A kind of oxyhydrogen flame numerical control punching and cutting process

A cutting process and oxyhydrogen flame technology, which is applied in the field of oxyhydrogen flame CNC punching and cutting process, can solve problems such as harm to the health of operators, quality accidents, safety accidents, etc., so as to save repairing time, reduce process costs, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

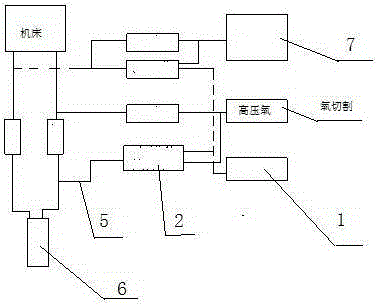

[0019] This embodiment adopts the stepless continuous control and pressure regulation mode controlled by the PLC controller 1 and the electric pressure regulating valve 2, taking cutting a 50mm steel plate as an example.

[0020] like figure 1 As shown, the cutting gas uses the hydrogen-oxygen mixture produced by the electrolytic water generator 7, and the cutting gas is directly connected to the cutting nozzle 6 of the CNC flame machine tool through the bus bar 5.

[0021] The electric pressure regulating valve 2 is directly arranged at the bus bar 5 , and the electric pressure regulating valve 2 controls the pressure of the cutting gas by controlling the gas flow in the bus bar 5 .

[0022] The PLC controller 1 is directly connected to the electric pressure regulating valve 2, and the pre-program in the PLC controller is to control the electric pressure regulating valve 2 within 4 seconds, so that the pressure of the cutting gas in the bus bar 5 increases from 0.1MPa to 0.3M...

Embodiment 2

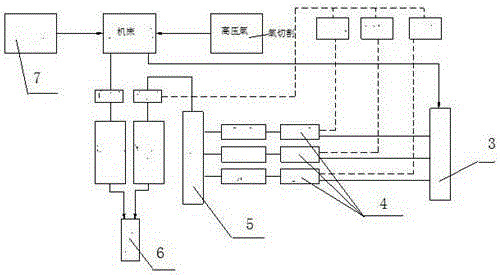

[0027] This embodiment adopts the step-by-step control and pressure regulation mode controlled by the time relay 3 and three solenoid valves 4, taking cutting a 70mm steel plate as an example.

[0028] like figure 2 As shown, the cutting gas uses the hydrogen-oxygen mixture produced by the electrolytic water generator 7, and the cutting gas is directly connected to the cutting nozzle 6 of the CNC flame machine tool through the bus bar 5.

[0029] The bus bar 5 is composed of three separate channels, each of which is connected to the cutting nozzle 6 of the CNC flame machine tool, and each separate channel is provided with a solenoid valve 4, and the three solenoid valves 4 are all connected to the time relay 3. Pass.

[0030] According to the steel plate thickness of 70mm, three gas pressure stages are set, which are 0.2MPa, 0.4MPa and 0.6MPa respectively. The time relay 3 controls the three solenoid valves 4 to open sequentially, and the time interval between each opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com