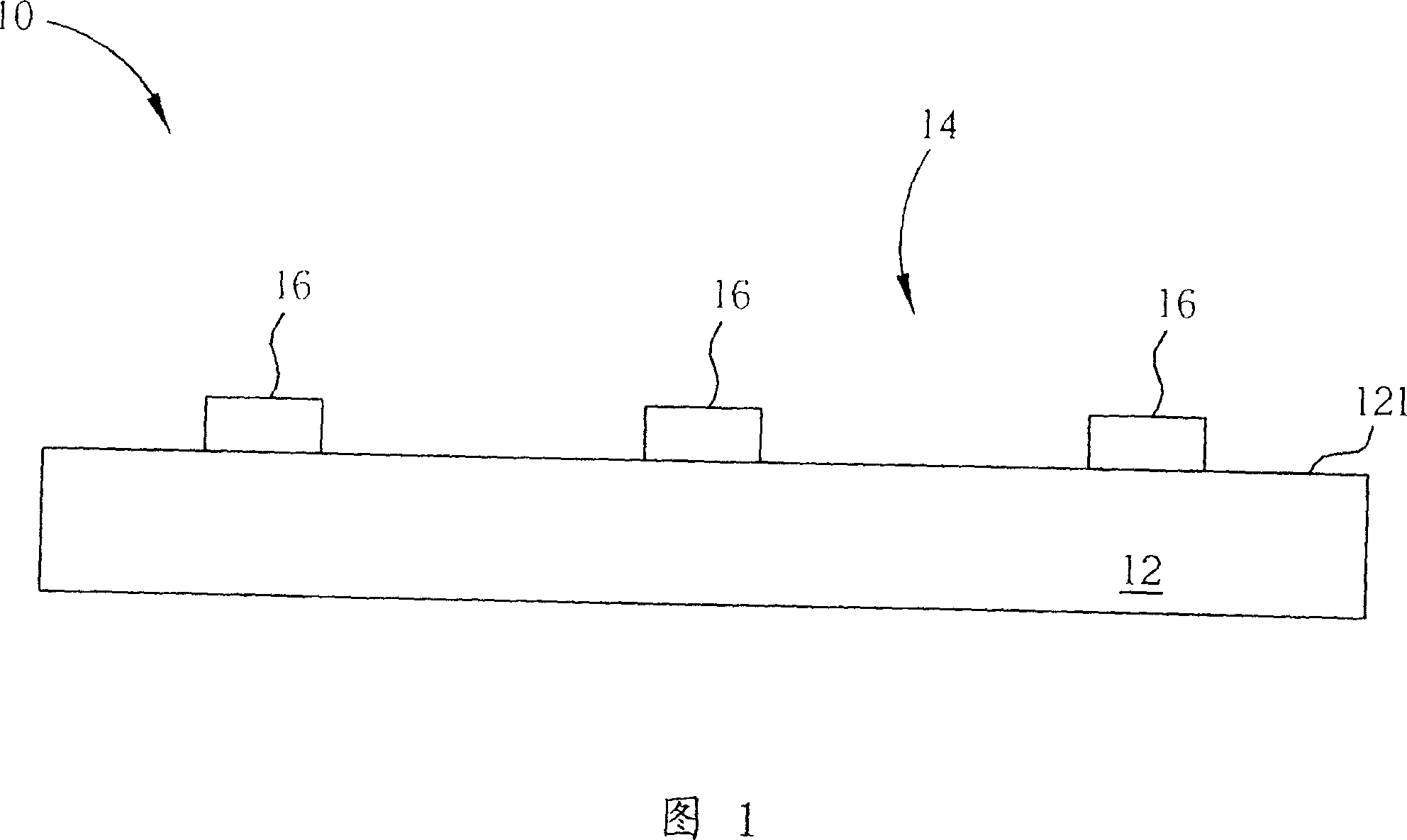

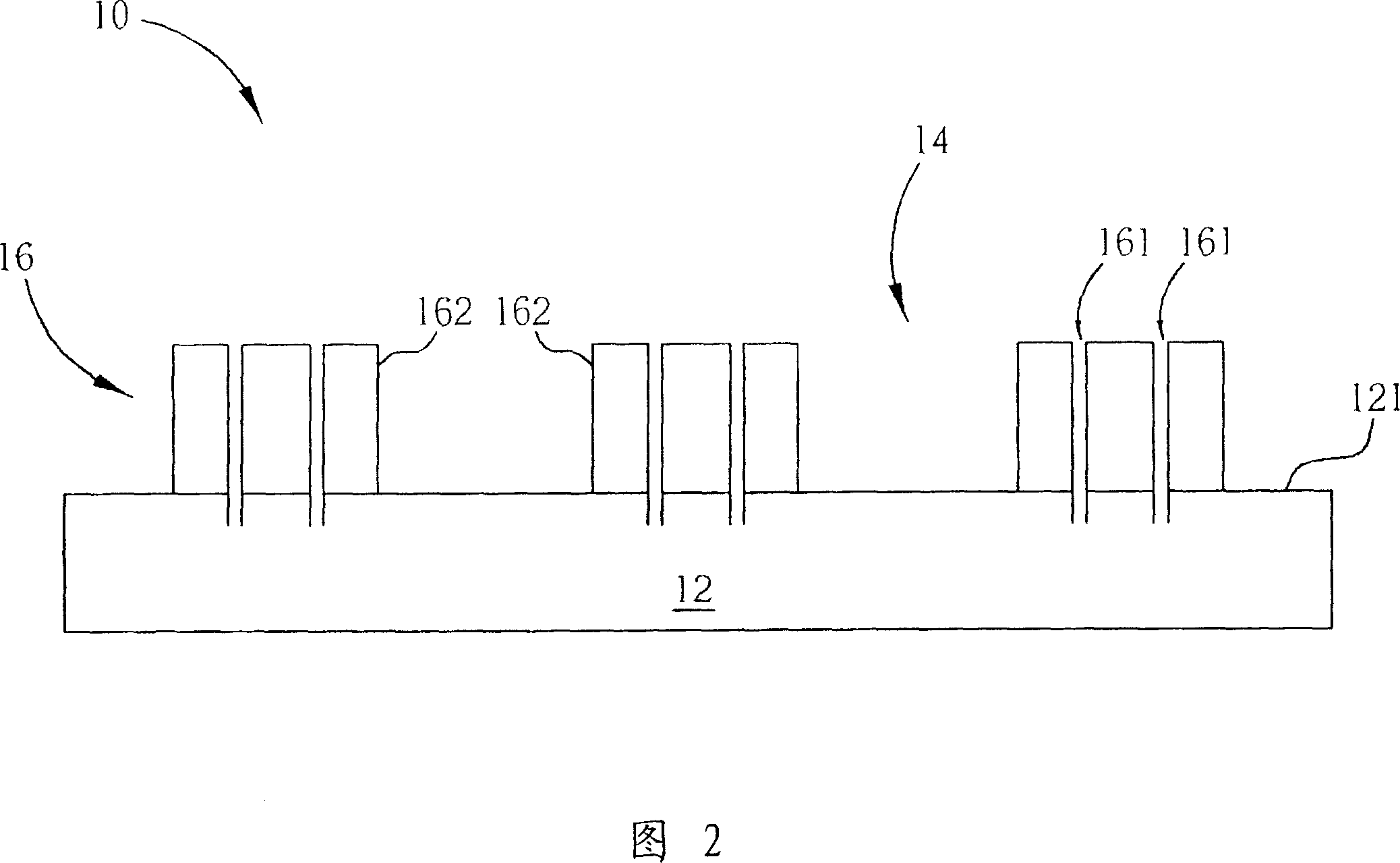

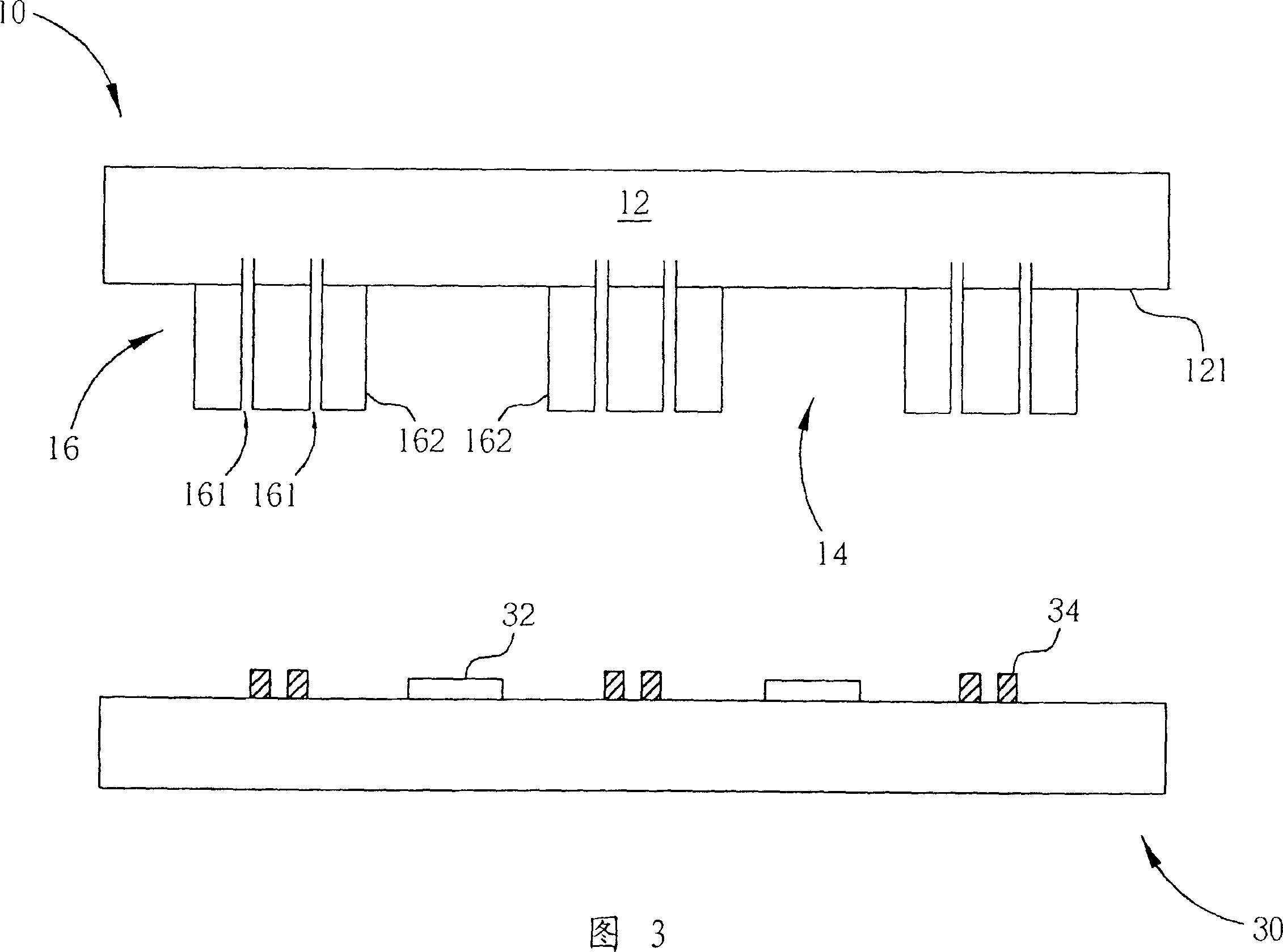

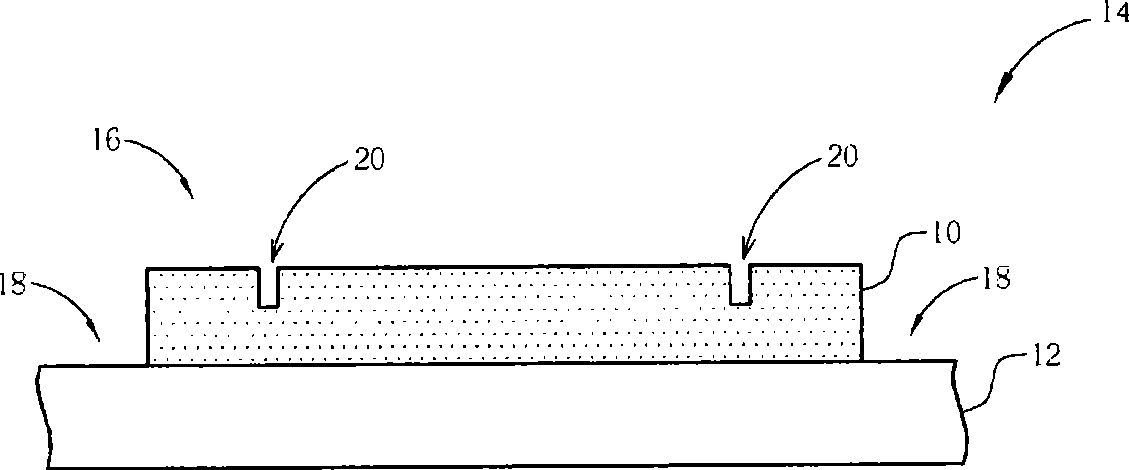

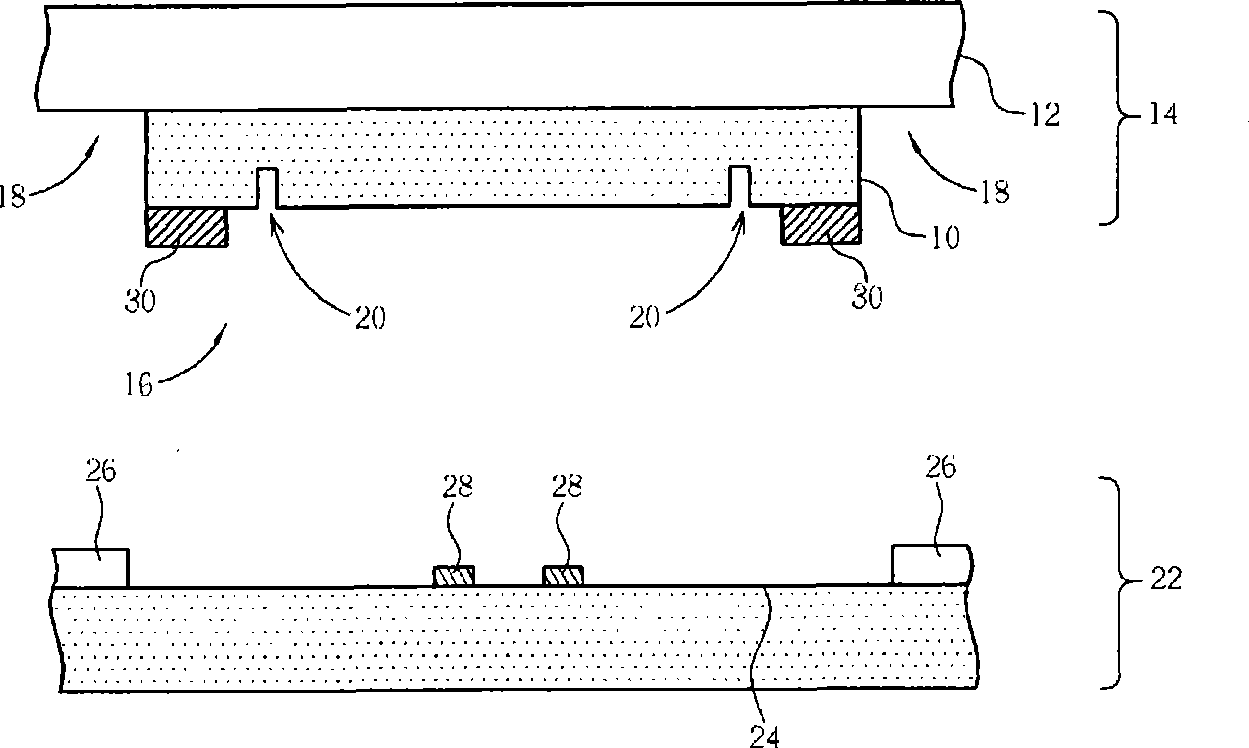

Wafer-level encapsulation and cutting method

InactiveCN101009230ASimple cutting processAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingWaferingBiomedical engineering

Firstly encapsulated wafer and component wafere are provided, and the frontispiece of the encapsulated wafer possesses many cavities and grooves. Then the encapsulated wafer and component wafere are jointed, and the first incising craft is preceded. Then the adhesion layer is adhibited to the encapsulated wafer, the second incising craft is preceded and the adhesion layer is removed to form the wafer-class encapsulation structure. At last, the wafer-class encapsulation structure is incised into several encapsulated cores.

Owner:TOUCH MICRO SYST TECH

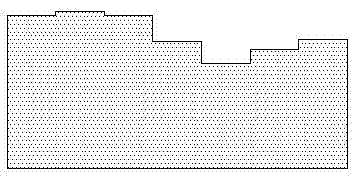

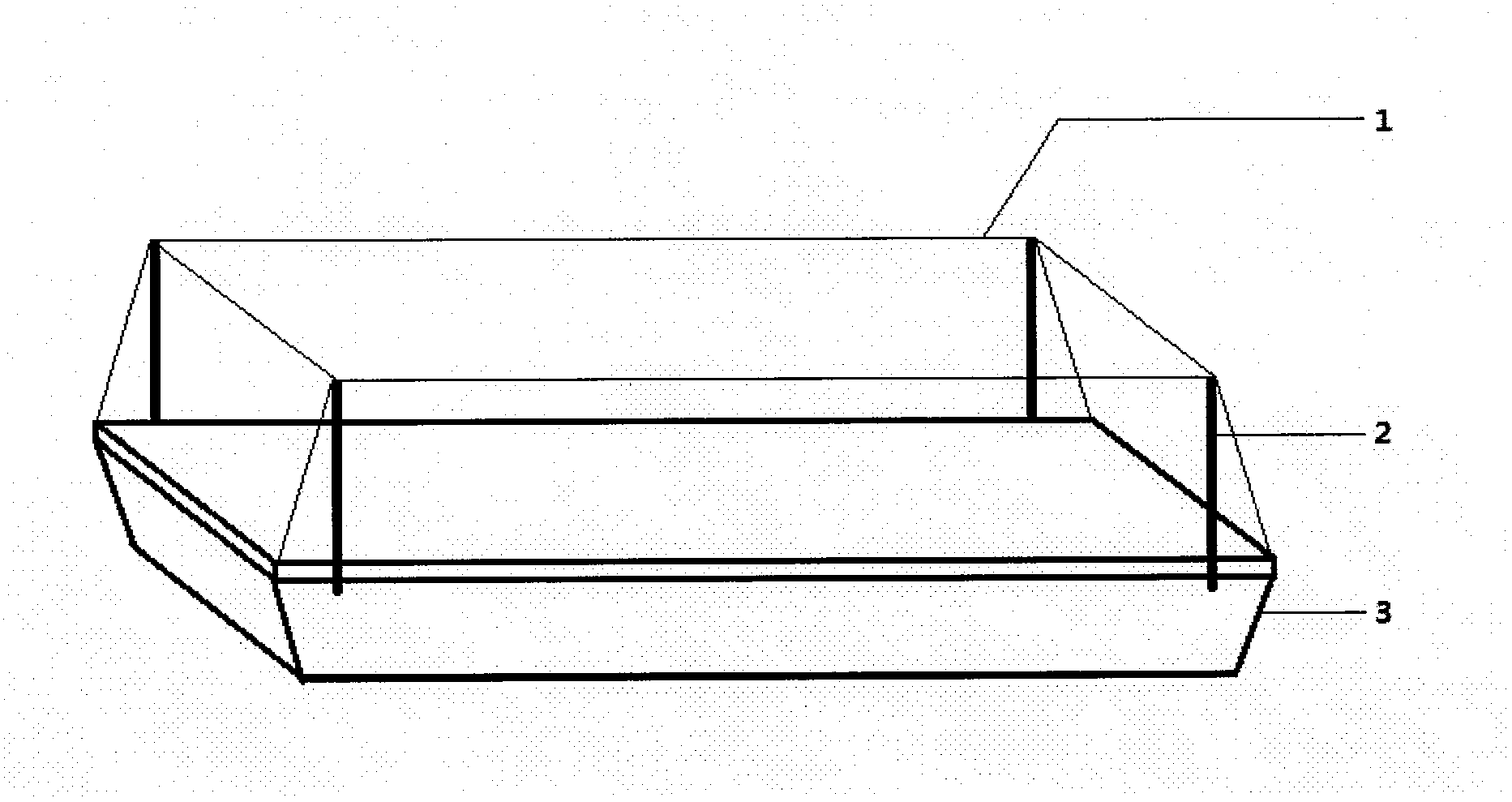

Digital die-free sand mould extrusion forming method

ActiveCN102773411AIncrease the level of automationThe preparation process is simple and controllableFoundry mouldsFoundry coresComputer Aided DesignMachining process

The invention relates to a digital die-free sand mould extrusion forming method, belonging to a combined casting and rapid forming field. The digital die-free sand mould extrusion forming method provided by the invention has the following steps of: establishing a CAD (Computer Aided Design) model according to a sand mould shape, establishing a similar model of a sand mould according to the CAD model, compiling an extrusion head control code, and controlling an extrusion head to generate a similar shape of the sand mould; intruding a shaping material and shaping through extrusion, so as to obtain a sand mould pre-forming piece; and milling the sand mould pre-forming piece so as to obtain a final sand mould. Compared with the conventional shaping method, according to the shaping method provided by the invention, the die manufacturing step is eliminated, the machining process is reduced, the production period is reduced, and the production cost of the sand mould is greatly reduced. The digital die-free sand mould extrusion forming method is particularly applicable to machining and manufacturing a small scale of the sand moulds with complex structures.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

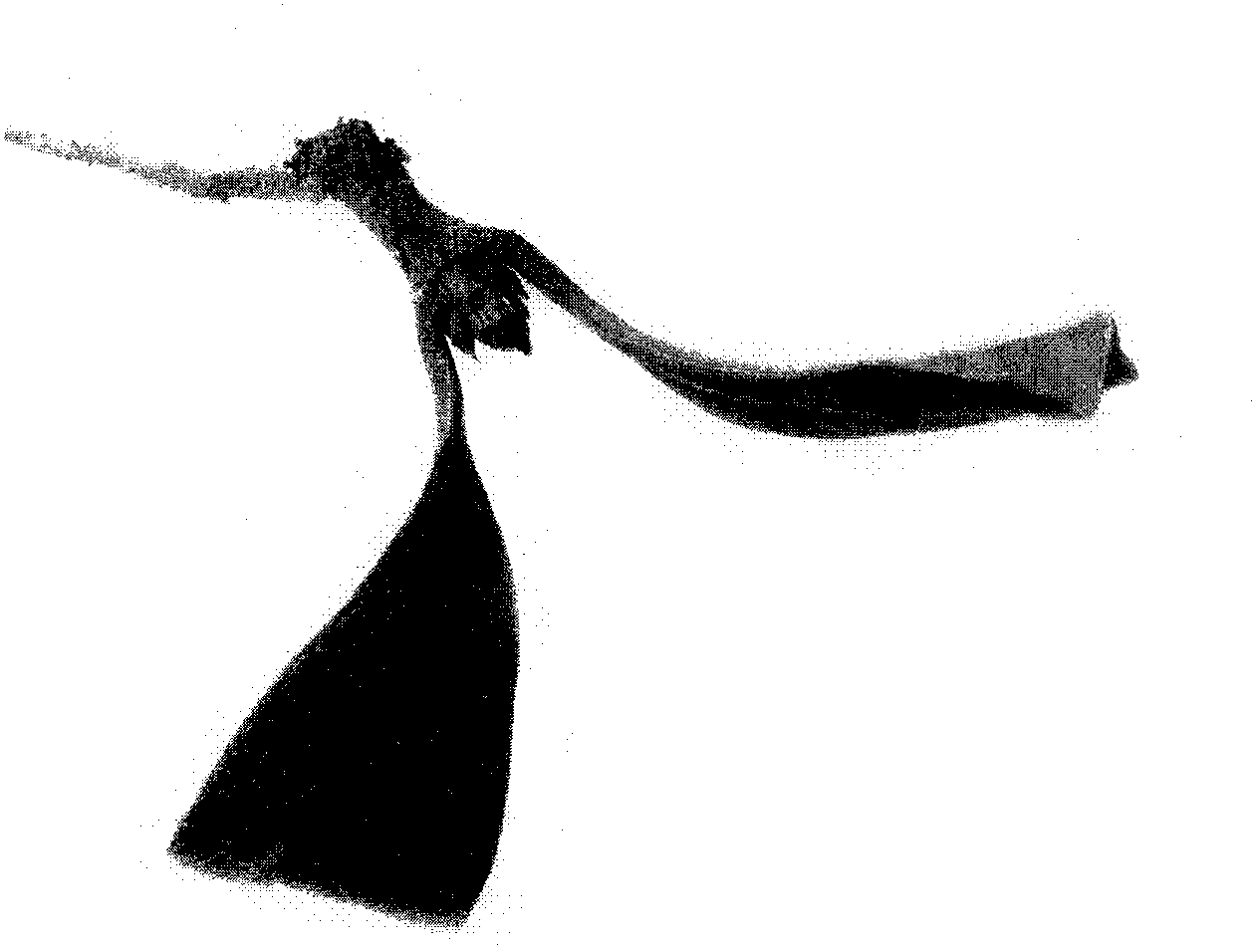

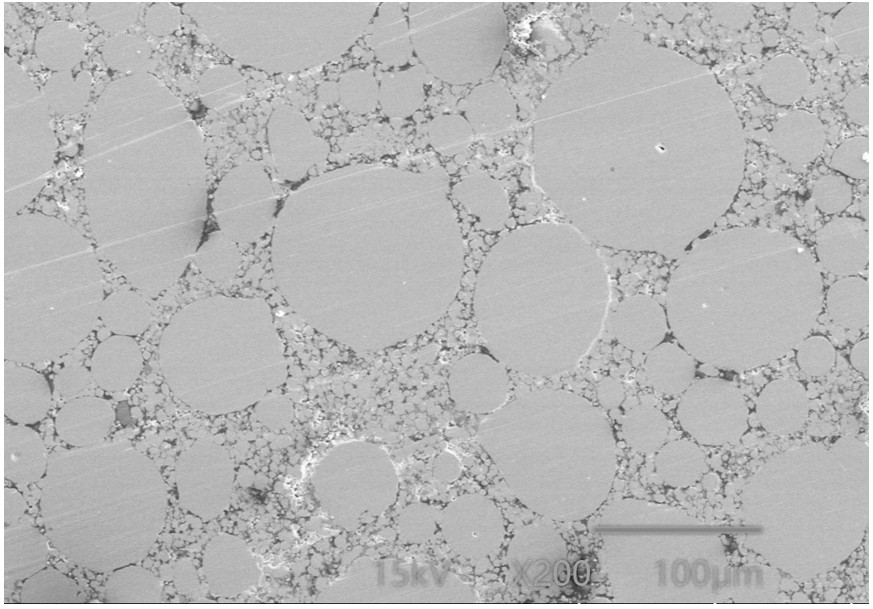

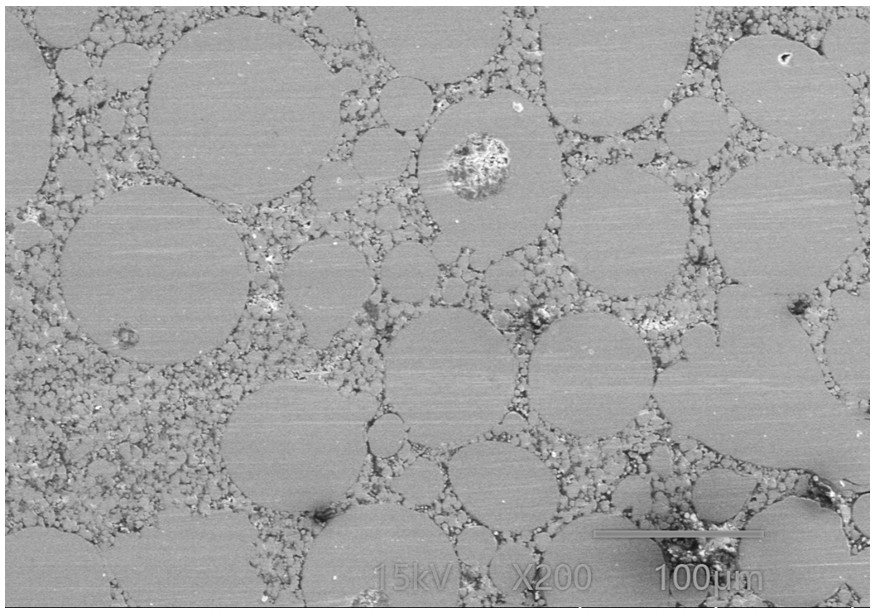

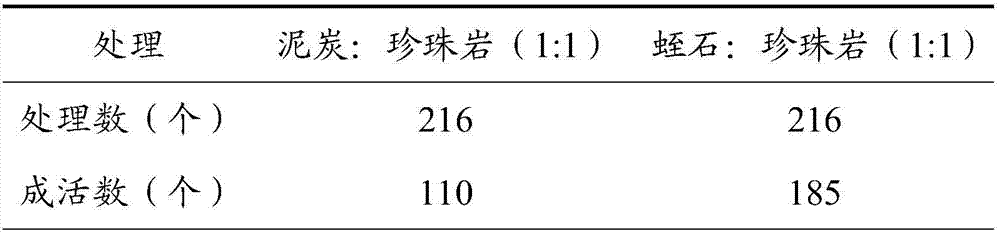

Micro-cuttage and rapid-propagation technology of sweet-scented osmanthus

ActiveCN103650816AShorten the lengthReduce the number of sectionsHorticultureGrowth hormoneCell budding

The invention belongs to the agricultural technology field, and particularly relates to a micro-cuttage and rapid-propagation technology of sweet-scented osmanthus. The micro-cuttage and rapid-propagation technology includes: selecting a plug tray of 40*40*45mm as a matrix vessel and constructing a support of covering films on the plug tray; mixing 30% of field and garden soil, 20% of plant ash, 20% of perlite and 30% of rice hull, using the mixture as a matrix, and disinfecting the matrix; selecting annual and lignified sweet-scented osmanthus branches as cuttings to be performed cuttage, and shearing the cuttings into small sections according to knot intervals, wherein each section is provided with only one bud knot and two leaves; cleaning and disinfecting the cuttings, and inserting the cuttings into the plug tray after performing glue enveloping on a section wound on each cutting; dropping growth hormone into each transplanting hole; sealing and moisturizing the plug tray. The micro-cuttage and rapid-propagation technology of the sweet-scented osmanthus greatly increases an expanding propagation multiple of cuttage propagation of the sweet-scented osmanthus by shortening the cuttings, enables survival rate of the cuttings to reach above 95% by improving the matrix of the plug tray and performing pretreatment before cuttage, and enables the rooting percentage of the cuttings to reach above 80% during one month by controlling temperature and humidity and processing the cuttings with the growth hormone.

Owner:SHENZHEN WENKE GARDENING IND

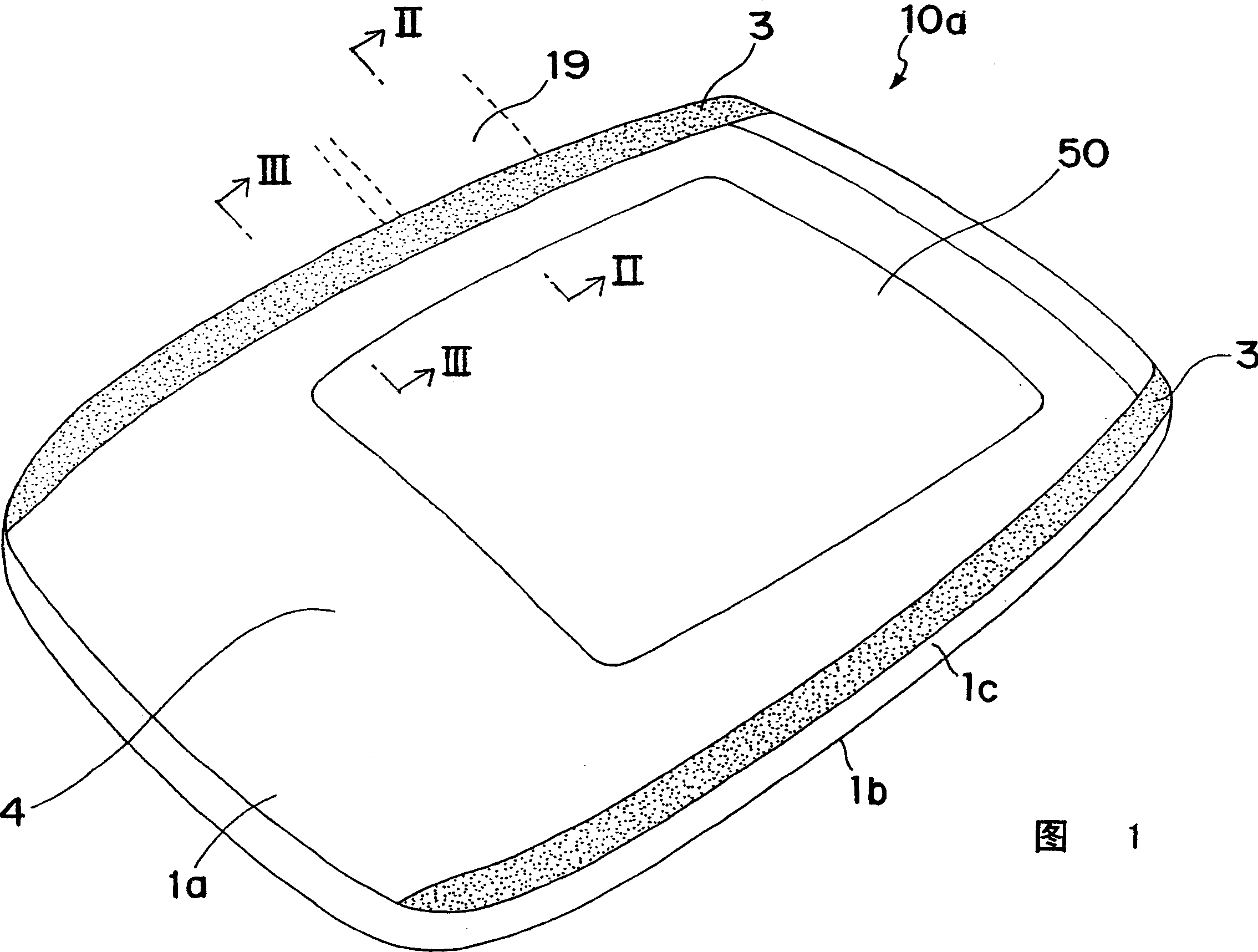

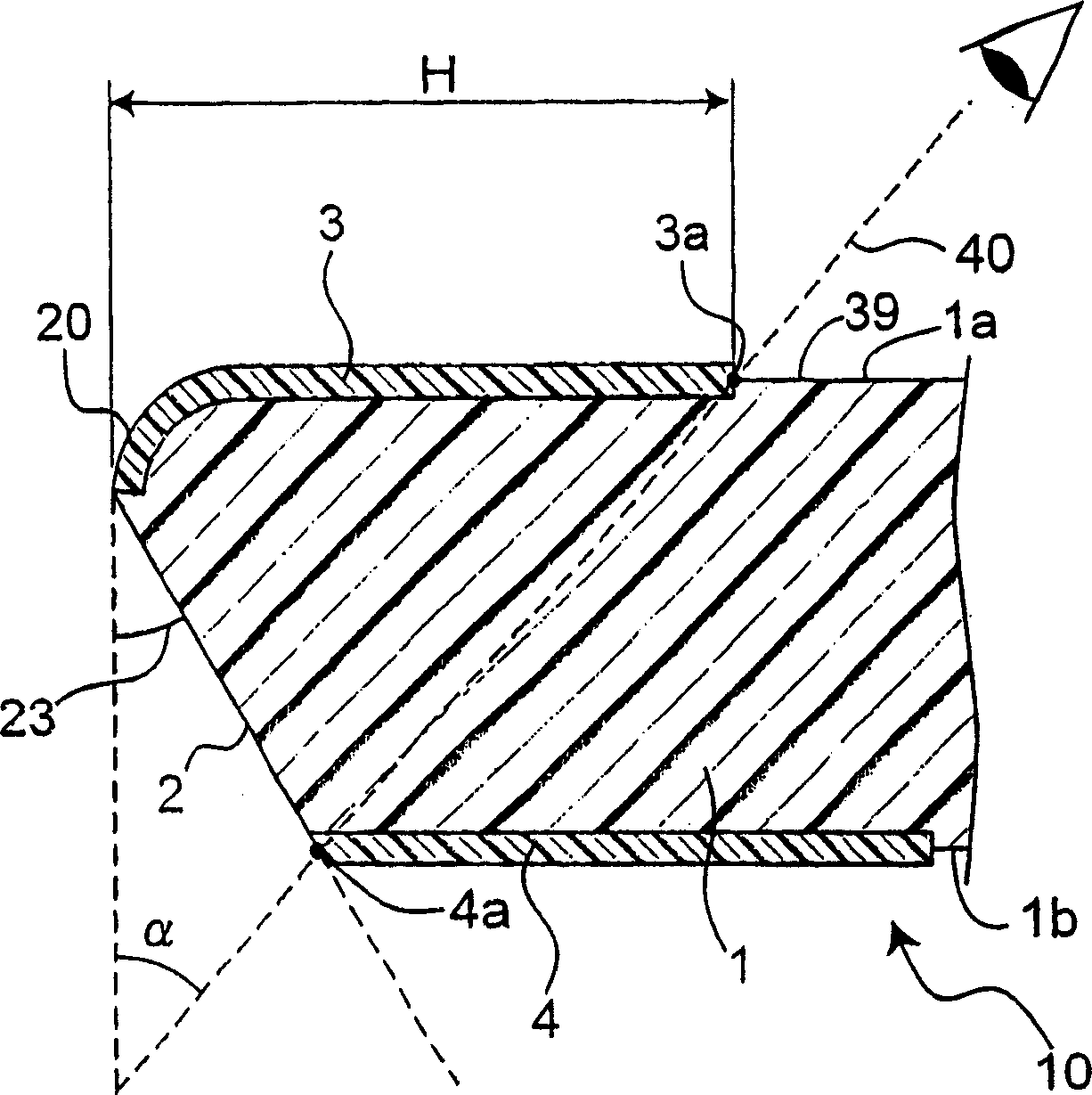

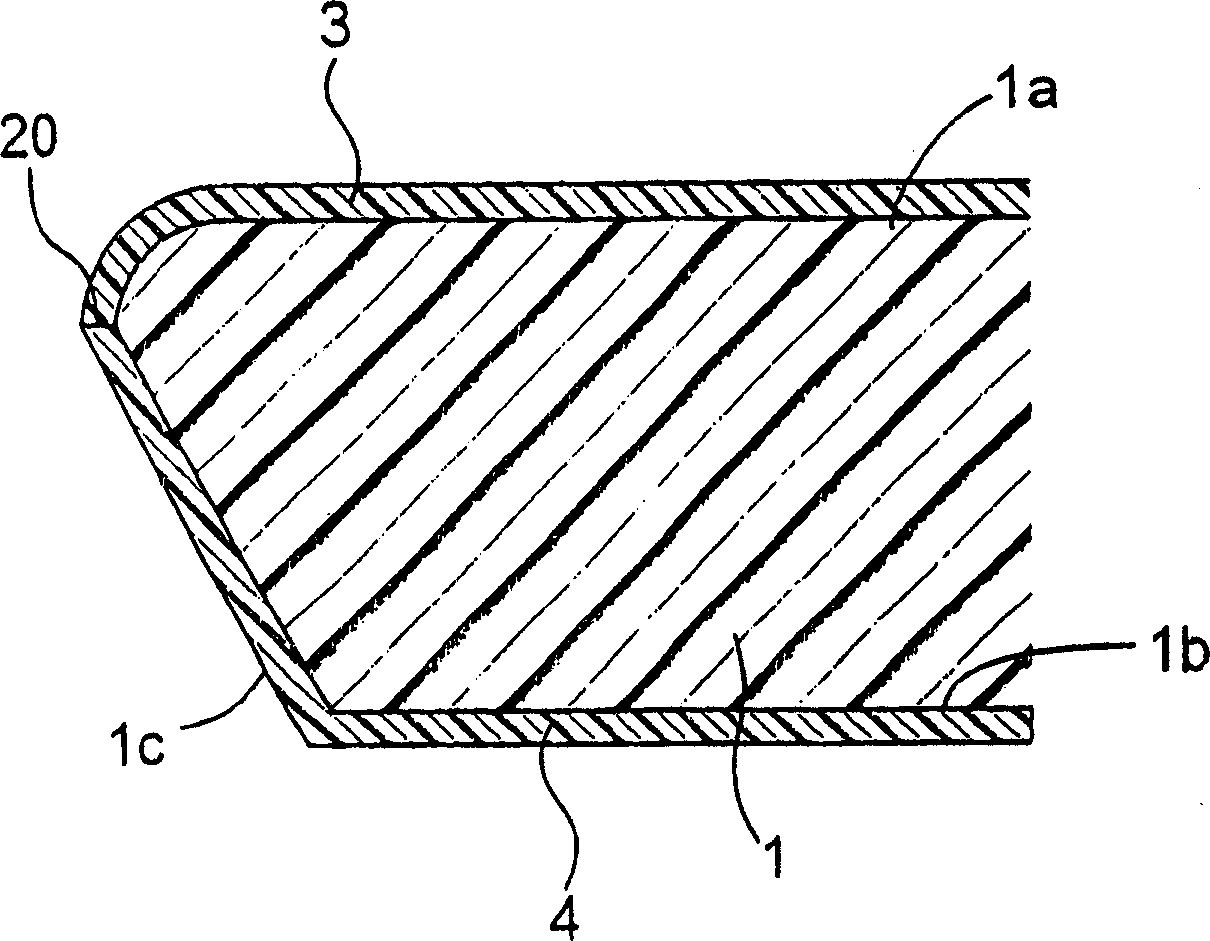

In-mold decorated molded product and method of manufacturing the same

InactiveCN1822941ADesignability can be maintainedSimple cutting processFlat articlesThin material handlingEngineeringCoating

An in-mold decorated molded article wherein a coating layer is formed on a top surface of a transparent molded resin body which is flattened in a thickness direction of the body, thereby covering an edge part of the top surface adjacent to a side face on with a side gate mark formed, in order for the side gate mark not to be seen from the top surface of the molded resin body, and a decorative layer is formed on a bottom surface of a decorative layer of the transparent molded resin body. According to an in-mold decorated molded article, even when the transparent molding resin is employed with the result that an agreeable appearance is not achieved despite of a treatment for the side gate mark, the design property of the in-mold decorated molded article can be maintained, the gate mark of unacceptable appearance being not seen from the top surface.

Owner:NISSHA PRINTING COMPANY

Hibiscus cuttage rapid propagation technology

The invention relates to a hibiscus cuttage rapid propagation technology. According to the technical scheme, the technology includes the steps that firstly, a cuttage bed is built by using perlite as matrix; secondly, a humidity control system and an automatic spray system are constructed, a spray device is controlled according to change conditions of surface humidity of the matrix, and the rooting and growing environment of cutting slips is provide and adjusted; thirdly, strong and semi-ligneous or ligneous branches which are not damaged by pests or diseases and grown in the current year or yearly are selected as cuttings, and pruning and cuttage are carried out in time; fourthly, the branches are treated by using a rooting agent to hasten rooting before cuttage is carried out; fifthly, spray equipment is started and humidity parameters are set after cuttage is carried out, automatic spray is changed into manual control after 10 days, seedlings can be lifted 25 days after cottage, the seedlings are filled into a pot and subject to hardening-off, and the seedlings are transplanted 15 days later. The hibiscus cuttage rapid propagation technology is short in propagation period of nursery stocks, low in cost input and capable of being widely applied to large-scale and industrialized landscape nursery stock development for individuals and enterprises.

Owner:SHENZHEN WENKE GARDENING IND

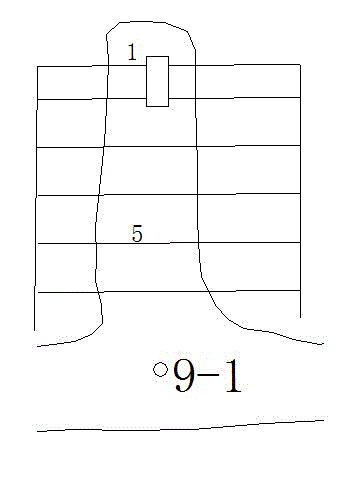

Cutting method combining deep hole cutting and small well cutting

InactiveCN102943673ASimple cutting processReduce cutting costsUnderground miningBlastingStructural engineeringEngineering physics

The present invention provides a cutting method combining deep hole cutting and small well cutting, and belongs to the technical field of ore belt mining. The invention adopts a cutting process combining deep hole cutting and small well cutting, not only cancels the roadway cutting, simplifies the cutting process, and reduces cutting cost significantly, but also provides an experimental basis to realize cutting of deep hole cutting blasting, and has strong promotion and application value. Medium-length holes on both sides of the small well are cut by dual radiation center construction. Taking the small well as a free surface, delay blasting is performed from small well center to the two sides to realize medium-length hole blasting pull trough without roadway cutting, and blasting initial free surfaces are created for follow-up blasting of medium-length hole breaking ground. The long axis direction of a cutting well is perpendicular to the row surface of the cutting deep hole, and the length direction is greater than the row spacing of the cutting deep hole, therefore the deep hole blasting gets the maximum free surface, greatly enhancing the blasting success rate which can reach 100%.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

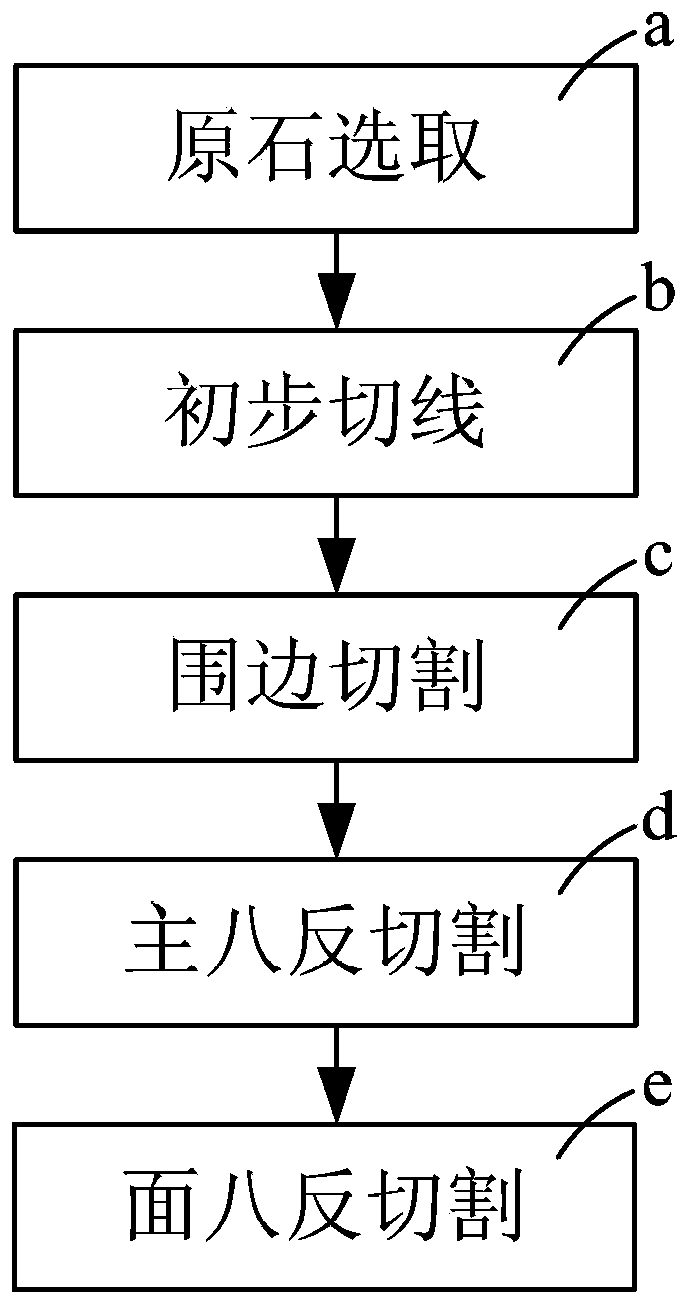

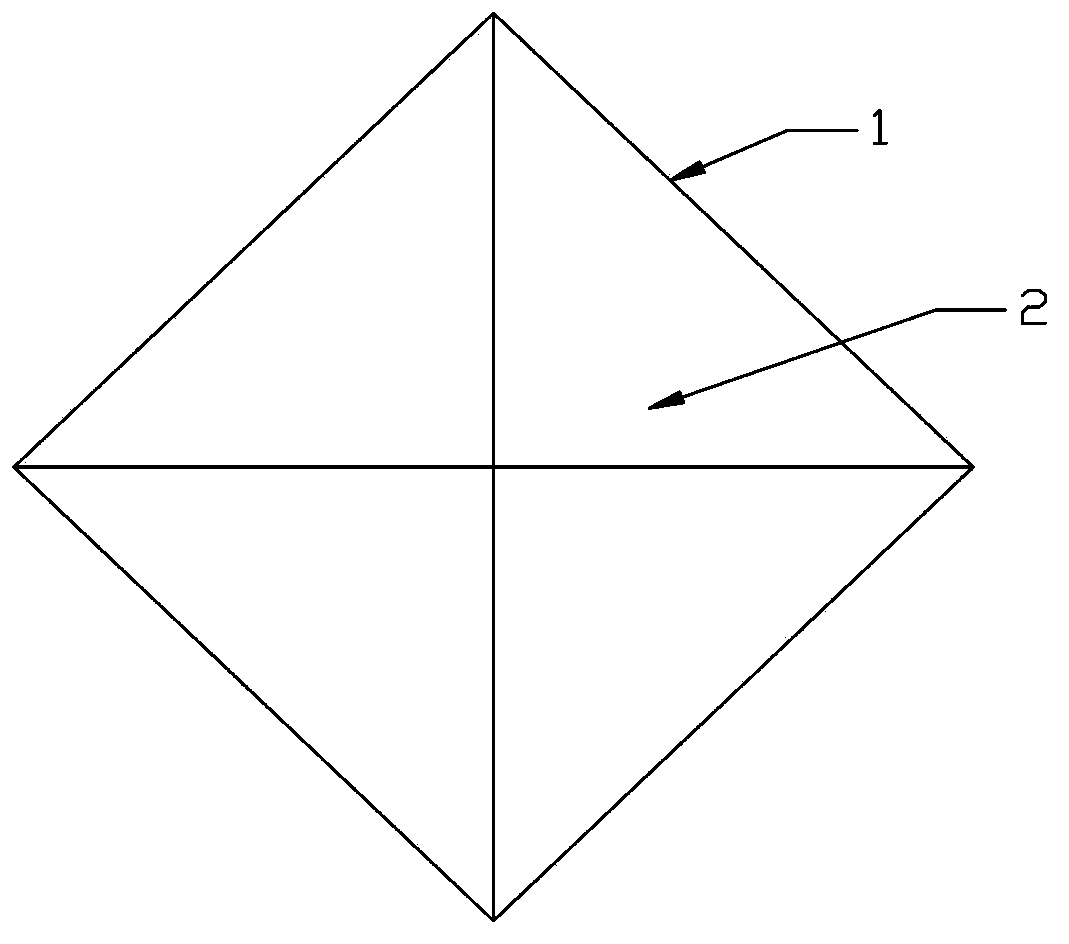

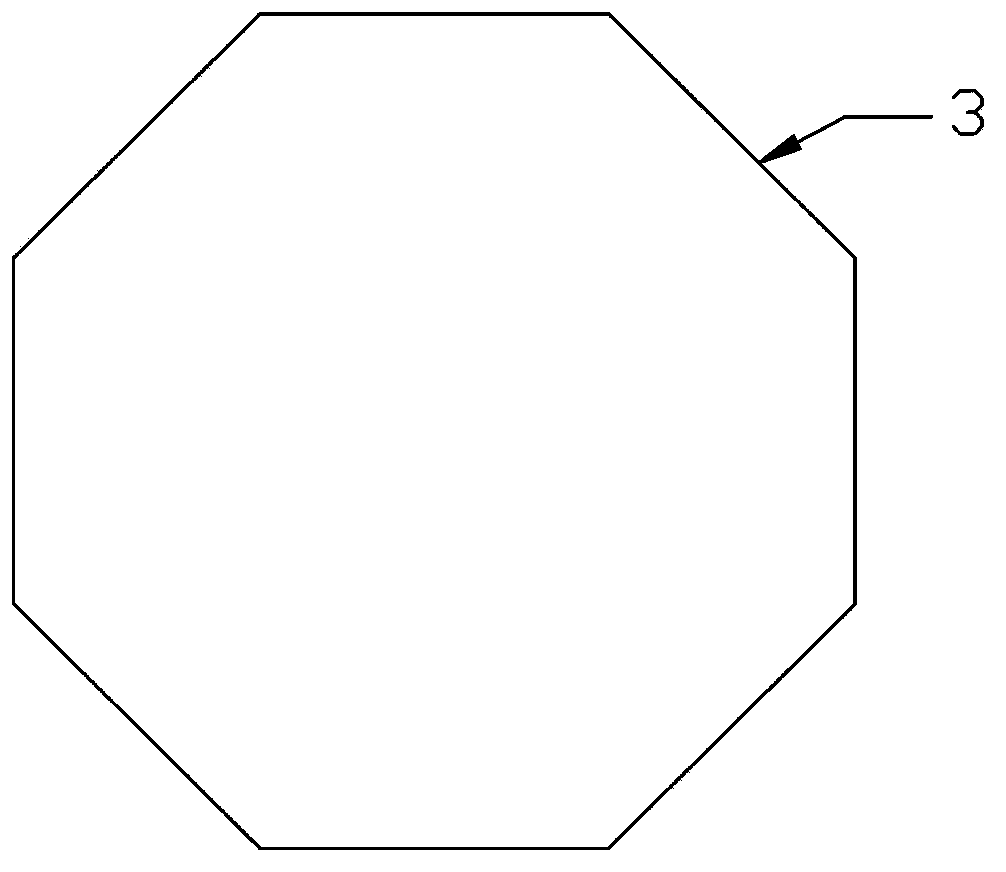

Manufacturing method of octagonal diamond with eight hearts and eight arrows inside

InactiveCN103504734AReduce lossReduce cutting stepsFine working devicesJewelleryMaterials scienceA diamond

The invention relates to a diamond cutting process, in particular to a manufacturing method of an octagonal diamond with eight hearts and eight arrows inside. The manufacturing method comprises the steps of raw diamond selecting, primary cutting, surrounding edge cutting, main octahedral cone anti-cutting, and surface octahedral cone anti-cutting. By the manufacturing method disclosed by the invention, the steps from raw diamond selecting to each surface cutting are realized by simple steps, so that the loss of the diamond in a cutting process is reduced, the cutting steps of the whole process are reduced, the cutting process of the diamond with eight hearts and eight arrows is simplified, and the product cost is reduced.

Owner:GUANGDONG SHINING HOUSE INT JEWELRY

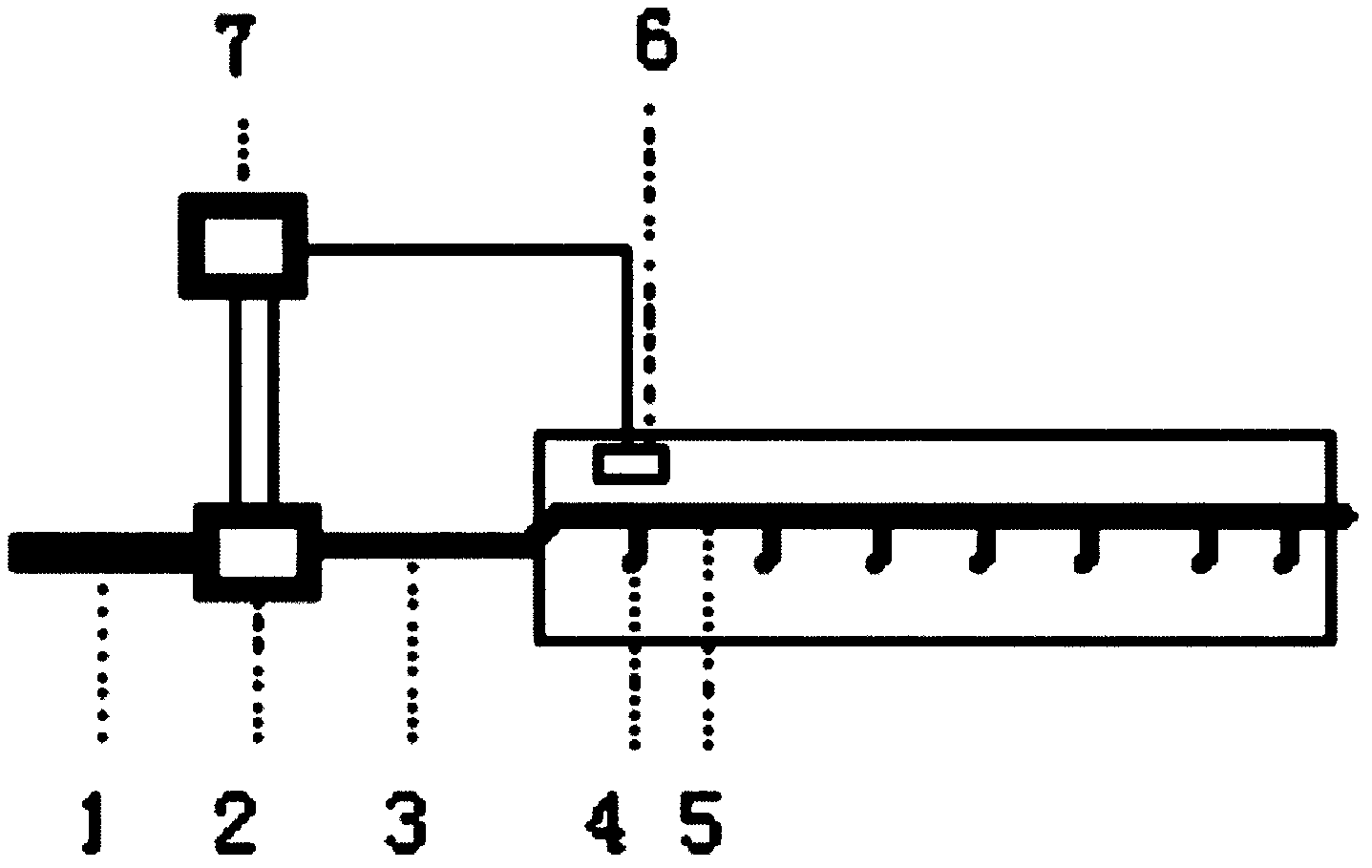

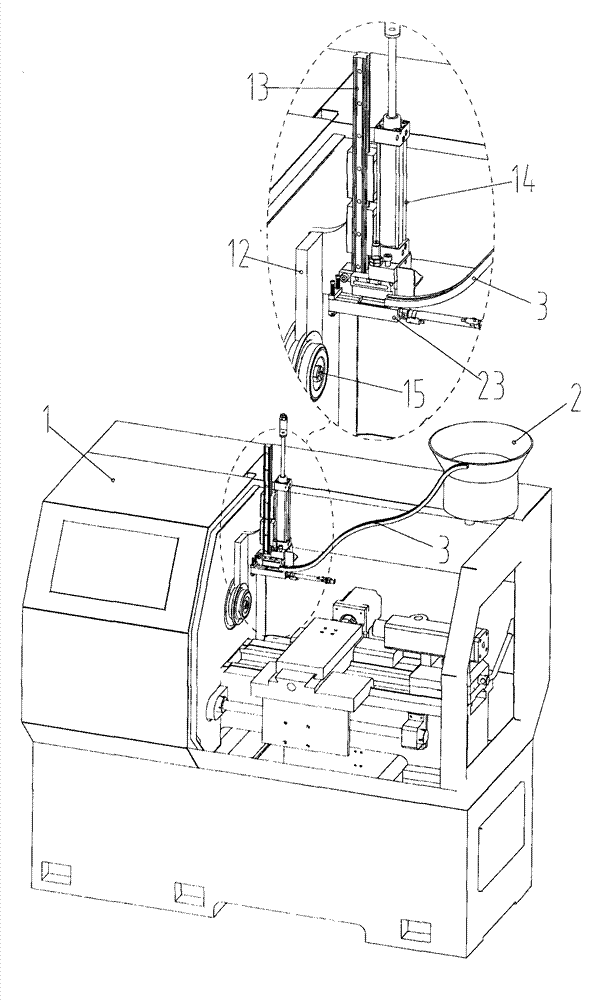

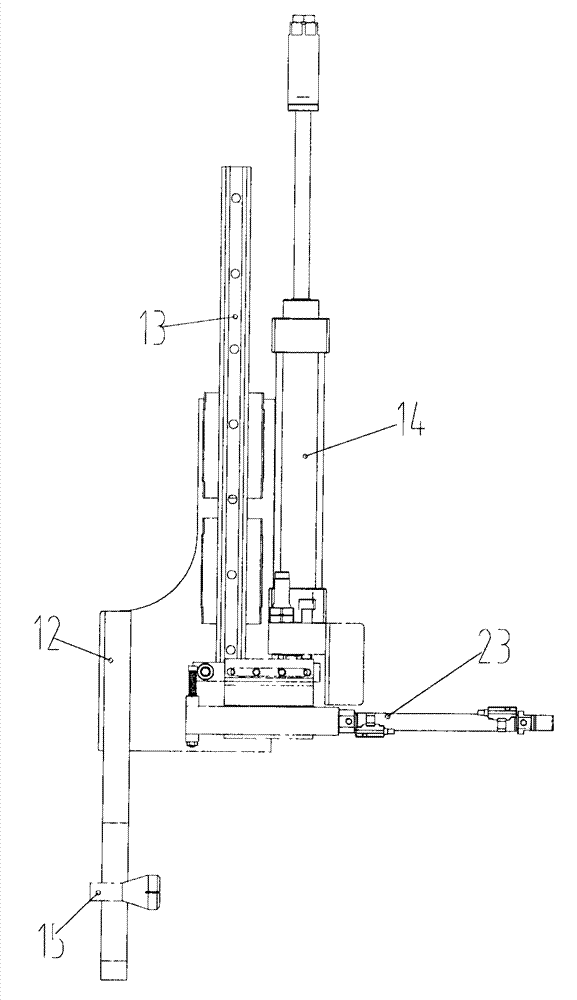

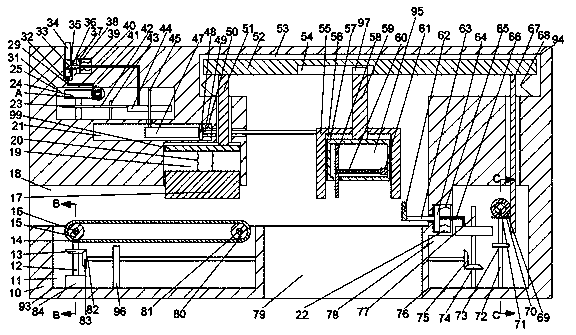

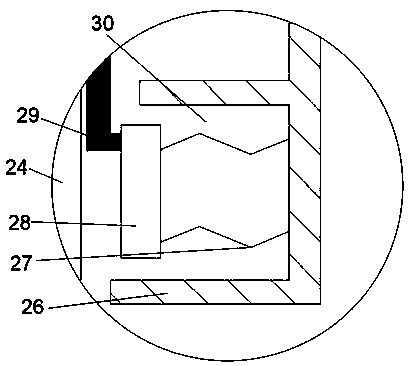

Direct-pushing-type numerically-controlled-lathe feeding-discharging assisting system

ActiveCN104741631APrecision mechanical structureSimple loadingAutomatic workpiece supply/removalMetal working apparatusPiston rodIndustrial engineering

The invention relates to a machining device, in particular to an automatic feeding-discharging system of a numerically-controlled lathe. The direct-pushing-type numerically-controlled-lathe feeding-discharging assisting system comprises a vibrating disc, a feeding mechanism, a discharging mechanism, a linear guide rail, a lifting air cylinder and a support. The support is fixedly connected to the numerically-controlled lathe. The linear guide rail is movably connected to the support, a lifting plate is fixedly connected with the tail end of the linear guide rail, the lifting air cylinder is fixedly connected to the support, and a piston rod of the lifting air cylinder is fixedly connected with the lifting plate. The feeding mechanism is fixedly connected to the lifting plate. A technology for achieving automatic feeding and automatic discharging of the numerically-controlled lathe is disclosed. By means of the direct-pushing-type numerically-controlled-lathe feeding-discharging assisting system, clamping jaws widely used in the industry are omitted, a simpler and more durable direct-pushing type mechanism is developed, and the feeding process and the discharging process of workpieces on a chuck of the numerically-controlled lathe are achieved. Motions are accurate in the feeding process, and the speed is high in the discharging process.

Owner:湖北信友汽车零部件有限公司

Laser engraved linear array light guide plate and preparation method thereof

InactiveCN101592756AEven reflectionGood effectOptical light guidesModel makingLight guideOptical transmittance

The invention discloses a laser engraved linear array light guide plate. The light guide plate made of an acryl flat plate comprises a reflecting layer, a light guide layer and a diffusing layer, wherein the reflecting layer is made of light reflecting materials with high reflectivity; the light guide layer is made of materials with high light transmittance; and the diffusing layer is made of light homogenizing materials. The laser engraved linear array light guide plate is characterized in that a plurality of linear arrays comprising light reflection diffusing lines engraved by a laser pulse are respectively distributed in the horizontal direction and the longitudinal direction on the light guide layer of the light guide plate, wherein the diffusing lines among the linear arrays of vertical light rays are parallel with each other and form arithmetic progression arrangement, and the linear arrays at a position of the light guide plate nearer a light source are sparser, and vice versa according to the practical requirements; and the diffusing lines among the linear arrays of parallel light rays are parallel with each other and form an equal distance. In addition, the invention also discloses a preparation method of the light guide plate. The light guide plate adopting the technical method has more even light emission and better effect.

Owner:SHANGHAI EDGE LIGHT IND

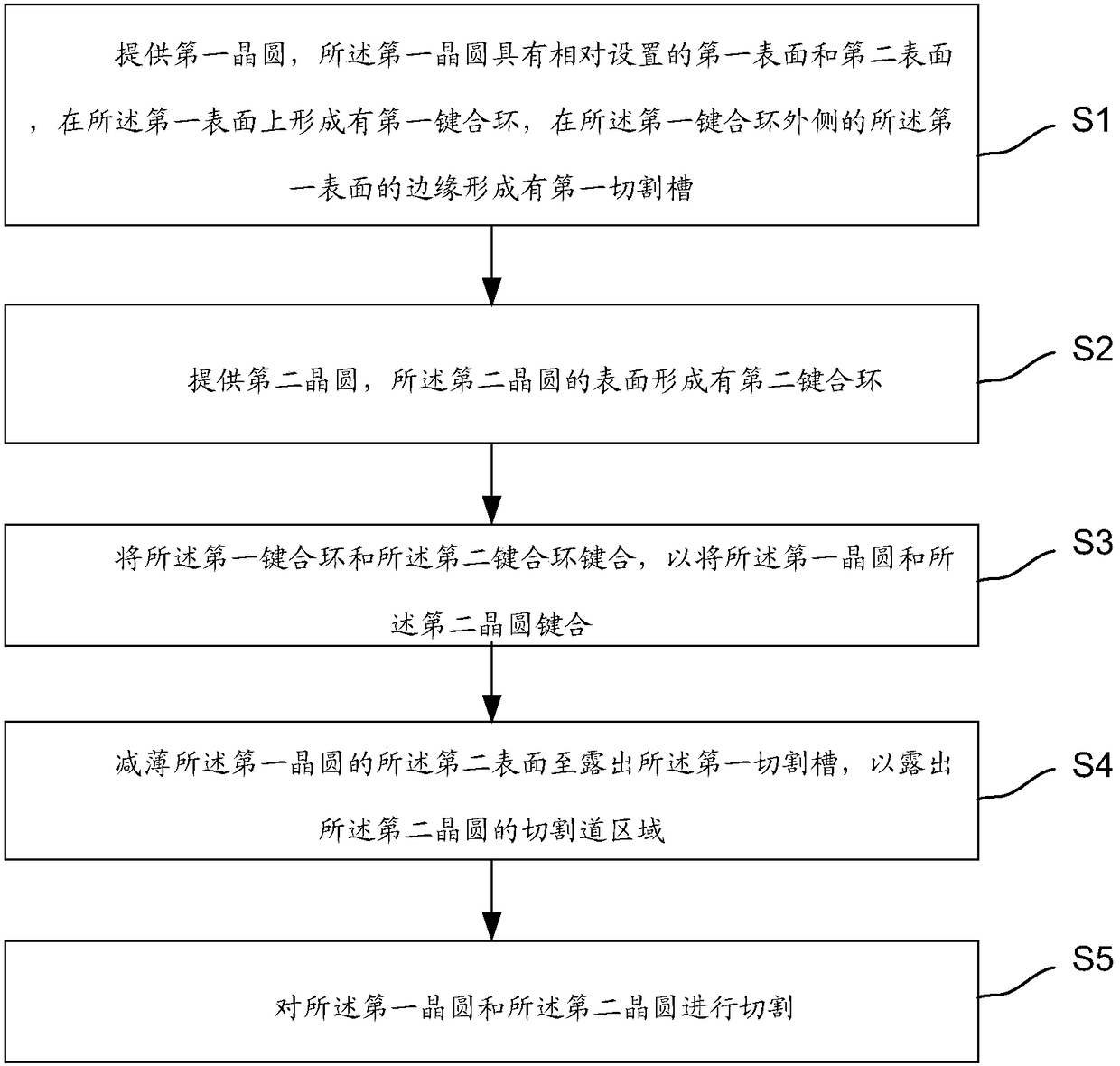

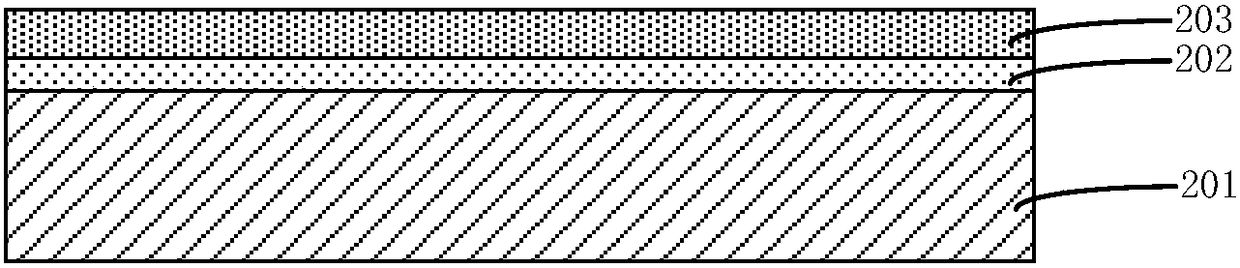

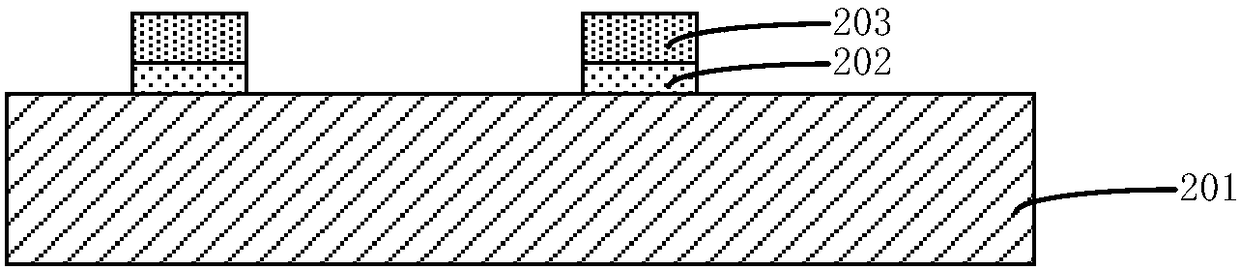

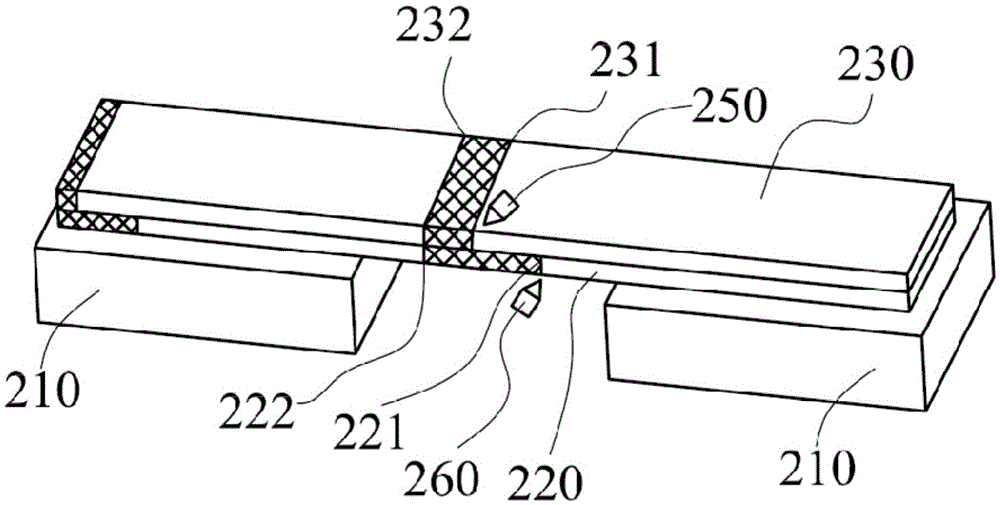

Semiconductor device and preparation method thereof, and electronic apparatus

ActiveCN108117042ASimple cutting processOmit blind cutPrecision positioning equipmentSoldering apparatusDevice materialEngineering

The invention relates to a semiconductor device and a preparation method thereof, and an electronic apparatus. The method comprises the following steps: providing a first wafer, wherein the first wafer has a first surface and a second surface, which are arranged to be opposite to each other, a first bonding ring is formed on the first surface, and a first scribe lane is formed on the edge of the first surface on the outer side of the first bonding ring; providing a second wafer, wherein a second bonding ring is formed on the surface of the second wafer; bonding the first bonding ring with thesecond bonding ring to bond the first wafer with the second wafer; thinning the second surface of the first wafer to expose the first scribe lane so as to expose a cutting channel area of the second wafer; and cutting the first wafer and the second wafer. The preparation method provided by the invention has the advantages of: 1. simplifying the cutting process (blind dicing and multiple alignmentoperations are omitted), reducing the cutting frequency, and effectively reducing the process cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

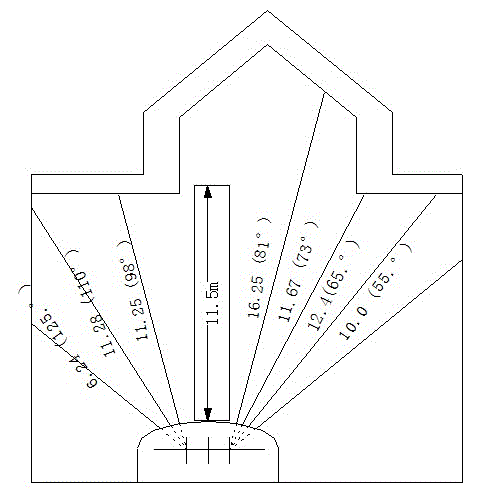

Double-emission-center cutting deep hole blasting technology

The invention discloses a double-emission-center cutting deep hole blasting technology. The double-emission-center cutting deep hole blasting technology comprises the following steps of arranging a cutting mine at an appropriate position of a cutting tunnel; confirming the long axis direction of the cutting mine and cutting a mine according to designed construction; designing and constructing middle deep holes which are formed in bilateral sides of the cutting mine with the utilization of double emission centers; confirming detonating ways of the cutting mine and performing on-line detonating. The double emission centers which are symmetrically arranged on bilateral sides of the center of the tunnel are 0.6 m far away from the tunnel center, the middle deep holes are formed with a left side emission center and a right side emission center serving as benchmarks, and 8 to 9 middle deep holes are uniformly formed according to the bottom distance of the holes. The hole diameter of the middle deep holes is 76 mm, the depth is from 6 to 17 m, the bottom distance is from 1.8 to 2.0 m, two rows of deep holes are formed inside the cutting mine, and the row interval is 1.5m. Successful application of the double-emission-center deep hole blasting technology has the advantages of cancelling cutting level tunnels, reducing cutting costs by a large margin, simplifying cutting technologies, providing technical guarantee for achieving a cutting mine and deep hole combined kerve and having strong popularization and application values.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

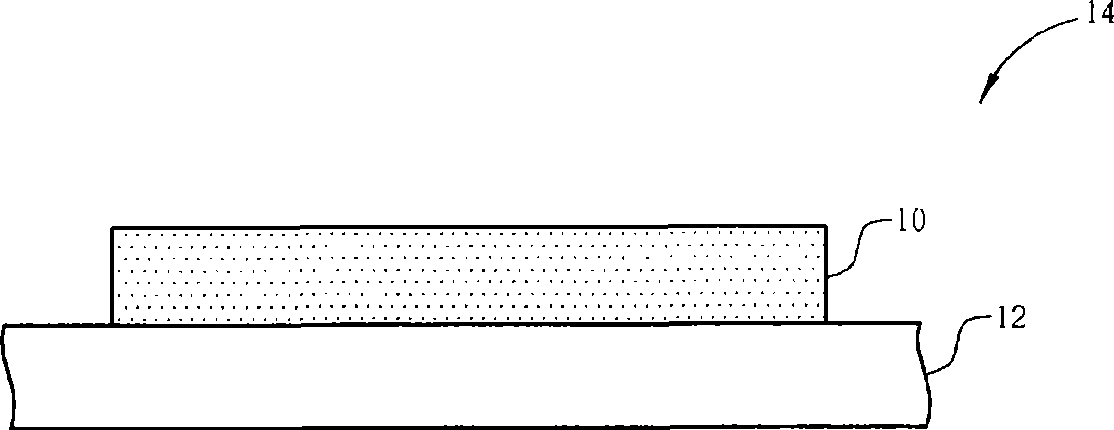

Wafer stage package cutting method protecting connection pad

InactiveCN101388348ASimple cutting processAvoid damageSemiconductor/solid-state device manufacturingWafer dicingEngineering

The invention discloses a cutting method for protecting the wafer-level packaging of a connecting pad, which comprises forming a plurality of cavities and pre-cutting channels on the front of an upper cover wafer, wherein the depth of each pre-cutting channel is smaller than the depth of each cavity, then bonding the upper wafer and an element wafer whose surface is provided with a plurality of elements and a plurality of connecting pads, then conducting the upper wafer cutting technology, cutting through the upper cover wafer along the pre-cutting channels, removing partial upper cover wafer which is not bonded with the element wafer to expose the connecting pads, finally conducting the element wafer cutting technology to form a plurality of package tube cores.

Owner:中国台湾格雷蒙股份有限公司

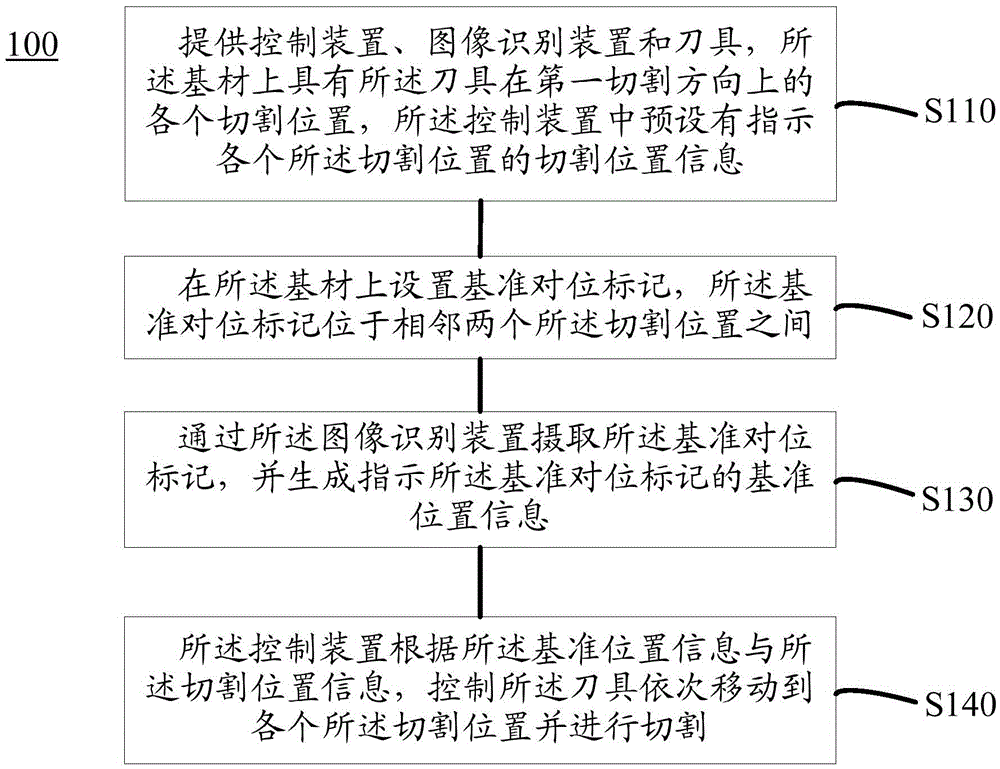

Method for cutting liquid crystal display panel

InactiveCN105652484ASimple cutting processImprove cutting efficiencyGlass severing apparatusMetal working apparatusLiquid-crystal displayEngineering

The invention discloses a method for cutting a liquid crystal display panel. The method comprises the steps of providing a control device, an image recognition device and a tool, wherein a substrate is provided with all cutting positions, in a first cutting direction, of the tool, and cutting position information indicating all the cutting positions is preset in the control device; arranging reference alignment marks on the substrate, wherein the reference alignment marks are located between every two adjacent cutting positions; shooting the reference alignment marks through the image recognition device, and generating reference positional information indicating the reference alignment marks; controlling the tool to move to the cutting positions in sequence for cutting through the control device according to the reference positional information and the cutting position information. By means of the cutting method, the cutting process can be simplified, and cutting efficiency can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Cutting method of super-hard crystal

InactiveCN101386192ARealize continuous cuttingReduce usageFine working devicesCopper wireReciprocating motion

The invention relates to a method for cutting superhard crystal, which belongs to the field of crystal processing. The invention adopts a wire-cutting method, prepares cutting slurry by mixing diamond micro-powder, boron carbide and olive oil according to proportion, and realizes the cutting of the superhard crystal by high-speed reciprocating motion of cutting copper wires and cutting slurry. The method can realize continuous cutting of the superhard crystal; comparing the preparation of the cutting slurry with a diamond cutting wire which directly uses the diamond micro-powder or plates diamond particles, the cutting cost is greatly reduced, the wafer angularity received by cutting is small with even thickness, thereby providing convenience for subsequent processing.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

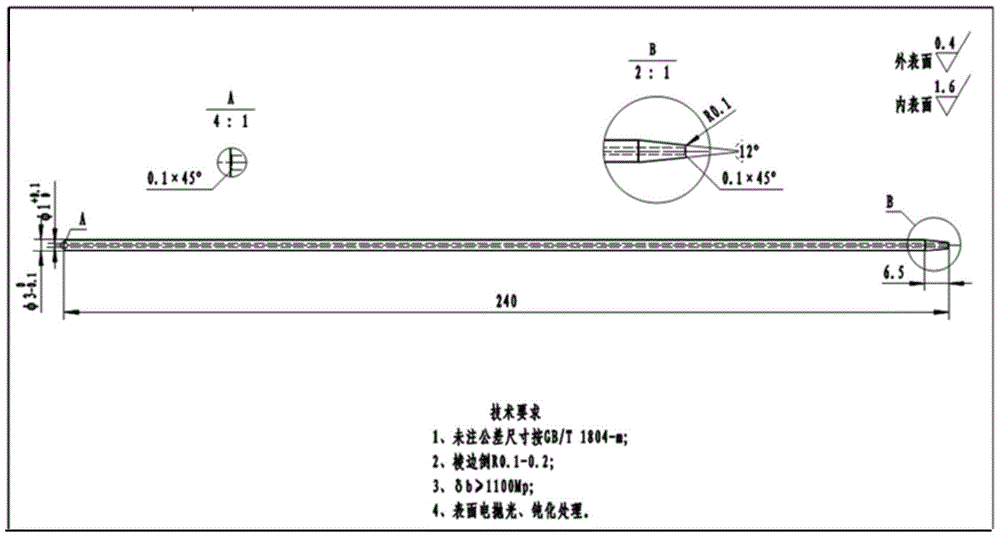

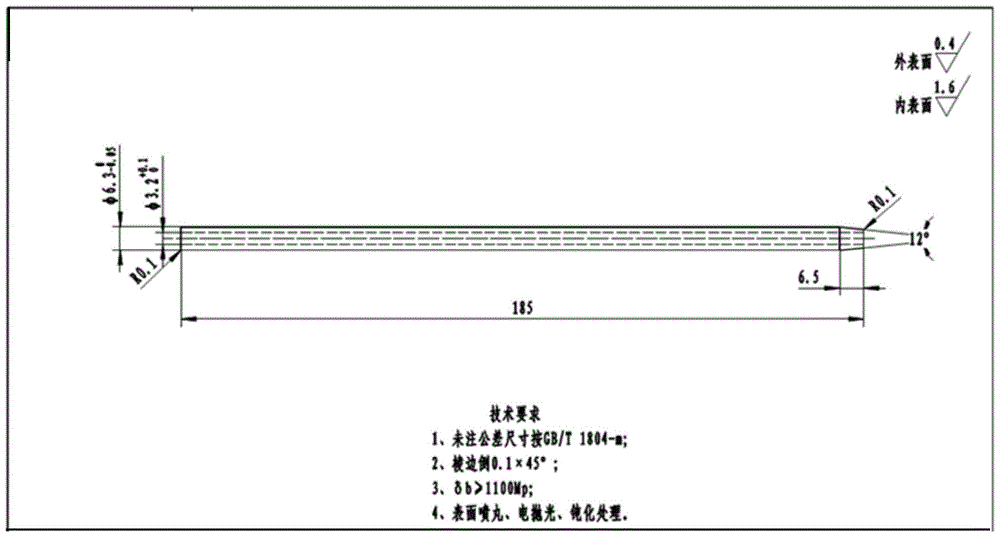

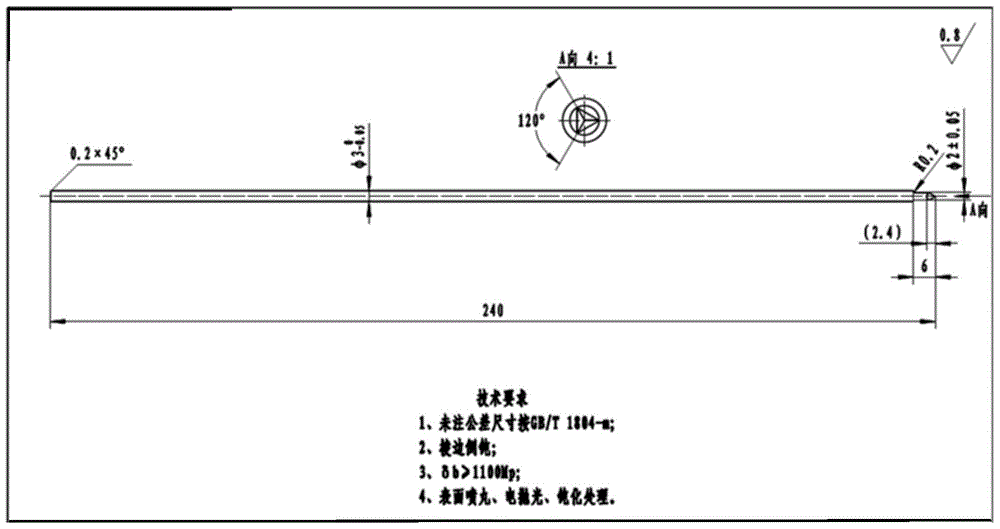

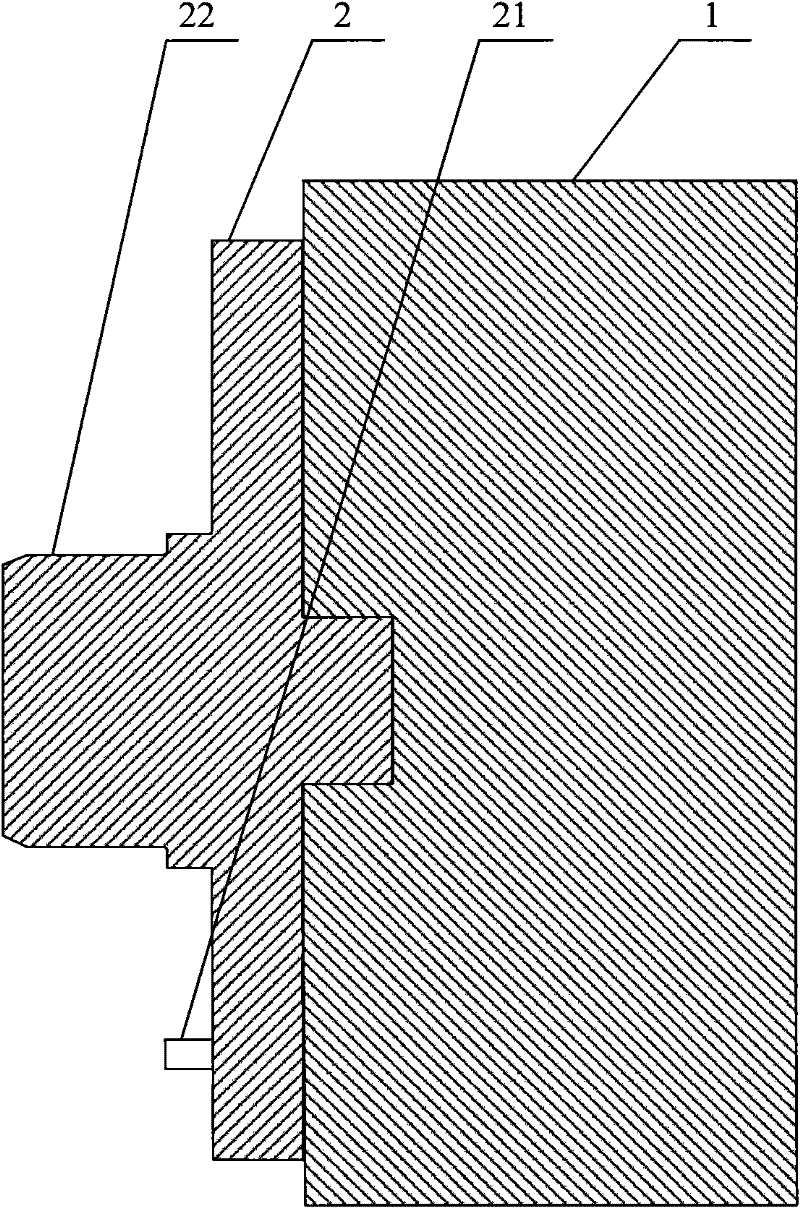

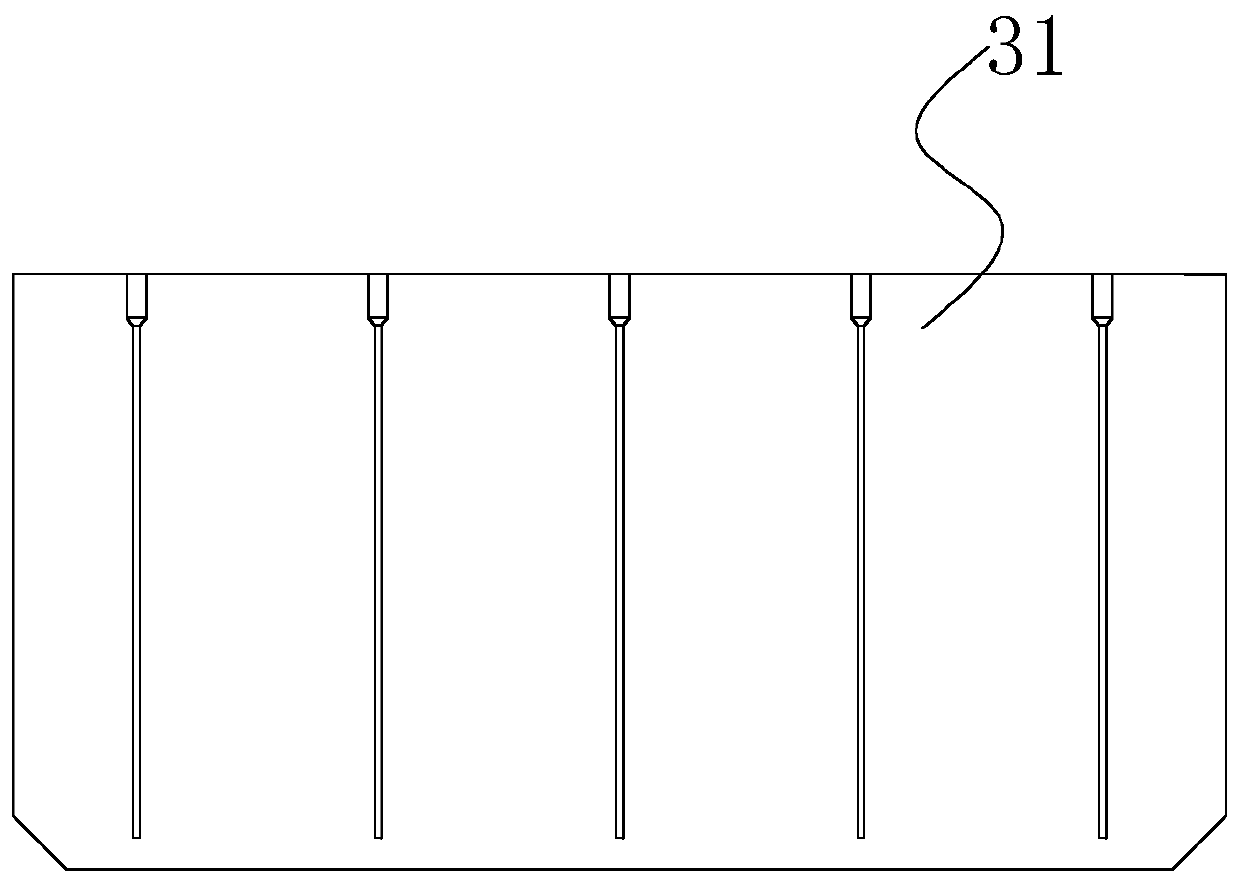

transforaminal puncture system

InactiveCN103976779BSimplified piercing processSimple cutting processCannulasSurgical needlesSacroiliac jointIntervertebral foramen

The invention relates to medical instruments, and discloses an intervertebral foramen mirror puncturing system. The intervertebral foramen mirror puncturing system comprises a one-level cannula, a two-level cannula, an opening awl, an anchor needle and a ring saw. The awl head of the opening awl is provided with a protection shoulder, the head end of the anchor needle is provided with a self-tapping thread and is blunt, the blunt head of the anchor needle is designed not to cause hurt easily when penetrating through the zygopophysis to be close to the nerve, and the bone way can be adjusted more easily and conveniently through the self-tapping thread of the head end of the anchor needle. The ring saw is used for cutting the zygopophysis from the side face by the angle by which the anchor needle enters the canalis vertebralis to expand the bone way until the diameter of the bone way is enough for an endoscope to be placed. By means of the intervertebral foramen mirror puncturing system, the puncturing process of the lumbar vertebra intervertebral foramen mirror operation is obviously simplified, operation is reliable and practical, the operation safety and the operation successful rate are improved, and the parts, exposed to the radiation, of an operator and a patient are greatly reduced.

Owner:SHANGHAI EAST HOSPITAL

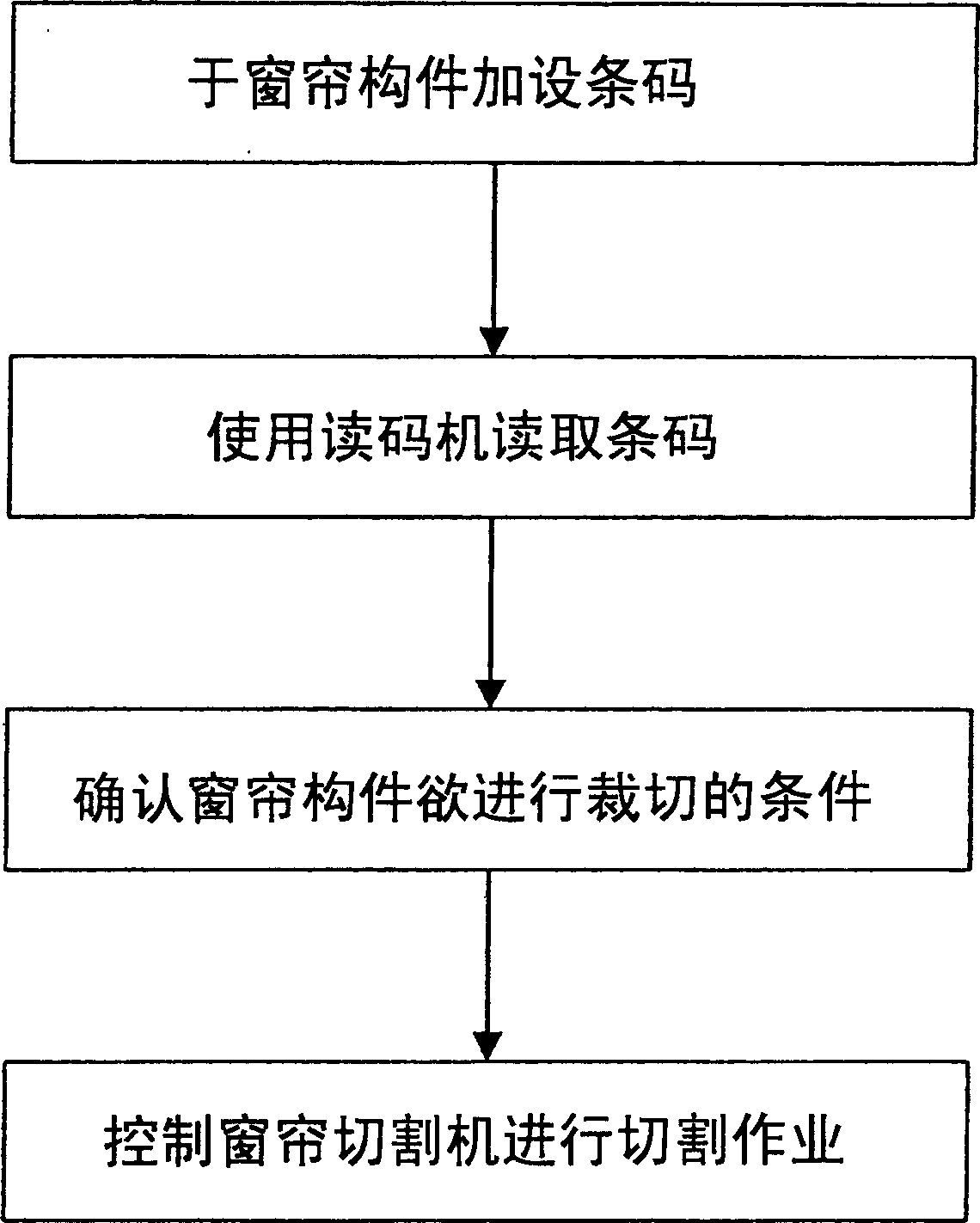

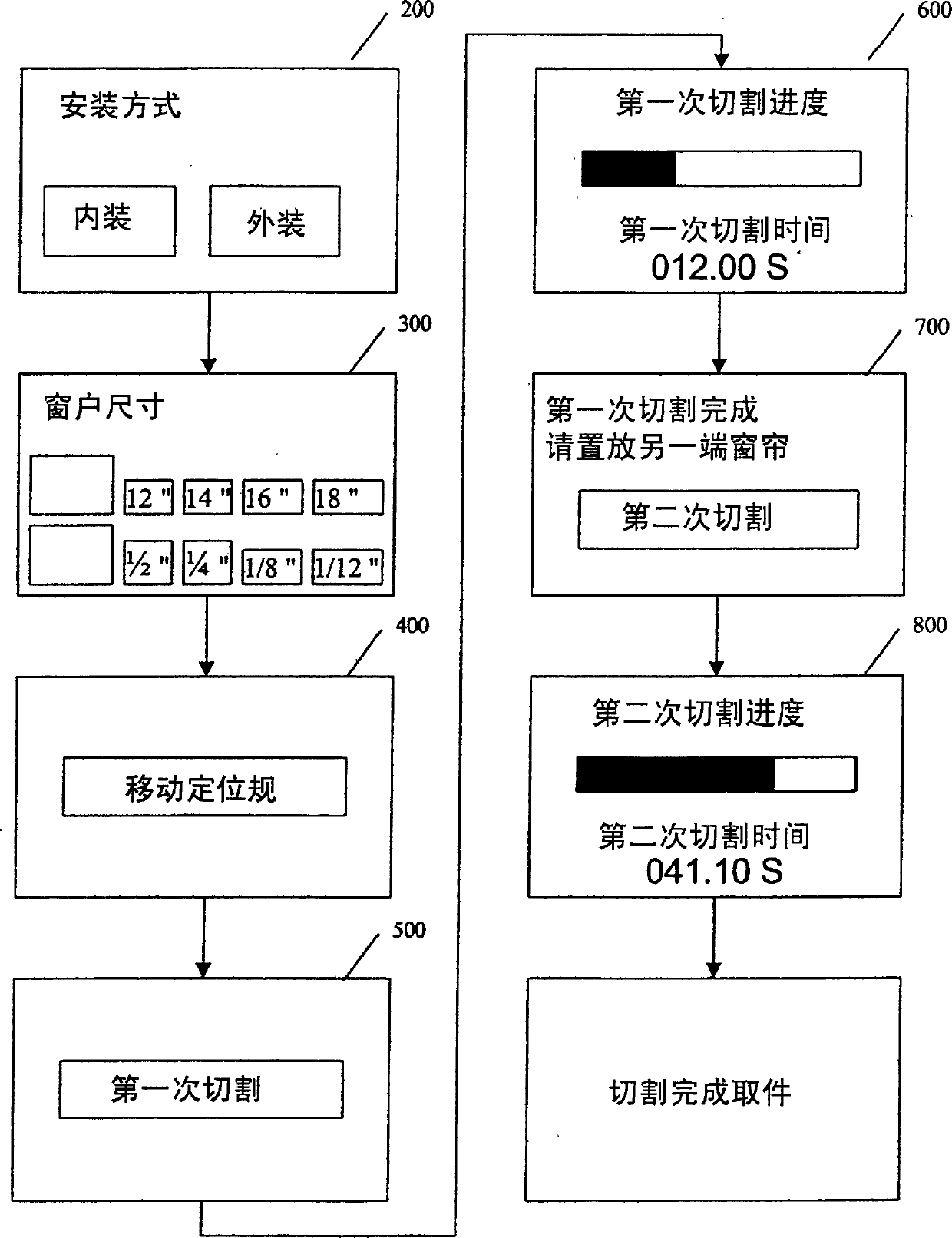

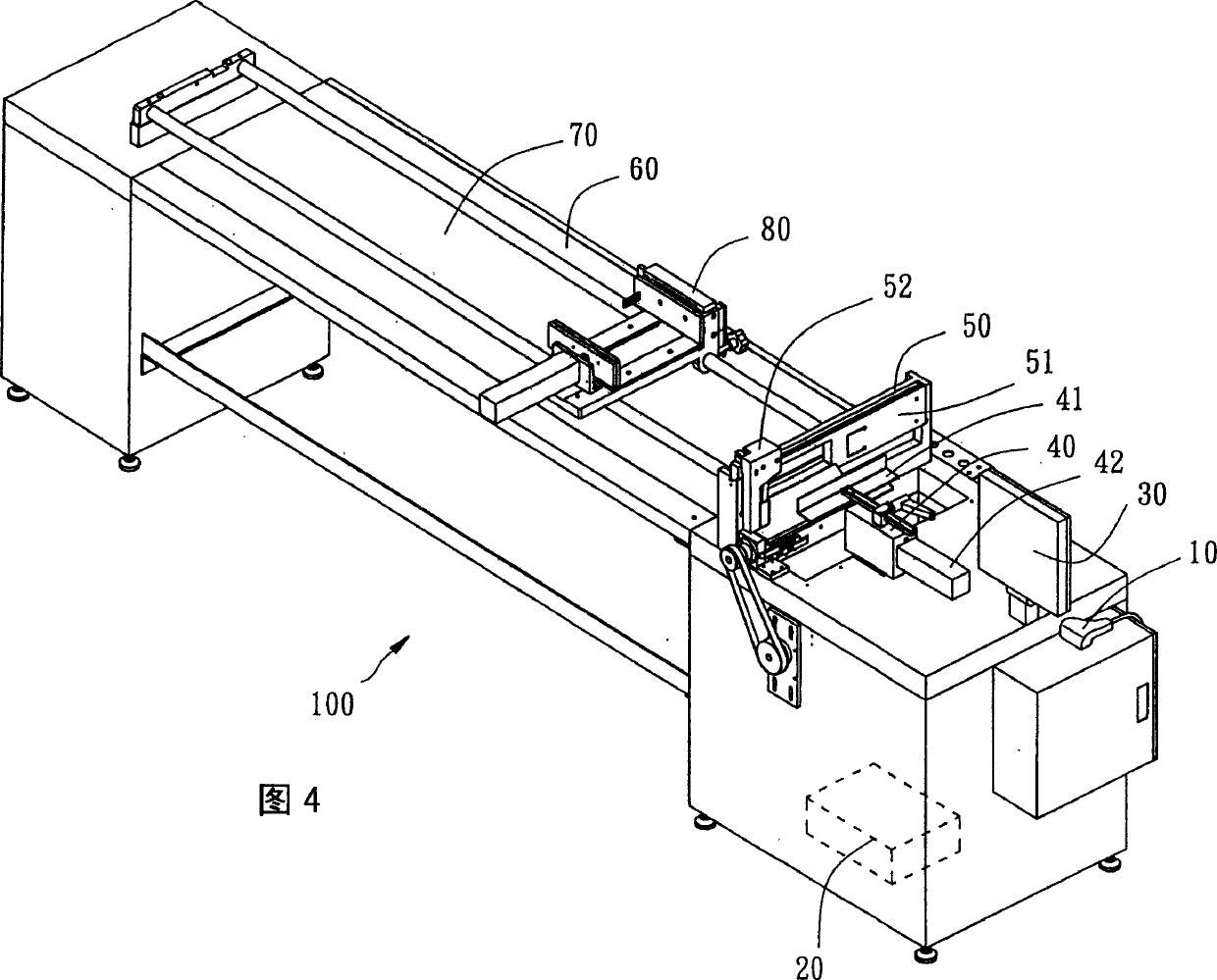

Method and apparatus for automatically defining cutting length by reading window curtain member code

InactiveCN1663755ASimple cutting processImprove work efficiencyDoor/window protective devicesStock shearing machinesAutomatic controlDisplay device

The invention discloses a method automatically setting the cut length according to reading curtain components' codes and its equipment. The process comprises: 1. read the product codes of the curtain components and display the information on the display of the equipment; 2. select the pattern of inputting the curtain components equipment and the window's size to compare it with the information of the curtain components and pre-calculate the cut size and display the results; 3. use the location device of the processor automatic control equipment to displace to the pre-location device, and use the processor to control a cutting unit to cut the curtain components.

Owner:NIEN MADE ENTERPRISE CO LTD +1

Flame cutting process and flame cutting positioning device

InactiveCN102259225ASimplify the cutting processImprove cutting accuracyGas flame welding apparatusFlame cuttingPulp and paper industry

The invention discloses a flame cutting process and a flame cutting positioning device. The flame cutting positioning device is used to be installed on the flame cutting equipment, and includes a tooling body, and the tooling body is provided with a positioning installation structure connected to the positioning structure on the part to be processed as the positioning reference for processing at both ends. The technical scheme of the invention can effectively realize the double-sided processing of the parts, thereby improving the cutting precision in the flame cutting processing of the parts and simplifying the processing technology.

Owner:HUAINAN ZHENG COAL MACHINE SHUNLI MACHINERY +1

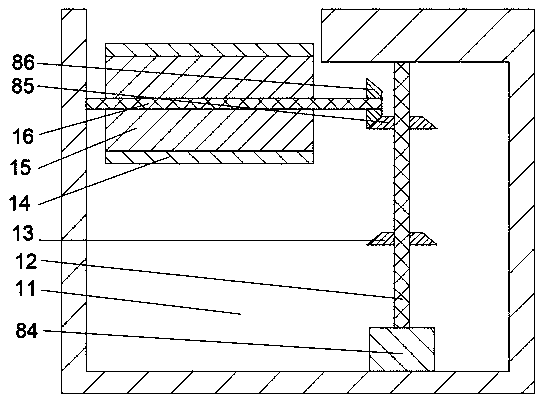

Tubular plastic part cutting device

ActiveCN110539347ASimple cutting processAdjustable sizeMetal working apparatusMechanical transmission

The invention discloses a tubular plastic part cutting device. The tubular plastic part cutting device comprises a machine shell. A collecting cavity is formed in the machine shell and used for takingout a cut plastic part, and the lower end of the collecting cavity is connected with the outside world. A driving mechanism which provides the power and drives the plastic part to move is arranged inthe left end wall of the collecting cavity, and a control mechanism which controls a machine to work is arranged in the right end wall of the collecting cavity. A working cavity is further formed inthe machine shell, and the left end of the working cavity is connected with the outside world. An adjusting mechanism which can adjust the length of the cut plastic part is arranged in the upper end wall of the left side of the working cavity, and a working mechanism which clamps and cuts the plastic part is arranged in the working cavity. The tubular plastic part cutting device can automaticallyconduct cutting treatment on the tubular plastic part, can also adjust the size of the cut plastic part, simplifies the cutting process of the tubular plastic part and improves the working efficiencythrough the mechanical transmission.

Owner:南通市欣金惠机械有限公司

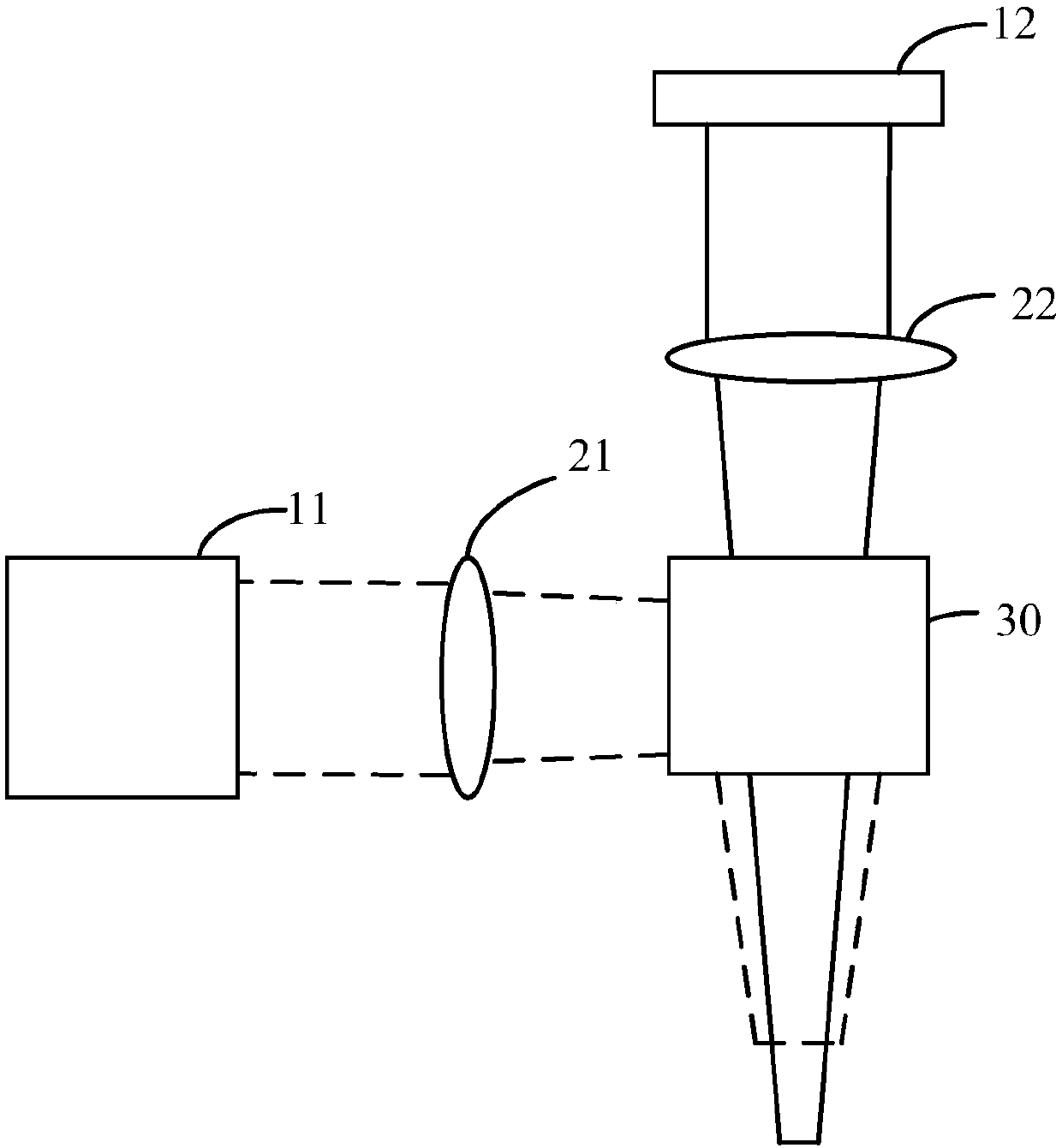

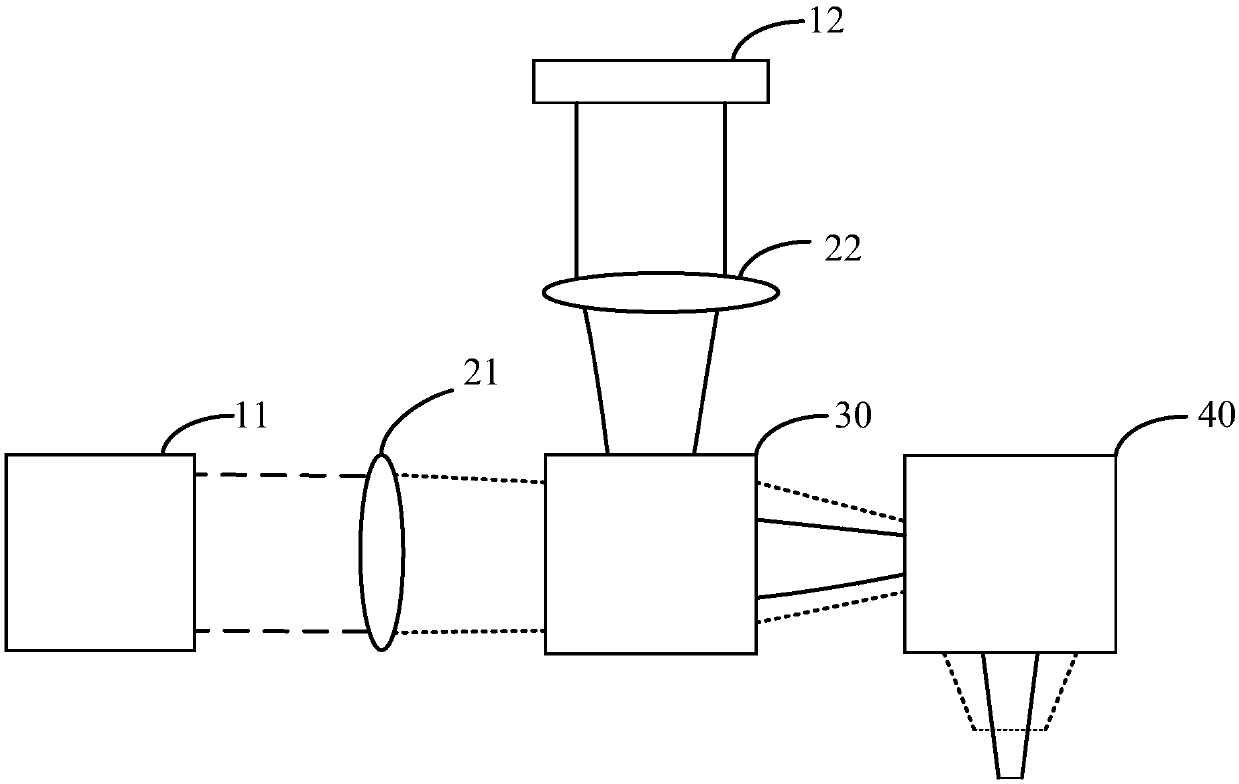

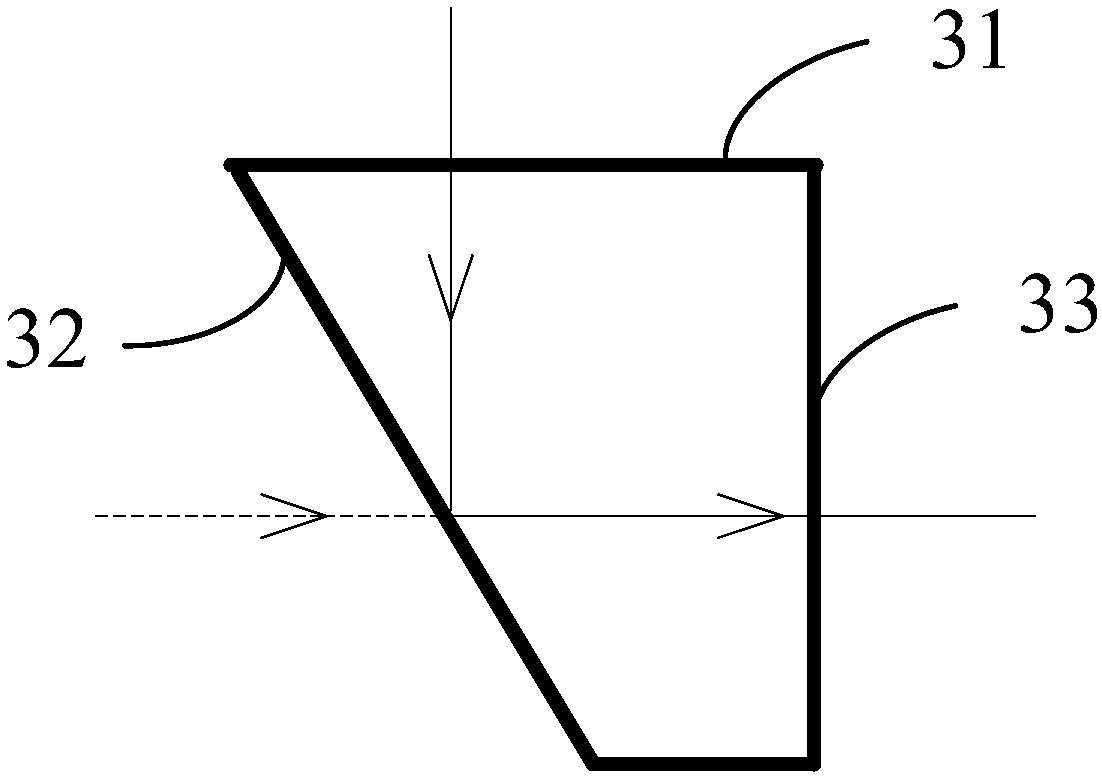

Laser machining system and method

PendingCN109909601AImprove cut qualityReduce cutting timeWelding/soldering/cutting articlesMetal working apparatusLaser processingOptoelectronics

The invention provides a laser machining system and method. The laser machining system comprises at least two lasers, focusing modules and a beam combining module, wherein the lasers are used for generating at least two laser beams; the focusing modules are arranged corresponding to at least two lasers in a one-to-one mode, and are used for adjusting the focusing positions of the laser beams generated by the corresponding lasers; and the beam combining module is used for receiving at least two laser beams with the adjusted focusing positions and coaxially outputting at least two laser beams. According to the system, the cutting quality of a to-be-machined workpiece can be improved, the reject ratio of the to-be-machined workpiece can be effectively reduced, meanwhile, the application rangeof the lasers can be expanded, and the flexibility of adjusting the focusing positions of the laser beams generated by the lasers can be improved.

Owner:BOE TECH GRP CO LTD +1

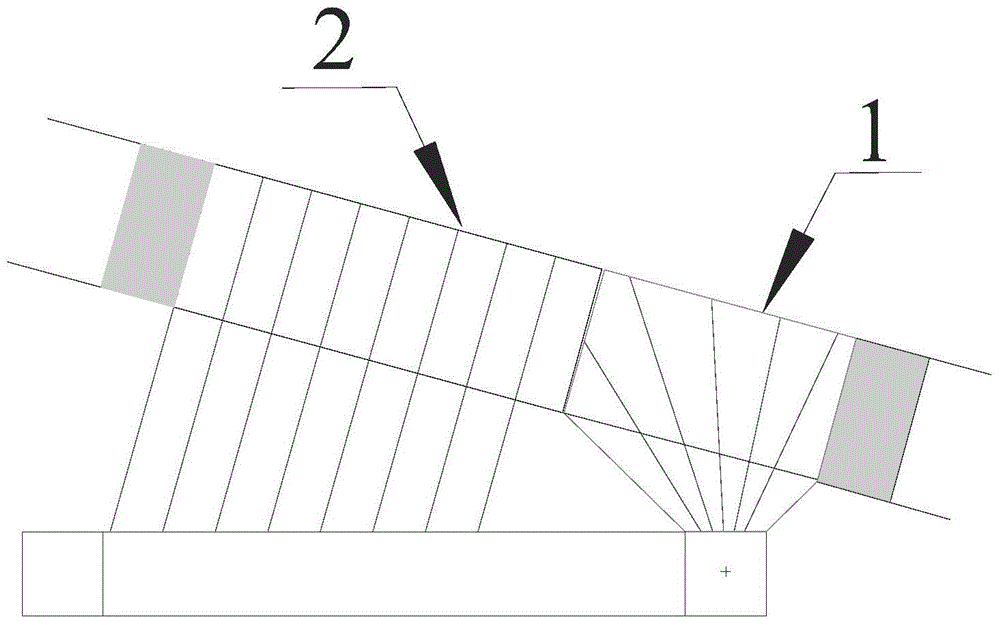

A Novel Mining Method for Gently Dipping Thin-Medium Thick Orebodies

InactiveCN103590831BRealize complementary advantagesJob safetyUnderground miningSurface miningWorkloadStoping

The invention discloses a novel mining method of gently-inclined thin and medium thickness ore bodies. According to the method, ore bodies in one stope are stoped by dividing the stope into two stope areas through steps: firstly, stoping is performed at the stope area (1) by using a pillarless sublevel caving method: the ore bodies are directly caved in single sublevel by using medium-length blastholes; a certain empty area formed after ore removal is used as a free surface for stoping of the stope area (2); then, the stoping is performed at the stope area (2) by using a blasting force carrying mining method; fan-shaped medium-length blastholes are arranged in a manner perpendicular to the ore body tendency, and are filled with powder according to sections, the decking parts are the parts from the lower disc boundaries of the ore bodies to the hole bottoms; the empty area formed during the stoping of the stope area (1) is used as a free surface for blasting row by row; ores in the stope area (2) are thrown in the empty area by using the blasting force. The method integrates the pillarless sublevel caving method and the blast force carrying mining method, so that the supporting difficulty and the workload are reduced, the operation is safer, the mining cost is low, and the labor productivity is high.

Owner:UNIV OF SCI & TECH BEIJING

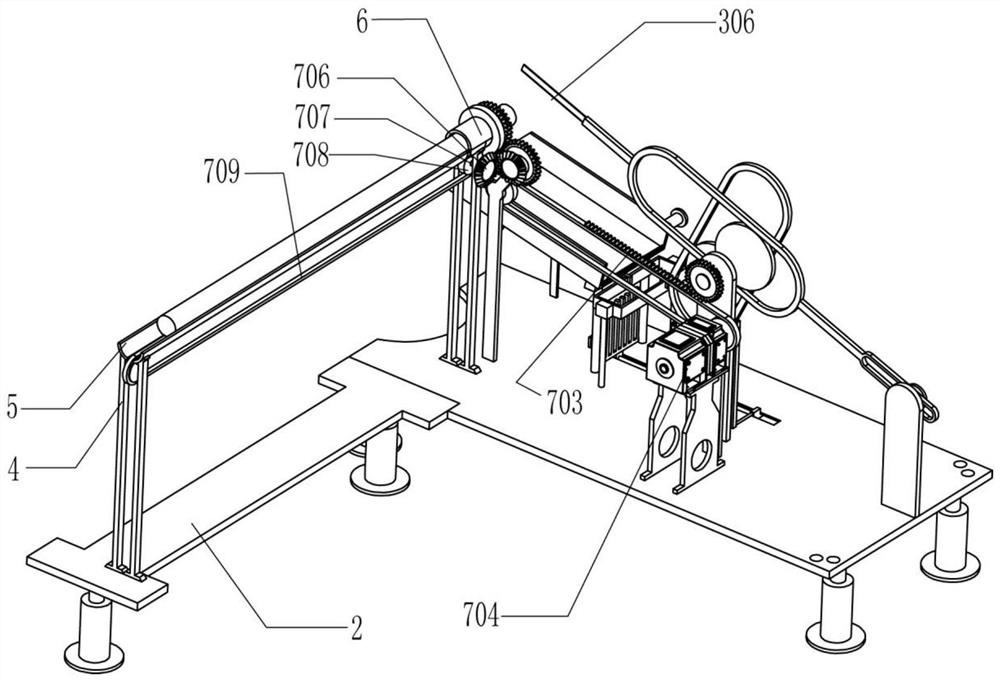

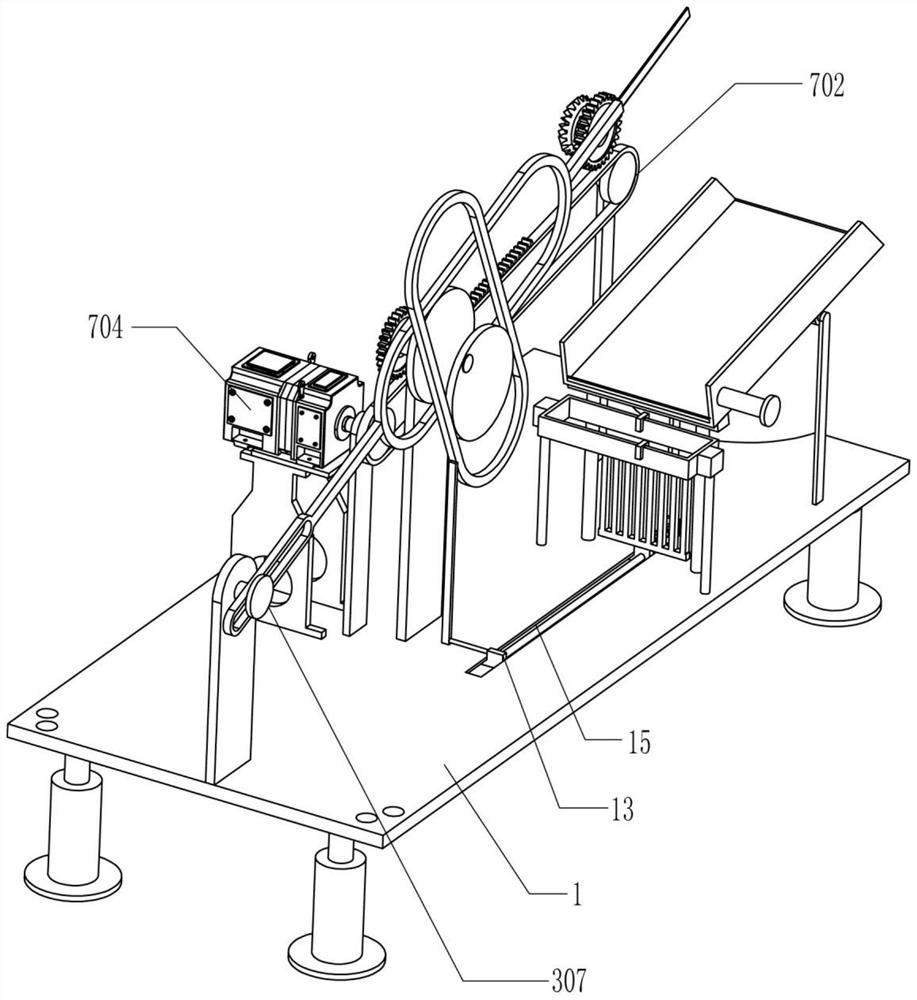

Equivalent slitting machine with automatic pushing function

ActiveCN111604964AImplement the function of moving forwardRealize the function of equal cuttingMetal working apparatusFood treatmentEngineeringMechanical engineering

The invention relates to the technical field of slitting equipment, in particular to an equivalent slitting machine with an automatic pushing function. The equivalent slitting machine with the automatic pushing function can achieve the purposes that sugarcane can be evenly and equivalently slit, the sugarcane can be automatically pushed, slit and collected integrally, and meanwhile the surface ofthe sugarcane can be cleaned. According to the technical scheme, the equivalent slitting machine with the automatic pushing function comprises a first base, a second base, a swing cutting device, supporting rods, an arc-shaped guide plate, a limiting arc-shaped plate, an intermittent transmission device and the like. The swing cutting device is mounted on one side face of the first base. By meansof the intermittent transmission device, the sugarcane in the arc-shaped guide plate can be pushed to be conveyed forwards intermittently, the swing cutting device can equivalently slit the conveyed sugarcane, and the effect of slitting one piece of sugarcane into multiple uniform and equivalent parts is achieved.

Owner:广西东门南华糖业有限责任公司

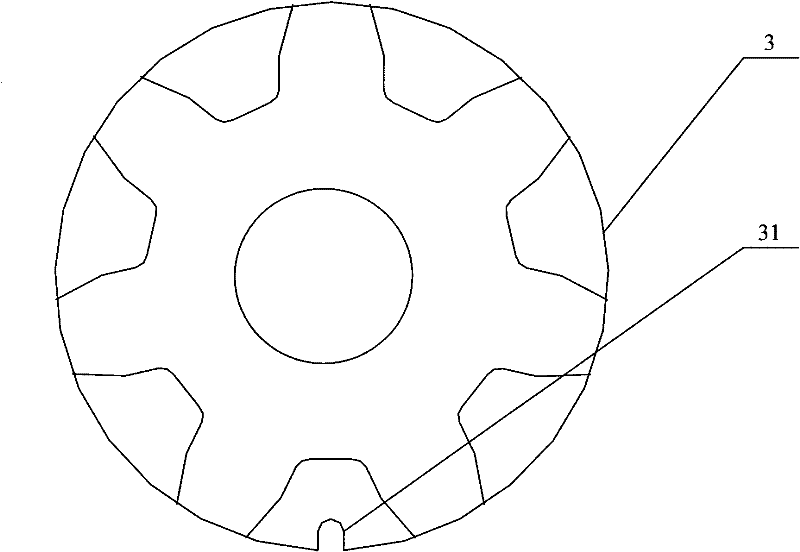

Preparation method of metal soft magnetic powder core with low forming pressure and high production efficiency

The invention relates to a preparation method of a metal soft magnetic powder core with low forming pressure and high production efficiency, and belongs to the technical field of preparation of metal soft magnetic powder cores. The preparation method comprises the following operation steps: (1) screening iron-based powder into three levels, and taking three kinds of iron-based powder according to the mass percent to obtain powder; (2) mixing the three kinds of powder to obtain mixed powder; (3) adding epoxy resin and zinc stearate into the mixed powder, and uniformly stirring to obtain blank powder; (4) performing extrusion processing on the blank powder in a screw extruder to obtain a hollow pipe, and cutting the hollow pipe into a magnet ring green body; and (5) baking the magnet ring green body in a box-type furnace to obtain a metal soft magnetic powder core; wherein the density of the metal soft magnetic powder core ranges from 5.78 g / cm<3> to 7.20 g / cm<3>, and the magnetic conductivity ranges from 48.0 to 49.5. The forming pressure of the metal soft magnetic powder core is remarkably reduced through the particle size ratio, so that the metal soft magnetic powder core can be formed in an extrusion and cutting mode, the cost is reduced, and the production efficiency is greatly improved.

Owner:江苏瑞德磁性材料有限公司

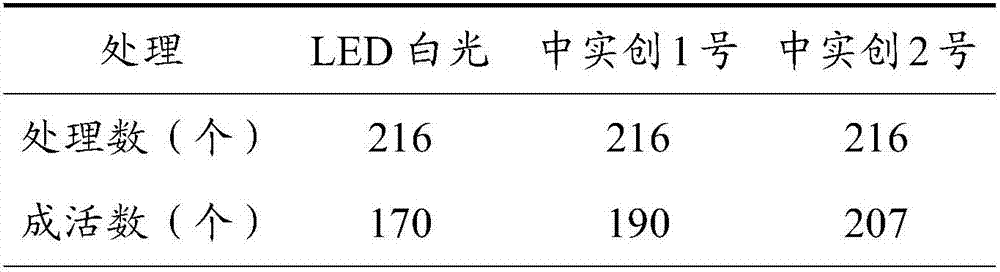

Rose cuttage propagation method and rose indoor cultivation method

InactiveCN107006353AImprove survival rateShorten the growth cycleSaving energy measuresCultivating equipmentsWater contentCLOCK

The invention relates to a rose cuttage propagation method. After being treated, cuttings are inserted in a108-hole aperture disk equipped with a cutting medium; management is performed according to the following conditions that cultivation is performed in a room, the relative humidity of ambient air is 75-85%, the temperature is 23-25 DEG C and the water content of the cutting medium is 75-80%; three days after cuttage, LED plant cultivation lamps are used for supplementing lighting, wherein the ratio of red light to blue light in light emitted by the LED plant cultivation lamps is 2:1 to 4:1, the wavelength of the red light is 650-660 nm, the wavelength of the blue light is 450-460 nm, the light intensity is 100-120 micro mol / m<2>, and light supplementing is conducted at 7 O'clock to 17 O'clock every day. By means of the cuttage propagation method, rose seedlings are high in survival rate, and the survival rate is as high as 96%. The invention further provides a rose indoor cultivation method, roses can thus germinate more branches and buds, the commodity of flowers can be improved, and the market demand is thus met better.

Owner:DONGGUAN SINOINNOVO SEMICON LIGHTING

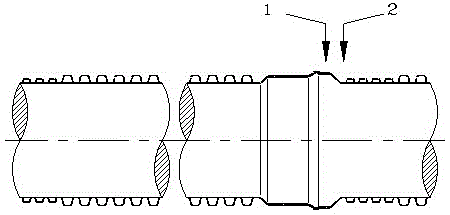

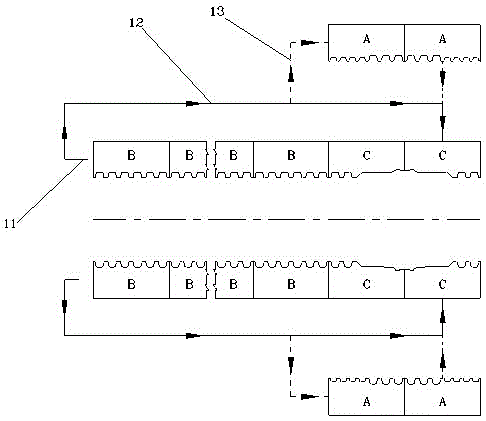

Production process and device for machining PE double-wall corrugated pipe with socket and spigot on line

ActiveCN105034397AReduce workloadSimplify the cutting processTubular articlesDouble walledMechanical engineering

The invention discloses a production process and device for machining a PE double-wall corrugated pipe with a socket and a spigot on line. A manner for forming the continuous pipe includes sequential circulation of a straight pipe section, a socket / spigot section, a symmetric socket / spigot section, a straight pipe section, a spigot / socket section and a symmetric spigot / socket section. When the formed continuous pipe is cut, the pipe is cut in the symmetric axis position of the socket / spigot section and the symmetric socket / spigot section so that a unit pipe with one end being a spigot section, the other end being a socket section and the middle being a straight pipe section can be obtained. The production process and device have the beneficial effects that when the pipe is produced, due to the fact that the structures of the spigot / socket section and the symmetric spigot / socket section are symmetric, a transitional part does not need to be designed, and no waste is generated in the whole manufacturing process.

Owner:公元管道(上海)有限公司

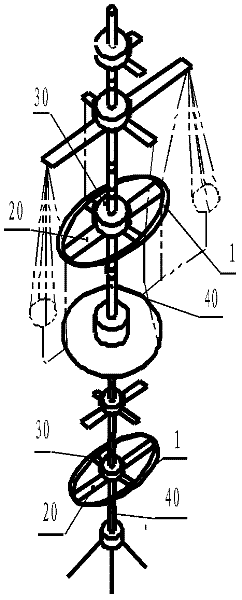

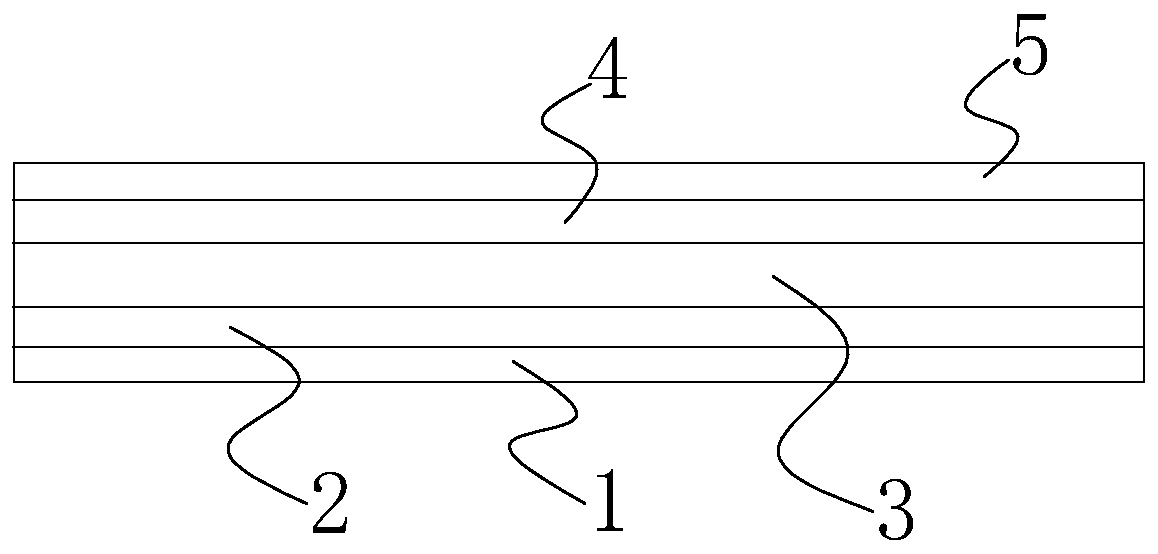

Framework model for measuring dress, cutting dress and fitting finished dress

InactiveCN102349718ASimple structureSimple cutting processClothes making applicancesBody typeMechanical engineering

The invention discloses a framework model for measuring dress, cutting dress and fitting finished dress. The framework model is formed by combining formwork assemblies; the formwork assemblies comprise a ruler sheet, a body width thick ruler, a fixing base and a central standpipe; the ruler sheet is connected with the body width thick ruler, the body width thick ruler is connected to the fixing base, and the fixing base is connected with the central standpipe; the ruler sheet comprises a ruler sheet body, and the middle of the ruler sheet body is provided with a movable ruler and a fastening device for connecting the ruler sheet body with the movable ruler; the body width thick ruler comprises a main sheet on which a movable sheet is arranged, one ends, at different sides, of the main sheet and the movable sheet are respectively provided with a fine rod hole through which a shaft rod can penetrate; and the fixing base comprises a clamping round disc for fixing the body width thickness ruler and a lower clamping round disc. The framework model has a simple structure and can be used for simplifying the dress measuring and cutting process, and the finished dress is suitable for a customized body type.

Owner:QILU UNIV OF TECH

Half-slice-laminated solar assembly and preparation method thereof

PendingCN110335915ALower resistanceImprove light utilizationFinal product manufacturePhotovoltaic energy generationToughened glassLaser

The invention provides a half-slice-laminated solar assembly and a preparation method thereof. The method comprises the following steps: S1) slicing a battery piece to obtained a sliced battery, and carrying out insulation treatment on the cutting edge by utilizing laser; S2) placing a solder strip on the sliced battery and welding the sliced battery and the solder strip together; S3) repeating the process of the S2) to obtain a plurality of sliced batteries having solder strips, and arranging and welding the plurality of sliced batteries in an overlapping manner in sequence through the solderstrips to obtain a battery string; S4) repeating the step S3) to obtain a plurality of battery strings, and arranging the plurality of battery strings according to the assembly layout to obtain a battery string assembly; S5) laying a first adhesive film layer on tempered glass, and placing the battery string assembly on the upper surface of the first adhesive film layer; S6) laying a second adhesive film layer on the upper surface of the battery string assembly, and then, placing a backboard material layer on the second adhesive film layer to obtain a laminated assembly; and S7) carrying outlamination processing on the laminated assembly, and then, carrying out package processing. The method has the advantages of simple process and firm and stable welding and the like.

Owner:河北绍博光伏科技有限公司

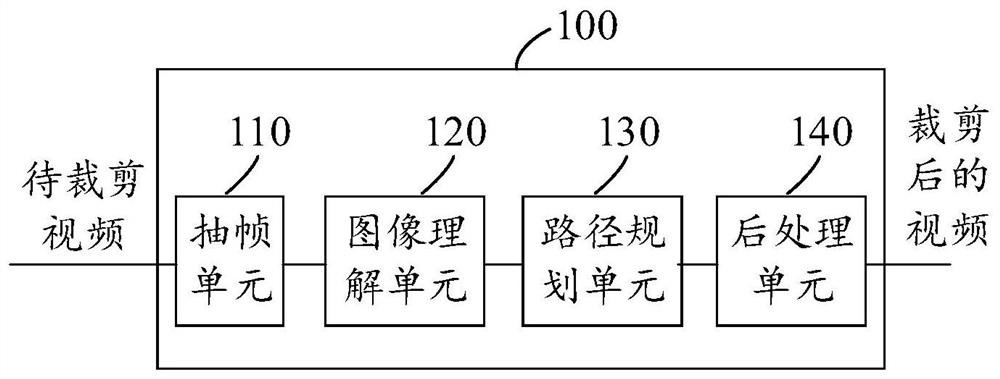

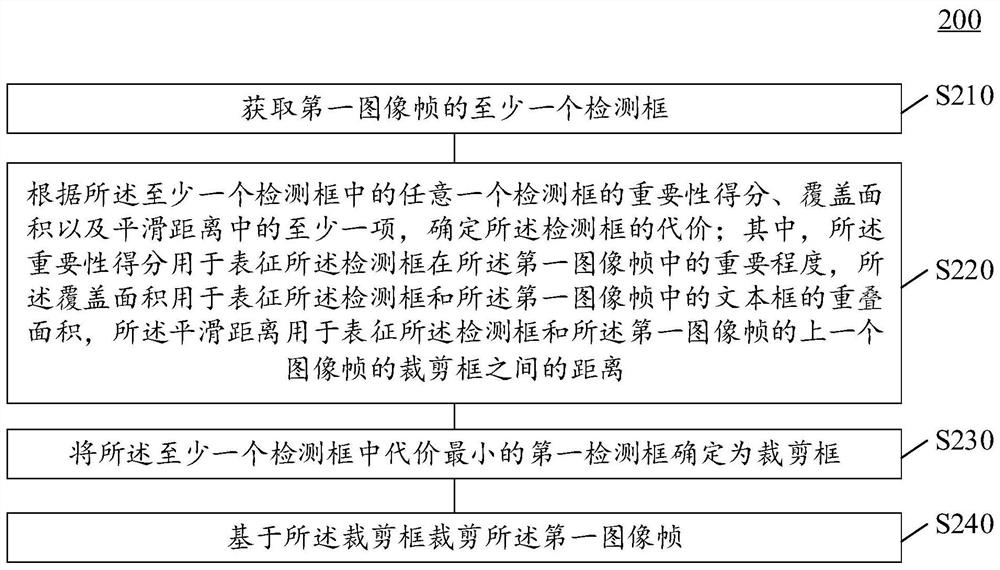

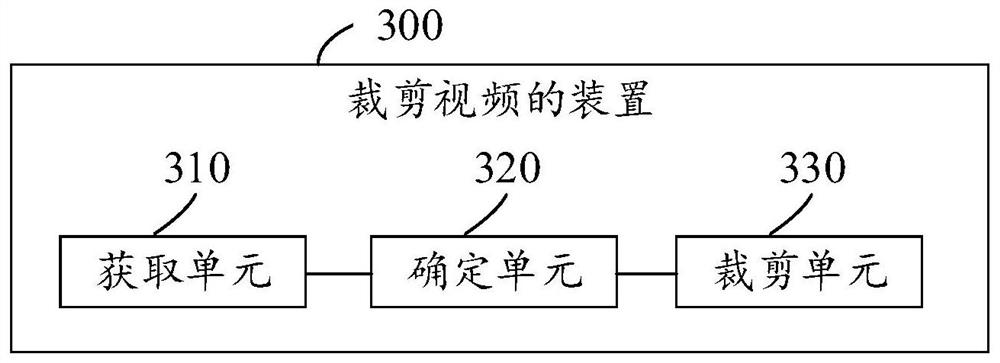

Video cropping method and device, equipment and storage medium

ActiveCN112188283AAchieve croppingIncrease flexibilitySelective content distributionImage enhancementAgricultural engineeringEngineering

The invention provides a video cropping method and device, equipment and a storage medium. The method comprises the following steps: acquiring at least one detection box of a first image frame; determining the cost of the detection box according to at least one selected from the importance score, the coverage area and the smooth distance of any detection box in the at least one detection box; determining the first detection box with the lowest cost in the at least one detection box as a cropping box; and cropping a first image frame based on the cropping frame. Based on the cost of each detection frame, the first detection frame with the minimum cost in the at least one detection frame is determined as the cropping frame so as to crop the first image frame, thereby improving the flexibility of video cropping and enhancing the cropping effect under the condition of ensuring the simplification of a video cropping process.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

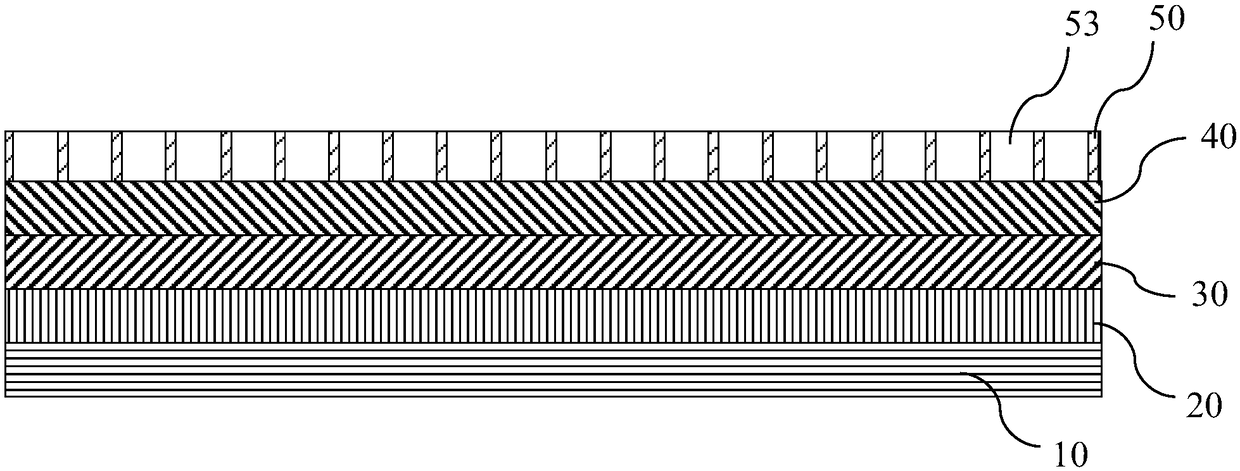

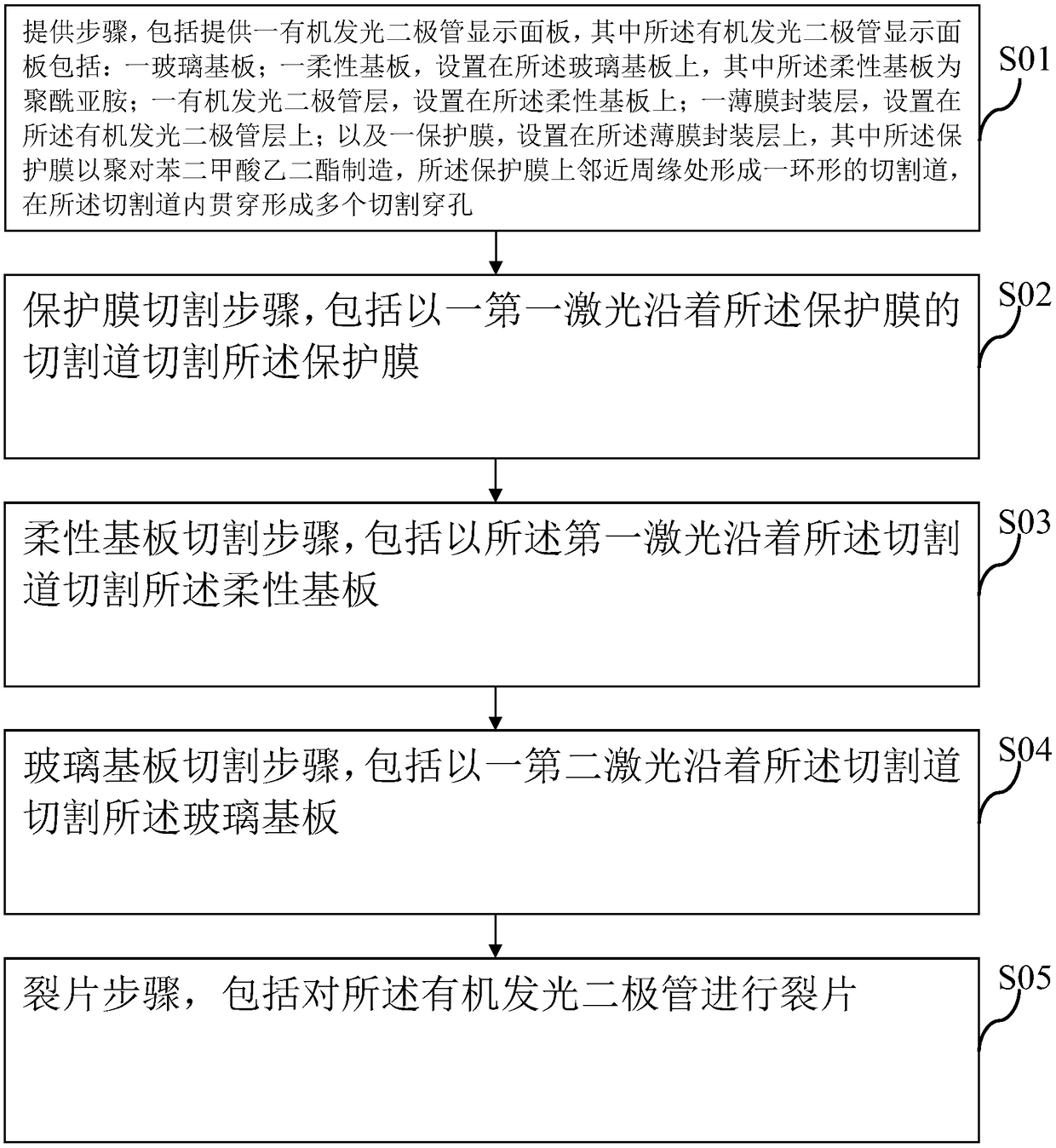

Organic light emitting diode display panel and cutting method thereof

ActiveCN109192881AReduce the amount of PETAvoid problems that reduce process efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPolyethylene terephthalateMaterial Perforation

An organic light emitting diode display panel includes a glass substrate, a flexible substrate, an organic light emitting diode layer, a thin film encapsulation layer, and a protective film. The flexible substrate is arranged on the glass substrate. The organic light emitting diode layer is arranged on the flexible substrate. The thin film encapsulation layer is arranged on the organic light emitting diode layer. The protective film is disposed on the thin film encapsulation layer, wherein the protective film is made of polyethylene terephthalate, an annular cutting channel is formed on the protective film adjacent to the peripheral edge, and a plurality of cutting perforations are formed through the cutting channel. The protective film with cutting perforation can reduce the number of laser alternating uses for cutting the display panel, thereby simplifying the cutting process and improving the yield of the display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com