Al-Zn-Mg aluminum alloy welding wire for arc additive manufacturing and preparation method of Al-Zn-Mg aluminum alloy welding wire

An aluminum alloy welding wire and additive manufacturing technology, applied in the direction of additive processing, etc., can solve the problems of large size deviation of welding wire, easy generation of scraping, increased pore content, etc., and achieve small size deviation, small thermal cracking tendency, and excellent plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the Al-Zn-Mg series aluminum alloy welding wire used for arc additive manufacturing according to the present invention comprises the following steps:

[0033] 1) Weighing aluminum ingots, zinc ingots and magnesium ingots, and then treating the surfaces of the aluminum ingots, zinc ingots and magnesium ingots;

[0034] 2) Melting the aluminum ingots, adding zinc ingots and magnesium ingots in turn, stirring and melting, then carrying out chloride refining and rotating argon blowing on the melt, and then removing slag from the melt;

[0035] 3) cooling the melt, and then casting it into an ingot;

[0036] 4) remove the oxide skin on the surface of the ingot, and then carry out homogenization treatment;

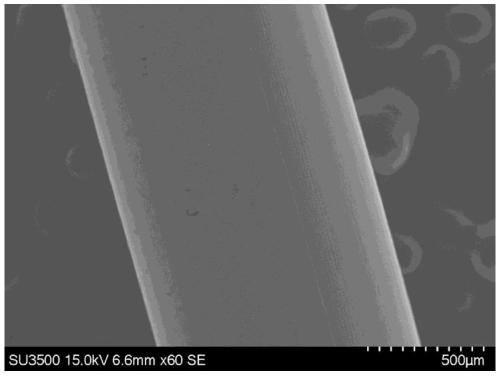

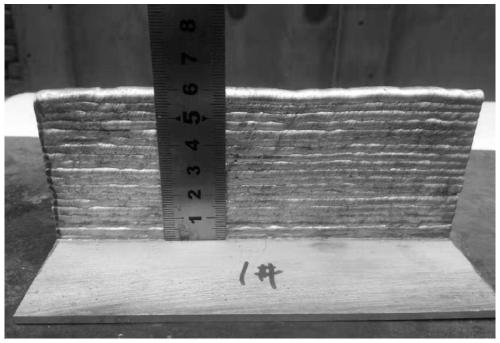

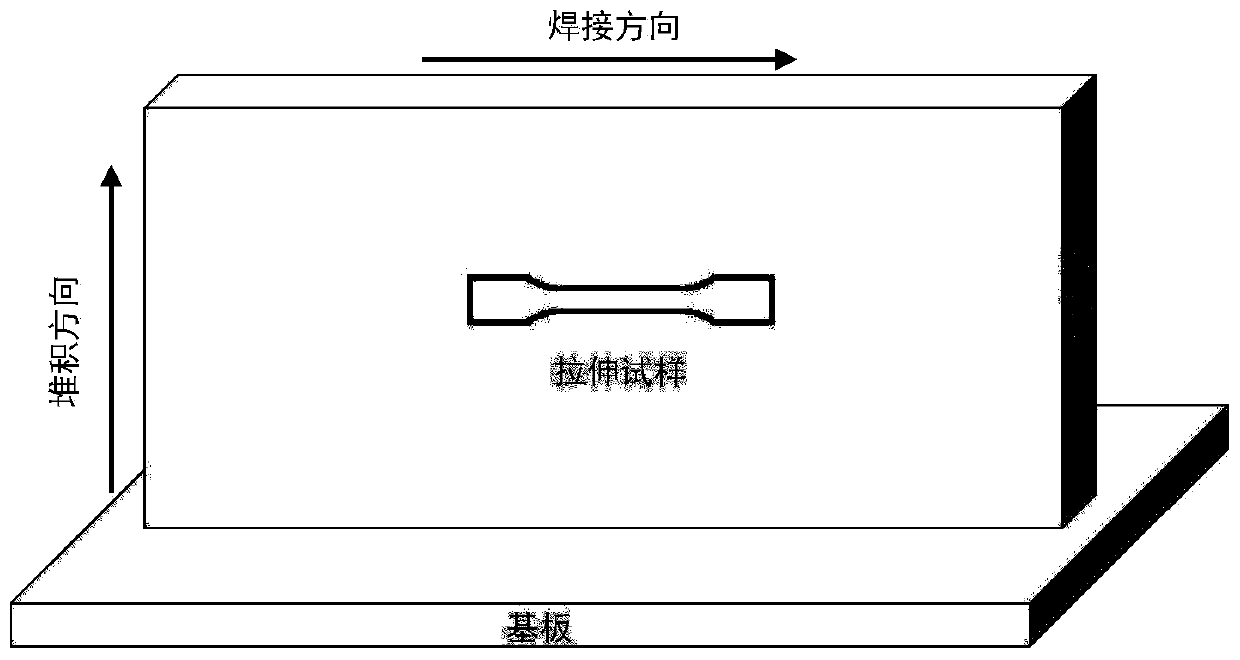

[0037] 5) Extruding, drawing, mechanically scraping and packaging the ingot processed in step 4) in sequence to obtain an Al-Zn-Mg series aluminum alloy welding wire for arc additive manufacturing.

[0038] The specific process of treating the ...

Embodiment 1

[0051] The preparation method of the Al-Zn-Mg series aluminum alloy welding wire used for arc additive manufacturing according to the present invention comprises the following steps:

[0052]1) Weighing aluminum ingots, zinc ingots and magnesium ingots, and then treating the surfaces of the aluminum ingots, zinc ingots and magnesium ingots;

[0053] The specific process of treating the surface of aluminum ingots, zinc ingots and magnesium ingots in step 1) is: sand the surfaces of aluminum ingots, zinc ingots and magnesium ingots with sandpaper, and then clean them with acetone to remove the aluminum ingots, zinc ingots and magnesium ingots. Oil and impurities on the surface of the ingot;

[0054] In step 1), the surfaces of the zinc ingot and the magnesium ingot are treated and wrapped with aluminum foil.

[0055] 2) Melting the aluminum ingots, adding zinc ingots and magnesium ingots in turn, stirring and melting, then carrying out chloride refining and rotating argon blowi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com