High-strength anti-swing bar

An anti-roll bar, high-strength technology, applied in the field of alloy materials, can solve the problems of insufficient function, easy loss of control of vehicles, rolling of vehicles, etc., and achieves the effects of light weight, reduced impurity content, and reduced hot cracking tendency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

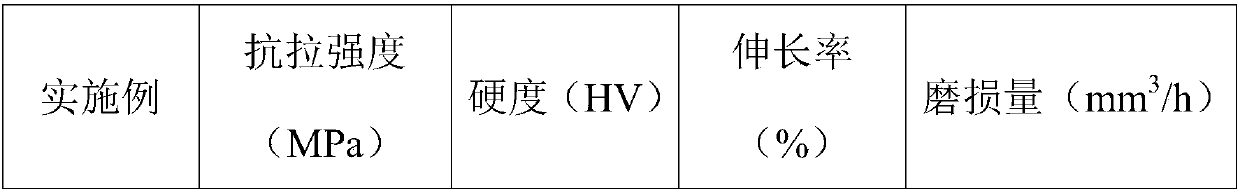

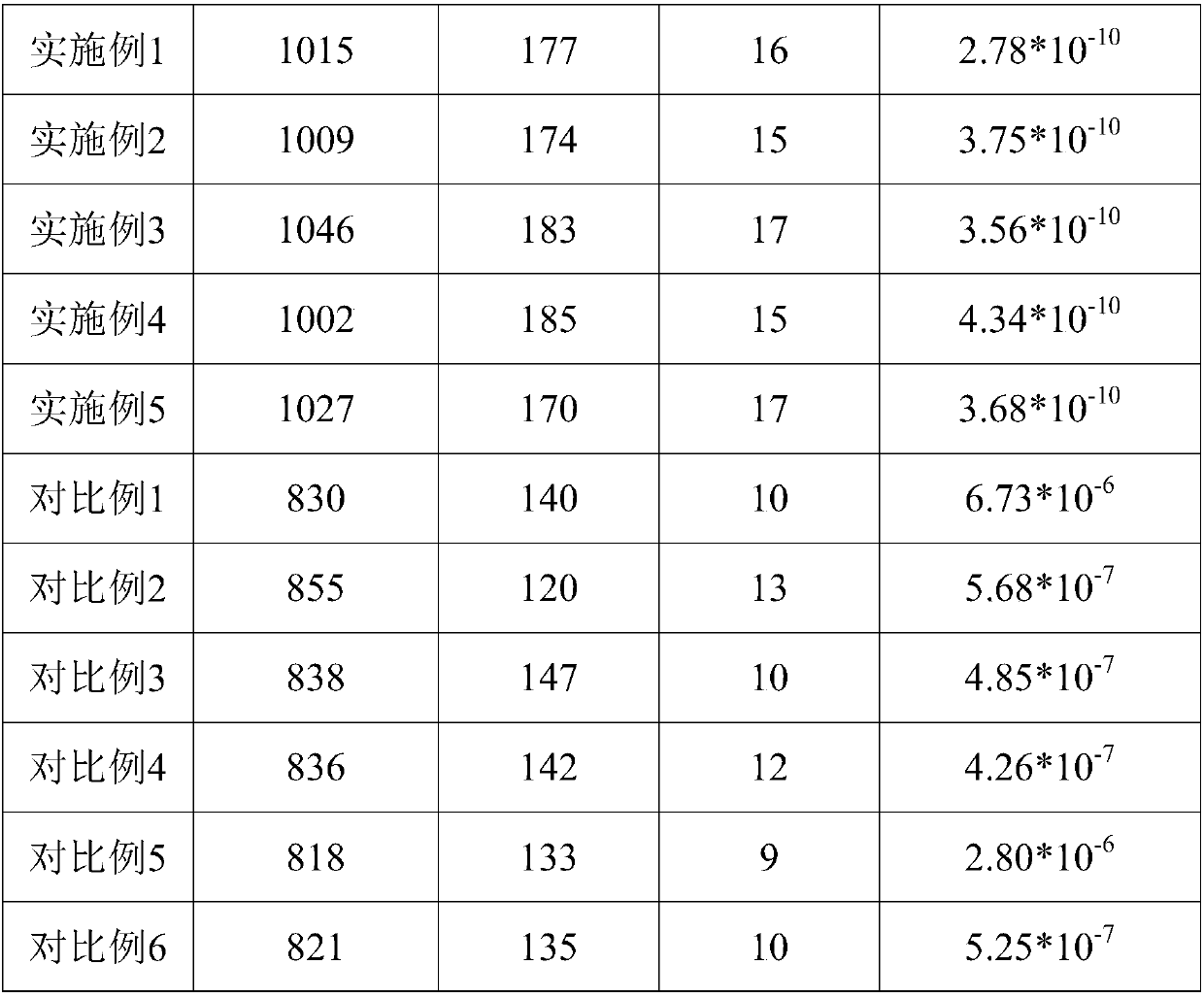

Examples

Embodiment 1

[0024] The aluminum alloy material for preparing the high-strength anti-roll bar is smelted, wherein the composition of the aluminum alloy material is: Si: 11.2%, Mg: 1.0%, Cr: 0.1%, Cu: 0.25%, Mn: 0.15%, Zr: 0.1%, the balance is Al and unavoidable impurity elements; while melting, add a covering agent with a mass of 2% of the aluminum alloy material, and the covering agent includes the following components in mass percentages: 40% KCl, 40% NaCl, 20% Cryolite; with C 2 Cl 6 Stand still for 20 minutes after removing slag and degassing, add K / Na modifier with a mass of 0.5% of aluminum alloy material, and then lower the temperature to cast high-strength anti-roll bar castings; heat-treat high-strength anti-roll bar castings, and modify the anode with rare earth After oxidation treatment and hole sealing treatment, high-strength anti-roll bar products are obtained. The heat treatment includes the following steps: the temperature of short-term uniform treatment is 450°C, and the ...

Embodiment 2

[0026] Melting the aluminum alloy material for preparing the high-strength anti-roll bar, wherein the composition of the aluminum alloy material is: Si: 11.4%, Mg: 1.2%, Cr: 0.13%, Cu: 0.26%, Mn: 0.18%, Zr: 0.15%, the balance is Al and unavoidable impurity elements; while smelting, add a covering agent with a mass of 2.8% of the aluminum alloy material, and the covering agent includes the following components in mass percentages: 43% KCl, 41% NaCl, 16% Cryolite; with C 2 Cl 6 Stand still for 23 minutes after removing slag and degassing, add K / Na modifier with a mass of 0.65% of the aluminum alloy material, and then lower the temperature to cast a high-strength anti-roll bar casting; heat-treat the high-strength anti-roll bar casting, and modify the anode with rare earth The high-strength anti-roll bar product is obtained after oxidation treatment and hole sealing treatment. The heat treatment includes the following steps: the temperature of short-term uniform treatment is 458...

Embodiment 3

[0028] Melting the aluminum alloy material for preparing the high-strength anti-roll bar, wherein the composition of the aluminum alloy material is: Si: 11.5%, Mg: 1.25%, Cr: 0.15%, Cu: 0.28%, Mn: 0.2%, Zr: 0.2%, the balance is Al and unavoidable impurity elements; while smelting, add a covering agent with a mass of 3.5% of the aluminum alloy material, and the covering agent includes the following components in mass percentages: 45% KCl, 40% NaCl, 15% Cryolite; with C 2 Cl 6 Stand still for 25 minutes after removing slag and degassing, add K / Na modifier with a mass of 0.75% of aluminum alloy material, and then lower the temperature to cast high-strength anti-roll bar castings; heat-treat high-strength anti-roll bar castings, and modify the anode with rare earth The high-strength anti-roll bar finished product is obtained after oxidation treatment and hole sealing treatment. The heat treatment includes the following steps: the temperature of short-term uniform treatment is 465...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com