Al-Zn-Mg-Cu-Sc-Zr-RE alloy capable of being used as ultrahigh-strength cast aluminum alloy and preparation method thereof

A technology of casting aluminum alloy and ultra-high strength, which is applied in the field of high-performance casting aluminum alloy material and its processing, can solve the problems such as the ultimate tensile strength is difficult to exceed 500MPa, the process is difficult to achieve, and the strength and toughness are insufficient, so as to change the solidification of the alloy. mode, the effect of suppressing dendrite growth and improving flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

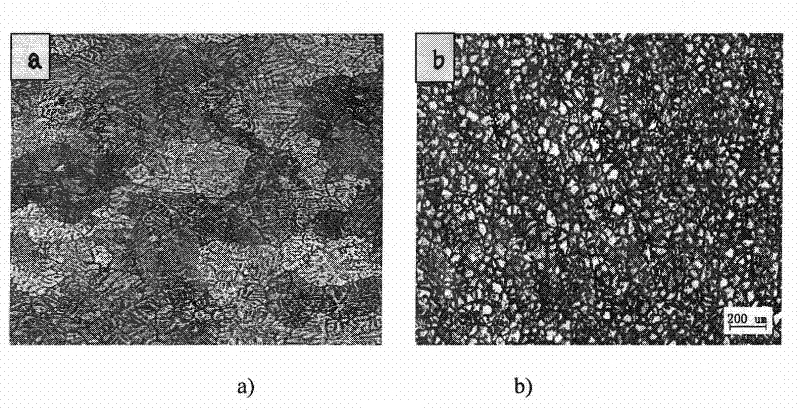

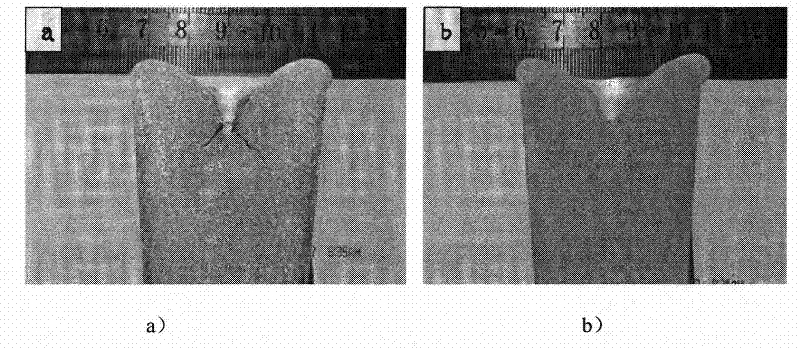

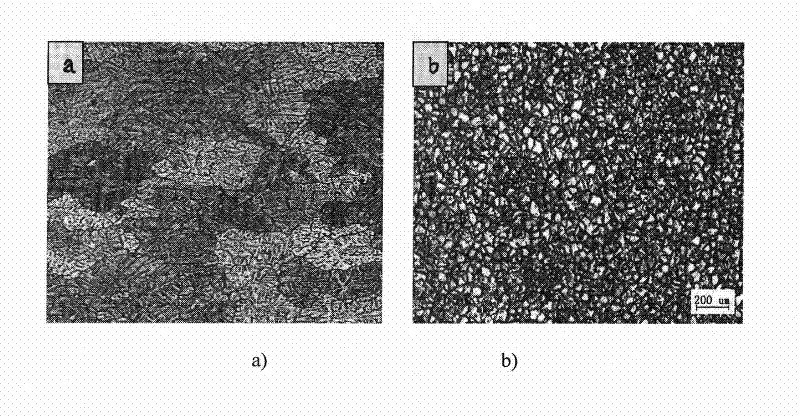

Image

Examples

Embodiment 1

[0031] Al-Zn-Mg-Cu-Mn-Sc-Zr-RE alloy, its chemical composition (wt.%) is: zinc (Zn) 7.2, magnesium (Mg) 1.7, copper (Cu) 1.6, manganese (Mn) 0.3 , zirconium (Zr) 0.15, scandium (Sc) 0.21, erbium (Er) 0.15, aluminum (Al) balance.

Embodiment 2

[0033] Al-Zn-Mg-Cu-Mn-Sc-Zr-RE alloy, its chemical composition (wt.%) is: zinc (Zn) 7.5, magnesium (Mg) 2.1, copper (Cu) 1.8, manganese (Mn) 0.4 , zirconium (Zr) 0.14, scandium (Sc) 0.19, yttrium (Yb) 0.15, aluminum (Al) balance

Embodiment 3

[0035] Al-Zn-Mg-Cu-Mn-Sc-Zr-RE alloy, its chemical composition (wt.%) is: zinc (Zn) 7.9, magnesium (Mg) 2.4, copper (Cu) 1.9, manganese (Mn) 0.3 , zirconium (Zr) 0.18, scandium (Sc) 0.20, erbium (Er) 0.10, yttrium (Yb) 0.10, aluminum (Al) balance

[0036] preparation:

[0037] (1) Raw material preparation: aluminum (Al), magnesium (Mg) and zinc (Zn) are added in the form of pure metal, and the alloying element manganese

[0038] (Mn), scandium (Sc), zirconium (Zr), erbium (Er) and yttrium (Yb) are all added in the form of Al-based master alloy;

[0039] (2) Alloy smelting: use resistance furnace and graphite crucible, and add the metal materials (pure aluminum and its intermediate alloys Al-10Mn, Al-2Sc, Al-4Zr, Al-10Er and Al-10Yb) after most of them are melted Covering agent (50% KCl+40% MgCl 2 +10%CaF 2 ), after the alloy material is completely melted, keep stirring, metal magnesium and zinc are covered with aluminum foil and finally pressed in; in order to fully melt t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com