Method for cutting ultrathin dimension stone in large specification by using small circular saw blade, and dedicated leveling splitting machine

A circular saw blade and large-scale technology, applied in the field of ultra-thin stone cutting, can solve the problems of unsatisfactory thickness uniformity of ultra-thin stone, difficulty in greatly improving performance, difficulty in processing ultra-thin stone slabs, etc., and achieve a high damage rate The effect of low cost, large reduction in production cost and reduction in geometric size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

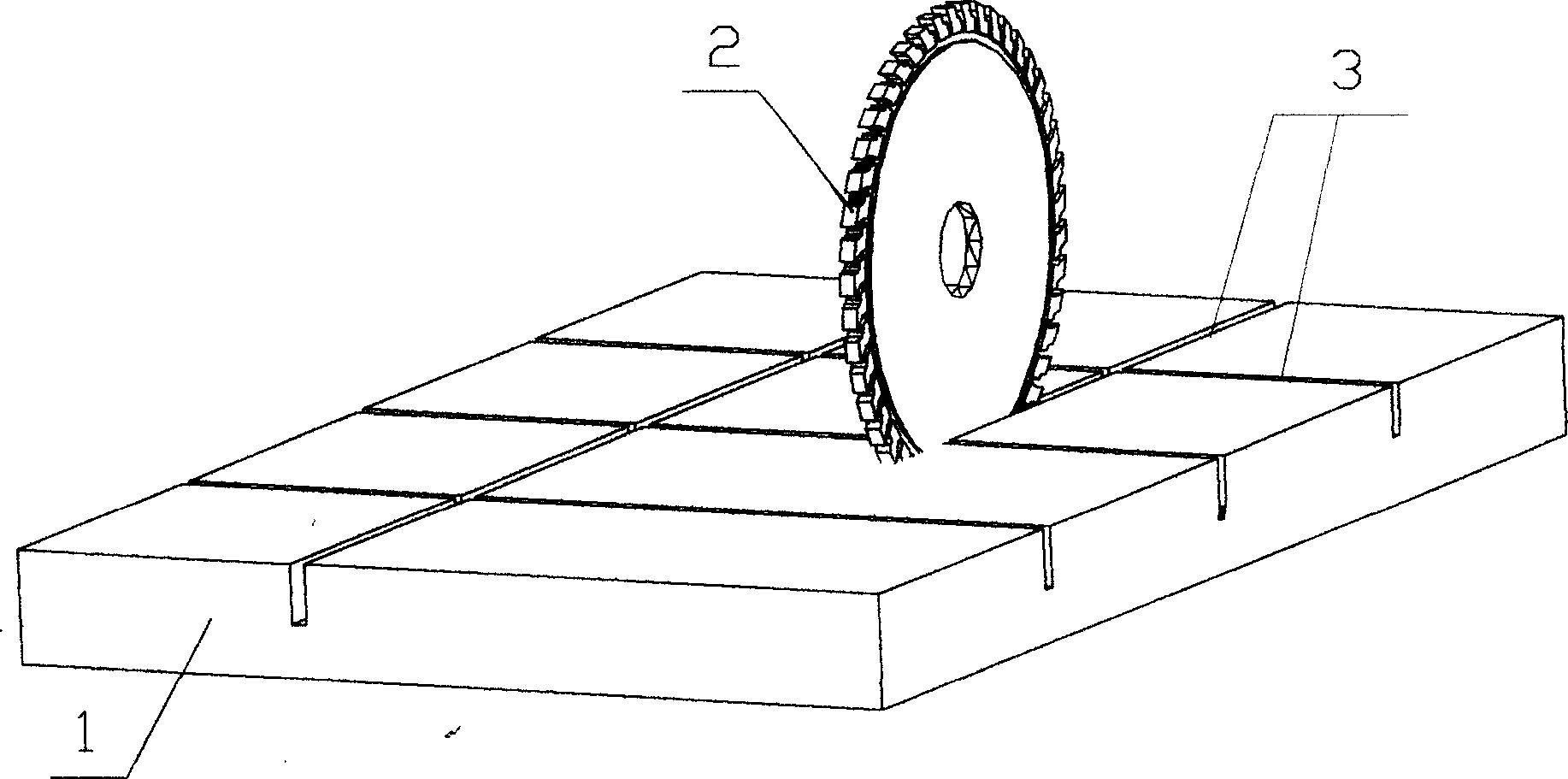

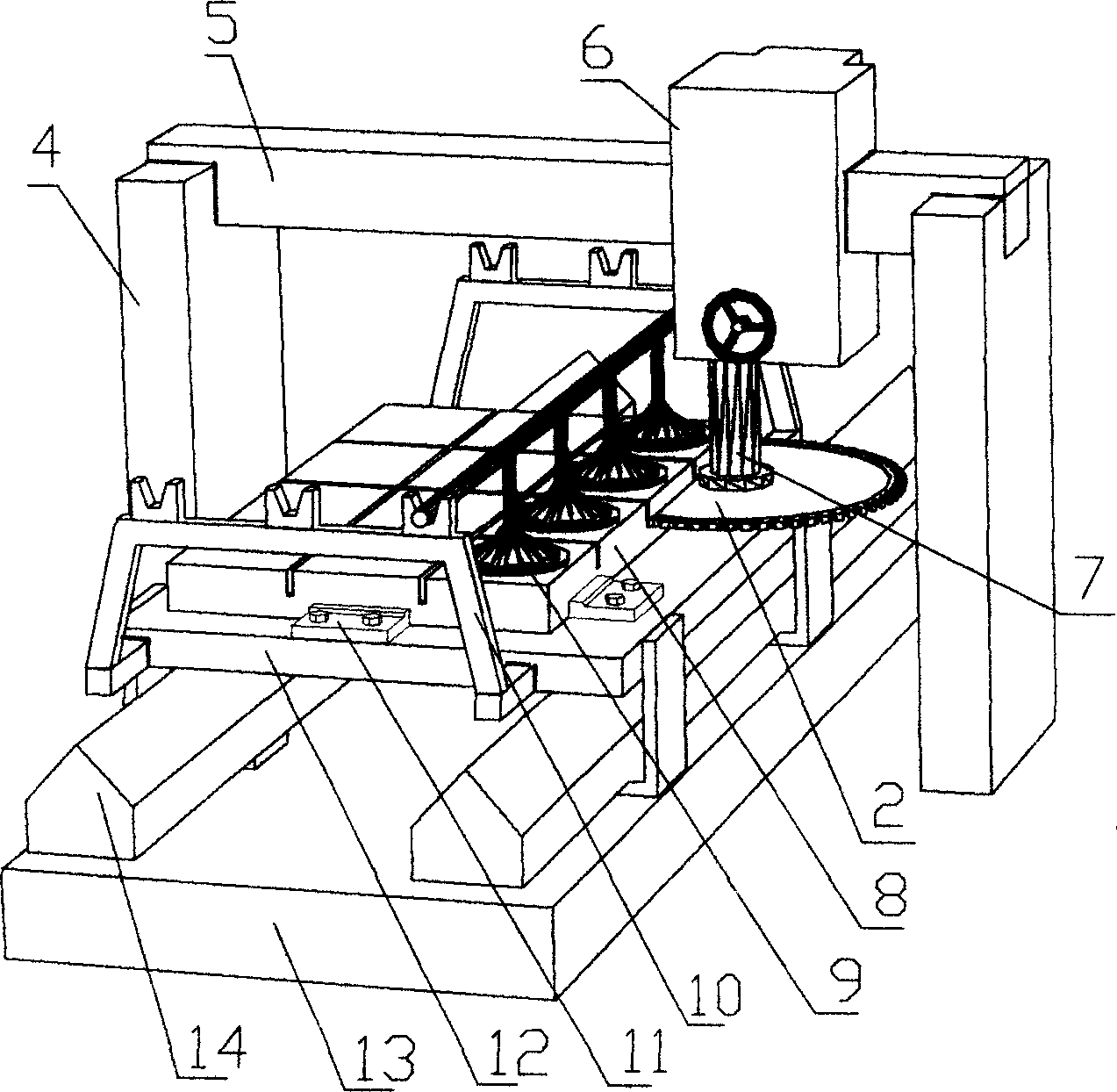

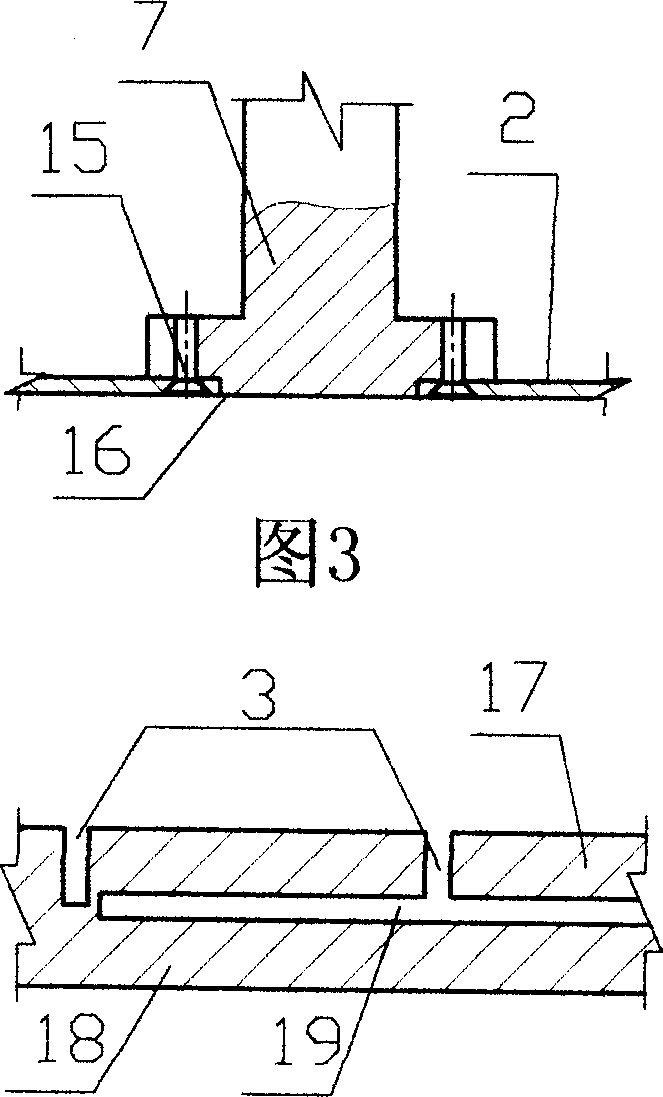

[0035] like figure 1 , figure 2 ,image 3, Figure 4 , Figure 5 Shown, the present invention cuts the method for large-scale ultra-thin stone with small circular saw blade, and its process step is as follows:

[0036] (1) According to the sum of the thicknesses of two stone slabs 18,17 to be obtained plus the thickness of the circular saw blade 2 plus the thickness of the circular saw blade 2 end face runouts, select the thickness of the required double-sided polished stone slab 1. For example: a double-sided polished 1600mm×800mm stone slab 1 is to be cut into one 1600mm×800mm×2mm and four 1600mm×200mm×4mm stone slabs. The circular saw blade 2 of φ500mm can be selected, the thickness of the circular saw blade 2 is 4mm, and the end face runout is 0.5mm, so the kerf 19 is 4.5mm, and the thickness of the selected stone plate 1 should be 10.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com