A method for controlling surface cracks of welding wire steel continuous casting slab

A surface crack and welding wire steel technology, which is applied in the field of iron and steel metallurgy, can solve problems such as micro-cracks, and achieve the effects of avoiding surface micro-cracks, reducing the amount of grinding, and optimizing the amount of cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

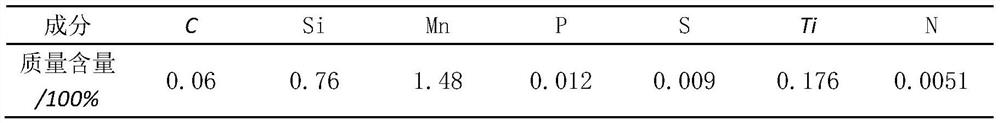

[0032] Taking AER70S-G high-titanium welding wire steel as an example, the present invention takes the following measures to realize the control of cracks on the surface of continuous casting slabs of high-titanium welding wire steel. In this embodiment, a high-titanium welding wire steel, its constituent elements and their element quality The percentage content is shown in Table 1 below. This embodiment contains C, Si, Mn, P, S, Ti and N, and the balance is iron and unavoidable impurities.

[0033] Table 1. Main chemical composition control of high titanium welding wire steel in embodiment 1

[0034]

[0035]A method for controlling surface cracks of welding wire steel continuous casting slabs, comprising the following steps:

[0036] 1. Process route: hot metal pretreatment → converter smelting → furnace refining (LF) → billet continuous casting (electromagnetic stirring) → inspection → large-scale factory.

[0037] 2. Pretreatment of molten iron: S selection of 0.0289% ...

Embodiment 2

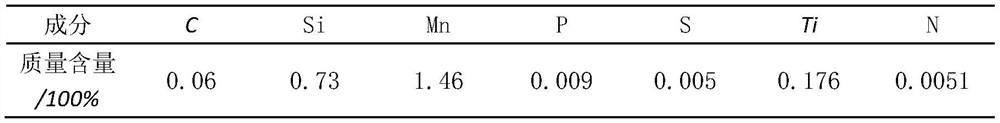

[0049] This embodiment is basically the same as the previous embodiment, and the special feature is that refining and adding wollastonite to control the sulfur in the molten steel. The present invention takes the following measures to realize the control of surface cracks of the high-titanium welding wire steel continuous casting slab,

[0050] In this embodiment, a high-titanium welding wire steel, its constituent elements and their element mass percentage content are shown in Table 1 below. This embodiment contains C, Si, Mn, P, S, Ti and N, and the balance is iron and unavoidable impurities.

[0051] Table 2. Control of Main Chemical Composition of High Titanium Welding Wire Steel in Example 2

[0052]

[0053] A method for controlling surface cracks of welding wire steel continuous casting slabs, comprising the following steps:

[0054] 1. Process route: hot metal pretreatment → converter smelting → furnace refining (LF) → billet continuous casting (electromagnetic sti...

Embodiment 3

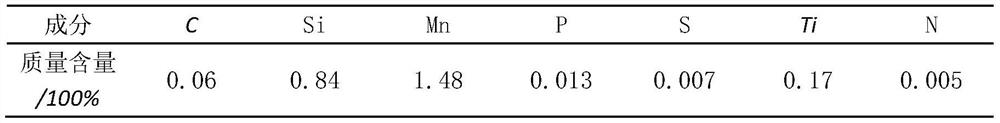

[0067] This embodiment is basically the same as the previous embodiment. The special feature is that the converter is smelted by double slag method, which not only ensures the carbon content, but also avoids high nitrogen in molten steel caused by long-term point blowing. The present invention adopts the following measures to achieve high control. Titanium welding wire steel continuous casting slab surface cracks,

[0068] In this embodiment, a high-titanium welding wire steel, its constituent elements and their element mass percentage content are shown in Table 1 below. This embodiment contains C, Si, Mn, P, S, Ti and N, and the balance is iron and unavoidable impurities.

[0069] Table 3. Control of Main Chemical Composition of High Titanium Welding Wire Steel in Example 3

[0070]

[0071] A method for controlling surface cracks of welding wire steel continuous casting slabs, comprising the following steps:

[0072] 1. Process route: hot metal pretreatment → converter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com