Preparation device and method of aluminum alloy ingot with ultra-large dimension

An aluminum alloy casting ingot, super-large-sized technology, applied in the field of metal material processing, can solve the problems of electromagnetic field intensity attenuation, low utilization rate of electromagnetic field, poor stirring effect at the core of the melt, etc., to achieve uniform temperature field and composition field, reduce Homogenization and processing costs, the effect of fine and uniform coagulation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

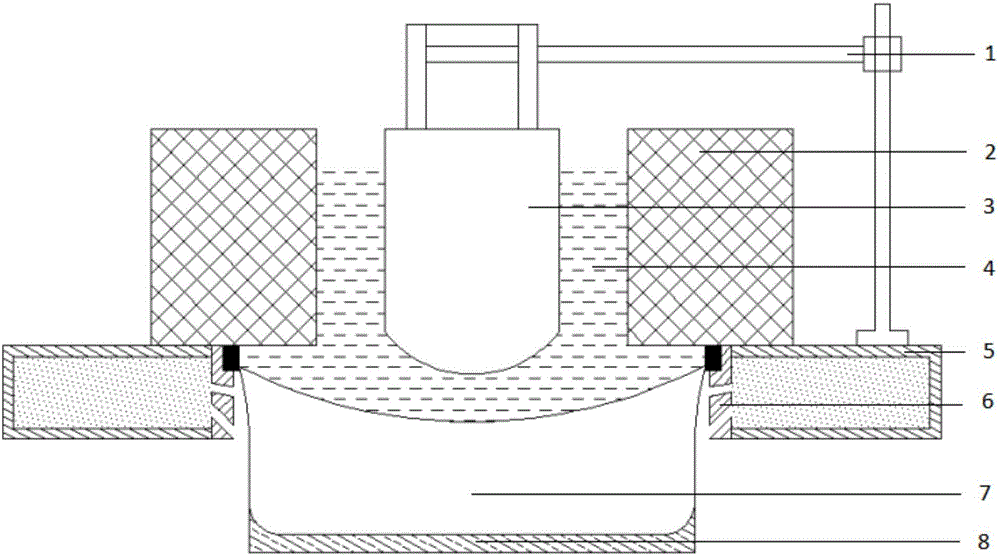

[0047] A large-scale aluminum processing enterprise produces 7005 aluminum alloy ingots with a specification of Φ788mm. It has strict requirements on the quality of the ingots: feathery grains, cracks, pores, and white spots are not allowed; porosity does not exceed 2 levels; bright grains do not exceed 10 points , each point ≤ 3mm; grain size lower than grade 2; slag inclusion: outer diameter ≤ 750mm requires no more than 2 points, single point area ≤ 0.3 square millimeters, outer diameter > 750mm requires no more than 4 points, single point Area ≤ 0.2 square millimeters.

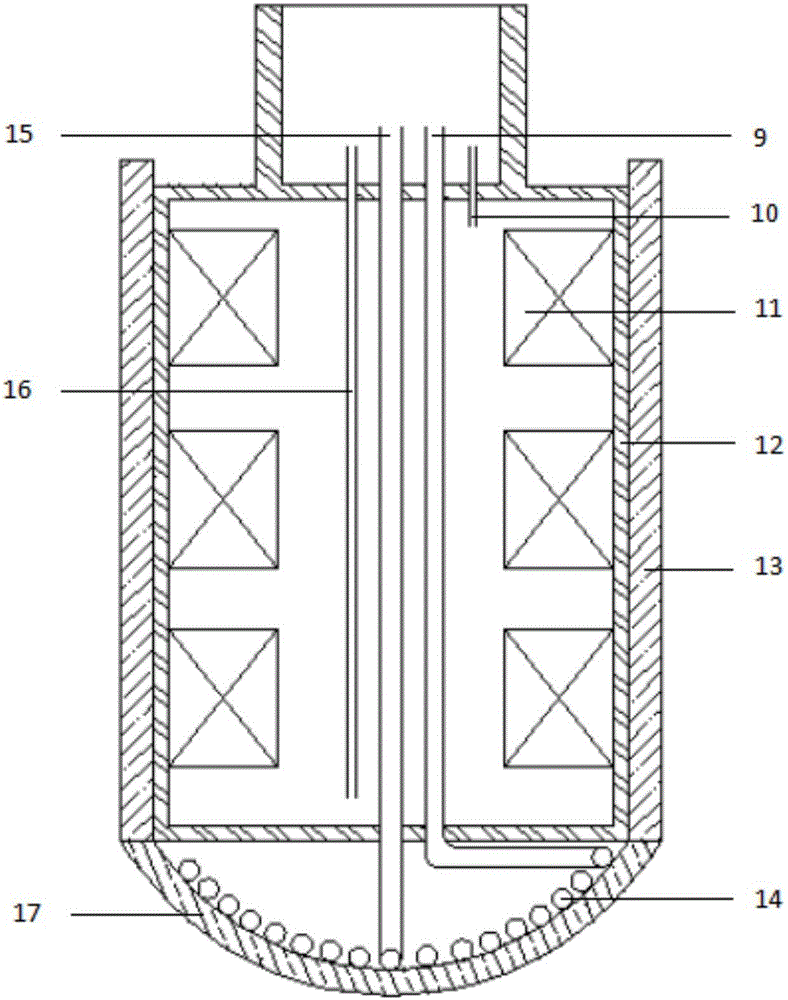

[0048] Adopt the 7005 aluminum alloy casting ingot produced by the present invention, the device structure parameter is: heat preservation unit 13 material is ceramic material, and wall thickness is 30mm; The material of support unit 12 is stainless steel, and external dimension is Φ300mm; The high thermal conductivity housing 17 of cooling unit The material is dispersed copper alloy, and the bottom hollow...

Embodiment 2

[0053] A large-scale aluminum processing enterprise prepares 5052 aluminum alloy flat ingots with specifications of 560mm×2240mm. It is required that there are no cracks, pores and inclusions inside the ingot; Grade II, and the lateral and longitudinal grain size deviation does not exceed 15%; the height of segregation nodules is less than 4mm.

[0054] The 5052 aluminum alloy flat ingot produced by the present invention has the structural parameters of the device: the heat preservation unit 13 is made of high-temperature ceramics with a thickness of 40 mm; the support unit 12 is made of stainless steel with an outer dimension of Φ200 mm; Copper alloy, the bottom hollow tube 14 is made of pure copper; two melt processors 3 are arranged equidistantly inside the hot top 2 and the crystallizer 6, and the center distance is 700mm. The bottom end of the high thermal conductivity shell 17 is flush with the bottom end of the crystallizer 6 . The ampere-turns of the electromagnetic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com