Casting process for high-manganese steel track plates

A casting process and track shoe technology, which is applied in the field of armored vehicle track shoe processing, can solve the problems that affect the service life of the track shoe, the normal driving of vehicles, the high crack rate, and the impact on tactical performance, so as to improve the quality level and achieve good economic benefits , The effect of improving the reliability of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

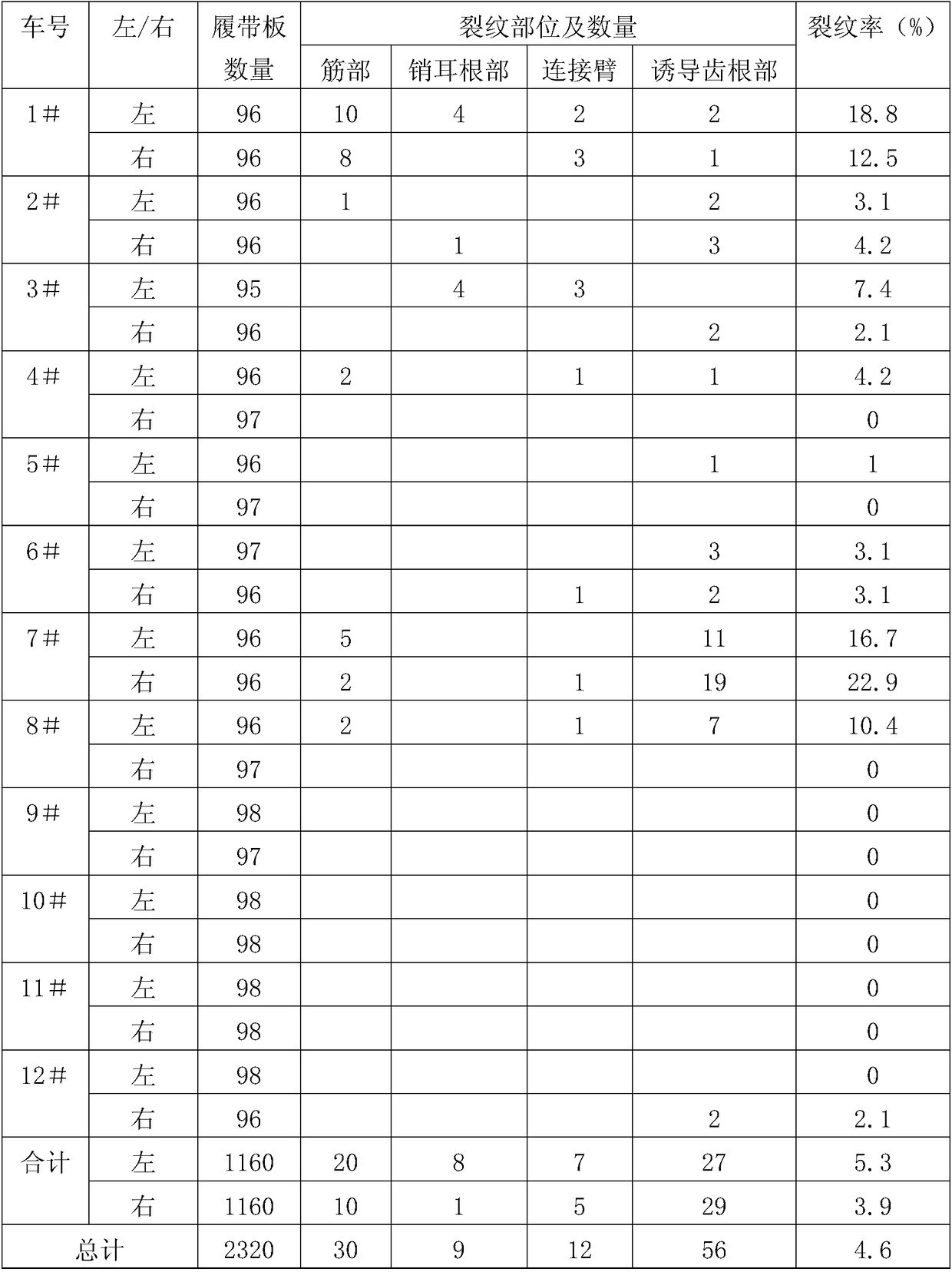

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The concrete steps of the casting process of a kind of high manganese steel crawler shoe of the present invention are as follows:

[0027] The first step is to determine the manufacturing mold.

[0028] The mold meets the following requirements,

[0029] (1) The connecting arm of the track shoe is flattened at the ground bar connected to it, which strengthens the strength of the connecting arm;

[0030] (2) The thickness of the pin lug reinforcing rib connecting the track shoe connecting arm to the inner side of the plate body is 10mm to 11mm, which strengthens the strength and reliability here;

[0031] (3) The landing surface of the connecting arm of the track shoe is raised by 2 mm upwards, thereby reducing the probability that the connecting arm directly touches the ground and bears the alternating load instantaneously;

[0032] (4) The track shoe connecting arm is inclined upwards from 1 / 3 length by 7mm to 8mm, so that the force distribution at 1 / 3 length is more...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com