Silicon carbide foam ceramic solar energy air heat-absorbing device

A technology of foam ceramics and silicon carbide, which is applied in the field of silicon carbide foam ceramic solar air heat absorbers, can solve the problems of limited high temperature use, complex structure, poor air flow stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

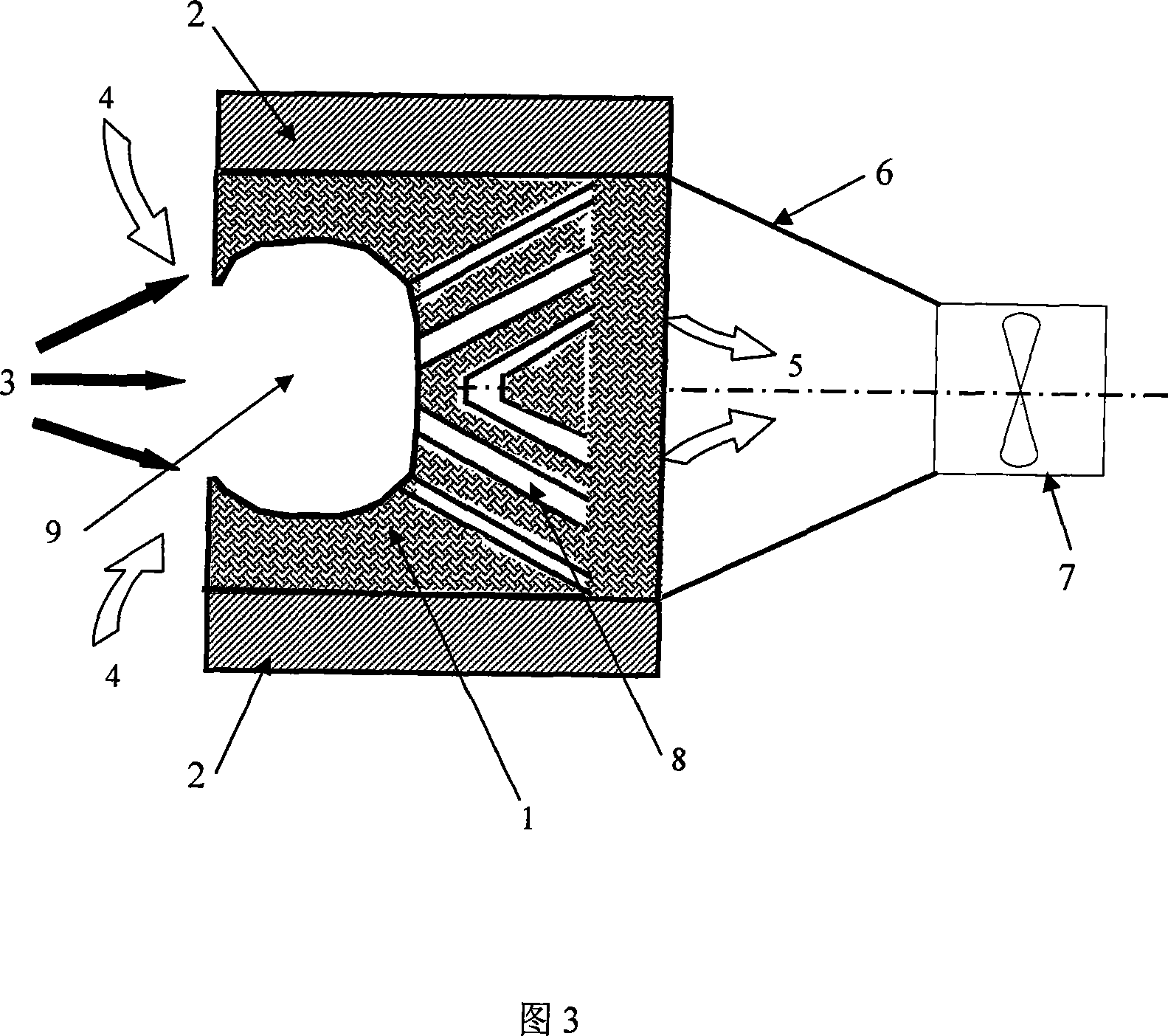

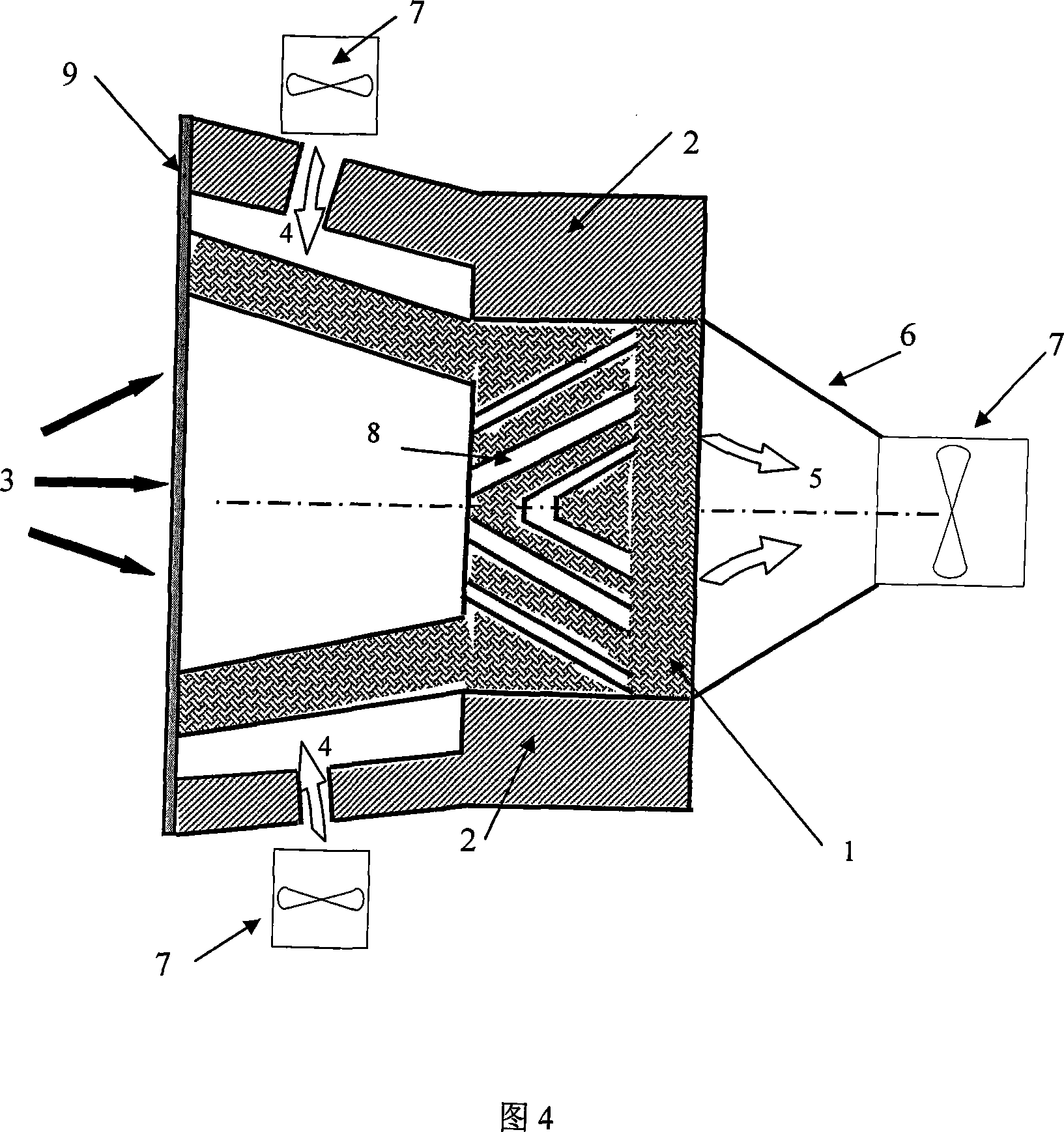

[0018] The invention has two external light-receiving modes of surface type and artificial black body type, and two sealing cavity modes of forward flow and reverse flow.

[0019]Fig. 2 shows the structure of the surface type silicon carbide foam ceramic solar air heat absorber of the present invention. The silicon carbide foam ceramic receiver 1 is covered with an insulating layer 2, the silicon carbide foam ceramic receiver 1 is sealed and connected with the flow guide device 6, the flow guide device 6 is sealed and connected with the fan 7, and the silicon carbide foam ceramic receiver 1 is on the radiation receiving side The air diversion channel 8 is pre-embedded, and its structure is an inclined cylindrical hole, a straight cylindrical hole or a combination of the two. The size and hole structure are determined by the air flow field parameters and the distribution of input radiation. The principle is that both The air at different temperatures can be fully mixed and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com