Ultra-fine grain aluminum alloy gold welding wire and preparation method thereof

A kind of aluminum alloy welding wire, ultra-fine grain technology, applied in welding equipment, metal processing equipment, welding medium and other directions, to achieve the effect of refining grain, reducing low strength and improving welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The composition of the ultra-fine grain aluminum alloy welding wire in this example is: 0.05% Sc, 0.05% Er, 0.6% mixed rare earth, 0.15% B, 0.2% Ti, 0.15% Cr, 0.15% Zr, 0.25% Mn, 0.3% Zn , 5.8% Mg, the rest is Al, as a component of rare earth composite microalloy welding wire, which is characterized by mixed rare earth, and the aluminum alloy welding wire is designed by using the characteristics of mixed rare earth.

[0030]The preparation process is as follows: firstly, according to the mass percentages of the above-mentioned components, combined with the total amount of aluminum alloy to be prepared, calculate the amount of each single-component element required, prepare the alloy ingredient list, and prepare materials according to the ingredient list. Add an appropriate amount of aluminum ingot or molten aluminum into the semi-closed reverberatory furnace according to the ingredient list, and heat to melt at 780°C. According to the ingredient list, add appropriate am...

Embodiment 2

[0032] In this example, the composition of the ultra-fine grained aluminum alloy welding wire is: 0.2%Sc, 0.1%Er, 0.01% mixed rare earth, 0.1%B, 0.1%Ti, 0.15%Cr, 0.2%Zr, 0.25%Mn, 0.2%Zn , 5% Mg, and the rest is Al, as a component of rare earth composite microalloy welding wire, which is characterized by mixed rare earths, and the aluminum alloy welding wire is designed by using the characteristics of mixed rare earths.

[0033] The preparation process is as follows: firstly, according to the mass percentages of the above-mentioned components, combined with the total amount of aluminum alloy to be prepared, calculate the amount of each single-component element required, prepare the alloy ingredient list, and prepare materials according to the ingredient list. Add an appropriate amount of aluminum ingots or molten aluminum into a semi-closed reverberatory furnace according to the ingredient list, and heat and melt at 760°C. According to the ingredient list, add appropriate amoun...

Embodiment 3

[0035] The base material for welding is a 7A52 aluminum alloy plate that has undergone solution-aging treatment. The size of the test plate is 15mm×200mm×300mm. The groove of the test plate is a 45°V-shaped groove. The prepared welding wire is welded thereto respectively. The welding process is shown in Table 1.

[0036] Table 1 welding process parameters

[0037]

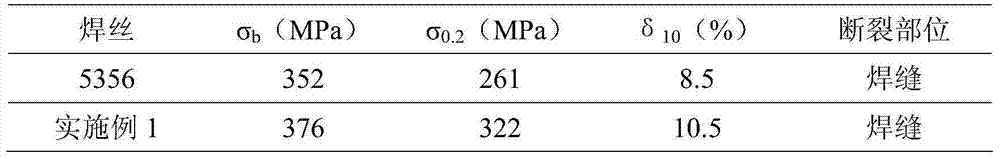

[0038] According to the national standard, the welded joints are processed into tensile specimens, and the tensile mechanical properties are tested with an electronic tensile machine to determine the strength coefficient of the welded joints. The mechanical properties of the welded joints after welding are shown in Table 2. It can be seen from Table 2 that under the same conditions, the welding wire prepared in Example 1 has improved performance of the welded joint of 7A52 high-strength aluminum alloy compared with the commonly used 5356 welding wire, in which the tensile strength is increased by 6.8%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com