Amorphous inoculant for high chromium cast iron and its preparation method and use method

A high-chromium cast iron and inoculant technology, applied in the field of cast iron alloys, can solve problems such as the strength, toughness, and splitting that are unfavorable to high-chromium cast iron alloys, and achieve the effects of reducing the solidification temperature range, improving fluidity, and increasing nucleation cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Type 1 amorphous inoculant is prepared according to the following elements and weight percentages:

[0029] Re of 21, Si of 44, Ti of 2.0, B of 0.1, Cr of 0.6, the balance of Fe; or: 22 of Re, Si of 42, Ti of 1.0, B of 0.05, Cu of 0.5, the balance of Fe ; Or: 24 Re, 40 Si, 0.05 Ti, 0.2 Cr, 0.1 Cu, and the balance Fe.

[0030] The preparation method of type 1 amorphous inoculant: put the raw materials of the above-mentioned elements of type 1 with a particle size of 2-8 mm into the water-cooled copper crucible of the vacuum quenching furnace, and adjust the position of the electrode so that it is between the raw material alloy particles in the crucible The distance is 0.5 ~ 1.5mm, close the furnace door, inlet and outlet and air release valve, vacuumize to 3-4 × 10-3Pa and then fill with protective gas argon, the pressure in the vacuum quenching furnace is kept at -0.04 ~ - It can be within the range of 0.06Pa. After the arc is started, the arc current is adjusted to g...

Embodiment 2

[0036] Type 2 amorphous inoculants are prepared according to the following elements and weight percentages:

[0037] Re of 24.7, Si of 43, Ti of 2.0, B of 0.2, Cr of 0.6, the balance of Fe; or: Re of 26, Si of 41, Ti of 1.0, B of 0.1, Cu of 0.5, the balance of Fe ; Or: 27 Re, 39 Si, 0.05 Ti, 0.2 Cr, 0.1 Cu, and the balance Fe.

[0038] The preparation method and use method of the type 2 amorphous inoculant are the same as in Example 1.

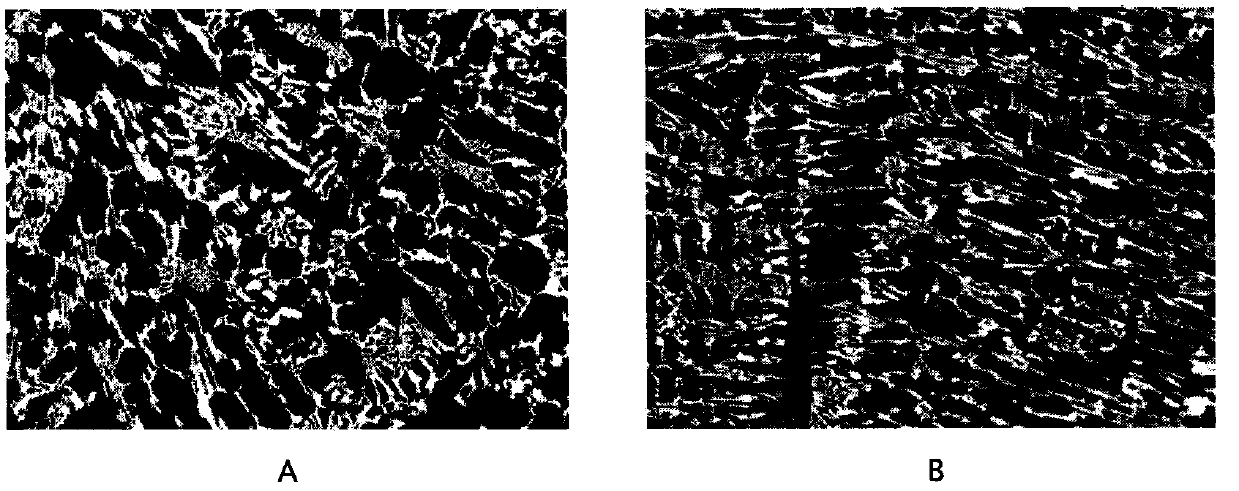

[0039] figure 2 A is the metallographic diagram of BTMCr12-GT high-chromium cast iron without adding type 2 amorphous inoculant, the relative amount of matrix: 69.52%, and the distance between dendrites: 46.62 μm.

[0040] figure 2 B is the metallographic diagram of BTMCr12-GT high-chromium cast iron added with Type 2 amorphous inoculant (the first combination), the relative amount of matrix: 83.67%, and the distance between dendrites: 23.34 μm.

Embodiment 3

[0042] Type 3 amorphous inoculants are prepared according to the following elements and weight percentages:

[0043] Re of 27, Si of 42, Ti of 2.0, B of 0.3, Cr of 0.6, the balance of Fe; or: Re of 28, Si of 40, Ti of 1.0, B of 0.15, Cu of 0.5, the balance of Fe ; Or: 30 of Re, 38 of Si, 0.05 of Ti, 0.2 of Cr, 0.1 of Cu, and the balance of Fe.

[0044] The preparation method and usage method of Type 3 amorphous inoculant are the same as those in Example 1.

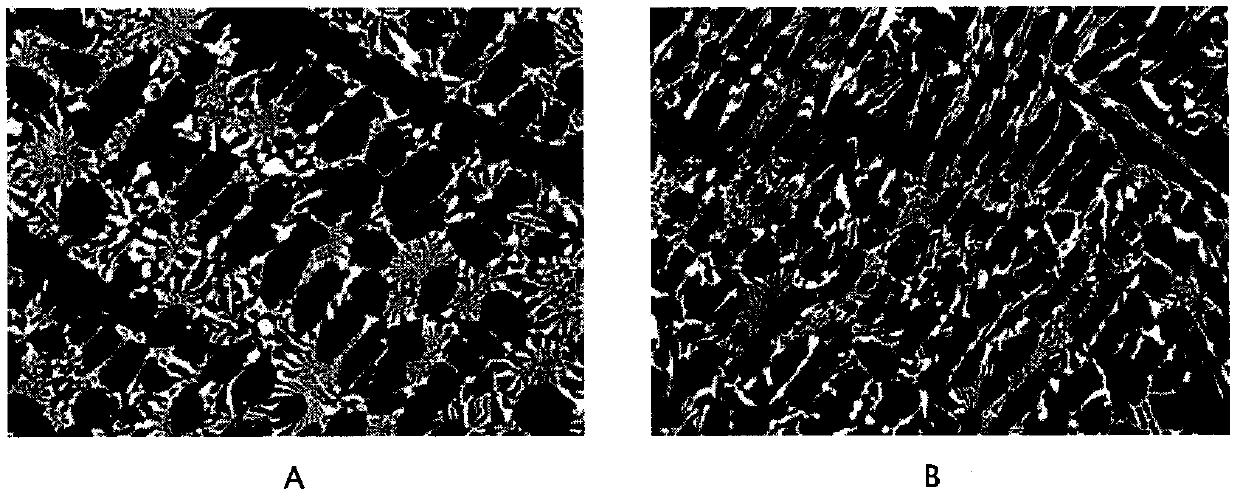

[0045] image 3 A is the metallographic diagram of BTMCr12-GT high-chromium cast iron without adding type 3 amorphous inoculant, the relative amount of matrix: 76.38%, and the distance between dendrites: 58.44 μm.

[0046] image 3 B is the metallographic diagram of BTMCr12-GT high chromium cast iron added with type 3 amorphous inoculant (the second combination), the relative amount of the matrix: 79.70%, and the distance between dendrites: 34.09 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com