Rock core wire cutting and sample splitting device

A wire cutting and core technology, applied in the field of core cutting, can solve the problems of core powder sand loss, difficult core acquisition, core waste, etc., and achieve the effects of reducing waste, firm fixing, and convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

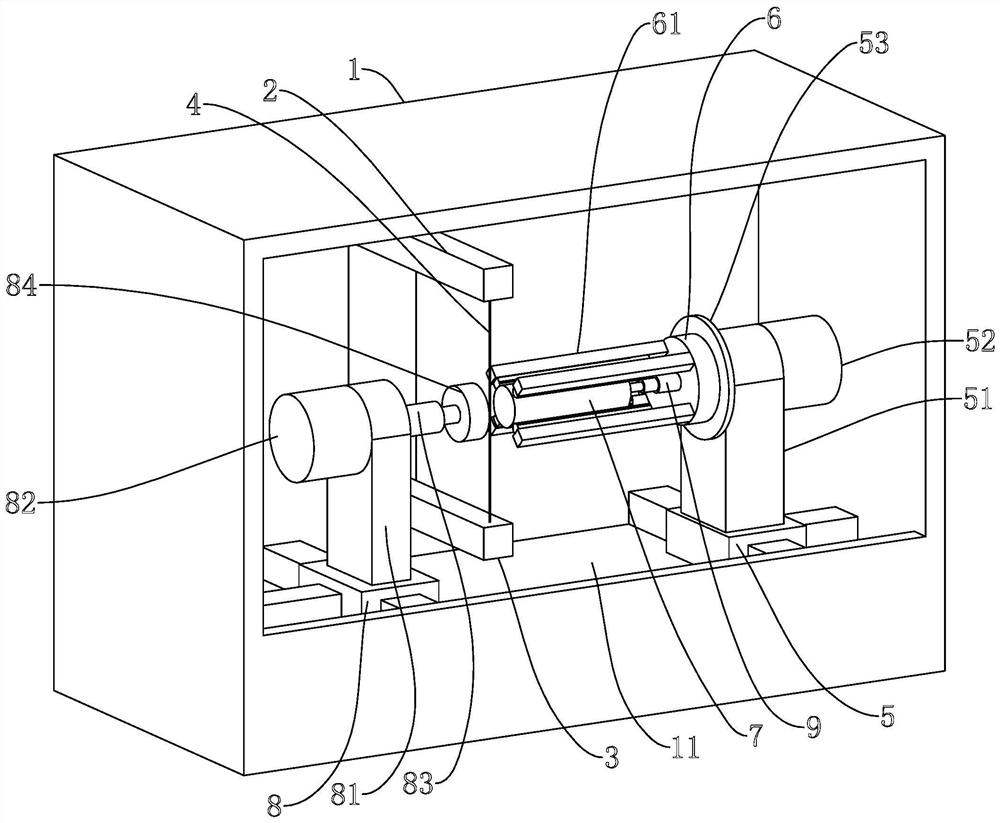

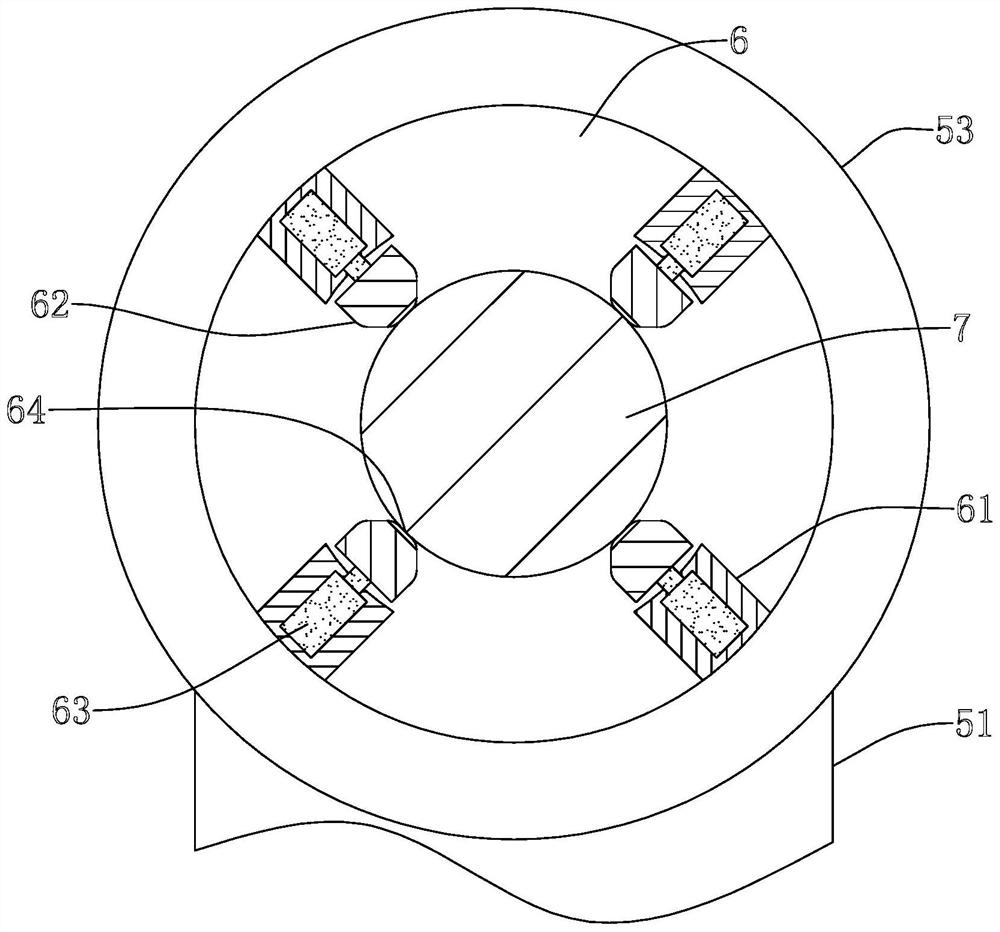

[0023] Embodiment, a kind of core wire cutting sample splitting device, such as figure 1 and figure 2 As shown, the body 1 is included, the body 1 is provided with a workbench 11, the top of the workbench 11 is provided with a first support arm 2 and a second support arm 3 connected to the body 1, and the first support arm 2 is arranged on the second support Above the arm 3, the first support arm 2 and the second support arm 3 are parallel to each other, and a gold wire 4 is vertically arranged between the first support arm 2 and the second support arm 3, and the gold wire 4 is used in conjunction with the body 1 One side of the gold steel wire 4 on the workbench 11 is provided with a first support plate 5 that can automatically move on a horizontal plane, and the upper end of the first support plate 5 is provided with a first support column 51, and the first support column 51 is far away from the gold One side of the steel wire 4 is provided with a first rotating motor 52, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com