Enhanced edge detection tool for edges of irregular surfaces

A tool and edge technology, applied in the field of enhanced edge detection tools, can solve problems such as difficulty in determining precise contours and/or positions, reduction of contour accuracy and resolution on edges, and edge contour distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

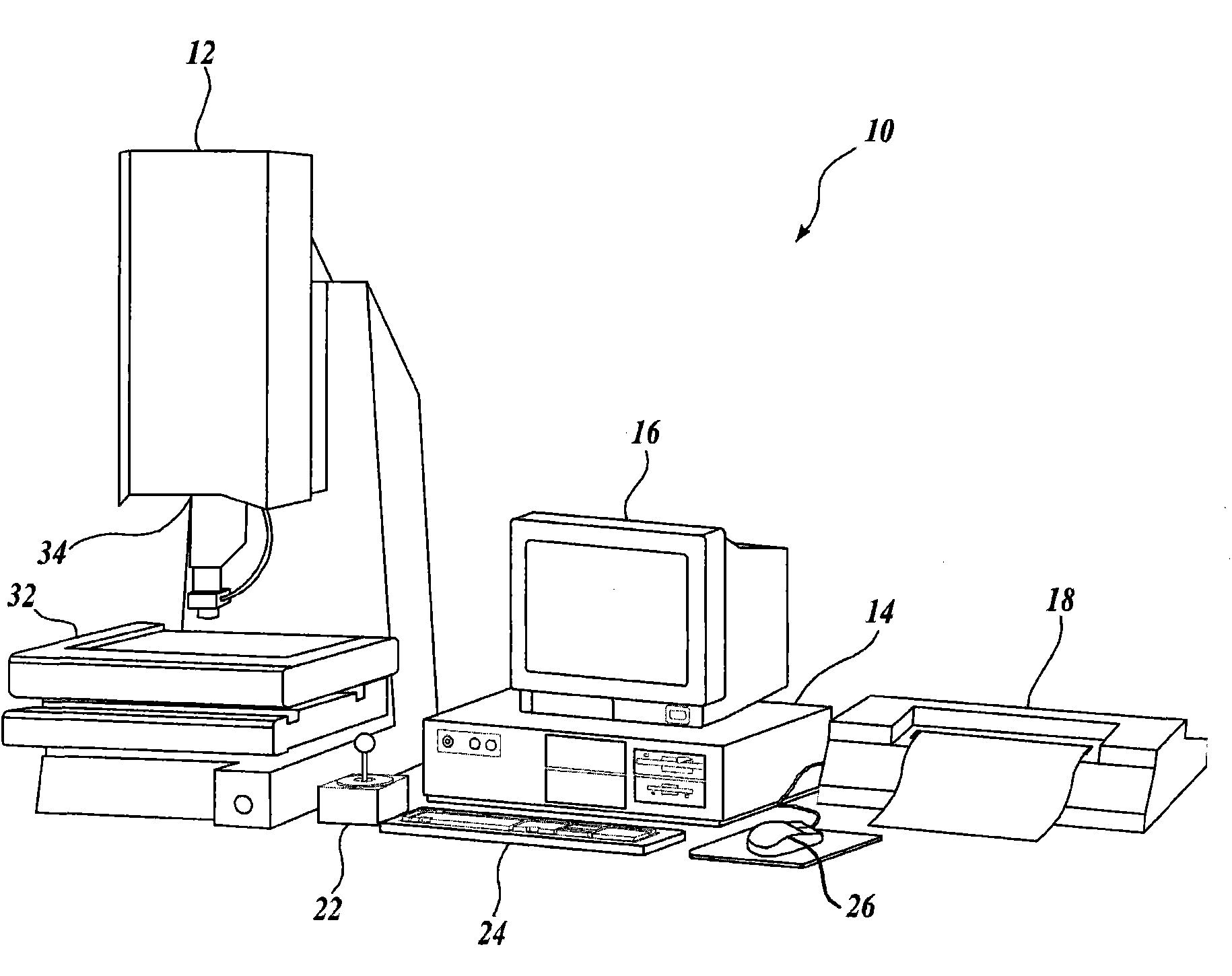

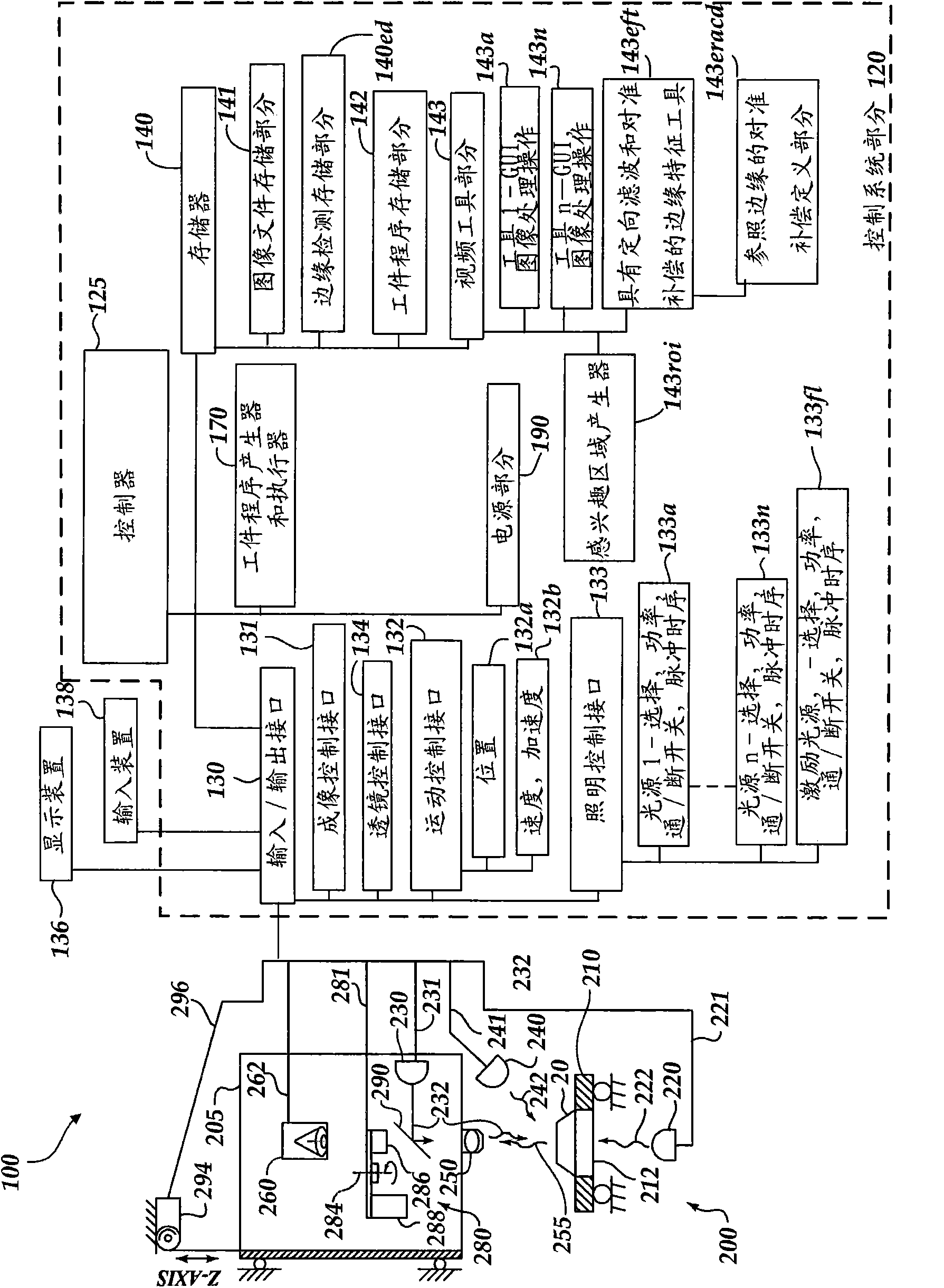

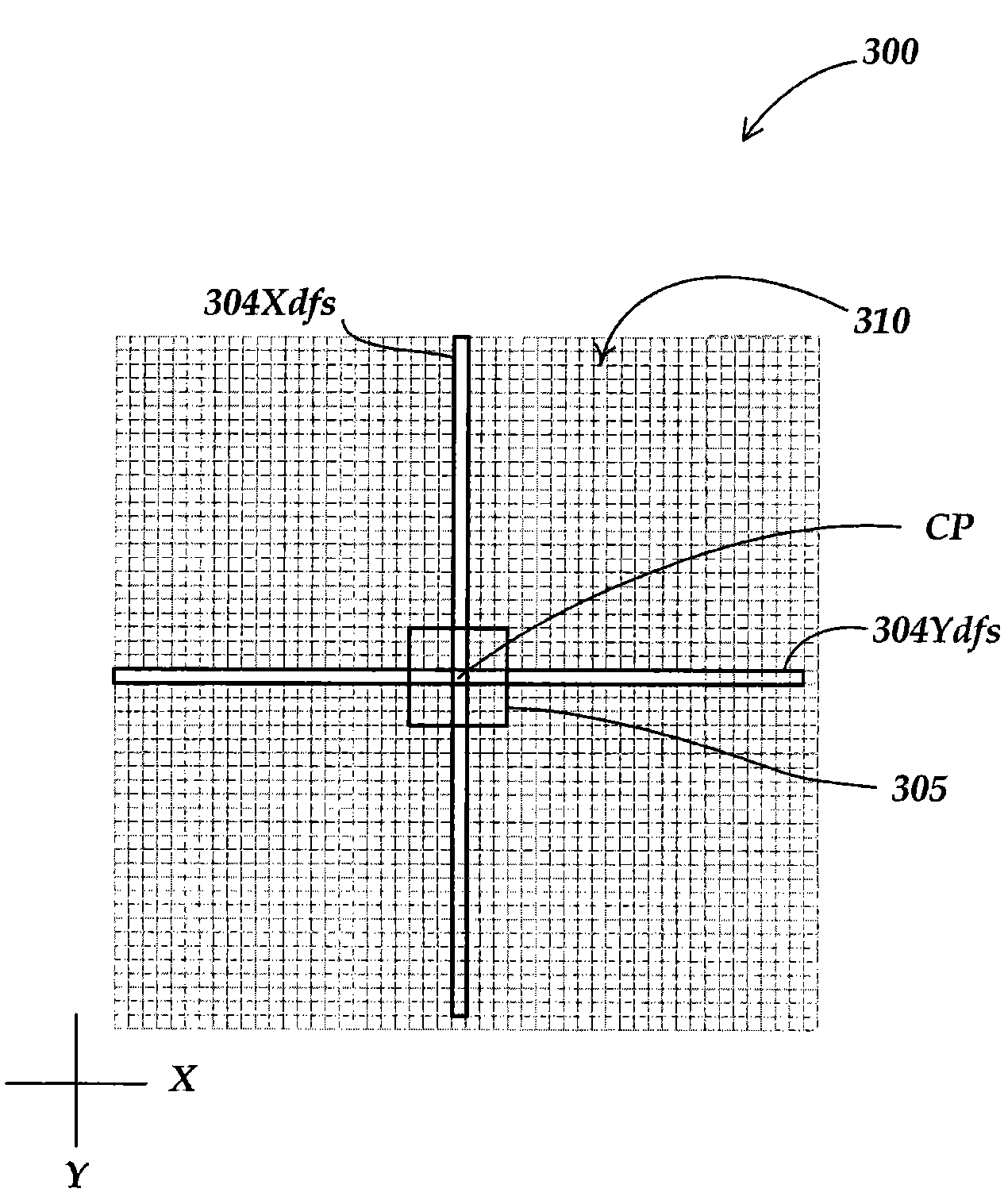

[0045] A method for enhanced edge detection of edges of irregular surfaces in a machine vision inspection system is disclosed herein. The machine vision inspection system may include an edge feature video tool comprising a region of interest defining portion, wherein the edge feature video tool is configured to determine profile data of edge features in the region of interest based on a plurality of differently focused images of the region of interest . The method includes positioning a workpiece within a field of view of a machine vision inspection system, manipulating an edge-featured video tool, and defining a video tool region of interest that includes edge features in an acquired image of the workpiece. manipulating the edge feature video tool to analyze the image data of at least one image of the workpiece in the region of interest to provide alignment compensation with reference to the edge substantially minimizing the offset of the edge feature at various locations alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com