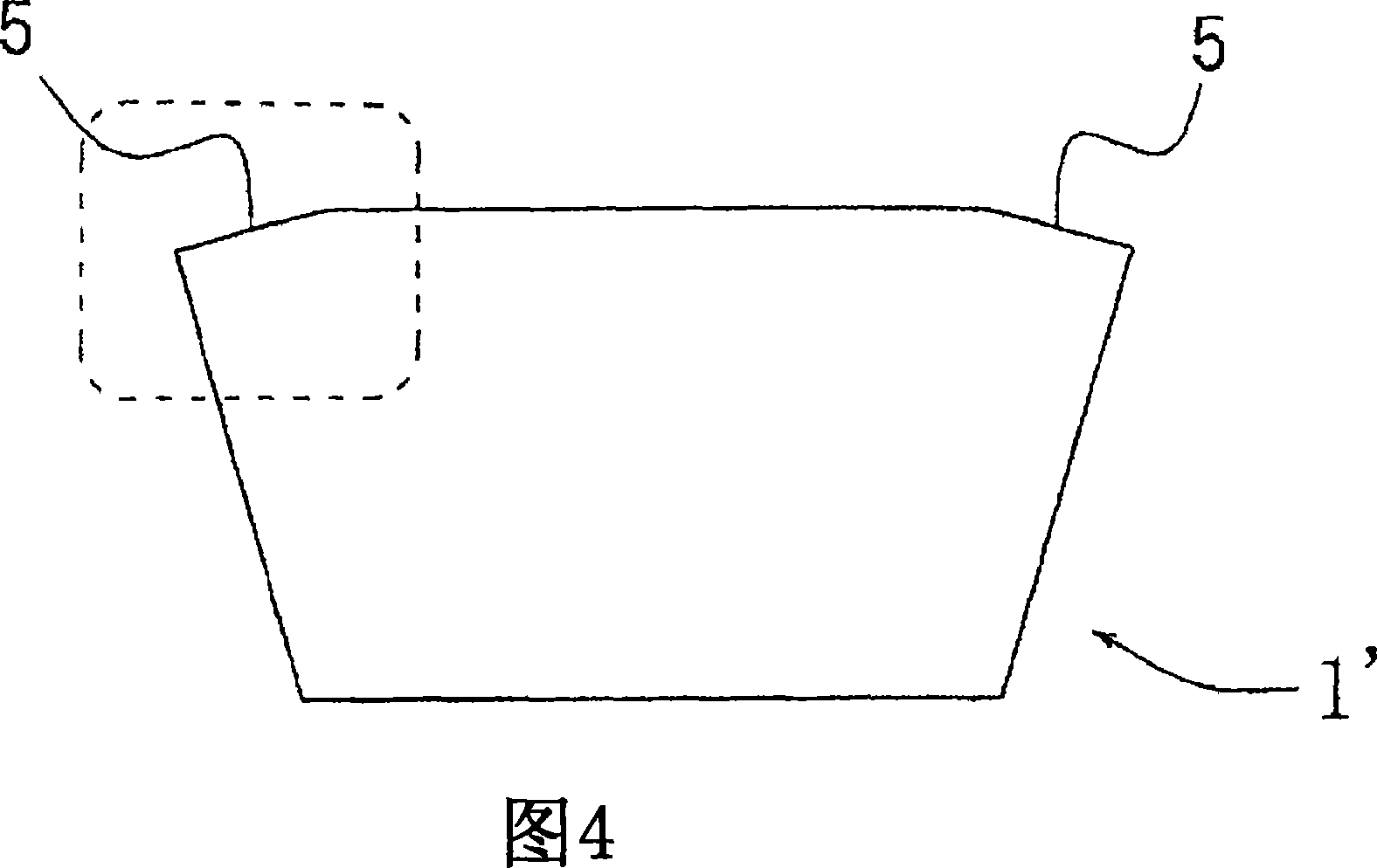

Sialon ceramic blade and cutting tool equipped therewith

A saran and ceramic technology, applied in the direction of cutting blades, manufacturing tools, accessories of toolholders, etc., can solve the problems of reduced strength, reduced strength, and difficulty in balancing the performance of blade materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] A preferred method of preparing the saran ceramic blade according to the first invention will be described in detail below. A powder containing the constituent elements of saran ceramics, such as Si 3 N 4 Powder, Al 2 o 3 powder and AlN powder with sintering aid, specifically a powder of a rare earth element oxide, such as SC 2 o 3 Powder, Y2O 3 Powder, CeO 2 Powder, Dy 2 o 3 Powder, Er 2 o 3 Powder, Yb 2 o 3 Powder and Lu 2 o 3 The powders are mixed to prepare powdery raw materials. The powdery raw material includes particles having an average particle diameter of 10 μm or less, preferably 5 μm or less, more preferably 3 μm or less. The content of each component of the powdery raw material is determined by the composition of the blade after sintering. Typically, the powdered feedstock contains 95 to 50 mol% Si 3 N 4 Powder, 0.5 to 20 mol% Al 2 o 3 powder, 0 to 40 mol% AlN powder, and 0.5 to 5 mol% sintering aid. The prepared powdery raw material is...

Embodiment 1-23 and comparative example 1-7

[0138] (1) Preparation of blades

[0139] In the quantities shown in Table 2, by mixing α-Si with an average particle size of 0.5 μm 3 N 4 Powder; selected from Sc with an average particle size of 1.0 μm 2 o 3 Powder, Y with an average particle size of 1.1 μm 2 o 3 Powder, CeO with an average particle size of 1.7 μm 2 Powder, Dy with an average particle size of 0.9 μm 2 O3 powder, Er with an average particle size of 1.0 μm 2 o 3 Powder, Yb with an average particle size of 1.1 μm 2 o 3 powder, and Lu with an average particle size of 1.0 μm 2 o 3 A sintering aid composed of powder; and further A1 having an average particle size of 0.4 μm 2 o 3 powder, AlN powder with an average particle size of 1.3 μm, TiN powder with an average particle size of 1.5 μm, TiC powder with an average particle size of 1.0 μm, and TiCN with an average particle size of 1.0 μm to prepare powdery raw material powders. Then, each powdery raw material was pressed into the blade-shaped grinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com