Diamond multi-wire electric spark discharge cutting method and diamond multi-wire electric spark discharge cutting wire cutting device

A cutting device and spark discharge technology, which is applied in the field of diamond cutting, can solve the problems of micro-cracks on the surface of semiconductor silicon wafer processing, difficulty in improving the processing technology level, and single function, so as to improve processing quality and material surface performance, and increase material removal rate , the effect of reducing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

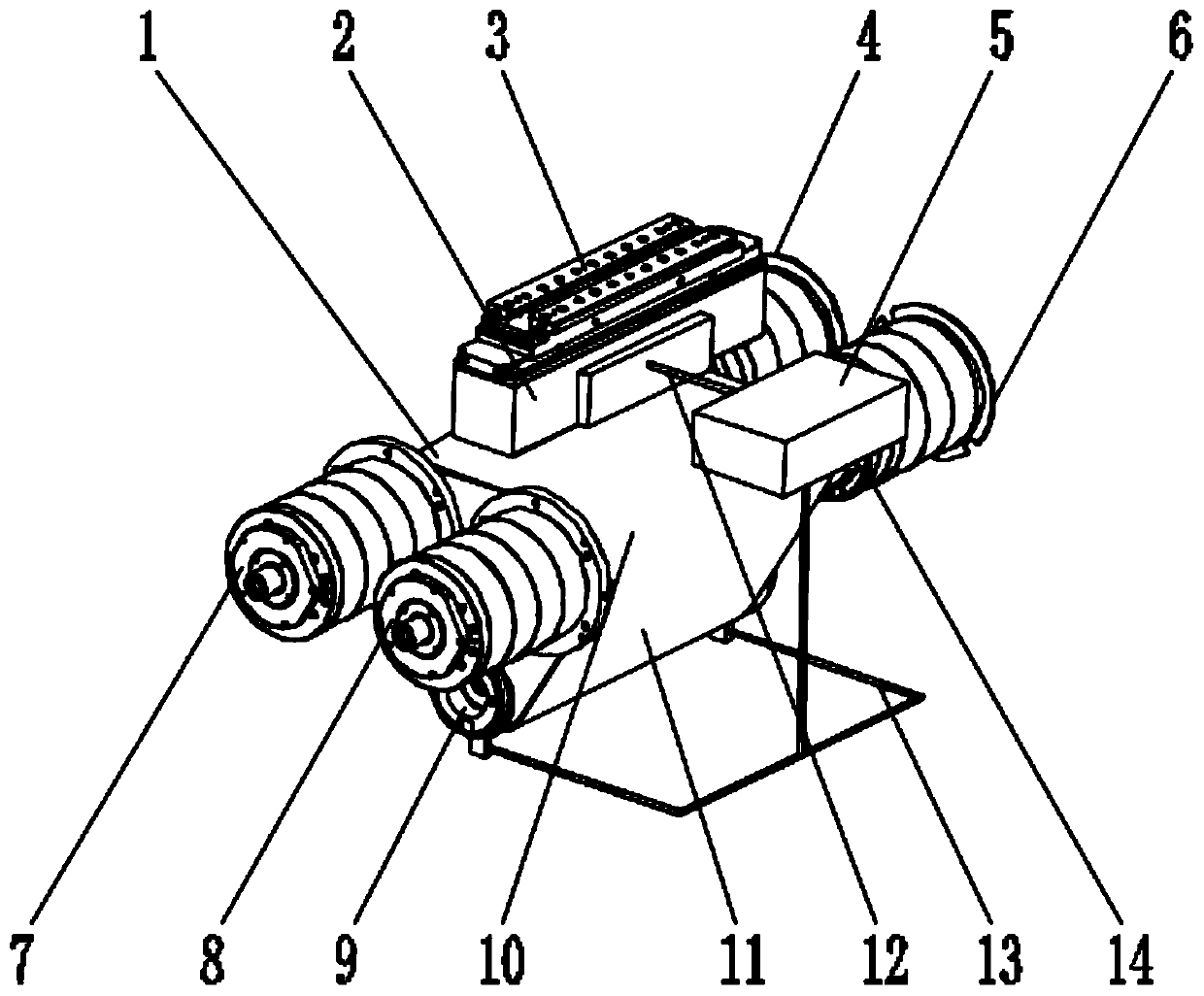

[0033] The invention proposes a diamond multi-wire cutting composite electric discharge wire cutting process method. The principle of diamond wire EDM multi-wire cutting is as follows: figure 1As shown, the middle side of the main body 14 of the cutting device is provided with a No. 1 cutting roller 1, a side of the No. 1 cutting roller 1 is provided with a No. 2 cutting roller 10, and the front end of the No. 1 cutting roller 1 is provided with a No. 1 driving spindle 7. The front end of No. 2 cutting roller 10 is provided with No. 2 driving main shaft 8, the rear end outer surface of No. 1 cutting roller 1 is provided with No. 1 driven main shaft 4, and the rear end outer surface of No. 2 cutting roller 10 is provided with No. 2 driven main shaft. 6. The outer surface of the upper middle part of the main body 14 of the cutting device is provided with a P-type silicon rod 2. On the basis of the diamond wire multi-wire cutting machine, the silicon material and the diamond wire...

Embodiment 2

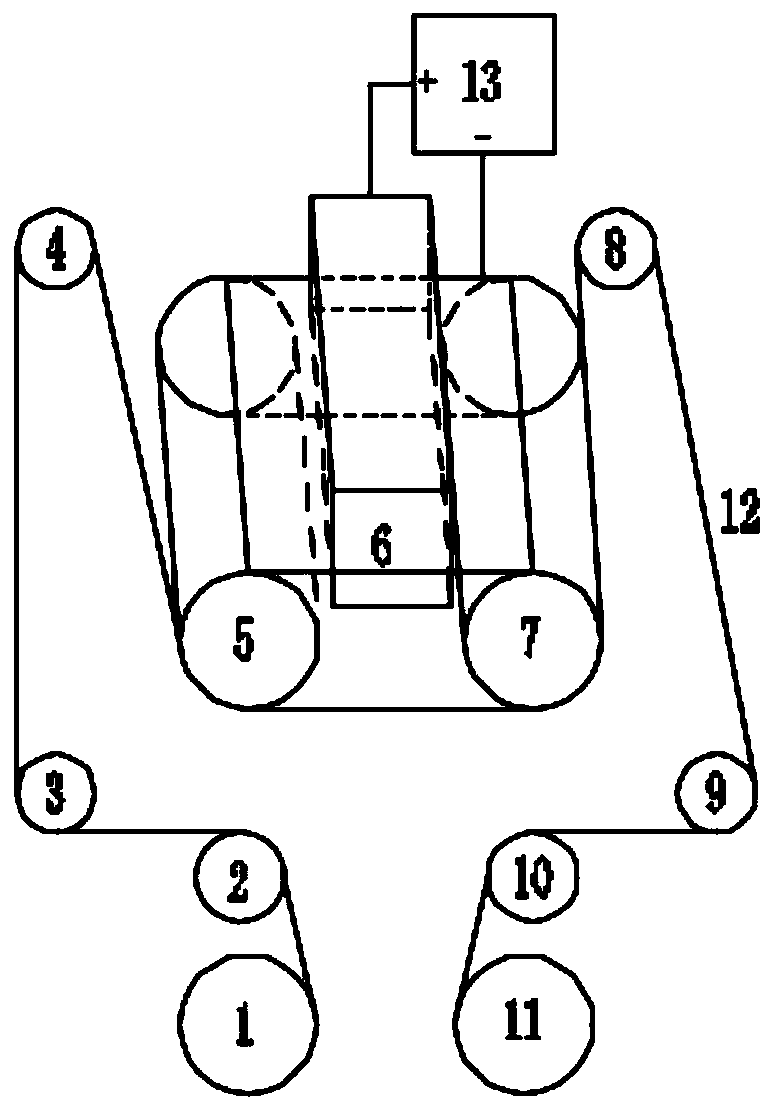

[0035] Such as image 3 As shown, the diamond wire is initially wound on the take-up and take-up wheel, then wound to the two processing rollers through the wire arranging wheel, the tension wheel and the guide wheel, and finally wound to the take-up and unwinding On the wire wheel, the diamond wire reciprocates, and the cutting wire network formed between the processing roller and the processing roller cuts the silicon material into silicon wafers by grinding.

Embodiment 3

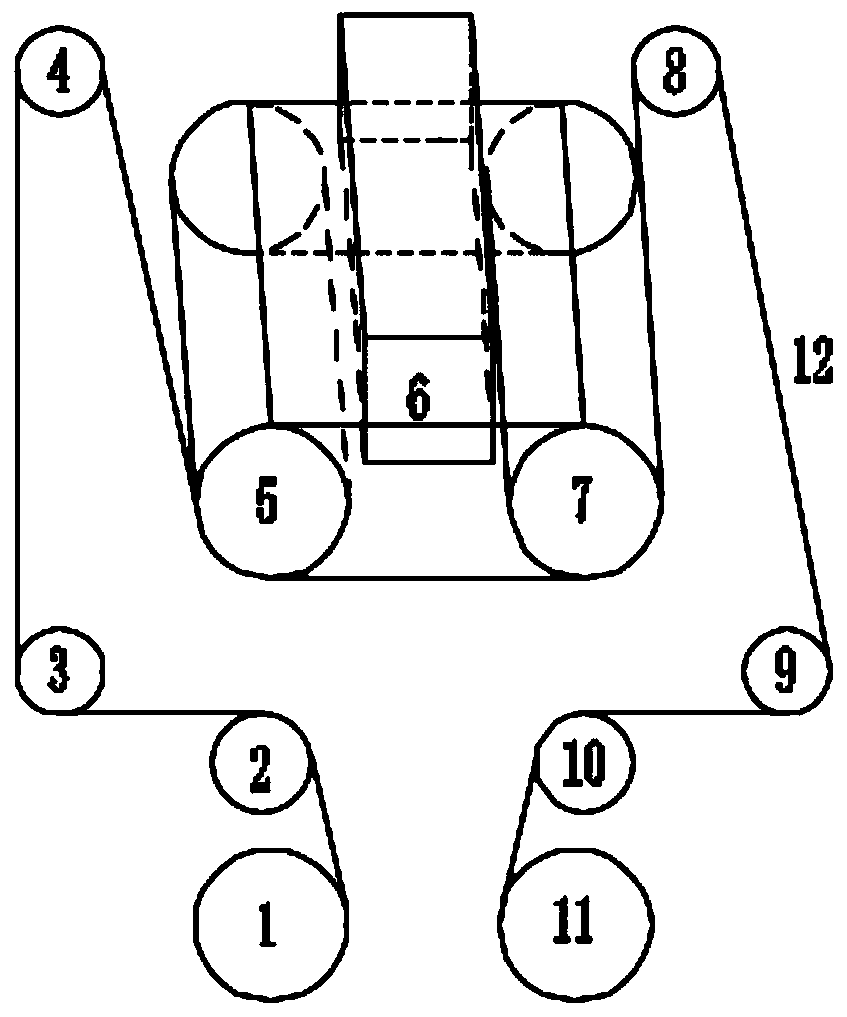

[0037] Such as Figure 4 As shown, the instantaneous high temperature generated by the pulsed spark discharge between the reciprocating molybdenum wire or the single-wire moving copper wire and the workpiece is used to realize the brittle cracking and erosion of the silicon material caused by local gas flow, melting or thermal stress to achieve the purpose of processing. The electrode wire starts from the wire drum and winds back to the wire drum through the guide wheel, guide wheel and guide wheel. The negative electrode of the pulse power supply is connected to the electrode wire, and the positive electrode of the pulse power supply is connected to the silicon material. The electrode wire moves in one direction (copper wire) or reciprocating (molybdenum wire). The silicon material cutting is realized by using the electric discharge between the electrode wire and the silicon material.

[0038] The present invention is a combination of diamond multi-wire cutting and electric d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com