Digital die-free sand mould extrusion forming method

A technology for extrusion forming and sand molding, which is applied in the directions of mold components, molds, and cores. Process controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

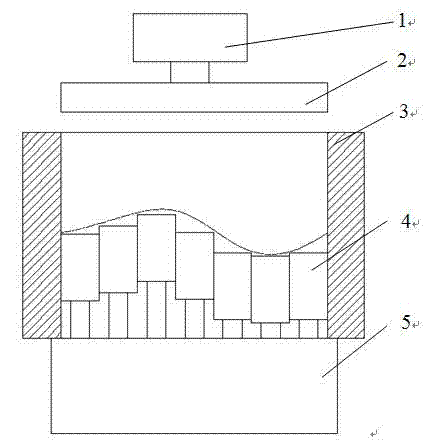

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] The specific steps of the digitized moldless sand extrusion forming method of the present invention are as follows:

[0032] A. Establish a CAD model according to the shape of the sand mold;

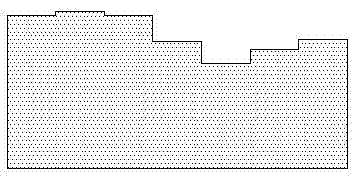

[0033] B, establish the approximate model of sand mold according to CAD model;

[0034] C. Write the extrusion array control code according to the approximate model of the sand mold;

[0035] D. Control the movement distance of the extrusion head (4) through CAD, so that each extrusion head (4) on the extrusion array generates an approximate shape of the sand mold;

[0036] E. Select the corresponding sand box (3) according to the size requirements of the sand mold, install and fix it on the workbench;

[0037] F. Introduce the uniformly stirred molding sand and binder into the sand box, lower the pressure plate (2), and carry out extrusion molding;

[0038] G. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com