Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Reference alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

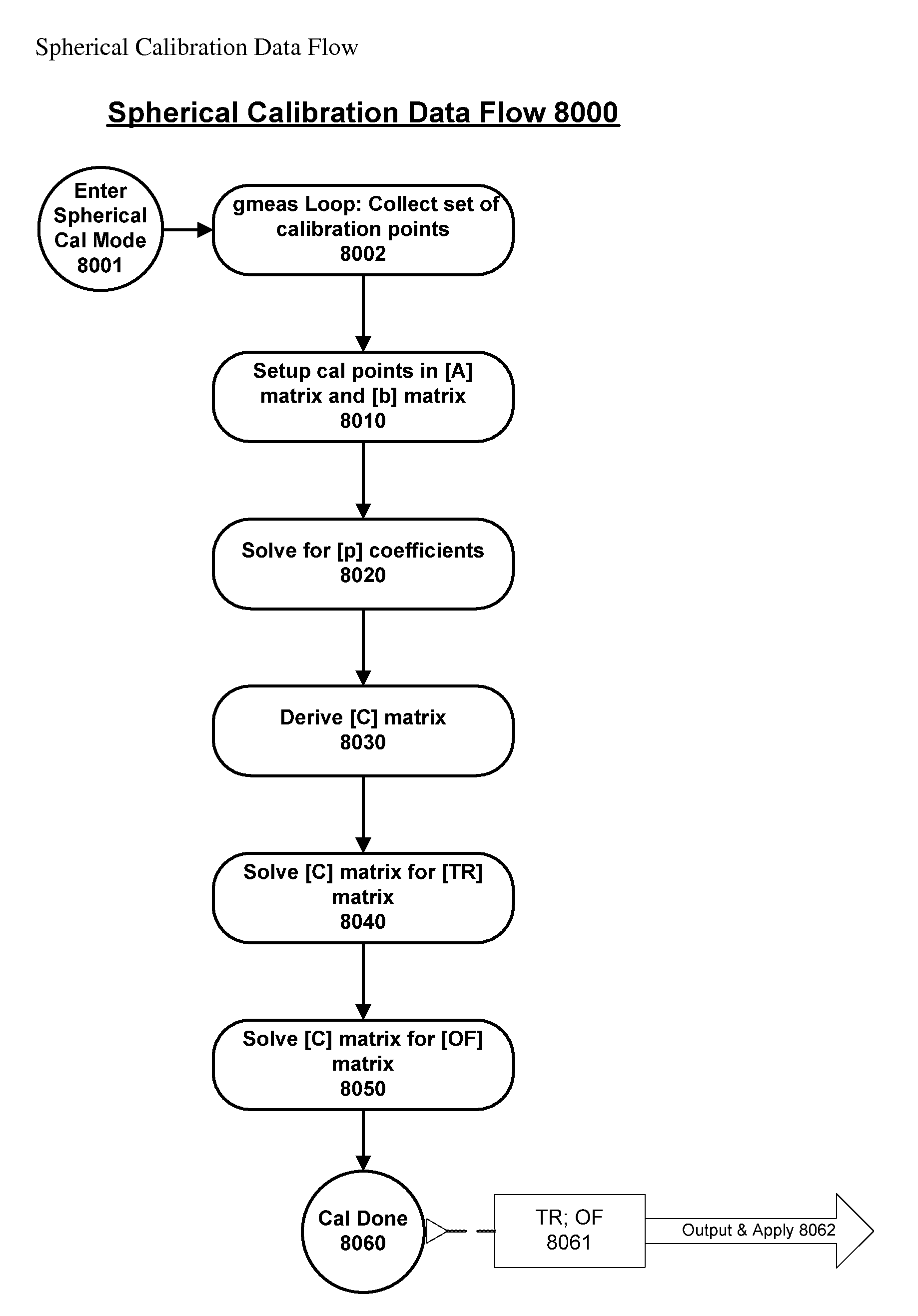

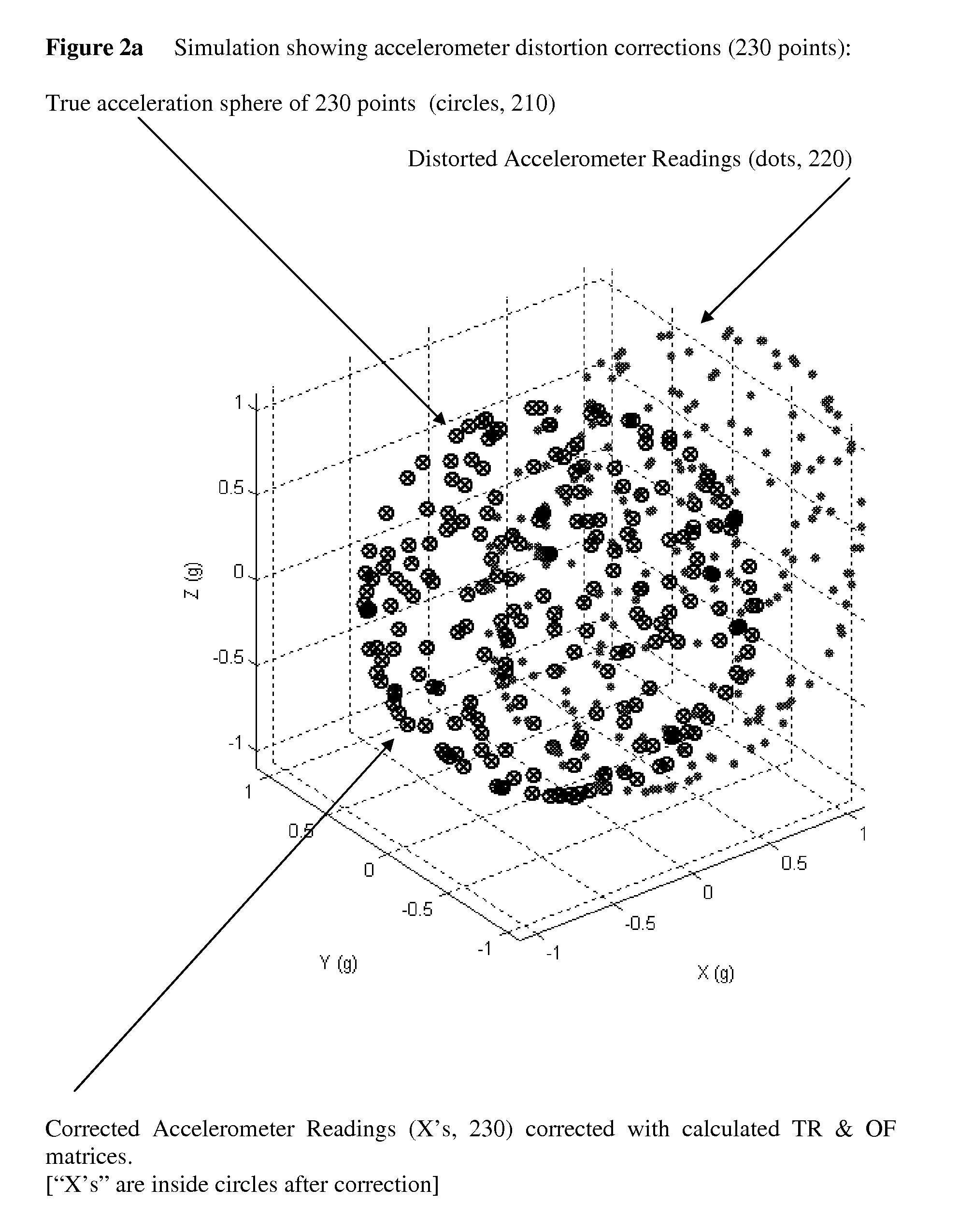

Spherical calibration and reference alignment algorithms

InactiveUS7930148B1Improve accuracyGain and offset errorSurveyAmplifier modifications to reduce noise influenceEllipseReference device

Inclinometer and directional field sensor readings can have gain, offset, and non-orthogonality errors, as well as reference alignment rotation errors. When a series of readings are taken by a three axis sensor with a variety of different orientations, the resulting dataset looks like a perfect hypothetical sphere in the absence of any errors; with errors as mentioned above the dataset looks like an offset, rotated, ellipsoidal quadratic surface. This invention provides a simple method of removing the above errors from a tilt reference device. A disclosed algorithm is divided into two distinct components: the ellipsoidal quadratic surface component, which covers gain, offset, and axis misalignment; and the rotation component, which covers rotation relative to a set of reference axes. The solution presented here addresses both components combined, or separated and for inclinometers, magnetometers and rate sensors.

Owner:P&I

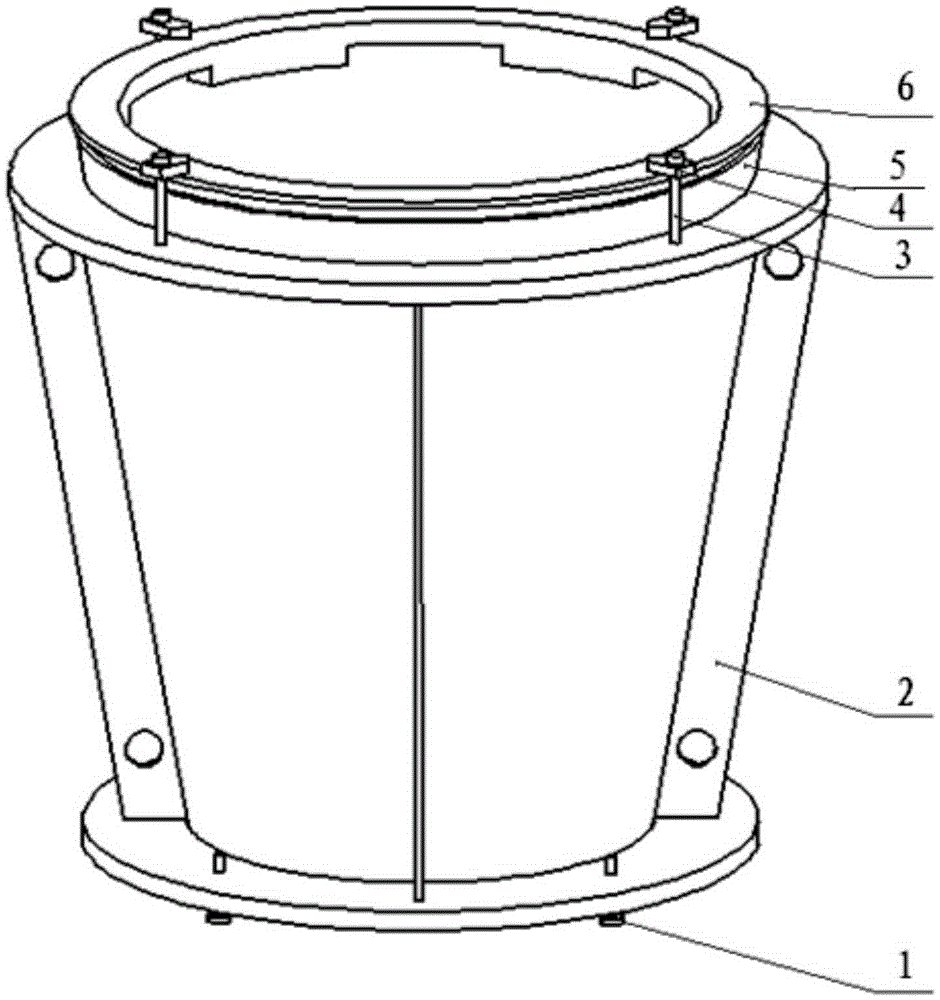

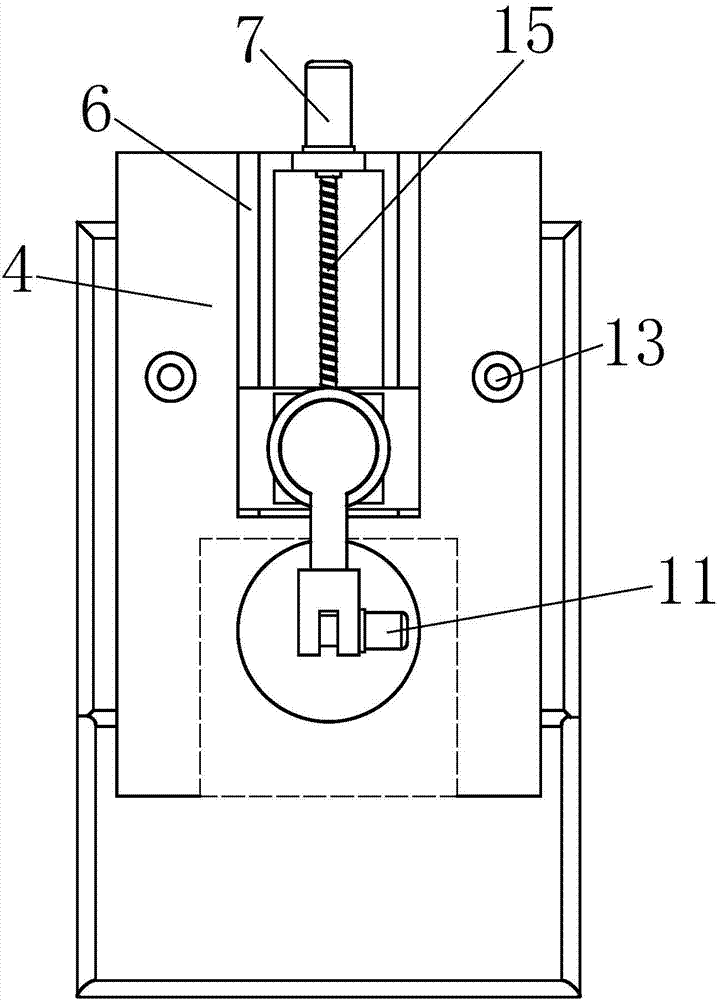

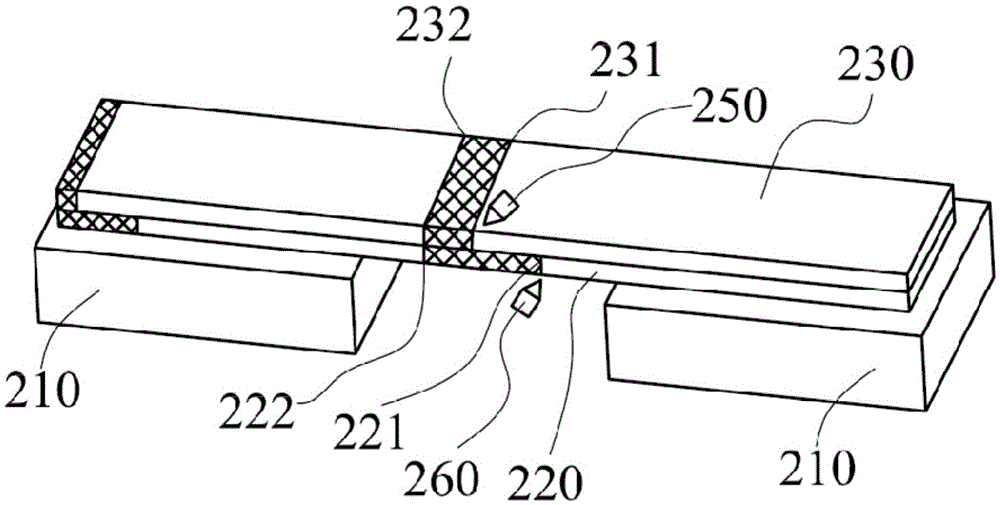

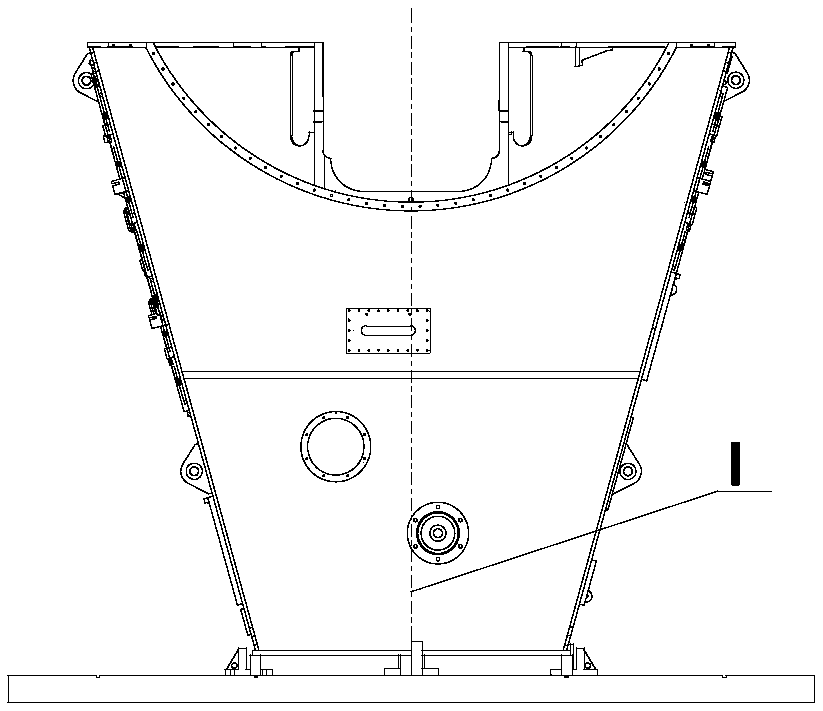

Numerical control machining clamping and positioning device for large thin-wall conical shell part

ActiveCN105345515ANo deformationAvoid giving up the knifePositioning apparatusMetal-working holdersNumerical controlReference alignment

The invention provides a numerical control machining clamping and positioning device for a large thin-wall conical shell part and belongs to the technical field of numerical control machining. The numerical control machining clamping and positioning device aims at solving the problems that when machining is conducted without an external clamping and fixing tool, the final size is difficult to guarantee, the part scrapping phenomenon is likely to happen, and the amount of feed is usually reduced in order to avoid the situation, so that machining efficiency is low, time is wasted, and the period is long. A conical barrel is supported on a workbench through supporting bolts of the clamping and positioning device, and the large-diameter end of the conical barrel is placed upwards; the machined workpiece is placed in the conical barrel, and the machined workpiece and the conical barrel are coaxially arranged; and a large-end conical ring liner plate is pressed on a large-end conical stop opening of the machined workpiece, and the machined workpiece is axially fixed through pressing plate bolts and pressing plates. It is guaranteed that the machined thin-wall conical shell part is not deformed in the machining process; angular reference alignment is convenient, and axial positioning is accurate; the structure is simple, and clamping and fixing are reliable; and the manufacturing period is short, and cost is low.

Owner:航天科工哈尔滨风华有限公司

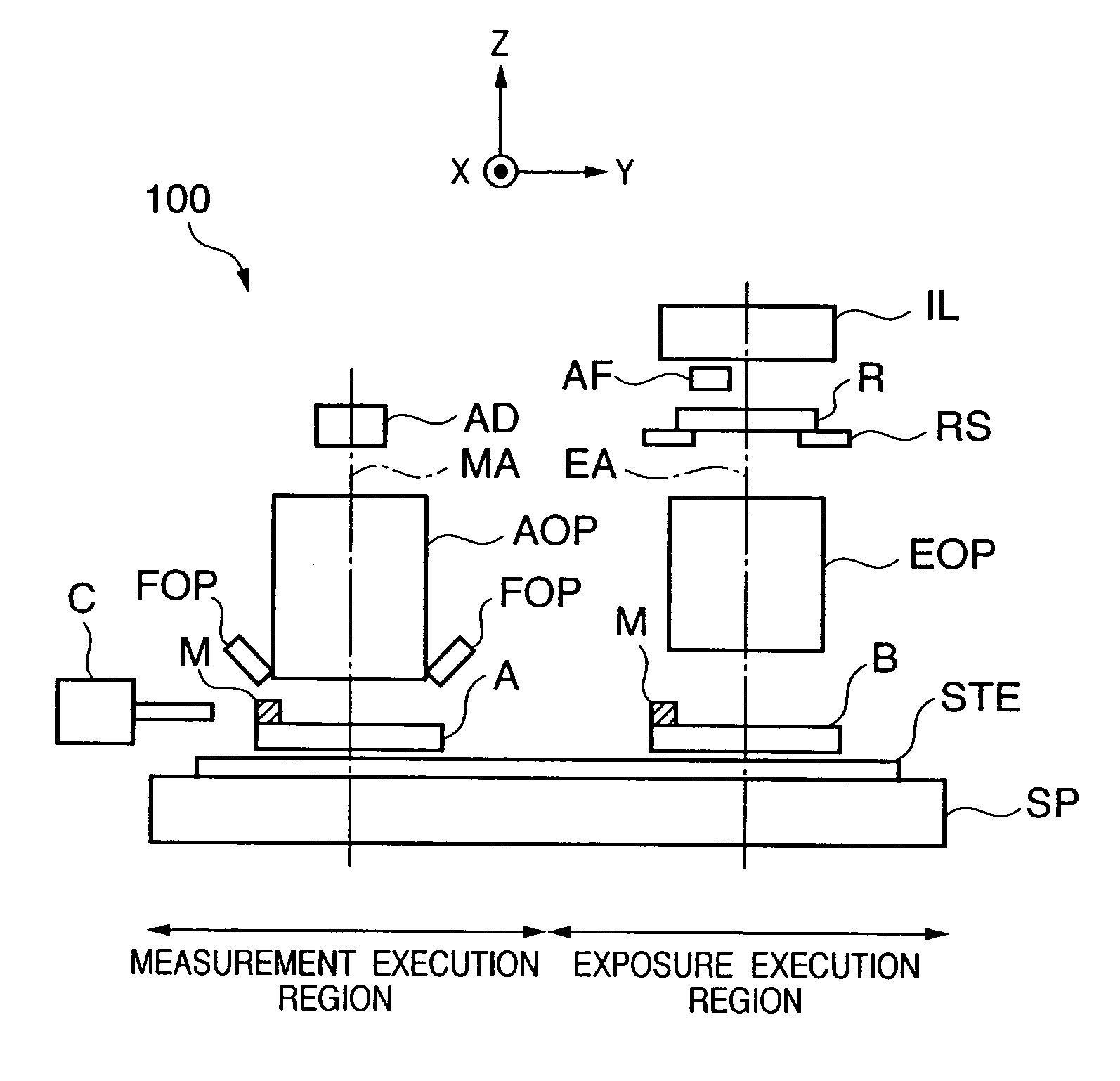

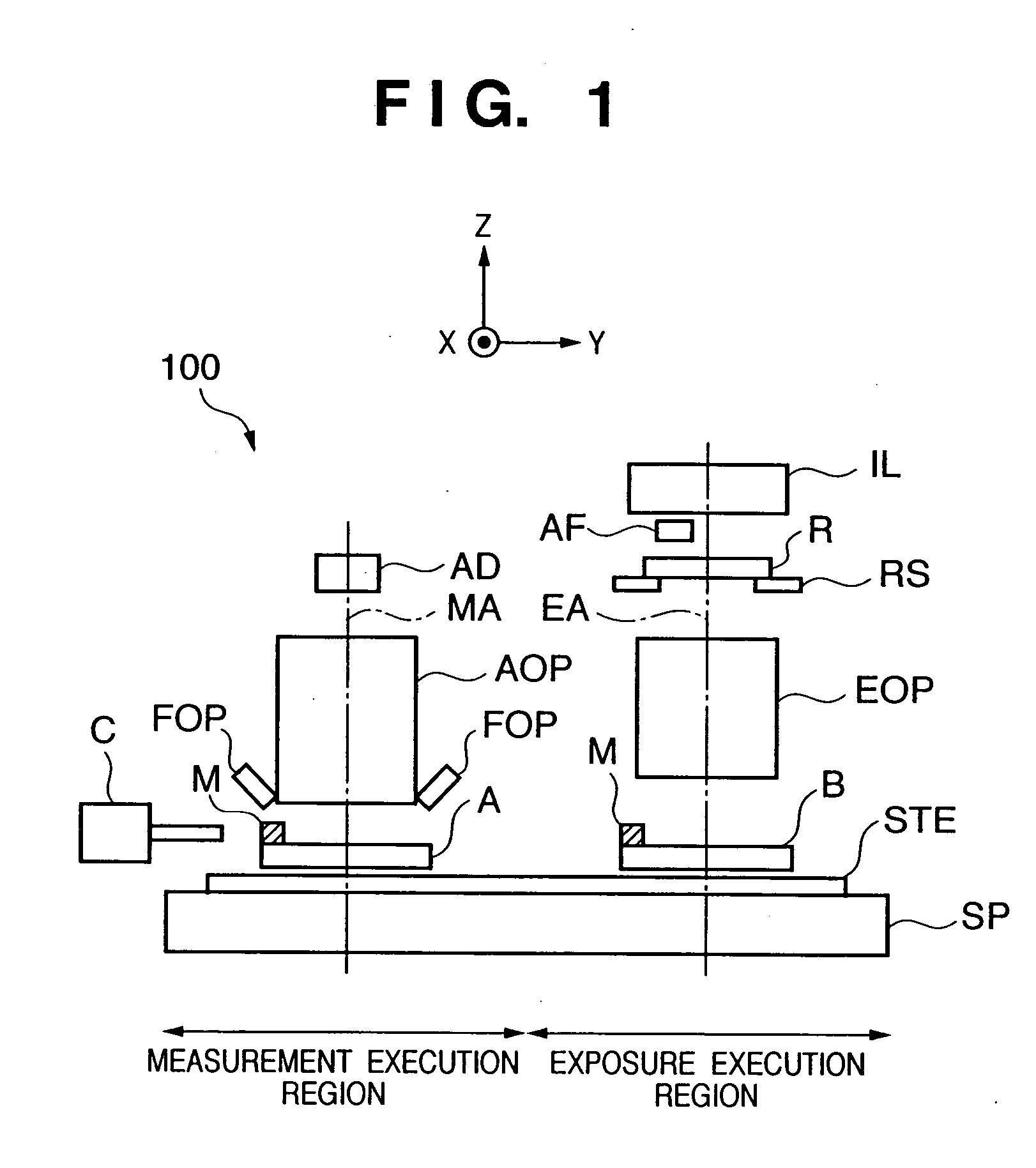

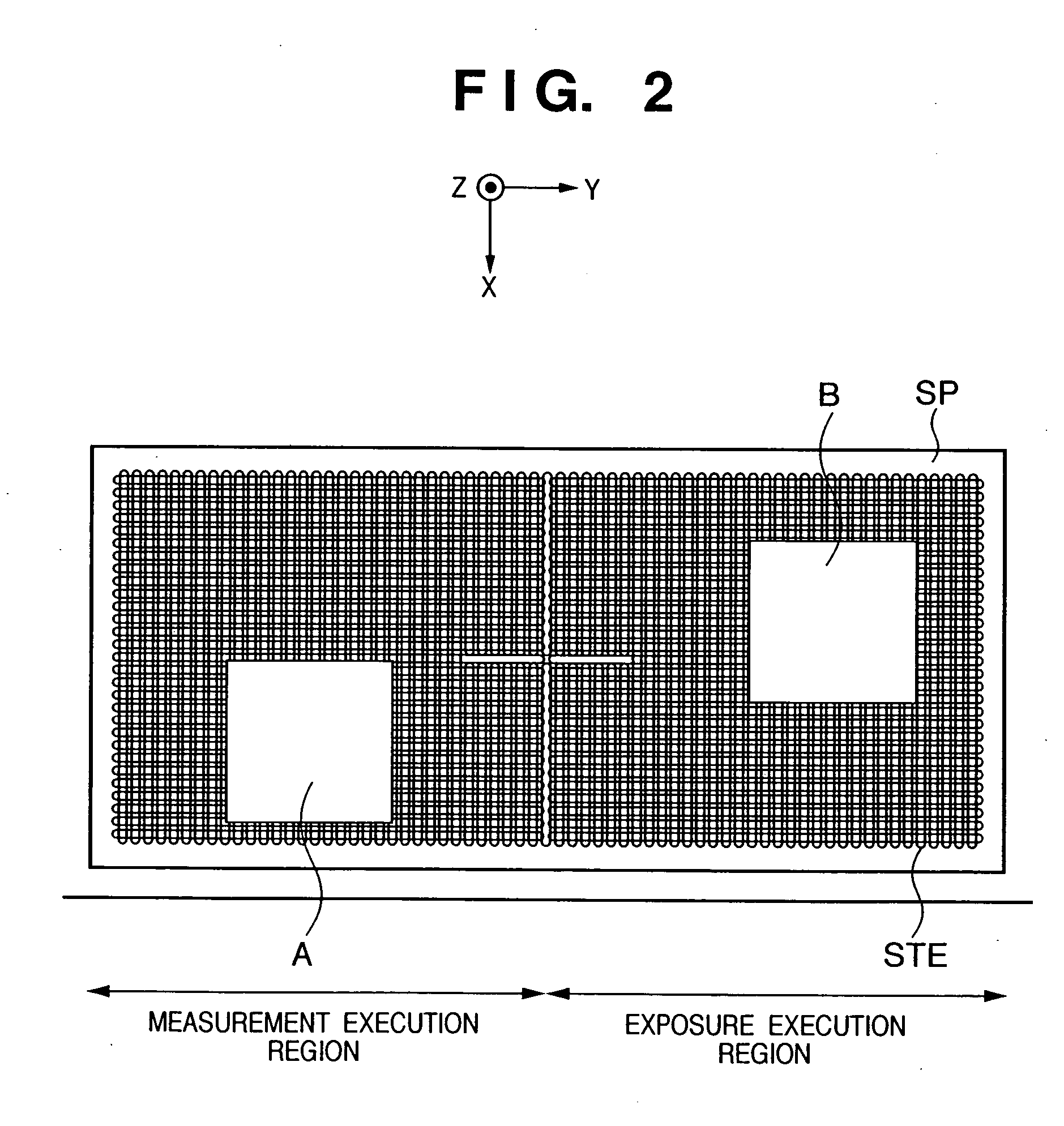

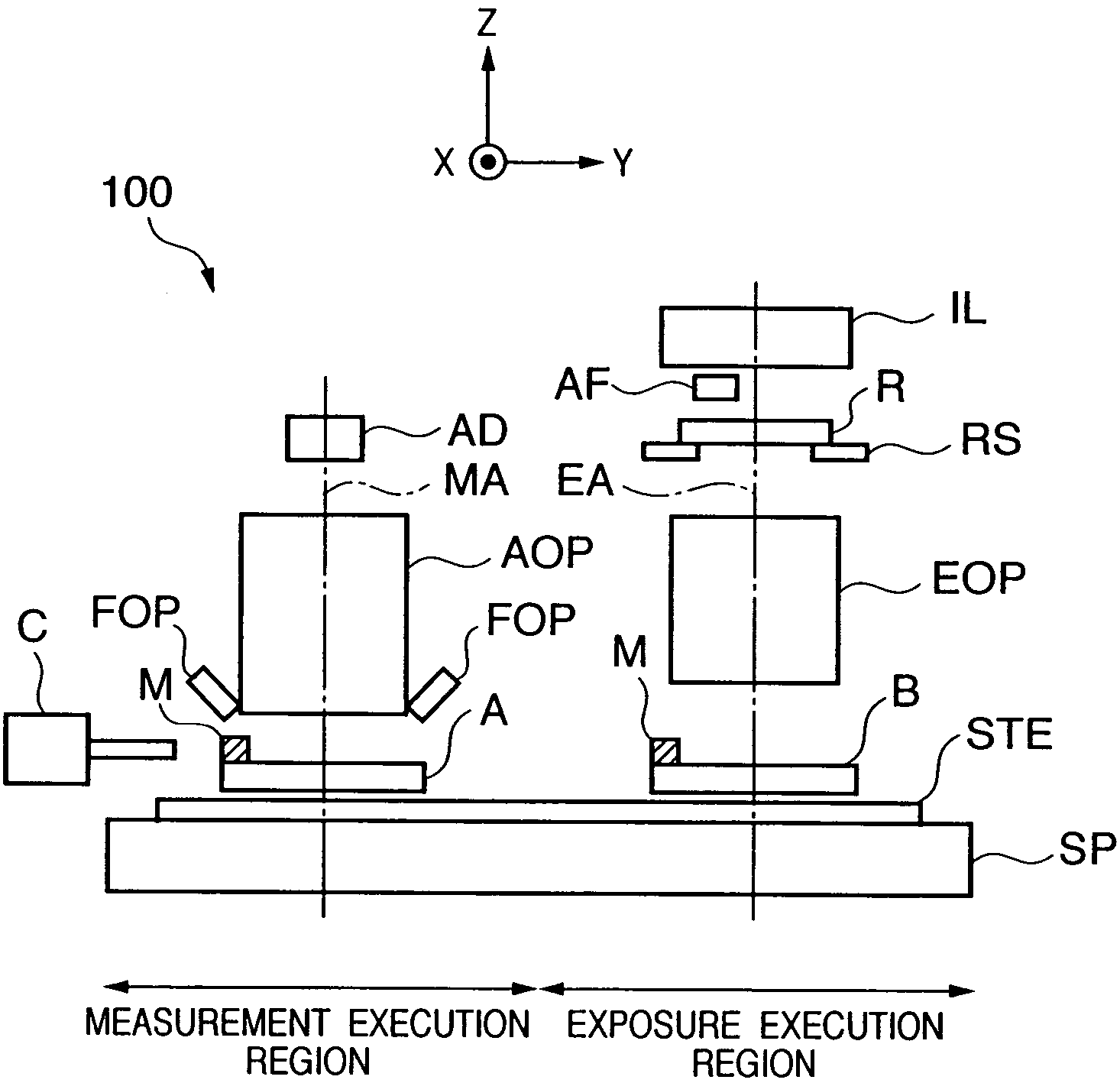

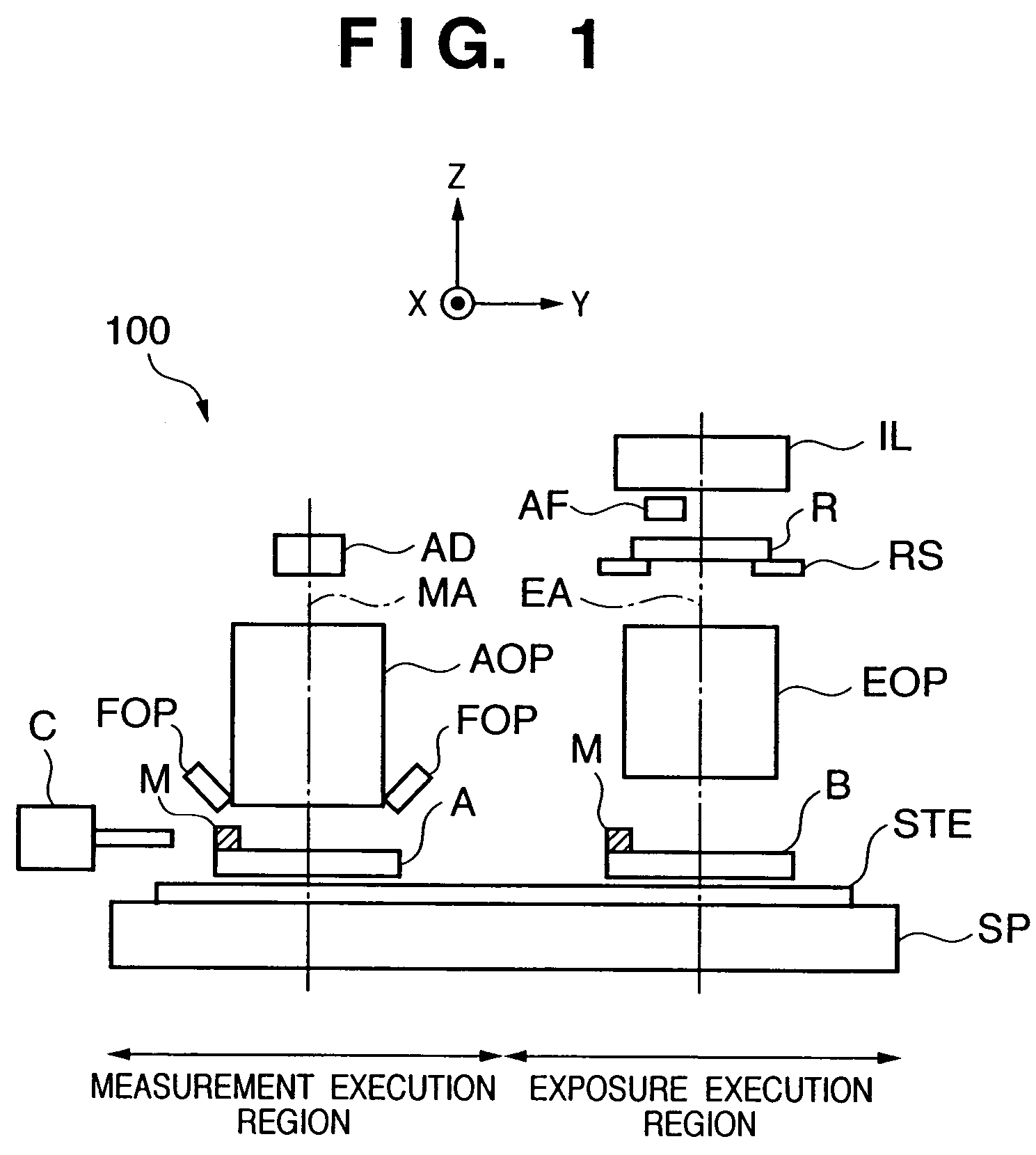

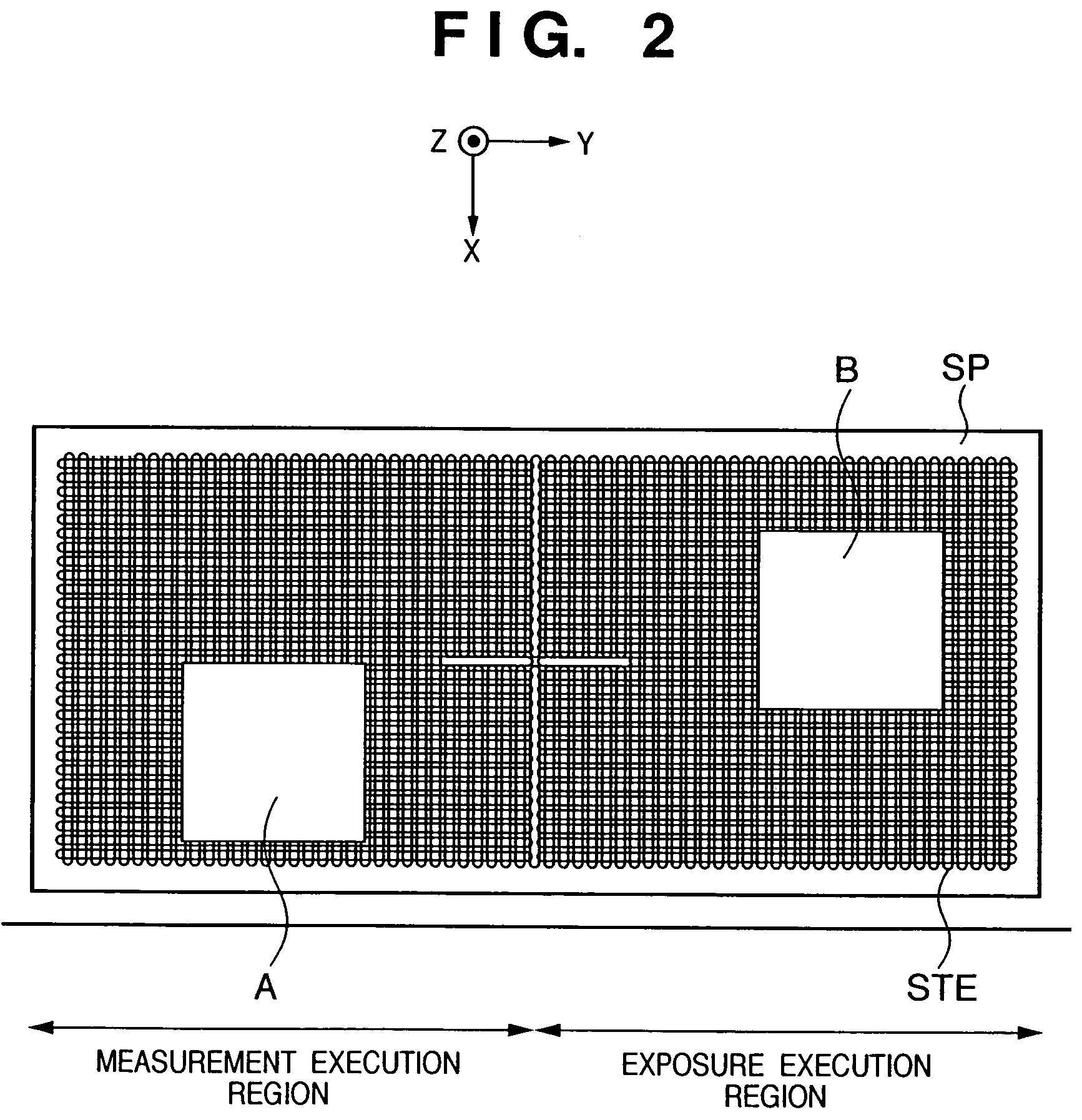

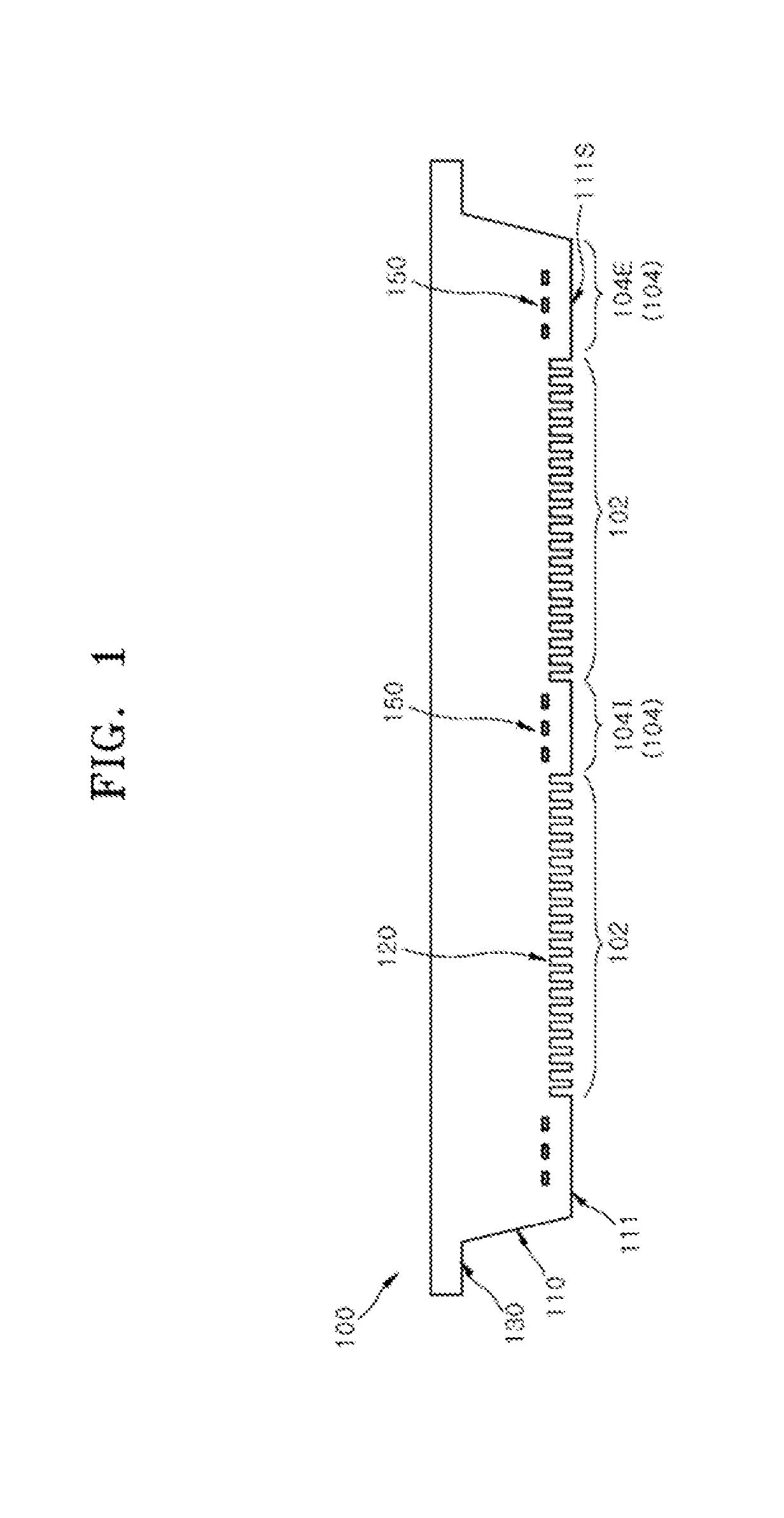

Exposure apparatus and device manufacturing method

InactiveUS20050219486A1Shorten the timeImprove productivitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMeasurement deviceOptical axis

The start of exposure or a process delays because reference alignment such as abutment must be executed along the optical axis after a substrate stage is moved between the exposure position and the processing position. To solve this problem, an exposure apparatus according to this invention includes an exposure optical system which exposes a substrate to a pattern, a substrate processing system which performs a predetermined process for the substrate at a position apart from the exposure optical system, a substrate stage which moves along a plane perpendicular to the optical axis of the exposure optical system, and a measurement device which continuously measures the position of the substrate stage along the optical axis in the moving range of the substrate stage while the substrate stage moves from below the substrate processing system to below the exposure optical system.

Owner:CANON KK

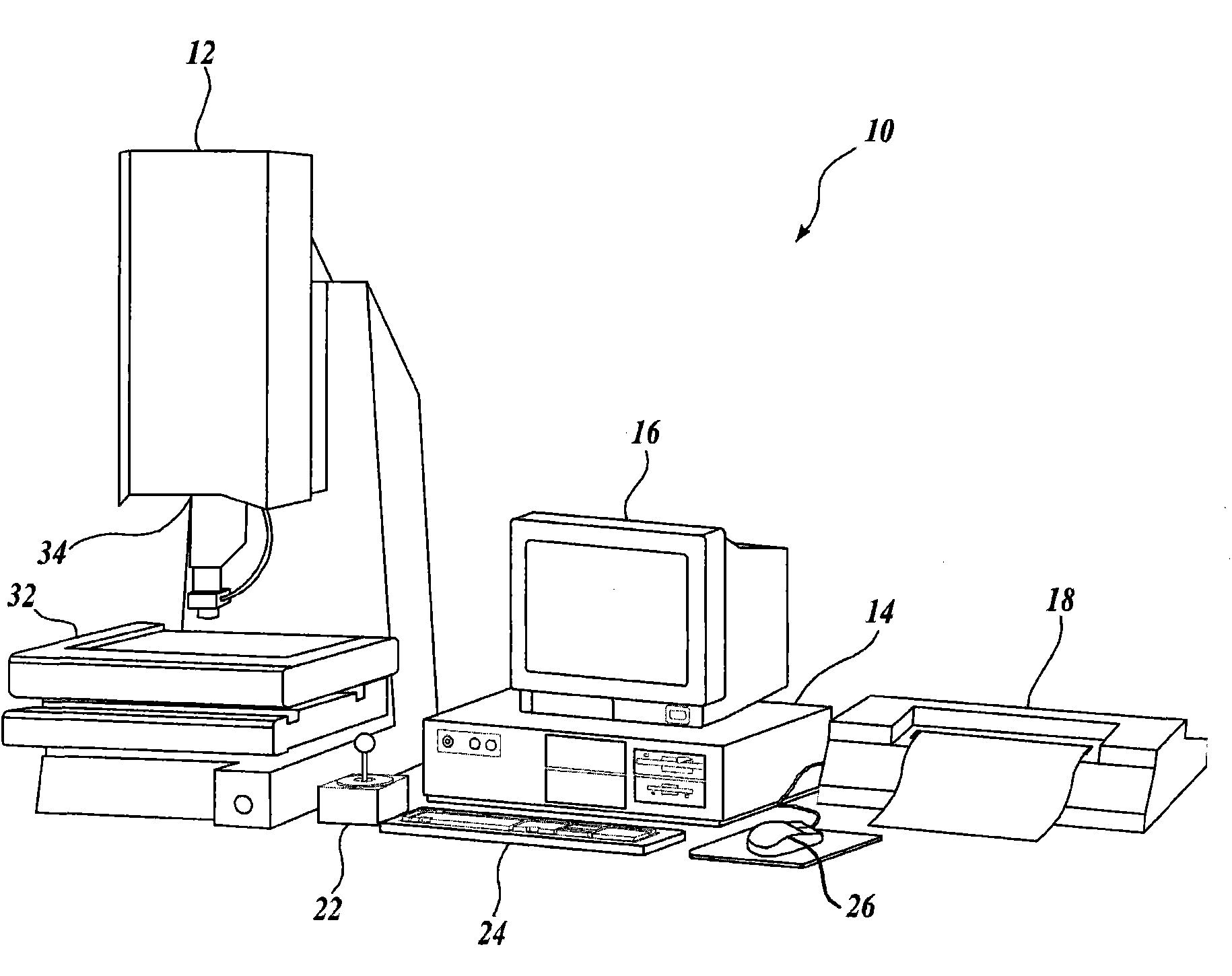

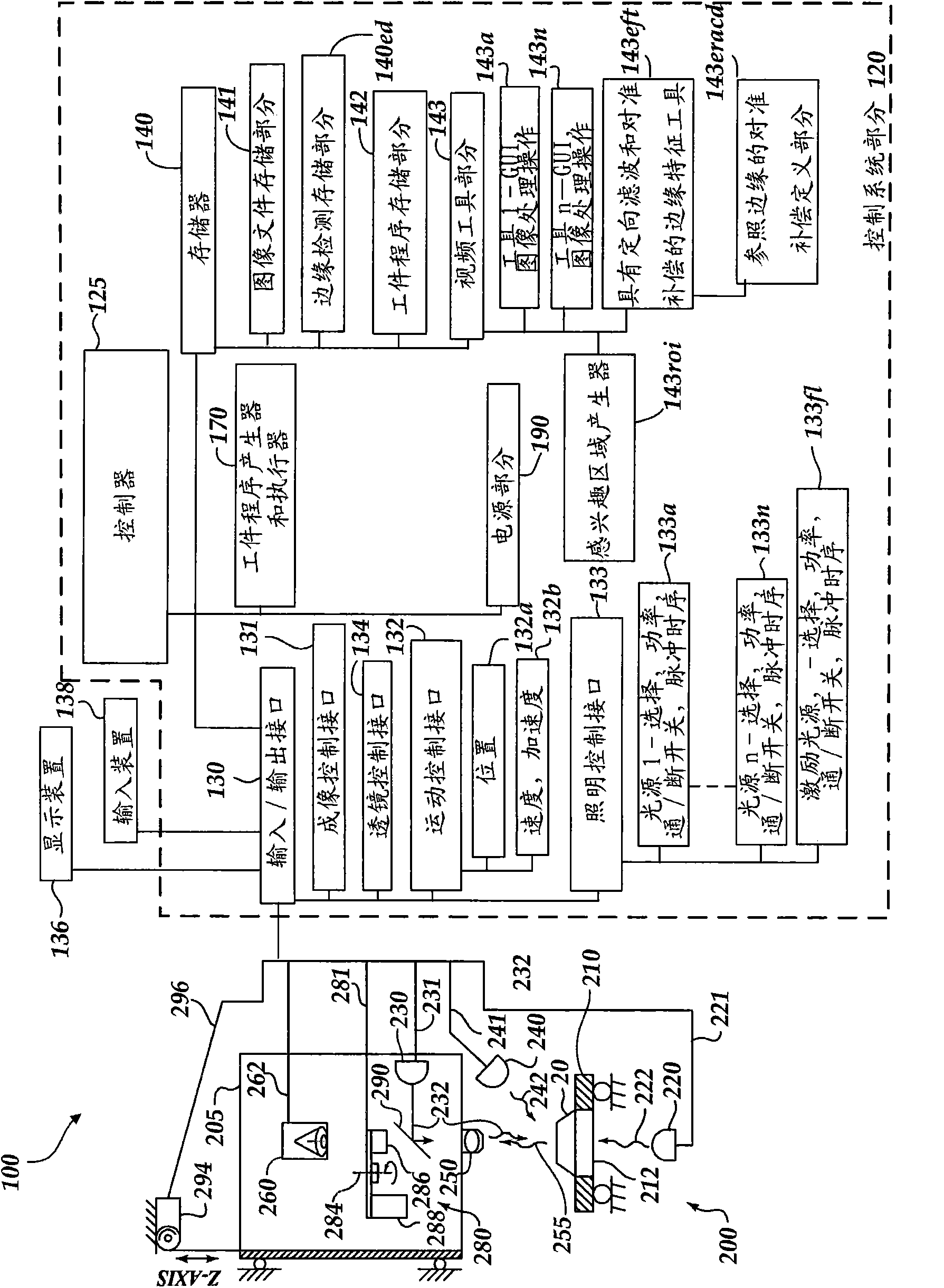

Enhanced edge detection tool for edges of irregular surfaces

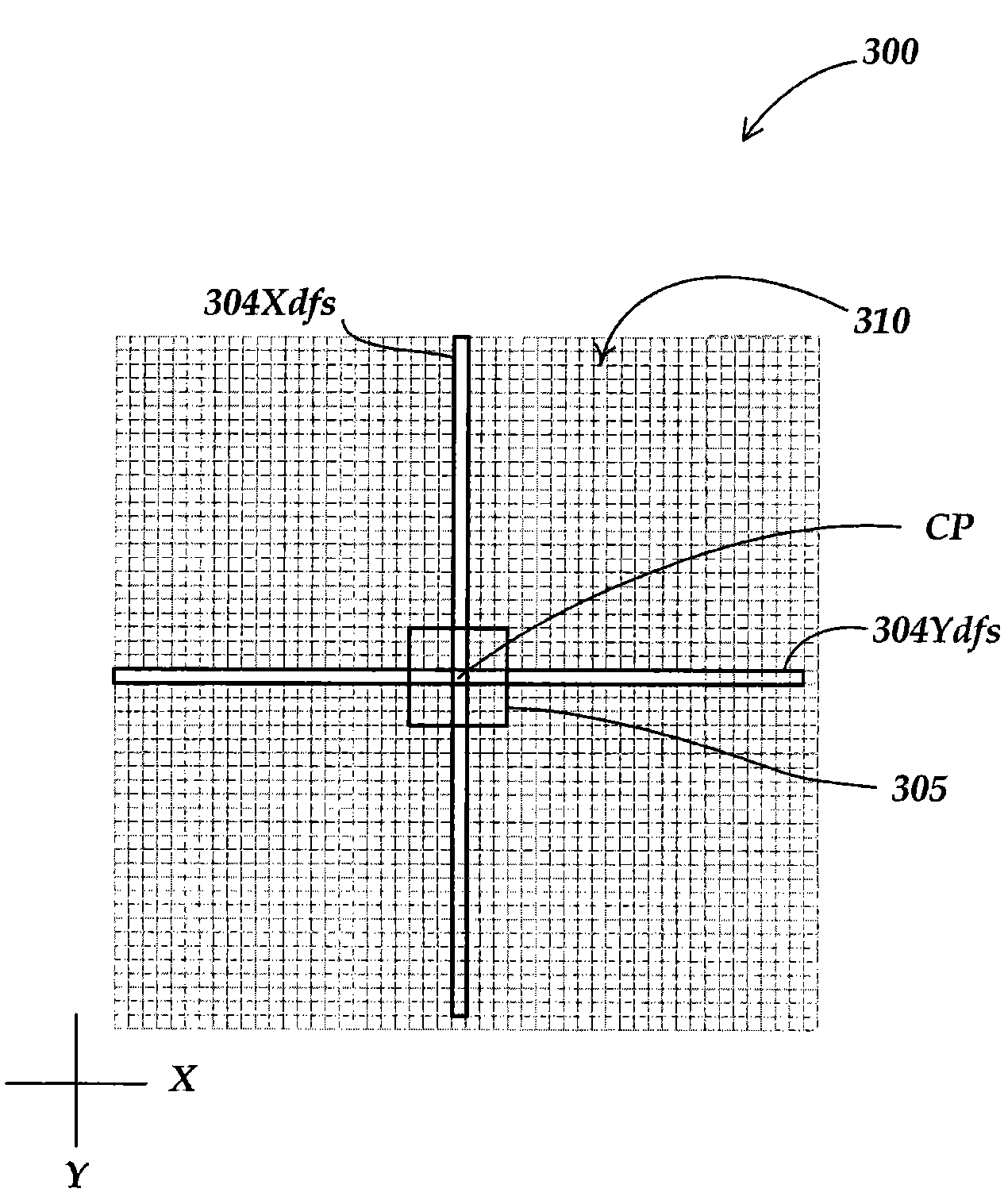

A method is provided for enhancing edge detection for edges of irregular surfaces in a machine vision inspection system. The inspection system comprises an edge feature video tool configured to determine profile data for an edge feature based on a plurality of differently focused images. An edge-referenced alignment compensation is provided related to substantially minimizing a respective offset amount of the edge feature at respective locations along a directional filtering direction used for directionally filtering the plurality of differently focused images prior to determining the profile data for the edge feature. In some embodiments, the plurality of differently focused images may be directionally filtered using a directional filtering sub region (DFS) defined relative to a point corresponding to a PFF basis pixel location in each of the plurality of images, each DFS having a relatively longer dimension along the directional filtering direction.

Owner:MITUTOYO CORP

Data processing system component alignment

InactiveUS6354861B2Incorrect coupling preventionDigital data processing detailsData processing systemComponent alignment

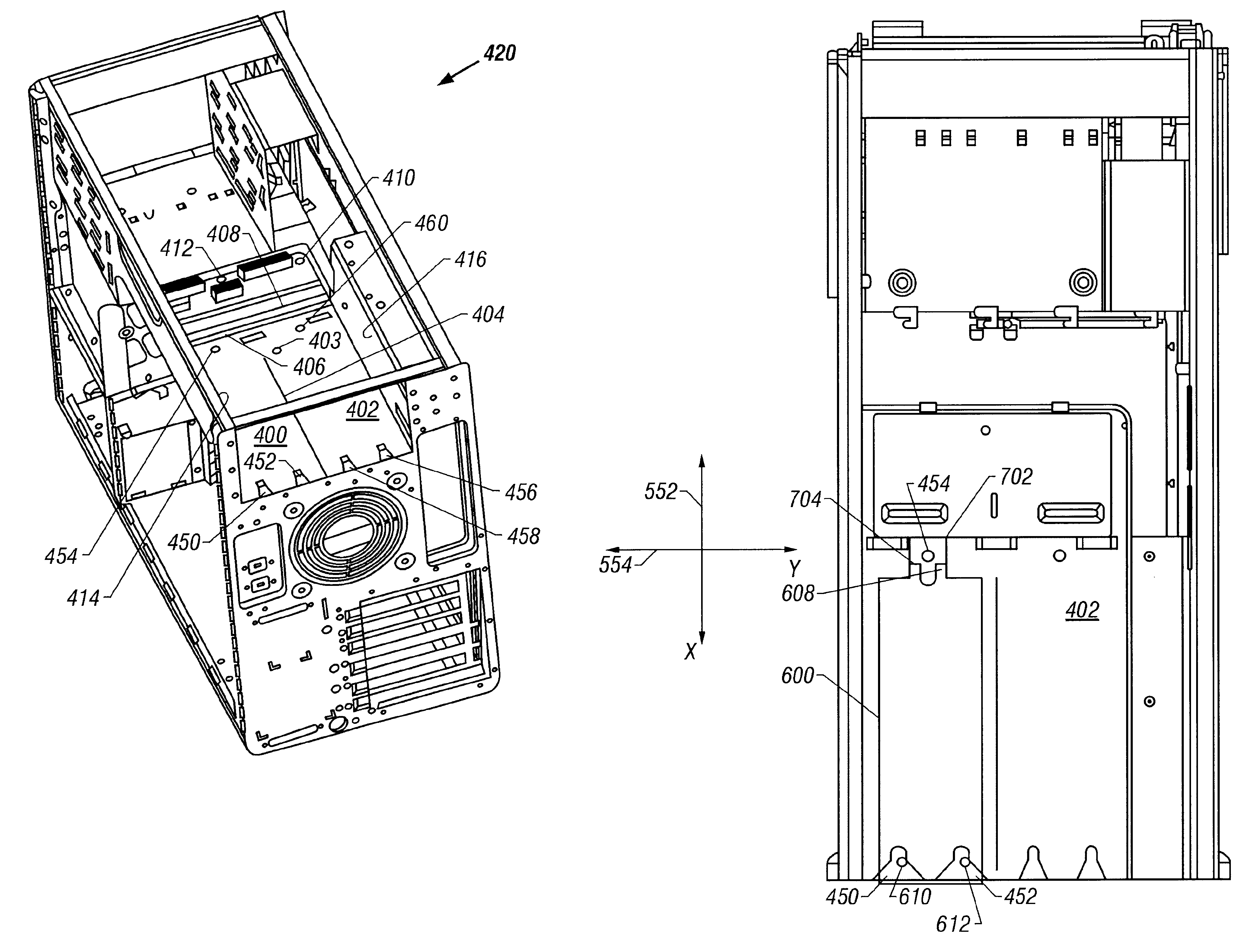

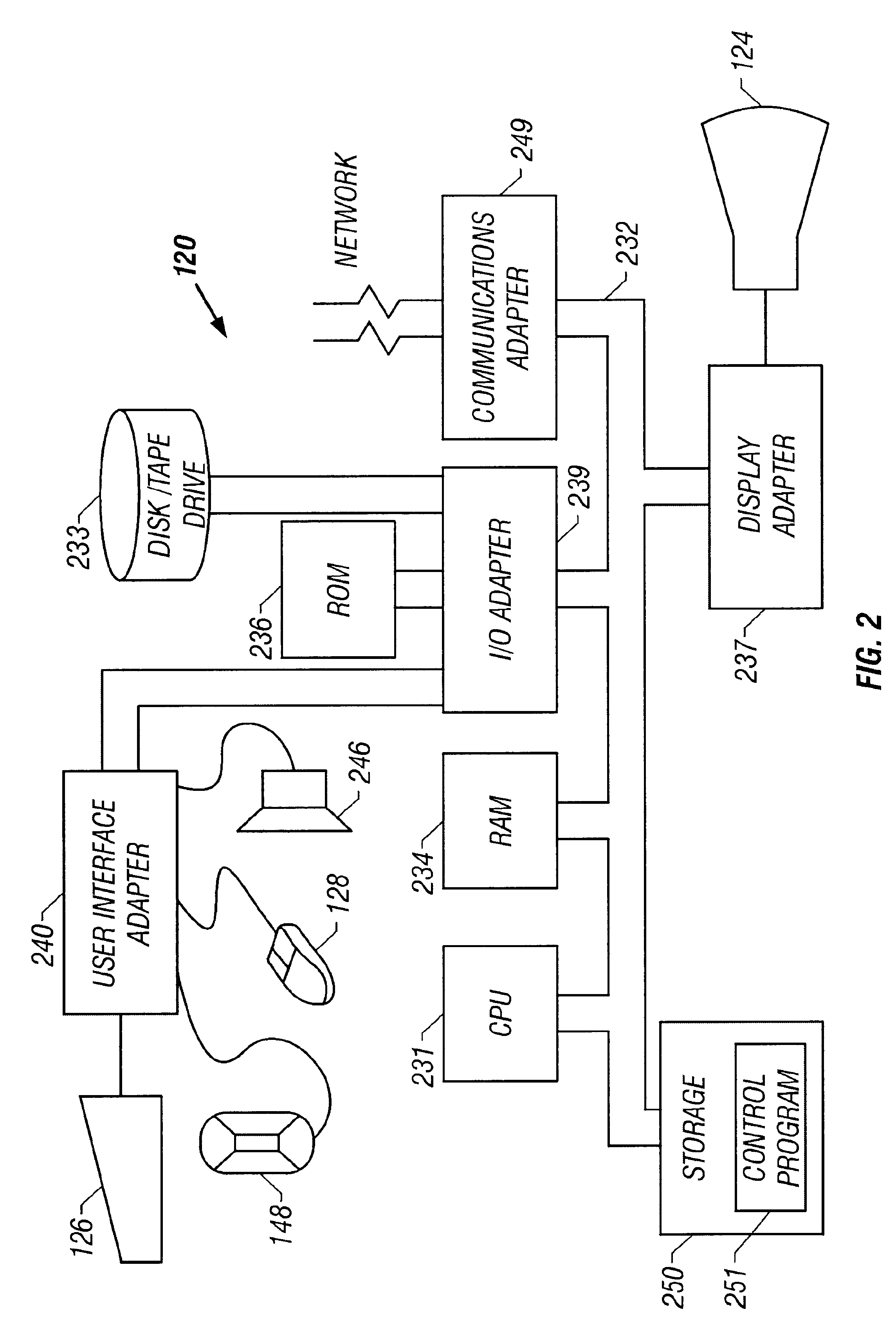

A method and apparatus related to a data processing system contiguous-reference connection alignment mechanism. In one embodiment, an apparatus includes but is not limited to a data processing system contiguous-reference connection alignment mechanism, wherein the data processing system contiguous-reference connection alignment mechanism further includes but is not limited to a y-axis direction contiguous-reference alignment mechanism, wherein the y-axis direction contiguous-reference alignment mechanism further includes but is not limited to at least one fore-positioned data processing system connection guidance cylinder slot formed to catch a connection guidance cylinder misaligned in the y-axis direction and guide the connection guidance cylinder into substantial y-axis direction alignment. In one embodiment, a computer system includes but is not limited to a data processing system contiguous-reference alignment mechanism.

Owner:DELL PROD LP

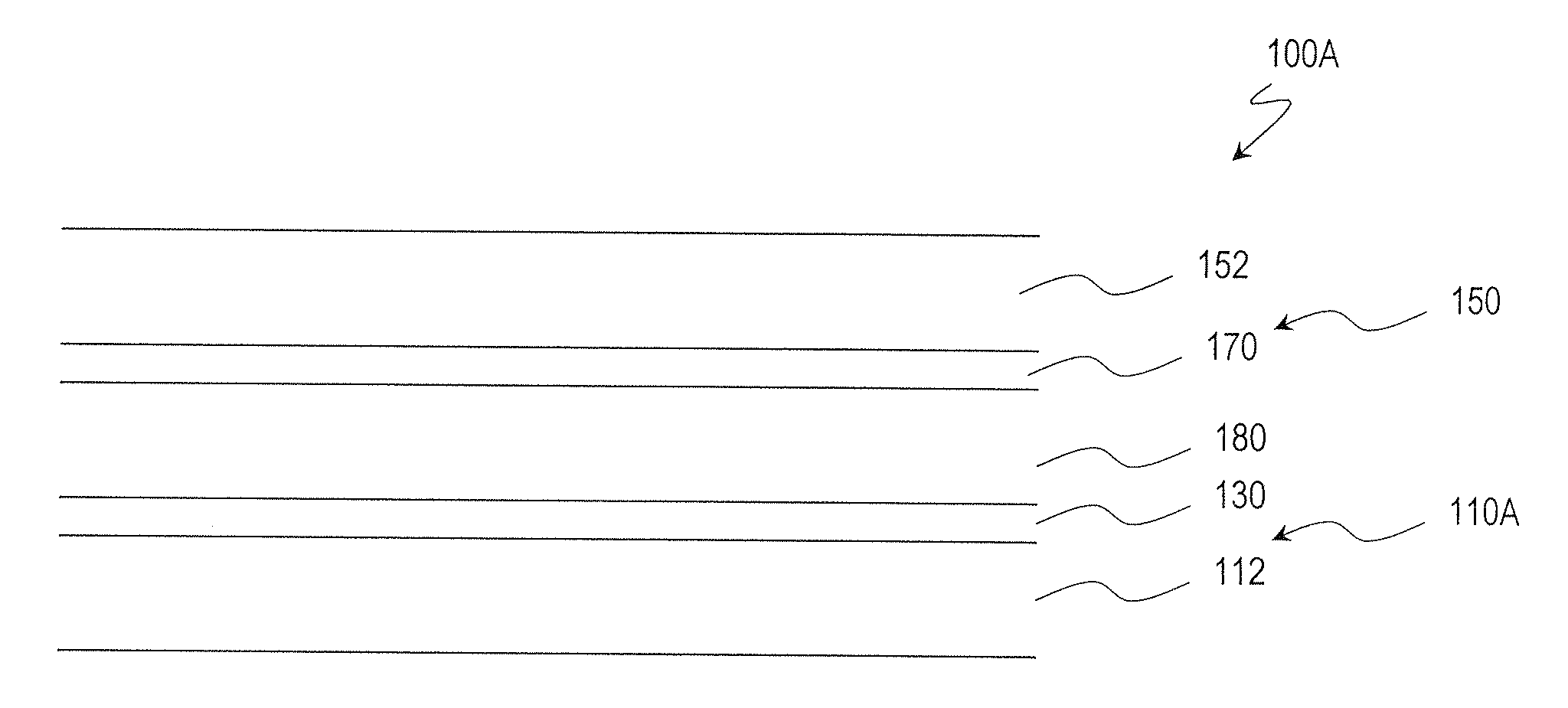

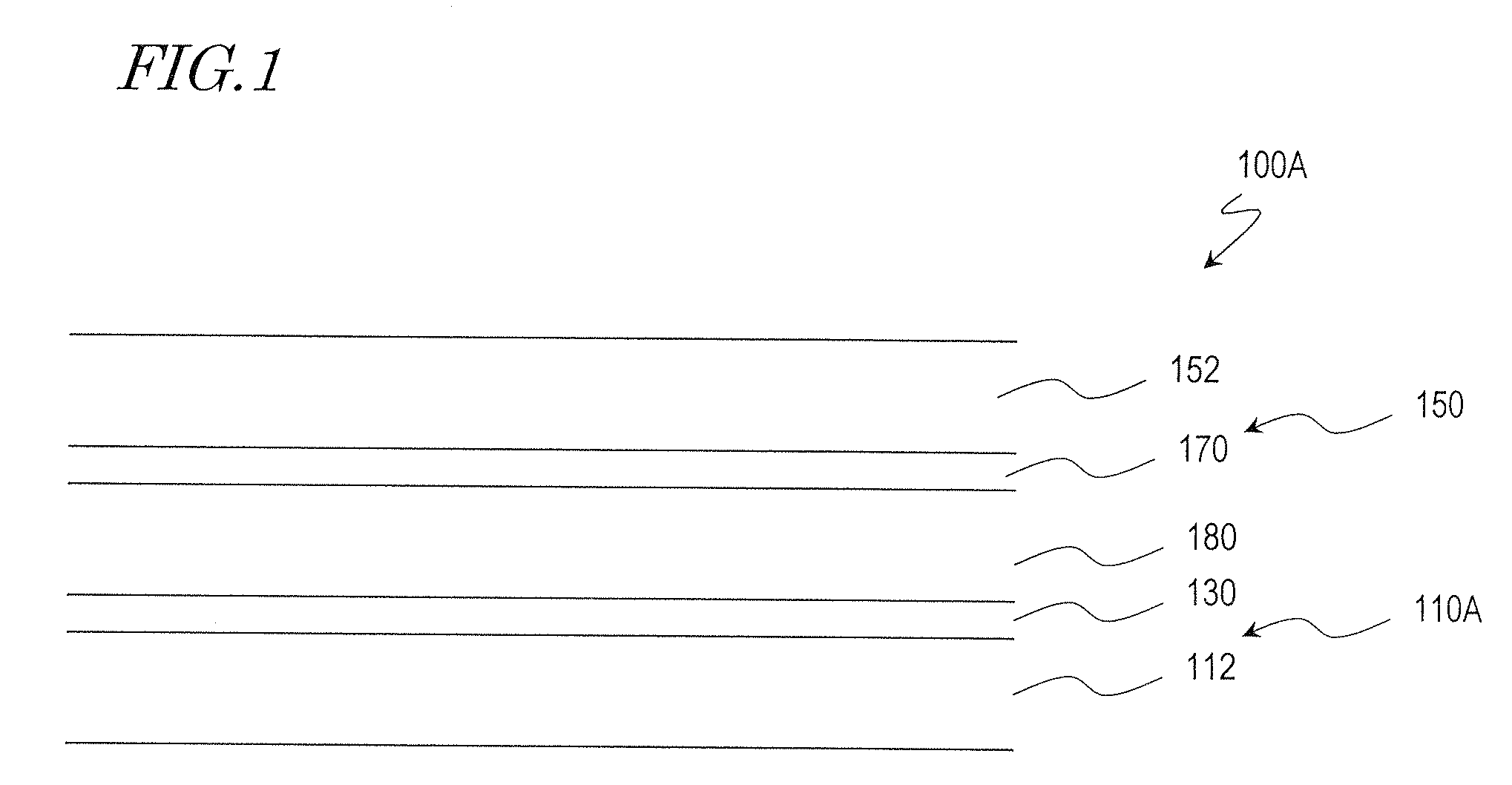

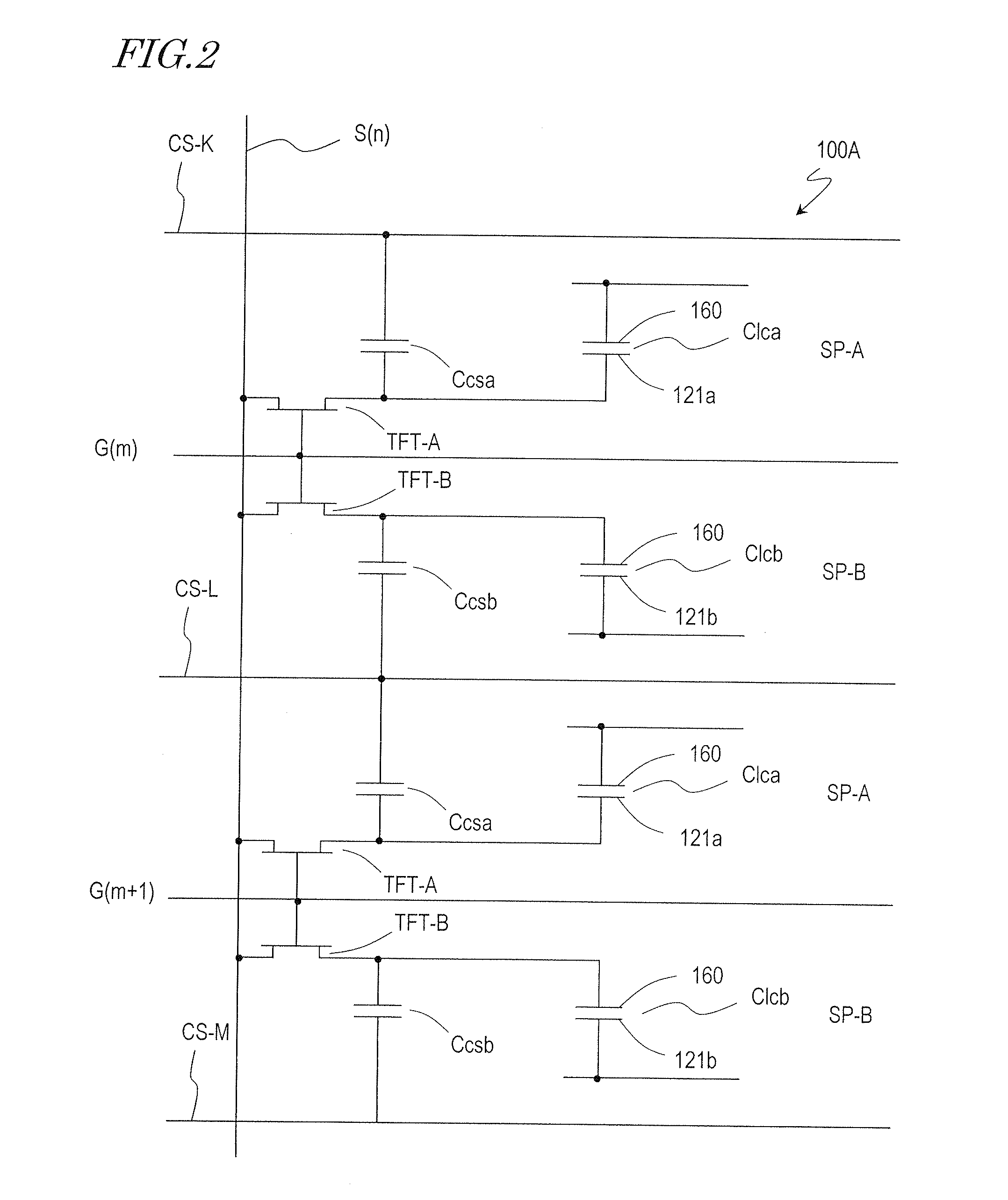

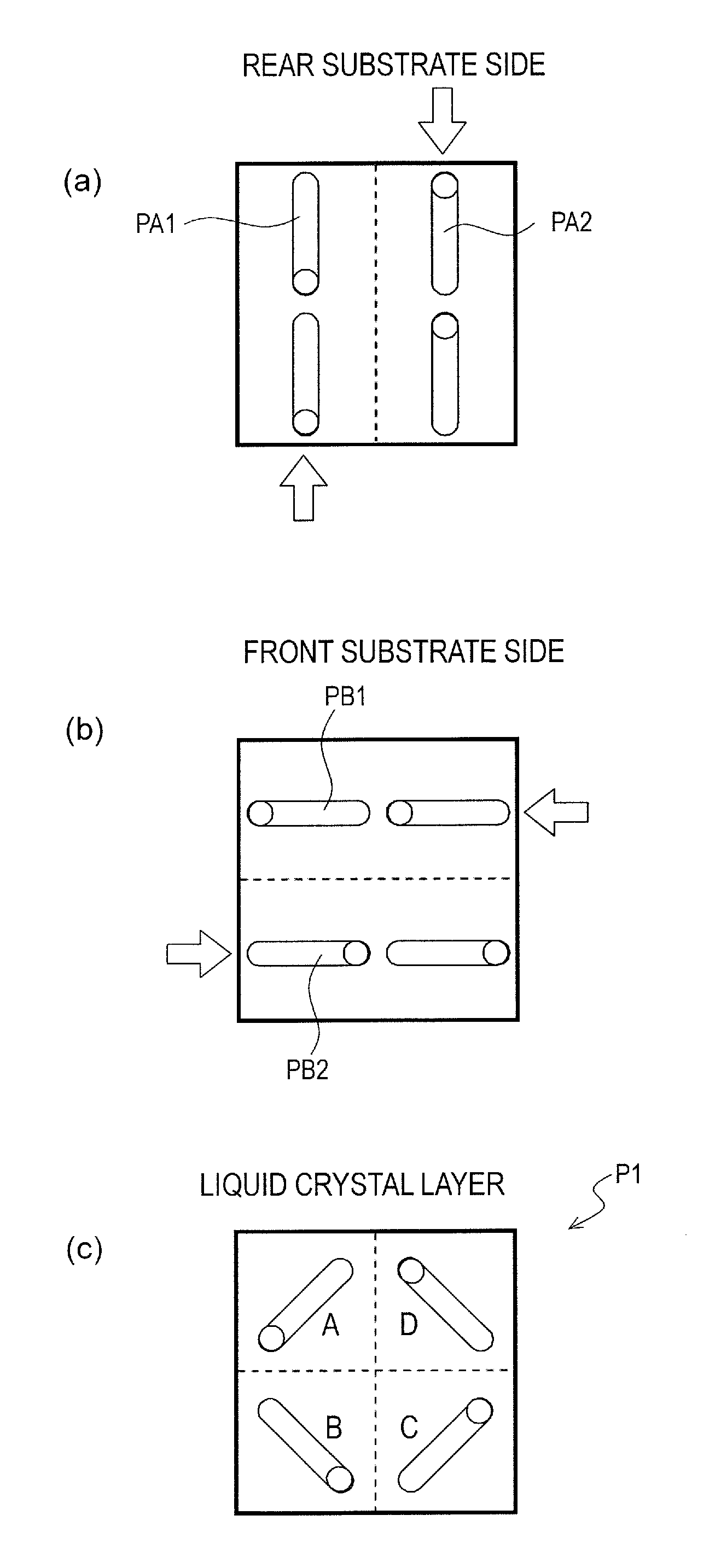

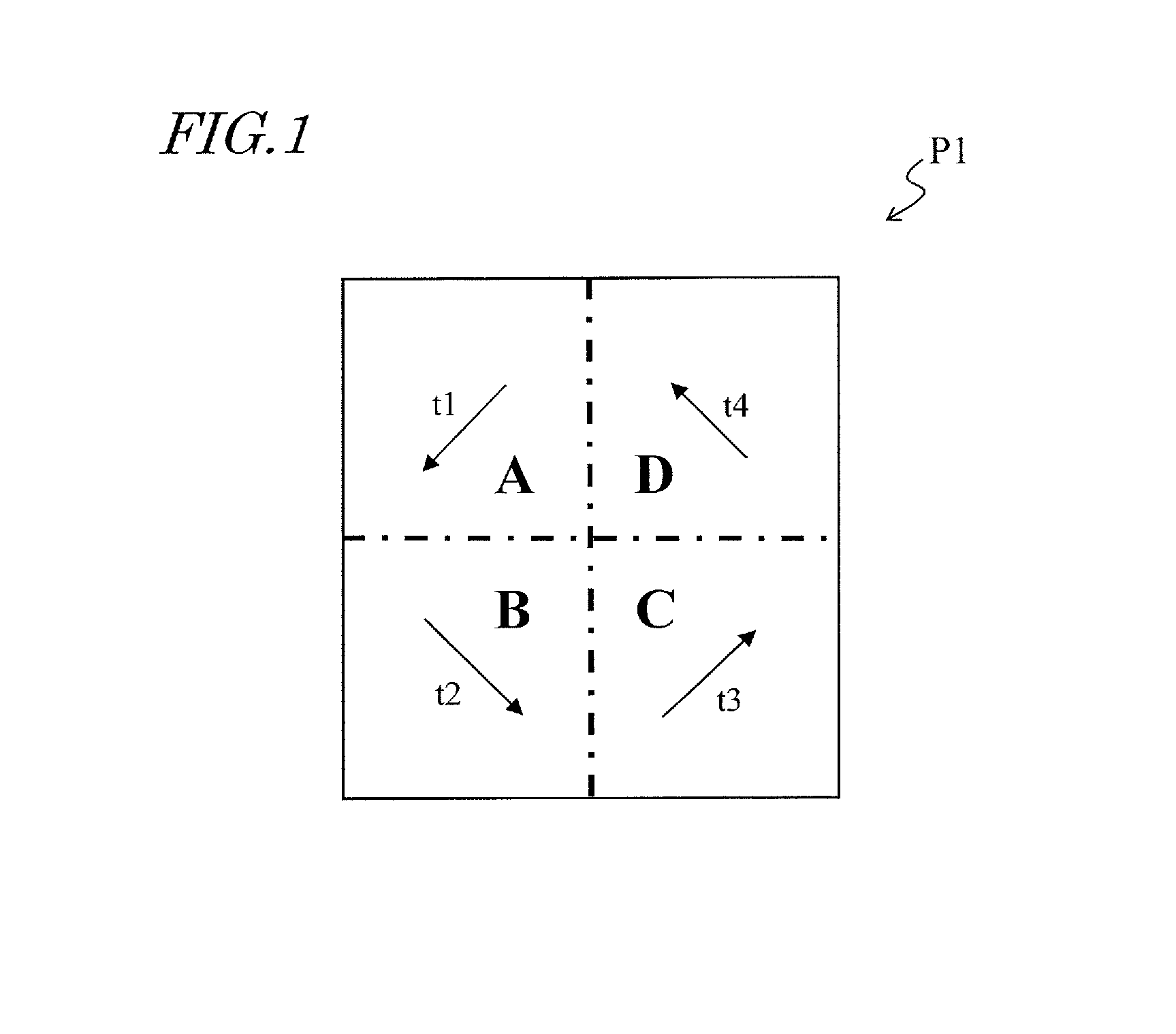

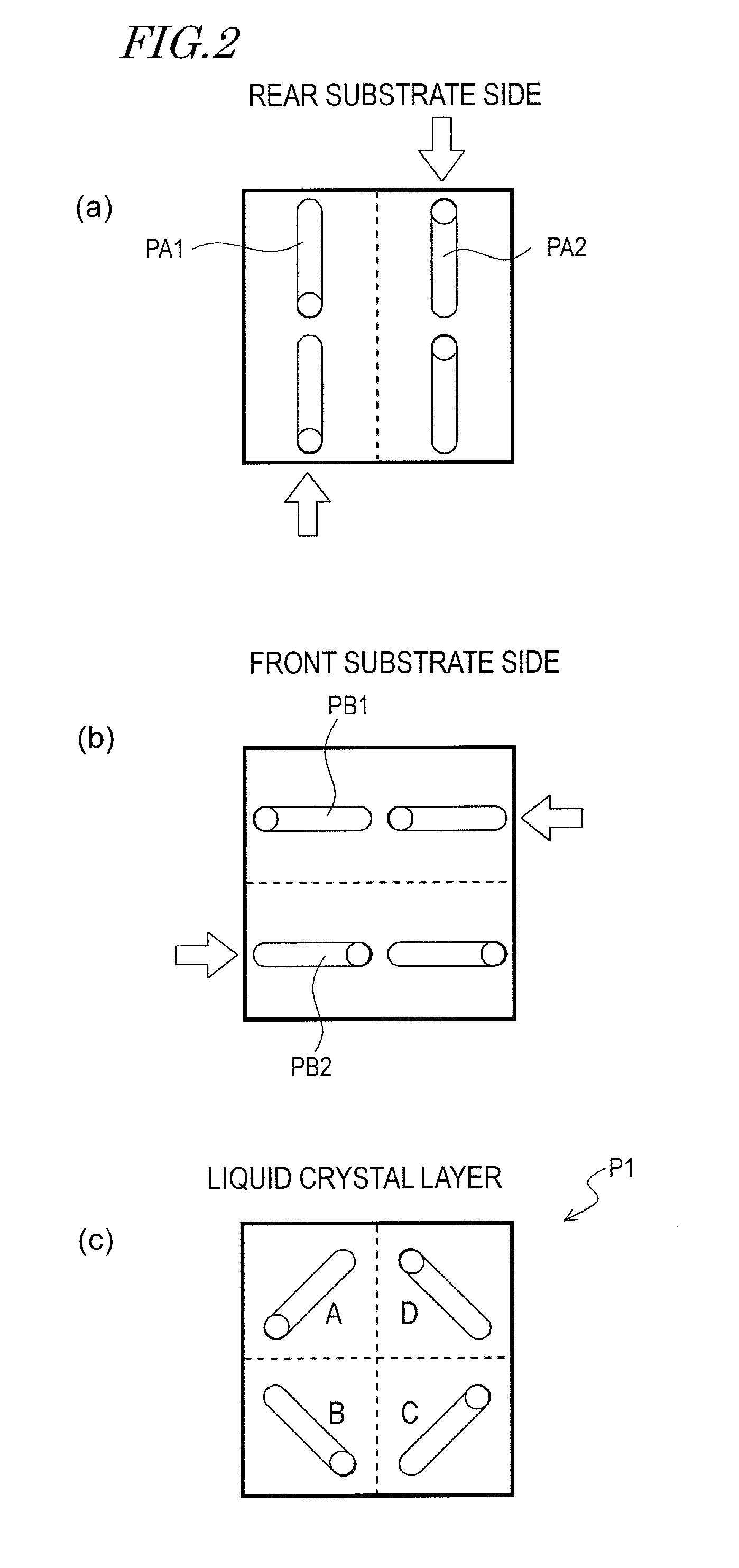

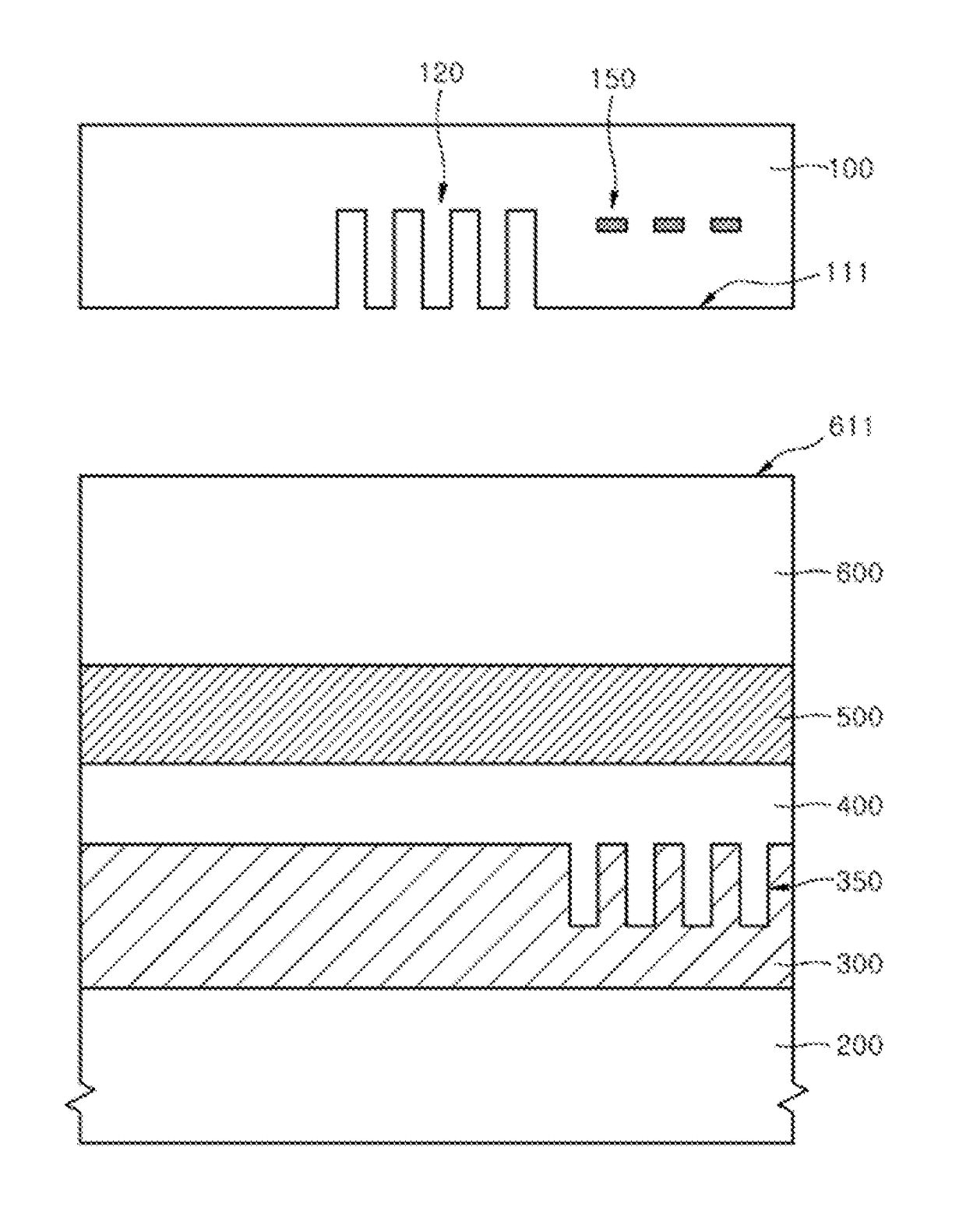

Liquid crystal display device

InactiveUS20110043741A1Decrease can be minimizedEasy maintenanceNon-linear opticsEngineeringReference alignment

In the liquid crystal display device (100A) of the present invention, the pixel electrode (121) has a notch (122a2) provided for a portion of a line. If the azimuthal component of liquid crystal molecules (182), located approximately at the middle of the thickness of a liquid crystal layer (180) in an area where the respective alignment regions of first and second alignment films (130) and (170) overlap with each other to a viewer's eye, is called a “reference alignment azimuth”, an oblique electric field, generated by a counter electrode (160) and the notch (122a2) of the pixel electrode (121) upon the application of a voltage, causes the azimuthal component of the liquid crystal molecules (182) in a region of the liquid crystal layer (180) associated with at least a portion of the notch (122a2) of the pixel electrode (121), to intersect with the reference alignment azimuth at an angle of 90 degrees or less.

Owner:SHARP KK

Exposure apparatus and device manufacturing method

InactiveUS7307692B2Shorten the timeImprove productivitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMeasurement deviceOptical axis

The start of exposure or a process delays because reference alignment such as abutment must be executed along the optical axis after a substrate stage is moved between the exposure position and the processing position. To solve this problem, an exposure apparatus according to this invention includes an exposure optical system which exposes a substrate to a pattern, a substrate processing system which performs a predetermined process for the substrate at a position apart from the exposure optical system, a substrate stage which moves along a plane perpendicular to the optical axis of the exposure optical system, and a measurement device which continuously measures the position of the substrate stage along the optical axis in the moving range of the substrate stage while the substrate stage moves from below the substrate processing system to below the exposure optical system.

Owner:CANON KK

Laying machine

ActiveCN104499696AAutomatic layingPlay a protective effectBuilding constructionsEngineeringReference alignment

The invention relates to a laying machine. The laying machine comprises a machine body, travelling wheels, a reference alignment device and a loading laying device, wherein the travelling wheels are fixed at the bottom of the machine body, a handle is arranged at the front part of the machine body, the reference alignment device is mounted on the upper end surface of the machine body, and the loading laying device is mounted at the middle part of the upper end of the reference alignment device. The laying machine disclosed by the invention has the advantages of being reasonable in structural design, high in automation degree, convenient to operate and control, and the like, can realize automatic laying of ceilings, replaces a traditional manner that builders climb a ladder for laying, improves the laying efficiency and has the protective effect on the builders.

Owner:WUHU YINXING AUTO PARTS

Liquid crystal display

This liquid crystal display device (100) includes: a vertical alignment liquid crystal layer (30); first and second substrates (10, 20); first and second electrodes (11, 21) arranged on the first and second substrates to face the liquid crystal layer; and two photo-alignment films (12, 22). Each pixel region includes first and second liquid crystal domains, of which the reference alignment directions defined by the two photo-alignment films are a first direction and a second direction different from the first direction, respectively. The first electrode has a slit cut region (11R1), through which a slit (11s) has been cut to run substantially parallel to the reference alignment direction, in a part of a region allocated to each of the first and second liquid crystal domains. The width (W) of the slit is set so that when the highest grayscale voltage is applied to the first electrode, an effective applied voltage decreases by at least 0.5 V and the alignment direction of liquid crystal molecules (30a) shifts with respect to the reference alignment direction by less than 45 degrees.

Owner:SHARP KK

Gear scanning algorithm for template matching and point cloud comparison

PendingCN110599449AHigh speedHigh precisionImage enhancementImage analysisTemplate matchingPoint cloud

The invention discloses a gear scanning algorithm for template matching and point cloud comparison. The method comprises a line scanning algorithm, a splicing algorithm, a model matching algorithm anda model comparison algorithm, and the main working logic is that a line laser scans the surface contour of a workpiece through the movement of a linear module, and each section contour of the workpiece is obtained through the analysis and calculation of the line scanning algorithm; splicing the obtained section contours in real time through a splicing algorithm to obtain a three-dimensional pointcloud of an actual workpiece; aligning a theoretical three-dimensional model and the actual three-dimensional point cloud as a reference through a model matching algorithm; comparing the two three-dimensional models subjected to reference alignment to obtain the defect information of each gear. According to the method, a rapid algorithm for scanning the gears and determining the defect positionsis realized through the combination of various algorithms and hardware data, so that the speed and accuracy of determining the defect positions of the gears are greatly improved, and the subsequent determination of the positioning parameters for repairing the gears is facilitated.

Owner:SHANGHAI ZHONGHONG ELECTRONICS TECH

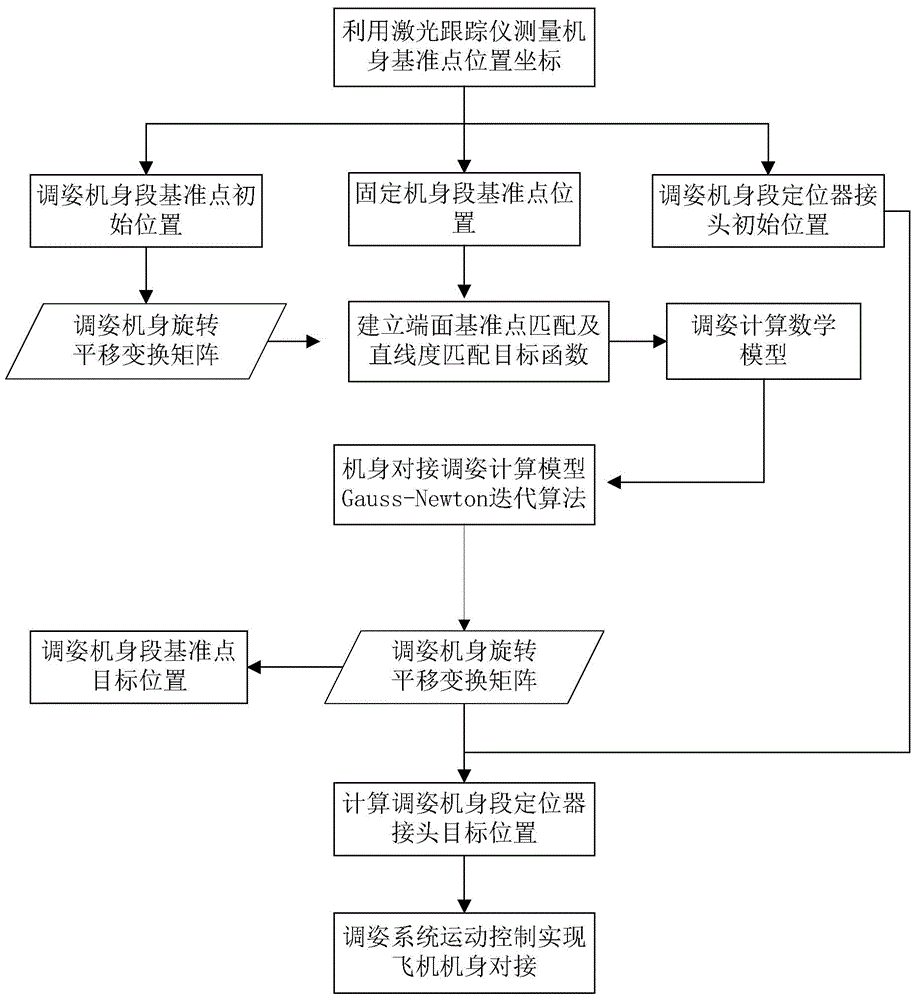

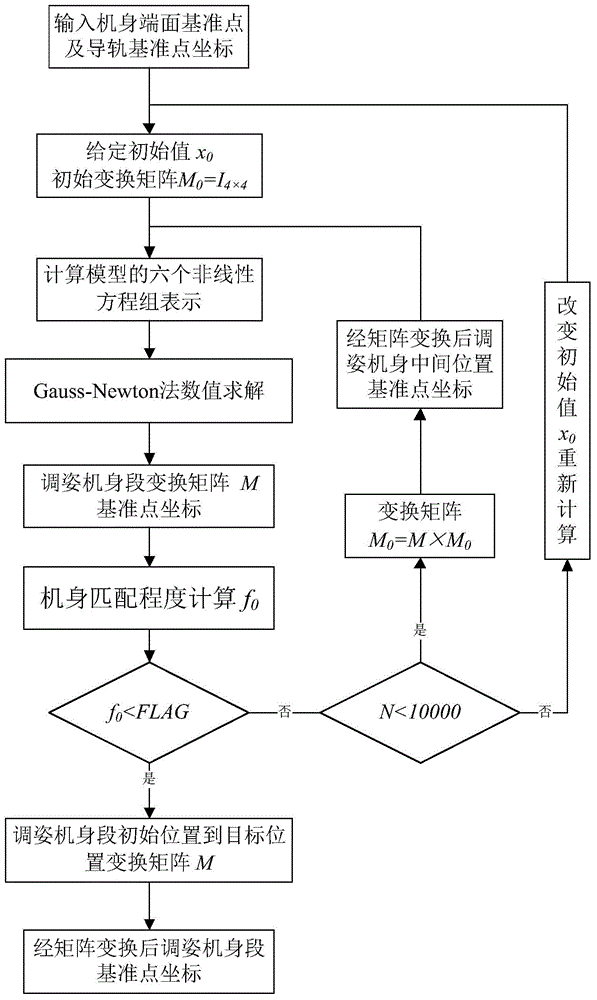

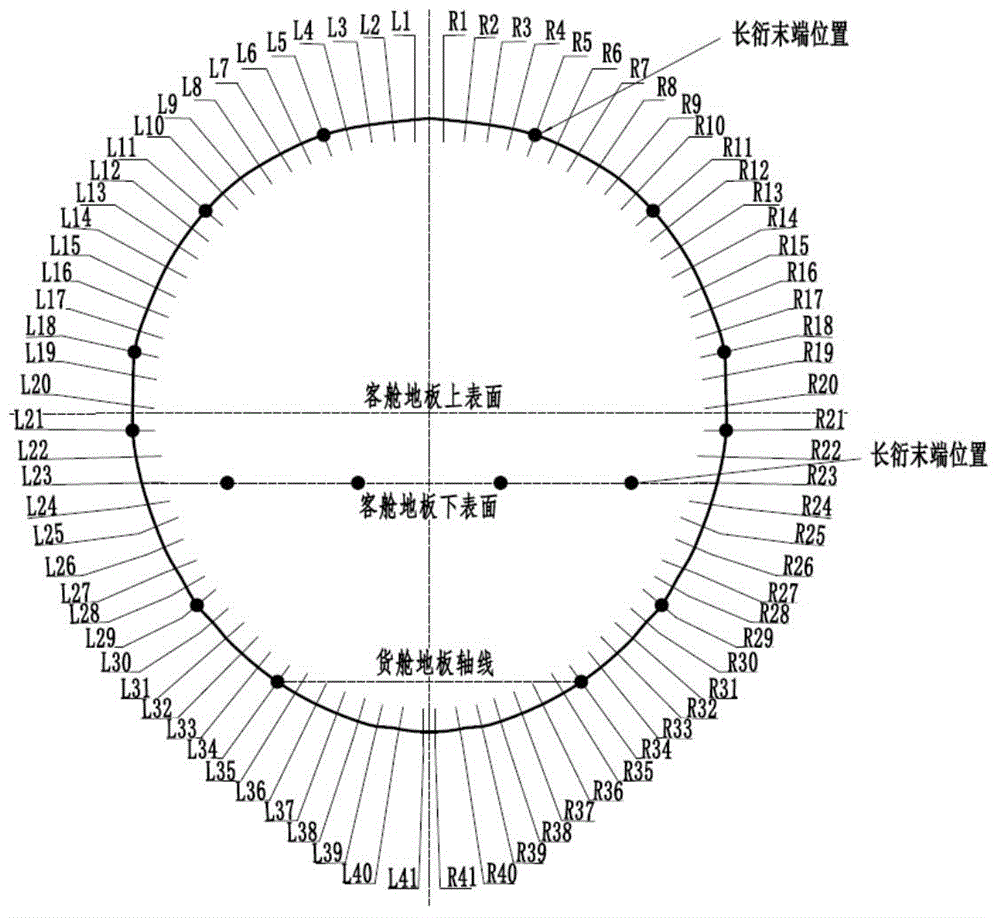

Airframe butt joint attitude-adjusting method meeting stringer reference alignment and straightness requirements

ActiveCN104477402ASolve the problem of not being able to consider the straightness of the aircraft fuselageImprove guidanceAircraft assemblyMathematical modelGauss newton method

An airframe butt joint attitude-adjusting method meeting stringer reference alignment and straightness requirements includes the steps: measuring end face reference points and linear guide rail reference points of a fixed airframe section and an attitude-adjusting airframe section and coordinates of the position of an attitude-adjusting system three-dimensional positioner connector connected with the attitude-adjusting airframe section by a laser tracker; building airframe end face reference point matching and straightness matching target functions, and accordingly building a mathematic model for airframe butt joint attitude-adjusting calculation; performing iterative calculation for the airframe butt attitude-adjusting model by a Gauss-Newton method to obtain coordinates of optimal butt joint positions of the attitude-adjusting airframe section and the fixed airframe section and obtain a transformational matrix from an initial position to a target position; calculating the coordinates of the target position of an attitude-adjusting system three-dimensional positioner connector connected with the attitude-adjusting airframe section according to the obtained transformational matrix, and butting the attitude-adjusting airframe section and the fixed airframe section by controlling movement of the attitude-adjusting system three-dimensional positioner from the initial position to the target position.

Owner:BEIHANG UNIV

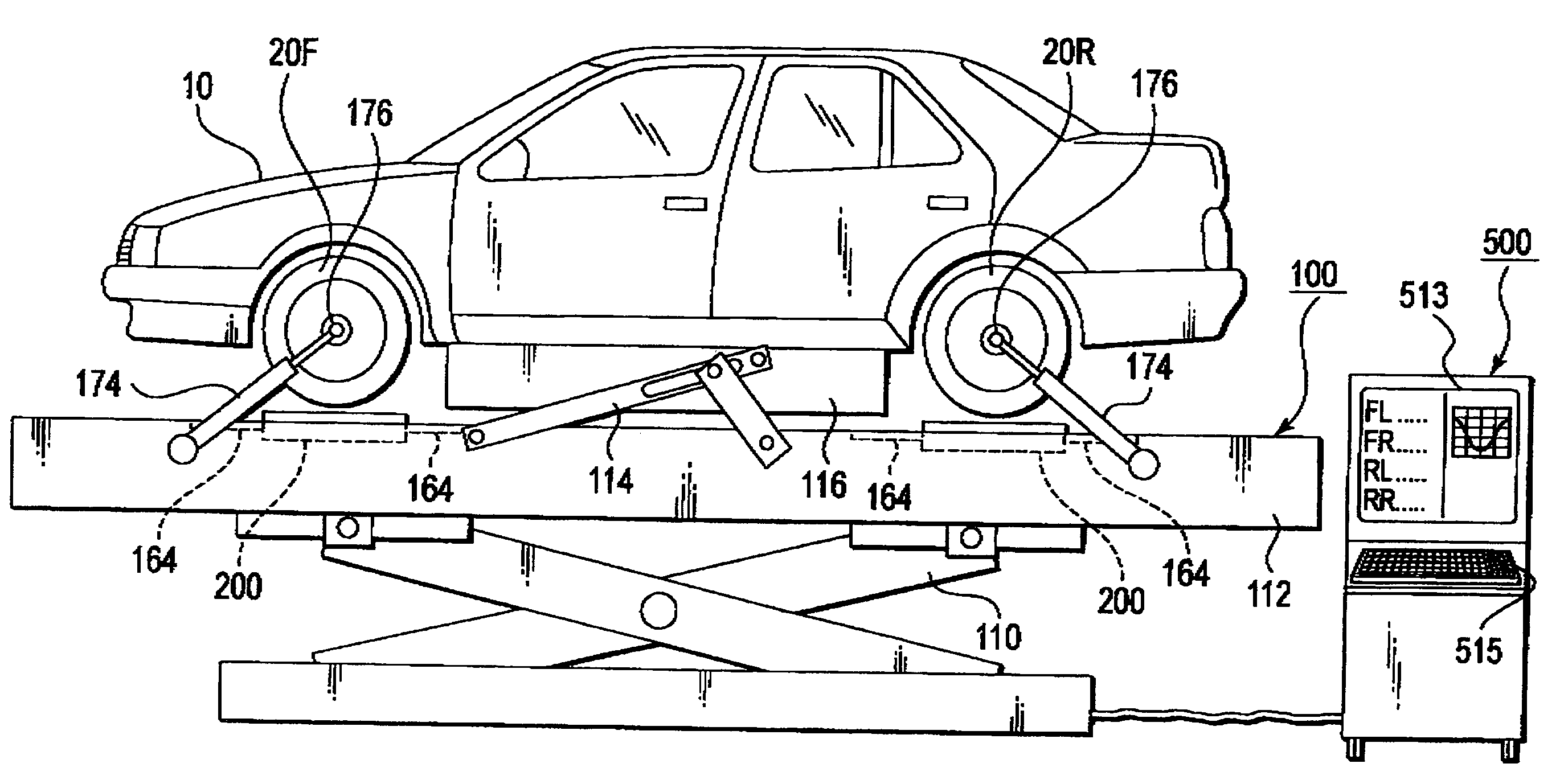

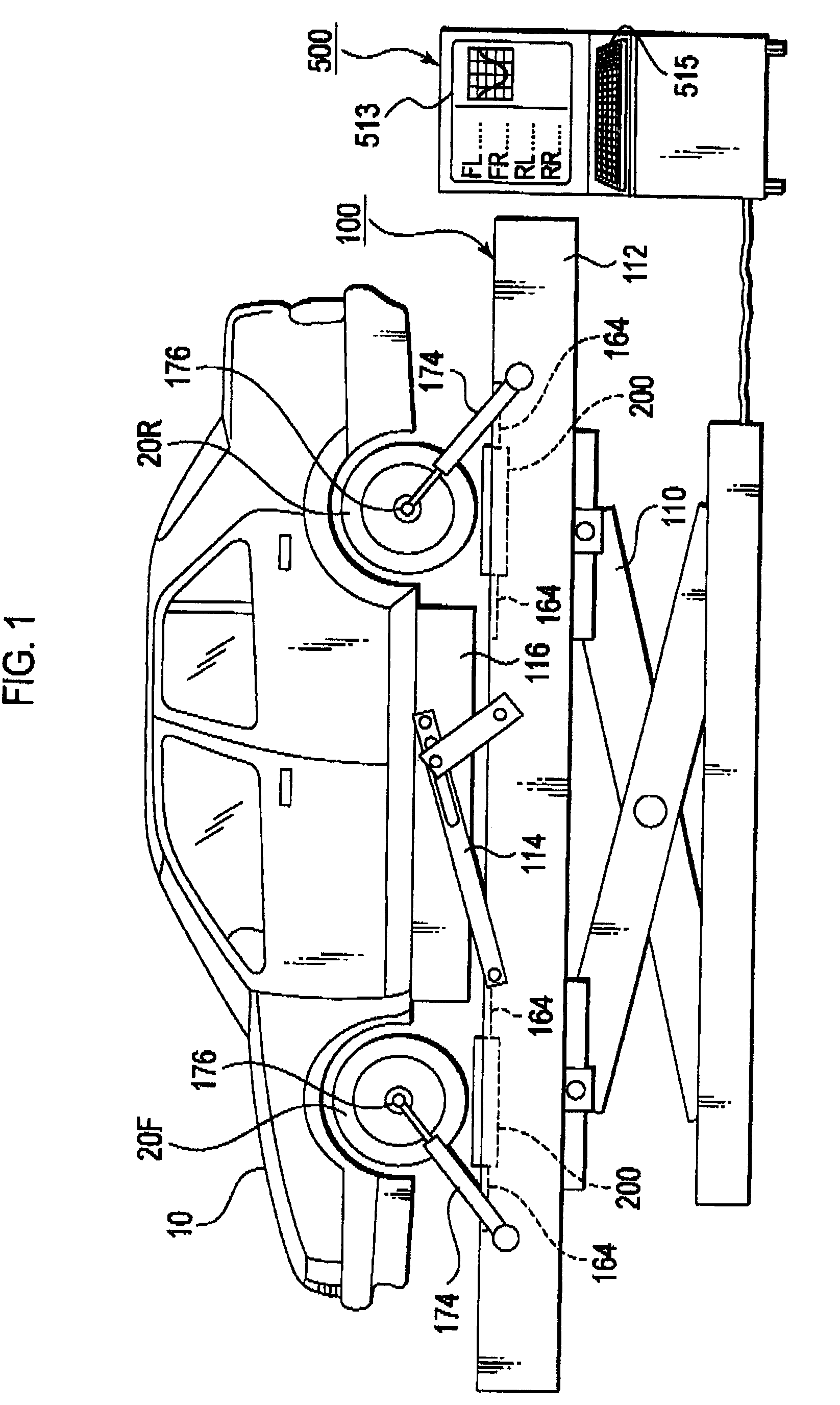

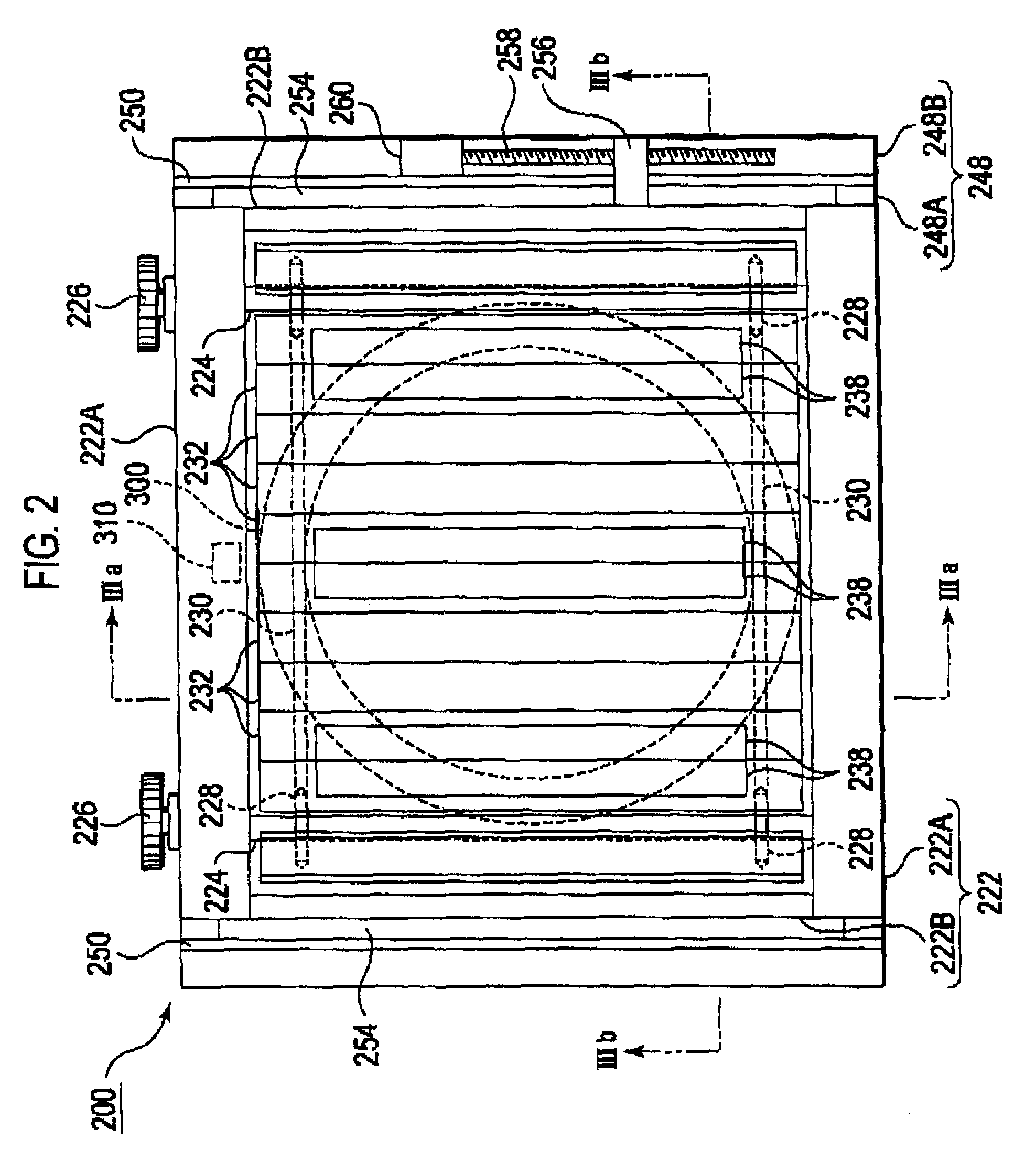

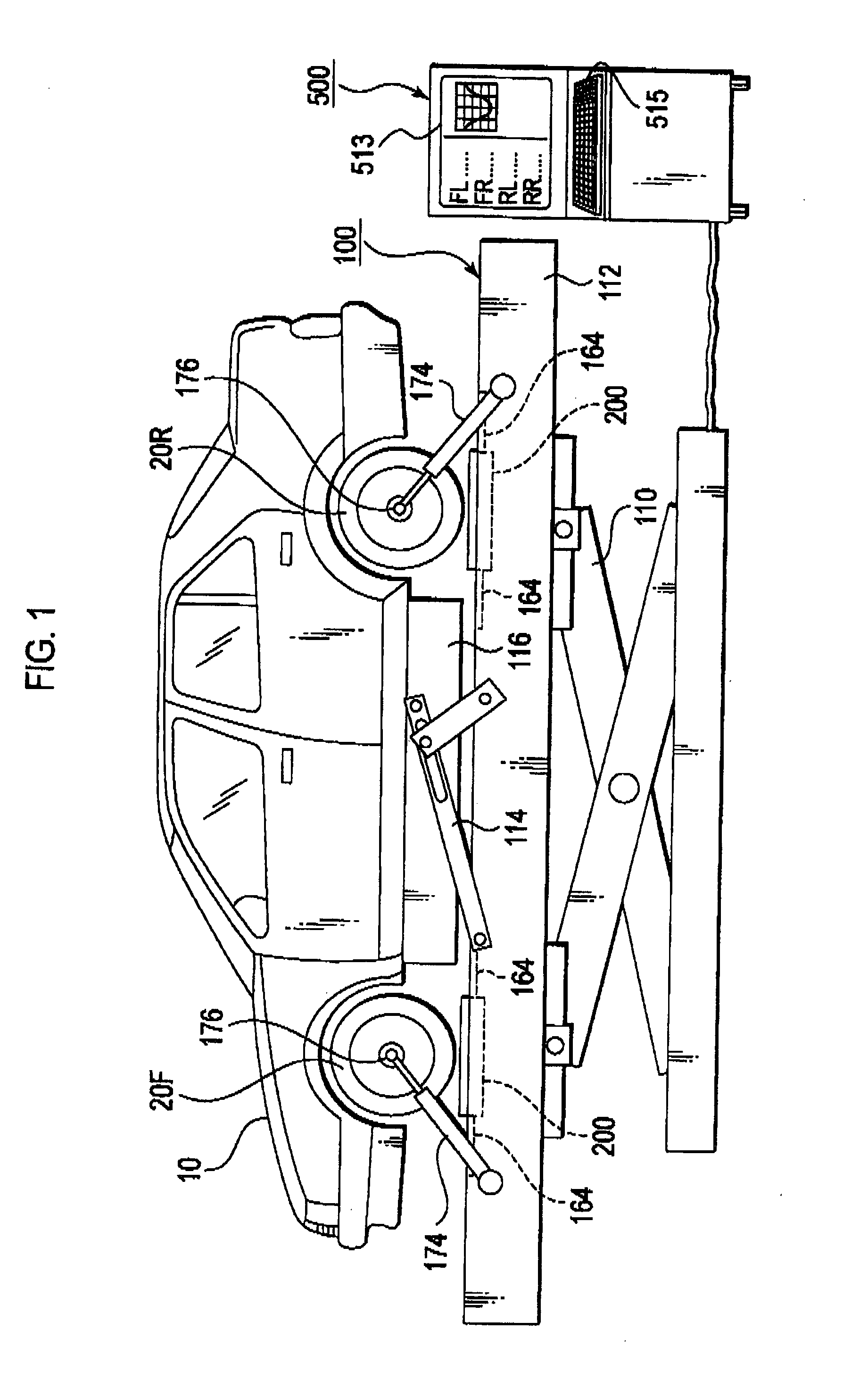

Wheel alignment angle measuring apparatus and wheel alignment angle measuring method

InactiveUS7415770B2Specified easily and reliablyVehicle testingAngles/taper measurementsMeasurement deviceEngineering

Owner:BRIDGESTONE CORP

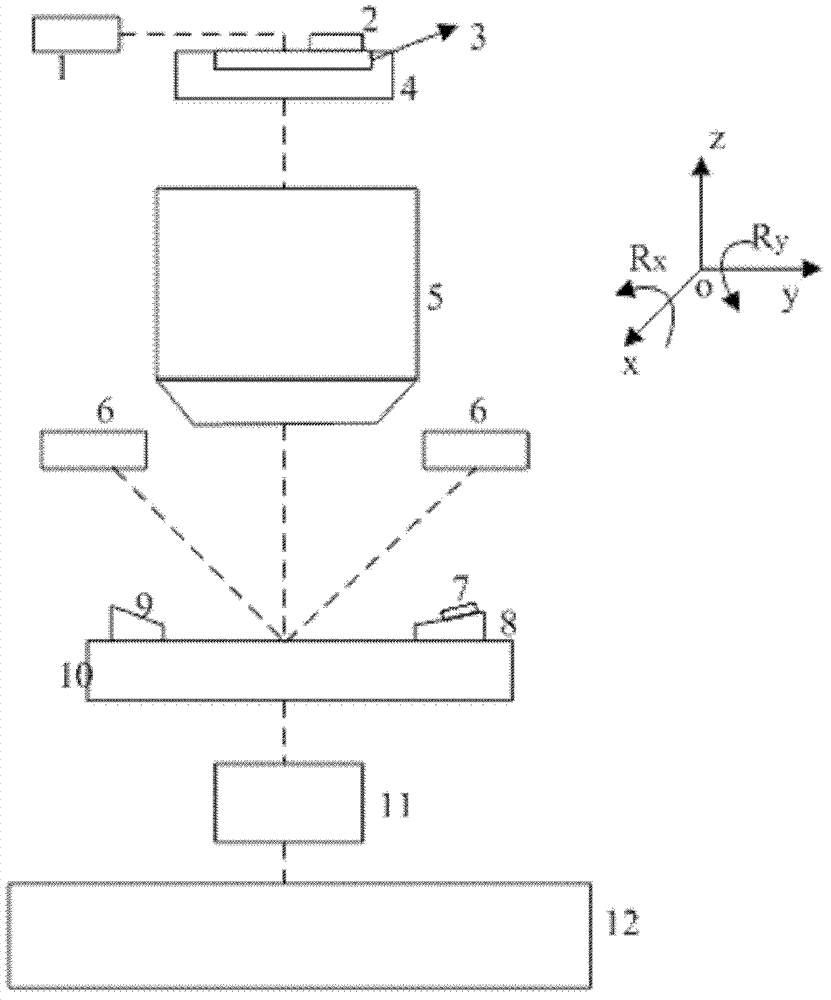

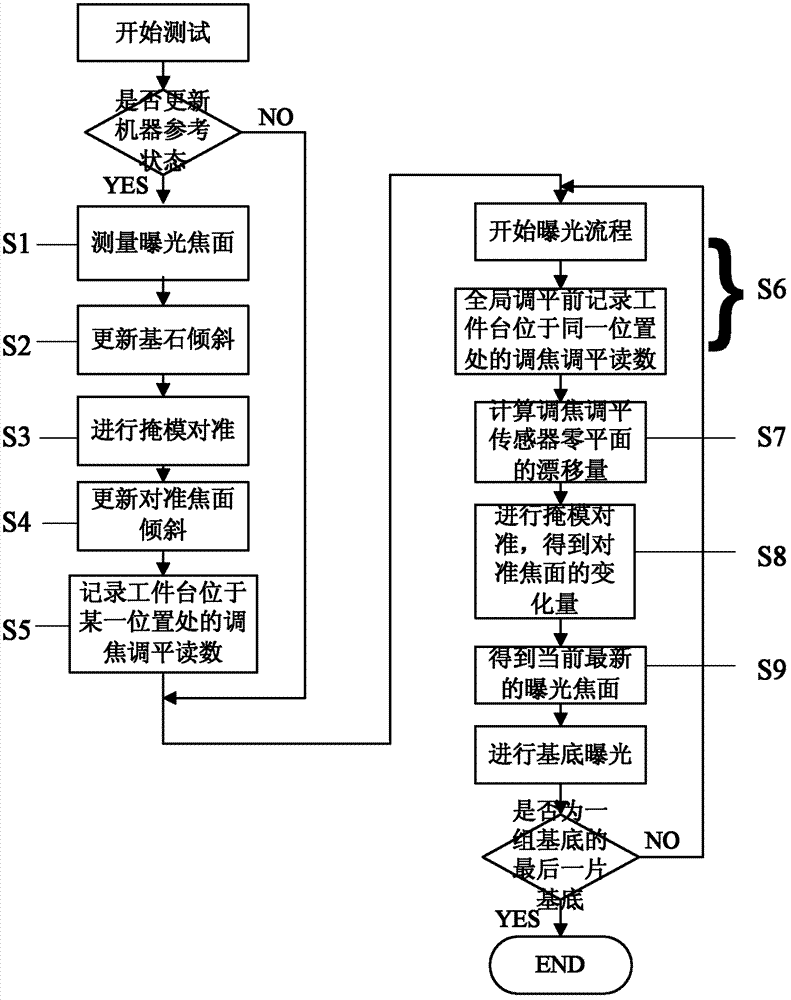

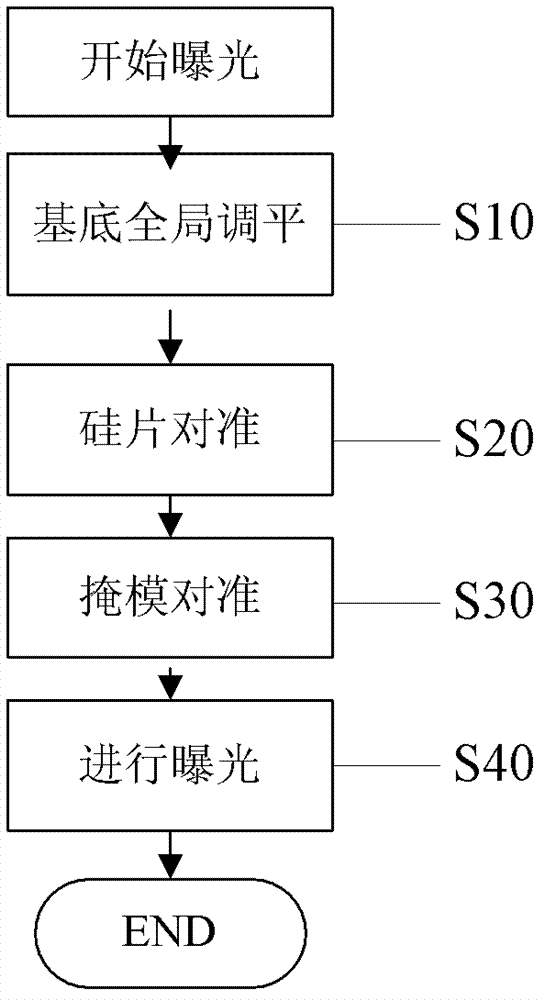

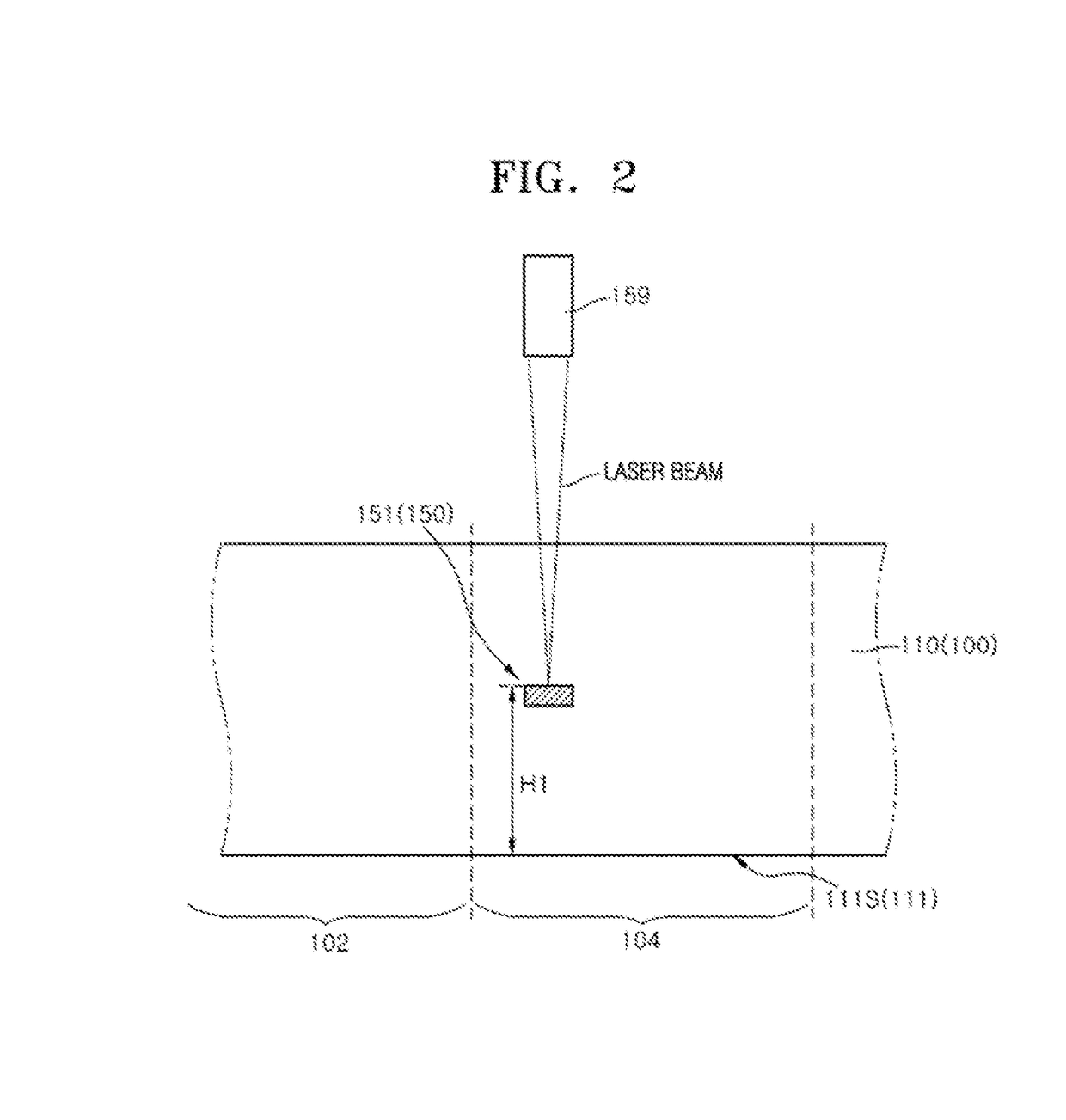

Apparatus and method for focal plane change measurement

ActiveCN103246169AGood focusFocusPhotomechanical exposure apparatusMicrolithography exposure apparatusMeasurement deviceLevel sensor

The invention provides an apparatus and a method for focal plane change measurement. The measurement method comprises the following steps of entering a reference state, calibrating a position of a reference exposure focal plane, updating inclination of a cornerstone relative to the reference exposure focal plane, aligning a reference mask to obtain a reference alignment focal plane change amount and calculate a position of the reference alignment focal plane, measuring the height and a tilt value of a reference leveling point of a workpiece table datum plate by using a focus and level sensor when the workpiece table datum plate moves to the reference position vertically; starting an exposure process, calculating a drift distance of zero plane of the focus and level sensor before wholly leveling the base; aligning a real mask, and calculating a real alignment focal plane change amount to obtain a position of the real alignment focal plane, thereby guaranteeing that the base is always at an optimum focal plane during the exposure.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

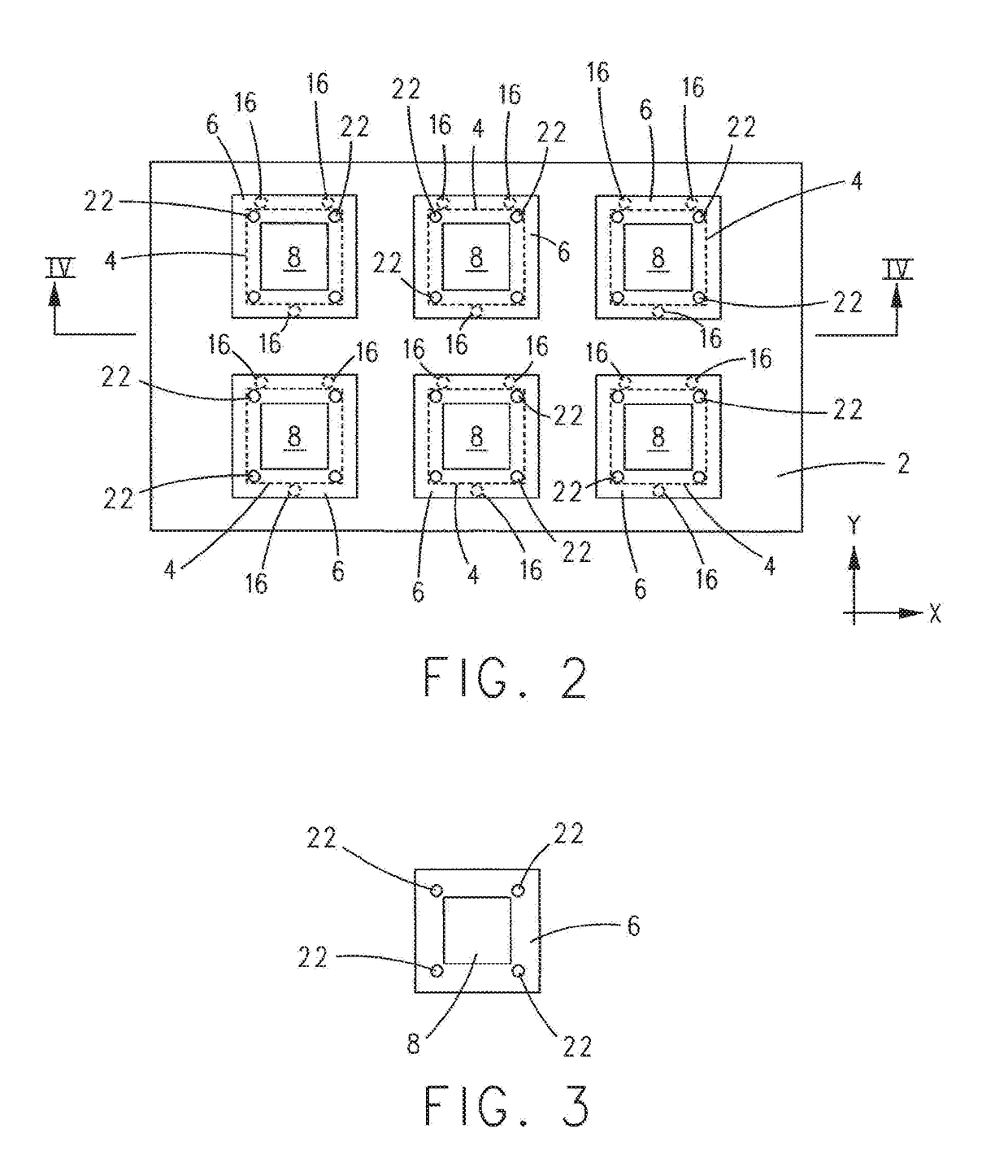

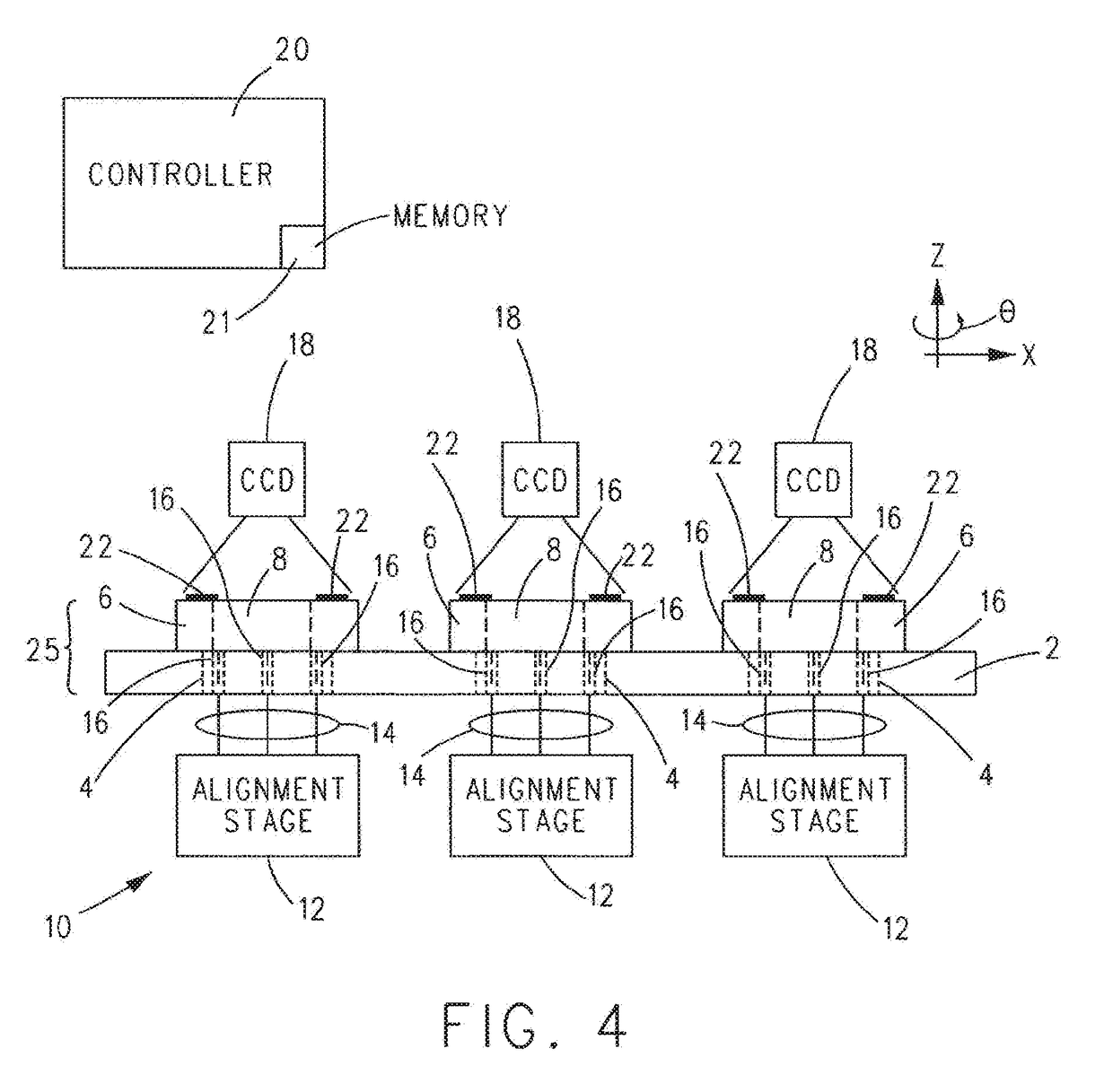

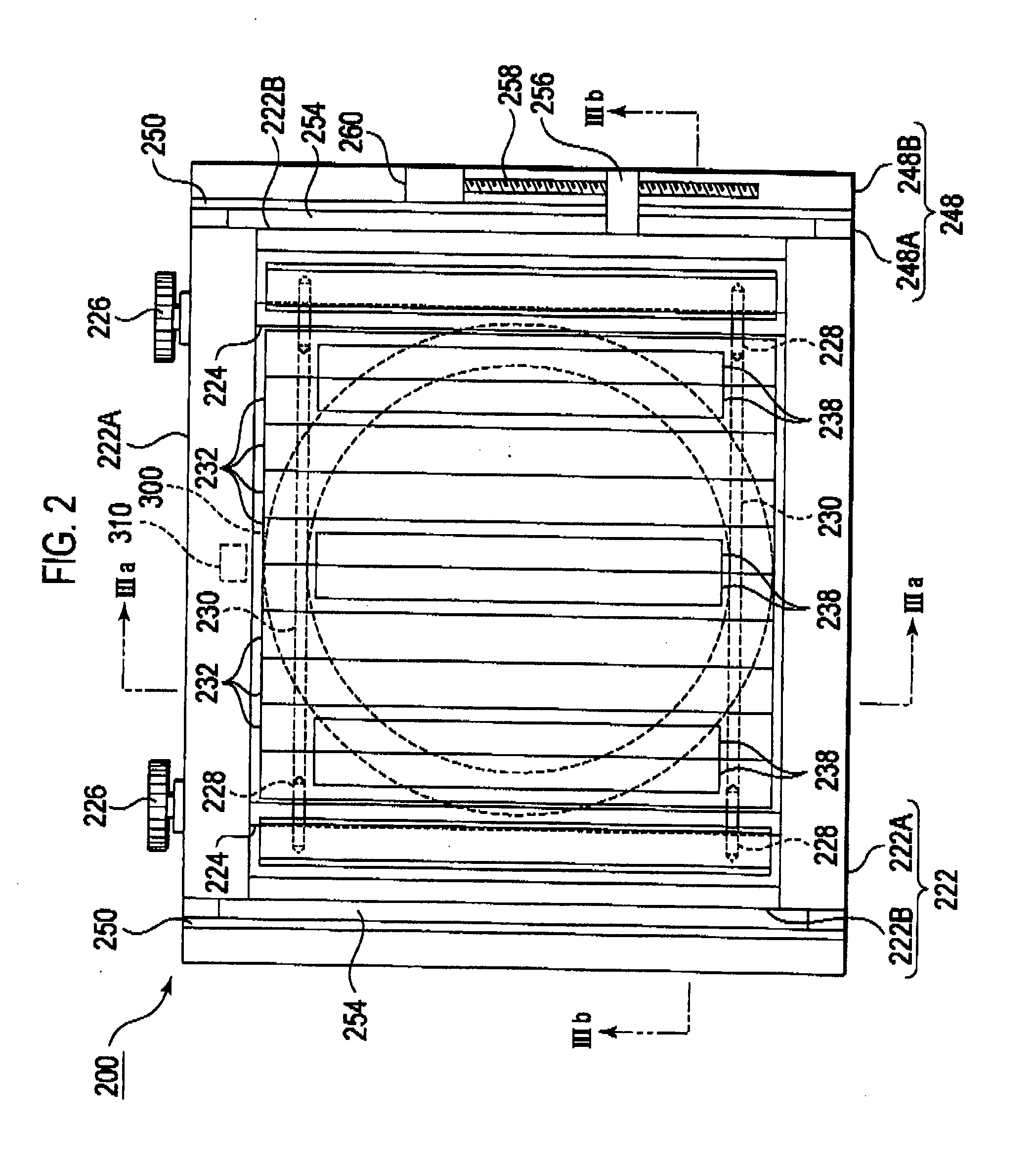

Apparatus and Method for Planarizing Multiple Shadow Masks on a Common Carrier Frame

In an apparatus and method for multi mask alignment, a carrier is provided that includes apertures therethrough. For each aperture, a combination frame and shadow mask that includes alignment features is positioned on spacers supported by the carrier with the shadow mask of the combination in coarse alignment with the aperture. Next, each combination frame and shadow mask is moved to a position spaced from the spacers whereupon the alignment system, under the control of a controller, individually aligns each combination frame and shadow mask to align the alignment features of the combination with reference alignment features associated with the combination. Each combination frame and shadow mask is then returned to a position on the spacers whereafter each combination frame and shadow mask is secured to the carrier. In an example, all of the combination frames and shadow masks can be aligned simultaneously.

Owner:ADVANTECH GLOBAL LTD

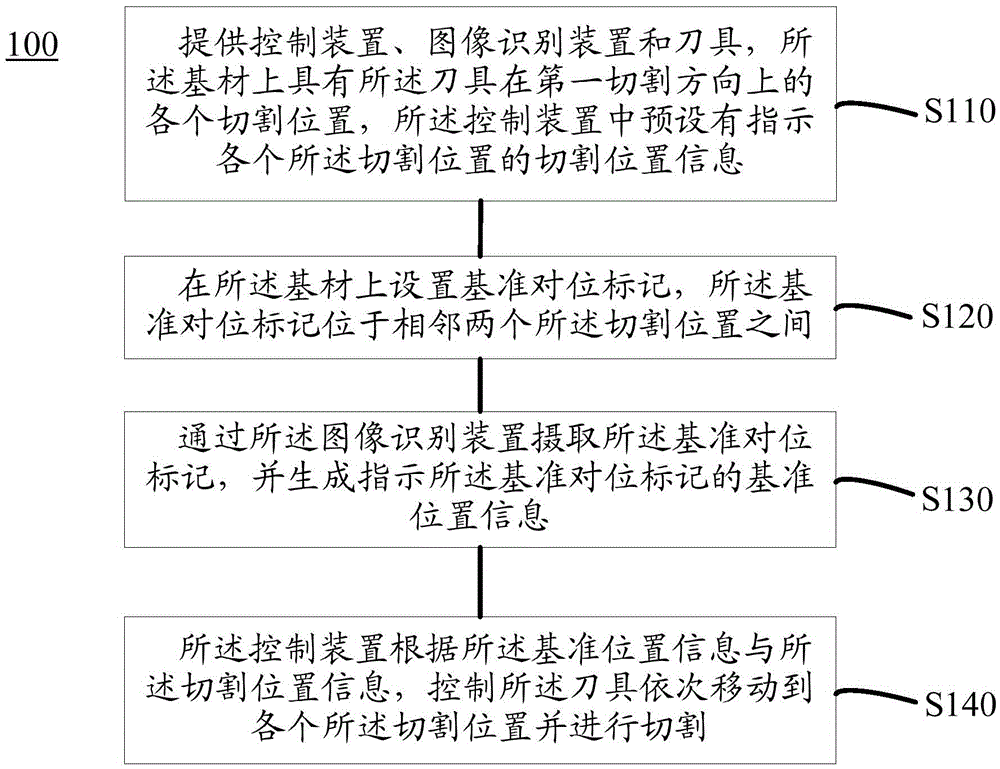

Method for cutting liquid crystal display panel

InactiveCN105652484ASimple cutting processImprove cutting efficiencyGlass severing apparatusMetal working apparatusLiquid-crystal displayEngineering

The invention discloses a method for cutting a liquid crystal display panel. The method comprises the steps of providing a control device, an image recognition device and a tool, wherein a substrate is provided with all cutting positions, in a first cutting direction, of the tool, and cutting position information indicating all the cutting positions is preset in the control device; arranging reference alignment marks on the substrate, wherein the reference alignment marks are located between every two adjacent cutting positions; shooting the reference alignment marks through the image recognition device, and generating reference positional information indicating the reference alignment marks; controlling the tool to move to the cutting positions in sequence for cutting through the control device according to the reference positional information and the cutting position information. By means of the cutting method, the cutting process can be simplified, and cutting efficiency can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

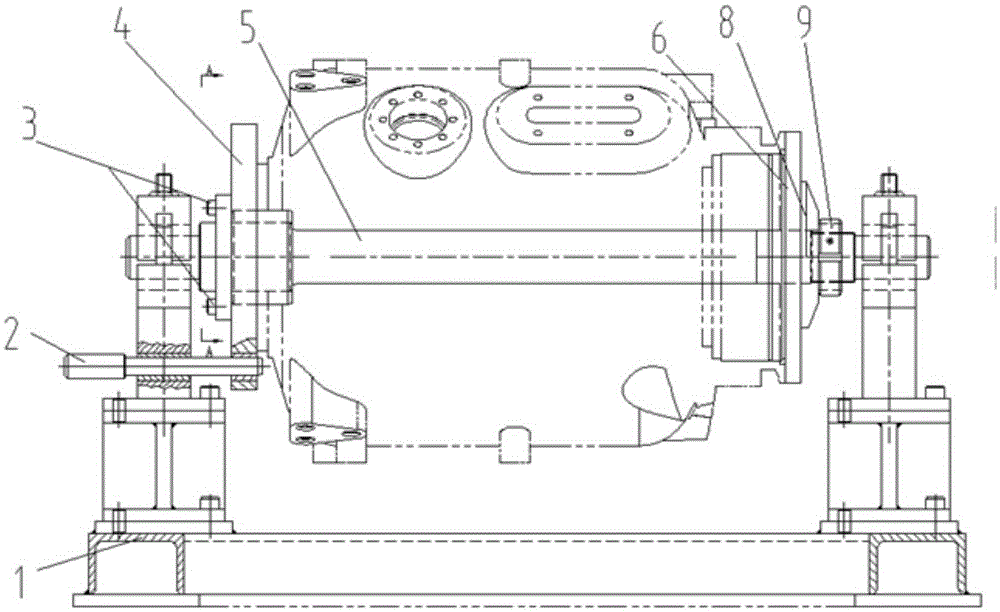

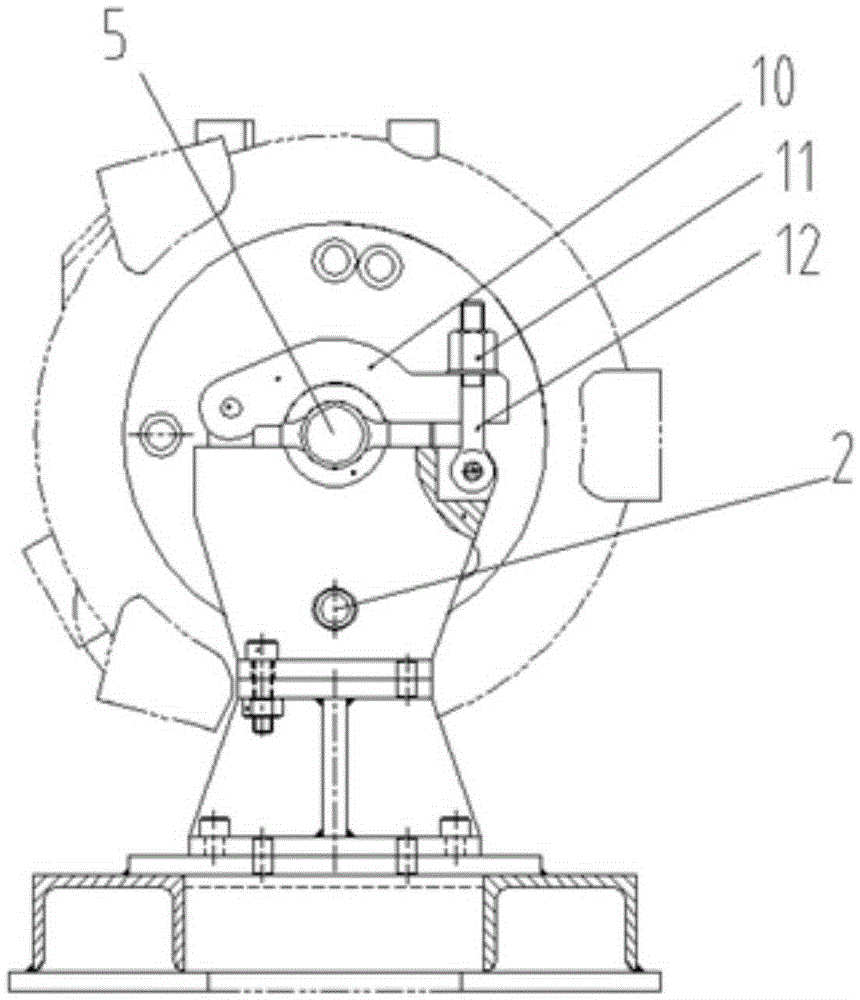

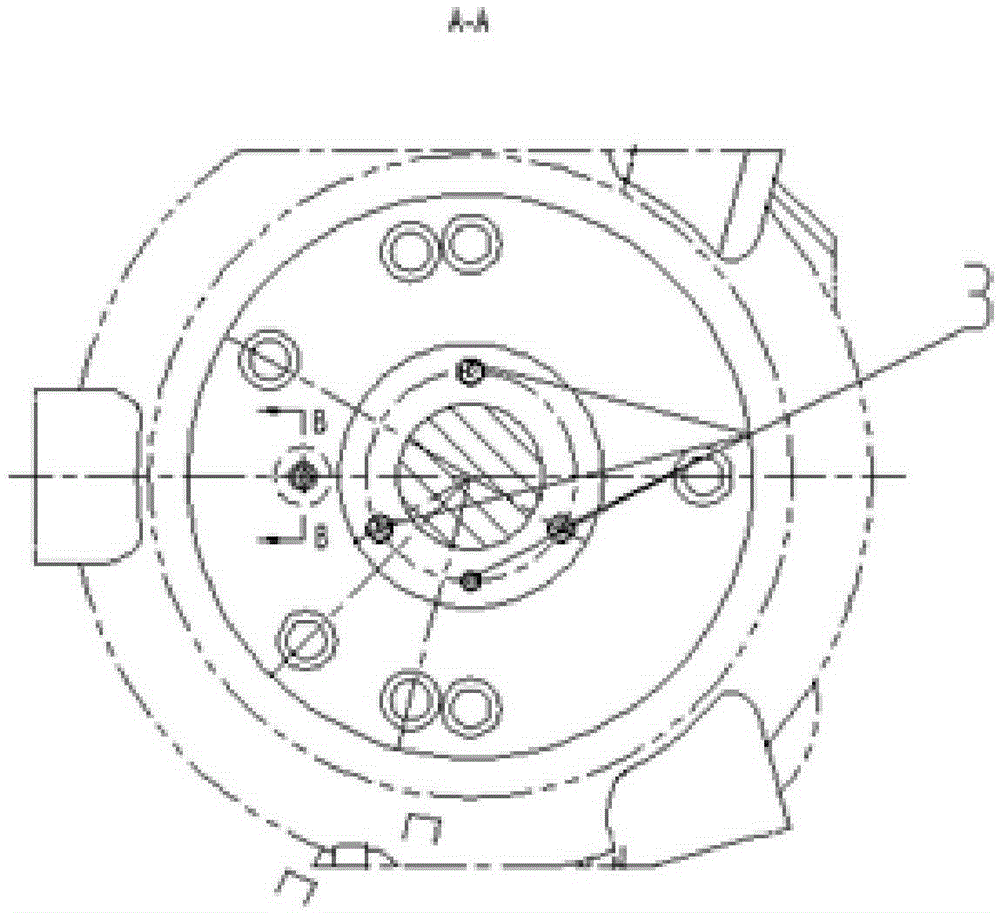

Quick milling positioning device

InactiveCN105415030ASolving Milling ProblemsImprove machining accuracyPositioning apparatusMetal-working holdersEngineeringReference alignment

The invention belongs to a tool design technology, and relates to a quick milling positioning device. A lot of irregular rotating parts exist in the field of mechanical manufacturing; and the parts are complex in appearance and incapable of being machined by a lathe, and need to be milled. As the parts are the rotating parts, are infirm in clamping on a milling machine and difficult in reference alignment, and have accumulation errors, the parts are low in machining efficiency, and the precision is difficult to satisfy assembly requirements. The quick milling positioning device of the rotating parts fixes the parts on the milling machine for machining through a pressing tool, and can adjust the machining positions of the parts through adjusting dowel pins. The quick milling positioning device solves the milling machining problem of the rotating parts on the milling machine, is high in part machining precision and stable in product quality, and improves the machining efficiency.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

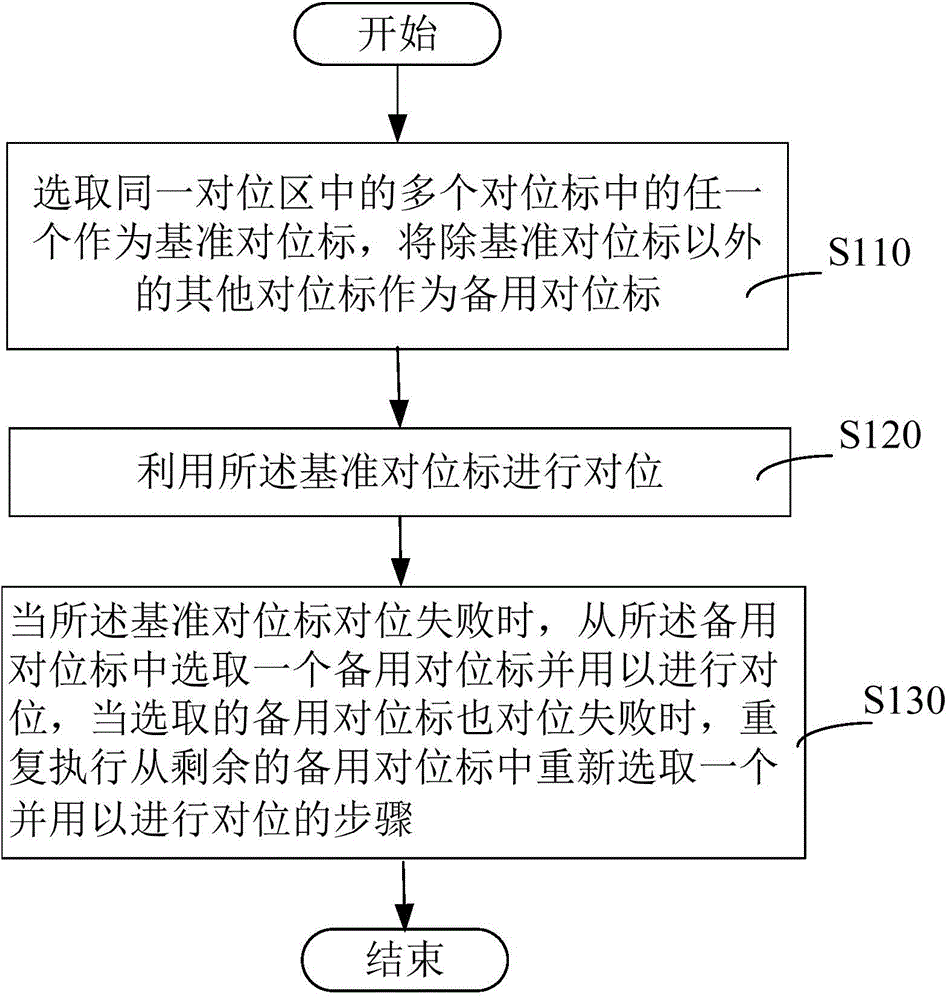

Alignment method for exposure machine

ActiveCN105629683AImprove alignment success rateReduce production lossPhotomechanical exposure apparatusMicrolithography exposure apparatusReference alignmentComputer science

The invention discloses an alignment method for an exposure machine. The alignment method comprises the following steps of taking any one of multiple alignment marks from a same alignment region as the reference alignment mark, and taking other alignment marks except the reference alignment mark as backup alignment marks; performing alignment by the reference alignment mark; choosing one of the backup alignment marks for performing alignment when the alignment is unsuccessful by the reference alignment mark; and when the alignment is also unsuccessful by the chosen backup alignment mark, repeatedly performing the operation of choosing one of the backup alignment marks for performing alignment. According to the alignment method for the exposure machine, after one time of wrong alignment occurs, the backup alignment marks are chosen automatically for performing alignment again; and therefore, the waste of production cost caused by automatic alarm and machine halt when the reference alignment is unsuccessful of the exposure machine, or the out-of-service of a substrate caused by partial failed alignment are avoided.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

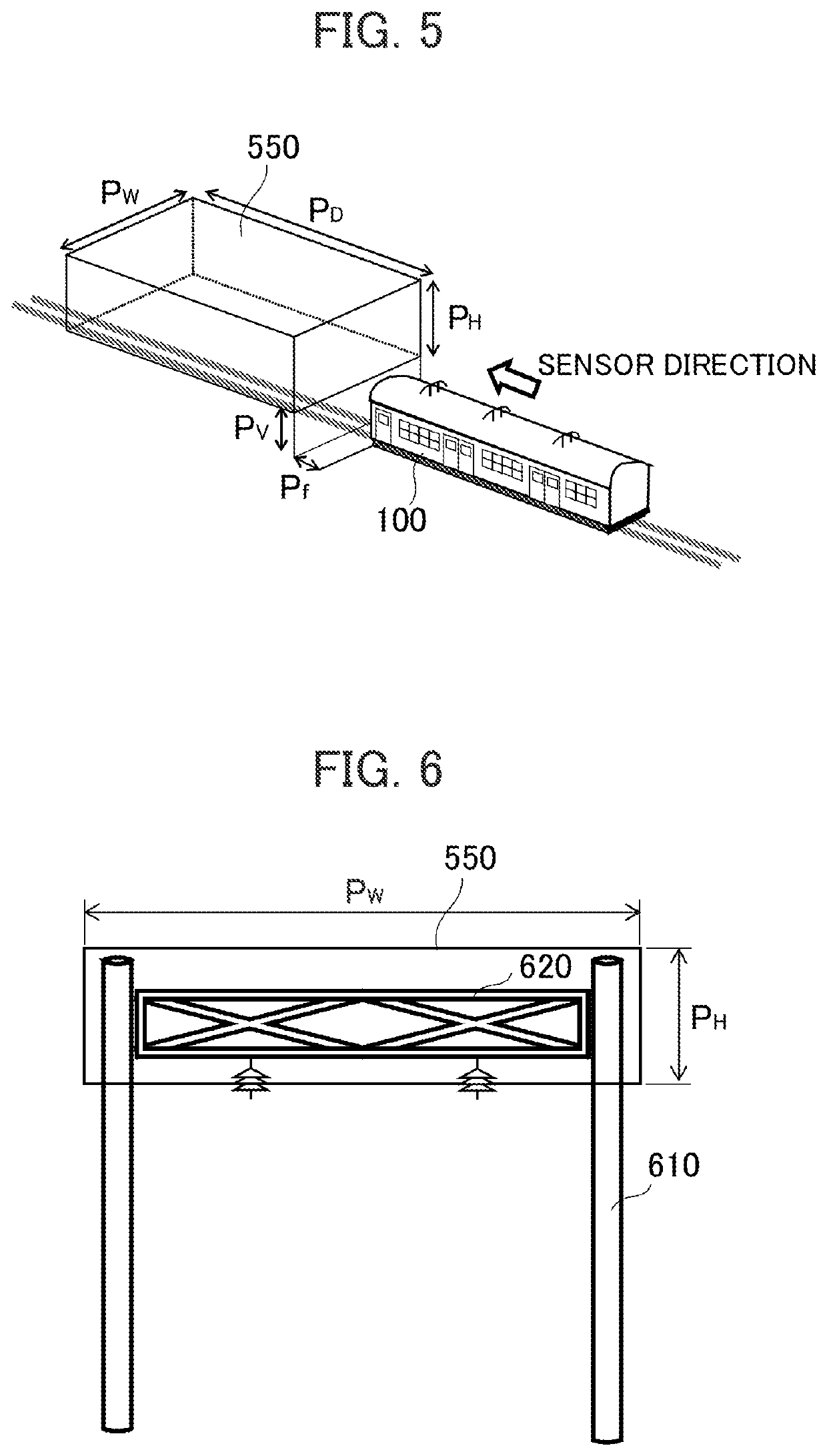

Facility inspection system and facility inspection method

ActiveUS20190392225A1Avoid detectionScene recognitionSignalling indicators on vehicleMobile vehiclePoint cloud

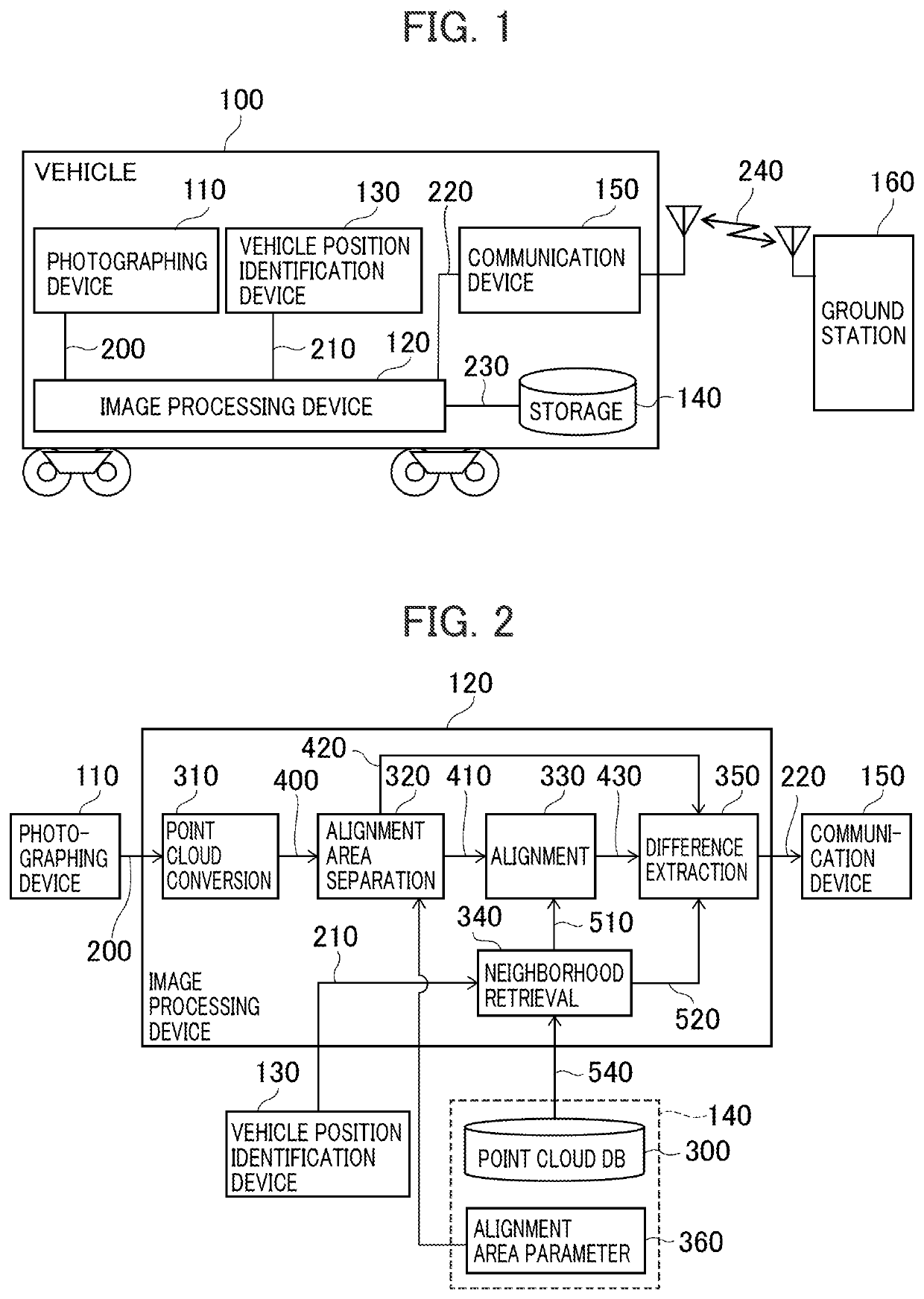

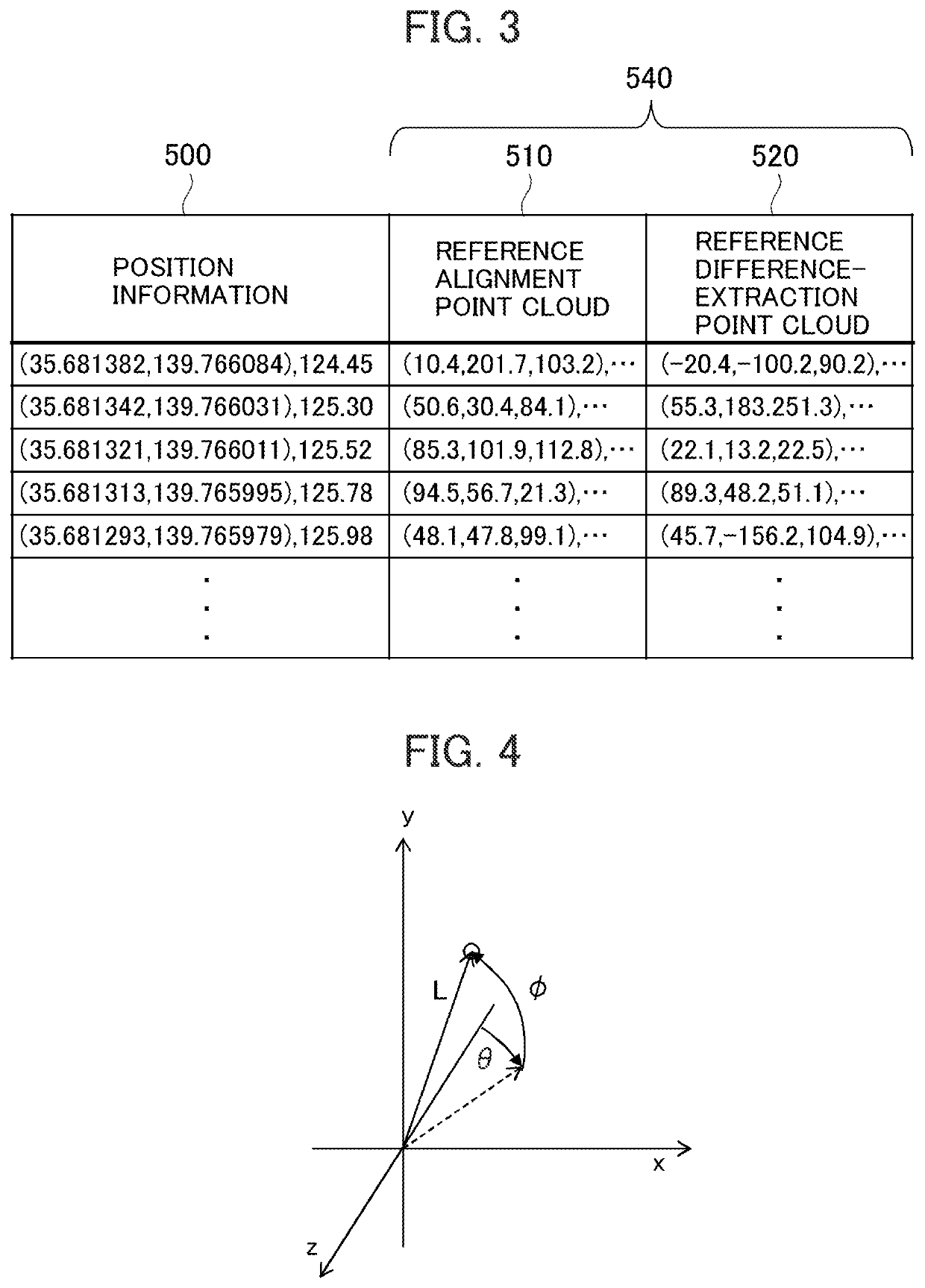

A facility inspection system prevents a normal part from being detected as an abnormal part caused by a deviation in an alignment due to a presence / absence of a moving object in detecting the abnormal part in a surrounding environment of a vehicle moving on a track. The system includes a photographing device, storage device, separation unit, an alignment unit, and a extraction unit. The photographing device photographs the surrounding environment of the moving vehicle. The storage device stores a reference alignment point cloud and a reference difference-extraction point cloud for each position on the track. The separation unit separates the alignment point cloud from a three-dimensional point cloud. The alignment unit aligns the reference alignment point cloud and the alignment point cloud and outputs alignment information. The extraction unit extracts a difference between the three-dimensional point cloud deformed based on the alignment information and the reference difference-extraction point cloud.

Owner:HITACHI HIGH TECH SOLUTIONS CORP

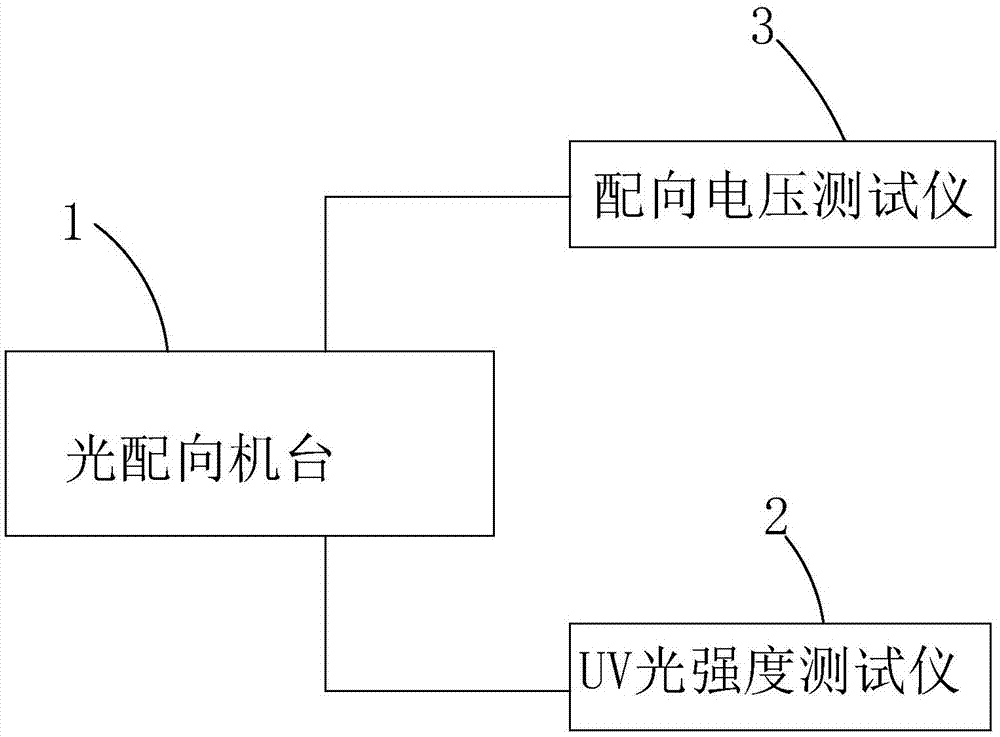

Optical alignment method for liquid crystal display panel

ActiveCN108008579AAvoid uneven anglesReduce intensityNon-linear opticsLiquid-crystal displayEngineering

The invention provides an optical alignment method for a liquid crystal display panel. The method comprises: using a UV light intensity detector and an alignment voltage detector to respectively detect actual UV light intensity and actual alignment voltage which make liquid crystal of a liquid crystal display panel of a reference alignment machine reach a target pretilt angle, and according to theactual UV light intensity and actual alignment voltage of the reference alignment machine, adjusting alignment parameters of a to-be-debugged alignment machine, to make the actual UV light intensityand actual alignment voltage of the to-be-debugged alignment machine be same with the actual UV light intensity and actual alignment voltage of the reference alignment machine. The method can reduce differences of the alignment voltage and UV light intensity of the alignment machines, and prevent phenomenon of non-uniform angles of the pretilt angles of the liquid crystal display panels, and improve product process yield.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

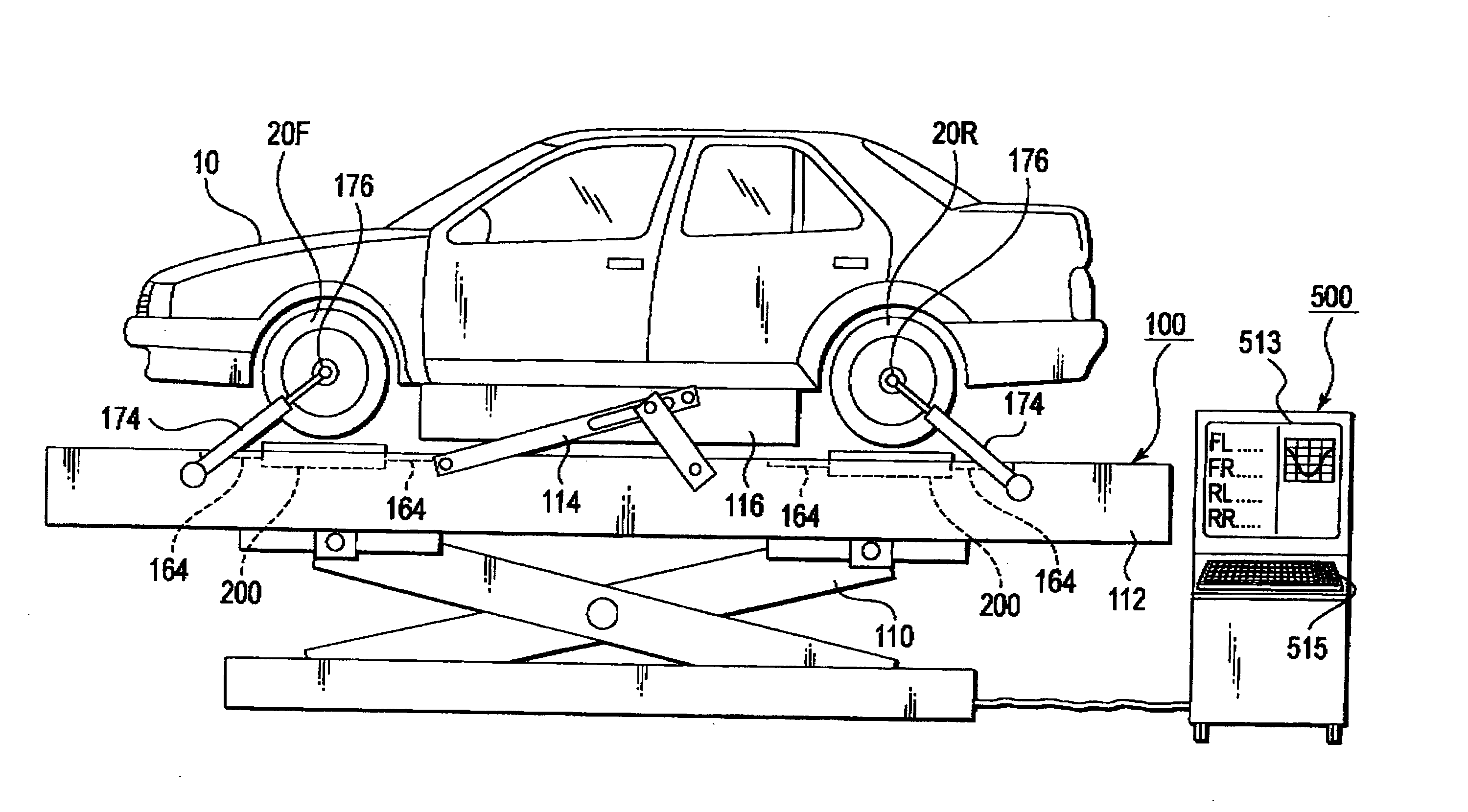

Wheel Allignment Angle Measuring Apparatus and Wheel Alignment Angle Measuring Method

InactiveUS20080022540A1Specified easily and reliablyVehicle testingAngles/taper measurementsMeasurement deviceEngineering

A wheel alignment angle measuring apparatus according to the present invention computes variation energy sums EA″ and EB″ and a reference wheel referencing alignment angle (a toe angle TBR) based on an anteroposterior force variation rate dFx and a lateral force variation rate dFy generated in a reference wheel (RL). Furthermore, the alignment angle measuring apparatus computes a non-reference wheel referencing alignment angle (a toe angle TNBR) of a non-reference wheel (FL), and then computes a toe angle TNBA to be specified for the non-reference wheel, based on the toe angle TNBR and a difference between a toe angle TBR and the toe angle TI. According to the thus configured wheel alignment angle measuring apparatus, it is possible to determine a value of an alignment angle that allows characteristics of lateral forces generated in front and rear wheels to be approximated to each other, when the alignment angles of wheels are adjusted based on the characteristics of the lateral forces generated in the wheels.

Owner:BRIDGESTONE CORP

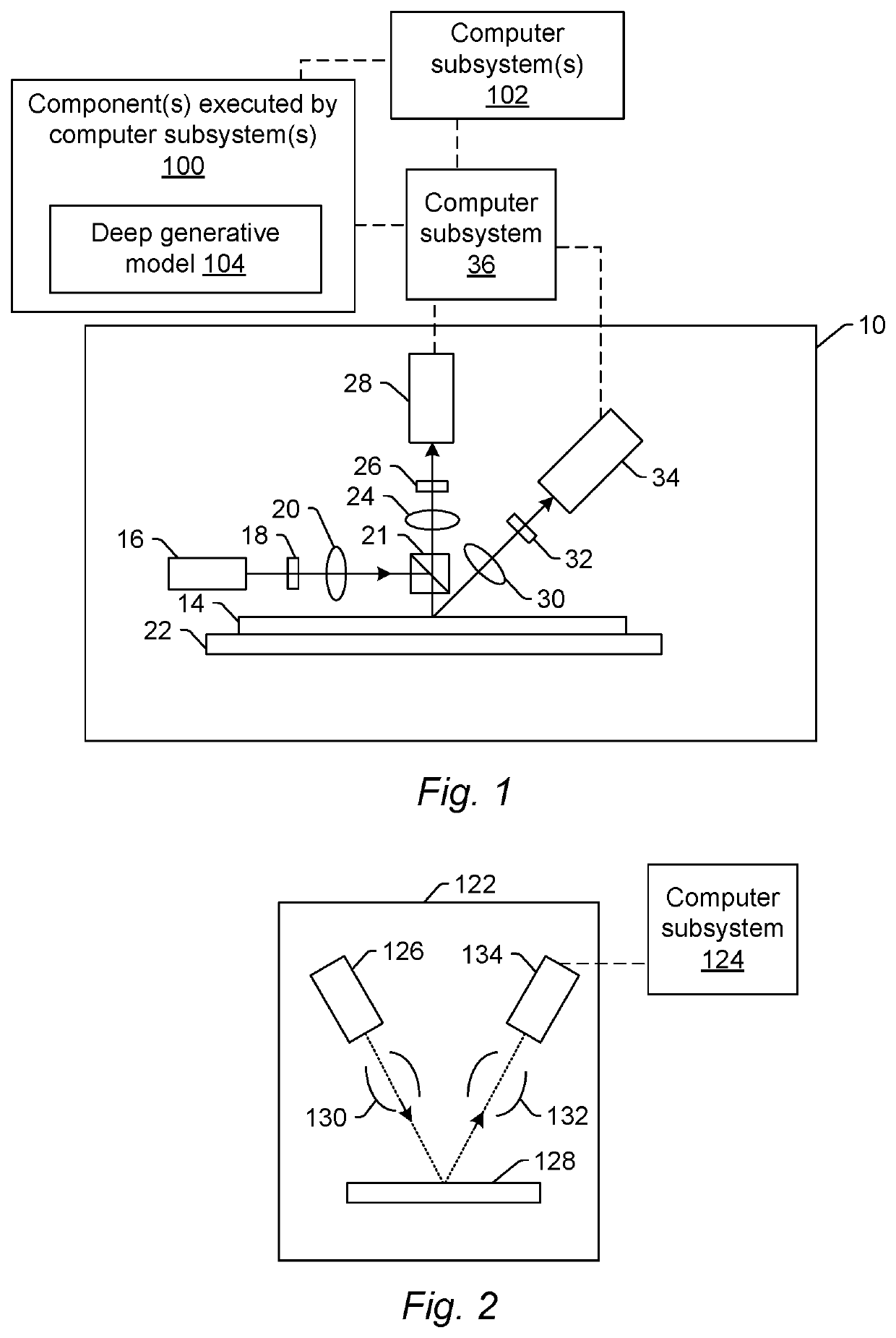

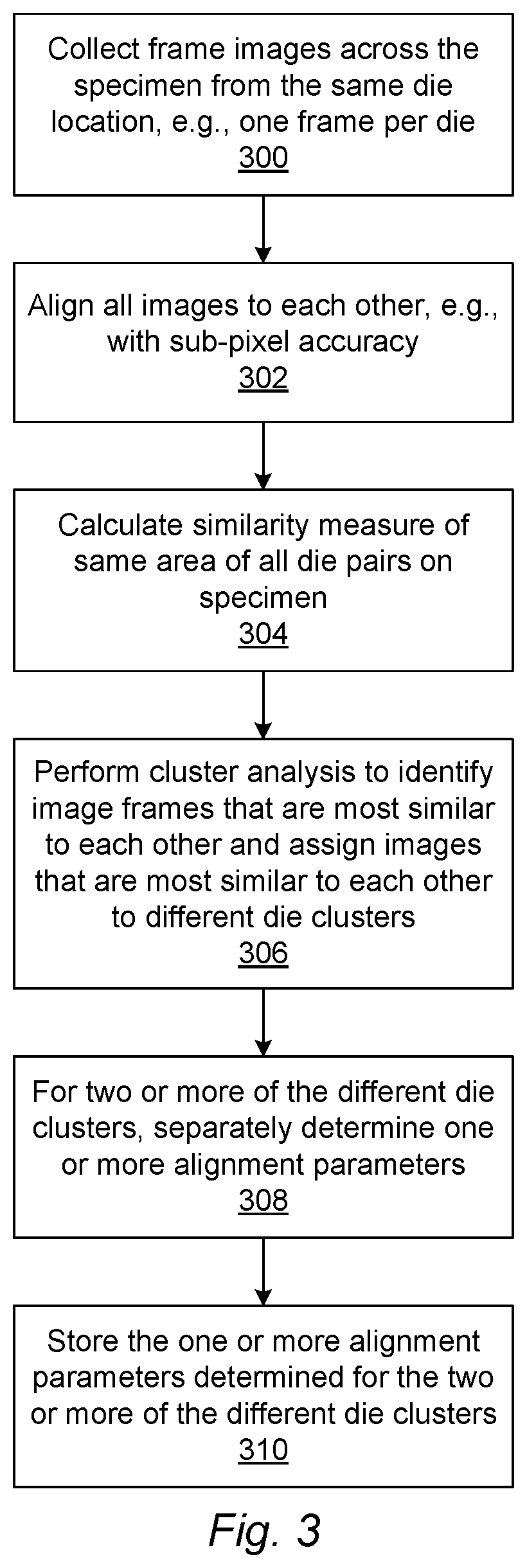

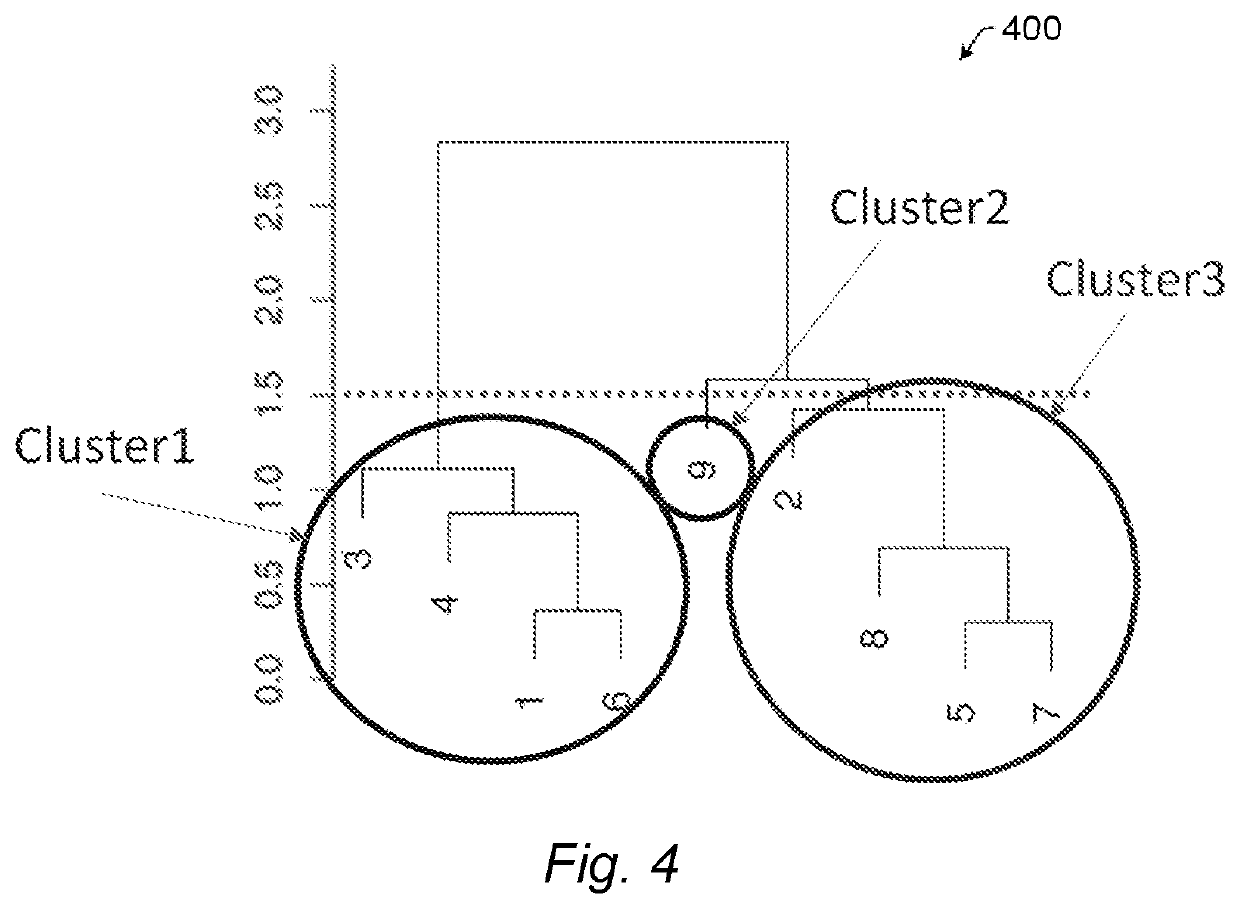

Image alignment setup for specimens with intra- and inter-specimen variations using unsupervised learning and adaptive database generation methods

Methods and systems for determining one or more alignment parameters for use in a process performed on a specimen are provided. One method includes determining measures of similarity between images generated by an imaging system for corresponding locations in each of two or more pairs of dies on a specimen and performing cluster analysis based on the determined measures of similarity to identify the images that are most similar to each other and to assign different subsets of the images that are most similar to each other to different die clusters, respectively. The method also includes separately determining one or more alignment parameters for two or more of the different die clusters. The one or more alignment parameters are used for aligning images generated by the imaging system for the specimen or another specimen to a common reference.

Owner:KLA TENCOR TECH CORP

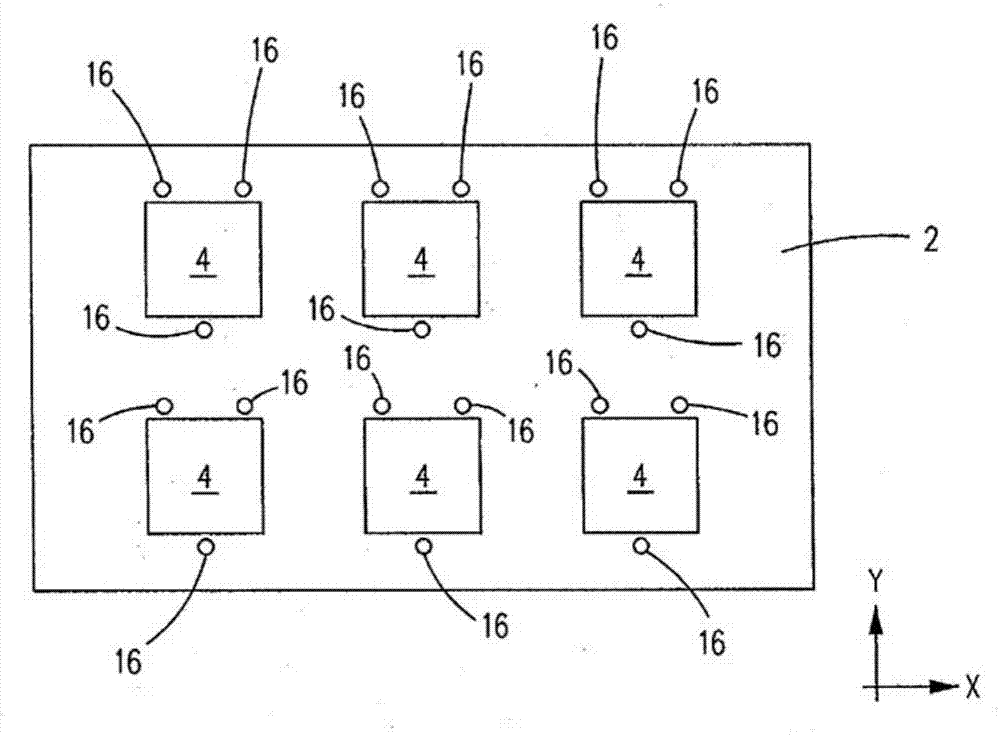

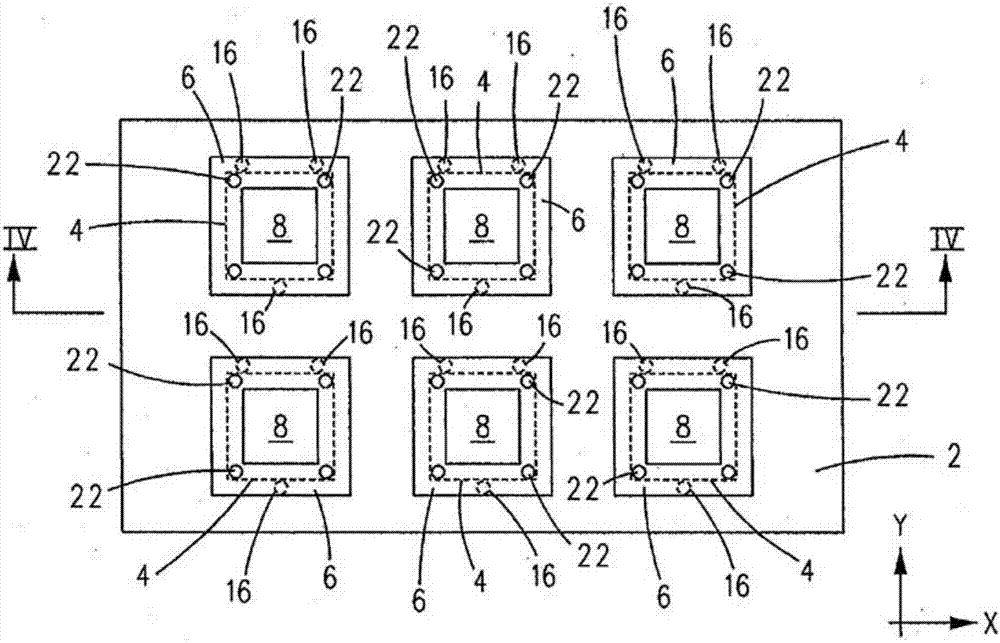

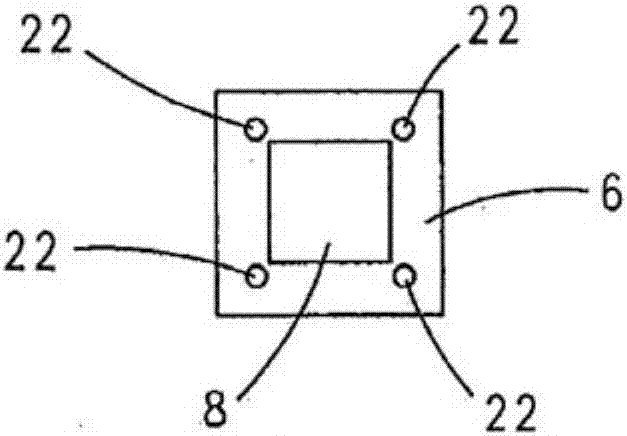

Apparatus and method for planarizing multiple shadow masks on a common carrier frame

The invention discloses an apparatus and method for multi-mask alignment. In an apparatus and method for multi-mask alignment, a carrier is provided that includes apertures therethrough. For each aperture, a combination frame and shadow mask that includes alignment features is positioned on spacers supported by the carrier with the shadow mask of the combination in coarse alignment with the aperture. Next, each combination frame and shadow mask is moved to a position spaced from the spacers whereupon the alignment system, under the control of a controller, individually aligns each combination frame and shadow mask to align the alignment features of the combination with reference alignment features associated with the combination. Each combination frame and shadow mask is then returned to a position on the spacers whereafter each combination frame and shadow mask is secured to the carrier. In an example, all of the combination frames and shadow masks can be aligned simultaneously.

Owner:ADVANTECH GLOBAL LTD

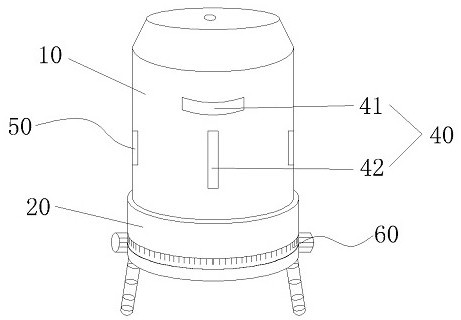

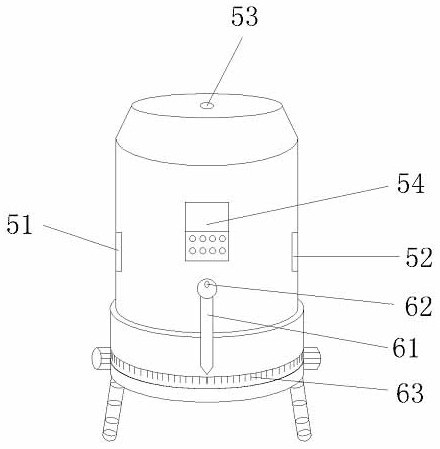

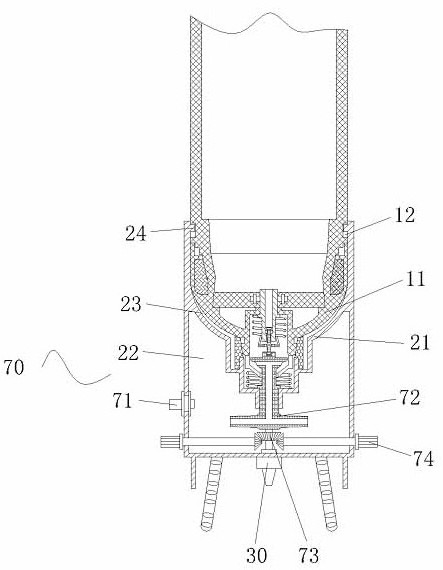

Three-dimensional range finder and measuring and using method thereof

ActiveCN111707222AOptical rangefindersUsing optical meansThree dimensional measurementReference alignment

The invention provides a three-dimensional range finder, which comprises: a shell; a supporting disc, wherein the shell is coaxially and rotationally arranged above the supporting disc, and a verticalpoint alignment device is fixedly arranged in the center of the bottom of the supporting disc; a reference alignment device, wherein the outer peripheral surface of the shell is fixedly provided withthe reference alignment device used for being aligned with a reference line; a distance measurement processing system comprising a data processing module, an interaction module and a distance measurement module, wherein the data processing module is electrically connected with the interaction module and the distance measurement module, and the measurement direction of the distance measurement module is perpendicular to the alignment direction of the reference alignment device; and a level adjusting device, wherein the supporting disc is provided with the level adjusting device used for keeping the shell horizontal. Through the cooperation of the reference alignment device and the level adjusting device, in combination with the arrangement that the measurement direction of the distance measurement module is perpendicular to the alignment direction of the reference alignment device, three-dimensional measurement can be accurately conducted on the distance and flatness of a to-be-measured wall, so that the measurement error is small, and use is convenient.

Owner:盐城幼儿师范高等专科学校

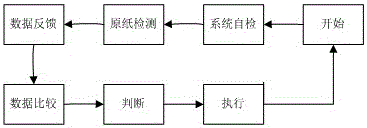

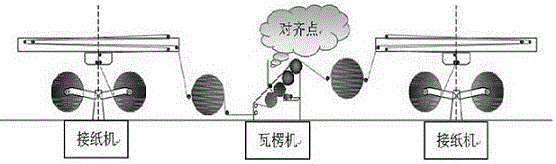

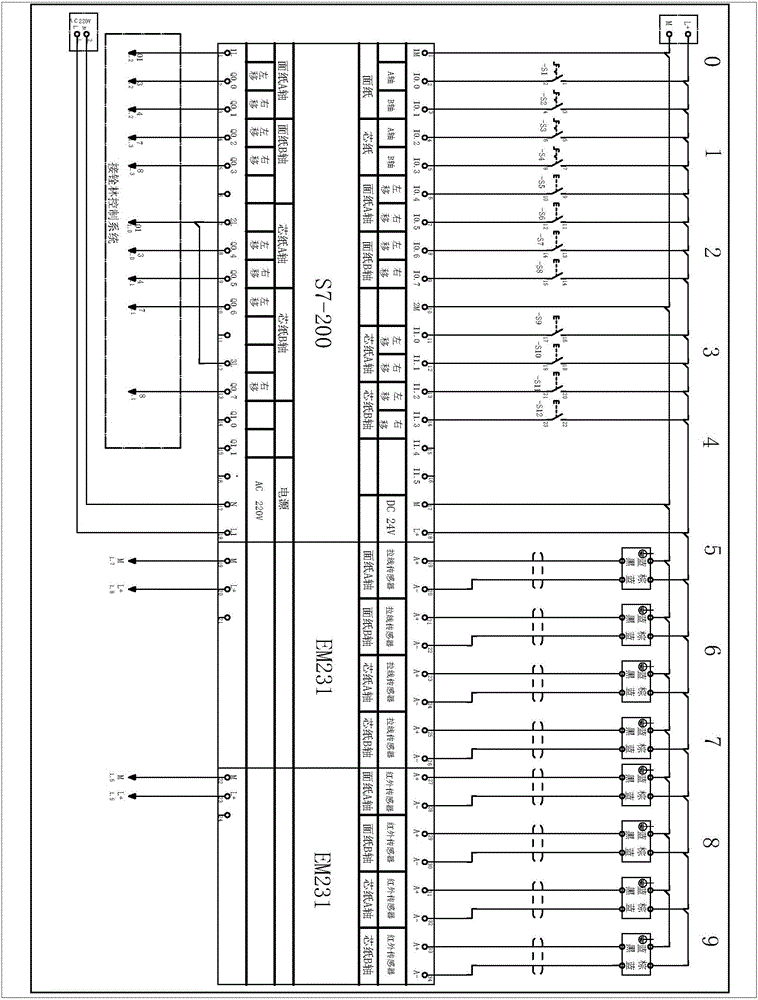

Automatic paper receiving and aligning system for corrugated board production line

ActiveCN106829597ATo achieve the purpose of automatic synchronization and alignmentAvoid misalignment biasMechanical working/deformationWebs handlingProduction linePaperboard

Currently, when base paper is replaced during corrugated board production, because no device for reference alignment exists, an operator performs alignment in a naked eye manner, the problem that deviation is large exists, and consequently the base paper consumed because of paperboard ridge exposing generated due to the fact that the base paper is not aligned with one another accounts for a large consumption proportion. The invention relates to the field of manufacturing industry and particularly provides an automatic paper receiving and aligning system for a corrugated board production line. The system comprises a control unit, a display unit, a fixing unit and a feeding-back unit. According to the system, by adding a movable monitoring alignment device, during machine table producing, paper changing and shifting of base paper in the manufacturing process, automatic identification is performed; the left and right positions of the remaining base paper are synchronously adjusted, and the purpose of automatic and synchronous alignment is achieved; and the malposition deviation generated because of manual naked eye alignment is avoided, the product ridge exposing is effectively eradicated, the alignment precision is high, the alignment speed is high, and the malposition of a paperboard is smaller than 2 mm.

Owner:GUANGXI ZHENLONG IND

Imprint templates with alignment marks and methods of forming imprint patterns using the same

ActiveUS20180259862A1Photomechanical apparatusSemiconductor/solid-state device manufacturingResistComputational physics

There is provided a method of performing a nanoimprint lithography process. The method includes providing an imprint template having field patterns and an alignment mark. The field patterns are defined by a concave and convex surface profile of each of field regions of the imprint template, and the alignment mark is embedded in a boundary region of the imprint template. A resist layer is formed on a substrate having a reference alignment mark. The field patterns are imprinted on the resist layer to embed the field patterns into the resist layer while the imprint template is aligned with the substrate using the alignment mark and the reference alignment mark. Related imprint template structures are also provided.

Owner:SK HYNIX INC

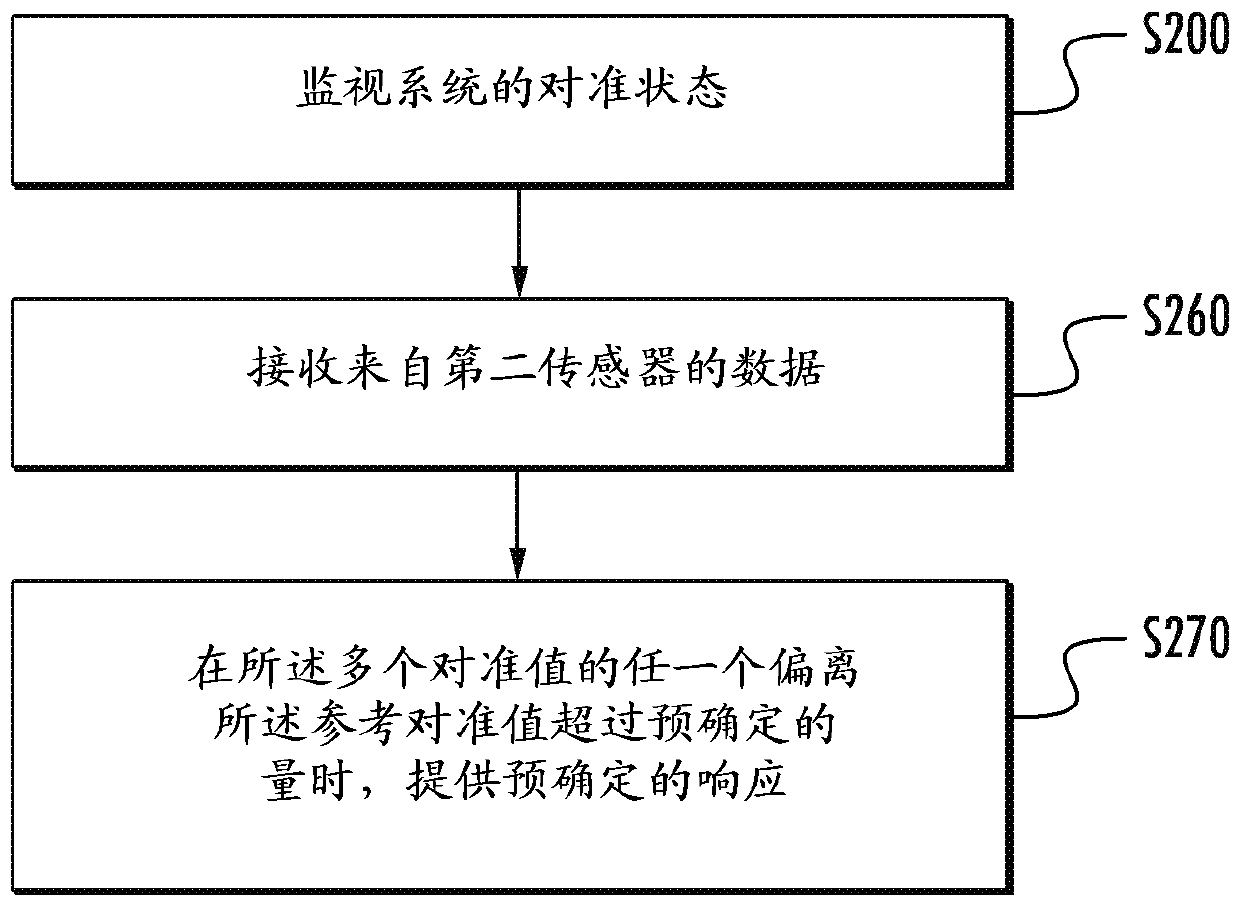

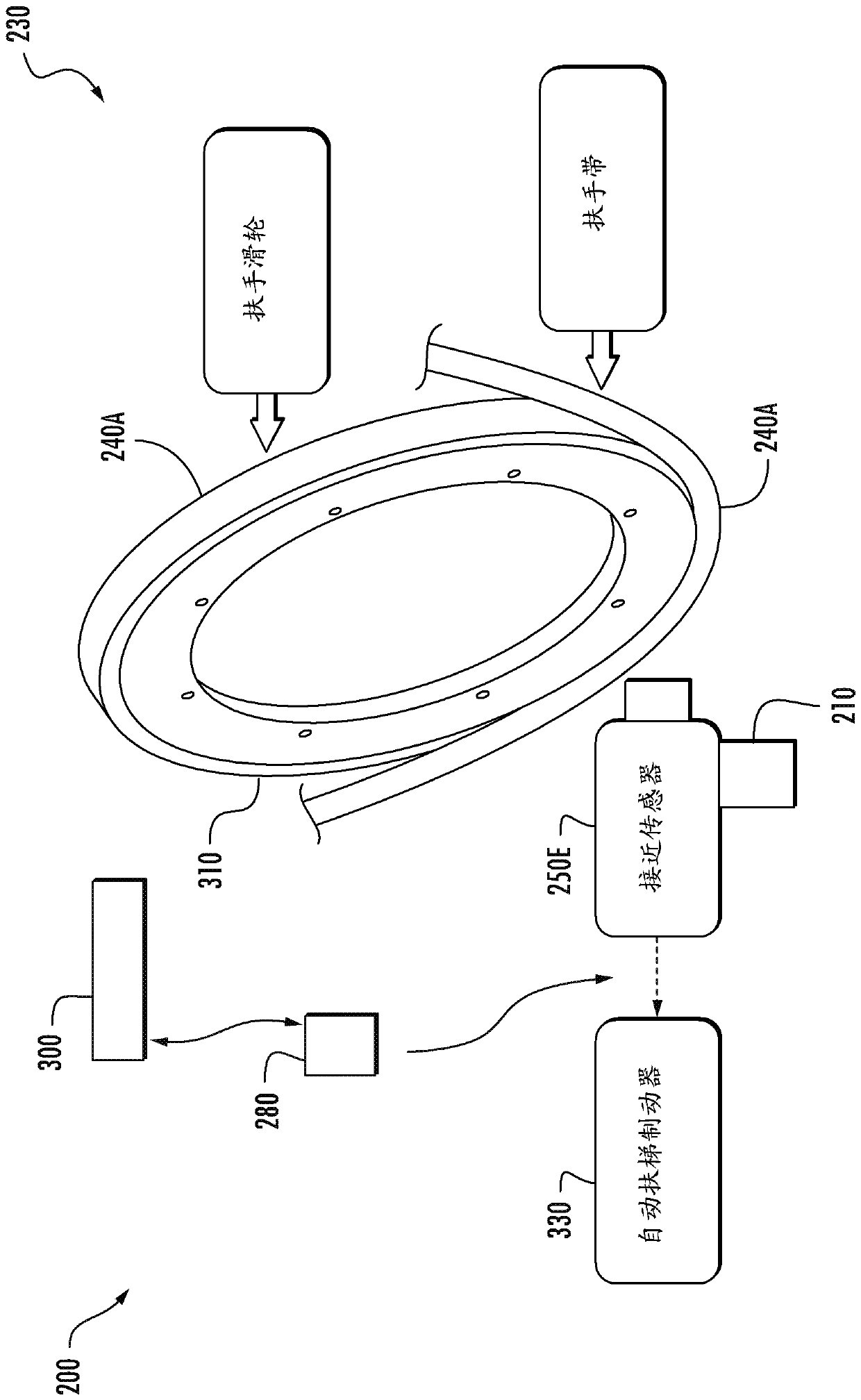

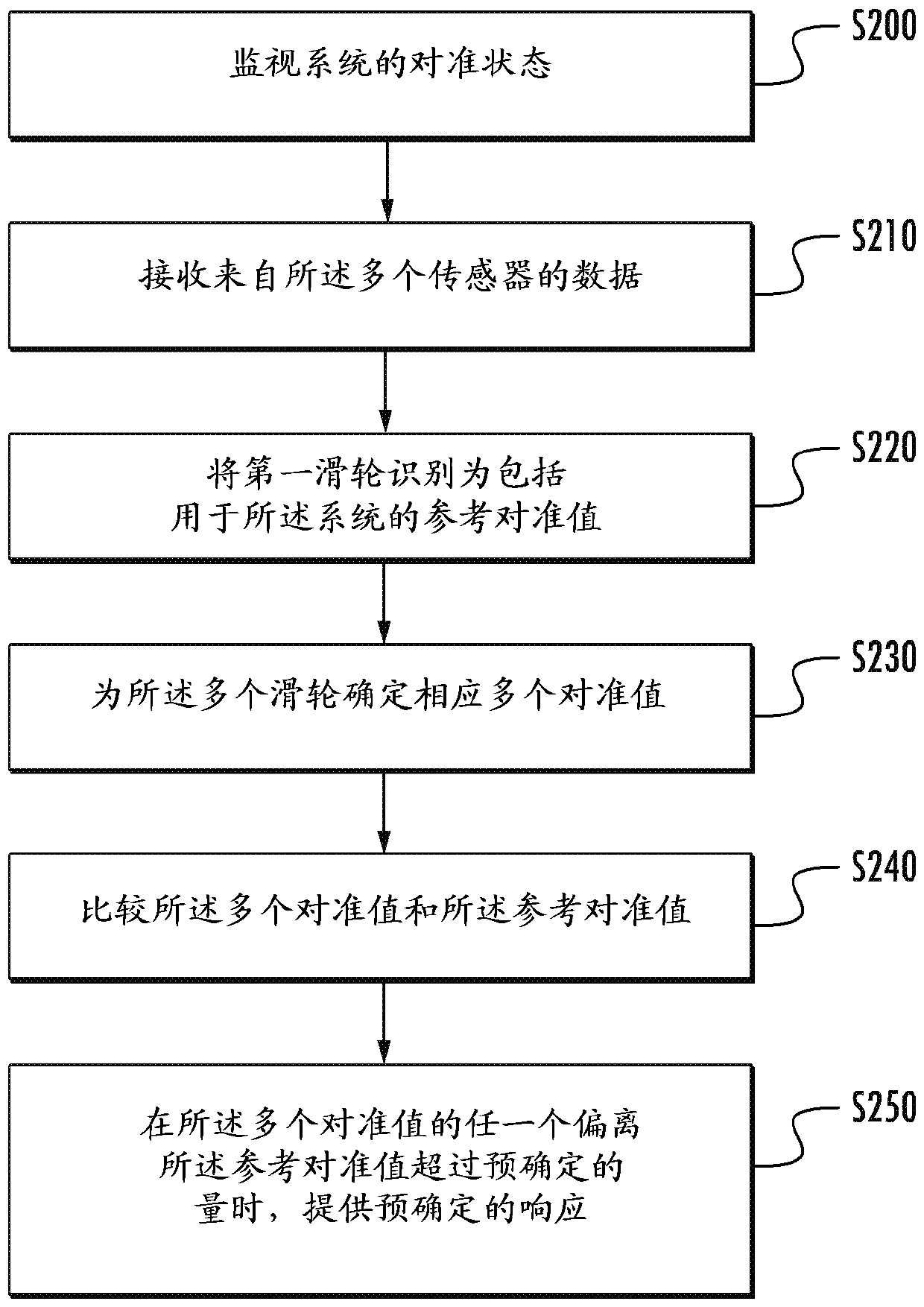

Escalator with a sensor for detecting sheave misalignment

Disclosed is an escalator system wherein when a handrail belt is moving from rotation of a plurality of elevator sheaves: a controller receives data from a plurality of sensors, identifies from the data a first sheave of the plurality of sheaves as comprising reference alignment value for the system, determines for the plurality of sheaves a respective plurality of alignment values, compares the plurality of alignment values with the reference alignment value, and provides a predetermined response when any of the plurality of alignment values diverges from the reference alignment value by morethan a predetermined amount.

Owner:OTIS ELEVATOR CO

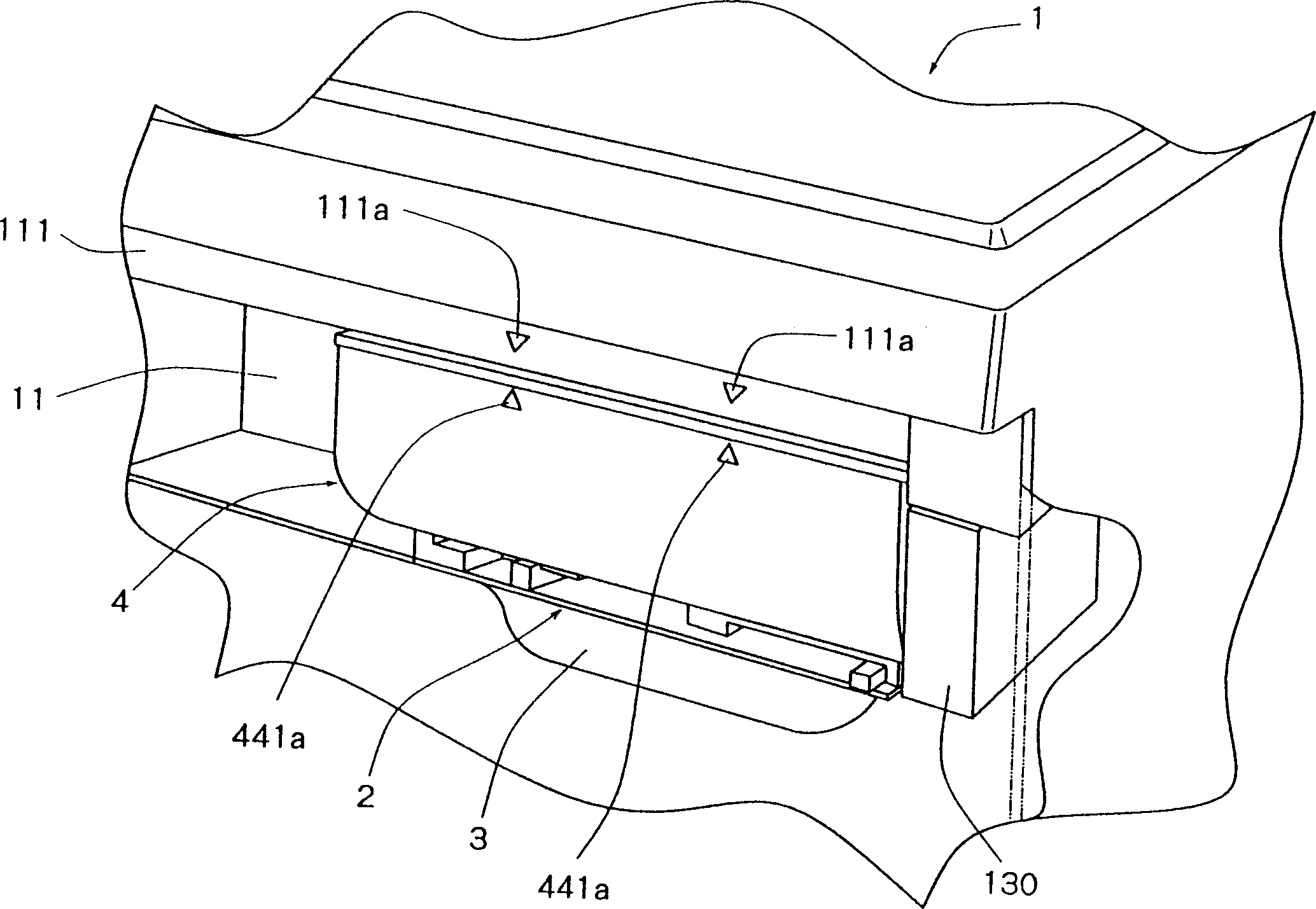

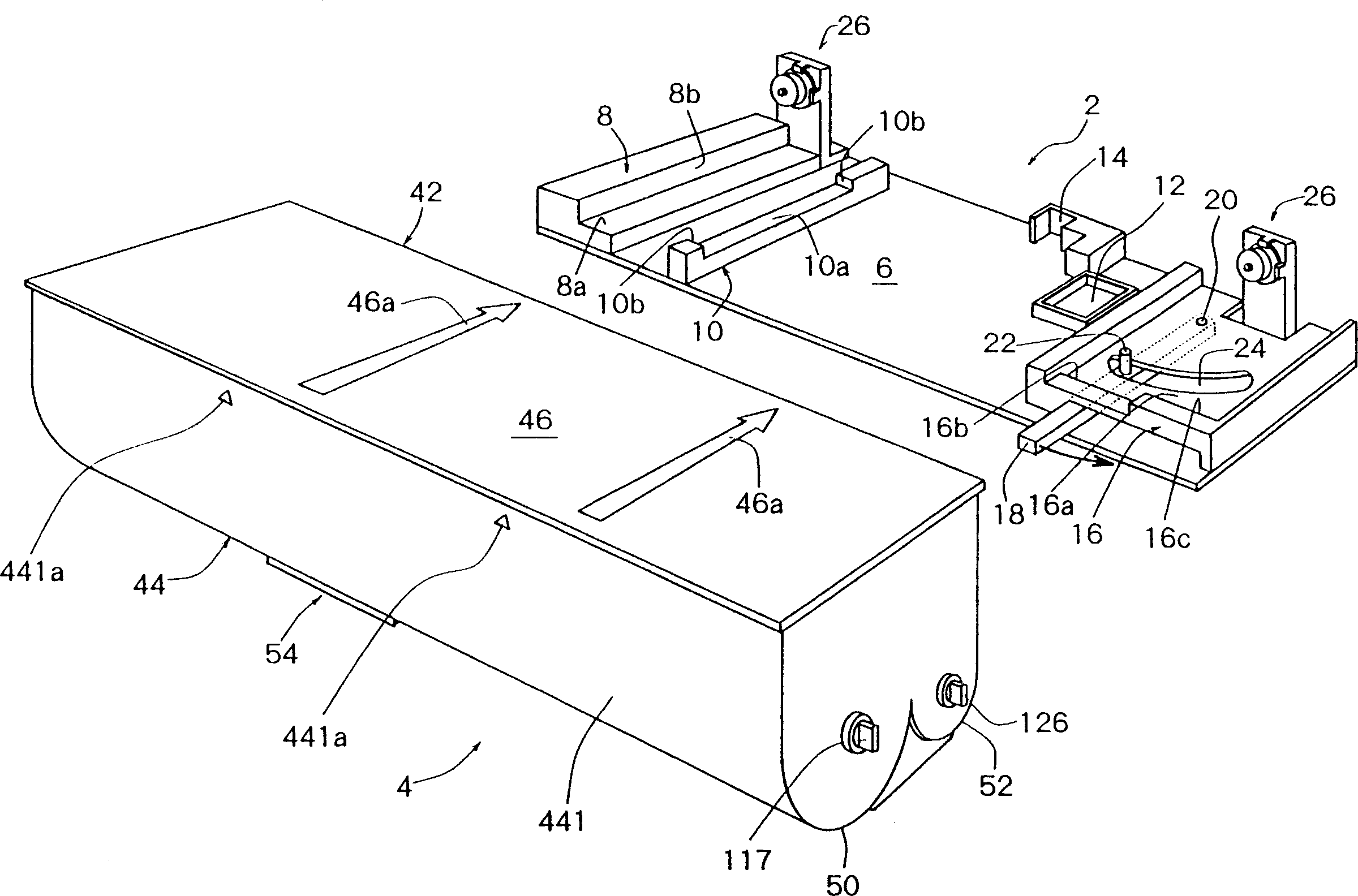

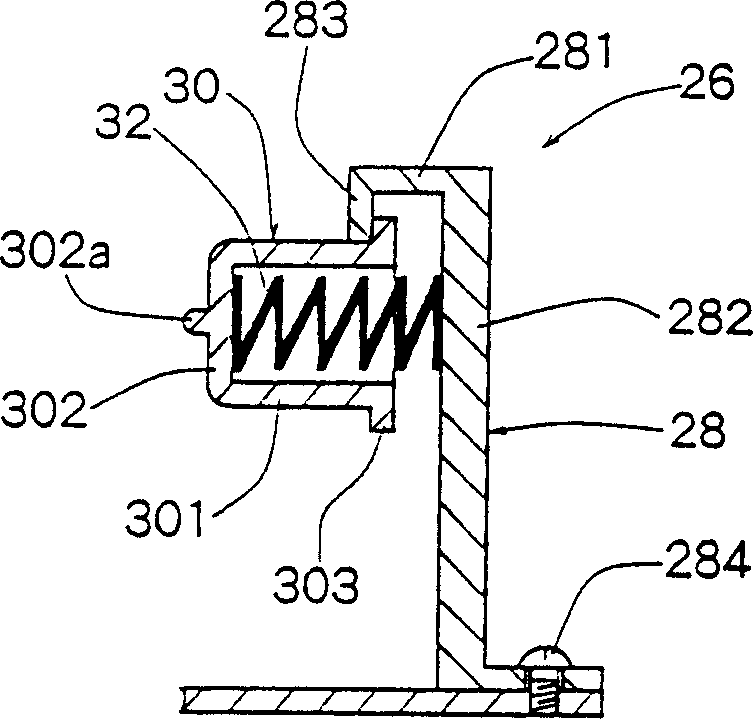

Colouring agent compensator of image forming machine and colouring agent box therefor

A toner replenishing device of an image forming machine, including a toner cartridge receiving member (2) disposed in a machine body and having a cartridge inserting position and a cartridge mounting position; and a toner cartridge (4) having a container body with a toner discharge opening (88) and mounted detachably on the toner cartridge receiving member; wherein a reference alignment mark (111a) is provided at a machine body wall portion positioned above the toner cartridge receiving member, a first alignment mark (46a) is provided in the container body of the toner cartridge at a position opposite the reference alignment mark at the cartridge inserting position, and a second alignment mark (441a) is provided in the container body of the toner cartridge at a position opposite the reference alignment mark (111a) at the cartridge mounting position.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

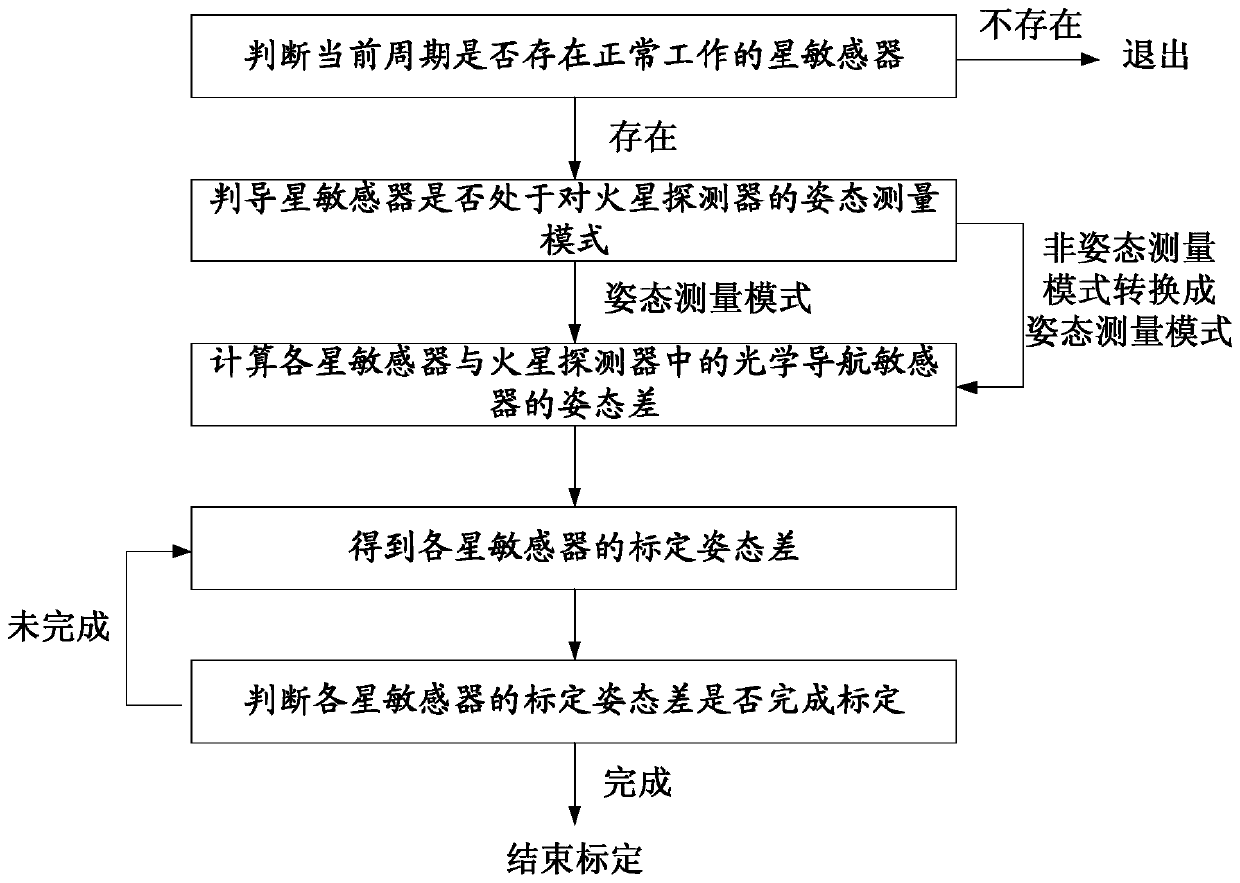

Inertial reference space-time accurate alignment method of optical navigation sensor

ActiveCN111220179AAvoiding the effects of autonomous optical navigationMeasurement devicesReference spaceEngineering

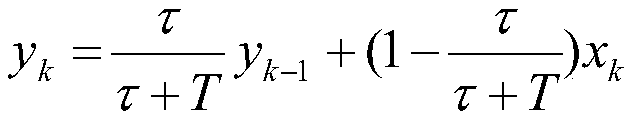

The invention relates to an inertial reference space-time accurate alignment method of an optical navigation sensor, and belongs to the technical field of Mars surround optical navigation sensor inertial reference alignment. The method comprises the following steps: step 1, when a normally working star sensor exists, entering step 2; otherwise, exiting the calibration process; 2, when the star sensor is in an attitude measurement mode, entering a step 3; otherwise, switching to an attitude measurement mode, and entering the step 3; step 3, calculating an attitude difference xk between each star sensor and the optical navigation sensor, wherein k is the serial number of the star sensor; 4, obtaining a calibration attitude difference yk of each star sensor by adopting a calibration algorithm; step 5, when the calibration attitude difference yk of the star sensor completes calibration, ending the attitude difference calibration work of the star sensor and the optical navigation sensor; otherwise, continuing to perform attitude difference calibration on the star sensor. According to the invention, error sources such as installation measurement errors and thermal deformation errors areavoided, and the in-orbit alignment precision of the optical navigation sensor is improved.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

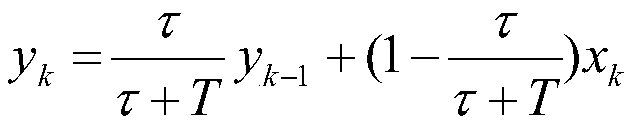

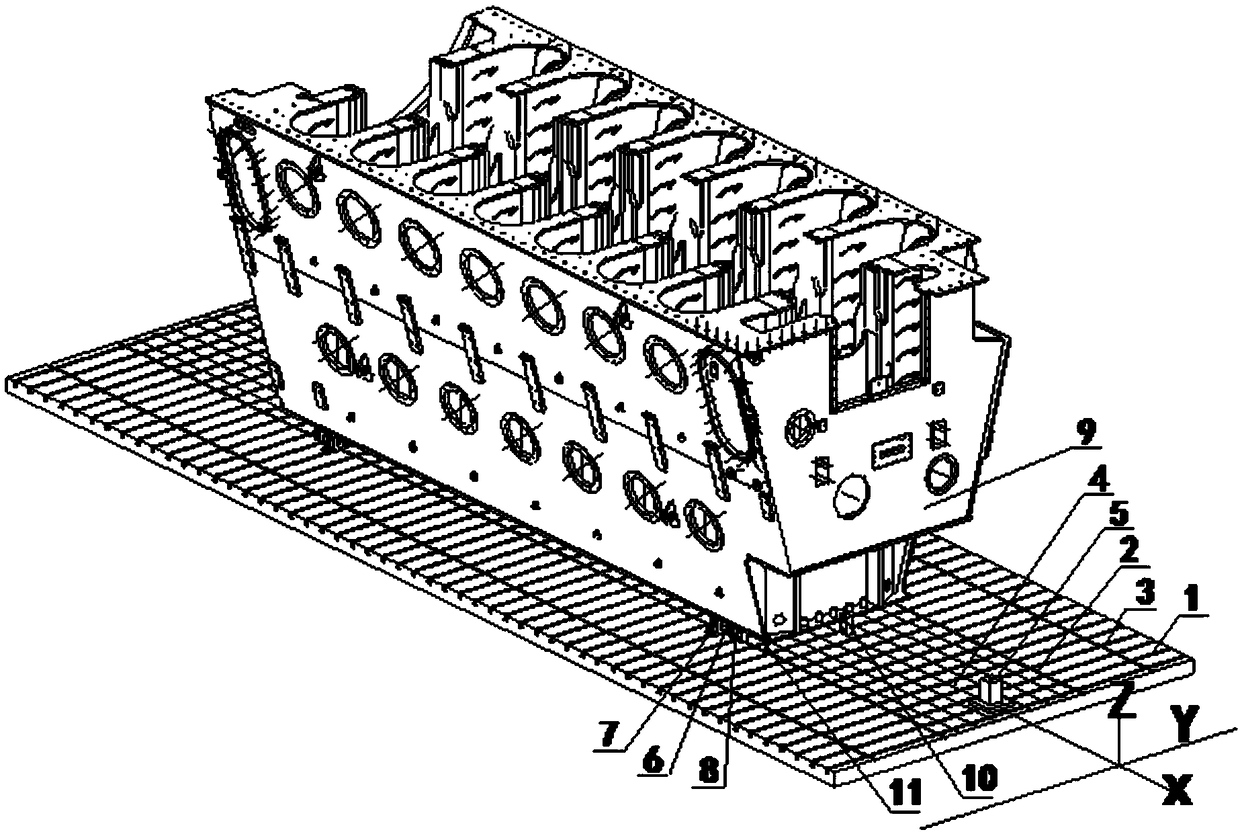

Rapid getting-on correcting method of large-scale diesel engine rack on gantry milling machine

ActiveCN108748064AReduce turning timesReduce labor intensityAutomatic control devicesFeeding apparatusNumerical controlKeel

The invention provides a rapid getting-on correcting method of a large-scale diesel engine rack on a gantry milling machine. The rapid getting-on correcting method comprises that wherein X, Y and Z coordinate processing lines, a waist line, a workpiece center line and a workpiece zero position reference line are marked by adopting a laser reference scribing method, and further, a keel milling table top mark, a positioning and positioning groove, a positioning and supporting stop block, a positioning key, a reference alignment tool block, an adjusting cushion block, a correcting block, a reference measuring block and a machine frame laser scribing technical measure are further adopted on numerical control keel milling, so that the machine frame is guaranteed to be rapidly corrected, and coordinate setting is completed. The method has the advantages of being easy to operate, safe, efficient and convenient to adjust, and has the beneficial effects of reducing the machine frame getting-oncorrecting time and reducing the labor intensity of workers, and the rapid getting-on correcting method is particularly suitable for on-line correction, positioning and coordinate setting of large-scale diesel engine racks and similar large-scale parts on the numerical control keel milling.

Owner:CSSC MES DIESEL

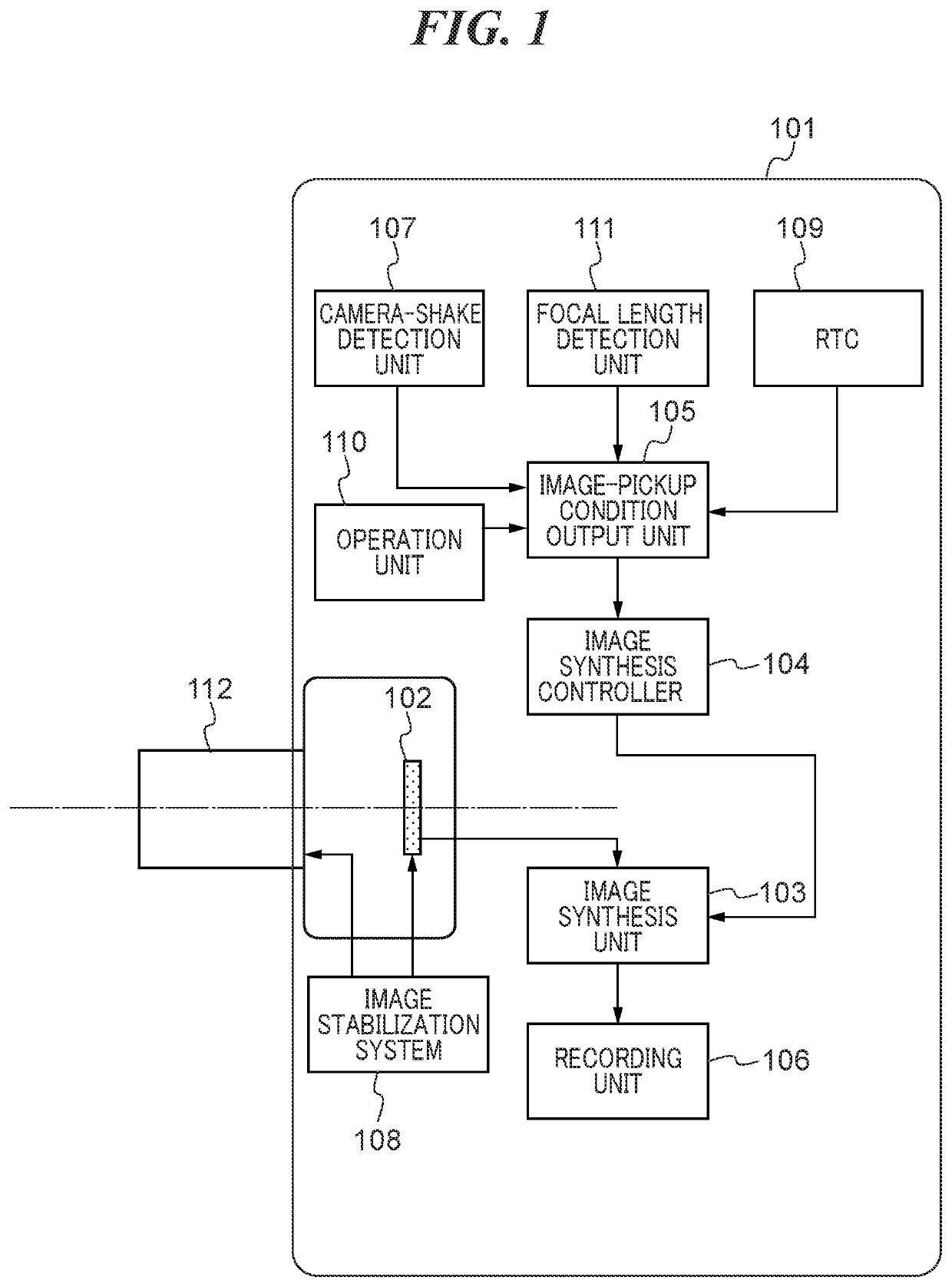

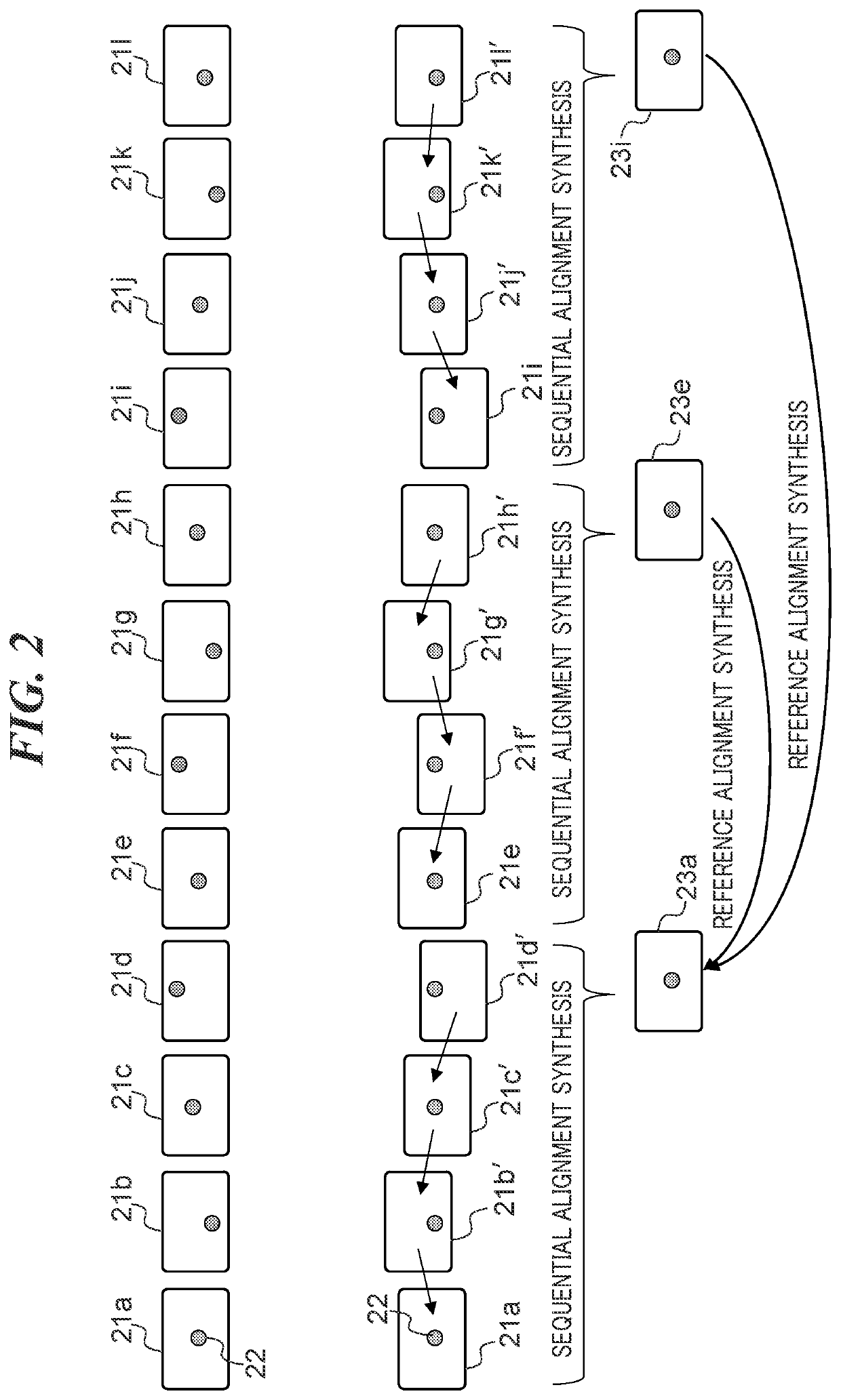

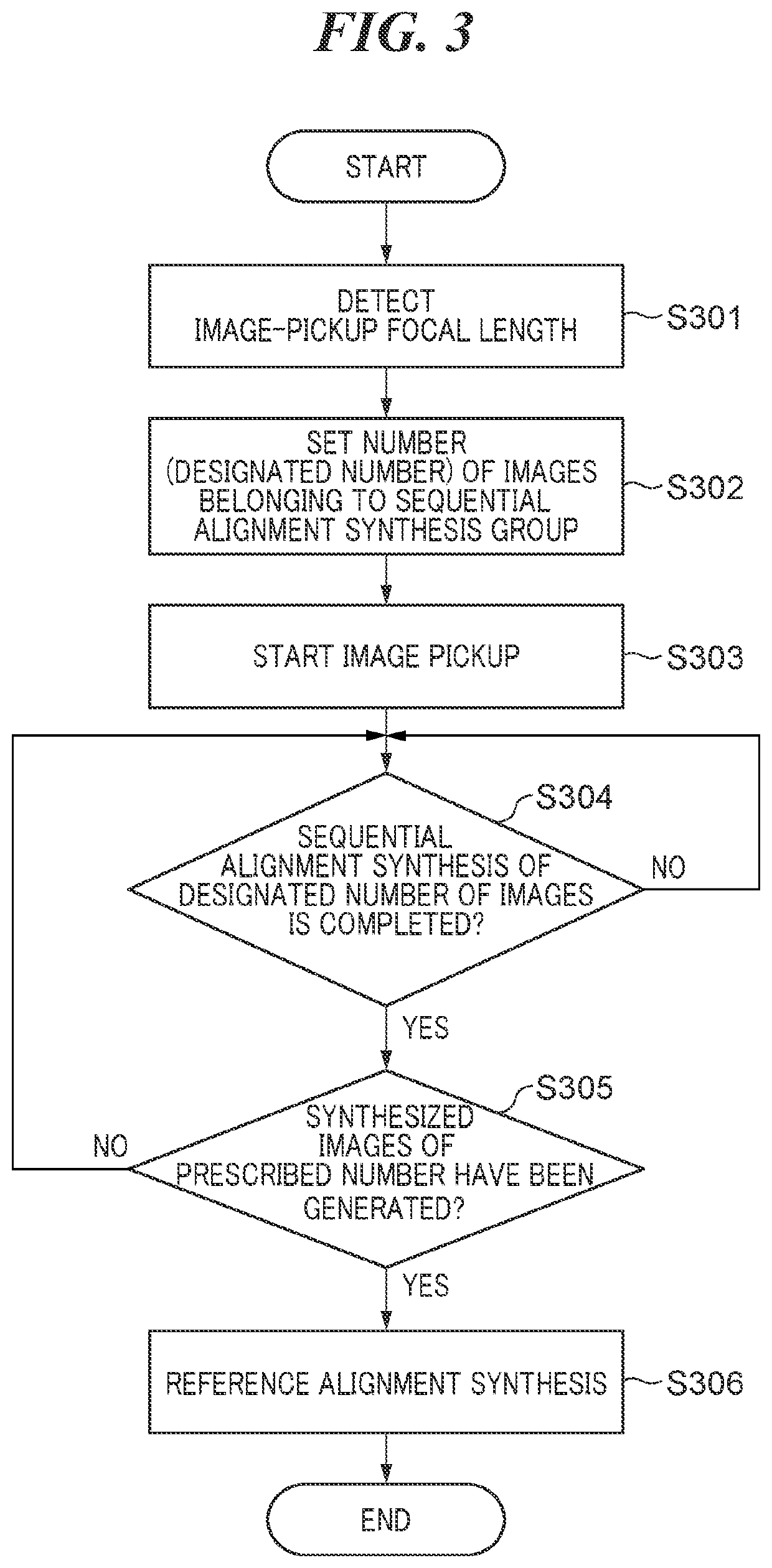

Image processing apparatus that aligns images, image pickup apparatus including image processing apparatus, and control method for image processing apparatus

PendingUS20220076390A1Reduce alignmentTelevision system detailsImage enhancementImaging processingRadiology

An image processing apparatus that can obtain a high-definition image by reducing an alignment mistake of a plurality of images. The image processing apparatus includes an alignment unit that performs sequential alignment that aligns adjacent images and reference alignment that aligns images other than a reference image to the reference image, and a control unit that controls the alignment unit to align a plurality of images that include a same object and are continuously picked up by an image pickup unit in time series by combining the sequential alignment and the reference alignment.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com