Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Small kerf" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

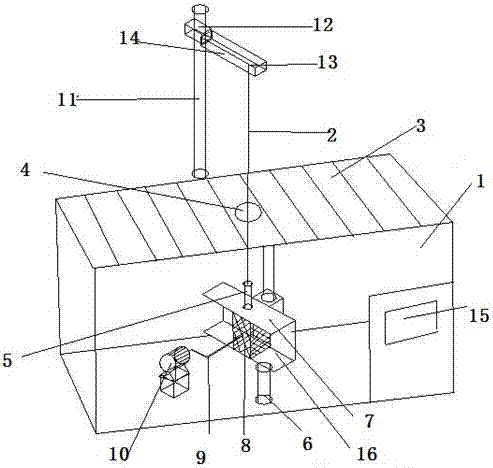

Method and device for cutting transparent material by using ultra-short pulse laser

ActiveCN102785031AAccelerateSmall kerfFine working devicesGlass severing apparatusMaterial consumptionTransfer procedure

The invention provides a method for cutting a transparent material by using ultra-short pulse laser. The ultra-short pulse laser output by an ultra-short pulse laser generating device is condensed by a condensation device so as to form a bunching laser beam; the bunching laser beam enters from the surface of the transparent material to be machined, so that the center refractive index at a laser application point is increased to form a waveguide structure along a laser emitting direction; the laser is transmitted to the inside of the transparent material along the waveguide structure, and continuously generates a waveguide structure along the laser emitting direction in a transmission process until the entire waveguide structure and the laser penetrate through the transparent material; and therefore, the laser moves in a direction which is vertical to the surface of the transparent material at uniform speed, so that a waveguide plane is formed in the transparent material. The invention further provides a device for cutting the transparent material by using the ultra-short pulse laser. The method and the device for cutting the transparent material by using the ultra-short pulse laser provided by the invention have the advantages of fast cutting speed, small cutting seam, no material consumption and no powder pollution. When the machined material bears a suitable external force, the material is cracked only along a stress fault surface; the broken surface nearly has no conical degree; and the roughness is good.

Owner:WUHAN JUNNO TECH

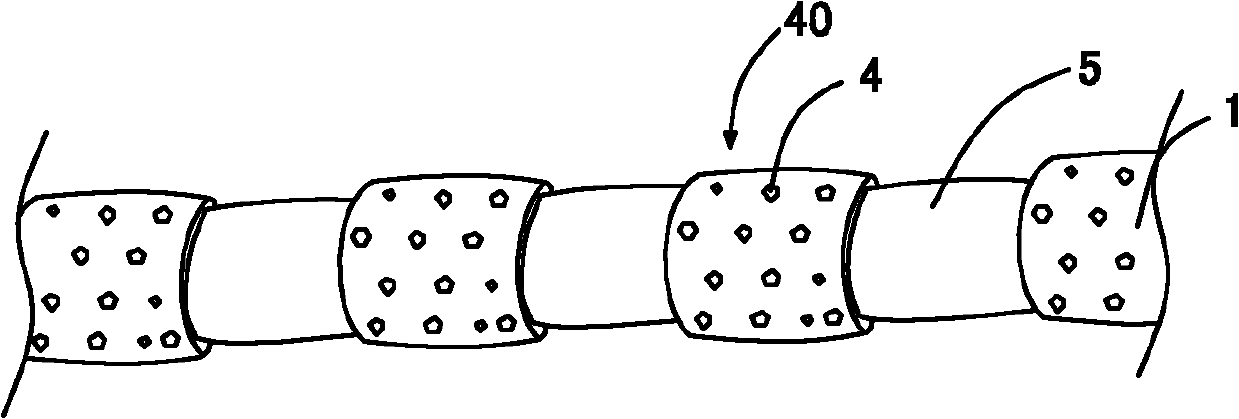

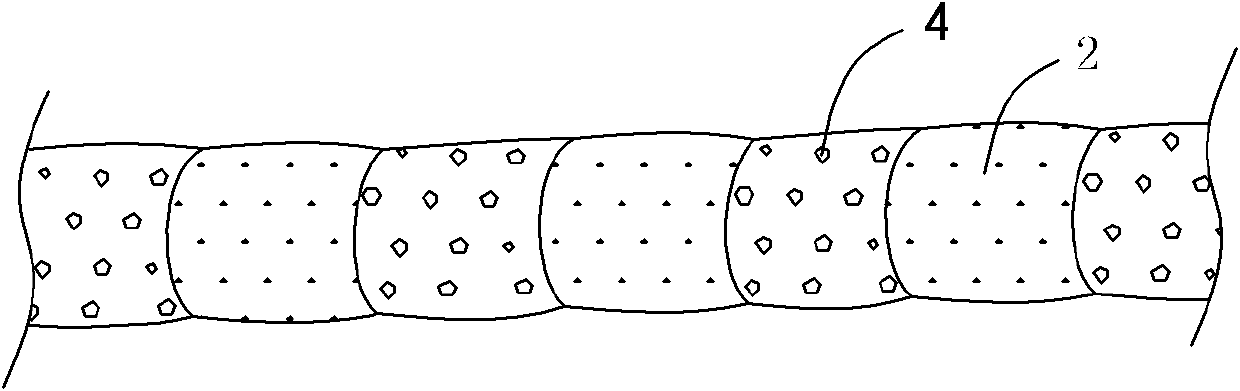

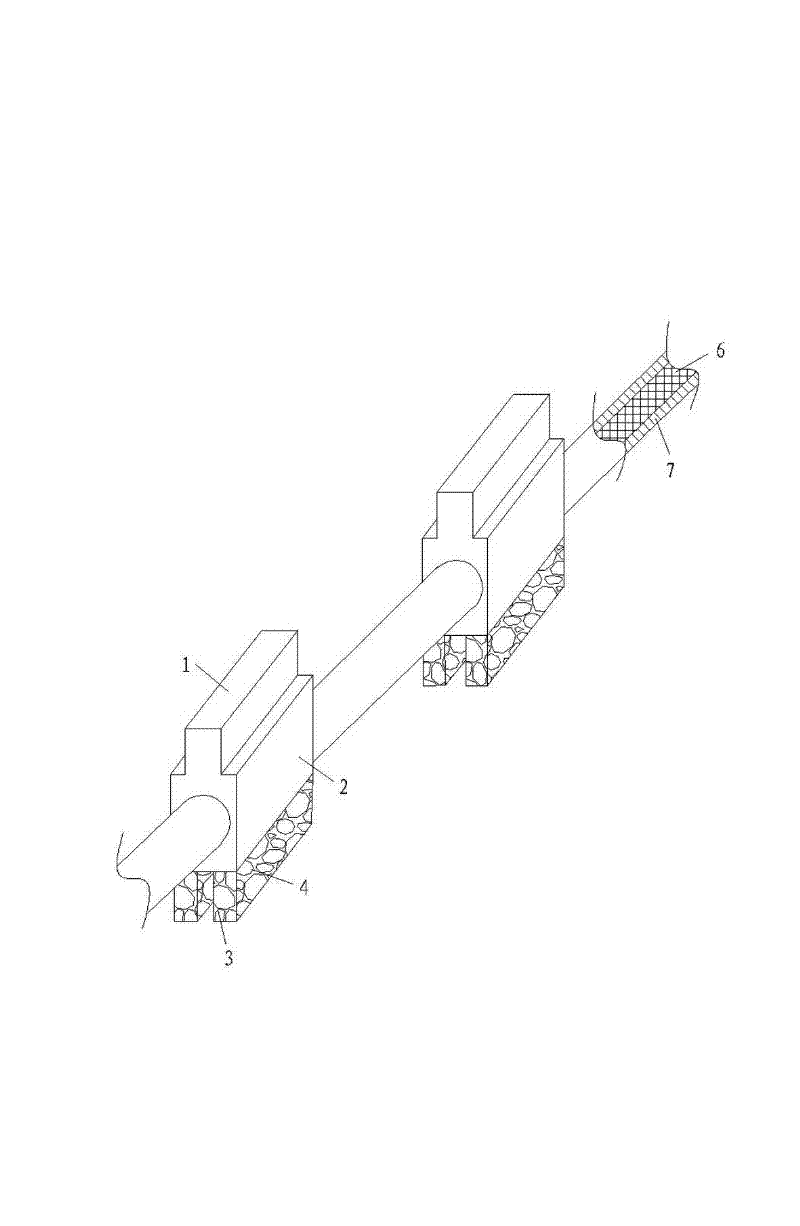

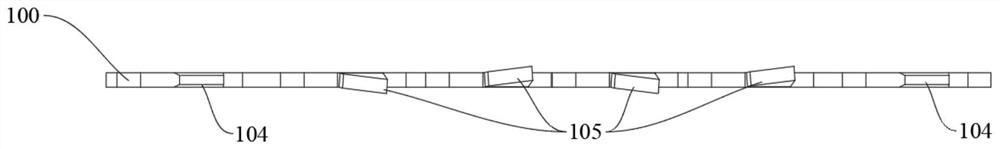

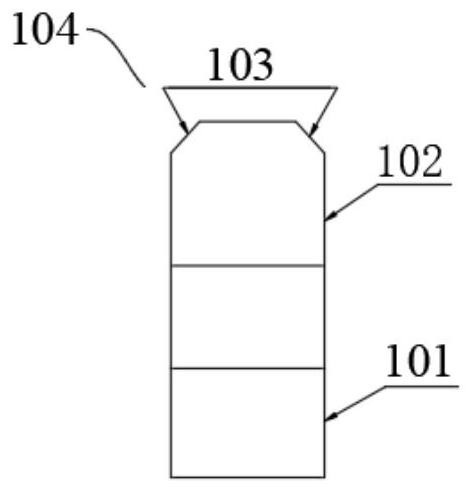

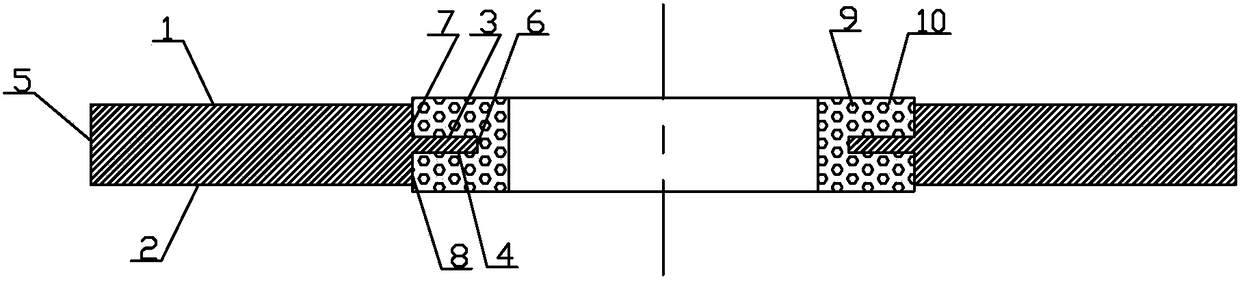

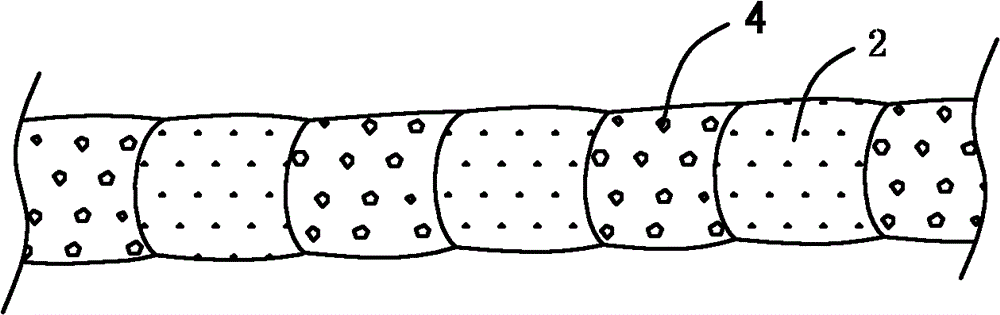

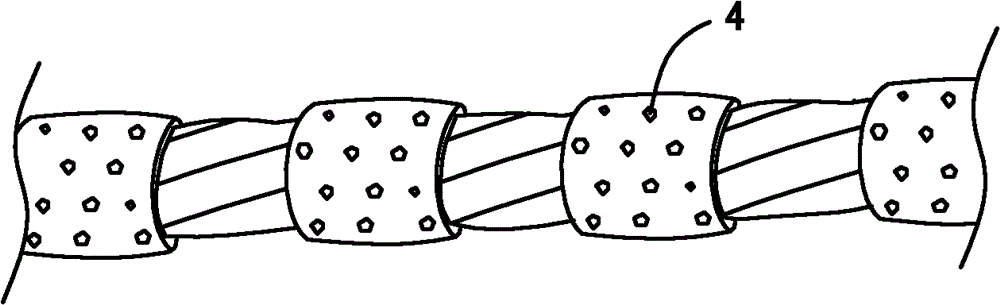

Diamond bead string and manufacturing method thereof as well as rope saw without base body supporting layer

ActiveCN102825254AReasonable ratioSmall kerfMetal sawing toolsStone-like material working toolsHot pressWire rope

The invention discloses a diamond bead string and a manufacturing method thereof as well as a diamond bead string rope saw without a base body supporting layer. The manufacturing method of the diamond bead string comprises the following steps of: uniformly mixing metal powder, diamond and an organic binding agent; manufacturing a rough blank of the diamond bead string through a pre-hot-pressing modeling or metal injection molding (MIM) process; and obtaining a finished product of the diamond bead string by placing the rough blank in a high-temperature furnace for one-step sintering modeling process after degreasing. The manufacturing method of the diamond bead string provided by the invention can be used for sintering the rough blank in one step to form an entire cylindrical bead string without a bead string base body layer; the external diameter of the bead string becomes smaller, so that the bead string can be directly stringed into a steel wire rope to obtain a diamond rope saw with a smaller external diameter; the bead string is molded through one step without a last-stage permeation process, so that the production cost of the diamond bead string is greatly reduced. Furthermore, the diameter of the diamond rope saw is smaller, and a cutting seam of a stone material to be cut is smaller, so that the yield of rough stone block is improved. The manufacturing method of the diamond bead string is beneficial to large-range popularization and utilization of the diamond rope saw.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

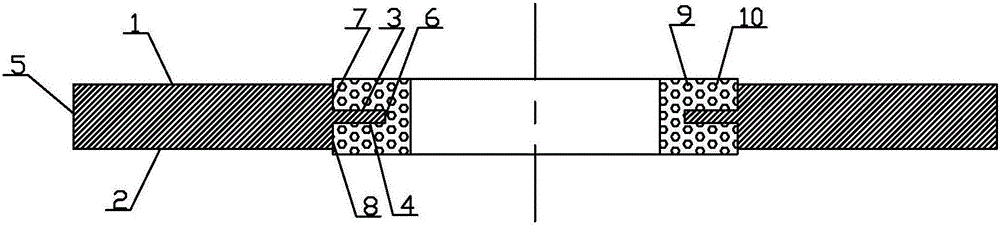

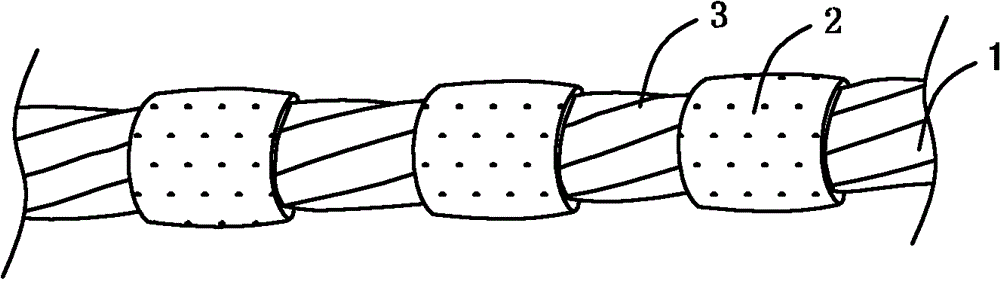

Diamond wire saw and manufacturing method thereof

ActiveCN101905491APrevent infiltrationGuaranteed softnessGrinding devicesFine working devicesDiamond wire sawPlastic materials

The invention discloses a diamond wire saw and a preparation method thereof. The diamond wire saw comprises a bending-resistant flexible multi-strand rope. The preparation method comprises the following steps: a, removing oil from the surface of the flexible multi-strand rope and coating high-temperature resistant inorganic glue onto the flexible multi-strand rope at intervals, so as to form an isolated coating layer after the glue is cured; b, adding metal soldering materials into the organic glue to prepare a pastry mixture; c, coating or impregnating the pastry metal soldering materials onto the spaced parts of the flexible multi-strand rope, and then spreading diamond abrasive particles onto the rope; spraying or cold-pressing a layer of metal soldering materials onto the surface of the rope after the organic glue is cured; d, putting the obtained flexible multi-strand rope into a vacuum brazing furnace for sintering, taking the rope out of the furnace and then removing the inorganic glue; after heat treatment, coating a layer of rubber-plastic material protection layer onto the spaced parts of the flexible multi-strand rope; after the glue is cured, obtaining the diamond wire saw. The diamond wire saw can effectively prevent a braze-welding material from entering into gaps of the flexible multi-strand rope so as to solve the problem that the conventional diamond wire saw manufactured by taking the flexible multi-strand rope as a centre line is too inflexible and is entirely unusable.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

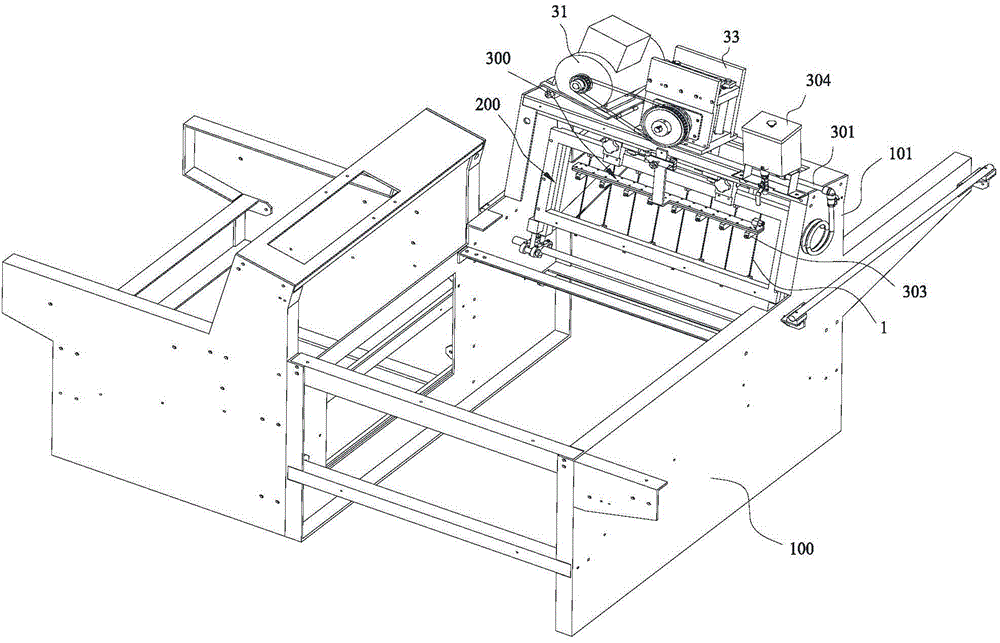

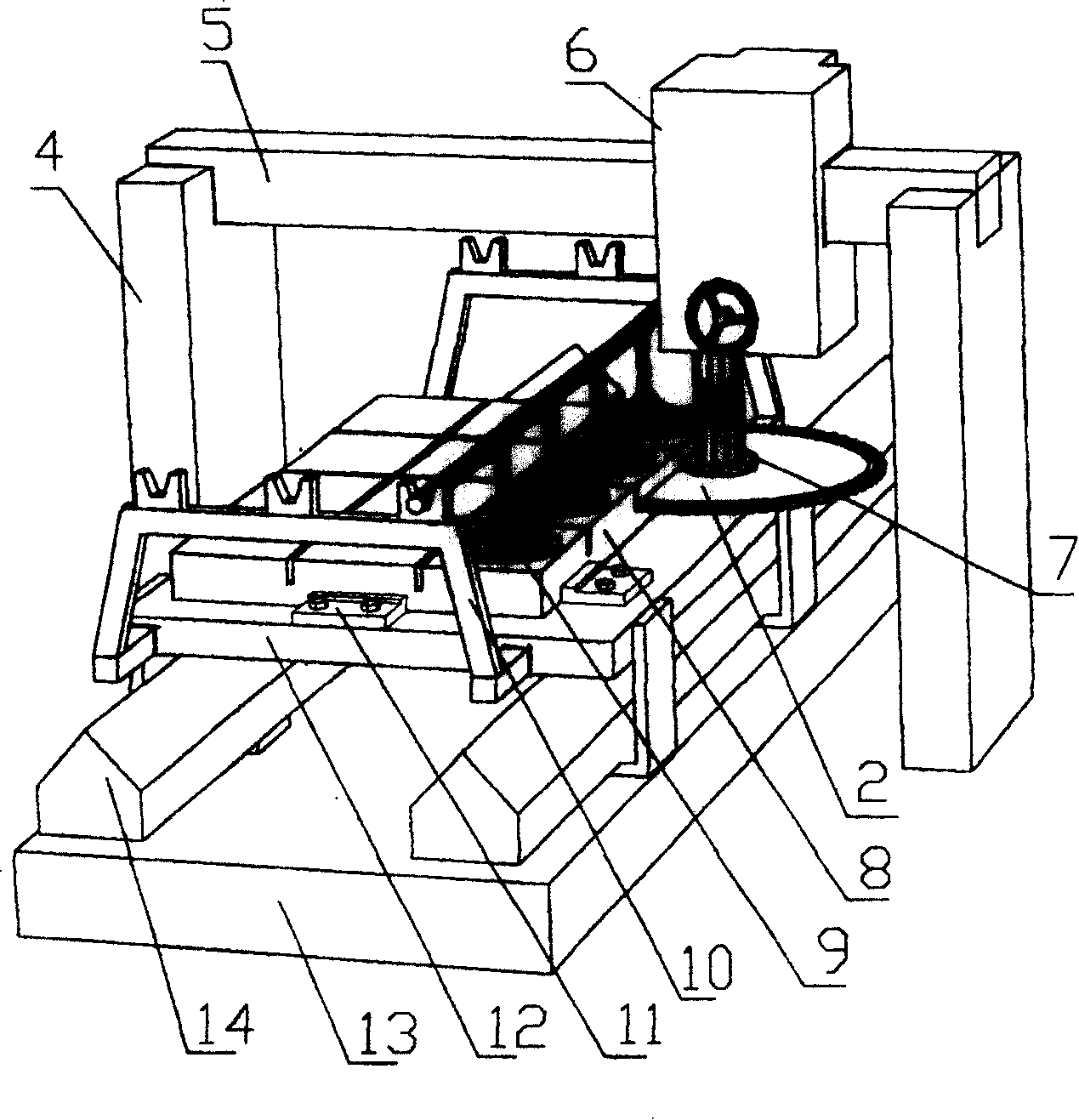

Novel stone cutting winding device and stone cutting sawing machine

ActiveCN109866338ASolve major problems with a one-time passSmall kerfStone-like material working toolsWire cuttingEngineering

The invention relates to a novel stone cutting winding device and a stone cutting sawing machine. A stone transferring trolley and two parallel cutting transferring supports are included, and cuttingtransferring guide rails are arranged at the top ends of the cutting transferring supports. The stone transferring trolley is evenly provided with a plurality of sets of vertically-arranged oil cylinders, and the tops of each set of oil cylinders are connected through a horizontal supporting rod. The cutting transferring guide rails are provided with a cutting base, installing bases are fixedly arranged at the two ends of the cutting base, and a wire passing guide wheel and a first cutting guide wheel which are horizontally arranged are arranged between the upper portions of the two installingbases, and a horizontally-arranged second cutting guide wheel is arranged between the lower portions of the two installing bases. Through a wire passing guide rail, the angle of a diamond cutting wire passing through the wire passing guide wheel changes, and accordingly, a front diamond wire cutting wire and a rear diamond wire cutting wire are located on the same plane. Each set of oil cylinderscan sequentially ascend and descend according to needs to support smooth passing of a cutting wire net, and accordingly, the wire net smoothly passes through a loading trolley under the situation that the loading trolley is not damaged.

Owner:厦门品河精密科技有限公司

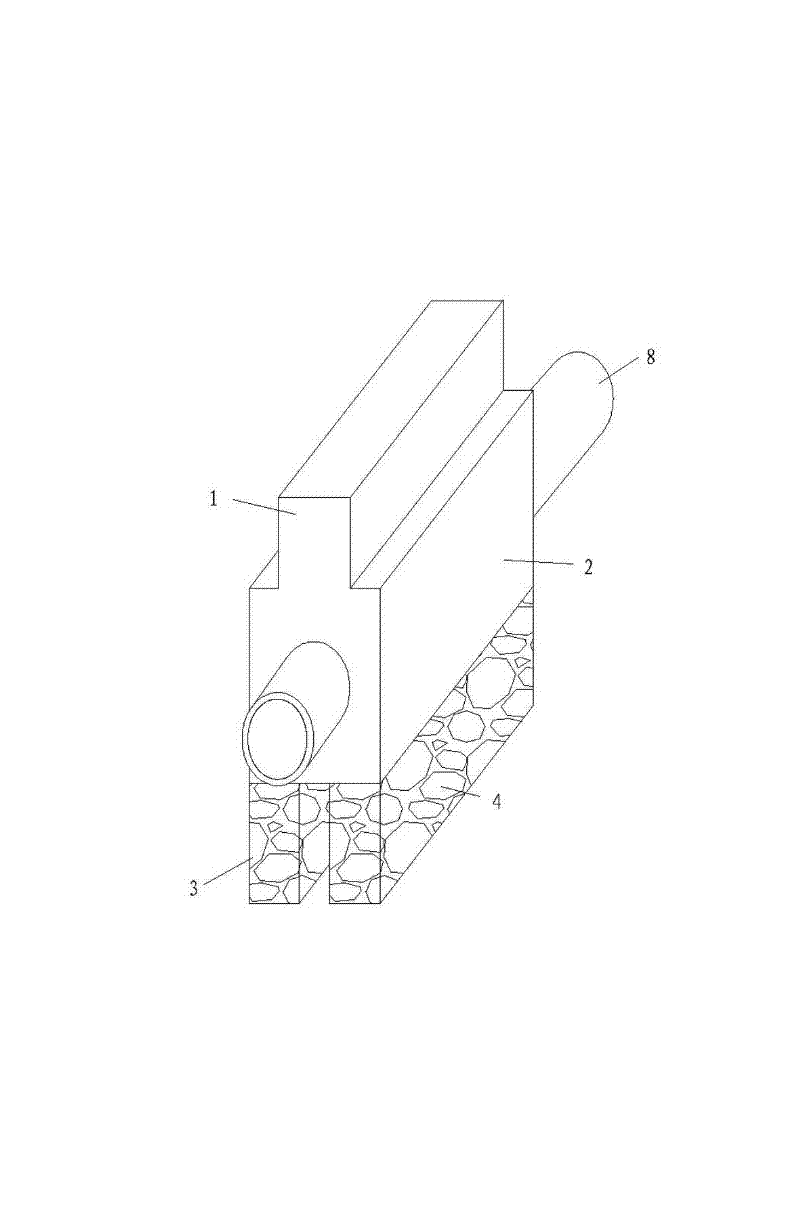

Large area super-flat reinforced concrete floor and colorful diamond sand surface layer one-step forming method

InactiveCN107060171ALow costSolve common quality problemsFloorsFlooringSurface layerReinforced concrete

The invention relates to a large area super-flat reinforced concrete floor and colorful diamond sand surface layer one-step forming method. The one-step forming method comprises the steps of template erection, steel bar binding, expansion reinforcing band arrangement, elevation measurement, steel bar elevation check, laser leveler adjustment, concrete pouring, laser leveler leveling, professional leveling, diamond sand spreading, grinding and flexible compacting, polishing, construction seam cutting, curing, finished product curing and upper structure construction. According to the one-step forming method, a structural floor is used as a base layer, a diamond sand floor surface layer and a structure are subjected to one-step pouring forming, the common quality problem that the floor surface layer is prone to forming hollow protrusions due to secondary pouring is avoided, meanwhile, one concrete base layer is reduced, and cost is greatly reduced. The floor is fully covered with recyclable materials such as plastic films and templates so that an upper main structure can continue to be conveniently constructed.

Owner:SHANGHAI SENXIN CONSTR ENG

All-powder ultrathin diamond saw blade

InactiveCN101987382AReduce wasteImprove cutting efficiencyMetal sawing tool makingMetal sawing toolsMaterials scienceDiamond

The invention relates to an all-powder ultrathin diamond saw blade, which comprises the following matrix elements in percentage by mass: 45 to 65 percent of Cu, 8 to 12 percent of Sn, 8 to 12 percent of Co, 2 to 4 percent of Ni, 2 to 4 percent of Ag, 0.3 to 0.5 percent of S, 0.2 to 0.3 percent of P, 0.2 to 0.3 percent of C, and the balance of Fe. Based on 100 percent of concentration of standard 0.88g / cm<3> diamond, the diamond concentration is 16 to 28 percent. By the technical scheme, the all-powder ultrathin diamond saw blade has the advantages that: 1, there is no matrix, and matrix waste is greatly reduced; 2, the thickness can reach 0.3 to 0.6mm; and 3, the height of a tool bit is 30 percent of the outer diameter of the saw blade, the service life of the product is long, the cutting efficiency is high, and a sawn joint is small.

Owner:JIANGSU YOUHE TOOLS CO LTD

Method and device for cutting transparent material by using ultra-short pulse laser

ActiveCN102785031BNo pollution in the processNo generationFine working devicesGlass severing apparatusTransfer procedureRefractive index

The invention provides a method for cutting a transparent material by using ultra-short pulse laser. The ultra-short pulse laser output by an ultra-short pulse laser generating device is condensed by a condensation device so as to form a bunching laser beam; the bunching laser beam enters from the surface of the transparent material to be machined, so that the center refractive index at a laser application point is increased to form a waveguide structure along a laser emitting direction; the laser is transmitted to the inside of the transparent material along the waveguide structure, and continuously generates a waveguide structure along the laser emitting direction in a transmission process until the entire waveguide structure and the laser penetrate through the transparent material; and therefore, the laser moves in a direction which is vertical to the surface of the transparent material at uniform speed, so that a waveguide plane is formed in the transparent material. The invention further provides a device for cutting the transparent material by using the ultra-short pulse laser. The method and the device for cutting the transparent material by using the ultra-short pulse laser provided by the invention have the advantages of fast cutting speed, small cutting seam, no material consumption and no powder pollution. When the machined material bears a suitable external force, the material is cracked only along a stress fault surface; the broken surface nearly has no conical degree; and the roughness is good.

Owner:WUHAN JUNNO TECH

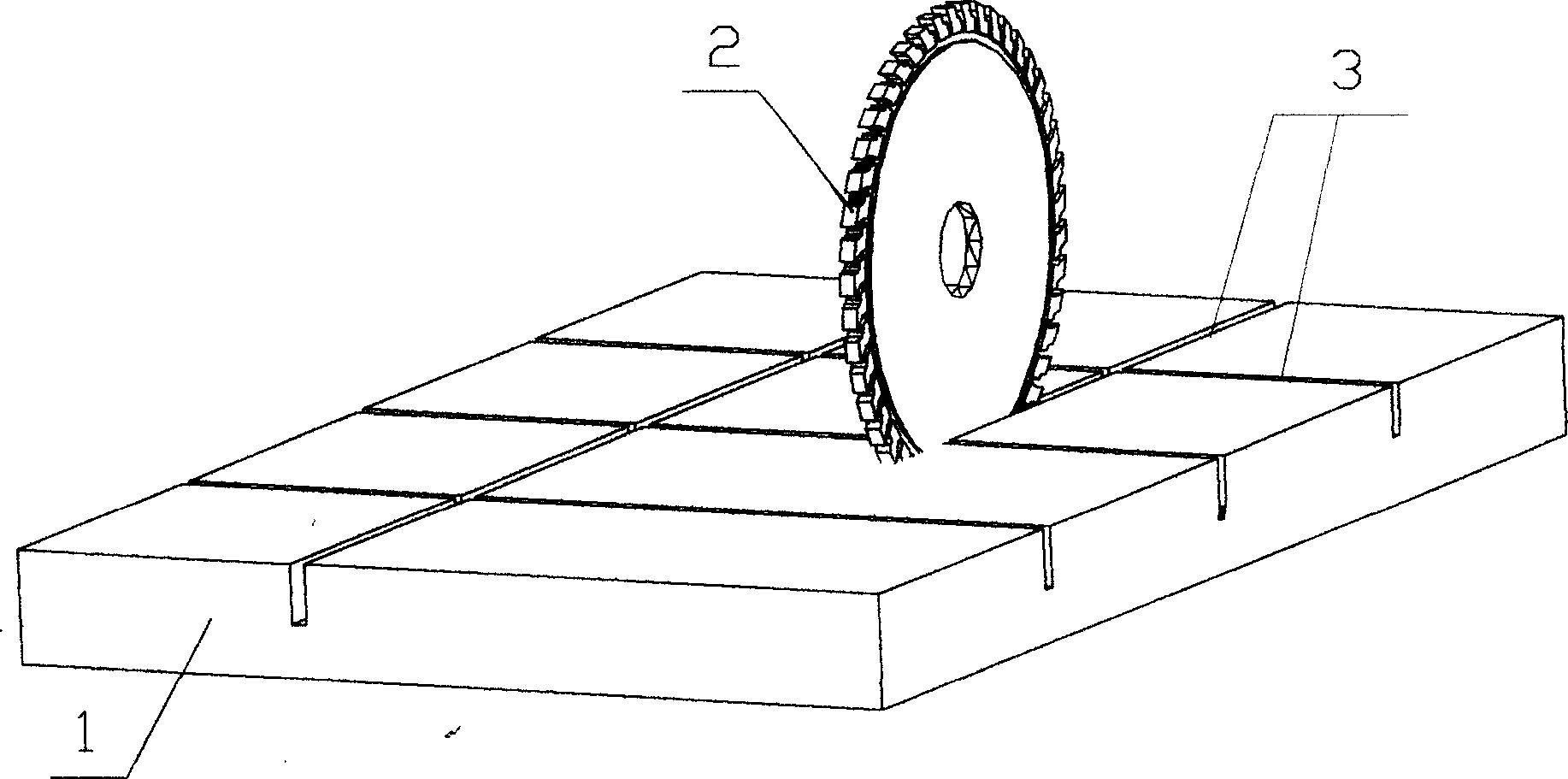

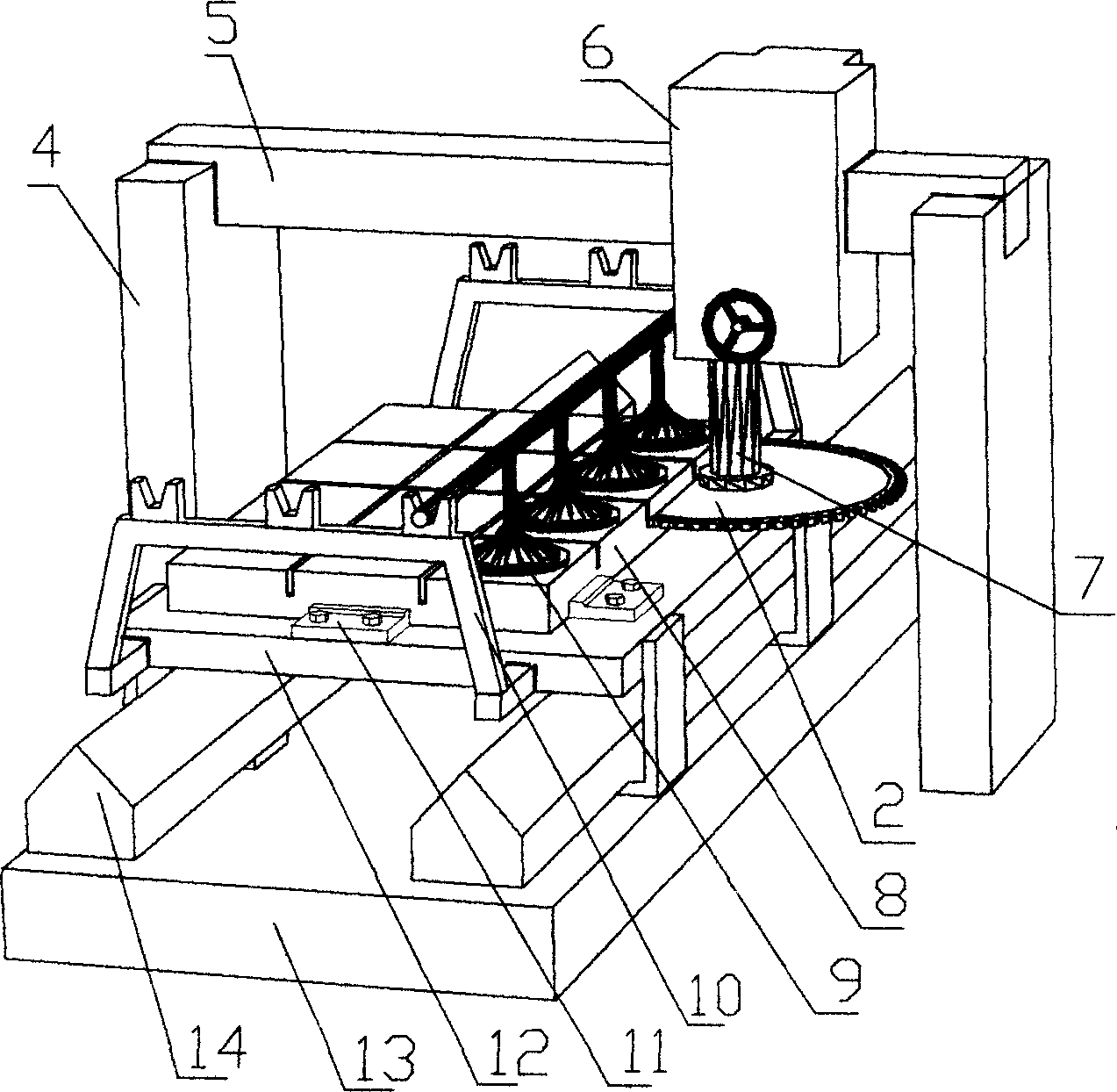

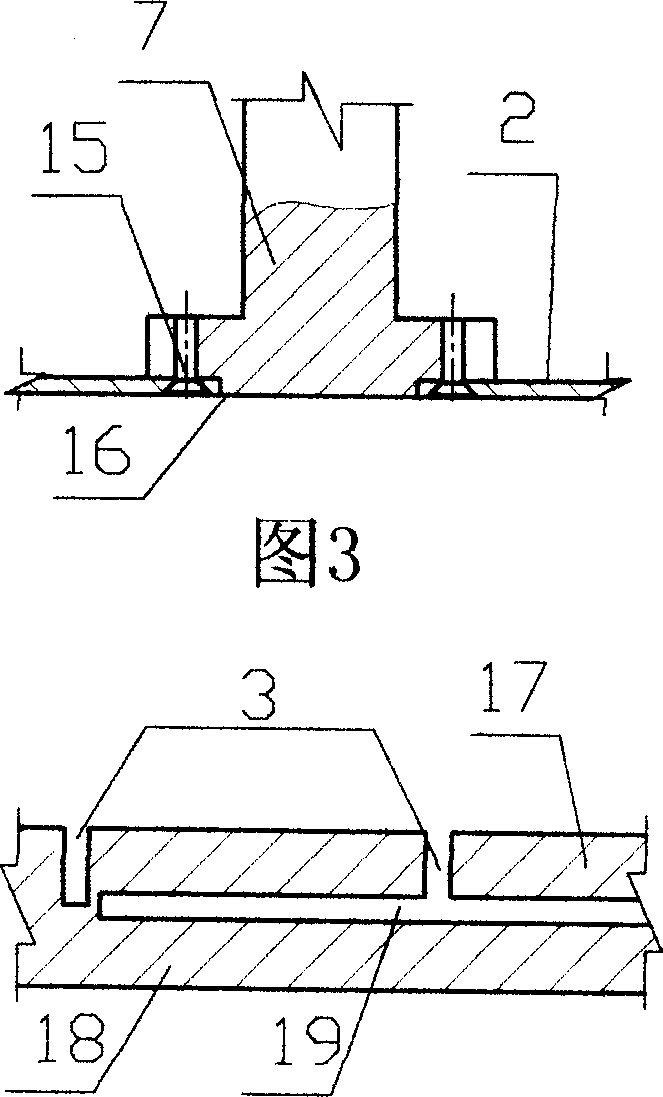

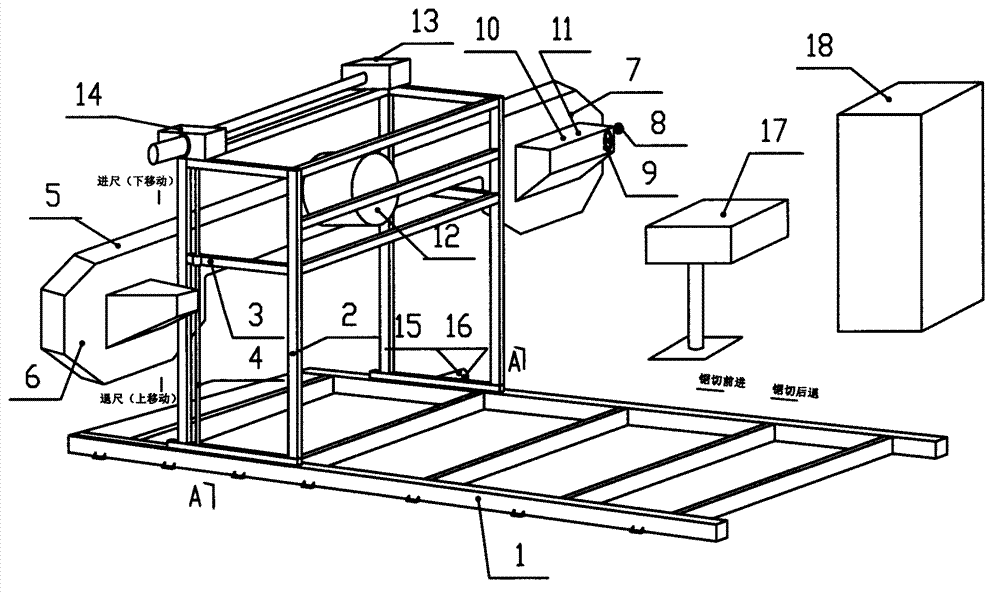

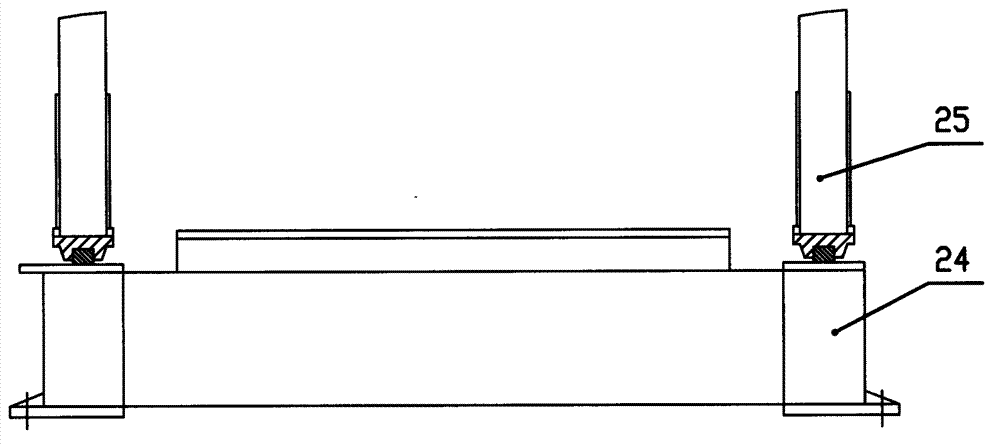

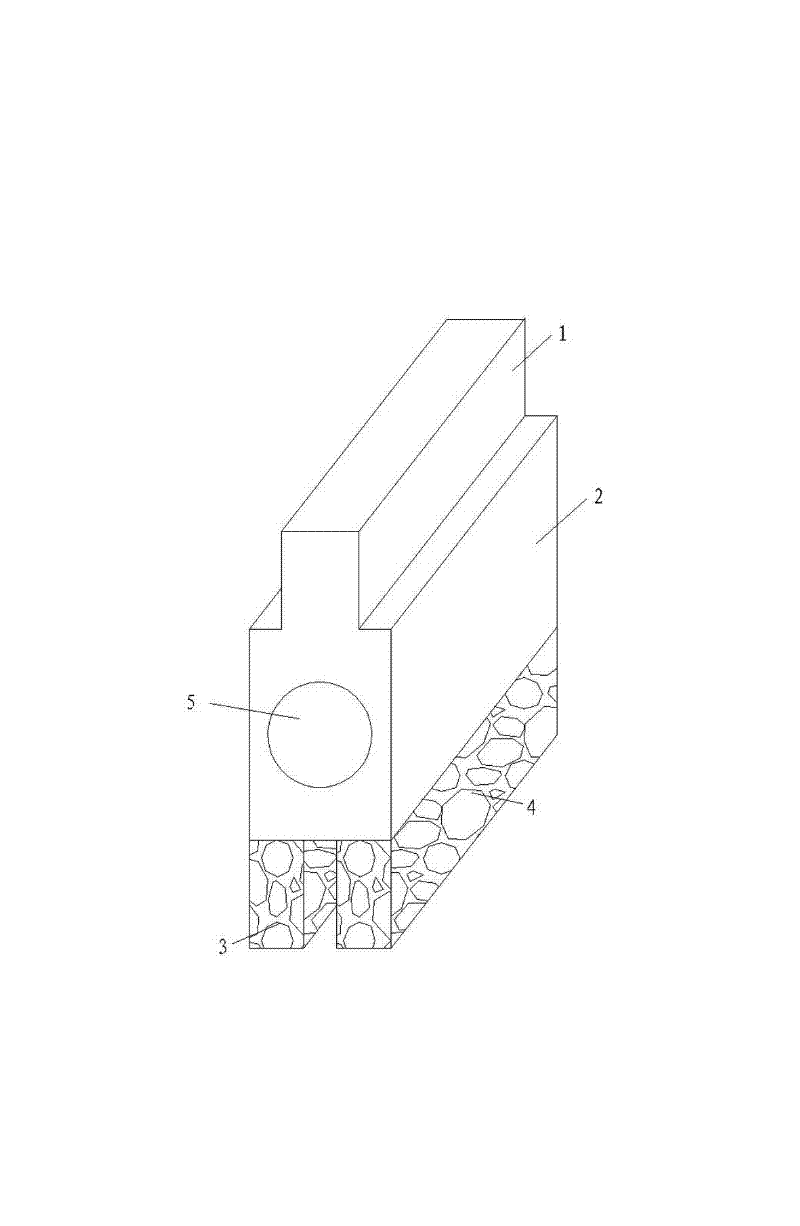

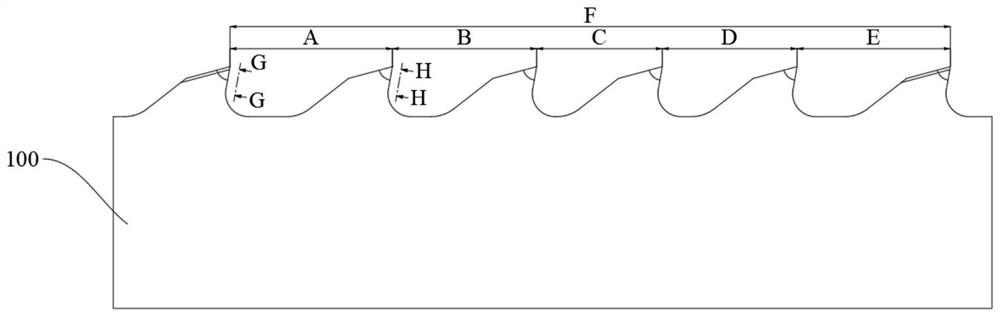

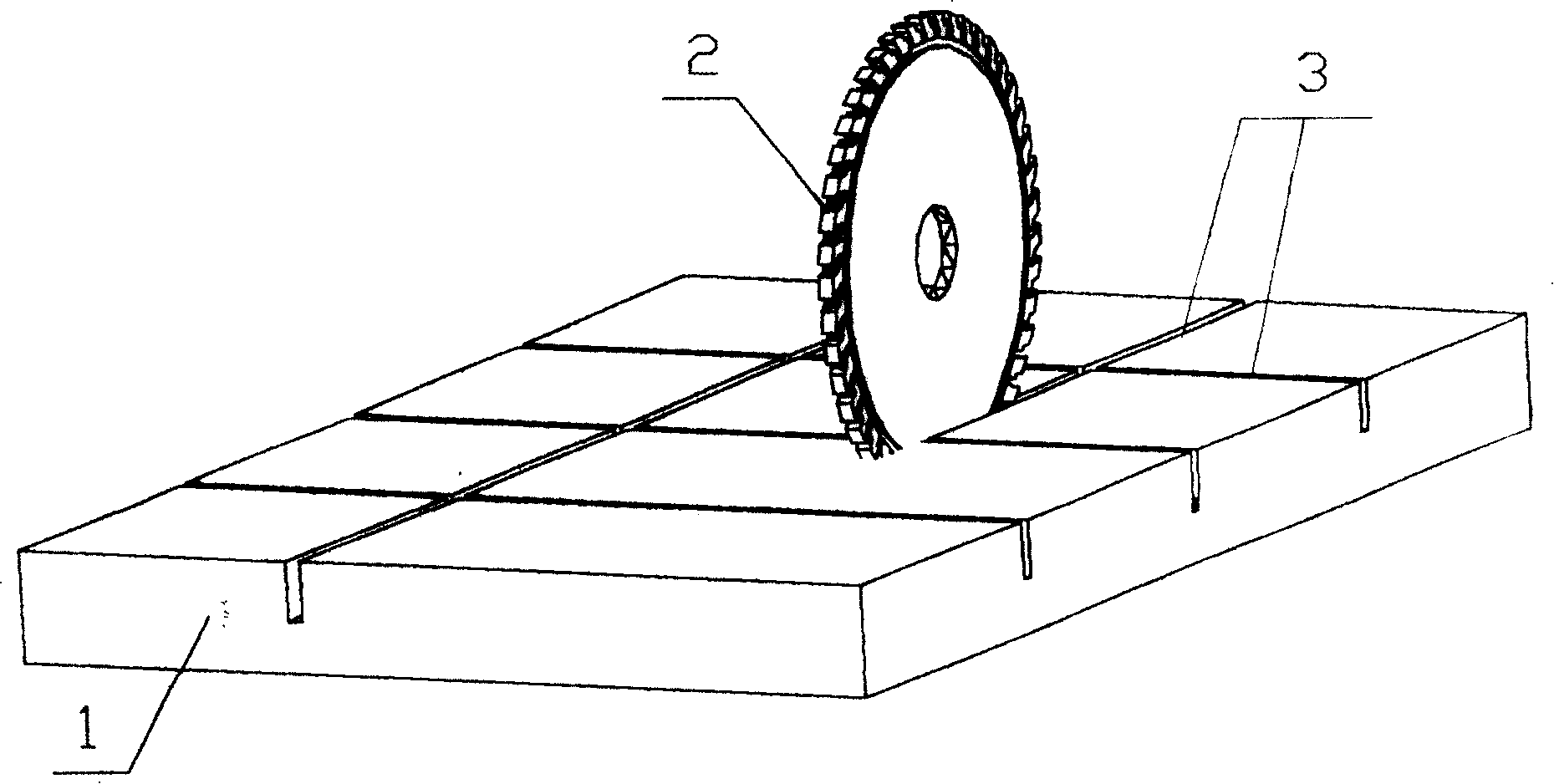

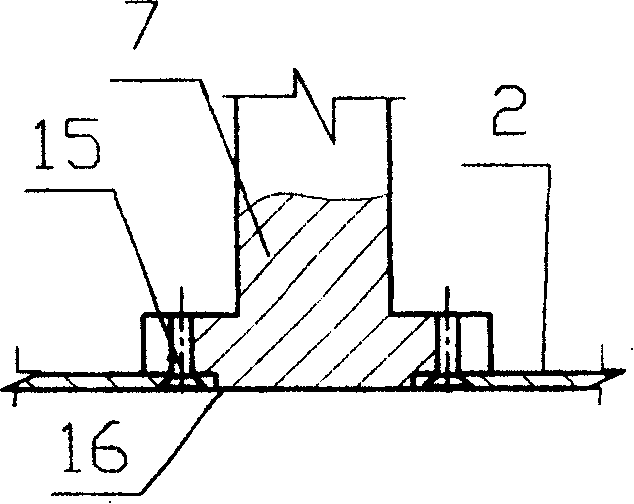

Method for cutting ultrathin dimension stone in large specification by using small circular saw blade, and dedicated leveling splitting machine

InactiveCN1727166ASmall sizeReduce use costWorking accessoriesStone-like material working toolsCircular sawEngineering

A method for preparing a large-area super-thin stone material by use of small circular saw blade includes such steps as cutting on the big stone slab according to the sizes of needed small stone slabs to form multiple ditches, fixing the big stone slab to the bench of a horizontal cutting machine, sucking the first needed small stone strip by a sucking unit, using small circular saw blade to saw the big stone slob for separating the first small stone strip from the big one, repeating said steps until all small stone strips are separated to obtain a large-area super-thin stone material and several small super-thin stone strips. Said horizontal cutting machine is also disclosed.

Owner:翦凝刚

Mixed metal ultrathin diamond saw blade

InactiveCN106270776AReduce wasteImprove cutting efficiencyMetal sawing tool makingMixed metalDiamond

The invention relates to an all-power ultrathin diamond saw blade. The formula of the all-power ultrathin diamond saw blade comprises, by weight, 45-65% of Cu, 8-12% of Sn, 8-12% of Co, 2-4% of Ni, 2-4% of Ag, 0.3-0.5% of S, 0.2-0.3% of P, 0.2-0.3% of C and the balance Fe. When the content of diamond is 0.88g / cm<3>, the concentration of diamond is 100%; the concentration of diamond is 16-28%. By employing the above technical scheme, the all-power ultrathin diamond saw blade is advantaged in that 1, the diamond saw blade does not have a substrate, and waste of the substrate is greatly reduced; 2, the thickness of the all-power ultrathin diamond saw blade can reach 0.3-0.6mm; 3, the height of the cutter head reaches 30% of the external diameter of the saw blade, and the all-power ultrathin diamond saw blade is long in service life, high in cutting efficiency and small in saw kerf.

Owner:JIANGSU YOUHE TOOLS CO LTD

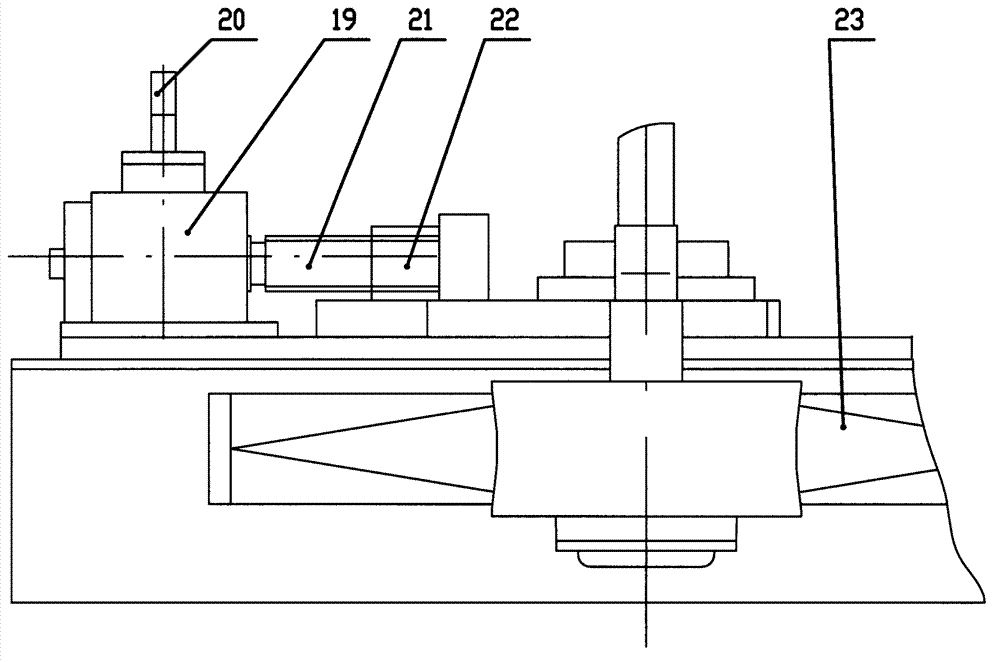

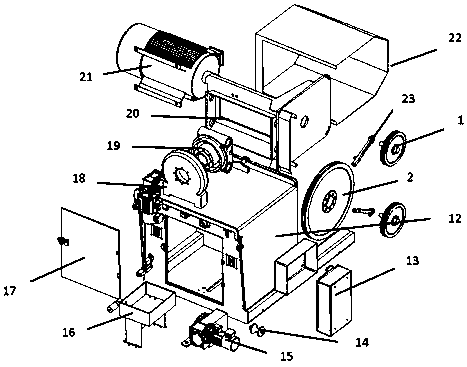

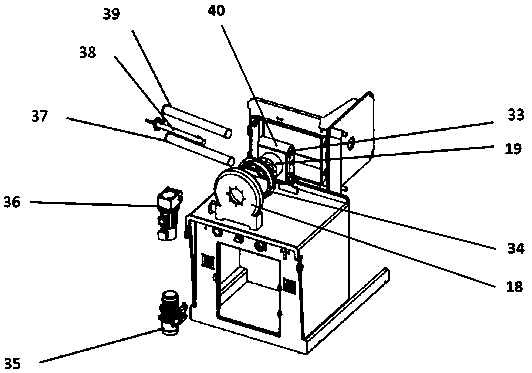

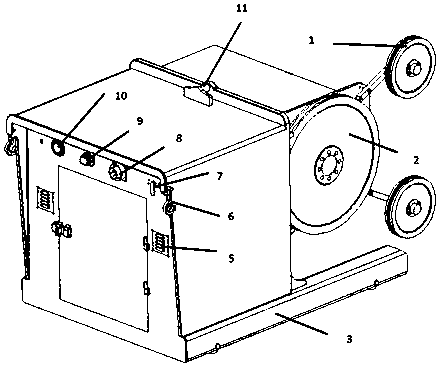

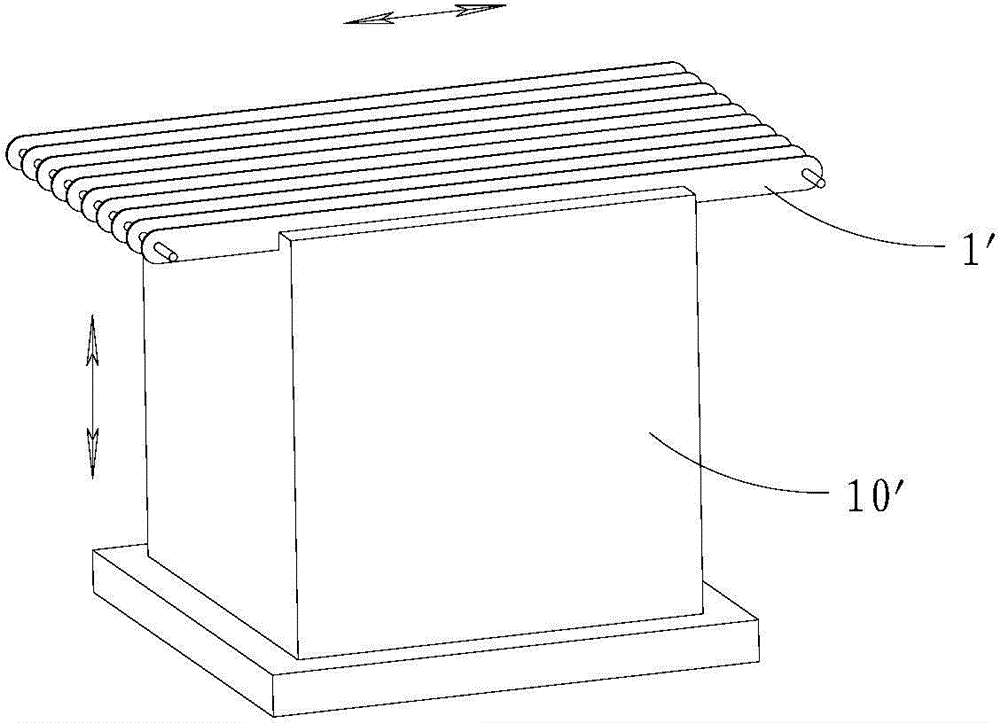

Numerical-control band saw machine for sawing American cork wood

ActiveCN102962870AShort dynamic response timeEasy and flexible clampingBand sawsNumerical controlDrive wheel

The invention relates to a numerical-control band saw machine for sawing American cork wood, and the numerical-control band saw machine comprises a saw machine, a saw frame, a vehicle body, a linear guideway pair, a ball screw, a variable frequency motor, a servo motor, an air pump, a numerical control operating desk, an electric control cabinet and the like; the sawing part of the saw machine comprises a band saw driving wheel, a band saw driven wheel, a tensioning mechanism, a tray, a housing and the like; the tension of a cutter is adjusted by virtue of an adjusting handwheel, the exposed teeth of the cutter are adjusted by a saw blade exposed tooth adjusting handwheel; the wood is clamped by a pneumatic device, the clamping force is adjusted by a regulation valve, the clamping force is realized by an operation handle, 01 gear is a wood clamping gear, N is a neutral gear, and 02 gear is a wood loosening gear; the linear guideway pair and the variable frequency motor are adopted for a walking part, the sawing precision is stable and reliable, the servo motor is adopted for a sawing part, the ball screw is lifted, an imported special cutter is adopted, and the numerical-control band saw machine is steady in operation, small in sawing kerf and high in yield.

Owner:江苏东巨机械科技有限公司

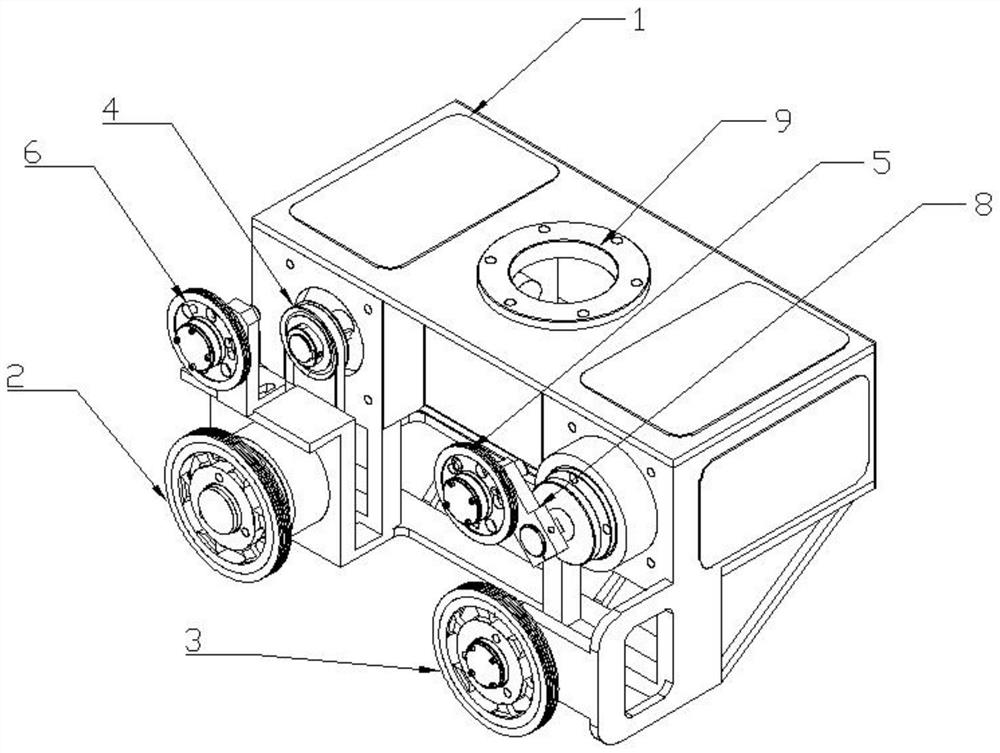

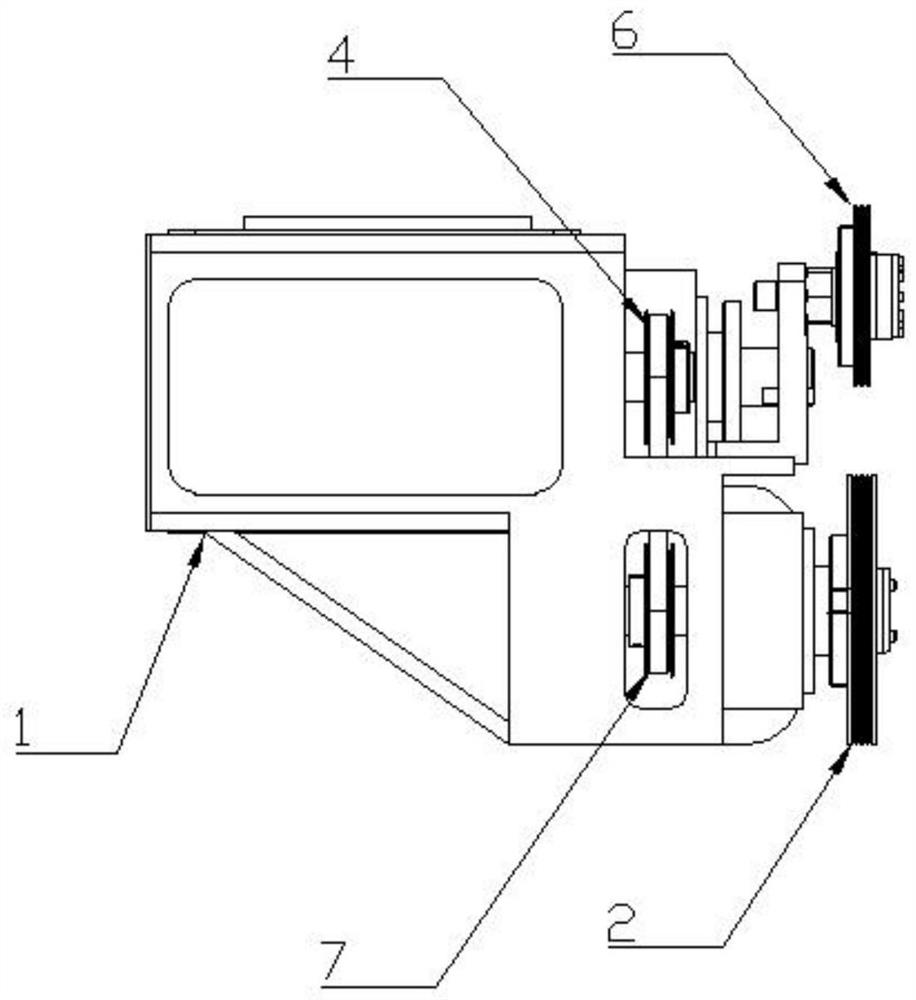

Diamond wire saw

InactiveCN107745451ALow failure rateGuaranteed uptimeWorking accessoriesStone-like material working toolsMachining vibrationsReduction drive

The invention relates to a diamond wire saw which comprises a power head, a rotation mechanism, a travelling mechanism, a box body and a control system. A transversely-moving shaft in the power head of the diamond wire saw is placed in a sliding bearing seat of a rotation spindle connecting piece in the rotation mechanism, and a transversely-moving oil cylinder is fixedly arranged in the rotationspindle connecting piece; a hydraulic station controls a piston rod of the transversely-moving oil cylinder to move, and the travelling mechanism comprises a vertical adjusting mechanism in an adjusting chain wheel and a chain track engaged mode; a traveling chain adopts a direct connection mode; a rotation spindle of the diamond wire saw is subjected to double supporting of a double-supporting rotation speed reducer and a rotation spindle bearing seat, and the power head supports force and stably rotates; the power head and a power wheel stably operate, drooping and shaking are avoided even if the power head is used for a long period, during cutting, shaking is small, and machine vibration is also small; transverse movement is achieved in a hydraulic mode, and the parallelism depth errorof movement in the up-down and left-right directions is small; and through the vertical adjusting mechanism, the diamond wire saw normally travels on various tracks, and the climbing ability of the diamond wire saw is improved.

Owner:毛光华

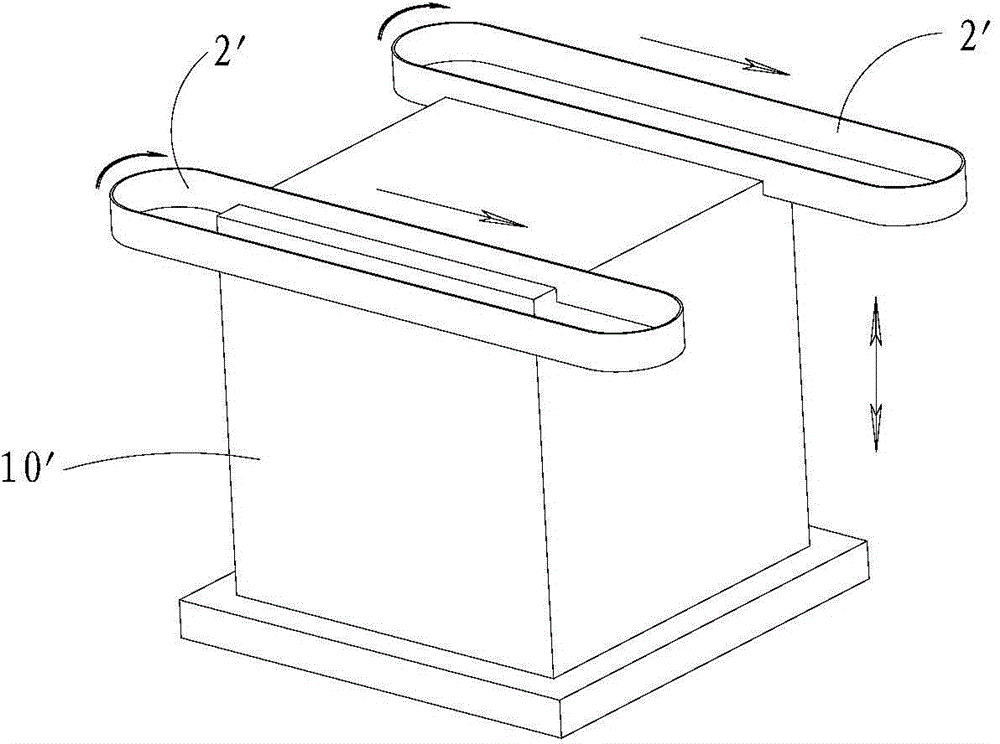

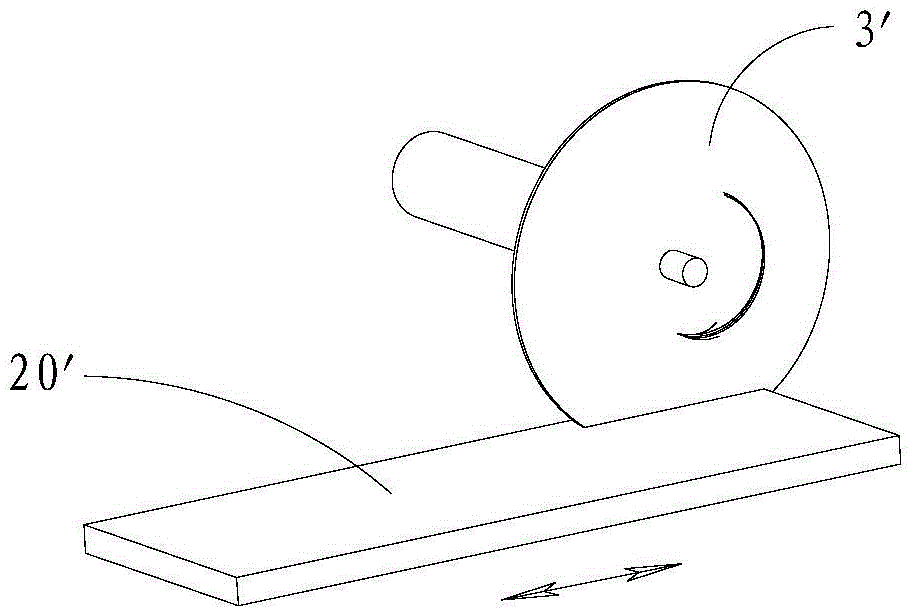

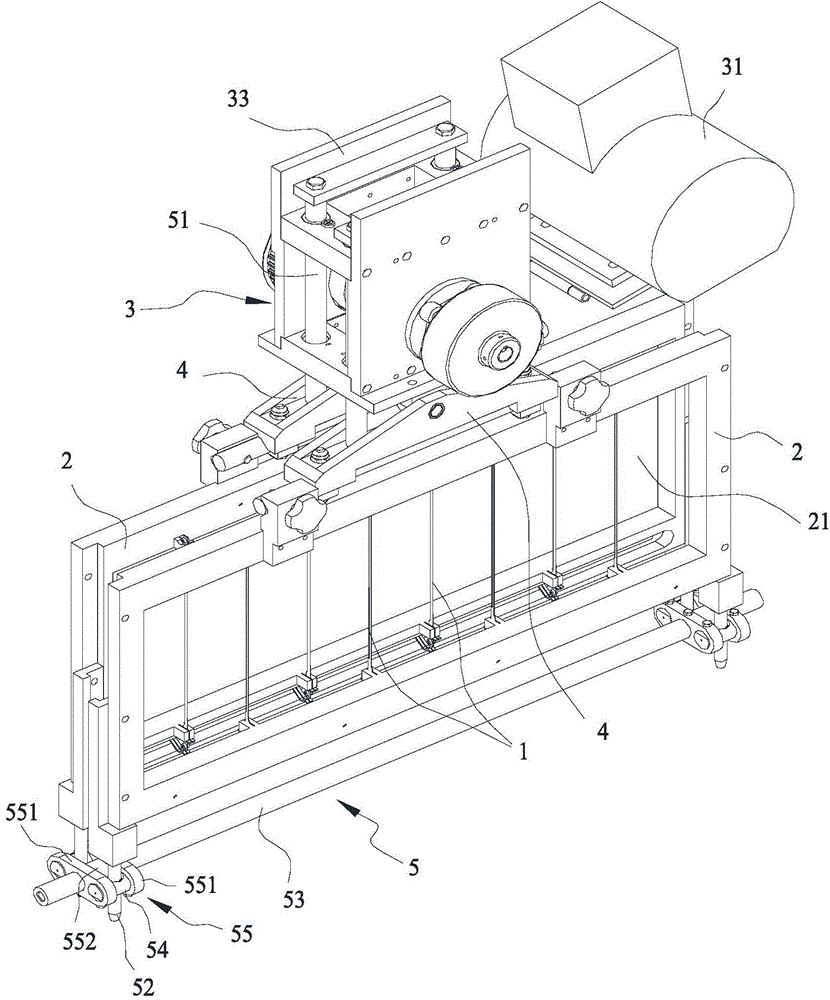

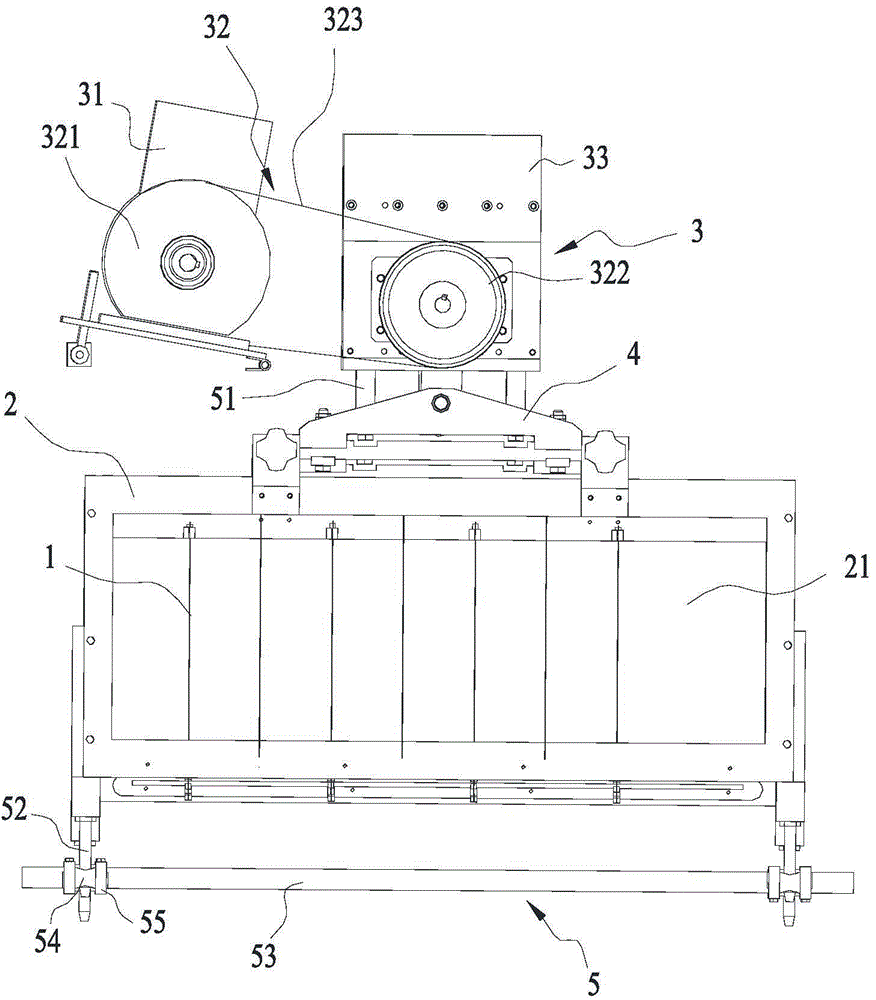

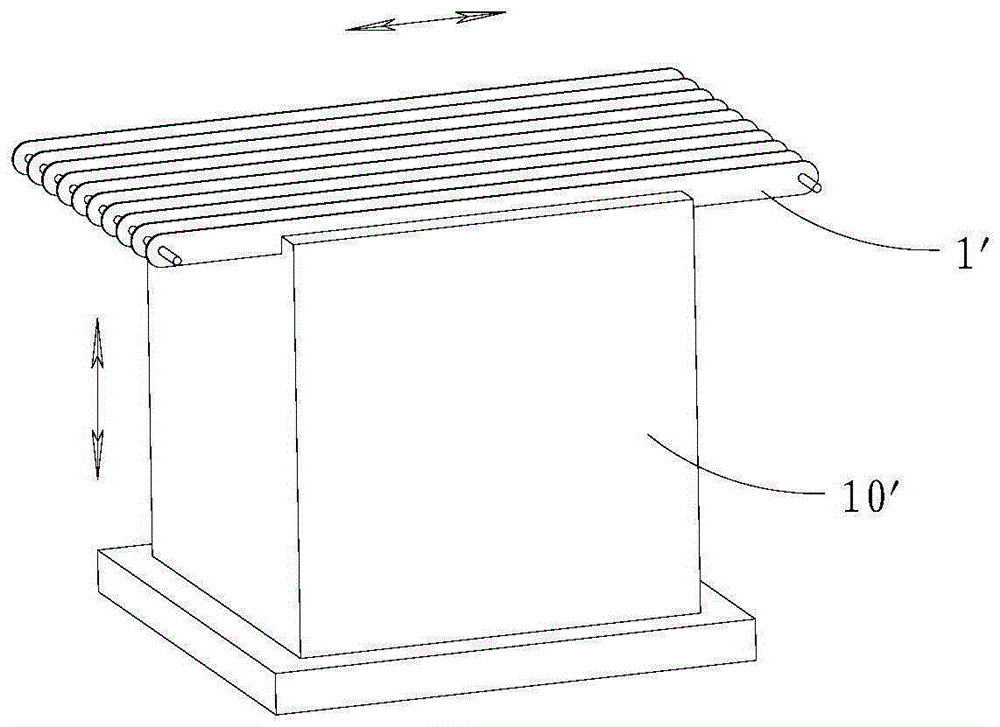

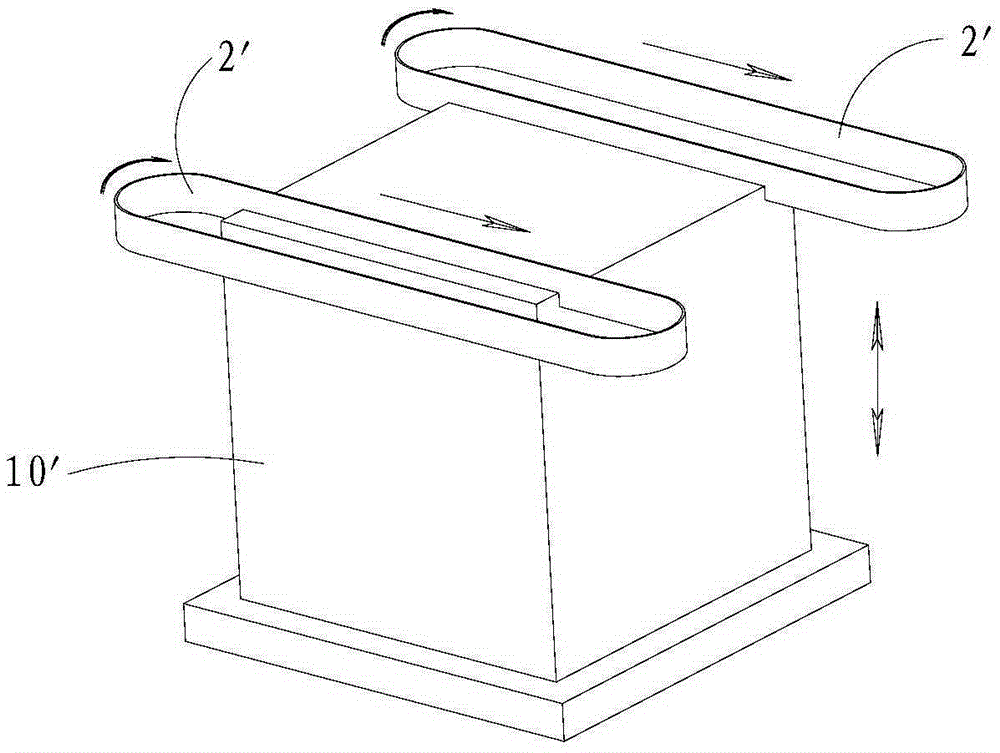

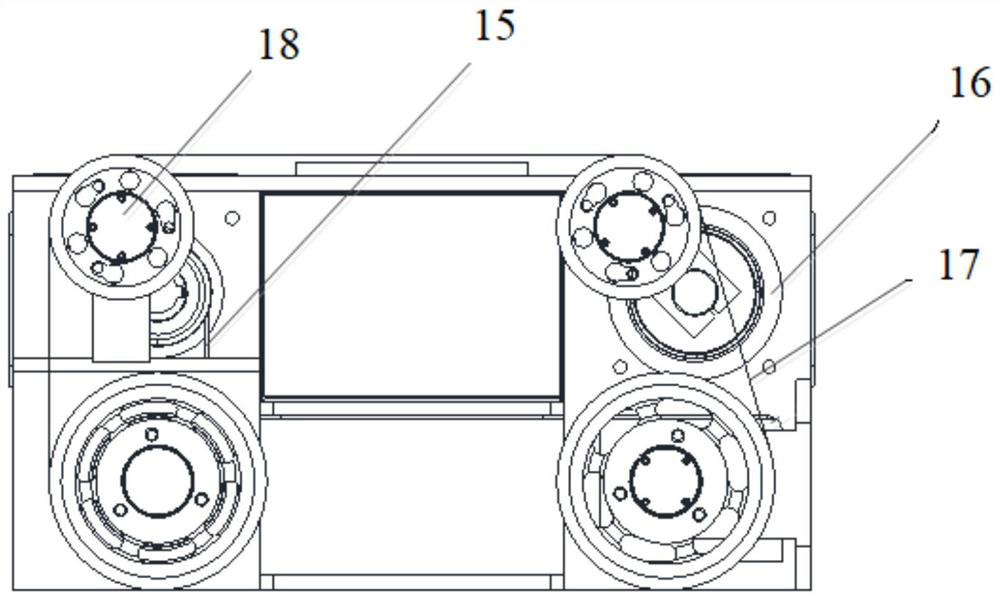

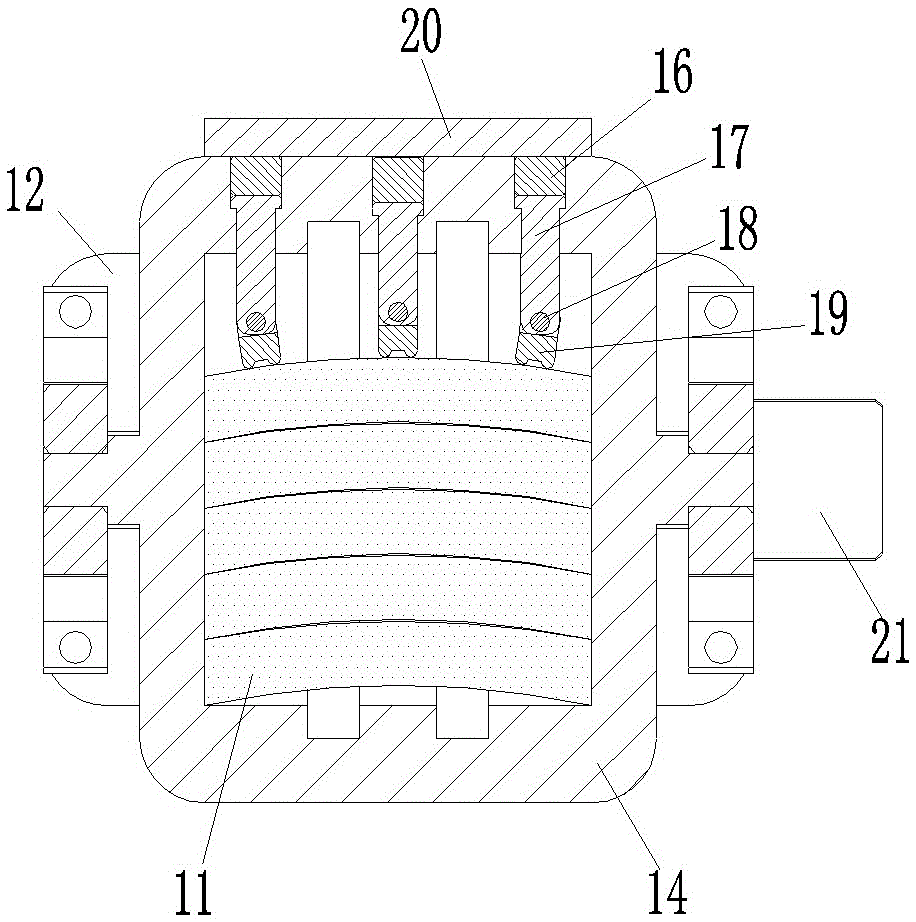

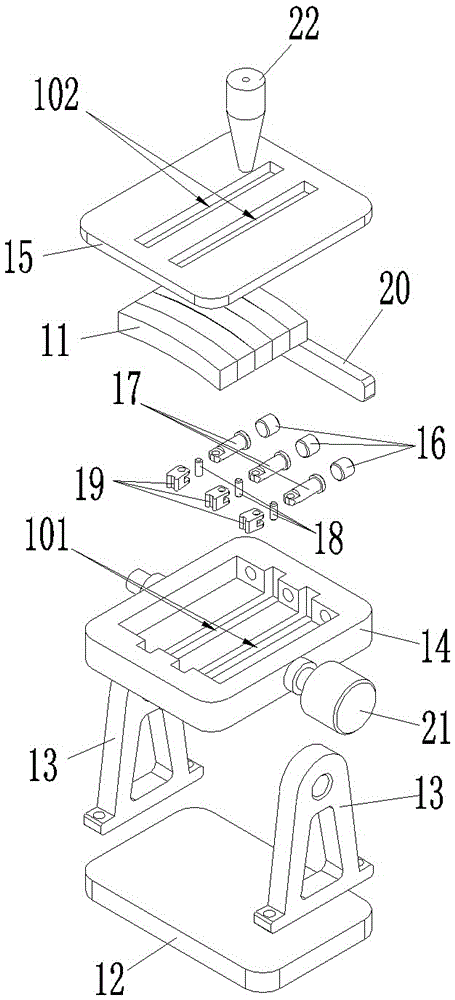

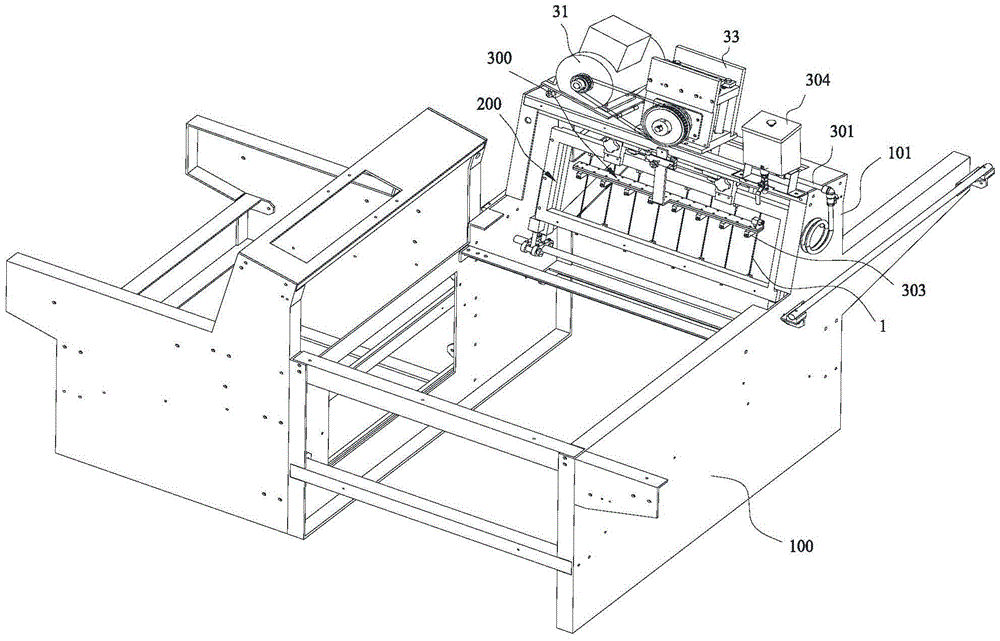

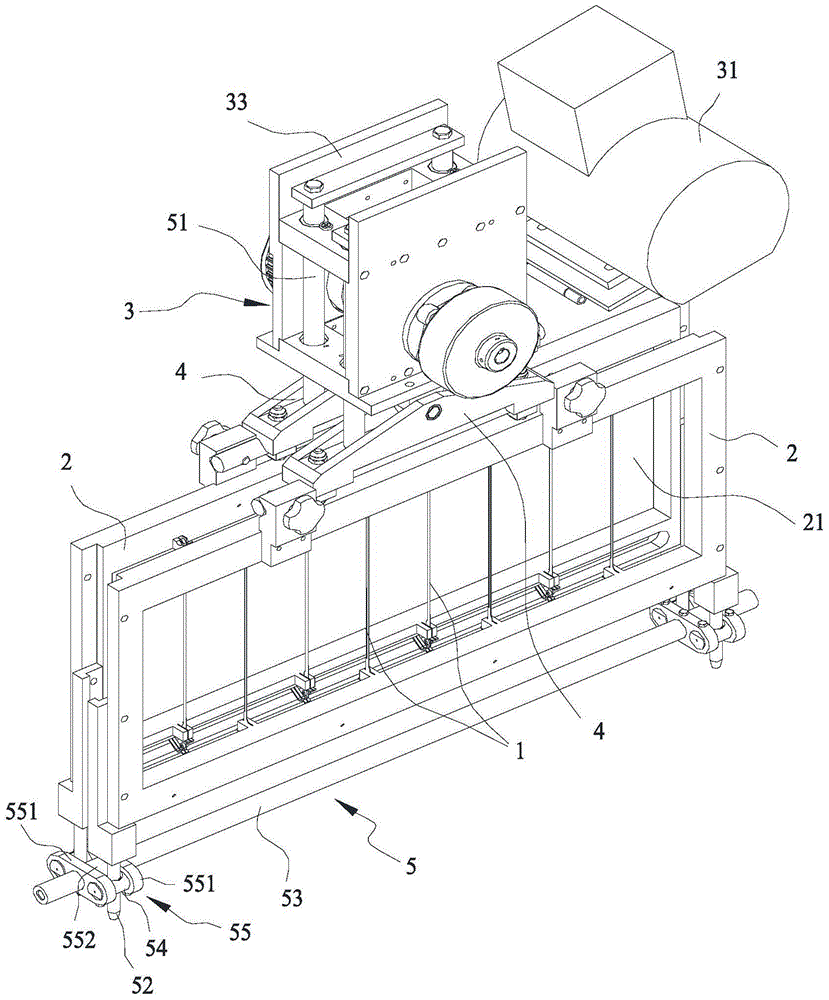

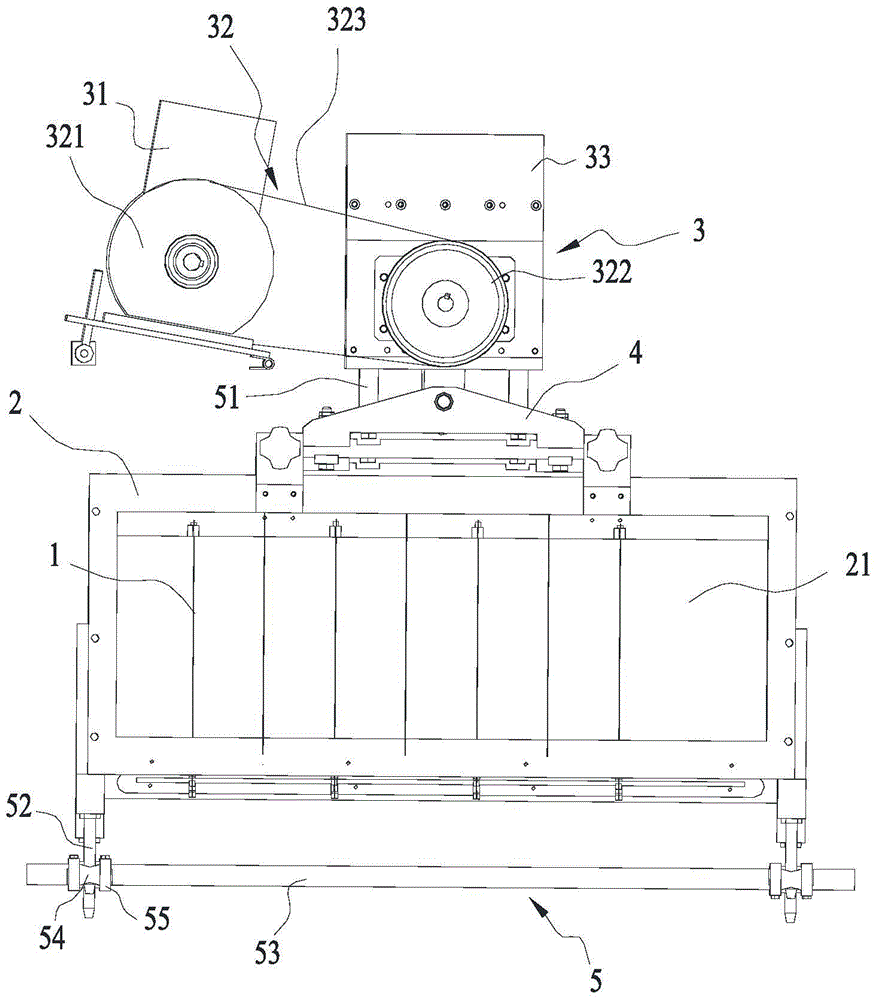

Swinging-type marble multi-wire sawing machine

ActiveCN104608264AReduce wasteImprove surface qualityWorking accessoriesStone-like material working toolsWire cuttingStructural engineering

The invention discloses a swinging-type marble multi-wire sawing machine which comprises a bed, a base and a mounting base. The base provided with a workbench is arranged on the bed, the mounting base located above the workbench is arranged on the bed, at least one of two components of the base and the mounting base is arranged on the base in a liftable manner, a wire sawing mechanism is arranged on the mounting base, multiple wire sawing wires are arranged on the wire sawing mechanism, a marble to be sawn is fixedly arranged on the workbench, the workbench is rotatably arranged on the base through a rotating shaft, a swinging device used for driving the workbench to swing around the rotating shaft is arranged between the base and the workbench, and an axial line of the rotating shaft and the extension direction of the wire sawing wires are mutually vertically arranged. The marble is sawn through the multi-wire sawing machine, sawing efficiency is high, and material waste rate is low.

Owner:SUZHOU SILICON PEAK SOLAR TECH

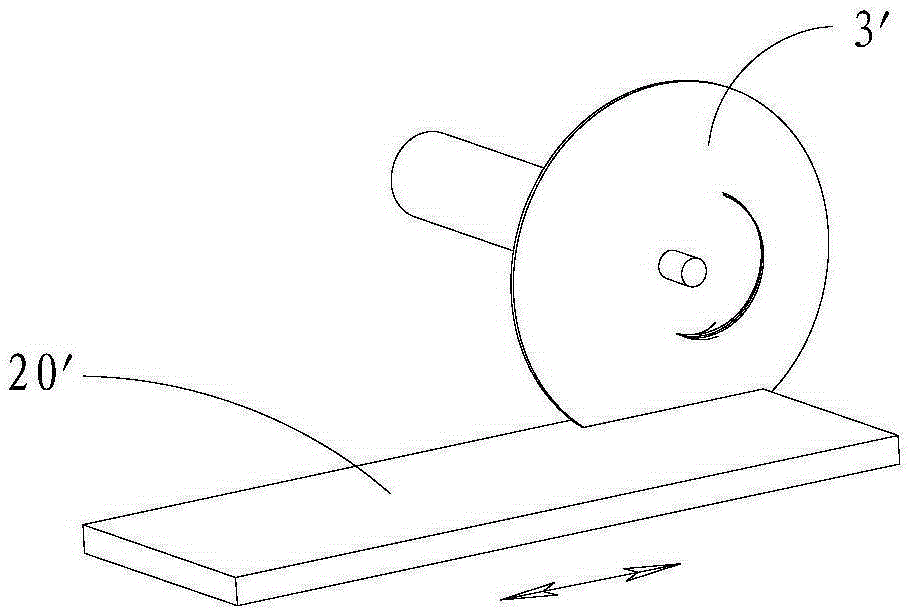

Food slicing device

ActiveCN104816331AReduce mistakesBalanced food tasteMetal working apparatusEngineeringMechanical engineering

The invention discloses a food slicing device. the food slicing device comprises a frame, a slicing mechanism and a conveying mechanism, wherein the blade mechanism and the conveying mechanism are arranged on the frame, and the conveying mechanism is used for conveying foods; the slicing mechanism comprises blades, a knife rest and a driving mechanism, the driving mechanism is used for driving the knife rest to move back and forth in a direction which is intersected with the conveying direction of the conveying mechanism, and the knife rest is provided with a window for foods to pass through; the blades are arranged on the window at intervals, one ends of the blades are fixedly connected to the upper edge of the window, and the other ends of the blades are fixedly connected to the lower edge of the window; the driving mechanism is connected with the knife rest in a driving way, the conveying mechanism is located below the blades, and the conveying direction of the conveying mechanism is parallel to the blade orientations of the blades. According to the food slicing mechanism provided by the invention, foods can be cut with smaller kerfs, the excessive residues of a food detergent can be prevented, and the balanced taste of the sliced foods can be ensured.

Owner:GUANGZHOU FUYA MACHINERY

Diamond inner circle cutting blade and preparation method thereof

ActiveCN106042200AIncrease the number of layersReduce blade thicknessElectrolytic coatingsFine working devicesMaterials scienceCoating

The invention discloses a diamond inner circle cutting blade and a preparation method thereof. The diamond inner circle cutting blade comprises a round matrix which comprises a first main surface, a second main surface, a third main surface, a fourth main surface, a first side surface located on the edge of the outer circumference, and a second side surface located on the edge of the inner circumference; the third main surface and the fourth main surface are correspondingly formed in the manner that the upper end and the lower end of the second side surface extend outwards in the direction of the first side surface by equal distances; the third main surface and the first main surface are connected through a first annular side face; the fourth main surface and the second main surface are connected through a second annular side face; the height of the first annular side face in the axial direction of the round matrix is equal to that of the second annular side face in the axial direction of the round matrix; and the third main surface, the fourth main surface and the second side surface are each provided with a diamond coating containing diamond particles.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

Swing Marble Multi-wire Cutting Machine

ActiveCN104608264BReduce wasteImprove surface qualityWorking accessoriesStone-like material working toolsWire cuttingEngineering

The invention discloses A sort of Swing Marble Multi-wire Cutting Machine , including a machine base, a base with a worktable on the base, a mounting seat on the base above the workbench, at least one of the two parts of the base and the mounting base A part is liftably arranged on the machine base, and a wire cutting mechanism is provided on the mounting base, and the wire cutting mechanism has a plurality of wire cutting wires, and the marble to be cut is fixed on the workbench, so The workbench is rotatably arranged on the base through a rotating shaft, and a swing device for driving the workbench to swing around the rotating shaft is provided between the base and the working table. The extending directions of the wire cutting wires are arranged perpendicular to each other. Using the multi-wire cutting machine to cut marble has high cutting efficiency and low material waste rate.

Owner:SUZHOU SILICON PEAK SOLAR TECH

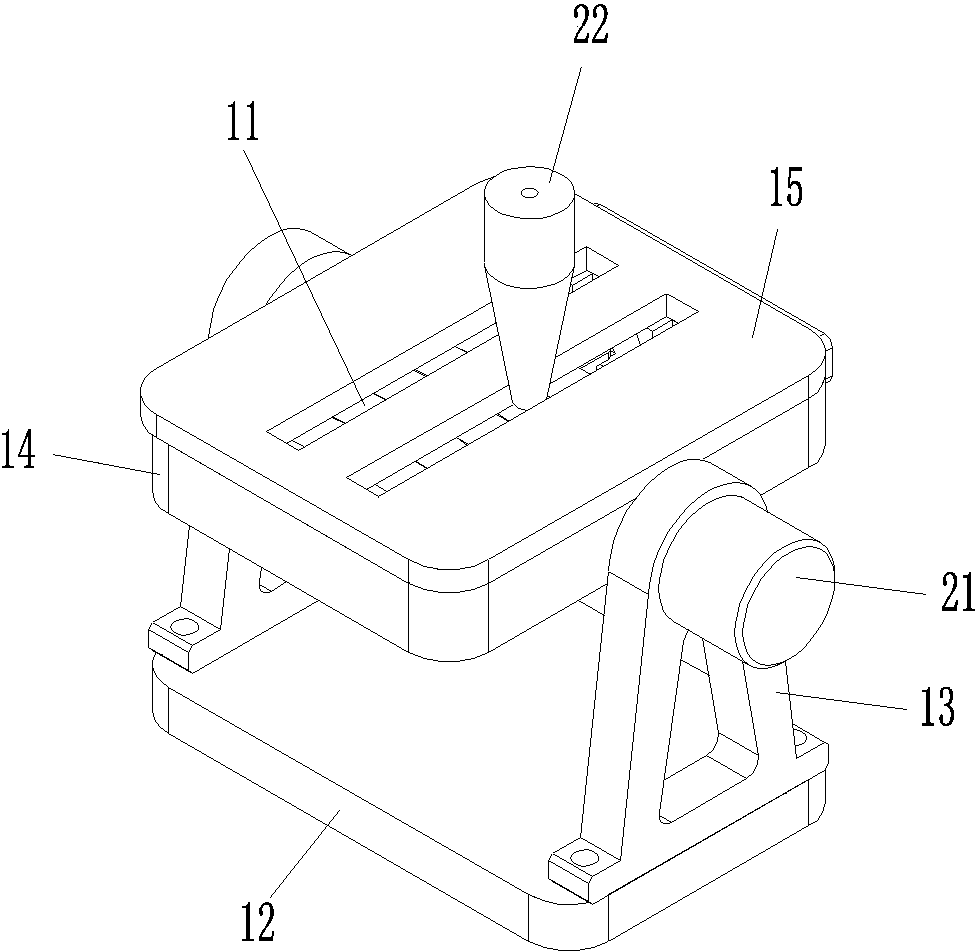

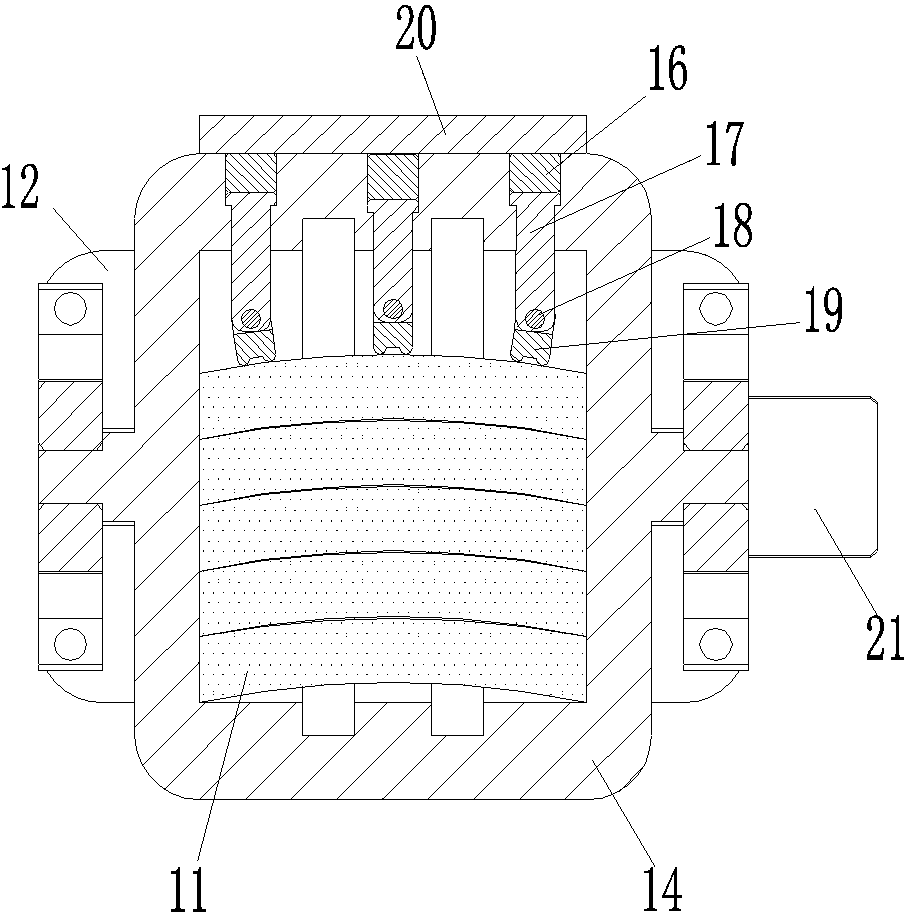

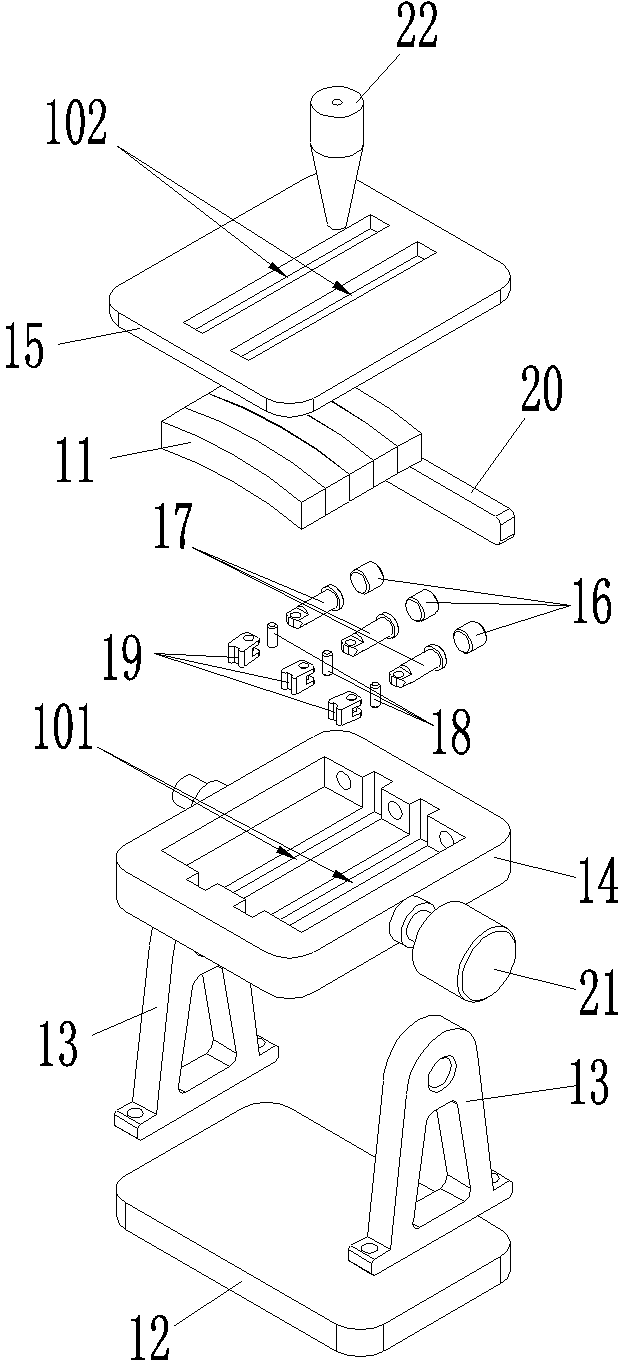

Tobacco block cutting machine

The invention relates to a tobacco block cutting machine. The tobacco cutting machine comprises an engine base, a placement platform used for placing a tobacco block is arranged on the engine base, the tobacco cutting machine further comprises a sawing mechanism, the sawing mechanism comprises a saw blade that move relative to the tobacco block to cut the tobacco block in use, the sawing mechanism further comprises a driving mechanism used for driving the saw blade to reciprocate or rotate, therefore the existing blade extrusion type segmented cutting and slicing can be converted into continuous movement cutting of the saw blade, a slicing operation can be realized without providing a larger driving force, and the seam of the sliced tobacco block is smaller, and the breaking influence is small.

Owner:CHINA TOBACCO HENAN IND

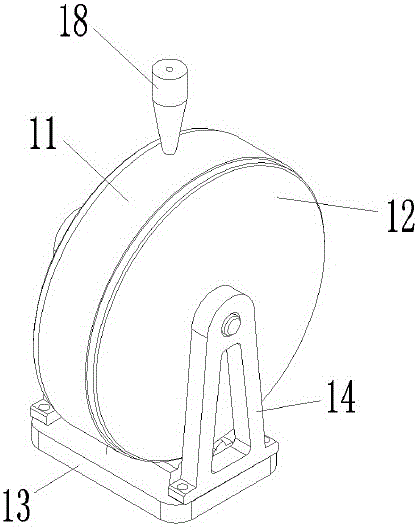

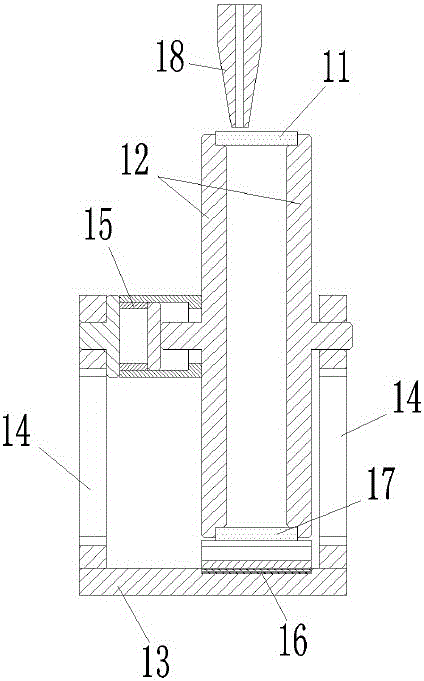

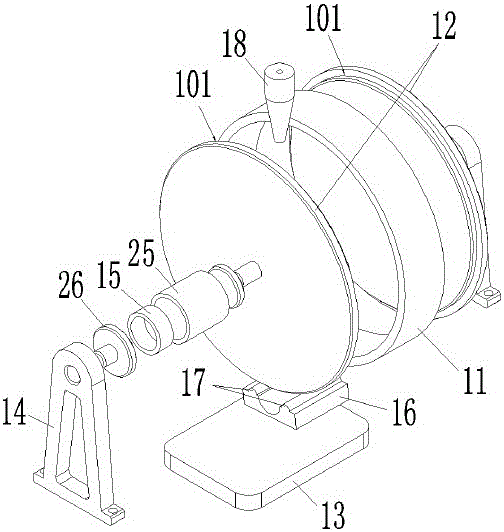

Rope saw

InactiveCN102161217AReduce wasteHigh yieldStone-like material working toolsFeeding forcePositive pressure

The present invention relates to a rope saw, especially to a rope saw used for cutting stone materials. The rope saw comprises a rope type strip cord and a plurality of saw blades, wherein the plurality of saw blades are fixed on the rope type strip cord, each saw blade comprises a midbody and a grinding-and-cutting portion under the midbody, and the midbody is provided with a pressure bearing portion for conveying outside pressure. The rope saw increases positive pressure through external feeding force, thereby solving the problem that a traditional rope saw is low in cutting efficiency and serious in stone material waste, and having the advantages of high efficiency, small cutting slit, low waste, long service lifetime, low power consumption, power and energy saving, less powder produced in cutting, environmental protection, low making cost, convenient popularization, etc.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

Robot flexible diamond wire cutting system

The invention discloses a robot flexible diamond wire cutting system. The cutting system comprises a cutting knife head and a mechanical arm for driving the cutting knife head to rotationally cut, wherein the cutting knife head comprises a cutting knife head frame; a main cutting motor is fixed on the cutting knife head frame; an output shaft of the main cutting motor is connected with a main cutting wheel in a power mode; an auxiliary cutting wheel is arranged on one side, corresponding to the main cutting wheel, of the cutting knife head frame; and a cutting wire net formed by diamond wiresis wound between the main cutting wheel and the auxiliary cutting wheel in a sleeving mode. The multi-shaft linkage mechanical arm is combined with the diamond wire cutting knife head, so that the purpose of flexible cutting is achieved; hard articles can be cut by using less driving force, so that energy is saved, cutting seams are small, and loss of cutting materials and energy consumption are low; and by arranging a transmission wheel and a yielding groove, the motor and the cutting wheels are not arranged coaxially, the cutting space of the diamond wire net is released, and larger materials are allowed and prevented from interfering or colliding with each other in the cutting process.

Owner:QINGDAO GAOCE TECH CO LTD

Substrate-free full powder ultra-thin diamond saw blade

InactiveCN108971634AReduce wasteImprove cutting efficiencyMetal sawing tool makingMetal sawing toolsCobaltTin

The invention relates to a substrate-free full powder ultra-thin diamond saw blade. A matrix is prepared by powder and diamond through a powder metallurgy method. The powder includes copper powder which is 35-55% of the total mass, cobalt powder which is 8-12% of the total mass, tin power which is 8-12% of the total mass, nickle powder which is 2-4% of the total mass, titanium powder which is 1-3%of the total mass, chromium powder which is 1-3% of the total mass, molybdenum powder which is 1-3% of the total mass, iron powder which is 5-20% of the total mass, tungsten powder which is 1-10% ofthe total mass, silver powder which is 0.5-1.5% of the total mass, silicon powder which is 0.3-0.5% of the total mass, phosphorus powder which is 0.2-0.3% of the total mass, and carbon power which is0.2-0.3% of the total mass. The volume concentration of the diamond is 2%-60% and the particle size is 0.04-0.25 mm. Because the technical scheme is used in the invention, the substrate-free full powder ultra-thin diamond saw blade has the following advantages: firstly, the substrate-free full powder ultra-thin diamond saw blade has no a substrate, which greatly reduces the waste of the substrate;secondly, the thickness can reach 0.3-1.0 mm; and thirdly, the height of a cutter head reaches 45% of the outer diameter of the saw blade, and so the service life of the product is long, the cuttingefficiency is high, the saw kerf is small, and the energy and the resources can be saved.

Owner:JIANGSU YOUHE TOOLS CO LTD

Bimetal road grinding band saw blade

The invention discloses a bimetal road grinding band saw blade. The bimetal road grinding band saw blade comprises a saw blade body and a plurality of groups of saw tooth groups arranged on the saw blade body. Each group of saw tooth groups comprises at least one first saw tooth, and the blade end width of each first saw tooth is greater than the width of the saw blade body in the thickness direction of the saw blade, chamfers are arranged on the two sides, in the width direction, of the blade end of each first saw tooth, and at least one side surface of each first saw tooth is an acute-angledinclined surface. The saw blade has a smooth and level saw cutting surface, a small saw kerf and a high advance, the saw cutting margin can be greatly reduced, the saw blade tooth tip wears slowly, and the service life is long.

Owner:新昌县智超邦金属材料科学技术研究院

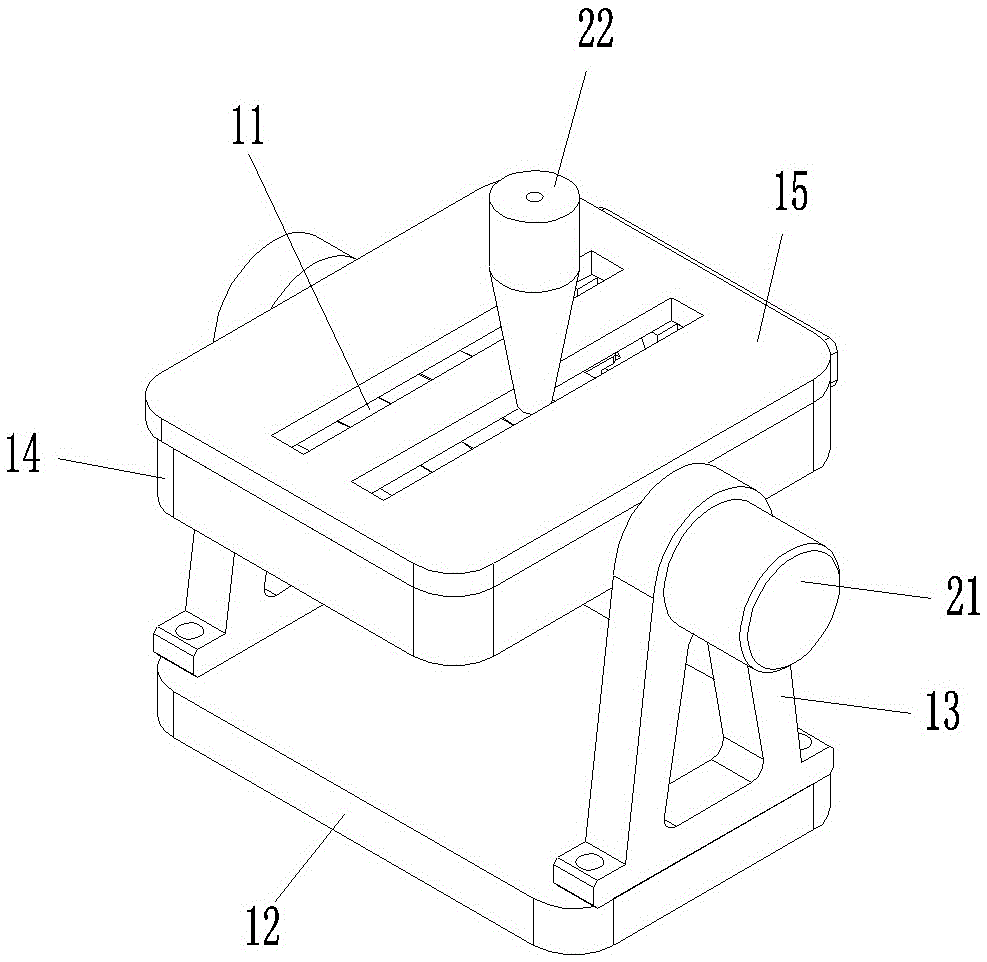

Grinding wheel segment manufacturing method and cutting jig implementing the method

InactiveCN104057405BFix poor qualityReduce wasteGrinding devicesLaser beam welding apparatusBack cuttingLaser cutting

The invention relates to the field of grinding wheel manufacturing, in particular to a method for manufacturing a grinding wheel segment and a cutting fixture for implementing the method. The manufacturing method of the grinding wheel segment includes the following steps: (1) loading the extended abrasive block into the corresponding cutting fixture, the cutting fixture is provided with at least one clamping position for the lengthened abrasive block, and the opposite sides of the clamping position are respectively provided with The front cutting relief groove and the back cutting relief groove, the corresponding front cutting relief groove and the reverse cutting relief groove are set opposite to each other; (2) Use the laser cutting machine to lengthen the abrasive block from the front and back of the corresponding clamping position respectively Make a cut. The manufacturing method of the grinding wheel segment of the invention solves the problems of low manufacturing efficiency of the grinding wheel segment, waste of materials and poor quality of the grinding wheel segment.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

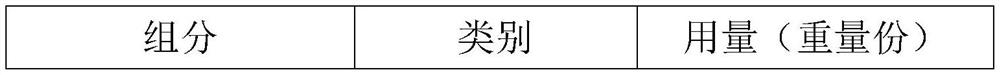

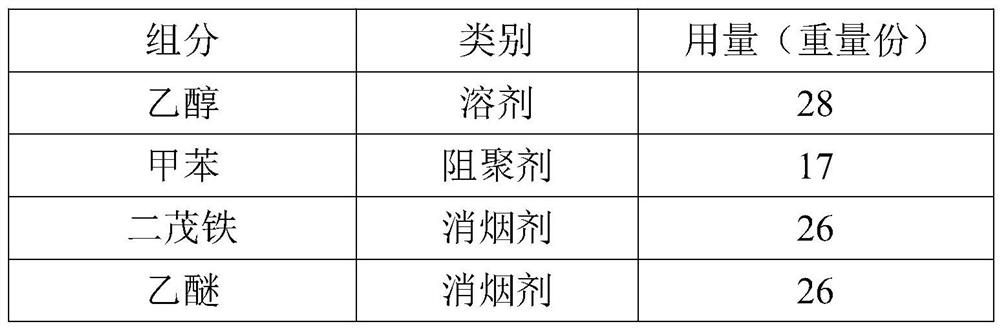

Industrial welding and cutting gas modified additive as well as preparation method and application thereof

ActiveCN114276844AAutomatically adjust the response speedEasy to cutLiquid carbonaceous fuelsGas flame welding apparatusPtru catalystProcess engineering

The invention provides an industrial welding and cutting gas modification additive. The industrial welding and cutting gas modification additive comprises the following components in parts by weight: 20-40 parts of a solvent, 10-30 parts of a polymerization inhibitor, 40-60 parts of a smoke suppressor, 0.5-4 parts of a catalyst, 0.1-1.5 parts of a stabilizer and 31-75 parts of an oxygen generating agent. According to the application of the industrial welding and cutting fuel gas modified additive, the modified additive is added into industrial fuel gas with C3 and C4 as mother liquor according to the ratio of 2-3 wt% for use. The modified additive disclosed by the invention is added into industrial fuel gases such as propane and liquefied gas, so that the gasification and activation performance of mother liquor fuel gas is improved, the wavelength and the frequency of combustion of mother liquor in oxygen are changed, and the combustion performance is improved; the flame combustion temperature of the industrial fuel gas added with the modified additive can reach about 3410 DEG C, the industrial fuel gas is superior to acetylene in the aspects of temperature, heat value, cutting effect, environmental protection, energy conservation, safety cost and the like, the cutting and welding performance of the industrial fuel gas reaches or exceeds that of acetylene gas, and the industrial fuel gas can completely replace acetylene to complete cutting and welding of metal.

Owner:HEBEI XINDA IRON & STEEL GRP CO LTD

Grinding wheel segment manufacturing method and cutting clamp for implementing same

InactiveCN104057405ASolve efficiency problemsSolve material wasteGrinding devicesLaser beam welding apparatusGrinding wheelLaser

The invention relates to the field of grinding wheel manufacturing, in particular to a grinding wheel segment manufacturing method and a cutting clamp for implementing the same. The grinding wheel segment manufacturing method comprises the following steps that (1) a lengthened grinding material block is loaded into the corresponding cutting clamp, the cutting clamp is provided with at least one lengthened grinding material block clamping position, the two opposite sides of the clamping position are provided with a front face cutting receding groove and a back face cutting receding groove respectively, and the front face cutting receding groove and the back face cutting receding groove which correspond to each other are arranged oppositely; (2) a laser cutting machine is used for cutting the lengthened grinding material block from the front face and the back face of the corresponding clamping position. The grinding wheel segment manufacturing method solves the problems that grinding wheel segment is low in manufacturing efficiency, materials are wasted, and the quality of a grinding wheel segment is poor.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Diamond inner circular cutting blade and preparation method thereof

ActiveCN106042200BIncrease the number of layersReduce blade thicknessElectrolytic coatingsFine working devicesMaterials scienceCoating

The invention discloses a diamond inner circle cutting blade and a preparation method thereof. The diamond inner circle cutting blade comprises a round matrix which comprises a first main surface, a second main surface, a third main surface, a fourth main surface, a first side surface located on the edge of the outer circumference, and a second side surface located on the edge of the inner circumference; the third main surface and the fourth main surface are correspondingly formed in the manner that the upper end and the lower end of the second side surface extend outwards in the direction of the first side surface by equal distances; the third main surface and the first main surface are connected through a first annular side face; the fourth main surface and the second main surface are connected through a second annular side face; the height of the first annular side face in the axial direction of the round matrix is equal to that of the second annular side face in the axial direction of the round matrix; and the third main surface, the fourth main surface and the second side surface are each provided with a diamond coating containing diamond particles.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

food slicer

ActiveCN104816331BSmall kerfSmall size errorMetal working apparatusEngineeringMechanical engineering

The invention discloses a food slicing device. the food slicing device comprises a frame, a slicing mechanism and a conveying mechanism, wherein the blade mechanism and the conveying mechanism are arranged on the frame, and the conveying mechanism is used for conveying foods; the slicing mechanism comprises blades, a knife rest and a driving mechanism, the driving mechanism is used for driving the knife rest to move back and forth in a direction which is intersected with the conveying direction of the conveying mechanism, and the knife rest is provided with a window for foods to pass through; the blades are arranged on the window at intervals, one ends of the blades are fixedly connected to the upper edge of the window, and the other ends of the blades are fixedly connected to the lower edge of the window; the driving mechanism is connected with the knife rest in a driving way, the conveying mechanism is located below the blades, and the conveying direction of the conveying mechanism is parallel to the blade orientations of the blades. According to the food slicing mechanism provided by the invention, foods can be cut with smaller kerfs, the excessive residues of a food detergent can be prevented, and the balanced taste of the sliced foods can be ensured.

Owner:GUANGZHOU FUYA MACHINERY

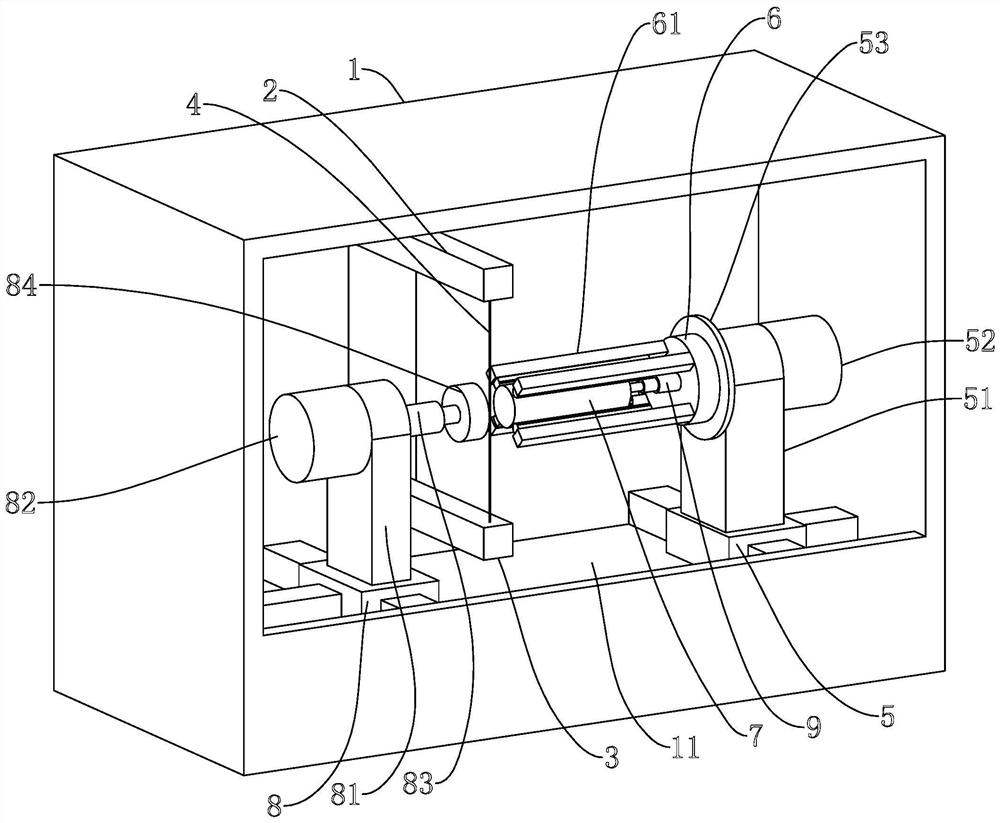

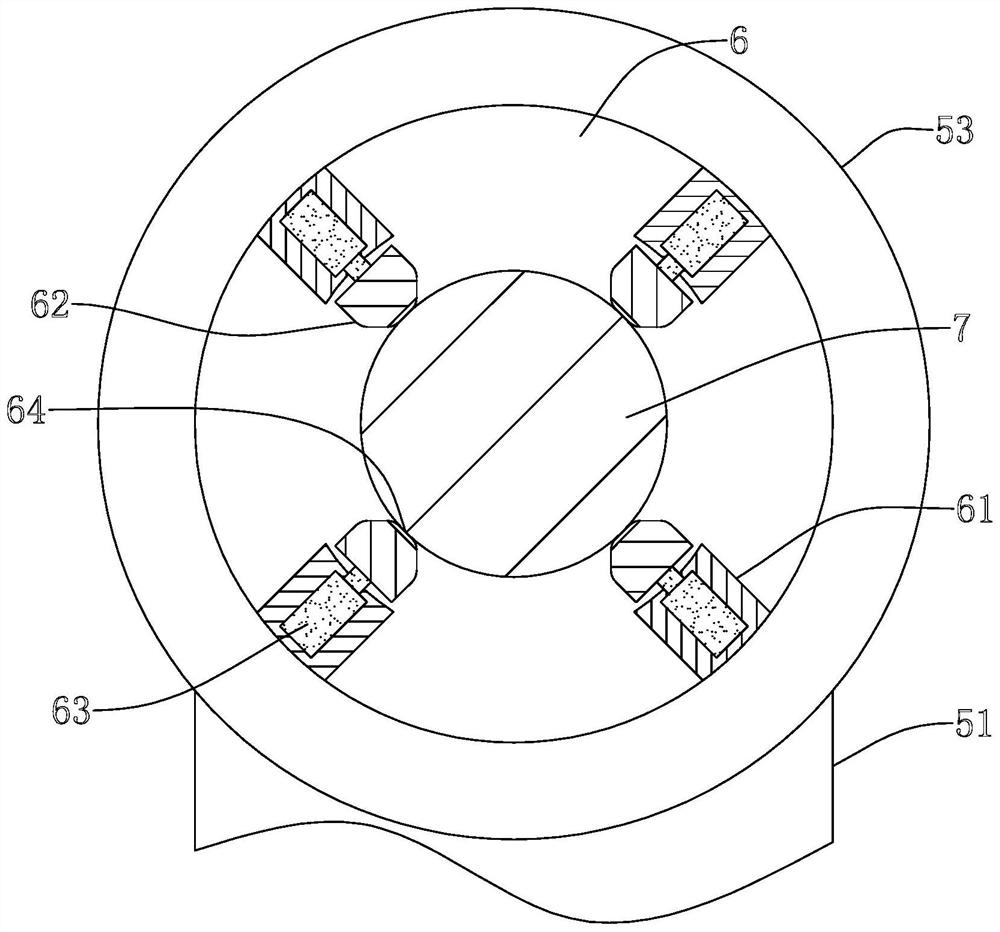

Rock core wire cutting and sample splitting device

The invention discloses a rock core wire cutting and sample splitting device which comprises a machine body, a workbench is arranged on the machine body, a first supporting arm and a second supporting arm which are connected to the machine body are arranged above the workbench, a diamond wire is arranged between the first supporting arm and the second supporting arm, a first supporting plate is arranged on the workbench, and a first supporting column is arranged at the upper end of the first supporting plate; a first rotating motor is arranged on the side, away from the diamond wire, of the first supporting column, a rotating disc is arranged on the side, close to the diamond wire, of the first supporting column, an output shaft of the first rotating motor is connected to the rotating disc, a supporting disc is installed on the side, close to the diamond wire, of the rotating disc, and four supporting rods are evenly arranged on the edge of the side, close to the diamond wire, of the supporting disc. Pressing strips are arranged on the sides, close to the axis, of the four supporting rods, first automatic telescopic rods are arranged in the supporting rods, and one ends of the first automatic telescopic rods stretch out of the supporting rods to be connected to the pressing strips. The fixed rock core is cut through the diamond wire, cutting is uniform, cutting seams are small, and waste of the rock core is reduced.

Owner:KUNMING METALLURGY COLLEGE

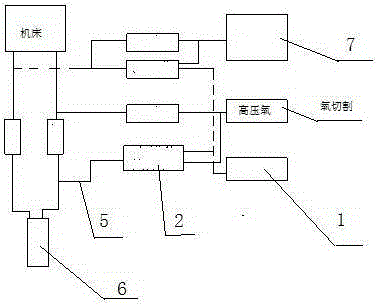

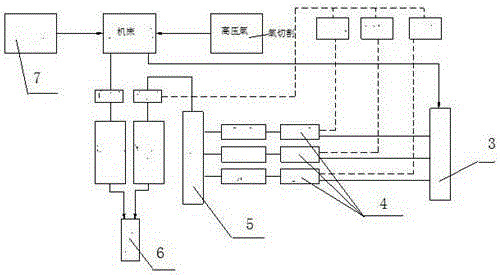

A kind of oxyhydrogen flame numerical control punching and cutting process

ActiveCN103203514BNo pollution in the processSafe to use at any timeGas flame welding apparatusNumerical controlPunching

The invention belongs to the technical field of metal flame cutting processing and provides an oxyhydrogen flame numerical control punching and cutting process. The oxyhydrogen flame numerical control punching and cutting process is characterized in that oxyhydrogen is adopted as cutting gas of a numerical control flame machine tool, the oxyhydrogen is delivered to a cutting torch (6) of the numerical control flame machine tool through a busbar (5), the pressure of the cutting gas is controlled to be in a range from 0.1MPa to 1.6MPa in a numerical control manner, and is gradually increased from low to high. The oxyhydrogen flame numerical control punching and cutting process adopts the oxyhydrogen and a gradually pressurizing mode to perform metal cutting, and solves the problem of serious pollution and potential safety hazards of the traditional process.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

Preparation method of narrow and thin superhard material grinding wheel ring and fixture for implementing the method

ActiveCN104084899BHigh strengthImprove yieldWelding/cutting auxillary devicesGrinding devicesSuperhard materialGrinding wheel

The invention relates to the manufacturing field of grinding materials and grinding tools, in particular to a method for manufacturing a grinding wheel ring made of a narrow and thin ultra-hard material and a clamp for implementing the method. The method for manufacturing the grinding wheel ring made of the narrow and thin ultra-hard material includes the following steps that (1) a blank body of the grinding wheel ring is manufactured, the width size of the blank body of the grinding wheel ring is slightly larger than the width size of the grinding wheel ring to be manufactured, and the thickness size is integral multiples the thickness size of the grinding wheel ring to be manufactured; (2) the manufactured blank body of the grinding wheel ring in the step (1) is dried, and then sintering and solidifying are conducted; (3) the treated blank body of the grinding wheel ring in the step (2) is segmented, so that the grinding wheel ring to be manufactured is obtained. By means of the method for manufacturing the grinding wheel ring made of the narrow and thin ultra-hard material and the clamp for implementing the method, the problems that the grinding wheel ring made of the narrow and thin ultra-hard material is low in rate of finished products, poor in precision and low in production efficiency are solved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Method for cutting ultrathin dimension stone in large specification by using small circular saw blade

InactiveCN100387415CSmall sizeReduce runoutWorking accessoriesStone-like material working toolsCircular sawEngineering

A method for preparing a large-area super-thin stone material by use of small circular saw blade includes such steps as cutting on the big stone slab according to the sizes of needed small stone slabs to form multiple ditches, fixing the big stone slab to the bench of a horizontal cutting machine, sucking the first needed small stone strip by a sucking unit, using small circular saw blade to saw the big stone slob for separating the first small stone strip from the big one, repeating said steps until all small stone strips are separated to obtain a large-area super-thin stone material and several small super-thin stone strips. Said horizontal cutting machine is also disclosed.

Owner:翦凝刚

Diamond wire saw and manufacturing method thereof

ActiveCN101905491BPrevent infiltrationGuaranteed softnessGrinding devicesFine working devicesDiamond wire sawWire saw

The invention discloses a diamond wire saw and a manufacturing method thereof. The diamond wire saw comprises a bending-resistant flexible multi-strand rope, wherein the flexible multi-strand rope has the diameter of 0.5 to 2.0mm, and is fixed with at least two diamond braze-welding layers with the thickness of 0.1 to 2.0mm that are spaced apart from each other. The diamond wire saw can effectively prevent a braze-welding material from entering into gaps of the flexible multi-strand rope so as to solve the problem that the conventional diamond wire saw manufactured by taking the flexible multi-strand rope as a centre line is too inflexible and is entirely unusable.

Owner:XIAMEN ZL DIAMOND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com