Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178results about How to "Reduced hot cracking tendency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and making method thereof

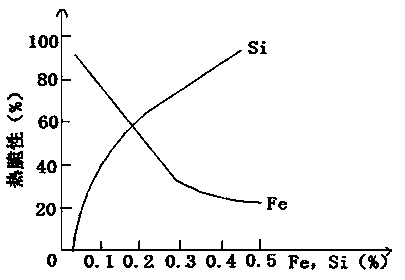

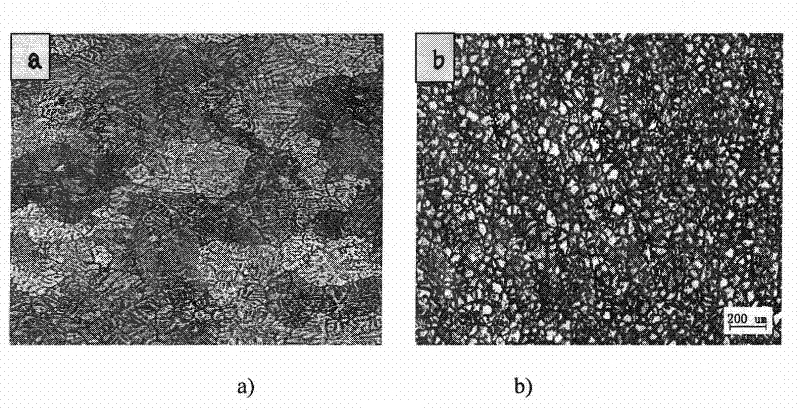

The invention discloses an ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and a making method thereof, and belongs to the aluminum alloy making field. The flat cast ingot comprises, by mass, 2.0-2.4% of Cu, 1.95-2.5% of Mg, 5.5-9.0% of Zn, 0.08-0.15% of Zr, 0.0003-0.0015% of Be, below 0.06% of Ti, below 0.04% of Cr, below 0.10% of Mn, 0.085% or less of Si, 0.14% or less of Fe, and the balance Al and inevitable elements, wherein the content of each of the inevitable elements is lower than 0.05%, the total amount of the inevitable elements is lower than 0.15%, and a content ratio of Fe to Si is not less than 1.6. The making method disclosed in the invention improves traditional making methods, and does not need pure aluminum bottoming, and the flat cast ingot made in the invention has the advantages of large size, high strength, no cracks, and high casting success rate.

Owner:广西南南铝加工有限公司

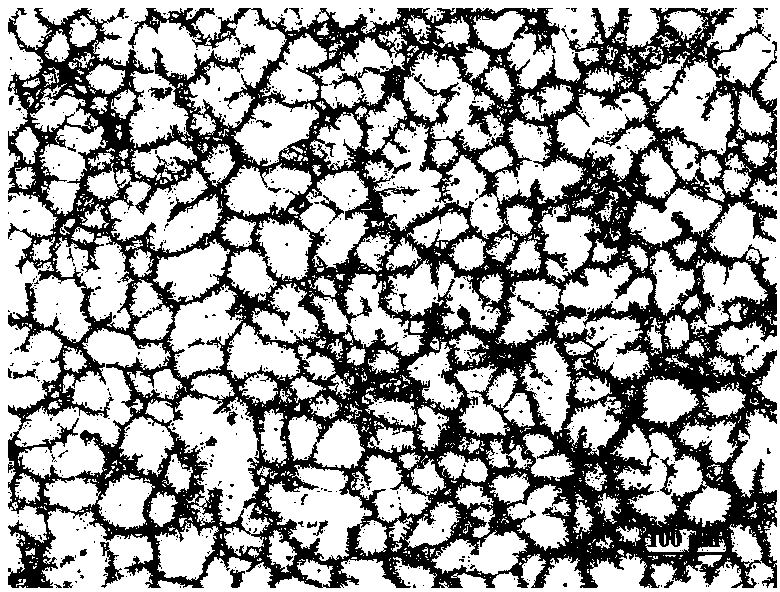

Al-Zn-Mg-Cu-Sc-Zr-RE alloy capable of being used as ultrahigh-strength cast aluminum alloy and preparation method thereof

ActiveCN102127665AChange the solidification methodReduced hot cracking tendencyRare-earth elementSolid solution

The invention discloses an Al-Zn-Mg-Cu-Sc-Zr-RE alloy capable of being used as an ultrahigh-strength cast aluminum alloy and a preparation method thereof. In the alloy, Zn and Mg with higher content are adopted, Sc and Zr are compositely microalloyed, and trace rare earth elements Er and / or Yb are added, so that the aims of increasing an eutectic phase proportion, thinning a grain structure, suppressing dendritic crystal growth and changing an alloy solidification mode are fulfilled to reduce the heat cracking tendency of the alloy and obviously improve the casting performance of the alloy. The alloy comprises the following components in percentage by weight: 7.0 to 8.0 percent of Zn, 1.5 to 2.5 percent of Mg, 1.4 to 2.0 percent of Cu, 0.2 to 0.5 percent of Mn, 0.15 to 0.25 percent of Sc,0.10 to 0.20 percent of Zr, 0.1 to 0.3 percent of Er and / or Yb and the balance of Al. The as-cast alloy can achieve high toughness performance through long-time variable-temperature homogenization, enhanced solid solution treatment and aging treatment, can be used for producing an aluminum alloy casting with the yield strength of more than 500MPa and the elongation rate of more than 5 percent andcan be used as an alternate material for the ultrahigh-strength wrought aluminum alloy.

Owner:有研金属复材技术有限公司

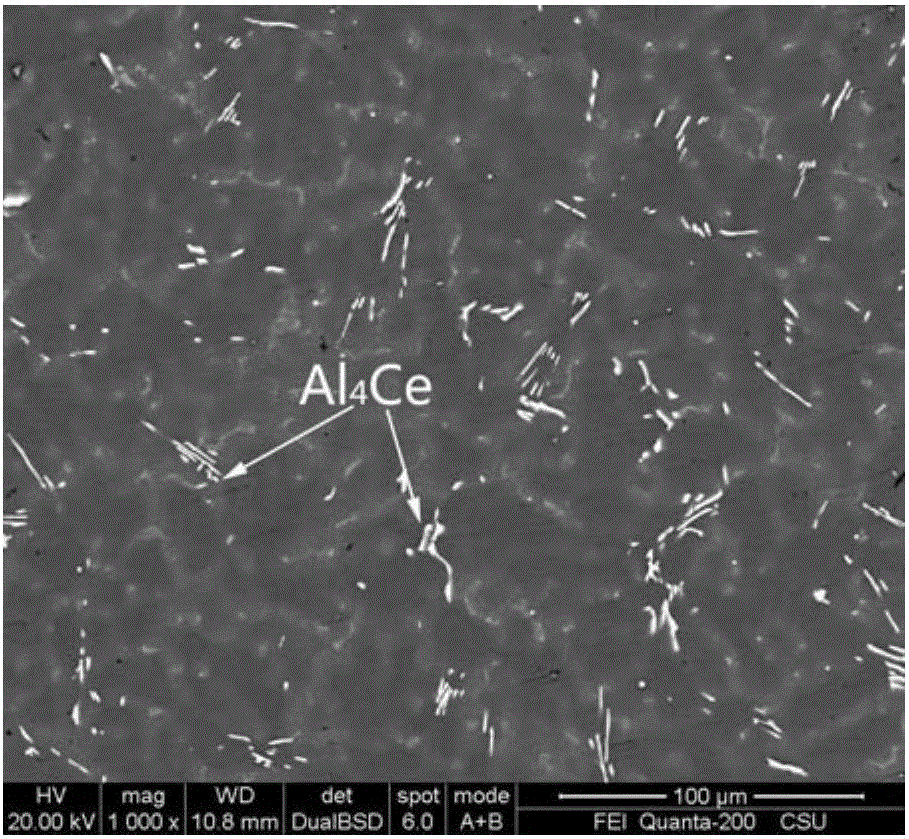

Light-weight and high-strength cast aluminum lithium alloy and preparation method thereof

The invention discloses a light-weight and high-strength cast aluminum lithium alloy and a preparation method thereof. The alloy consists of Li, Cu, Mg, Zn, Zr, Ti, Mn, Ce and impurity elements in specific percentages by weight as well as the balance of Al. During preparation, an aluminum alloy is obtained by smelting Al-Li, Al-Cu, Al-Zr, Al-Ti-B, Al-Mn, Al-Ce intermediate alloy, pure aluminum, pure Zn and Pure Mg, and then is subjected to two-stage solid solution heat treatment of 400-450 DEG C / 8-10h and 510-540 DEG C / 20-28h, and one-stage aging treatment of (120-190) DEG C* (30-48) h is carried out after hardening treatment to obtain the light-weight and high-strength cast aluminum lithium alloy. The mechanical properties such as room temperature strength, hardness, rigidity and breaking tenacity of the prepared aluminum lithium alloy are superior to those of a traditional business aluminum alloy, and the aluminum lithium alloy is also low in cost.

Owner:SHANGHAI JIAO TONG UNIV

Rare earth manganese brass alloy and producing process thereof

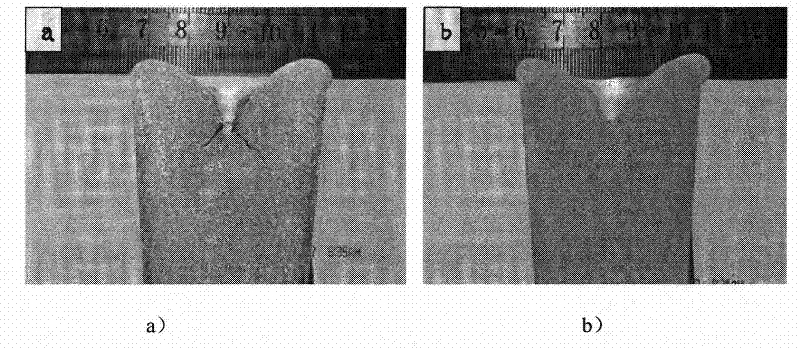

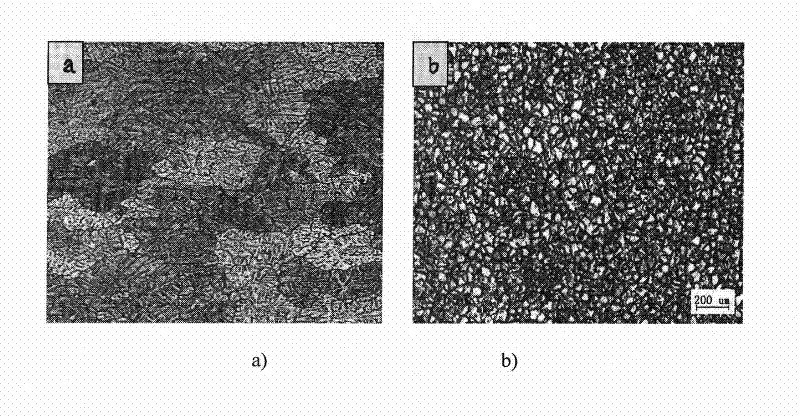

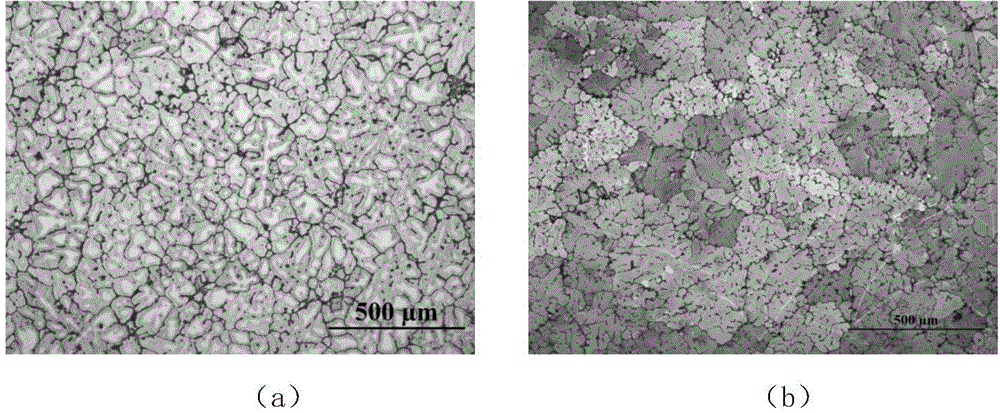

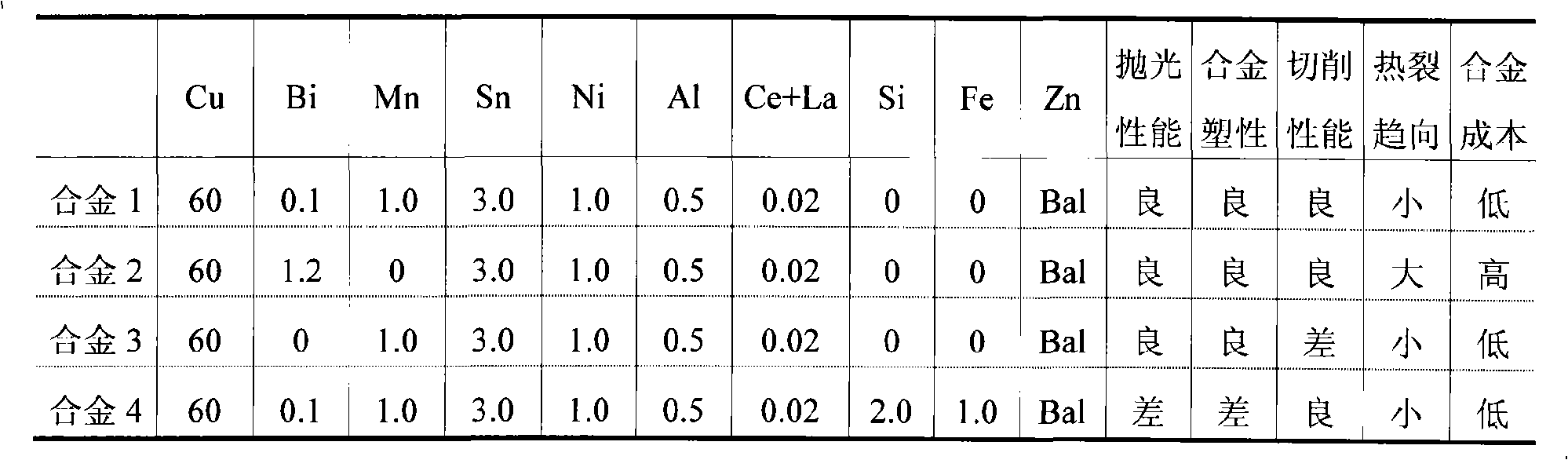

The invention relates to a rare earth brass alloy with environment protection and easy cutting, which achieves the purpose of improving the easy cutting of the alloy by adding Bi and Mn to replace the lead in Pb brass. The alloy has the components of 55.0-65wt percent of Cu, 0.1-2.5wt percent of Bi, 0.1-1.0wt percent of Mn, 0-3.0wt percent of Sn, 0-1.0wt percent of Ni, 0.1-1.0wt percent of Al, 0.01-0.05wt percent of one or two of Ce and La, the rest of Zn and other inevitable impurities, wherein Bi, Si, Ce, La and Ce+La are added respectively in the form of master alloys of Cu-Bi, Cu-Si, Cu-Ce, Cu-La and Cu-Ce-La. The alloy has the advantages of favorable cutting performance, cold and hot working performances and cast performance, little thermal fragment trend, simple production process of supporting preparation in the existing Pb brass production equipment, low alloy cost, good polishing performance and welding performance, etc.

Owner:XIAMEN LOTA INT CO LTD

Iron-based alloy powder material for plasma cladding quick forming

InactiveCN101709469AImprove toughnessModerate hardnessMetallic material coating processesHardnessWear resistance

The invention discloses an iron-based alloy powder material for plasma cladding quick forming, which comprises the following alloy components in percentage by weight: 0.05-0.15 percent of C, 4-8 percent of Ni,10-15 percent of Cr, 0.1-1 percent of B, 0.8-1.2 percent of Si, 0.8-1.2 percent of Mo, 0.25-0.70 percent of Nb, 0.25-3.5 percent of mixed RE(containing 47 percent of Ce, 26 percent of La,18 percent of Nd and 5 percent of Pr in percentage by mass) and the balance of Fe. The iron-based alloy powder with the components is especially suitable for plasma cladding quick forming, and a cladding layer has medium hardness and wear-resistance. The iron-based alloy powder has little tendency to crack and other cladding defects under the condition of multi-layer cladding, and the cladding process is excellent with low powder cost. The powder can be also used for restoring work-piece size or used as a bottom layer before a functional cladding layer is formed during plasma single-layer cladding repair, and can be applied to wider application needs.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

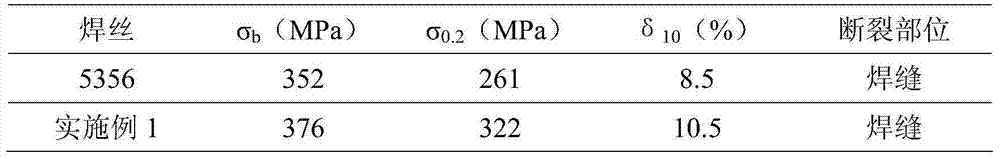

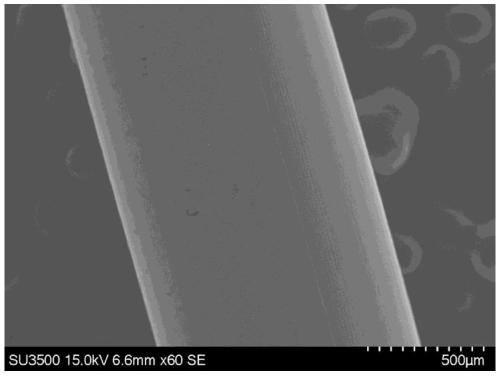

Ultra-fine grain aluminum alloy gold welding wire and preparation method thereof

InactiveCN104722945AQuality improvementImprove welding effectWelding/cutting media/materialsSoldering mediaMisch metalIngot casting

The invention relates to an ultra-fine grain aluminum alloy gold welding wire and a preparation method of the ultra-fine grain aluminum alloy gold welding wire. The ultra-fine grain aluminum alloy gold welding wire includes the following components: SC 0.05%-0.8%, Er 0.05%-0.6%, misch metal 0.01%-0.8%, B 0.01%-0.5%, Ti 0.1%-0.3%, Cr 0.05%-0.4%, Zr 0.05%-0.2%, Mn 0.1%-0.6%, Zn 0.2%-1.0%, Mg 4%-8%, and the rest is Al. The preparation method is as follows: adding an aluminum ingot or the molten aluminum into a semi-closed reverberatory furnace firstly; adding Mn, Ti, Zr, Cr and Zn; adding B and the misch metal; conducting the furnace refining on the alloy melt; slagging the alloy melt after the refining; pressing Mg into the alloy melt after stewing; adjusting the temperature of the melt for standby; pouring the melt in an electromagnetic continuous casting machine; preparing an aluminum alloy ingot casting; lifting up the aluminum alloy ingot casting for homogenizing annealing and scalping for standby; putting the aluminum alloy ingot casting into an extrusion die for extrusion, extruding an aluminum alloy wire disc; and conducting wire drawing till the specification and the diameter reach the standard and using. The ultra-fine grain aluminum alloy gold welding wire can effectively improve the structural strength of a welding structure and the welding performance, and overcomes the welding defects of the low strength of an aluminum alloy welding joint and welding cracks.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

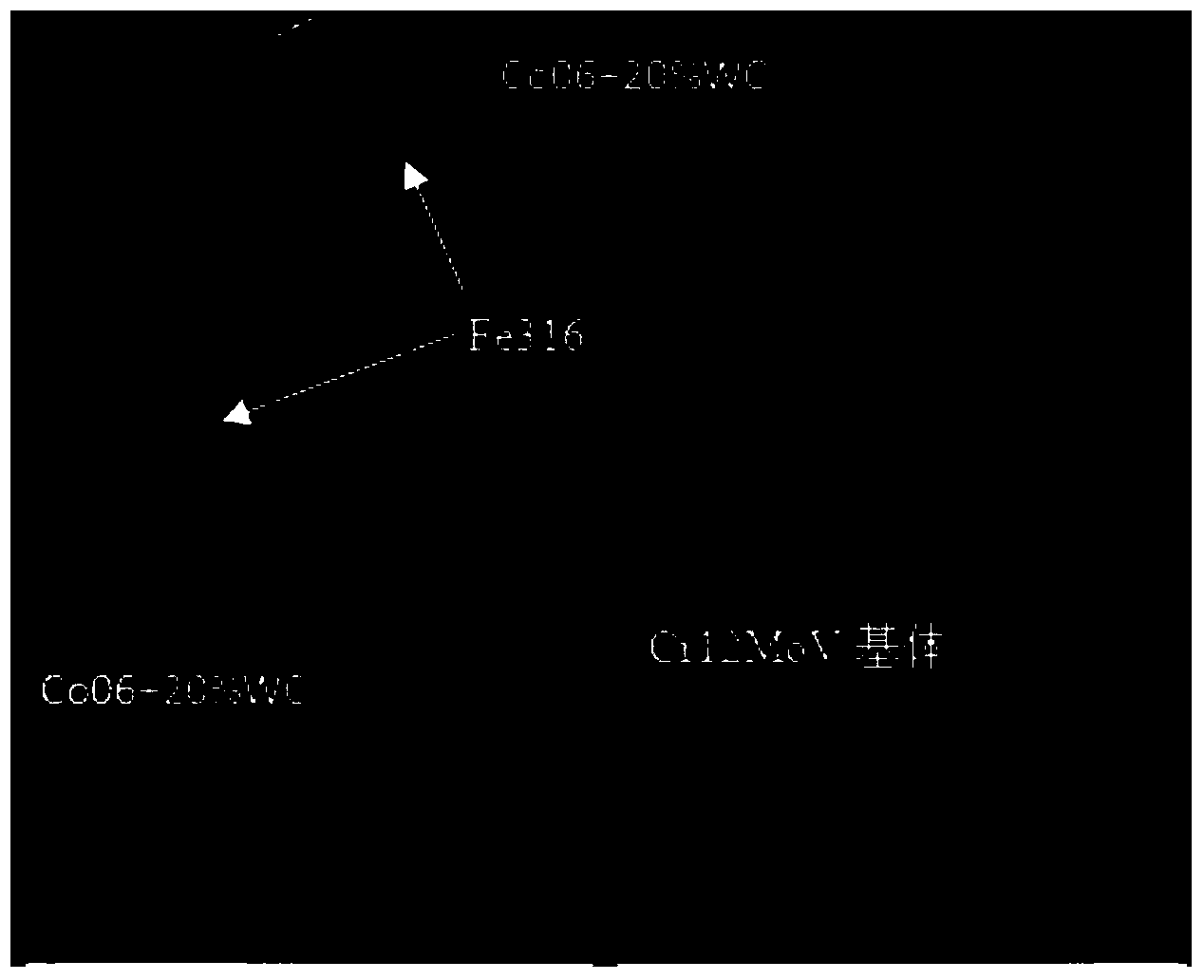

Cr12MoV cold stamping mold laser repair technology using cobalt-based tungsten carbide as fusion covering alloy

InactiveCN103911612ADense tissueSmall heat affected zoneMetallic material coating processesAlloyOptoelectronics

The invention discloses a Cr12MoV cold stamping mold laser repair technology using cobalt-based tungsten carbide as fusion covering alloy. The Cr12MoV cold stamping mold laser repair technology comprises the following steps: (1) cleaning defects on the surface of a cold stamping mold, and removing grinding racks, oil stains and microcracks on the surface; (2) using Fe316 alloy powder as a bottoming layer, and carrying out laser bottoming fusion covering; (3) using Co06+WC alloy powder as a covering layer, and after cooling the mold to 300-600 DEG C, carrying out laser fusion covering on the covering layer; and (4) carrying out mechanical machining on the surface of the fusion covering layer. According to the technology, the fusion covering layer with high interface bonding strength and compact structure and without cracks is obtained without preheating, the microhardness of the fusion covering layer reaches 58-62HRC9.8N, particularly the fusion covering layer has good abrasive resistance and can meet the production requirements, and the service life of the cold stamping mold can be prolonged.

Owner:SHANDONG UNIV

Ni-P alloy coating continuous casting crystallizer copper plate and preparation process thereof

ActiveCN102773432AImprove bindingReduced hot cracking tendencyMetal layered productsAlloy coatingCopper

The invention discloses a continuous casting crystallizer copper plate plating layer and a preparation process thereof. The Ni-P crystallizer copper plate plating layer comprises a crystallizer copper plate base body, wherein an Ni-P alloy layer is plated on the surface of the crystallizer copper plate base body, and contains nickel with the mass ratio being 95 percent to 99.7 percent, and phosphorus with the mass ratio being 0.3 percent to 5 percent. The preparation process of the continuous casting crystallizer copper plate plating layer comprises the following steps of: a, preplating the base body; b, preparing composite electroplate liquid containing Ni-P materials in a plating bath; and c, electroplating the Ni-P alloy layer. Due to the adoption of the scheme, the defects of low steel production, large abrasion, frequent repair of the continuous casting crystallizer copper plate can be overcome, and the continuous casting crystallizer copper plate plating layer with uniform densification, favorable binding force, low heat crack tendency, small internal stress, excellent wear-resisting property and long life cycle is obtained.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

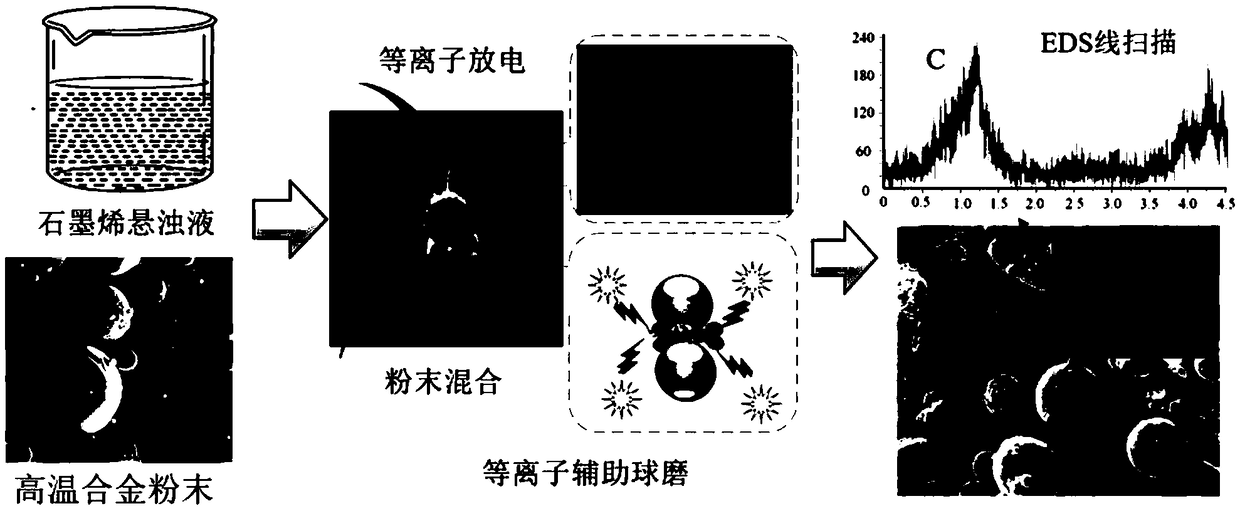

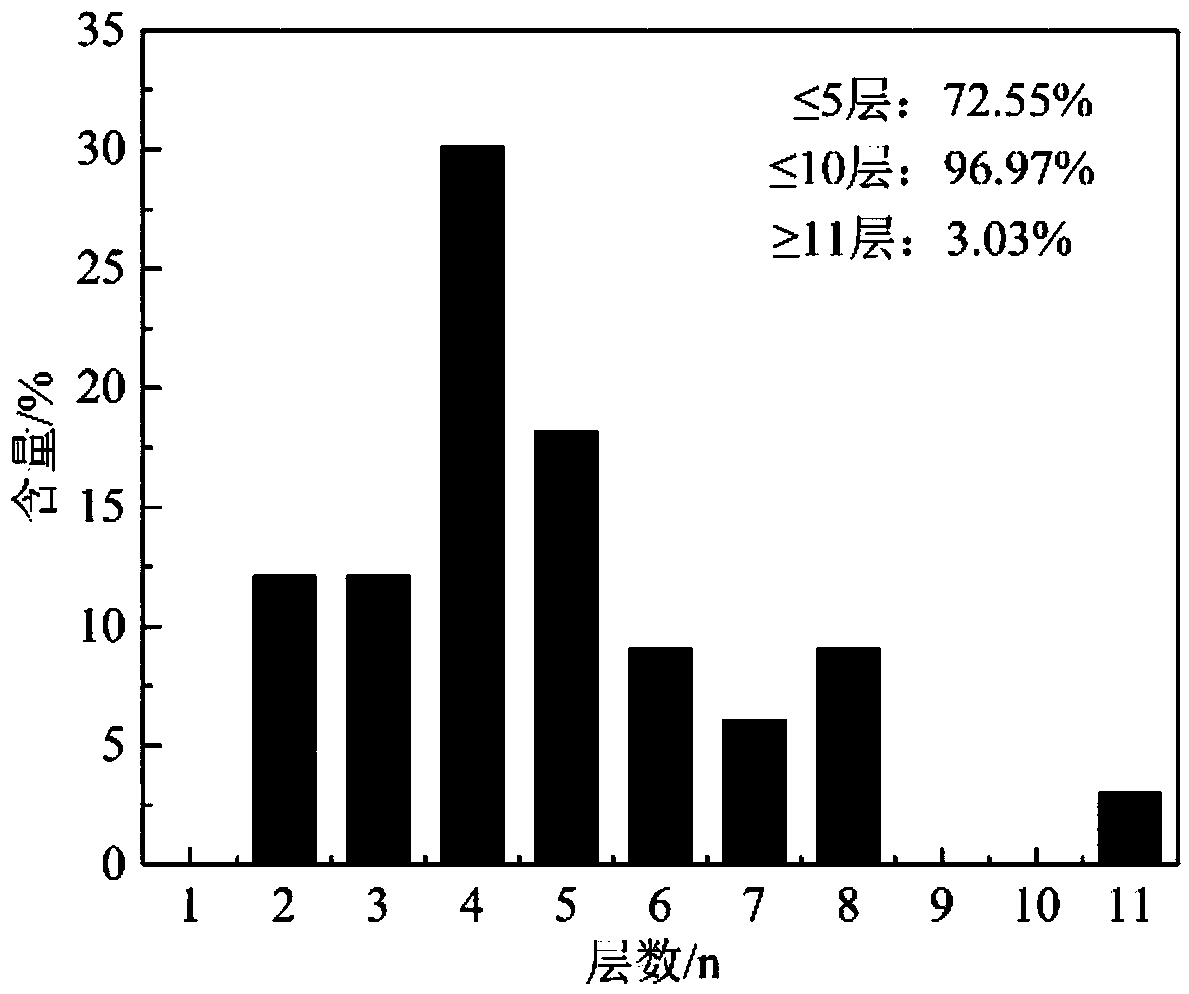

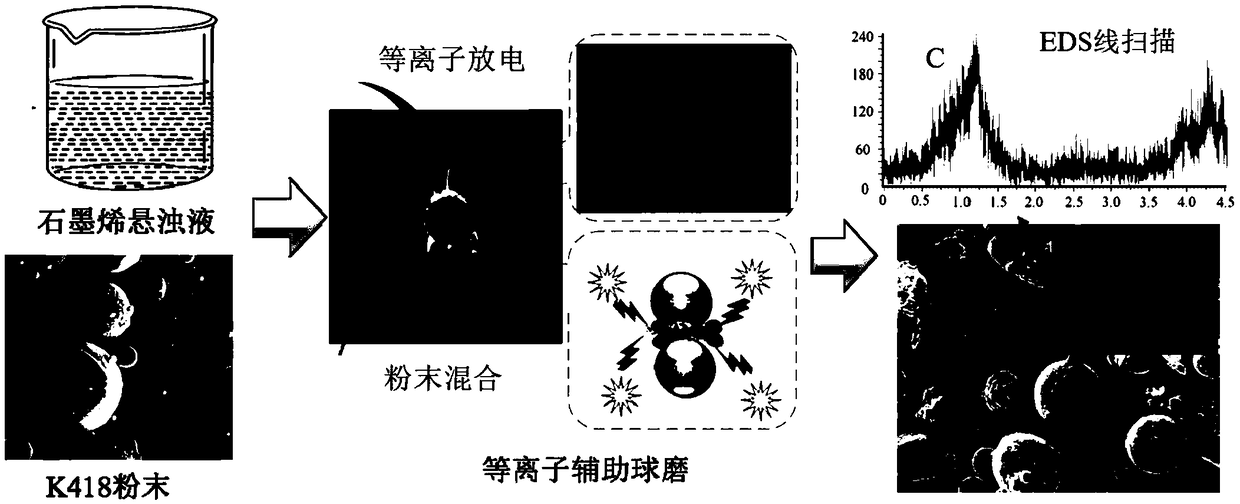

Preparation method of graphene alloy nanocomposite and SLM (Selective Laser Melting) forming process

InactiveCN109454240AImproves Strength and ToughnessReduced hot cracking tendencyAdditive manufacturing apparatusIncreasing energy efficiencyCvd grapheneInterfacial reaction

The invention discloses a preparation method of a graphene alloy nanocomposite and an SLM (Selective Laser Melting) forming process. According to the preparation method, turbid liquid is prepared through the ultrasonic vibration of anhydrous ethanol, so that the graphene is uniformly dispersed in the anhydrous ethanol, the graphene is uniformly dispersed, then after the graphene anhydrous ethanolturbid liquid is mixed with high-temperature alloy in proportion, the graphene and partial residue are distributed in the grain boundary and crystals by participating in the interfacial reaction, so that the strength and toughness of a formed part are improved, and the hot cracking tendency is reduced; the addition of graphene changes the organization form of the material; and in the SLM forming process, the graphene in the graphene high temperature alloy nanocomposite is used as a heterogeneous nucleating agent, and increases the nucleation rate in the solidification crystallization process.The graphene high temperature alloy nanocomposite is prepared by the dielectric barrier discharge plasma-assisted ball milling technique. The plasma enhances the activity of powder, so that columnar crystals preferentially growing change to isometric crystals, grains are refined and the performances are improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

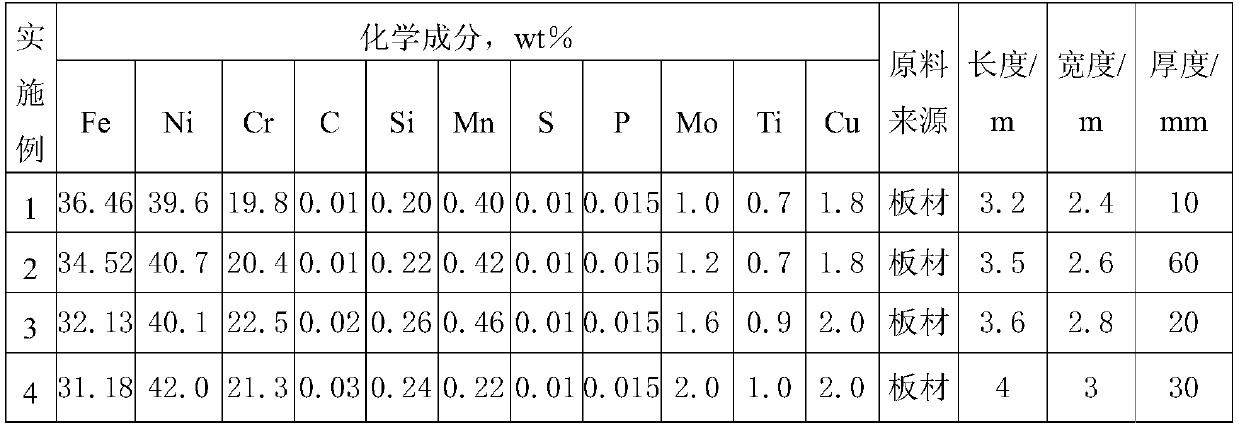

Double-phase stainless steel smelting technology

The invention belongs to the technical field of steel smelting, and relates to a double-phase stainless steel smelting technology. According to the technology, a carbon steel material head, a stainless steel material head, stainless steel cuttings and high carbon ferro-chrome are adopted to serve as raw materials, high-chromium high-carbon molten steel is smelted through an intermediate frequency furnace, and relatively-high-cost low-carbon or micro-carbon chromium iron is not required to be adopted for smelting; after the temperature is proper, the molten steel is transferred into an AOD furnace from a steel ladle; smelting devices like the AOD furnace is adopted for conducting oxygen blowing, decarbonization and molten steel refining, and nitrogen is blown to the steel for increasing nitrogen to the steel; the cost generated by adopting nitralloy for nitrogen adding is reduced, and after the components are qualified, the steel is cast into an electrode blank; when electric slag is remelted, argon or dry air is adopted for protection, and the suction amount of a furnace hearth is further reduced; and the voltage and the current are adjusted to control the melting rate. The double-phase stainless steel smelting technology is also suitable for other applicable fields.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

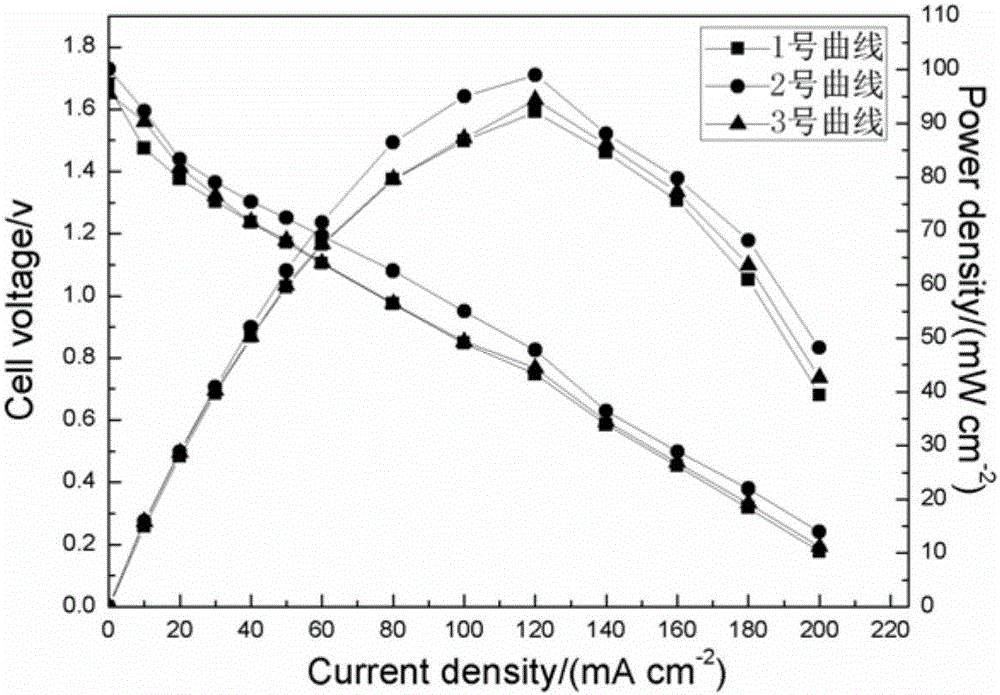

Mg alloy anode material and preparation method thereof

ActiveCN105925862AImprove electrochemical performanceUniform performanceChemical compositionElectrochemistry

The invention relates to a Mg alloy anode material and a preparation method thereof, and belongs to the technical field of development and preparation of novel anode materials for high-power chemical power sources. The Mg alloy anode material can be utilized as an anode material for a seawater battery or an air battery, and comprises the following chemical components in percentage by mass: 4-7% of Al, 0.5-1.5% of Sn, 0.05-0.5% of Ce, and the balance of Mg and impurities, wherein the total content of the impurities is lower than or equal to 0.01%. A Mg alloy plate being good in electrochemical property, relatively low in self-corrosion rate and high in anode efficiency is obtained by subjecting the Mg alloy anode material to such metal material machining processes as smelting, heat treatment, extrusion and rolling. The Mg alloy anode material provided by the invention has the advantages that the component design is reasonable, the preparation process is simple, the properties of the obtained product are good, and the large-scale industrialized application is facilitated.

Owner:HUNAN HYDRO DYNAMIC NEW MATERIAL CO LTD

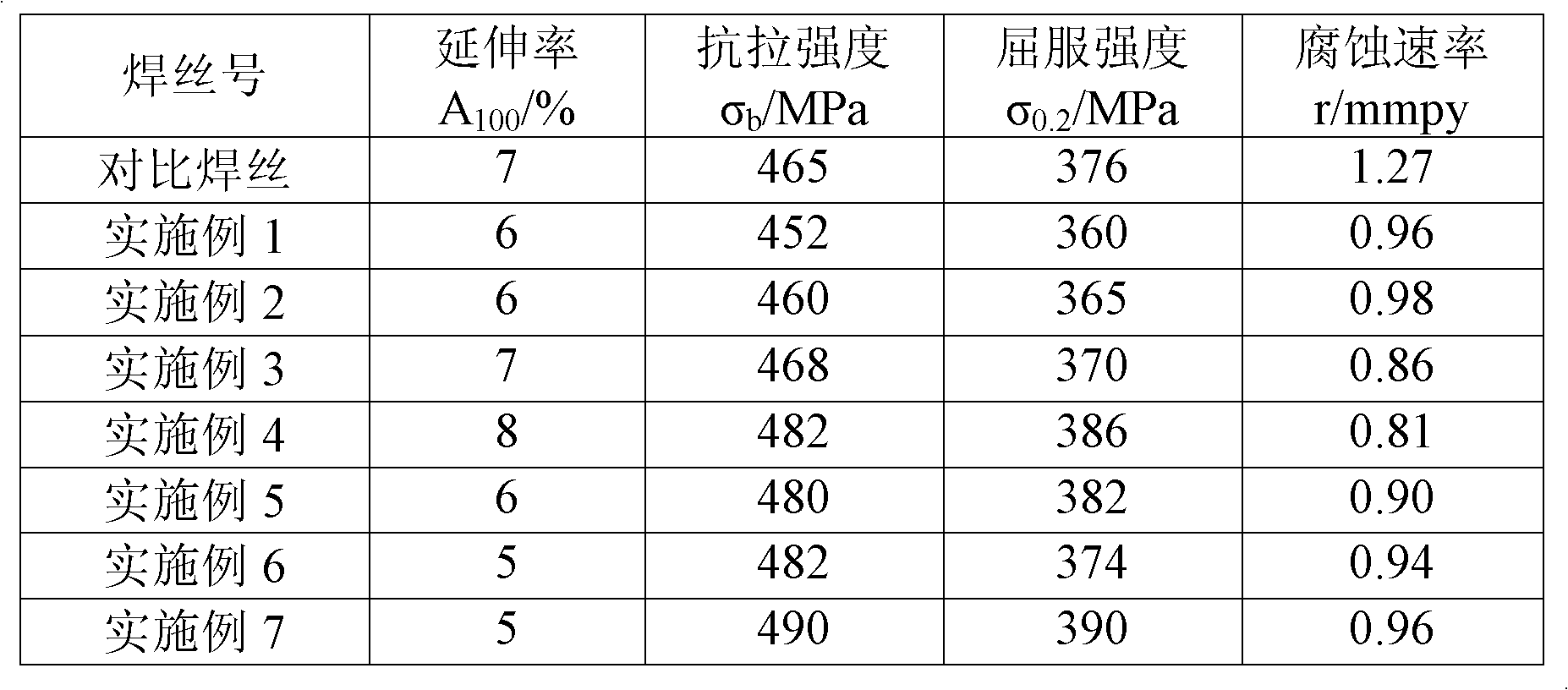

Multi-element compounded micro-alloyed Al-Mg-Sc series welding wire and preparation method thereof

InactiveCN102079019AImprove liquidityWeaken the effect of pouringWelding/cutting media/materialsSoldering mediaCeriumManganese

The invention discloses a multi-element compounded micro-alloyed Al-Mg-Sc series welding wire. The welding wire comprises the following components in percentage by mass: 4.5 to 7.5 percent of magnesium, 0.3 to 0.63 percent of manganese, 0.1 to 0.2 percent of zirconium, 0.18 to 0.4 percent of scandium, 0.25 to 0.4 percent of cerium and lanthanum and the balance of Al. When the Sc and Zr multi-element compounded micro-alloyed Al-Mg-Sc series welding wire is used for the fusion welding of an Al-Zn-Mg (Sc) series alloy and an Al-Mg (Sc) series alloy, the welding seam alloy has fine and uniform textures and the hot cracking tendency of a welded joint is obviously reduced. The alloy welding wire has relatively high fluidity at a welding temperature, can obtain more excellent welding seam textures, reduces the welding hot cracking tendency of the welding seam alloy, obtains relatively high strength of the joint after welding and has relatively strong corrosion resistance.

Owner:ZHEJIANG YINYU WELDING NEW MATERIAL TECH

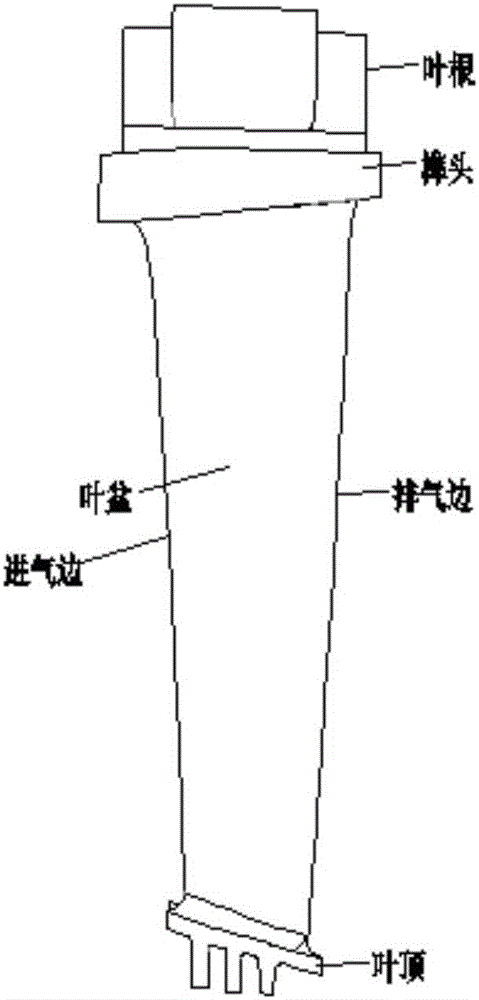

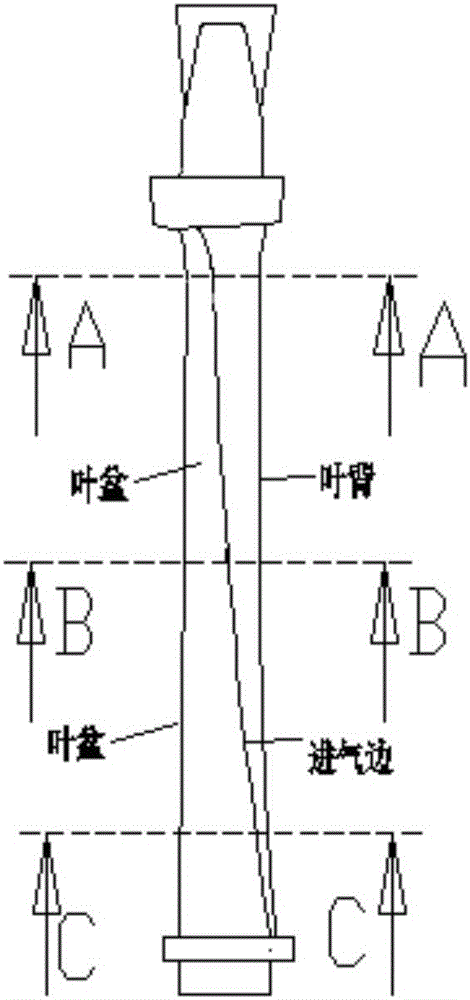

Ceramic shell manufacturing method and method for manufacturing ceramic shell of turbine blade

InactiveCN105855468ADoes not affect concessionGood size controlFoundry mouldsFoundry coresWaxTurbine blade

The invention discloses a ceramic shell manufacturing method. The ceramic shell manufacturing method comprises the following steps: step one, fixing reinforcing ribs on a part which easily deforms due to bulging at least during casting of the outside of the ceramic shell; and step two, after the ceramic shell obtained from the step one is fully dried, removing a wax mould in the ceramic shell, then removing residual wax, and roasting to obtain the required ceramic shell finally. During construction of the ceramic shell manufactured by the method, problems of heat crack of castings due to over high strength of the ceramic shell and bulging deformation of the castings due to over-low strength of the ceramic shell can be relieved at least. The invention discloses a method for manufacturing a ceramic shell of a turbine blade, and the ceramic shell manufacturing method is used.

Owner:DONGFANG TURBINE CO LTD

Preparation method for magnesium alloy cast paint

InactiveCN101342570AReduced hot cracking tendencyImprove insulation effectFoundry mouldsFoundry coresWrinkle skinPhosphoric acid

The present invention relates to a method for preparing magnesium casting coating; 0.7 percent of paligorskite clay that is configured with 17 percent of water is milled for 3 hours to be made into solution A; secondly 5 percent of talcum powder, 3 percent of diatomite, 0.5 percent of KBF4 and 1 percent of aluminium phosphate are put into a spherical mill, and is respectively mixed with solution A, 3 percent of silica sol and 67.6 percent of water to be milled for 3 hours to obtain the magnesium alloy metal-typed casting coating; metal mould is heated to be about 200 DEG C, and then is sprayed with a layer of magnesium alloy casting coating on the surface, and is dried finally. The method of the present invention has the advantages of strong heat preservation, flame retardant performance, sticking performance and coating performance, favorable suspension performance and less heat fracture of the casting piece. Oxidation is prevented, so the surface is bright and smooth and is free from oxidized wrinkle.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

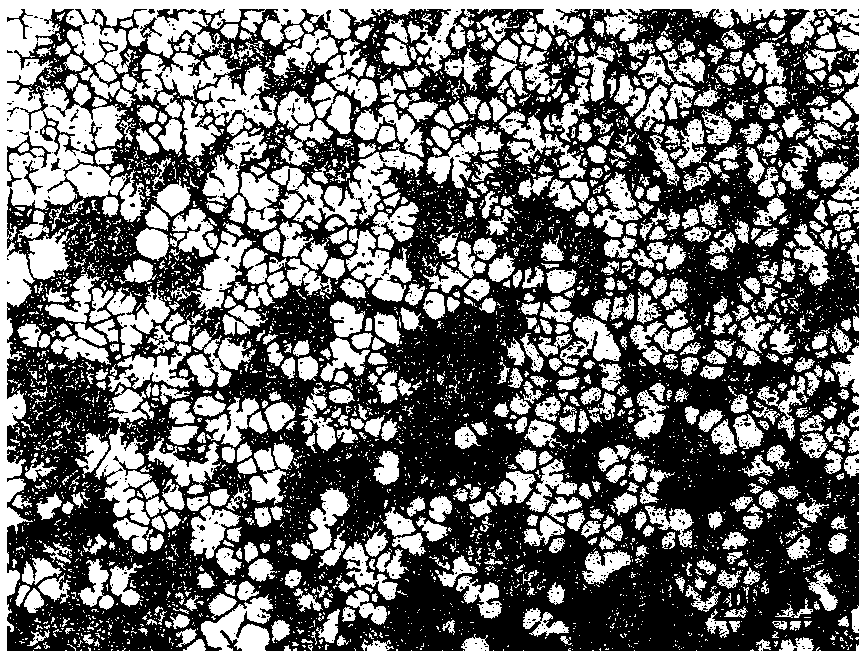

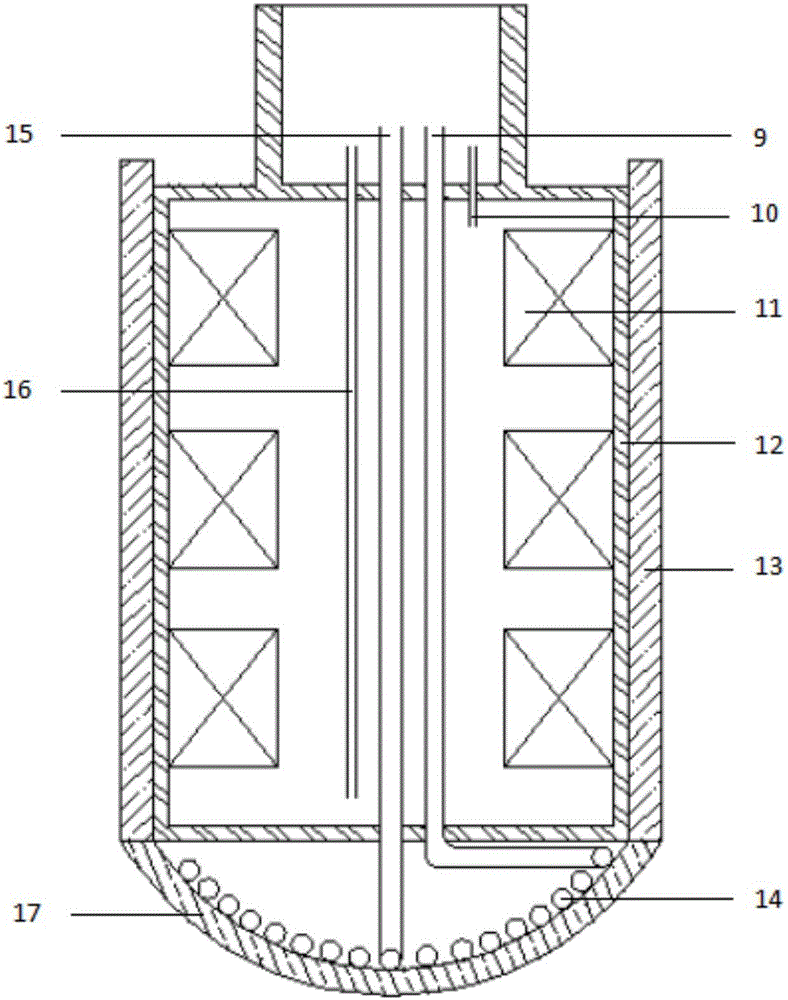

Manufacture device and method for large-size fine-grain homogeneous aluminum alloy cast ingot

The invention relates to a manufacture device and method for a large-size fine-grain homogeneous aluminum alloy cast ingot, belonging to the field of metal material machinery. The device mainly comprises a uniform cooler, a thermal ejector, an electromagnetic stirrer, a crystallizer and a dummy ingot, wherein the thermal ejector is arranged above the crystallizer; the electromagnetic stirrer is arranged on the periphery of the thermal ejector and the crystallizer; the dummy ingot is arranged below the crystallizer; the uniform cooler is arranged in the crystallizer; and the uniform cooler consists of an inner pipe and an outer pipe. According to the manufacture device and method, through special coupling treatment of uniform cooling in the crystallizer and electromagnetic stirring outside the crystallizer is applied to an alloy melt, so that effective control on uniformity of a temperature field and a component field of the large-size alloy melt is realized, and the large-size aluminum alloy cast ingot with uniform and fine structure and uniform components is manufactured. The manufacture device is simple in structure, feasible in method, obvious in effect, high in production efficiency and easy for combination with large-scale industrial production, and has a wide industrial application prospect in the fields of aerospace, rail transportation and manufacture of ships and the like.

Owner:有研金属复材技术有限公司

Extrusion cast aluminum alloy material and preparation method thereof

ActiveCN108642336AReduce the tendency of alloy hot crackingImprove casting performanceRare-earth elementMetallic materials

The invention belongs to the technical field of metal materials, and in particular, relates to an extrusion cast aluminum alloy material and a preparation method thereof. The extrusion cast aluminum alloy material comprises the following elements in percentage by mass: 2.5-6.0% of Mg, 3.0-6.0% of Zn, 0.5-2.0% of Cu, 0.01-1.5% of rare earth element RE, 0.00005-0.2% of Ti, 0.00001-0.1% of B, 0-0.2%of Sr, 0-0.2% of Zr, the balance of Al, and impurities not more than 0.45%, wherein the rare earth element is one or combination of more in Ce, Y, La, Pr, Nd, Sm, Eu, Gd, Dy, Ho, Er, Tm, Yb and Lu. The aluminum alloy material is excellent in room-temperature comprehensive mechanical performance and casting performance.

Owner:SHANGHAI JIAO TONG UNIV

Metal-Me gravity casting aluminum alloy material and preparation method thereof

The invention belongs to the technical field of metal materials, and particularly relates to a metal-type gravity casting aluminum alloy material and a preparation method thereof. The metal-type gravity casting aluminum alloy material is prepared from the following elements in percentage by mass: 2.0 to 4.5 percent of Mg, 3.0 to 5.5 percent of Zn, 0.5 to 1.5 percent of Cu, 0.01 to 1.5 percent of rare earth element RE, 0.00005 to 0.2 percent of Ti, 0.00001 to 0.1 percent of B, 0 to 0.2 percent of Sr, 0 to 0.2 percent of Zr, the balance Al, and less than or equal to 0.30 percent of impurities, wherein the rare earth element is one or combination of multiple elements of Ce, Y, La, Pr, Nd, Sm, Eu, Gd, Dy, Ho, Er, Tm, Yb and Lu. The aluminum alloy material is excellent in indoor temperature integrated mechanical properties and favorable in casting performance.

Owner:SHANGHAI JIAO TONG UNIV

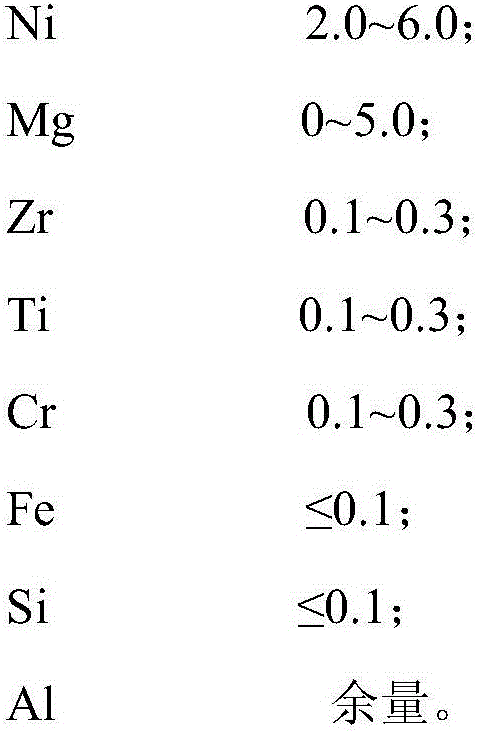

Welding wire special for 7XXX series aluminum alloy and manufacturing method thereof

ActiveCN105710557AHigh strengthReduced hot cracking tendencyWelding/cutting media/materialsWelding/soldering/cutting articlesUltimate tensile strengthFusion welding

The invention discloses a welding wire special for 7XXX series aluminum alloy and a manufacturing method thereof. The special welding wire is composed of, by mass, 2.0%-6.0% of Ni, 0-5.0% of Mg, 0.1%-0.3% of Zr, 0.1%-0.3% of Ti, 0.1%-0.3% of Cr, 0-0.1% of Fe, 0-0.1% of Si, and the balance Al. The manufacturing steps comprise burdening, smelting, sampling analysis, semicontinuous casting, homogenizing heat treatment, extruding, wire drawing, surface treatment, cleaning, drying and packaging. According to the welding wire, the element Ni which can be subjected to the eutectic reaction with the Al is selected, so that the hot tearing tendency of welds is reduced by forming eutectic structures. The welding wire is suitable for all 7XXX series aluminum alloy and is mainly specific to welding of the high-strength 7XXX series aluminum alloy with poor welding performance. By adopting the welding wire for fusion welding of the 7XXX series aluminum alloy, welding cracks can be effectively avoided, and the weldability of the high-strength 7XXX series aluminum alloy is improved. Through proper heat treatment of welding joints, the strength of the welds is not lower than 260 MPa, and elongation is not lower than 3%.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

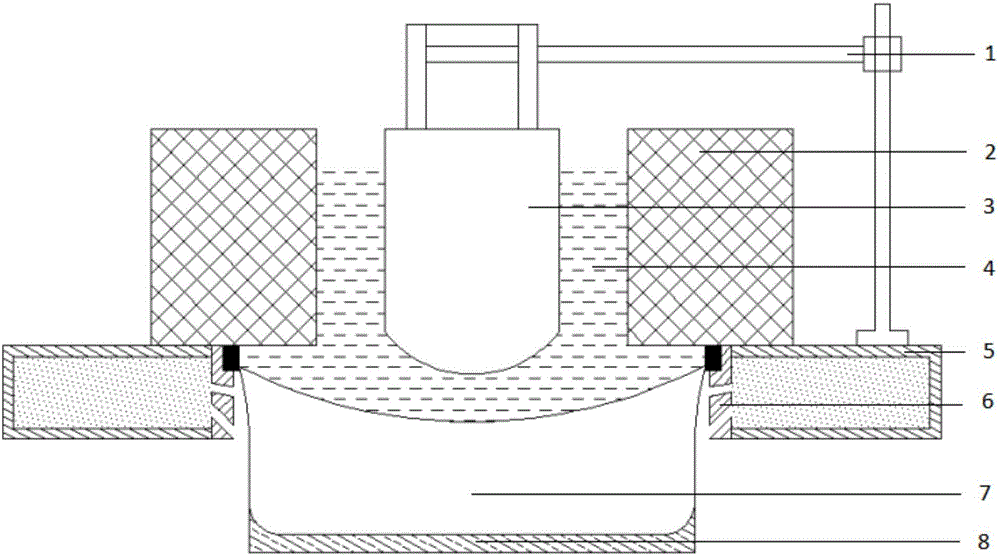

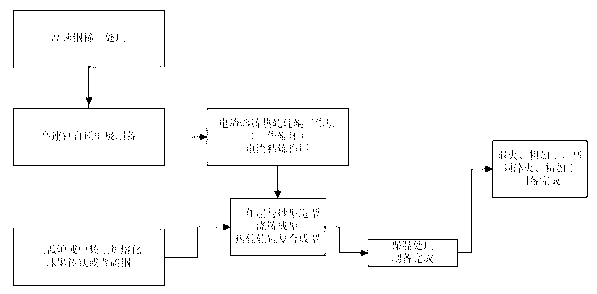

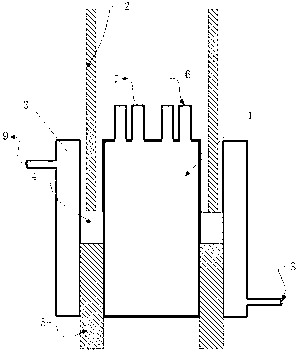

Preparation device and method of aluminum alloy ingot with ultra-large dimension

ActiveCN106623832AUniform temperatureUniform composition fieldMetallic materialsMaterials processing

The invention relates to a preparation device and method of an aluminum alloy ingot with the ultra-large dimension, and belongs to the field metal material processing. The device mainly comprises a melt processor, a lifting mechanism, a hot top, a crystallizer, a water tank and a dummy ingot; the hot top is installed above the crystallizer, the dummy ingot is arranged below the crystallizer, the crystallizer is fixedly installed on the water tank, the metal processor is connected with the lifting mechanism, the lifting mechanism is fixed to the water tank, and in the casting process, the melt processor is placed on the hot top and / or inside the crystallizer through the lifting mechanism. Accordingly, electromagnetic field applying and forced cooling are conducted on alloy melt on the hot top and inside the crystallizer in the continuous casting process from the interior, heat exchange and mass transfer of the core of the alloy melt are accelerated, the uniformity of a temperature field and a component field of the melt is improved, and fine grain homogeneous casting of the aluminum alloy ingot with the ultra-large dimension is achieved. According to the preparation device and method of the aluminum alloy ingot with the ultra-large dimension, the implementation effect is significant, the production efficiency is high, and the preparation device and method are likely to be combined with large-scale industrial production and have a wide industrial application prospect in the manufacturing fields of aerospace, rail transit, ships and the like.

Owner:有研金属复材技术有限公司

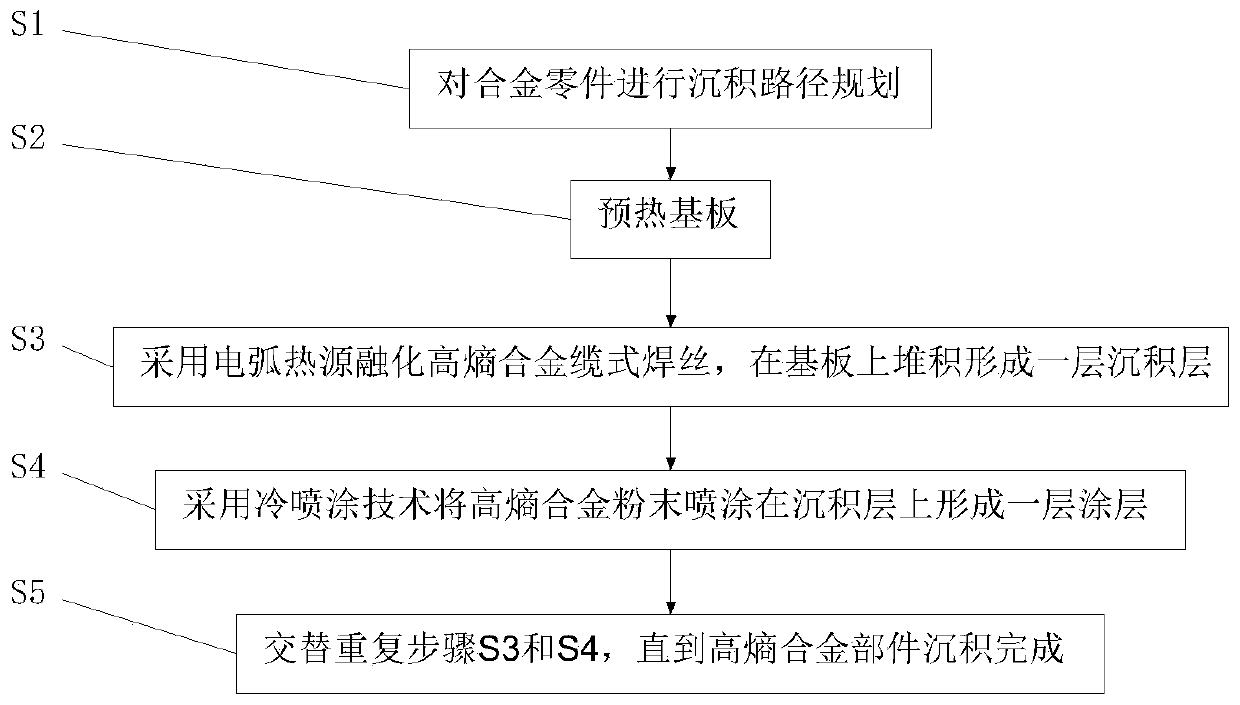

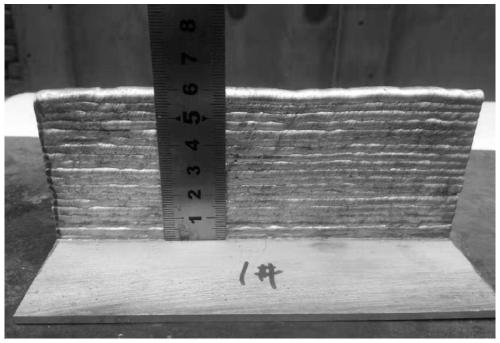

High-entropy alloy fine grain in-situ additive manufacturing method

InactiveCN110629218AUniform compositionImprove performanceAdditive manufacturing apparatusSuperimposed coating processHigh entropy alloysWelding residual stress

The invention discloses a high-entropy alloy fine grain in-situ additive manufacturing method. High-entropy alloy fine grain in-situ additive manufacturing is alternately achieved by combining high-entropy alloy cable type welding wire additive manufacturing and cold spraying technology strengthening. High-entropy alloy powder (mixed elementary substance powder) matched with high-entropy alloy cable type welding wires is adopted in cold spraying, powder particle high-speed flow impacts an overlay welding layer, and element burning loss brought by electric arc additives is made up; the impact effect and the fine grain strengthening effect are achieved; a cold spraying layer has the residual compressive stress effect, and the welding residual stress of the electric arc additives is releasedor reduced or eliminated; and phase change is promoted by controlling the powder composition and strong plastic deformation of powder particles, and the element and the structure of a high-entropy alloy forming component are controlled.

Owner:FOSHAN UNIVERSITY

High-thermal-conductivity die-casting magnesium alloy and preparation technology thereof

The invention discloses high-thermal-conductivity die-casting magnesium alloy and a preparation technology thereof. Chemical components of the high-thermal-conductivity die-casting magnesium alloy comprise, by mass, 8-13% of Zn, 0.1-1% of Ca, 0-1% of Mn, 0-1% of La, 0-1% of Ce and the balance Mg, wherein the content of Mn, the content of La and the content of Ce are not zero at the same time. The magnesium alloy is suitable for die casting and has excellent mechanical properties and high thermal conductivity, the thermal conductivity of the magnesium alloy at room temperature can reach about two times that of commonly used die-casting AZ91, and the tensile strength of the magnesium alloy is similar to that of AZ91 magnesium alloy.

Owner:BAOSHAN IRON & STEEL CO LTD

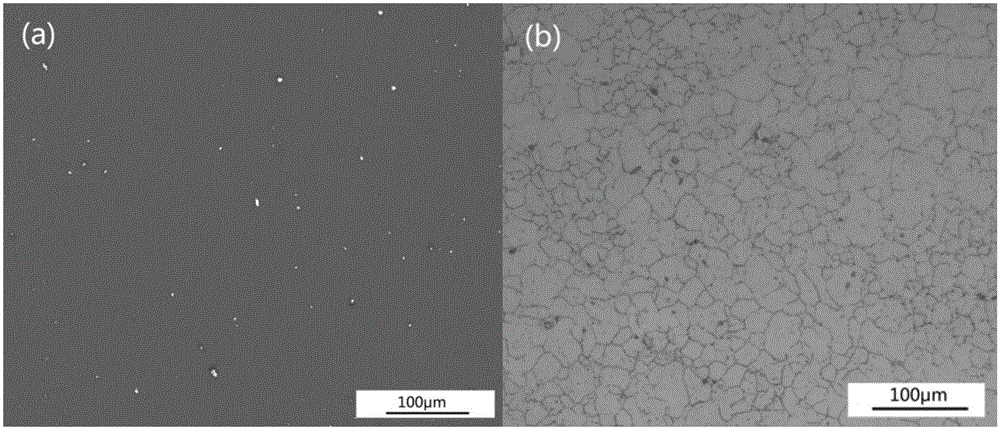

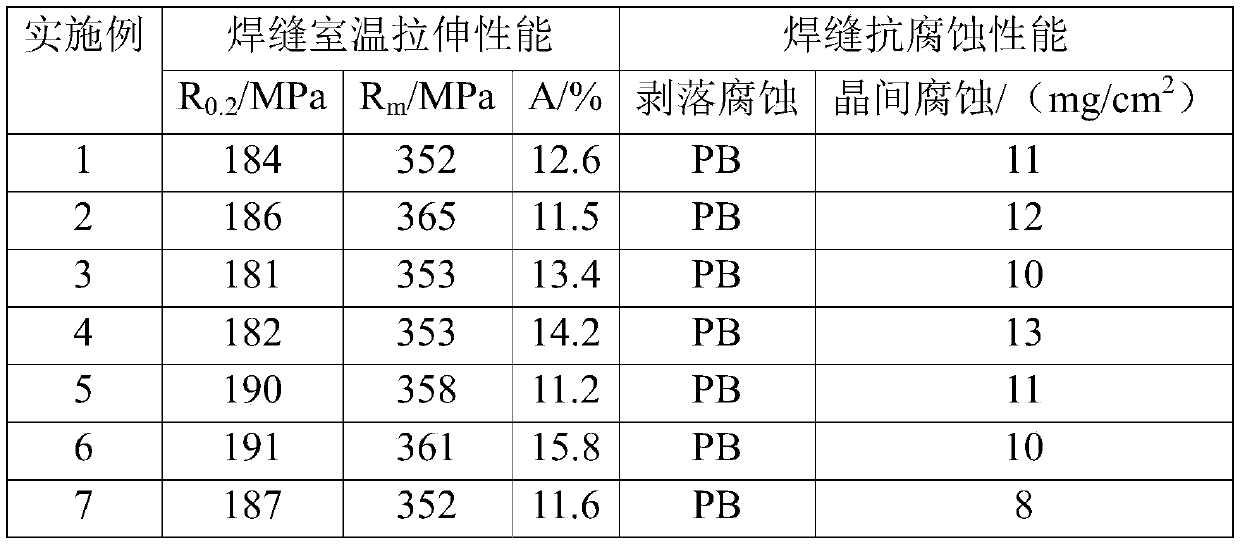

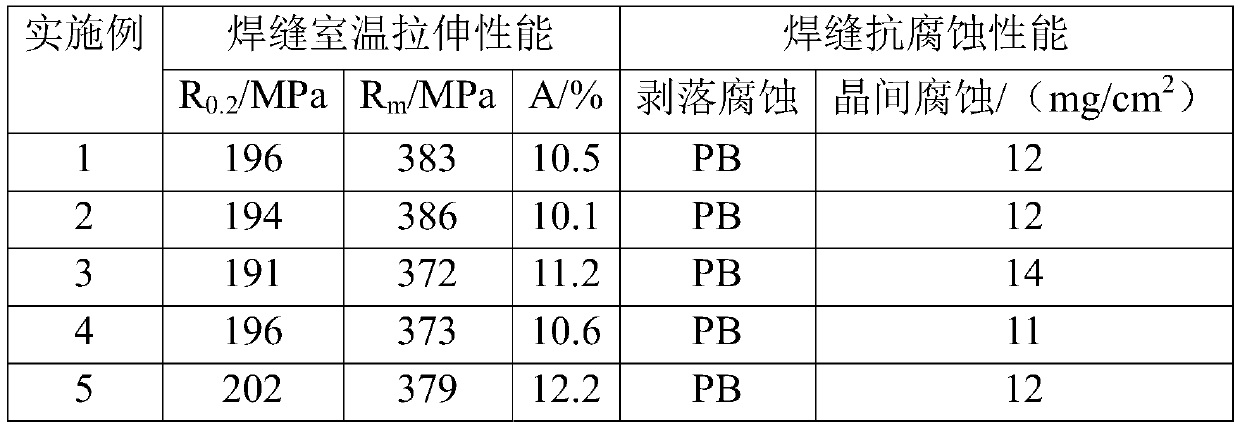

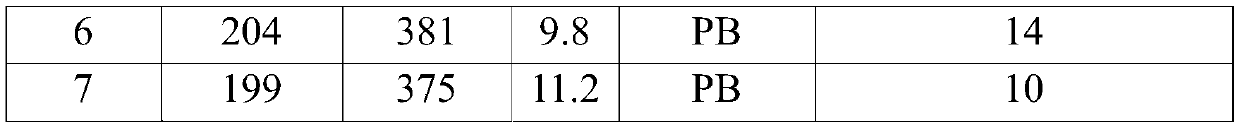

High-strength and corrosion-resistant Al-Mg-Zr aluminum alloy welding stick and preparation method thereof

ActiveCN109955003AHigh strengthGood formabilityWelding/cutting media/materialsSoldering mediaZincUltimate tensile strength

The invention discloses a high-strength and corrosion-resistant Al-Mg-Zr aluminum alloy welding stick and a preparation method thereof. The proportion of alloy elements in an Al-Mg-Zr alloy is controlled in an optimized manner, and meanwhile, powder preparation, hot isostatic pressing, extrusion, continuous extrusion and drawing processes are adopted for preparing the welding stick with the fine crystalline grains, uniform structure and the good comprehensive performance. The novel alloy welding stick has the good formability and the low hot cracking tendency in the TIG or MIG welding formingprocess, a welding joint has the high strength and excellent corrosion resistance, the welding stick can be used for welding corrosion-resistant Al-Mg series alloys and high-strength Al-Zr-Mg series alloys, welding requirements of all-aluminum ship and warship bodies and armor protection decks are met, and the application prospects are broad.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High-strength anti-swing bar

InactiveCN107739917AImprove mobilityReduced hot cracking tendencyAnodisationCorrosionAluminium alloy

The invention relates to an anti-swing bar, in particular to an aluminum alloy high-strength anti-swing bar, and belongs to the technical field of alloy materials. The high-strength anti-swing bar ismade of an aluminum alloy material, and the aluminum alloy material consists of the following components in percentage by mass: 11.2-11.8% of Si, 1.0-1.5% of Mg, 0.1-0.2% of Cr, 0.25-0.3% of Cu, 0.15-0.25% of Mn, 0.1-0.3% of Zr, and the balance of Al and inevitable impurity elements. The high-strength anti-swing bar is manufactured from the aluminum alloy material, and is added with a covering agent and a K / Na modifier in a preparation process, so that the alloy has high strength and good stress corrosion resistance.

Owner:NINGBO HUAYUAN JINGTE METAL PROD CO LTD

Novel high-strength high-toughness Al-Cu alloy

The invention aims at providing novel high-strength high-toughness Al-Cu alloy. The novel high-strength high-toughness Al-Cu alloy is good in forming property, small in hot cracking tendency, good in liquid die forging forming property and feeding property and small in amount of loose tissue. The novel high-strength high-toughness Al-Cu alloy is composed of, by weight, 0.05%-0.2% of Zr, 0.005%-0.06% of B, 4.6%-7.0% of Cu, 0.15%-0.35% of Ti, 0.3%-0.5% of Mn, 0.05%-0.3% of V, 0.15%-0.25% of Cd, 0.12%-0.18% of Fe, 0.03%-0.09% of Si and the balance Al.

Owner:ZHONGBEI UNIV +2

Tungsten electrode argon arc welding process of dissimilar materials of titanium alloy and nickel alloy

InactiveCN103878470APrevent welding oxidationSolve the problem that it is difficult to fuse each other to form a weldArc welding apparatusWelding/cutting media/materialsFilling materialsCerium

The invention discloses a tungsten electrode argon arc welding process of dissimilar materials of titanium alloy and nickel alloy. Ni-Cu alloy welding wires are selected to serve as filling materials, a cerium-tungsten electrode is adopted for argon arc welding, the end of the electrode is abraded to be a cone of 30-45 degrees, argon is adopted as the protective gas, the melting and solidification conditions of a welding molten pool of the titanium alloy and the nickel alloy are controlled through preparation before welding, preheating, welding, cooling after welding and adjustment on welding process parameters, and a welding connector which is attractive in appearance of a weld and does not have the defects of cracks or air holes can be obtained. According to the method, the welding efficiency is high, cost is low, operation is convenient and flexible, and the use requirement of the welding connector of the dissimilar materials of the titanium alloy and the nickel alloy can be met.

Owner:SHANDONG UNIV

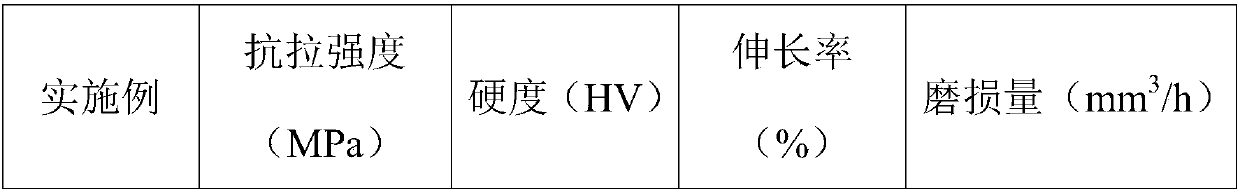

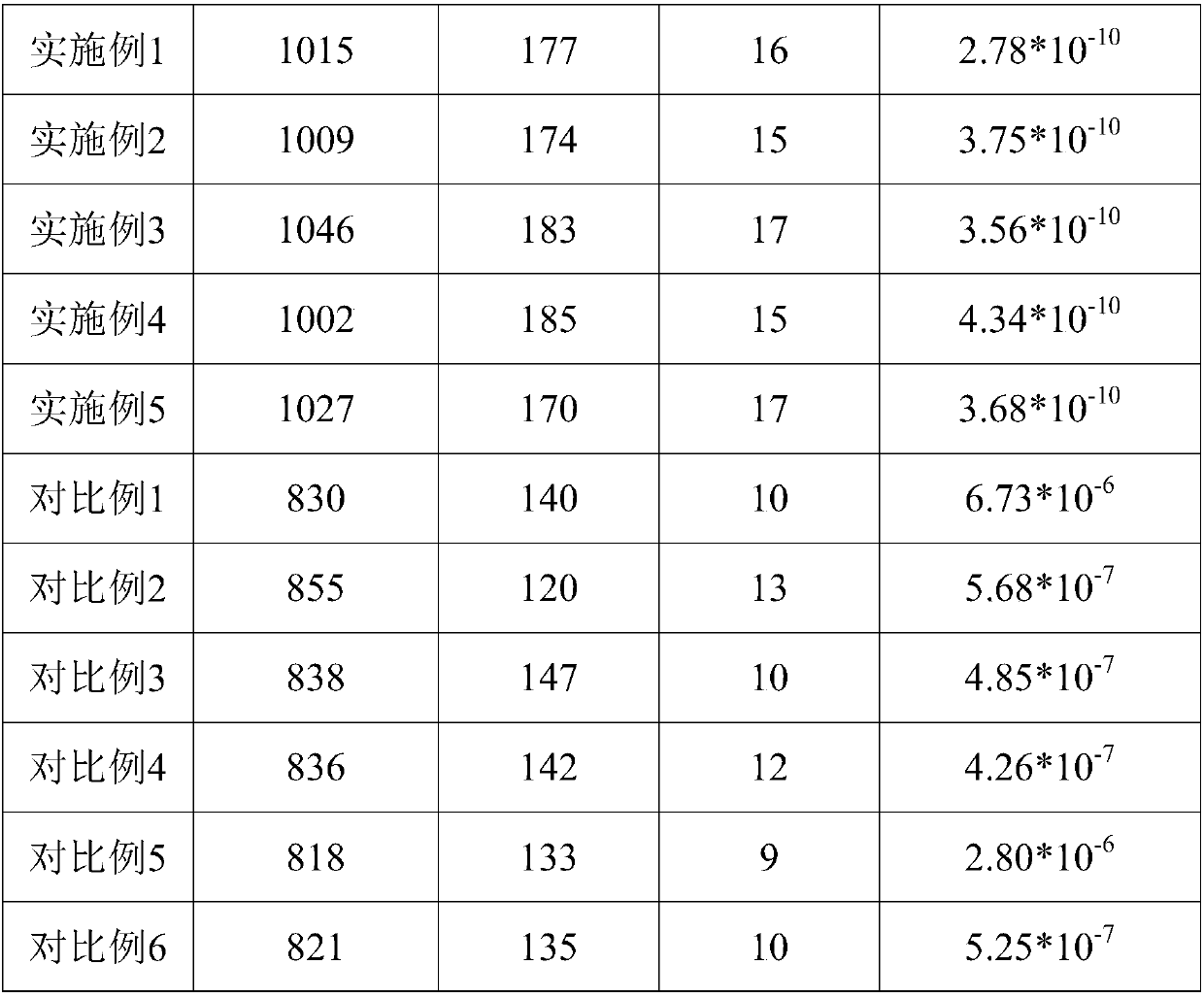

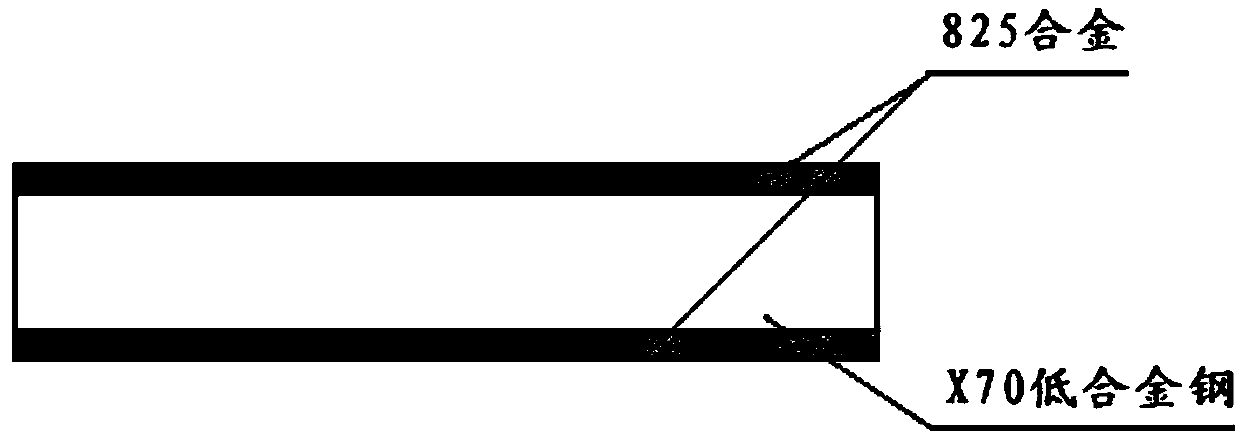

825/X70/825 double-sided clad plate and production method thereof

ActiveCN109693072AImprove structural performanceTaking into account the mechanical properties of the structureMetal layered productsVacuum pumpingReduction rate

The invention discloses an 825 / X70 / 825 double-sided clad plate and a production method thereof. A composite blank for preparing the clad plate includes an X70 low alloy steel base material and an 825alloy composite; the lengths and widths of the base material and composite are the same, the lengths are 2-4 m, the widths are 1-3 m, and the thickness ratio is 2-10; the composite blank can be formedby the composite and base material which are successively stacked and machined according to the sequence of the composite, the base material and the composite, and vacuum electron beam seal welding can be performed on the composite blank after vacuum pumping; and the welded composite blank can be heated to 1,200-1,250 DEG C to perform heat preservation, an initial rolling temperature is 1,180-1,200 DEG C, a single pass reduction rate is greater than or equal to 10%, and the first three pass reduction rates are greater than or equal to 15%, and the total reduction rate is greater than or equalto 75%. The produced clad plate of 5-70 mm is excellent in corrosion resistance on inner and outer sides, excellent in mechanical properties of center parts, and suitable for making requests of highcorrosion resistance for the inner and outer sides and simultaneously considering the pipeline manufacturing of whole structure mechanical properties.

Owner:ANGANG STEEL CO LTD

Method for preparing high-speed steel composite roll for hot rolling

The invention discloses a method for preparing a high-speed steel composite roll for hot rolling. The method is characterized by comprising the following steps of: firstly, manufacturing a regenerated high-speed steel composite roll collar by adopting an electroslag hollow stripping method; melting low-cost nodular cast iron or plain carbon steel by utilizing an intermediate frequency furnace or an electric arc furnace; manufacturing a roll core by a casting method; and fusing the roll outer collar and the roll core together in the manner of casting to prepare the composite roll for the hot rolling, wherein the working roll collar of the composite roll for the hot rolling is made of high-speed steel, and the roll core is made of the nodular cast iron or the plain carbon steel. The high-speed steel composite roll prepared by the method disclosed by the invention has the characteristics that the outer layer thickness is even, the tissue is fine and compact, and the nodular cast iron or the plain carbon steel is adopted to serve as the material of the roll core. The quality of the working face of the roll is comprehensively improved by utilizing the dual action of rare earth treatment and electroslag refining during a process of manufacturing the roll collar, and the service life is long. A roll body and the roll core are respectively made of the nodular cast iron or plain carbon steel, so that the integrated cost is low. The method disclosed by the invention is suitable for manufacturing the high-speed steel composite roll for the hot rolling and can be widely applied in metallurgical industry and renewable resource industry.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Toughened glass insulator and fabrication method thereof

The invention discloses a toughened glass insulator and a fabrication method thereof. The insulator at least can resist lightning steep slope peak 6,000kV / s and can stand repeated circulation impact of -50 to 50 DEG C in a standard load condition, a standard load can be still supported after self explosion at 0 DEG C, the surface pressure stress is not lower than 150Mpa, the impact strength of an U-shaped gap is not lower than 20J / cm<2>, and the light transmittance is not lower than 98%. On the basis that lead glass belonging to toughened glass, lanthanum oxide and bismuth oxide which are used for improving chemical stability and light transmittance of glass are added, zirconium oxide and titanium oxide which are used for improving acid and alkali resistance, light transmittance and radiation protection capability of the glass are also added, and the toughened glass insulator is finally fabricated through tempering under the protection of nitrogen. The toughened glass insulator has the advantages of good electrical property, high automatic fracture toughness, high light transmittance, good integrated mechanical property, long service lifetime and good economy.

Owner:河南新弘电力科技有限公司

Preparation method for magnesium alloy cast paint

InactiveCN101342571AReduced hot cracking tendencyImprove insulation effectFoundry mouldsFoundry coresWrinkle skinBoric acid

The present invention relates to a method for preparing the magnesium casting coating; 0.8 percent paligorskite clay that is configured with 17 percent of water is milled for 3 hours to be made into solution A; secondly 3 percent of talcum powder, 4 percent of diatomite, 0.6 percent of NH4BF4 and 3 percent of boric acid are put into a spherical mill, and is respectively mixed with solution A, 4 percent of silica sol and 67.6 of percent water to be milled for 3 hours to obtain the magnesium alloy metal-typed casting coating; metal mould is heated to be about 200 DEG C, and then is sprayed with a layer of magnesium alloy casting coating on the surface, and is dried finally. The method of the present invention has the advantages of strong heat preservation, flame retardant performance, sticking performance and coating performance, favorable suspension performance and less heat fracture of the casting piece. Oxidation is prevented, so the surface is bright and smooth and is free from oxidized wrinkle.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

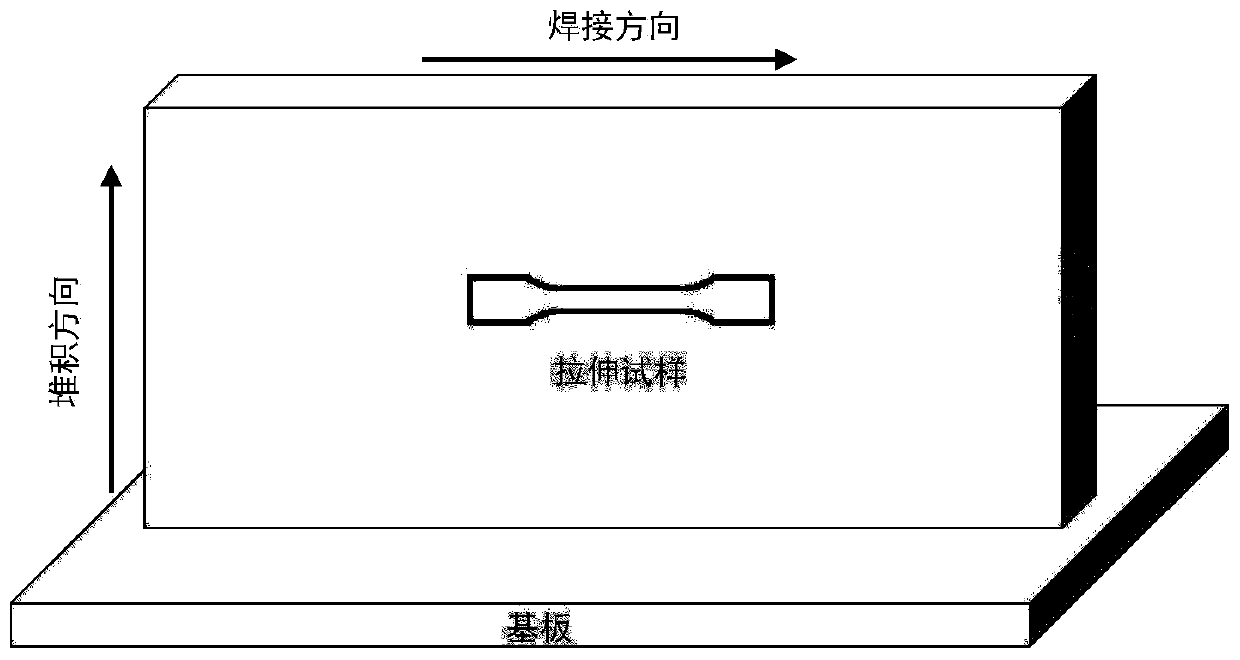

Al-Zn-Mg aluminum alloy welding wire for arc additive manufacturing and preparation method of Al-Zn-Mg aluminum alloy welding wire

ActiveCN111411272AHigh strengthImprove plasticityAdditive manufacturing apparatusUltimate tensile strengthAluminium alloy

The invention discloses an Al-Zn-Mg aluminum alloy welding wire for arc additive manufacturing and a preparation method of the Al-Zn-Mg aluminum alloy welding wire. The welding wire is prepared from Zn, Mg, Al and impurity elements. The welding wire contains the components in percentage by mass as follows: 6.25%-6.75% of Zn, 2.25%-2.75% of Mg and less than 0.2% of the impurity elements, wherein the mass percentage of single impurity element is less than 0.1%. The welding wire can be used for arc additive manufacturing and has high deposit strength.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com