Multi-element compounded micro-alloyed Al-Mg-Sc series welding wire and preparation method thereof

A micro-alloying and multi-composite technology, applied in welding equipment, metal processing equipment, welding medium, etc., to achieve the effects of excellent corrosion resistance, strong corrosion resistance, and high joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

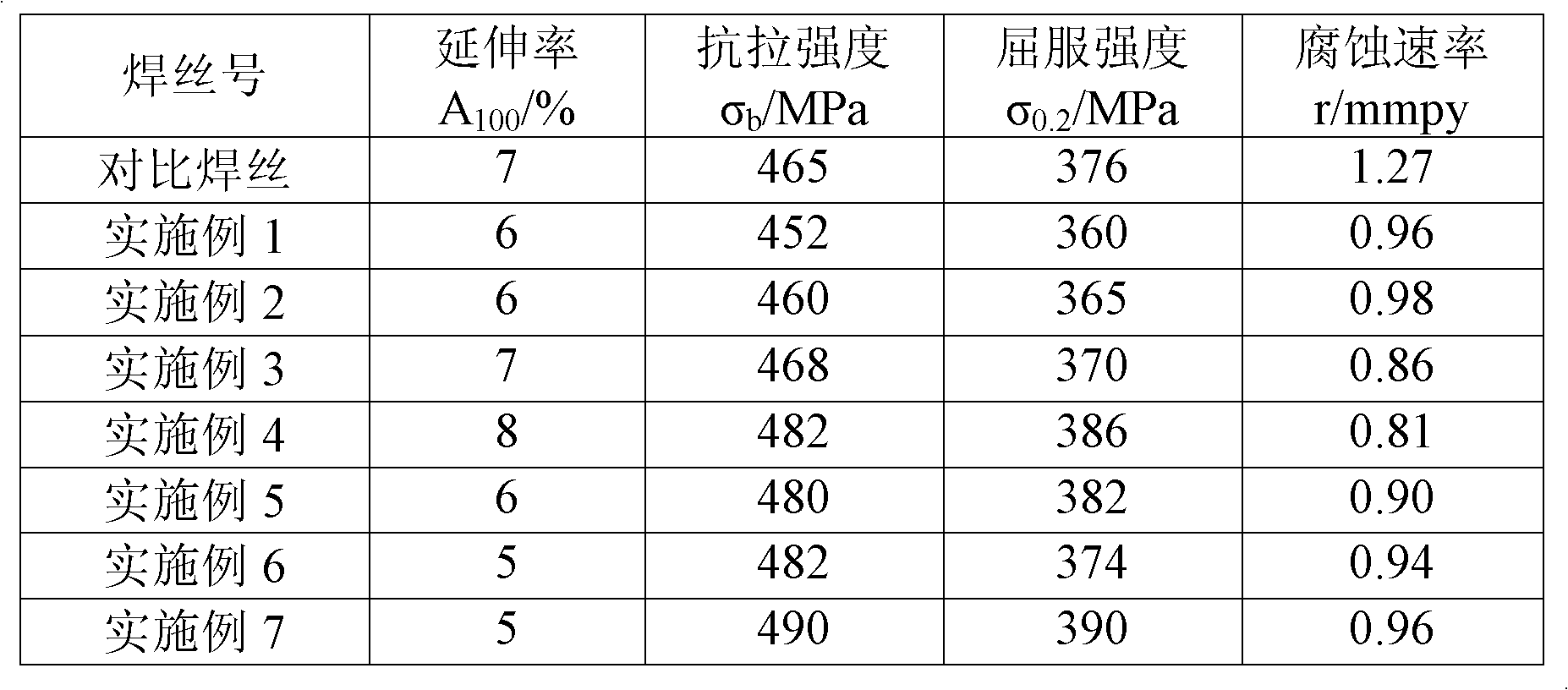

Examples

preparation example Construction

[0027] In the preparation method of the present invention, the processes not specifically described in this specification all adopt conventional processes.

[0028] When welding, according to the selected fusion welding method and its welding specification parameters, manual welding or automatic welding can be used to send the welding wire into the welding pool for welding.

Embodiment 1

[0030] Its main chemical composition (mass percentage) is: magnesium (Mg) 4.5%, manganese (Mn) 0.30%, zirconium (Zr) 0.10%, scandium (Sc) 0.18%, cerium (Ce) + lanthanum (La) 0.25%, The rest is Al and unavoidable impurities. Among them, cerium (Ce) is 60% to 80%, and lanthanum (La) is 40% to 20%.

[0031] (1) Preparation of raw materials: Aluminum (Al) and magnesium (Mg) are added in the form of pure metals, and alloying elements manganese (Mn), scandium (Sc), zirconium (Zr), lanthanum (La) and cerium (Ce) are all added in the form of Al Added in the form of base master alloy, prepared according to mass percentage;

[0032] (2) Alloy smelting: heating and smelting in a resistance furnace, in the covering agent CaF 2 +MgCl 2 +CaCl 2 Melting and furnace body purification are carried out under the protection of the furnace, and cast into Alloy ingot, wherein the melting temperature is 760°C, the pouring temperature is 730°C, and the content of hydrogen in the alloy is controll...

Embodiment 2

[0036] Its main chemical composition (mass percentage) is: magnesium (Mg) 5.0%, manganese (Mn) 0.40%, zirconium (Zr) 0.15%, scandium (Sc) 0.25%, cerium (Ce) + lanthanum (La) 0.28%, The rest is Al and unavoidable impurities. Among them, cerium (Ce) is 60% to 80%, and lanthanum (La) is 40% to 20%.

[0037] (1) Preparation of raw materials: Aluminum (Al) and magnesium (Mg) are added in the form of pure metals, and alloying elements manganese (Mn), scandium (Sc), zirconium (Zr), lanthanum (La) and cerium (Ce) are all added in the form of Al Added in the form of base master alloy, prepared according to mass percentage;

[0038] (2) Alloy smelting: heating and smelting in a resistance furnace, in the covering agent CaF 2 +MgCl 2 +CaCl 2 Melting and furnace body purification are carried out under the protection of the furnace, and cast into Alloy ingots, where the melting temperature is set at 780°C, the pouring temperature is 720°C, and the content of hydrogen in the alloy is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com