Halogen-free flame-retardant high-toughness bulk molding compound and method for preparing same

A flame-retardant, high-toughness technology, used in the formulation and preparation of halogen-free flame-retardant high-toughness bulk molding compounds, can solve problems such as toxicity, corrosiveness, environmental safety hazards, etc., achieve good flame retardant performance, avoid The effect of surface micro-cracks and small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

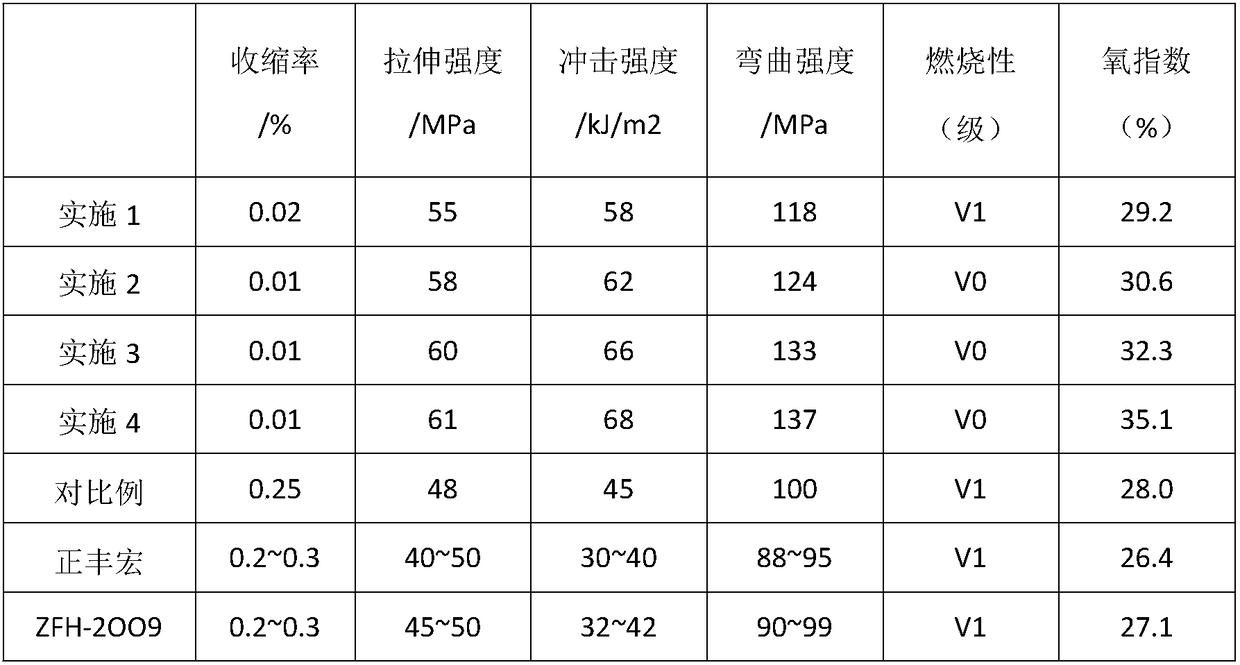

Examples

Embodiment 1

[0033] A halogen-free flame-retardant high-toughness bulk molding compound, which consists of: 26 parts of unsaturated polyester-polyurethane composite resin, 1 part of curing agent, 29 parts of inorganic flame-retardant filler, and 10 parts of organic flame-retardant 16 parts of modified heavy calcium carbonate, 1 part of release agent, 14 parts of reinforcing fiber, 1 part of auxiliary agent and 2 parts of toner;

[0034] The preparation steps are:

[0035] (1) First add the unsaturated polyester-polyurethane composite resin, curing agent, release agent, and additives into a high-shear mixer and mix at high speed for 12-20 minutes. After stirring evenly, slowly add the modified inorganic resist Combustible filler, organic flame retardant, modified ground calcium carbonate and toner are mixed and stirred for 8-10 minutes, and after vacuum defoaming for 30 minutes, the materials are discharged to obtain resin premixed slurry.

[0036] (2) Add the premixed slurry in the above ...

Embodiment 2

[0049] A halogen-free flame-retardant high-toughness bulk molding compound, which consists of: 27 parts of unsaturated polyester-polyurethane composite resin, 1 part of curing agent, 27 parts of inorganic flame-retardant filler, 12 parts of organic flame retardant, 14 parts of modified ground calcium carbonate, 1 part of release agent, 15 parts of reinforcing fiber, 1 part of auxiliary agent and 2 parts of toner.

[0050] The preparation steps are:

[0051] (1) First add the unsaturated polyester-polyurethane composite resin, curing agent, release agent, and additives into a high-shear mixer and mix at high speed for 12-20 minutes. After stirring evenly, slowly add the modified inorganic resist Combustible filler, organic flame retardant, modified ground calcium carbonate and toner are mixed and stirred for 8-10 minutes, and after vacuum defoaming for 30 minutes, the materials are discharged to obtain resin premixed slurry.

[0052] (2) Add the premixed slurry in the above st...

Embodiment 3

[0065] A halogen-free flame-retardant high-toughness bulk molding compound, which consists of: 27 parts of unsaturated polyester-polyurethane composite resin, 1 part of curing agent, 26 parts of inorganic flame-retardant filler, 13 parts of organic flame retardant, 13 parts of modified ground calcium carbonate, 1 part of release agent, 16 parts of reinforcing fiber, 1 part of auxiliary agent and 2 parts of toner.

[0066] (1) First add the unsaturated polyester-polyurethane composite resin, curing agent, release agent, and additives into a high-shear mixer and mix at high speed for 12-20 minutes. After stirring evenly, slowly add the modified inorganic resist Combustible filler, organic flame retardant, modified ground calcium carbonate and toner are mixed and stirred for 8-10 minutes, and after vacuum defoaming for 30 minutes, the materials are discharged to obtain resin premixed slurry.

[0067] (2) Add the premixed slurry in the above step (1) into a biaxial kneader, then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com