Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

562results about How to "Guaranteed cutting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

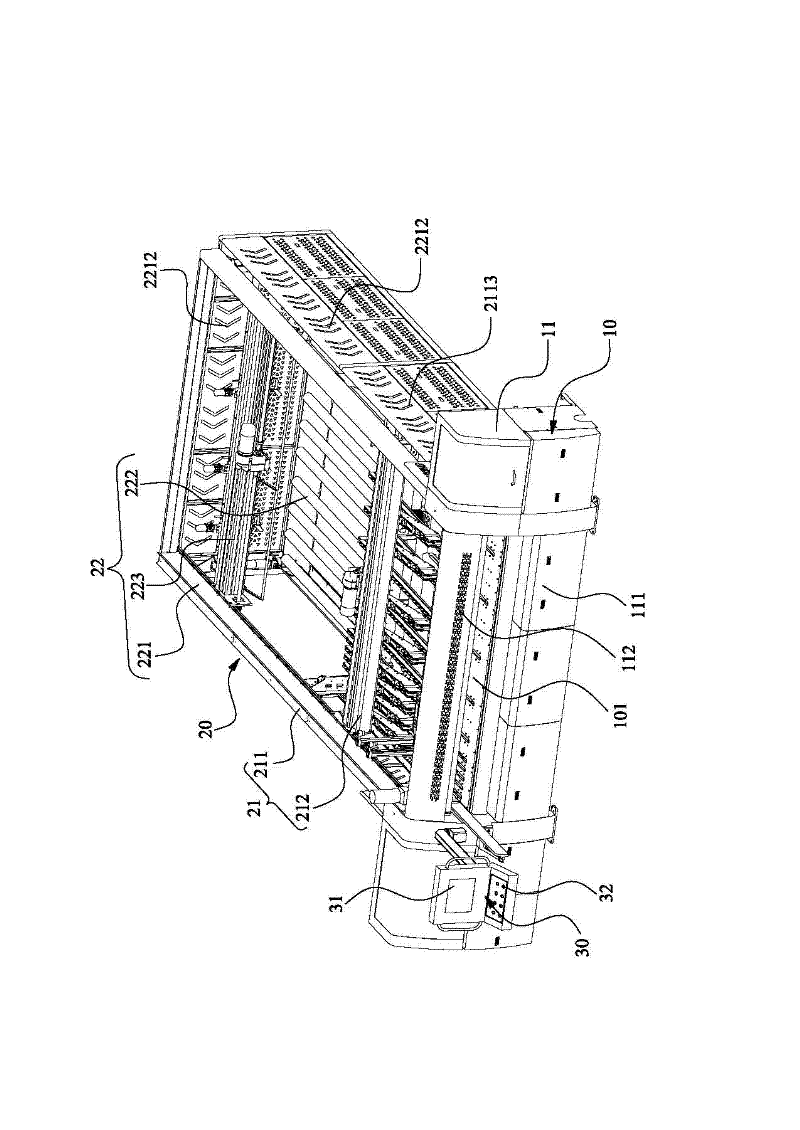

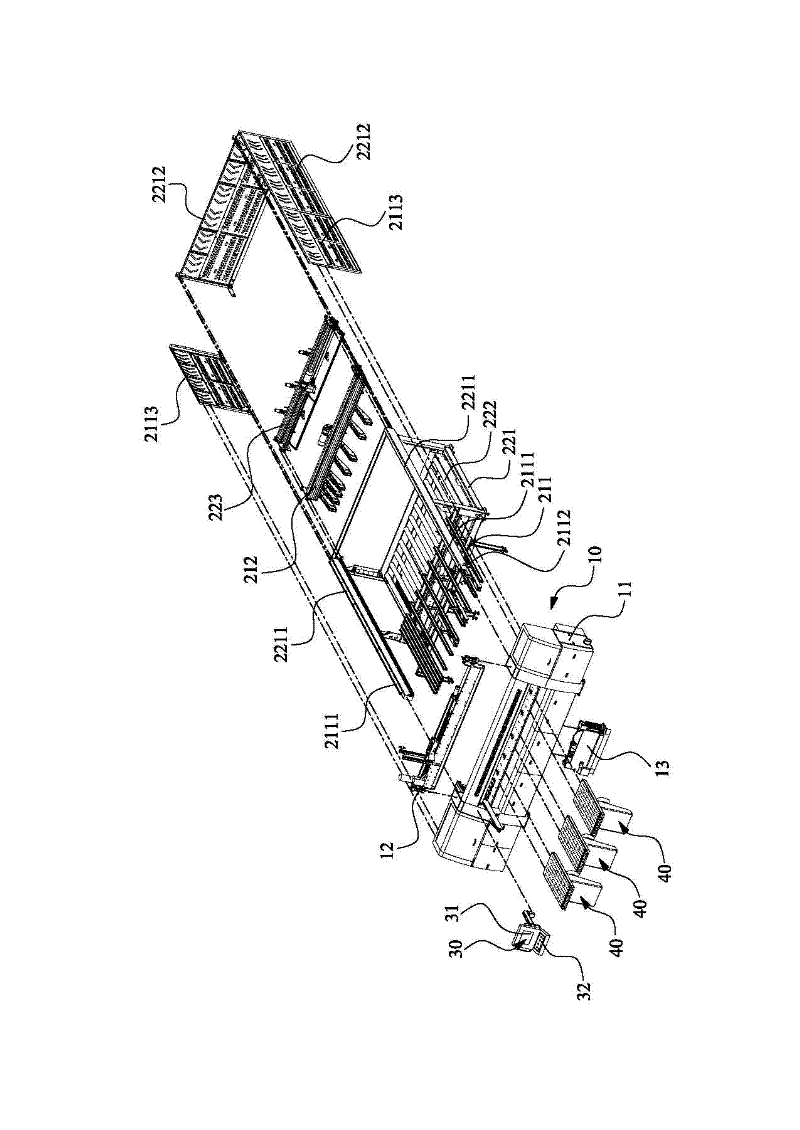

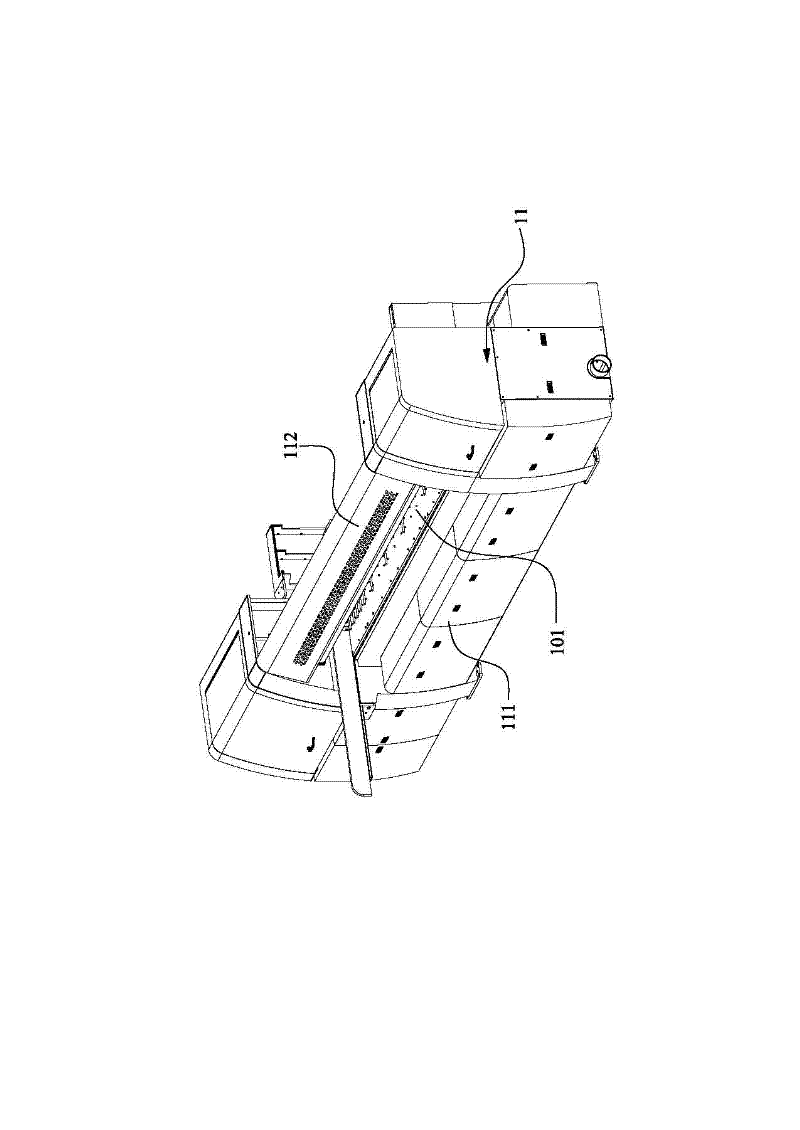

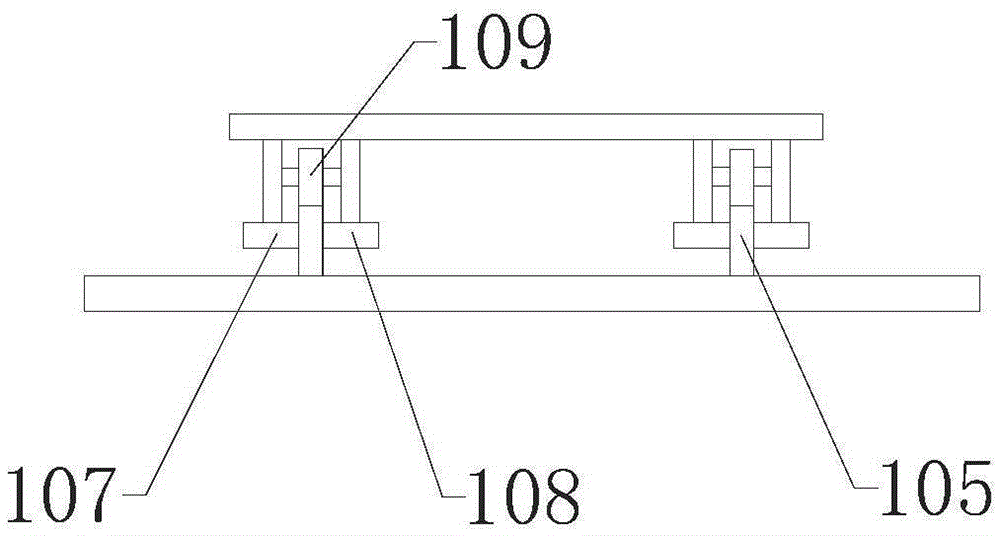

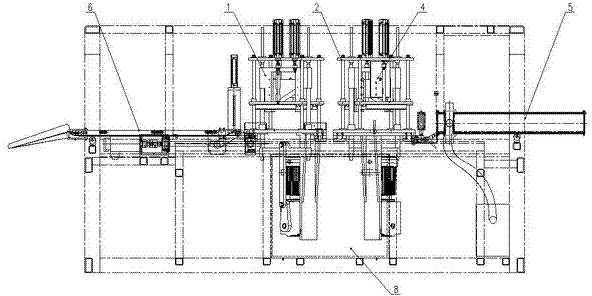

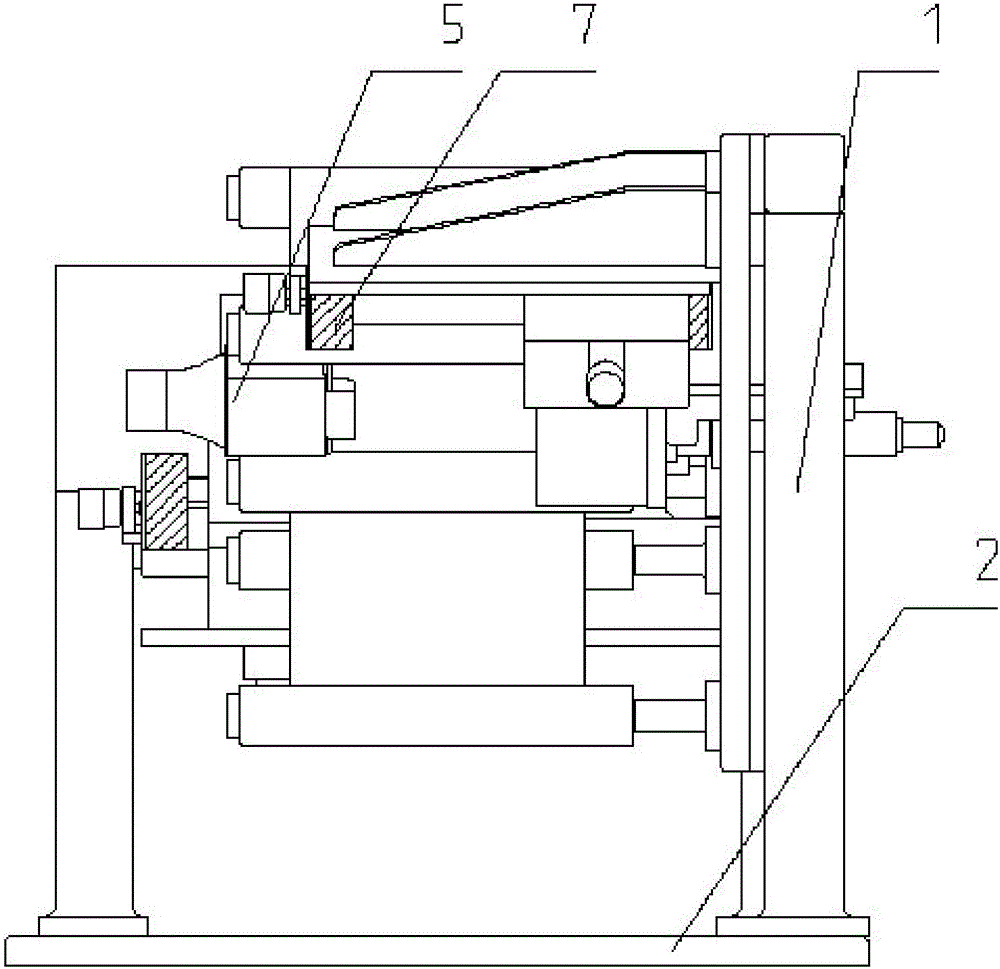

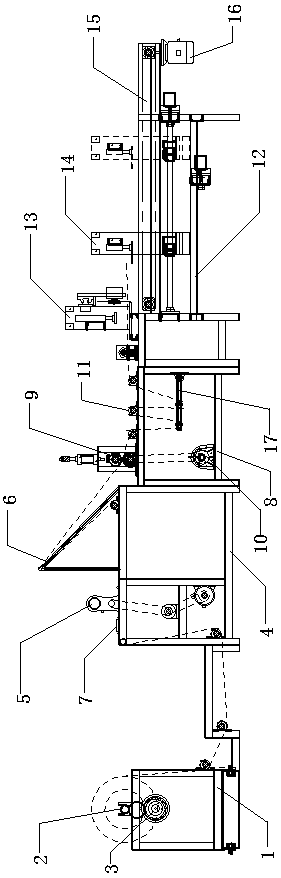

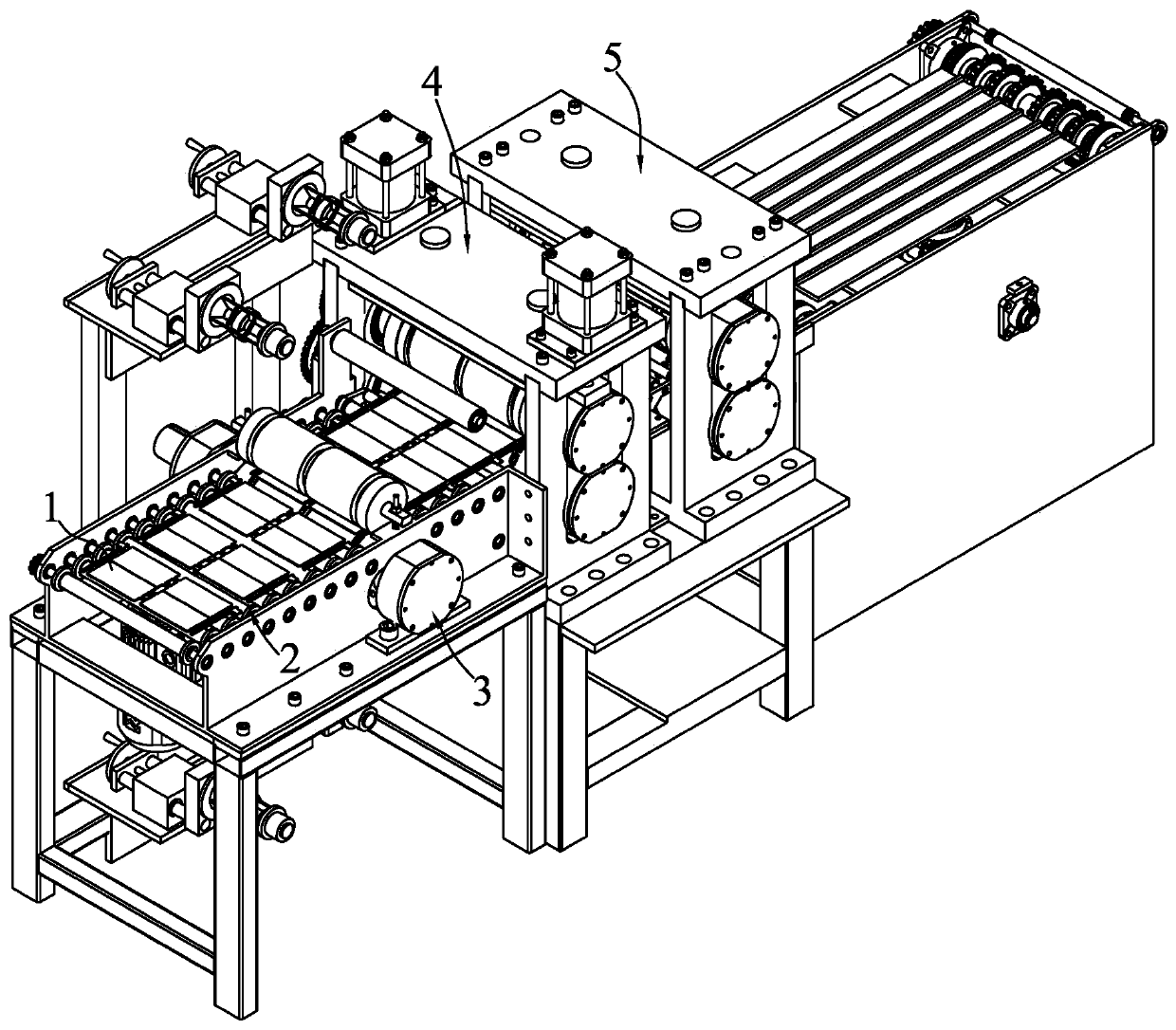

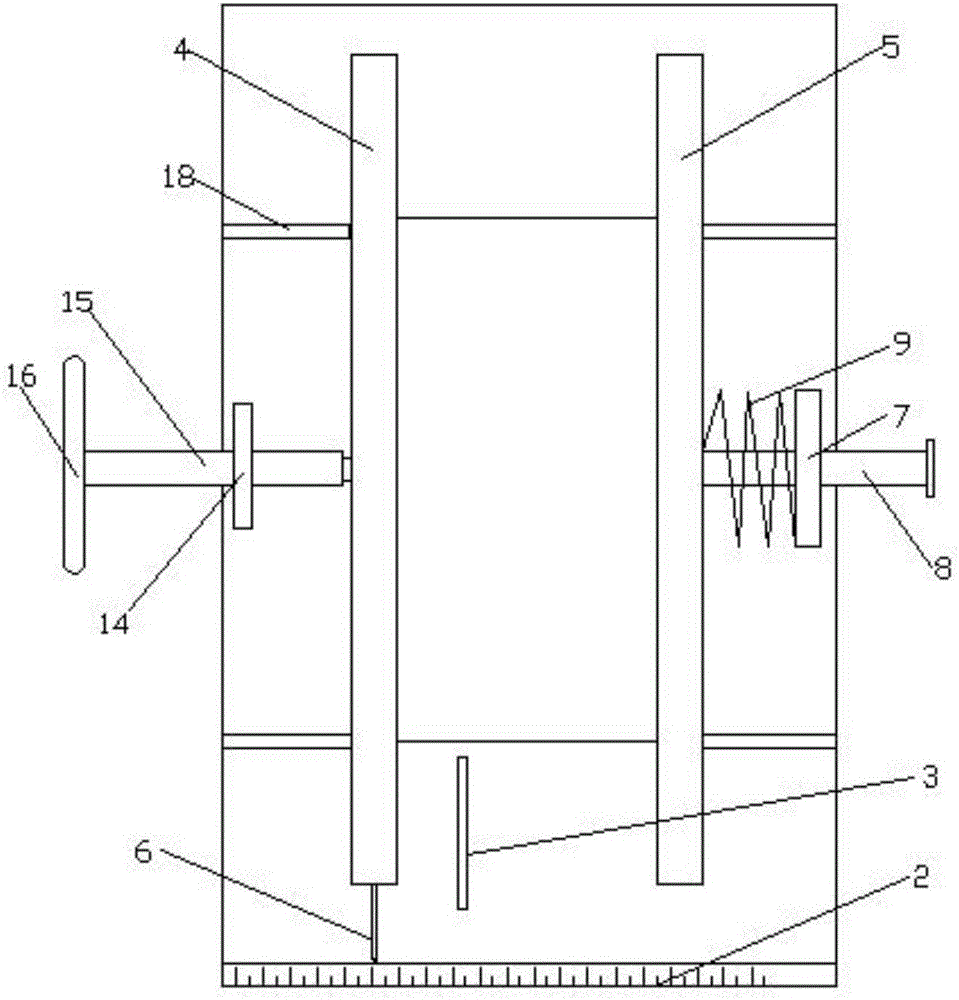

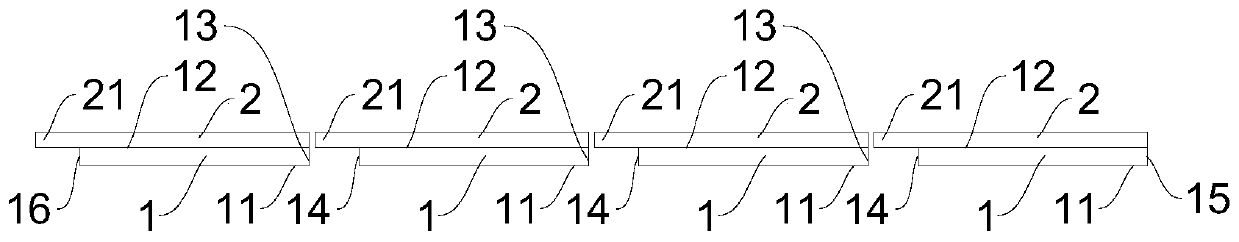

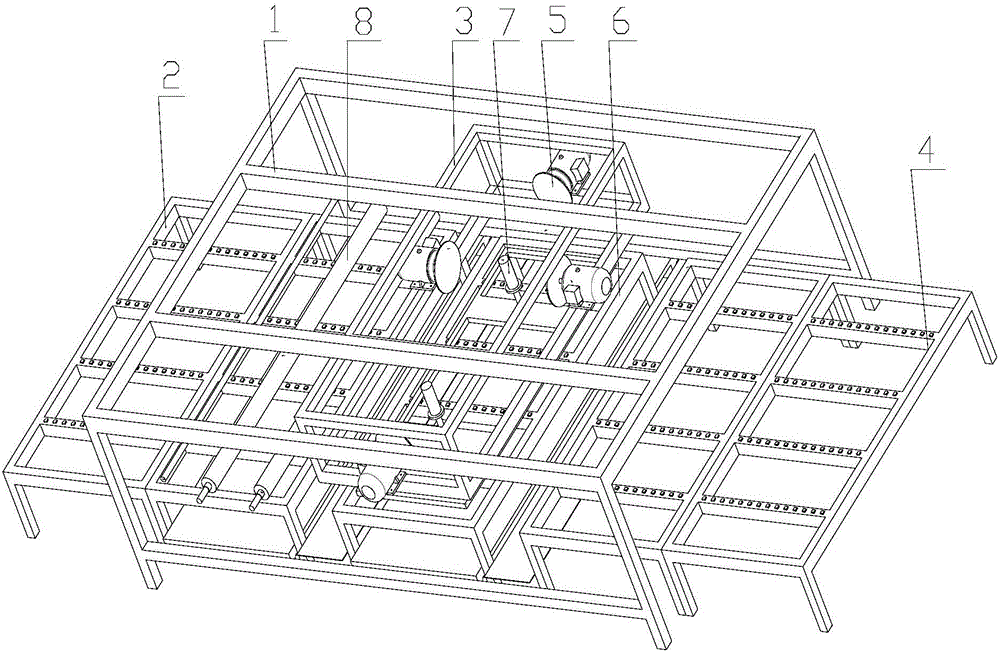

Back loading high-speed computer panel saw

ActiveCN102390063AGuaranteed cutting accuracyConducive to survivalFeeding devicesCircular sawsComputer control systemEngineering

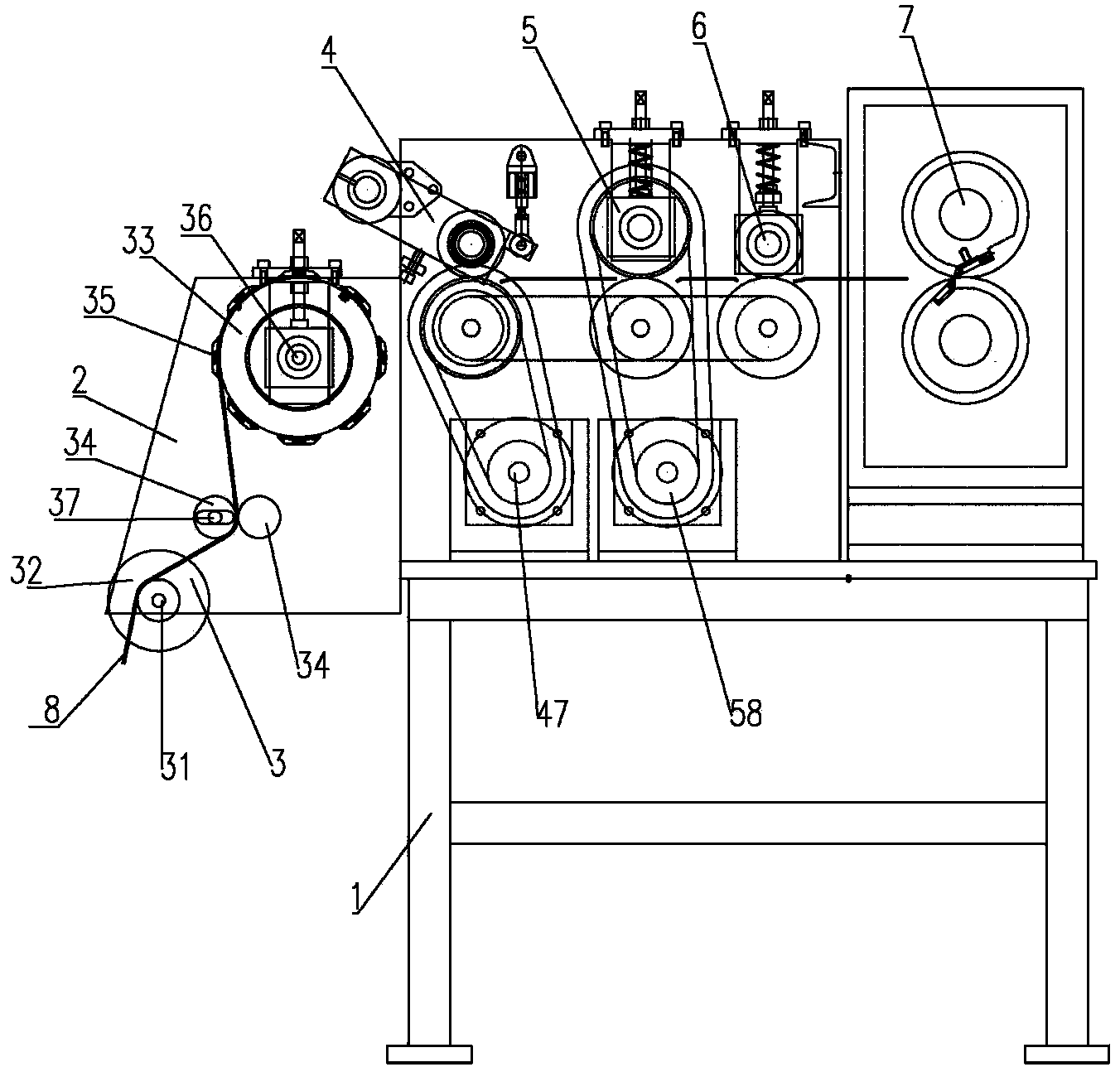

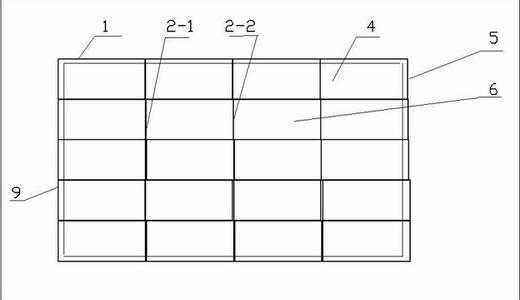

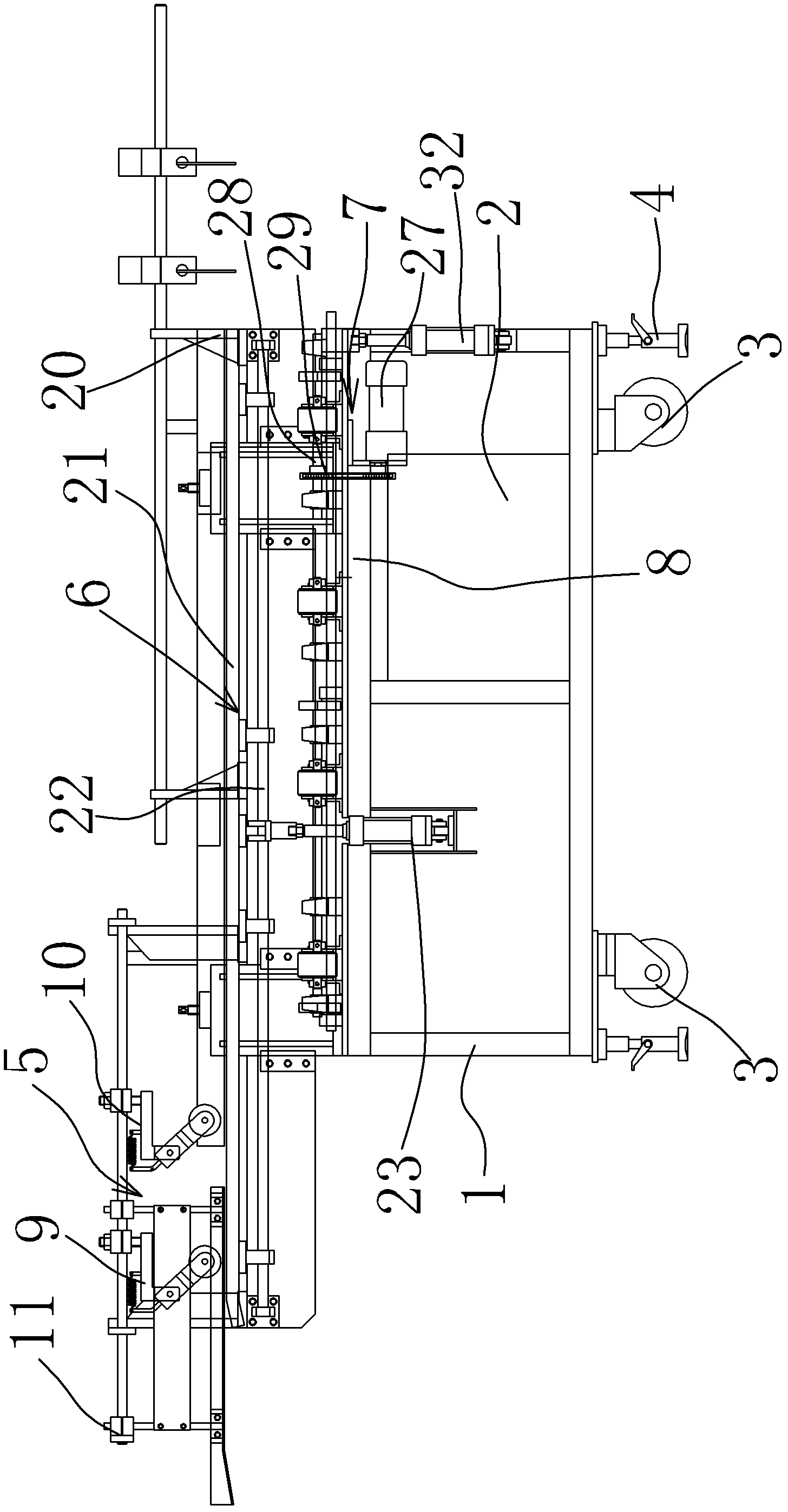

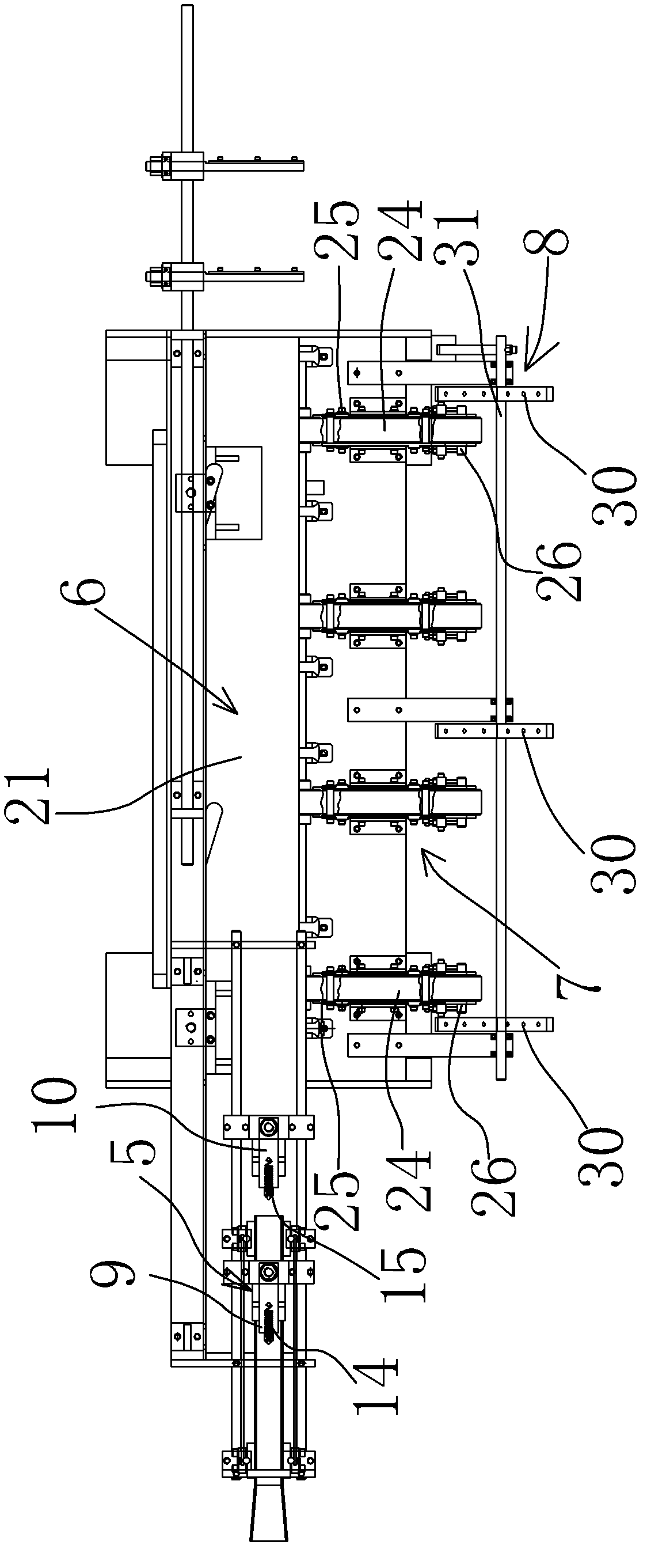

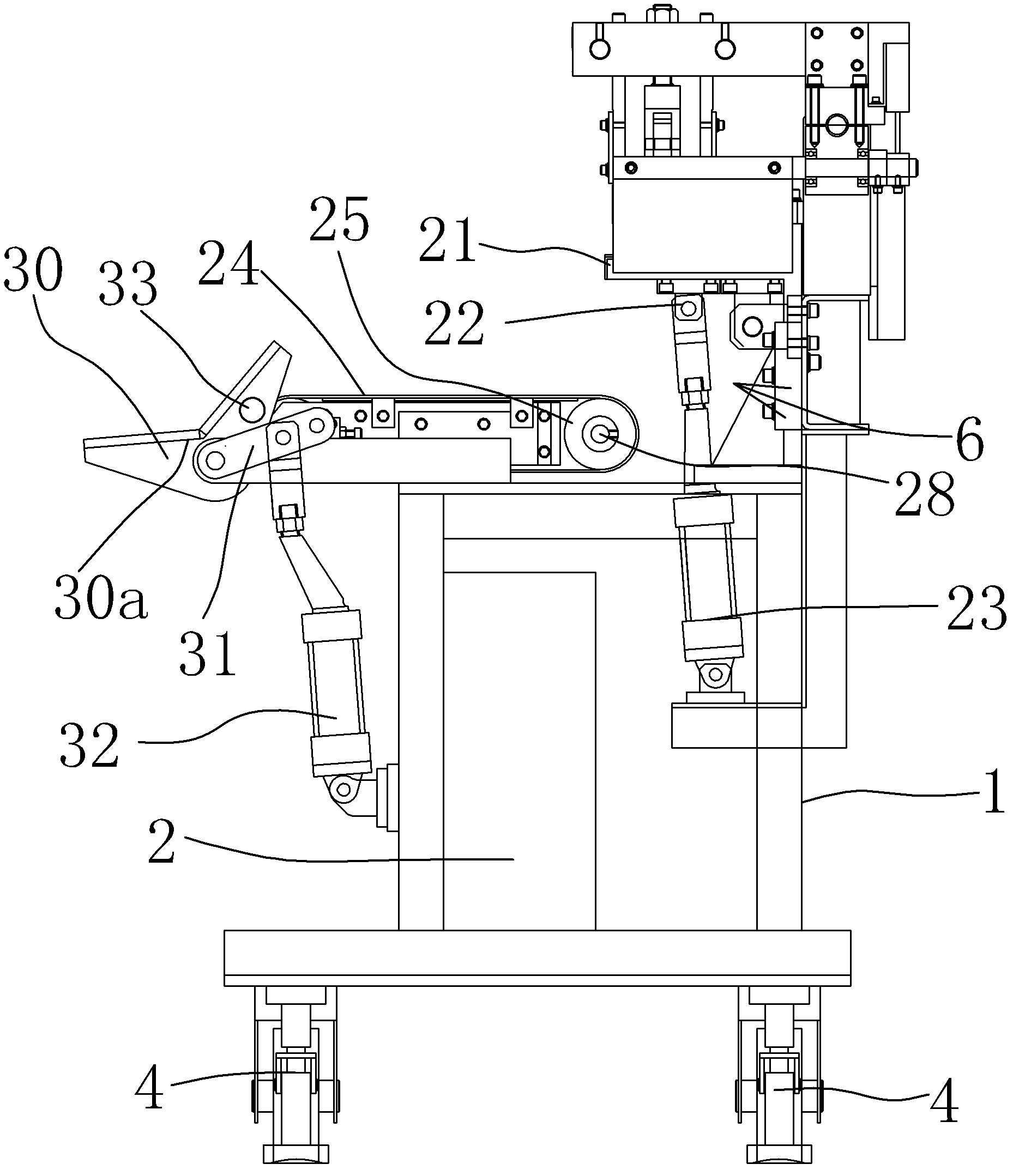

The invention discloses a back loading high-speed computer panel saw comprising a machine station main body, a material feeding unit and a computer control system, wherein the machine station main body comprises a worktable, a material pressing device and a cutting device; the material pressing device and the cutting device are both arranged on the worktable; the material feeding unit is arranged at the back side of the machine station main body; the material feeding unit comprises a material feeding device and a material loading device; the material feeding device is arranged between the machine station main body and the material loading device; the material feeding device comprises a material feeding bracket and a first propulsion mechanism; the material loading device comprises a material loading bracket, a lifting table and a second propulsion mechanism; the computer control system controls the work of the material pressing device, the cutting device, the material feeding device and the material loading device, thereby realizing automation operation in the overall process of panel cutting, being favorable for ensuring the cutting precision of panel material, improving the work efficiency effectively, reducing the number of operation personnel and reducing the work strength for workers, thus reducing the production cost for an enterprise and being beneficial to the survival of the enterprise.

Owner:NANXING MACHINERY CO LTD

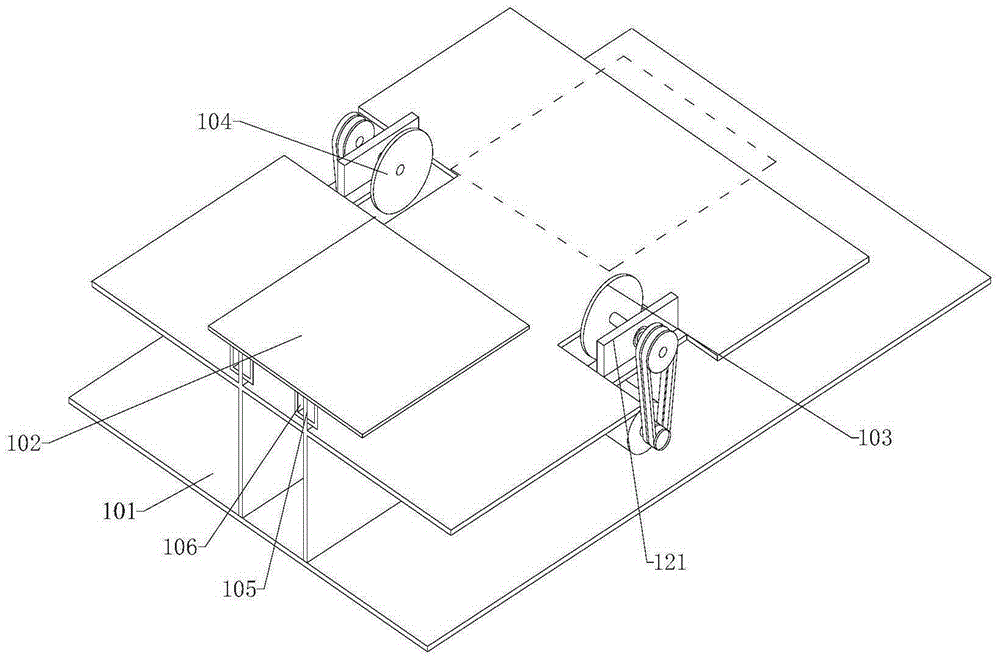

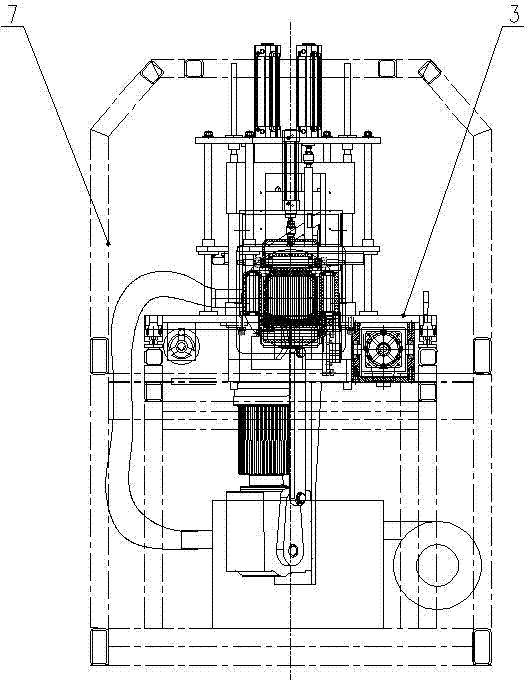

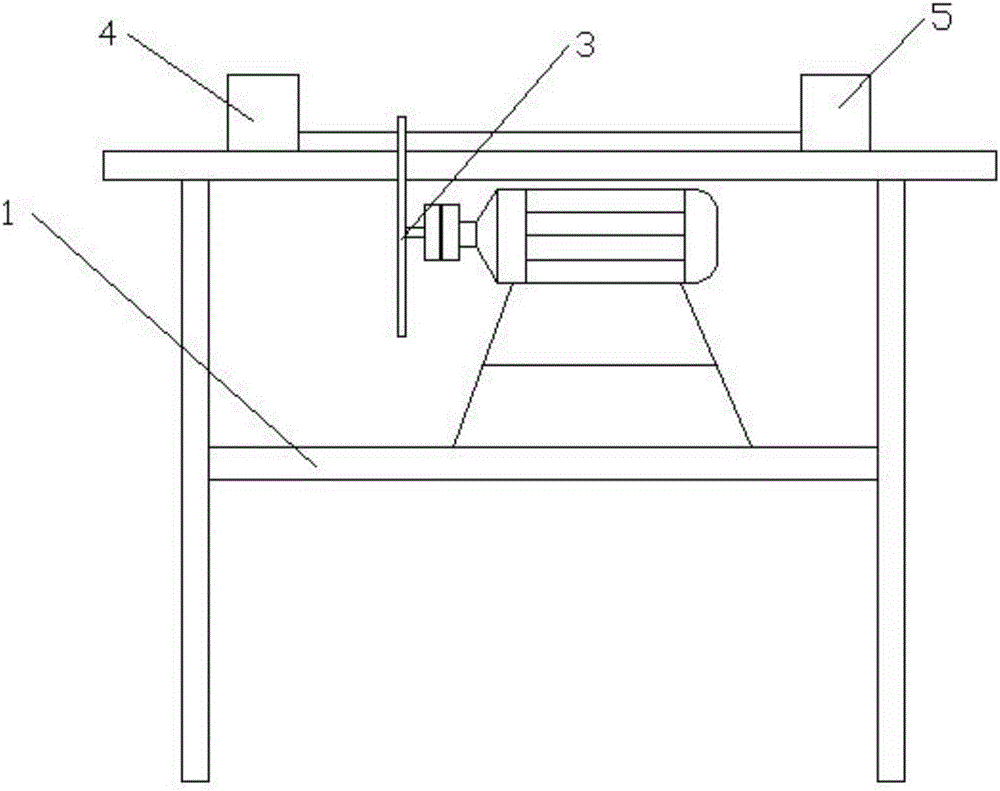

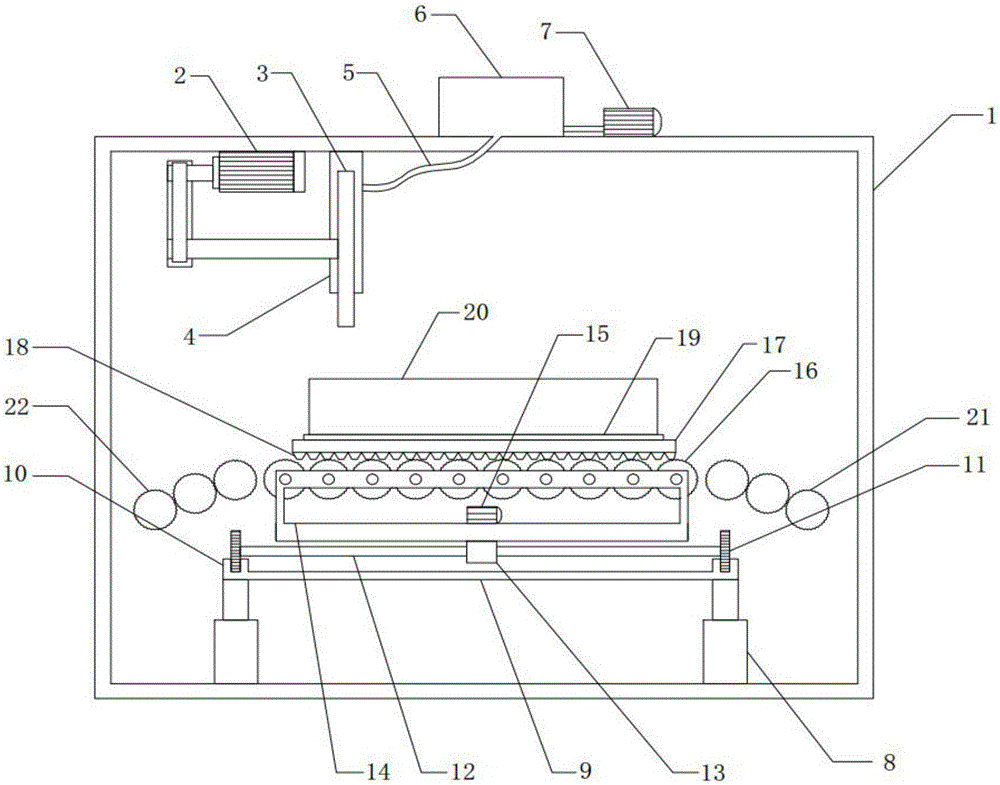

Cutting machine

InactiveCN105291198AReduce frictionReduce wearEdge grinding machinesSawing componentsEngineeringWood plank

The invention provides a cutting machine and belongs to the field of mechanical devices. The cutting machine comprises a rack body, a workbench, a drive device and a cutting part, wherein the rack body is provided with a first guide rail; the workbench is in sliding connection with the first guide rail; the drive device is connected with the workbench and the cutting part; the cutting part comprise a first longitudinal cutting part body and a second longitudinal cutting part body which are arranged symmetrically; the first longitudinal cutting part body and the second longitudinal cutting part body are connected with the rack body; the first longitudinal cutting part body is located on one side of the workbench in the direction of the first guide rail; the second longitudinal cutting part body is located on the side, away from the first longitudinal cutting part body, of the workbench. According to the cutting machine, the drive device drives the workbench to slide along the first guide rail, so that cutting machining of planks is automatic, the cutting precision of the planks can be ensured without experienced operators, work intensity of the operators is also relieved, and the plank machining efficiency is improved.

Owner:CHONGQING AIBUTE FURNITURE

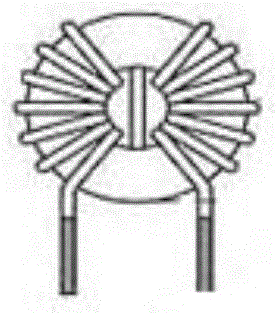

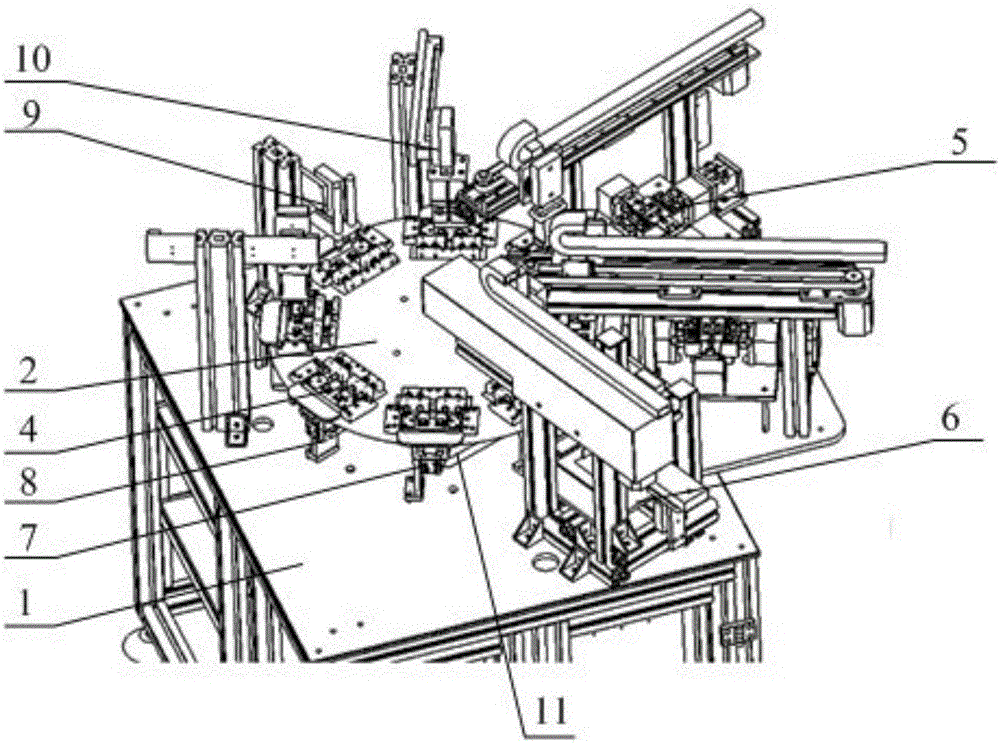

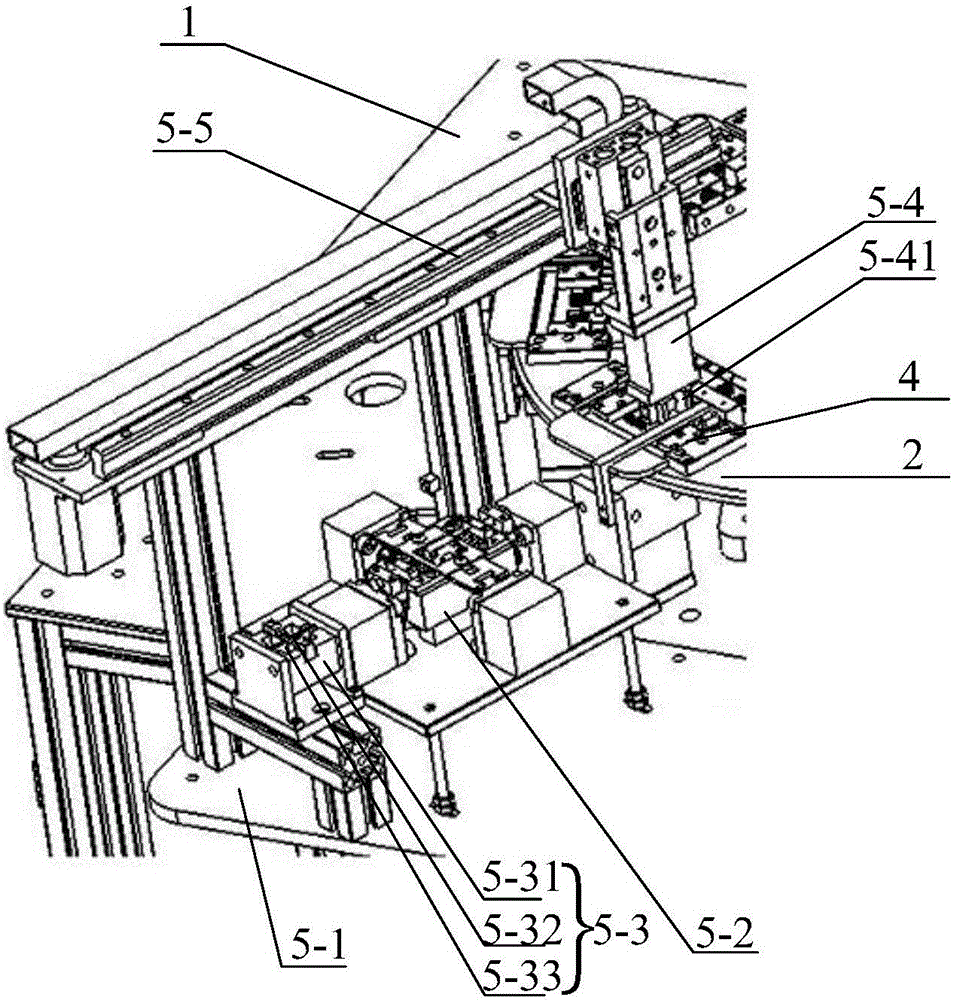

Automatic soldering and testing integrated machine for inductance coil and working method of automatic soldering and testing integrated machine

ActiveCN106601471AGuaranteed cutting accuracyGuaranteed soldering precisionSoldering apparatusMetal working apparatusEngineeringSoldering

The invention discloses an automatic soldering and testing integrated machine for an inductance coil and a working method of the automatic soldering and testing integrated machine and belongs to the technical field of electronic component processing. The automatic soldering and testing integrated machine for the inductance coil comprises a rack and a rotatable circular table, wherein the rotatable circular table is fixedly arranged on the rack; the table is provided with multiple stations; a clamping device for pinching the inductance coil is fixedly arranged on each station; and an automatic pin arranging and cutting feed mechanism, an automatic soldering device, a withstand voltage testing device and an inductance testing device are fixedly arranged on the periphery of the table corresponding to the stations in sequence. According to the automatic soldering and testing integrated machine for the inductance coil, the processing accuracy of pins of the inductance coil can be improved, the product processing accuracy is ensured, automatic production of inductance products can be achieved and the qualified rate of the products and the production efficiency are improved.

Owner:SHANDONG ZHONGRUI ELECTRONICS

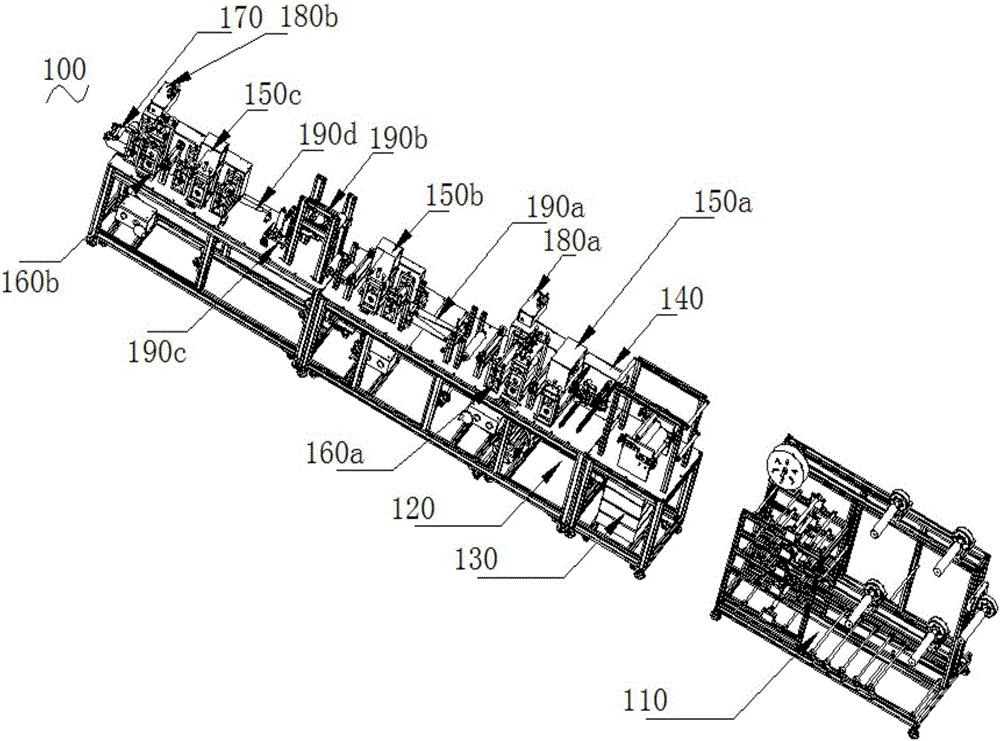

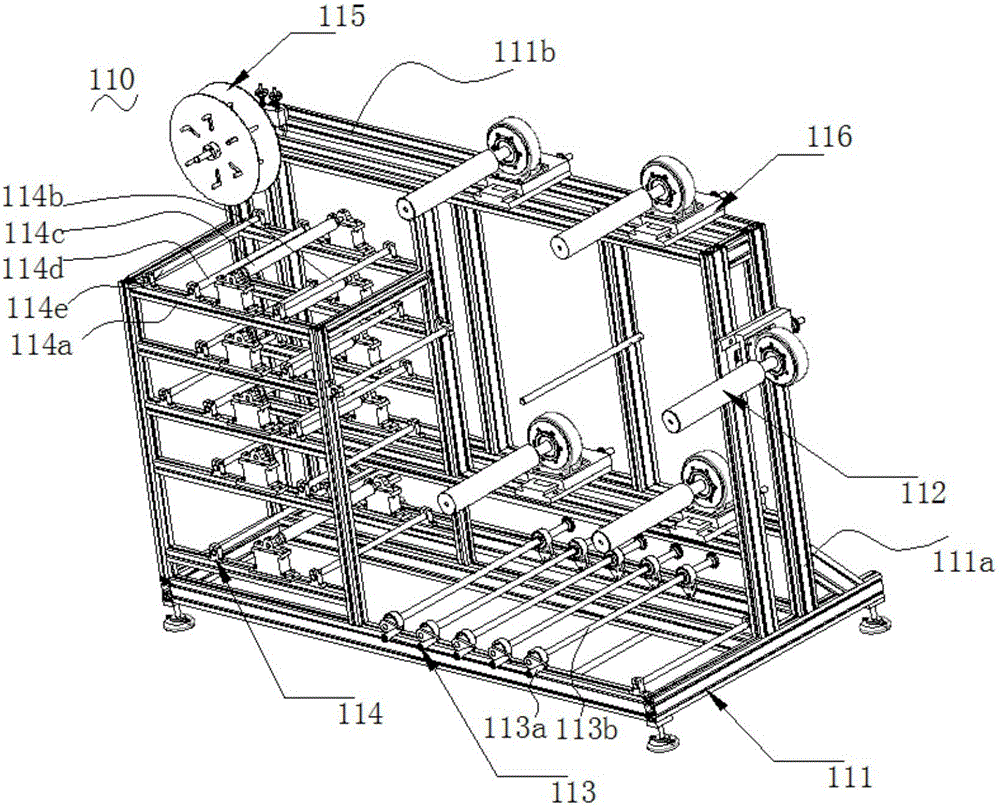

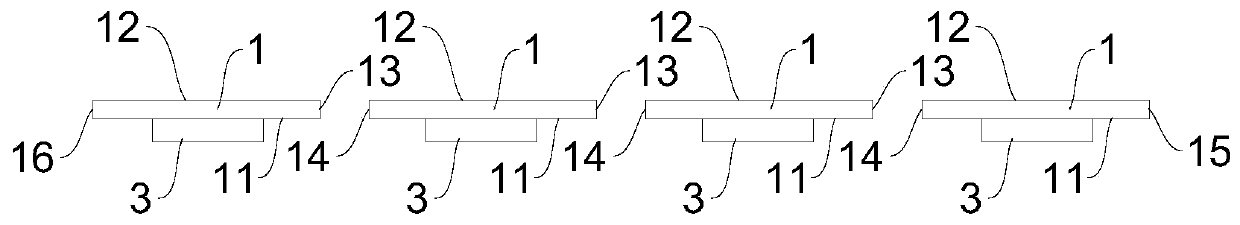

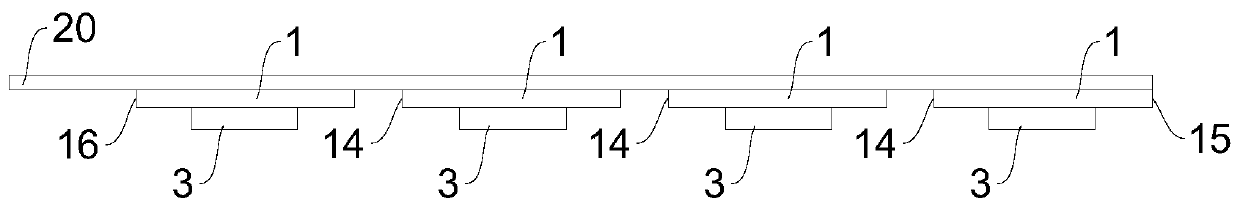

Face mask body making machine

ActiveCN105725309AHigh degree of automationImprove work efficiencyProtective garmentWoven fabricElectrical and Electronics engineering

The invention relates to the field of face mask production equipment, in particular to a face mask body making machine. The face mask body making machine comprises a feeding mechanism, a frame, a printing mechanism, a fixed nose bridge strip mechanism, a pattern mechanism, a cutting mechanism, a waste material collecting mechanism and a discharging mechanism, wherein the feeding mechanism is used for feeding non-woven fabrics and nose bridge strips; the printing mechanism is used for printing on the non-woven fabrics; the fixed nose bridge strip mechanism is used for welding the nose bridge strips on the non-woven fabrics; the pattern mechanism is used for molding patterns on the non-woven fabrics; the cutting mechanism is used for cutting corners of the non-woven fabrics on which the patterns are molded; the waste material collecting mechanism is used for recovering waste scraps; the discharging mechanism is used for discharging finished face masks; the printing mechanism, the fixed nose bridge strip mechanism, the pattern mechanism, the cutting mechanism, the waste collecting mechanism and the discharging mechanism are all arranged above the frame, and are all positioned behind the feeding mechanism. The face mask body making machine has high production efficiency, and has contribution to improvement of the face mask quality.

Owner:东莞市南方力劲机械有限公司

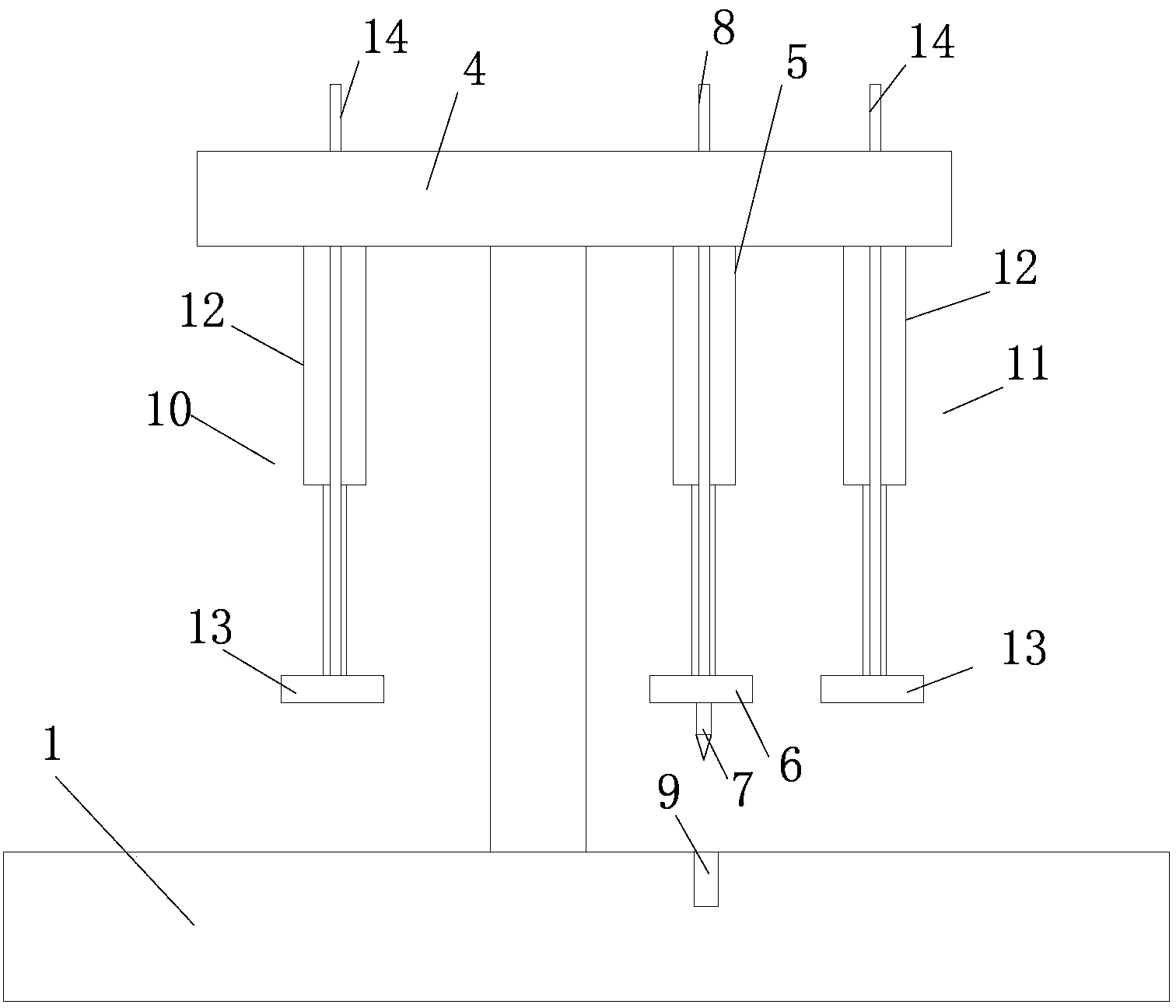

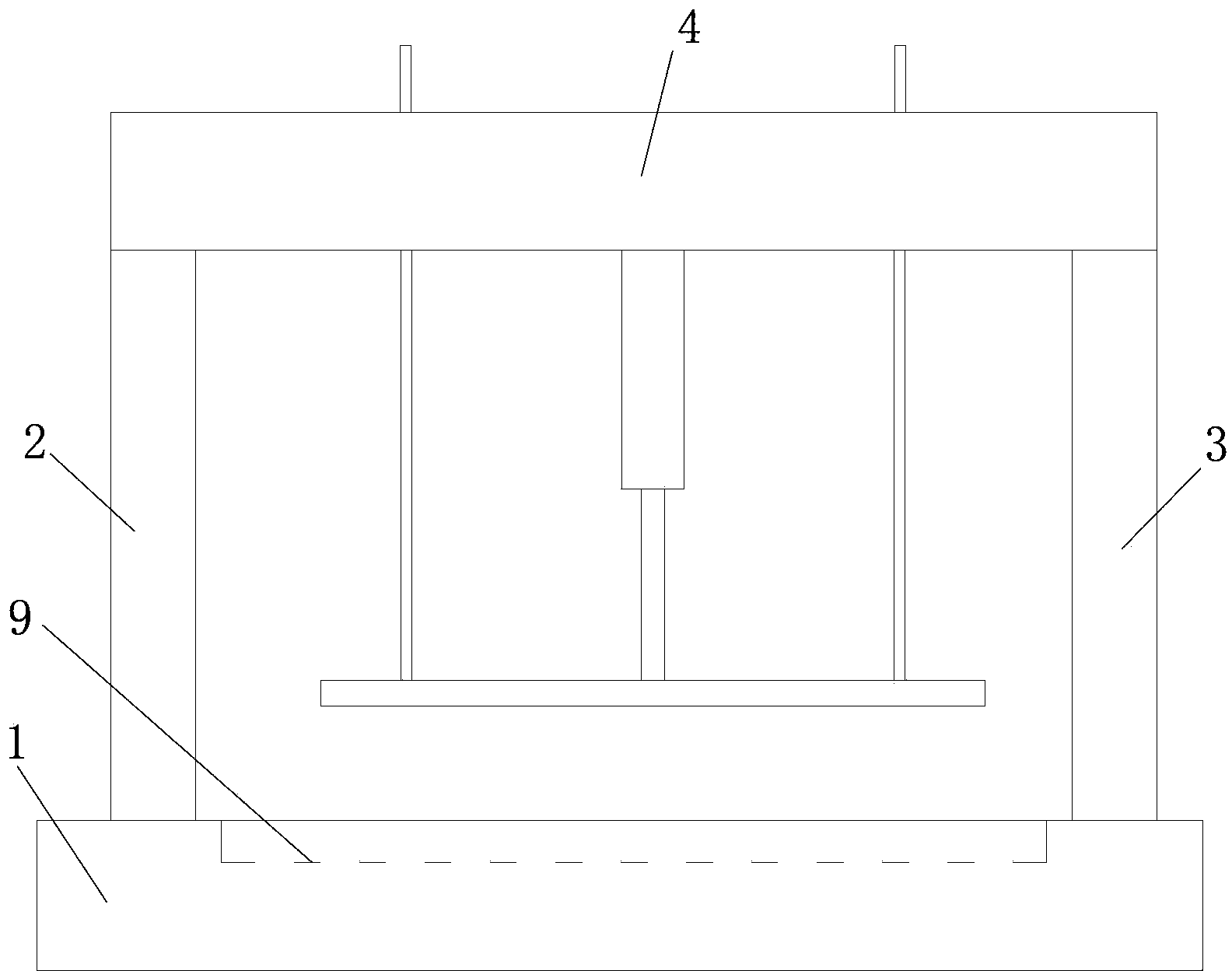

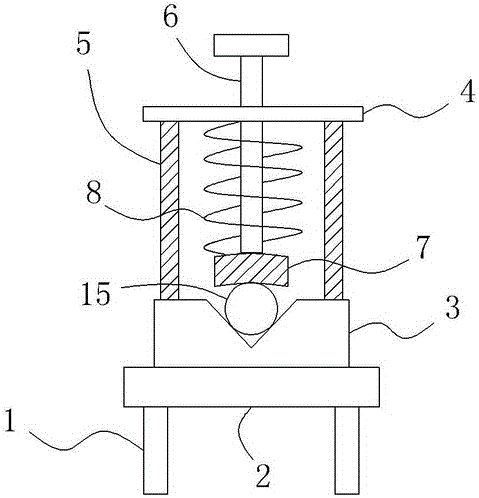

Cloth cutting device

The invention relates to a cloth cutting device capable of automatically cutting cloth. The cloth cutting device comprises a base, a first support, a second support and a third support, wherein the first support and the second support are vertically arranged on the upper end face of the base, and the third support is arranged at the upper ends of the first support and the second support. A cutting cylinder is arranged on the third support, a telescopic end of the cutting cylinder is connected with a blade holder, a cutting blade and a guide post are arranged on the blade holder, one end of the guide post is connected with the blade holder, the other end of the guide post penetrates the third support and guides lifting of the blade holder, a pressing mechanism is further arranged on the third support, lifts up and down and is used for pressing cloth, and a cutting notch matched with the cutting blade is formed in the base. When the cloth is cut, the cutting cylinder drives the blade holder and the cutting blade on the blade holder to descend, the cutting blade is matched with the cutting notch to cut the cloth, the pressing mechanism descends to press the cloth in the cutting process, so that the cloth is effectively prevented from turning upwards in the cutting process, and cutting precision of the cloth is ensured.

Owner:常州市嘉翔纺织印染有限公司

Dual-cutter dual-angle fixed-length crank cutting device

InactiveCN103568061AContinuously adjustable cutting lengthReduce wasteMetal working apparatusCrankControl cell

A dual-cutter dual-angle fixed-length crank cutting device is formed by two groups of cutting units, two groups of compacting units, two synchronous moving worktables, two groups of cutter heating units, a preheating heat, a conveying unit, a rack and a control unit; angles of cutting blades of the cutting units and the intervals of the moving worktables are adjustable; the cutting units, the compacting units and the cutter heating units are respectively mounted at table surfaces of the two synchronous moving worktables; the moving table surfaces are connected with the rack by linear guide tracks. The preheating unit is fixed on one synchronous worktable and moves along with the worktable. The conveying unit is fixedly connected onto the other synchronous moving worktable and moves together along with the worktable. The preheating unit and the conveying unit are fixedly connected with the rack. Cooperative actions of all the units are controlled by the control unit, the dual-cutter dual-angle fixed-length crank cutting device realizes the online automatic cutting of plastic linear section bars with the fixed length at 45-90 degrees, and the cutting length ranges from 600mm to 3100mm.

Owner:上海海弋机电科技有限公司

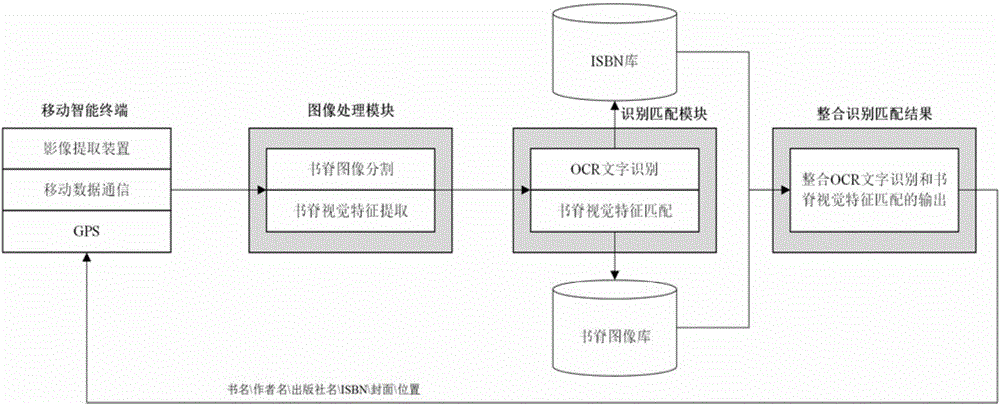

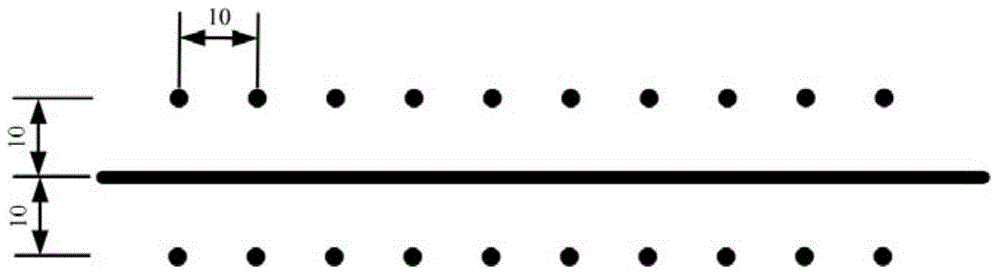

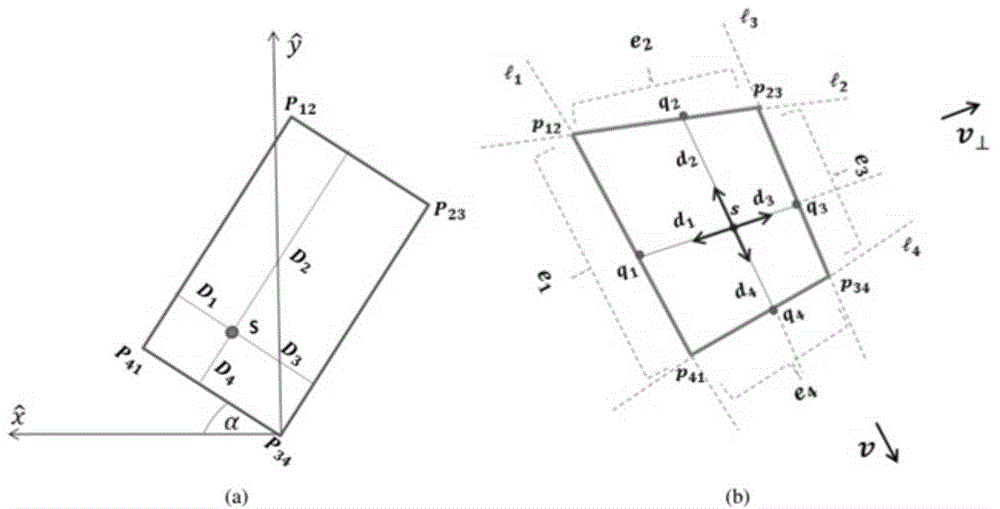

Spine image recognition method

ActiveCN104966081AGuaranteed cutting accuracySmall amount of calculationCharacter and pattern recognitionImage databaseFeature matching

The invention discloses a spine image recognition method, which comprises the steps of first cutting a spine image; detecting long line segments in the spine image, and finding out and using parallel line segments as a set of parallel long sides of a rectangular selected region; using an iterative algorithm for determining another two short sides of the rectangular selected region when the set of parallel long sides are fixed, and taking the detected rectangular selected region formed by the set of parallel long sides and the two short sides as a cutting result of a spine in the spine image; using a feature extraction algorithm for the cut spine image to describe the spine image into a set of descriptors including the image key point main direction, scale space and Haar wavelet coefficient; and performing feature matching for the spine image in a spine image database through the descriptors, and outputting a plurality of possible spine images corresponding to the spine image to be matched. The invention solves the problems of low accuracy, easy interference and poor robustness in the conventional spine image recognition technology.

Owner:GUANGZHOU MEISHI INFORMATION TECH CO LTD

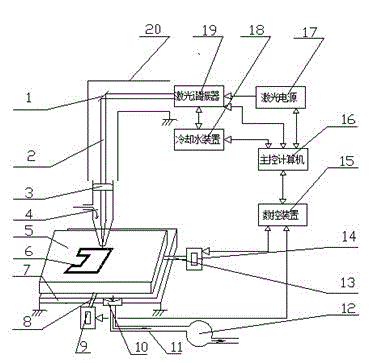

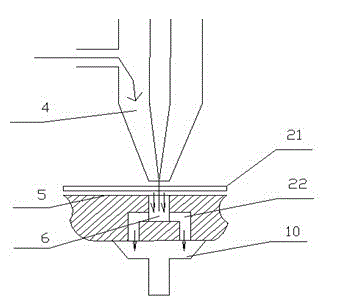

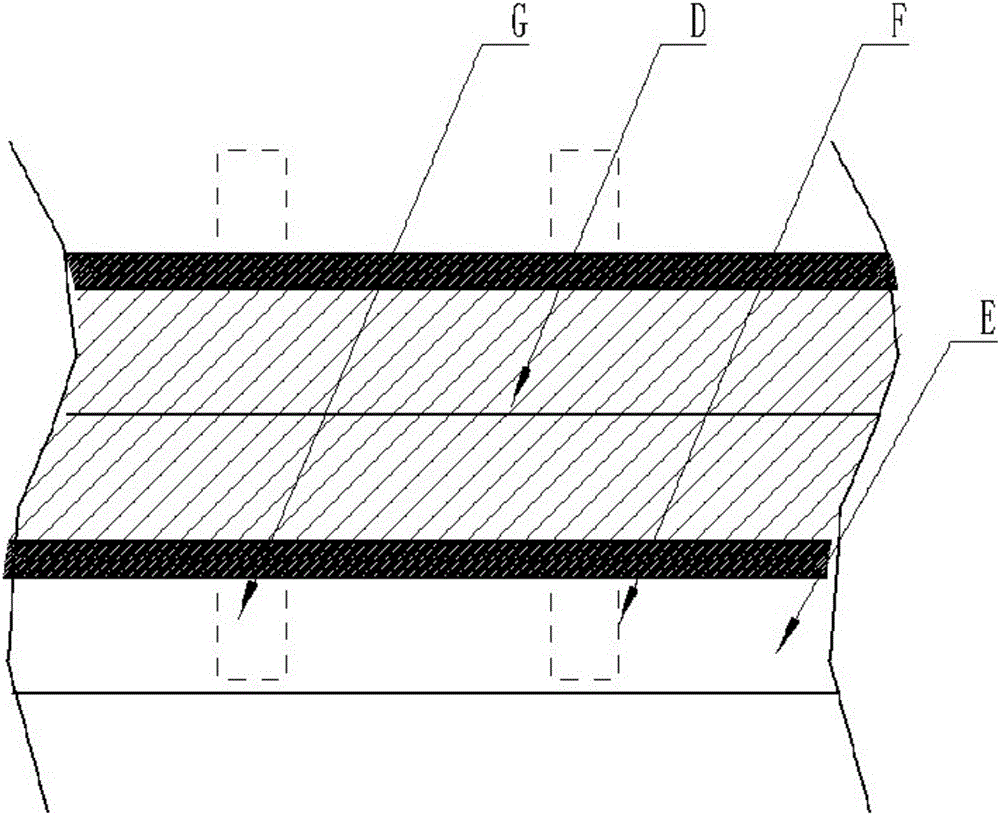

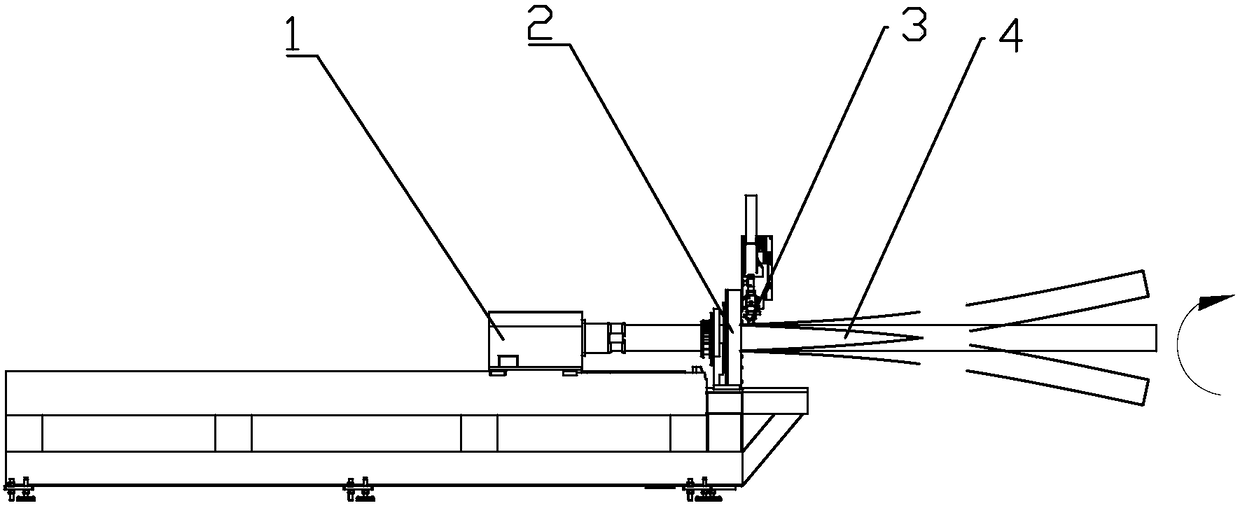

Laser cutting system for soft material cutting and cutting method of laser cutting system

InactiveCN103143842AReduce pollutionPrevent fallingLaser beam welding apparatusNumerical controlLaser cutting

The invention relates to a laser cutting system for soft material cutting, and a cutting method of the laser cutting system. The laser cutting system adopts the technical scheme that a lens (3) and a reflecting mirror (1) are mounted right above a workbench (5) in sequence; a laser resonator (19) is mounted on one side of a mirror surface of the reflecting mirror (1); a laser power supply (17), the laser resonator (19), a cooling water device (18) and a numerical control device (15) are connected with corresponding interfaces of a master control computer (16); an auxiliary gas nozzle (4) fixed under the lens (3) is over against the workbench (5); a pattern groove (6) is formed in an upper plane of the workbench (5); a transverse sliding block and a longitudinal sliding block that are fixed on a lower plane of the workbench (5) are mounted in a longitudinal sliding groove and a transverse sliding groove correspondingly and respectively; the longitudinal sliding groove and the transverse sliding groove are fixed in a workbench base (7); and a transverse servo motor (14) and a longitudinal servo motor (9) drive the transverse sliding block and the longitudinal sliding block by a transverse lead screw (13) and a longitudinal lead screw correspondingly and respectively. The laser cutting system and the cutting method have the characteristics that the laser cutting system and the cutting method are environmental-friendly and can improve the cutting efficiency and the cutting accuracy.

Owner:WUHAN UNIV OF SCI & TECH

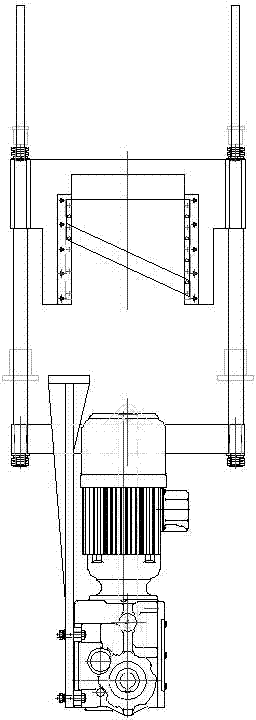

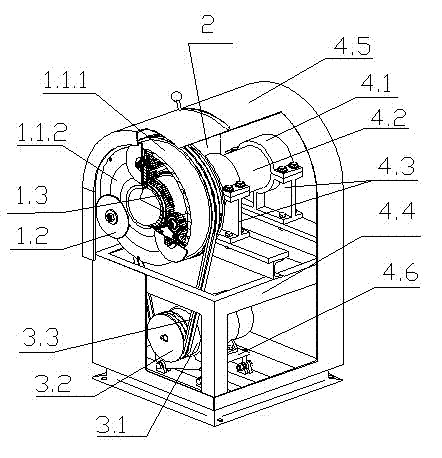

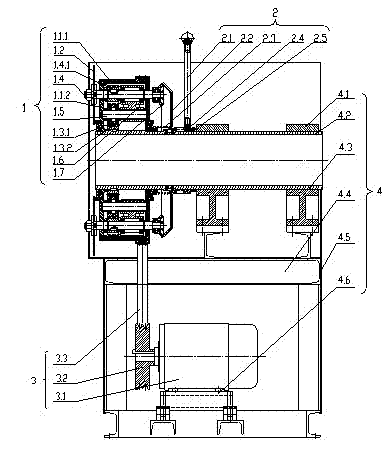

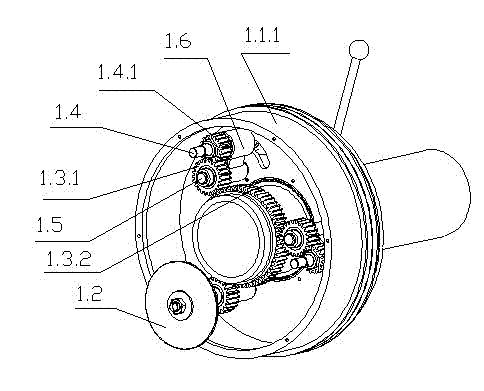

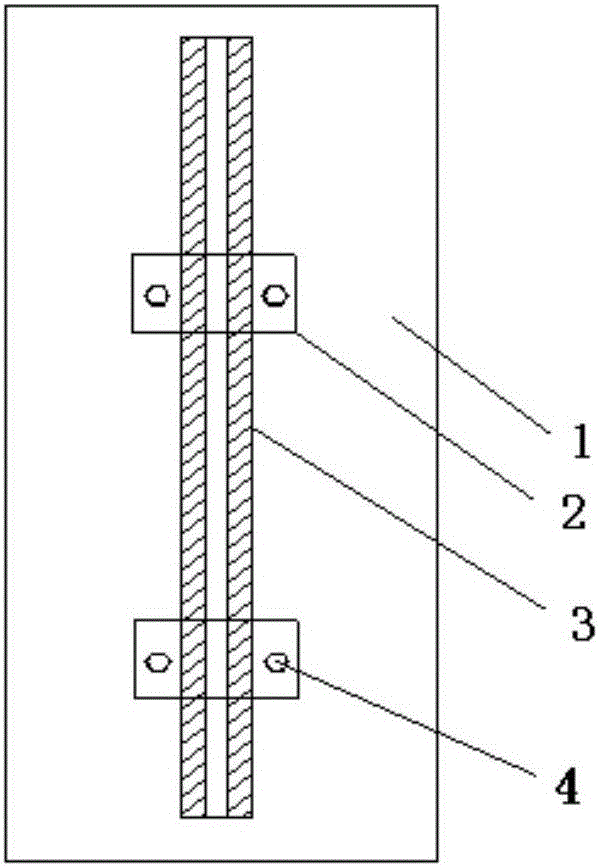

Rapid pipe cutting mechanism capable of moving compositely

InactiveCN102814543AEasy to feedSimple structureFeeding apparatusTube shearing machinesEngineeringGear train

The invention discloses a rapid pipe cutting mechanism capable of moving compositely. The rapid pipe cutting mechanism comprises a rotary blade (1.2), a blade rotating shaft (1.4), a blade rotating drive mechanism and a pipe clamping mechanism. The rapid pipe cutting mechanism is characterized by further comprising a planetary gear train (1.3), wherein the pipe clamping mechanism is coaxial with a sun wheel (1.3.2) of the planetary gear train; a blade wheel (1.4.1) on the blade rotating shaft (3.4) is meshed with a planet gear (1.3.1) of the planetary gear train; two drums of a double-drum swing arm (1.6) are respectively sheathed on the blade rotating shaft (1.4) and a planetary gear shaft (1.5); and the planetary wheel shaft (1.5) is fixed on a rotating gear box. The rapid pipe cutting mechanism capable of moving compositely is simple in structure, low in cost and complete in functions; and with the adoption of the rapid pipe cutting mechanism capable of moving compositely, the blade can perform self rotation and revolution and can cut through automatic rotation, so that the cutting surface is complete, and the cutting is efficient and rapid.

Owner:HUBEI UNIV OF TECH

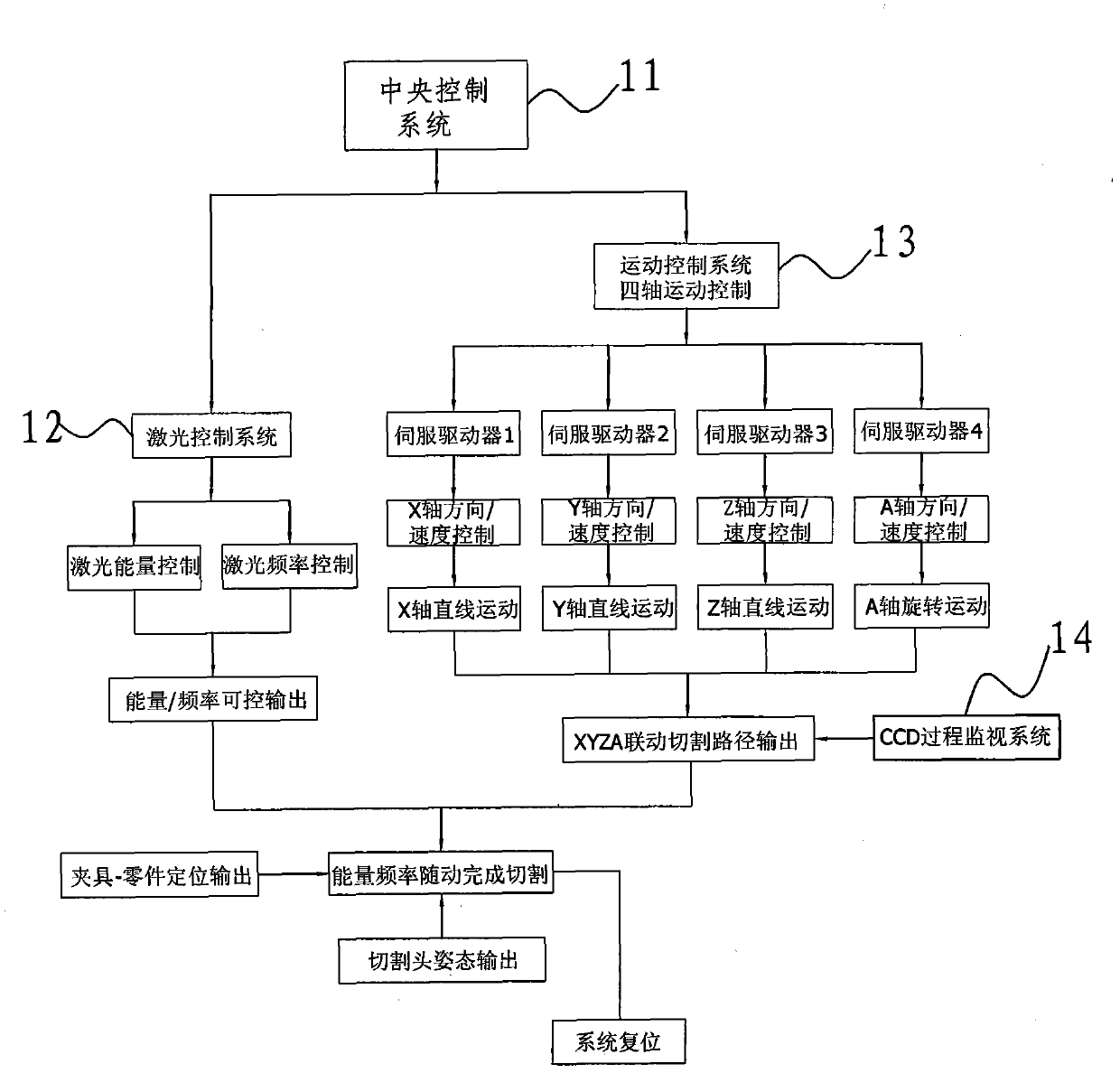

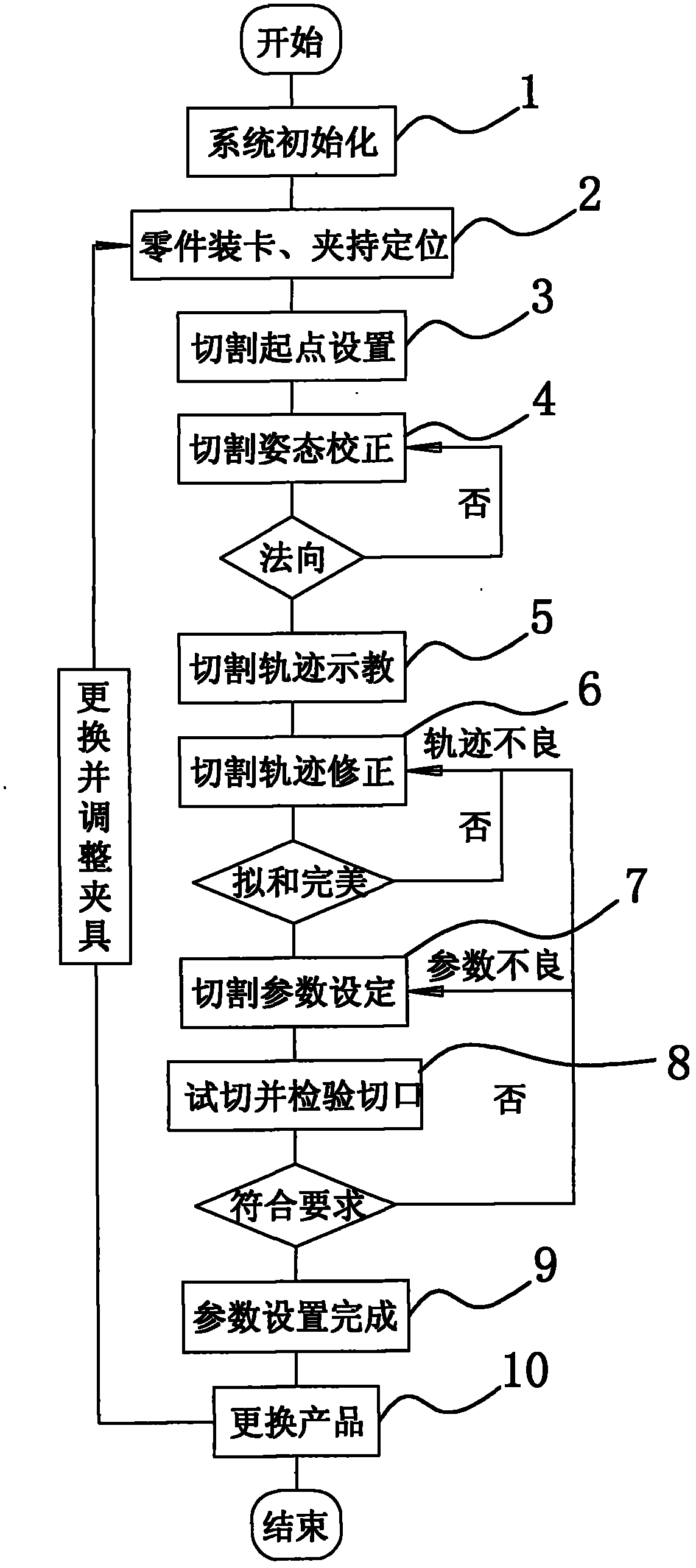

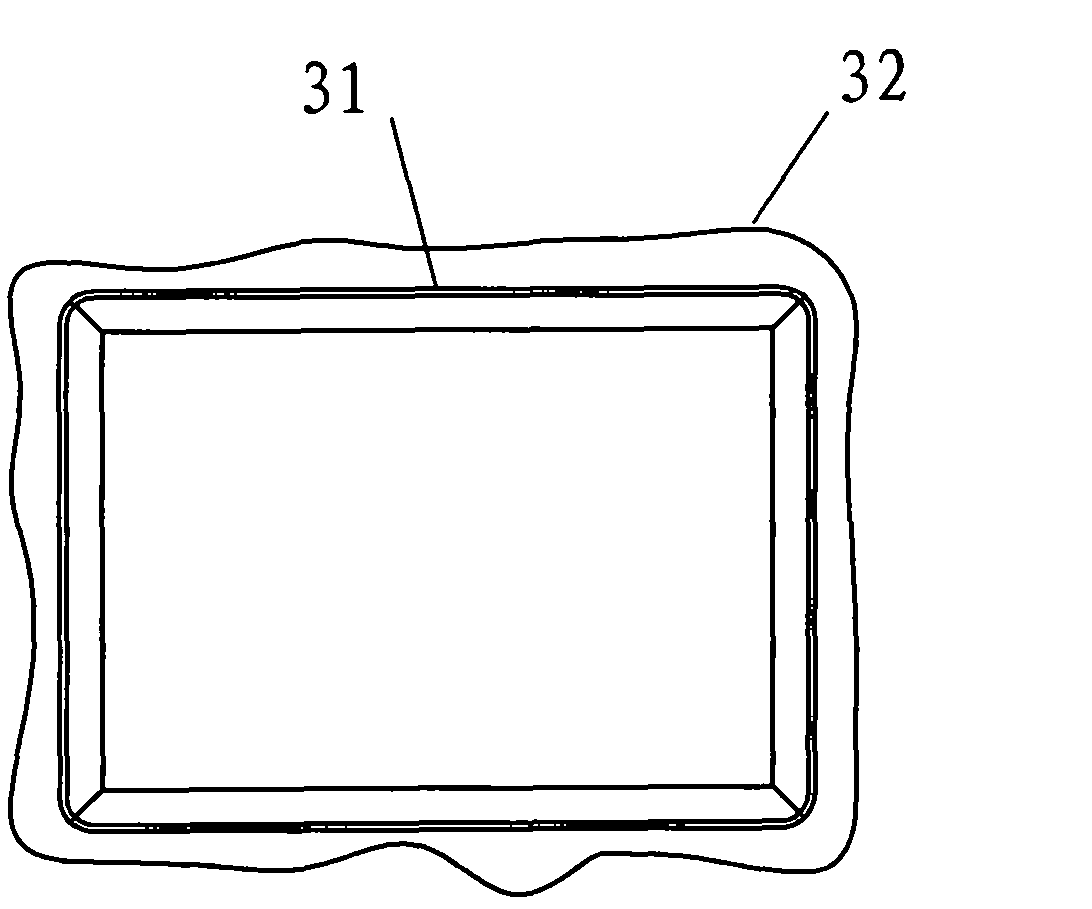

Laser cutting method

InactiveCN102000916ALower requirementGuaranteed continuityLaser beam welding apparatusNumerical controlEngineering

The invention provides a laser cutting method, in particular to a method for removing a water gap of an injection molding and a water gap of a film-covering piece by adopting a cutting path employing teaching programming and related program recording method. The teaching programming method comprises the following steps of: gradually recording the postures and the instant speeds of cutting heads on a curve one by one; associating the data to form continuous cutting motion; and teaching and storing a whole cutting path as a CNC (Computerized Numerical Control) program, wherein regular curves are used for teaching according to the characteristics, and irregular curves are used for teaching by adopting a short line segment fitting method. In the invention, by adopting a mode of controlling the motion of a worktable and the frequency and the energy of laser through program and a working mode of normal cutting, the requirement for operators can be lowered, meanwhile, the processing constancy and the joining continuity between a notch and an arc are ensured, the cutting quality is improved and the application range of laser cutting is further enlarged.

Owner:HANS LASER TECH IND GRP CO LTD

Laser die cutting device for battery core pole lugs

ActiveCN106425091AGuaranteed cutting accuracyWill not deformWelding/soldering/cutting articlesMetal working apparatusEngineeringPole piece

The invention relates to laser die cutting device for battery core pole lugs. The laser die cutting device is characterized by comprising laser die cutting mechanisms arranged on one side or two sides of a pole piece. Each laser die cutting mechanism comprises a laser head. A dedusting mechanism is arranged, in the directions facing the pole piece, on the laser heads and comprises a dedusting shell, a gap allowing penetration of the pole piece is formed in dedusting shell, and laser paths are formed in side plates, facing the laser head, of the dedusting shell. A left air blade and a right air blade are mounted on the dedusting shell, oppositely arranged on two sides of the pole piece and used for blowing symmetrically on two sides of the pole piece to keep constant position and constant distance between the pole piece and the dedusting shell. The dedusting shell is connected with an induced draft device. The laser die cutting device for the battery core pole lugs has the advantages that by symmetrical blowing from two sides of the pole piece during cutting, a good dedusting effect is achieved, the dedusting mechanism is prevented from interfering with the pole piece, and cutting precision of the pole lugs is guaranteed.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Inner hole machining method for molybdenum alloy thin-walled long pipe

ActiveCN105750843ARealization of inner hole processingBrittleHoning machinesBoring/drilling machinesAlloyLinearity

The invention belongs to the technical field of molybdenum alloy machining, and discloses an inner hole machining method for a molybdenum alloy thin-walled long pipe of a reactor. The method is a combined machining method in which gun drilling, linear cutting and honing are organically combined, and comprises the following steps: (1) outer circle reference machining of a molybdenum alloy bar, (2) gun drilling of a threading hole, (3) linear cutting of an inner hole and (4) honing finish machining of the inner hole. The linearity of the machined inner hole of the molybdenum alloy thin-walled long pipe is higher than 0.03 mm, the cylindricity of the inner hole is higher than 5 [mu]m, and the roughness of the inner hole is better than 0.2 [mu]m.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

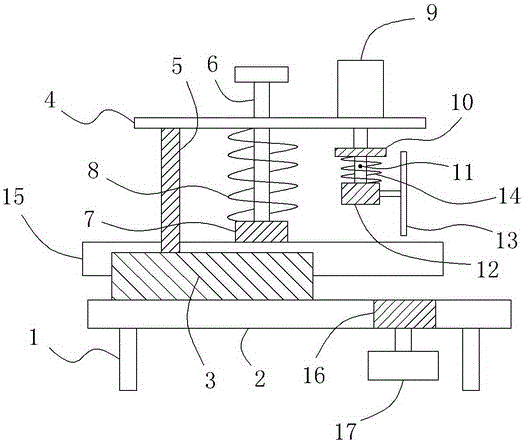

Novel building material cutting device

InactiveCN105965574AGuaranteed cutting accuracyAvoid damageMetal working apparatusHydraulic cylinderCoil spring

The invention relates to a novel building material cutting device. The device comprises a bracket and a base, wherein a support is arranged on the left side of the top of the base, a V-shaped groove is formed on the top plane of the support, a top plate is arranged above the support, at least one supporting rod is connected between the bottom end of the top plate and the top end of the support, a slide hole is formed in the top plate, a pressure lever is inserted into the slide hole, a handle is arranged at the top end of the pressure lever, a pressure plate is arranged at the bottom end of the pressure lever, a first spiral spring sleeves the part, positioned under the top plate, of the pressure lever, the right end of the top plate is fixedly connected to a hydraulic cylinder, the bottom of a piston rod of the hydraulic cylinder is connected to a middle plate, the bottom of the middle plate is connected to a telescopic pole, a motor is arranged at the bottom end of the telescopic pole, the right end of an output shaft of a motor is connected to a cutting blade, and a second spiral spring further externally sleeves the telescopic pole. By adopting the structure, the cutting precision of a tubular product can be effectively guaranteed, and meanwhile, the tubular product can be further effectively prevented from being damaged in the cutting process.

Owner:CHENGDU XUNDE SCI & TECH

Hemming, folding and fabric spreading cutting machine

PendingCN107697746ACompact structureReduce volumeWork-feeding meansSevering textilesTraction motorAgricultural engineering

The invention provides a hemming, folding and fabric spreading cutting machine. The hemming, folding and fabric spreading cutting machine sequentially comprises an unwinding mechanism, a hemming and fabric folding mechanism and a pulling storing mechanism in the feeding direction of fabrics, wherein the unwinding mechanism comprises an unwinding rack, an unwinding shaft and an unwinding motor; thehemming and fabric folding mechanism comprises a hemming and fabric folding rack, a hemming machine and a fabric folding rod; and the pulling storing mechanism comprises a pulling rack, a pulling roller, a pulling motor, a fabric guiding roller, a storing rack, a cutting device and a fabric spreading device. The hemming, folding and fabric spreading cutting machine can be used for the fabric spreading and stacking of thin elastic fabrics after hemming, folding and cutting and is efficient in running. Fabric spreading tension is effectively controlled so as to ensure cutting precision and further ensure the following processing quality.

Owner:盐城精通源机械有限公司

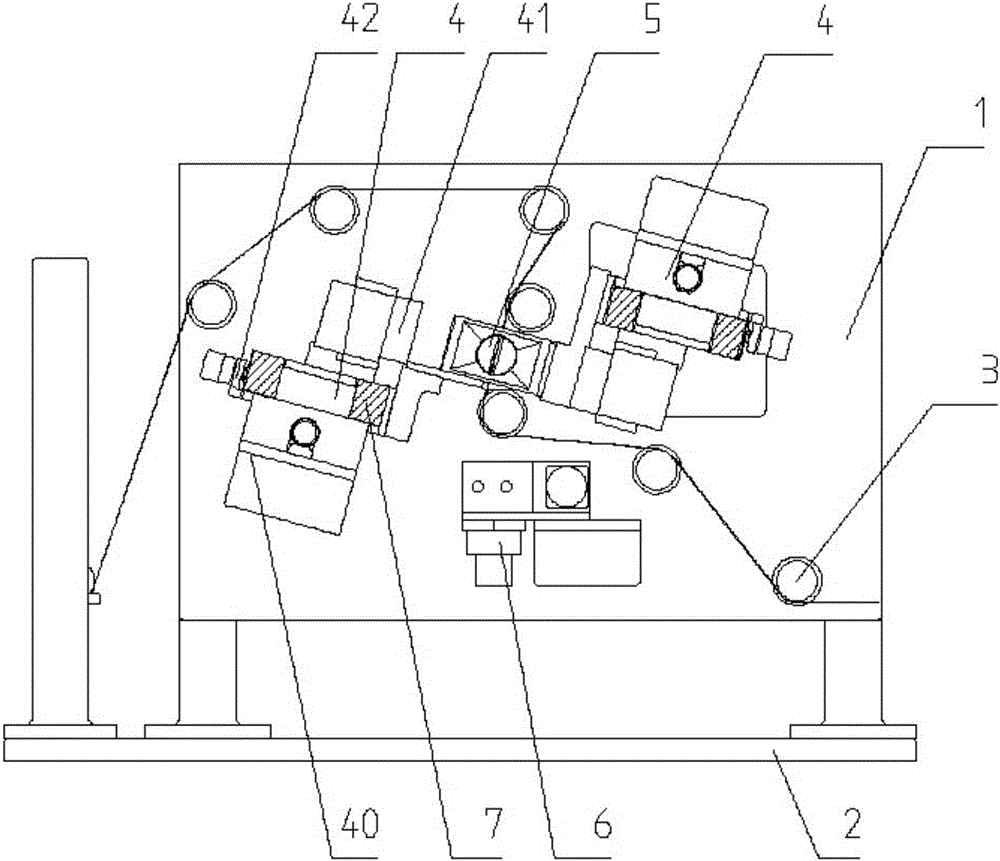

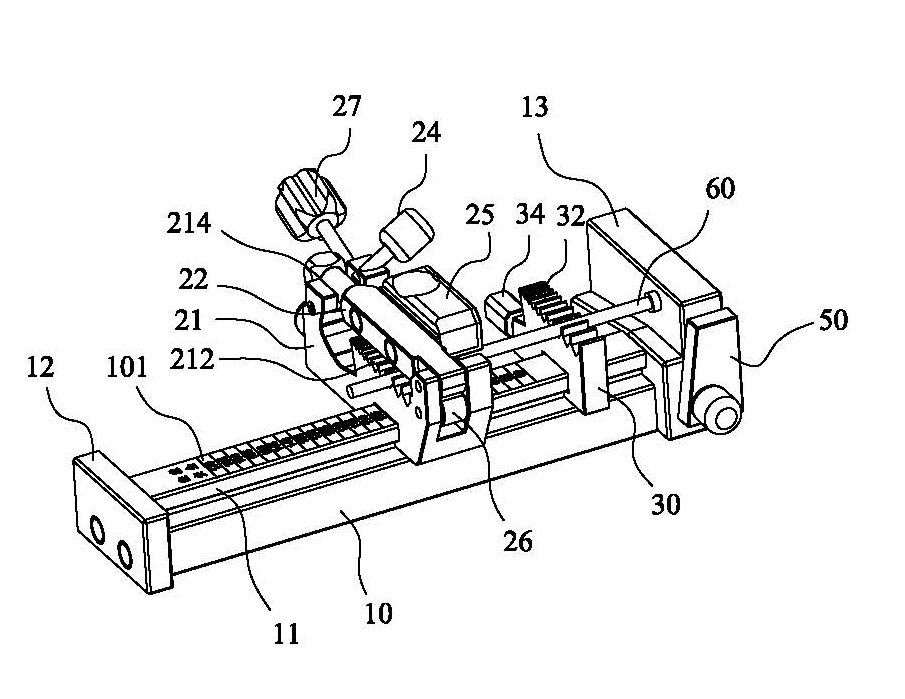

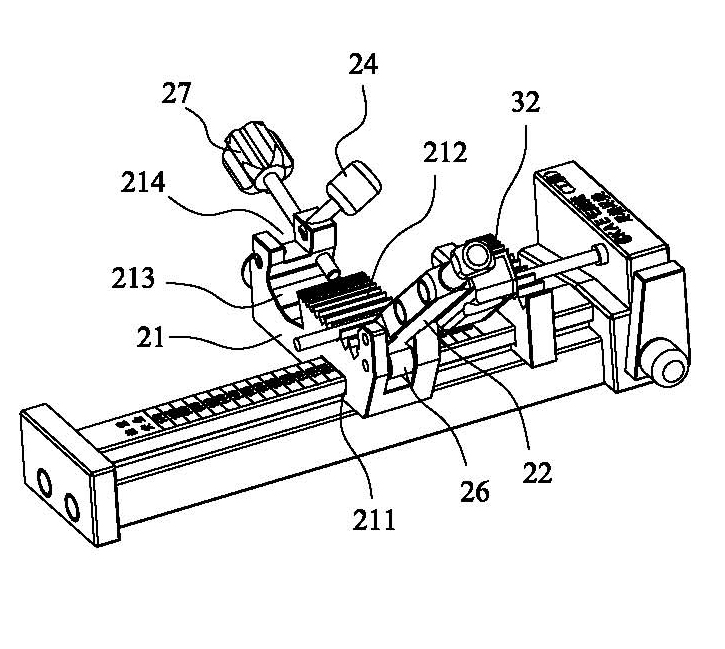

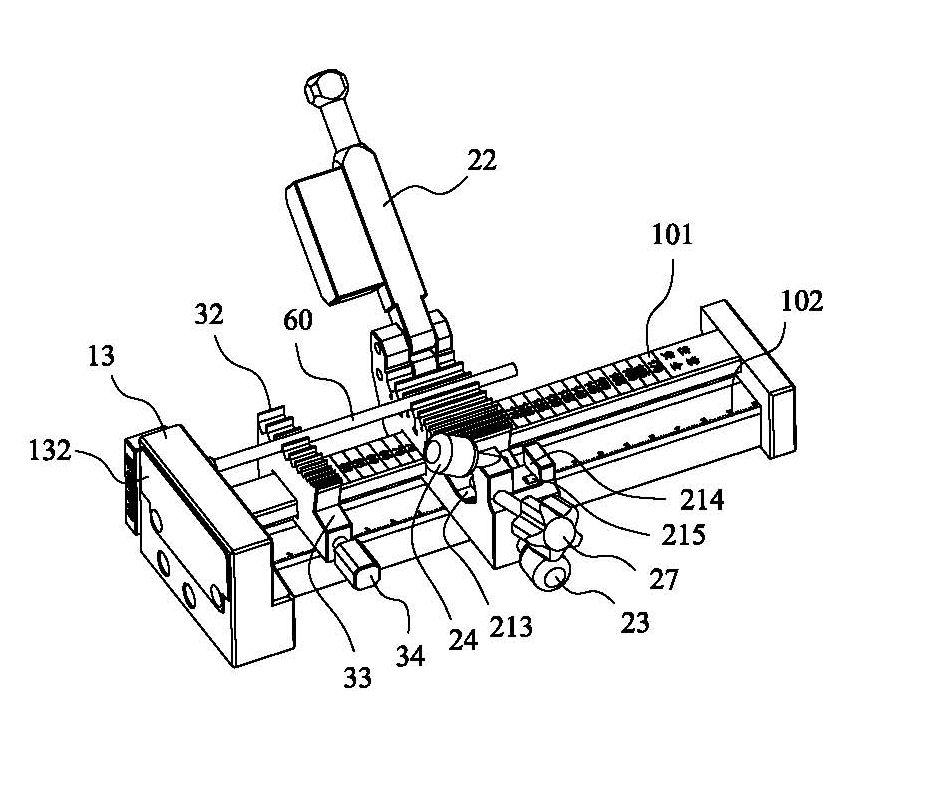

Special gripper for location on cutting of thimble

InactiveCN102039533APrevent back and forth movementEasy to adjustPositioning apparatusMetal-working holdersOperation modeEngineering

The invention discloses a special gripper for the location on the cutting of a thimble, comprising a base, a gripping device and a support slide block. The base is provided with a straight-line slide rail, the straight-line slide rail is provided with scales, a rear suck board is arranged at the rear end of the straight-line slide rail and is used for fixing the tail end of the thimble, a magnet is arranged in the rear suck board, the gripping device comprises a slide seat and a batten, and the slide seat and the support slide block can be connected on the slide rail in a freely sliding manner. In the invention, the root of the thimble is fixed by the adsorption function of the magnet in an adsorption manner, the free tail end of the thimble is gripped and the middle rear part of the thimble is located by the gripping device and the support slide block, and the positions of the gripping device and the support slide block can be regulated in a sliding manner; therefore, the thimble can be effectively prevented from moving back and force to ensure the precision of the thimble cutting in the length direction; meanwhile, the special gripper is more convenient for people to precisely regulate the working positions of the gripping device and the support slide block by matching with the scales on the slide rail; and the overturn type structure design of the batten provides more efficient operation mode for operators to change the thimble.

Owner:东莞市康捷塑胶模具有限公司

Repair method of NTC multi-wire sawing machine main roller and main roller structure after repair

ActiveCN103934626AAchieve reuseGuaranteed cutting accuracyShaft and bearingsFine working devicesEngineeringConical surface

The invention discloses a repair method of an NTC multi-wire sawing machine main roller and a main roller structure after repair. The repair method comprises the steps of shaft head removal, clamping hole machining, novel shaft head machining, mechanical fixing and the like. The reutilization of the NTC multi-wire sawing machine main roller is achieved with low investment, and the economic loss brought by conical surface abrasion is minimized. The repair method and the main roller structure have great economic value.

Owner:SUZHOU RUNDE NEW MATERIAL

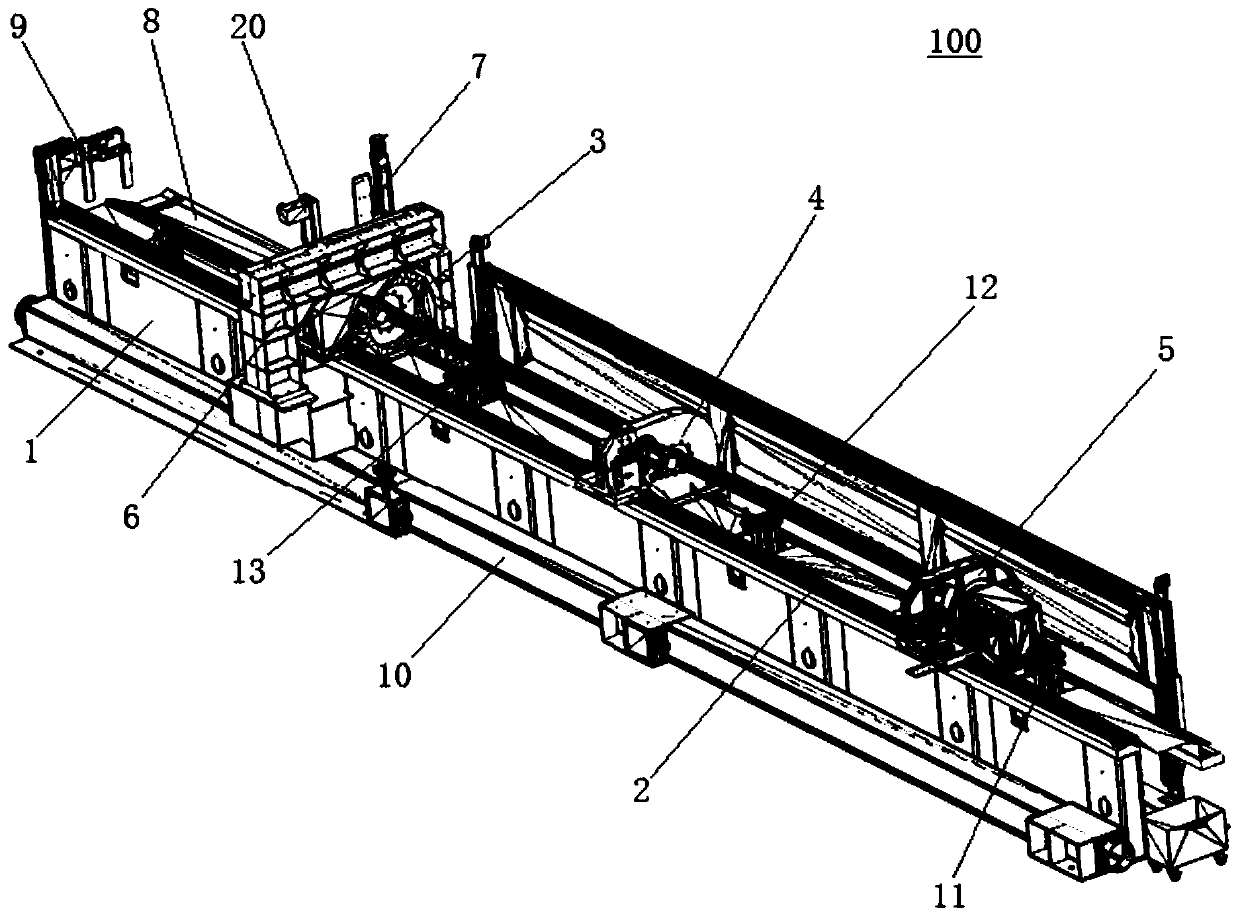

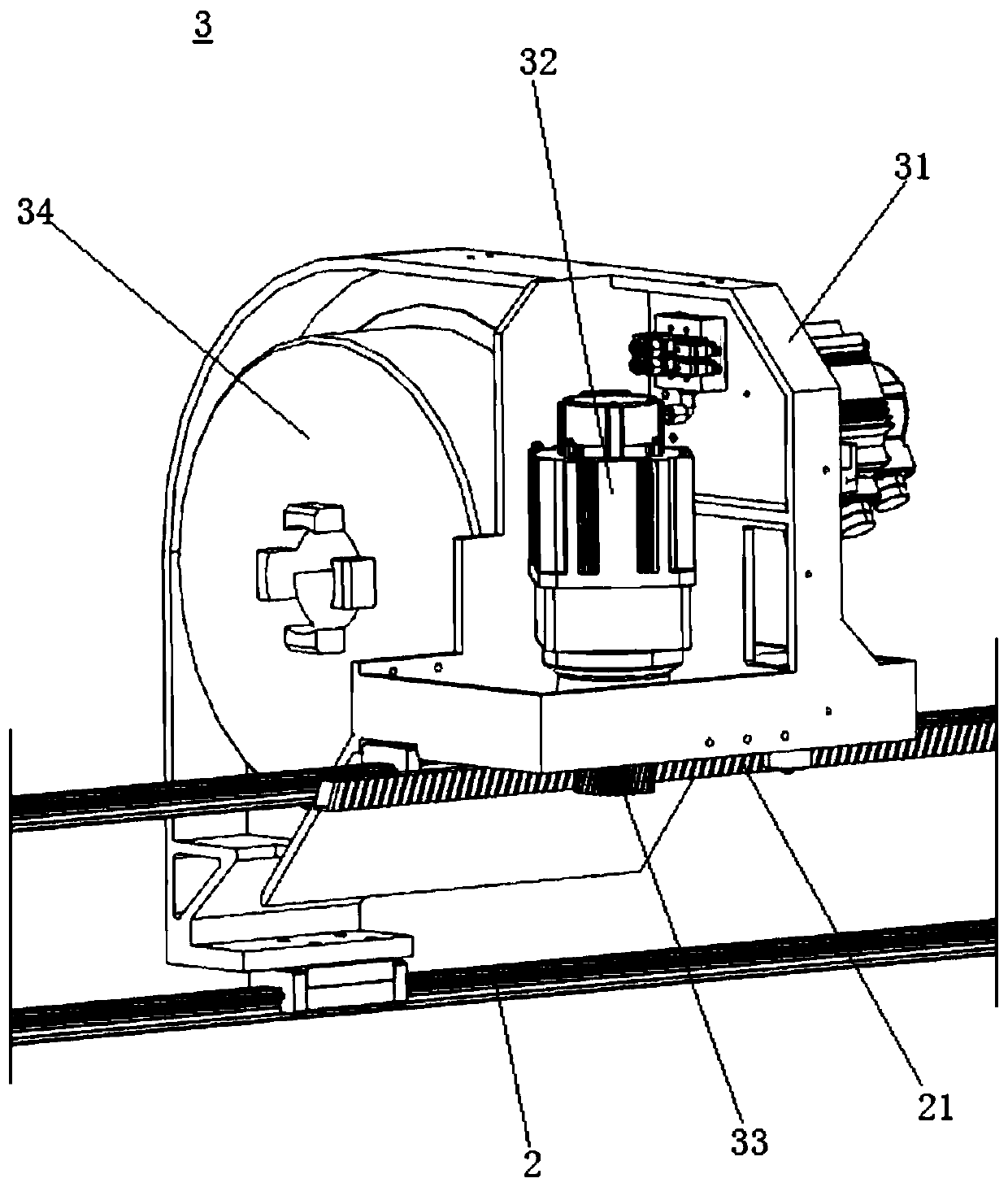

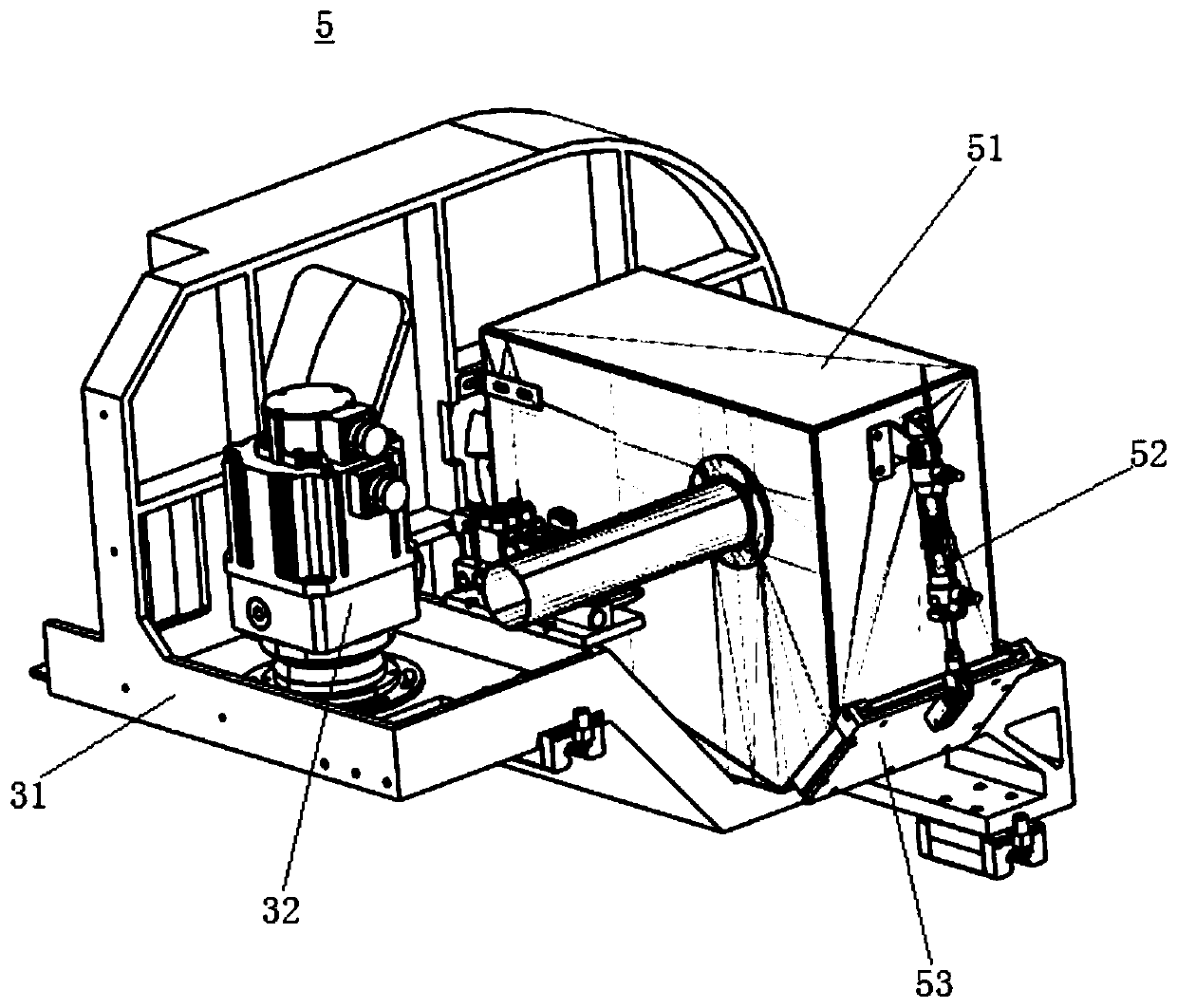

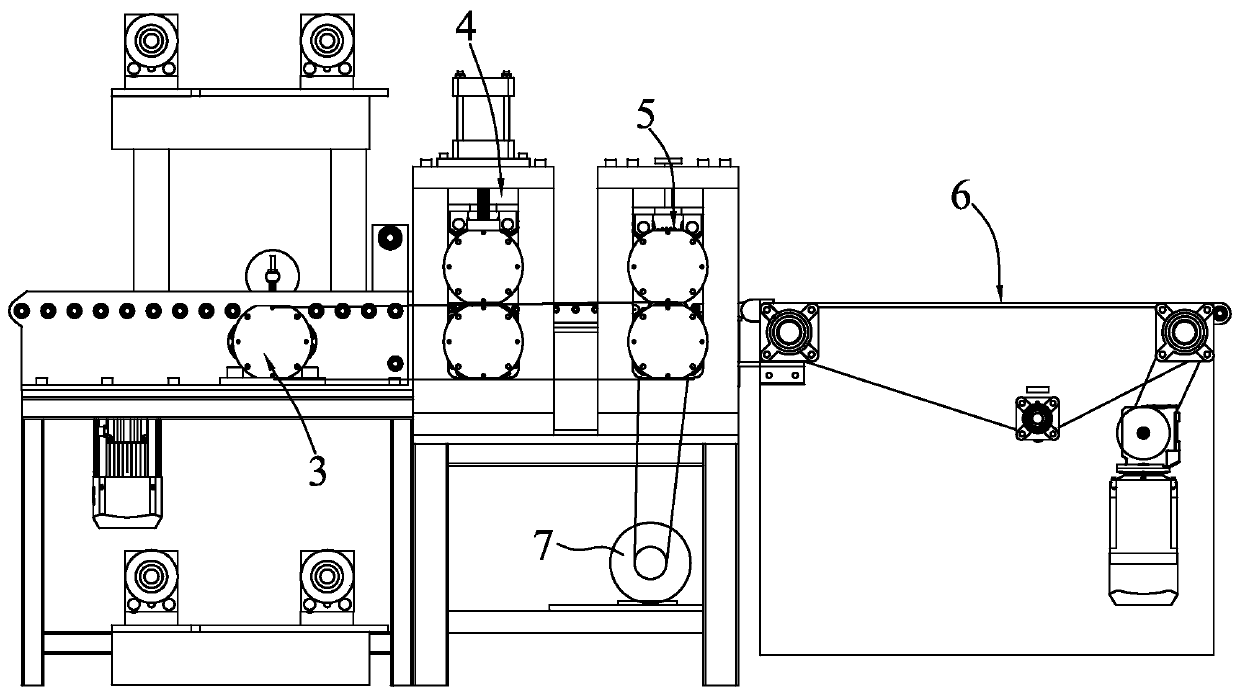

Three-chuck laser pipe cutter device

PendingCN110919206AGuaranteed cutting accuracySolve the problem of inertia swingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The invention discloses a three-chuck laser pipe cutter device. The three-chuck laser pipe cutter device comprises a machine tool, sliding rails, a front chuck unit, a middle chuck unit, a back chuckunit, a transverse beam support, a laser cutting head, a material-falling supporting plate unit, a discharging clamping unit and a plurality of supporting clamping units, wherein the sliding rails arearranged on the machine tool in parallel; the front chuck unit, the middle chuck unit and the back chuck unit can slide on the sliding rails; the transverse beam support is located above the machinetool; the laser cutting head is arranged on the transverse beam support; the material-falling supporting plate unit is located on the front side of the laser cutting head and can move up and down relative to the machine tool; the discharging clamping unit is located at the front end of the machine tool and assists in material falling; and the plurality of supporting clamping units are arranged atintervals along the sliding rails and can move up and down relative to the machine tool. By means of the three-chuck laser pipe cutter device, the pipe loading capacity and cutting efficiency are greatly improved, the problem that the residual tail material is long is solved, and the raw material cost is reduced.

Owner:SUZHOU QUICK LASER TECH

Edge cutting device capable of effectively preventing cloth from wrinkling

InactiveCN111826931ANo creases appearGuaranteed dimensional accuracySevering textilesStructural engineeringMechanical engineering

The invention discloses an edge cutting device capable of effectively preventing cloth from wrinkling, and relates to the technical field of cloth processing. To solve the wrinkle problem, specifically, the edge cutting device comprises a material guide mechanism and a cutting mechanism, wherein the material guide mechanism comprises two vertical plates fixed to the ground, as well as an adjustable clamping assembly, a damping clamping assembly and a tensioning assembly which are arranged on the outer walls of the vertical plates, the adjustable clamping assembly comprises pressing springs andfirst ejector pins, the tensioning assembly comprises tensioning springs and a tensioning roll, a tensioning frame is fixedly installed on the outer wall of each vertical plate, and a first sliding groove is formed in the inner wall of each tensioning frame. According to the edge cutting device, the damping clamping assembly and the tensioning assembly are arranged, when a conveying assembly is used for conveying, the damping clamping assembly can provide moving damping force for rotation of a cloth roll, due to the damping force, the two tensioning springs are pressed, thus downward tensionforce is generated for the cloth, so that the whole cloth is in a tension state, then wrinkles are avoided, and further, the size accuracy of a cutting assembly during cutting is guaranteed.

Owner:安徽工美服装有限公司

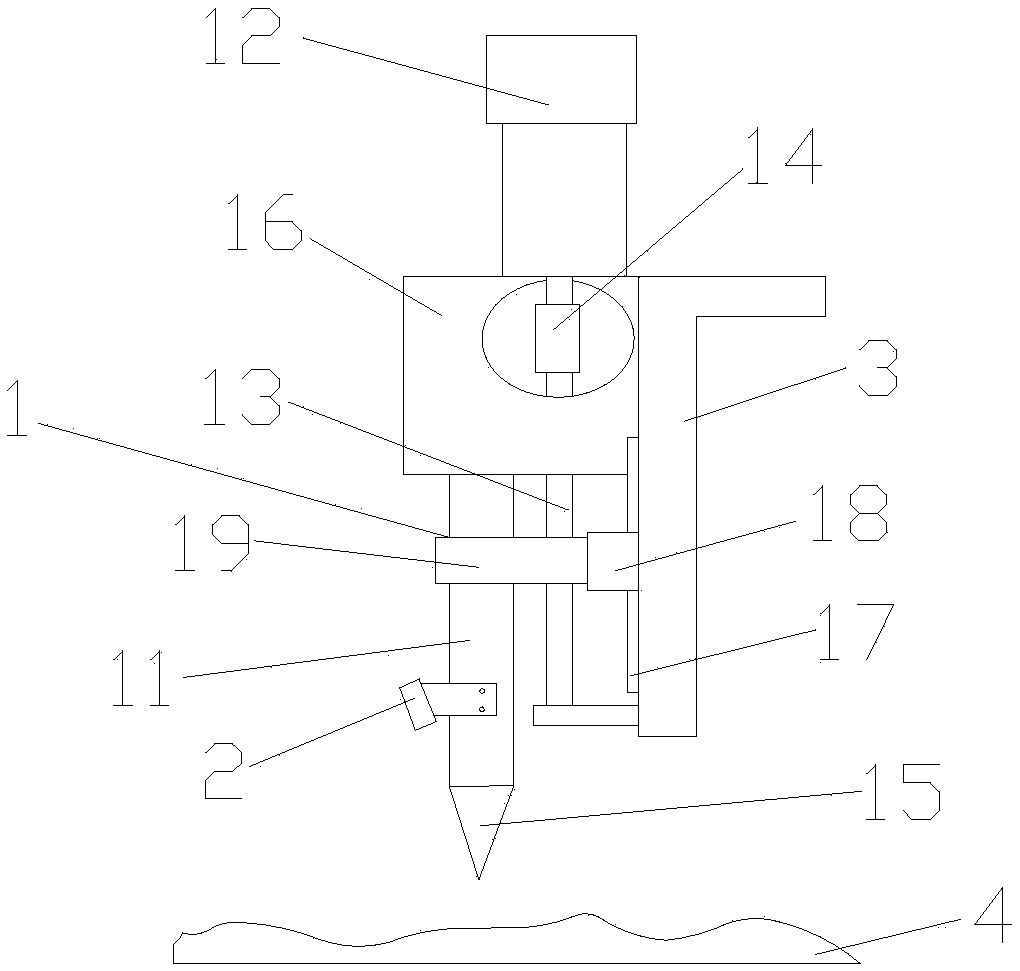

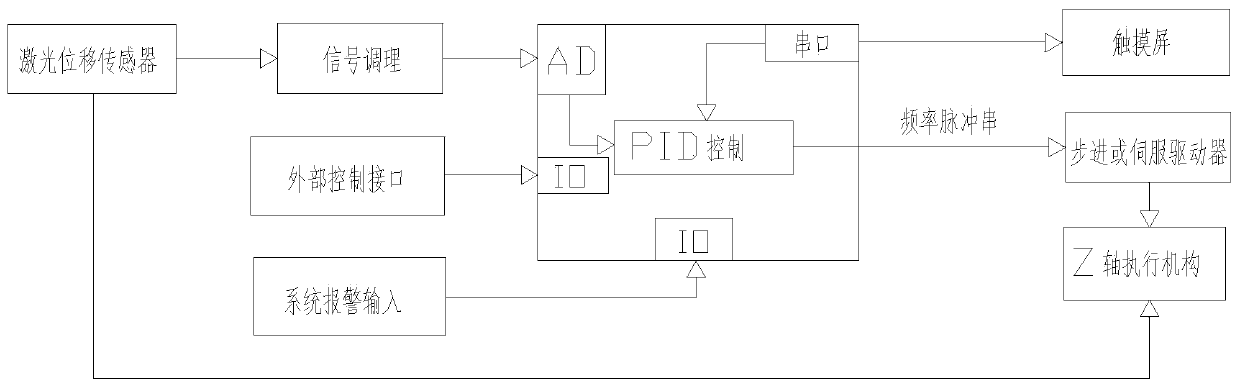

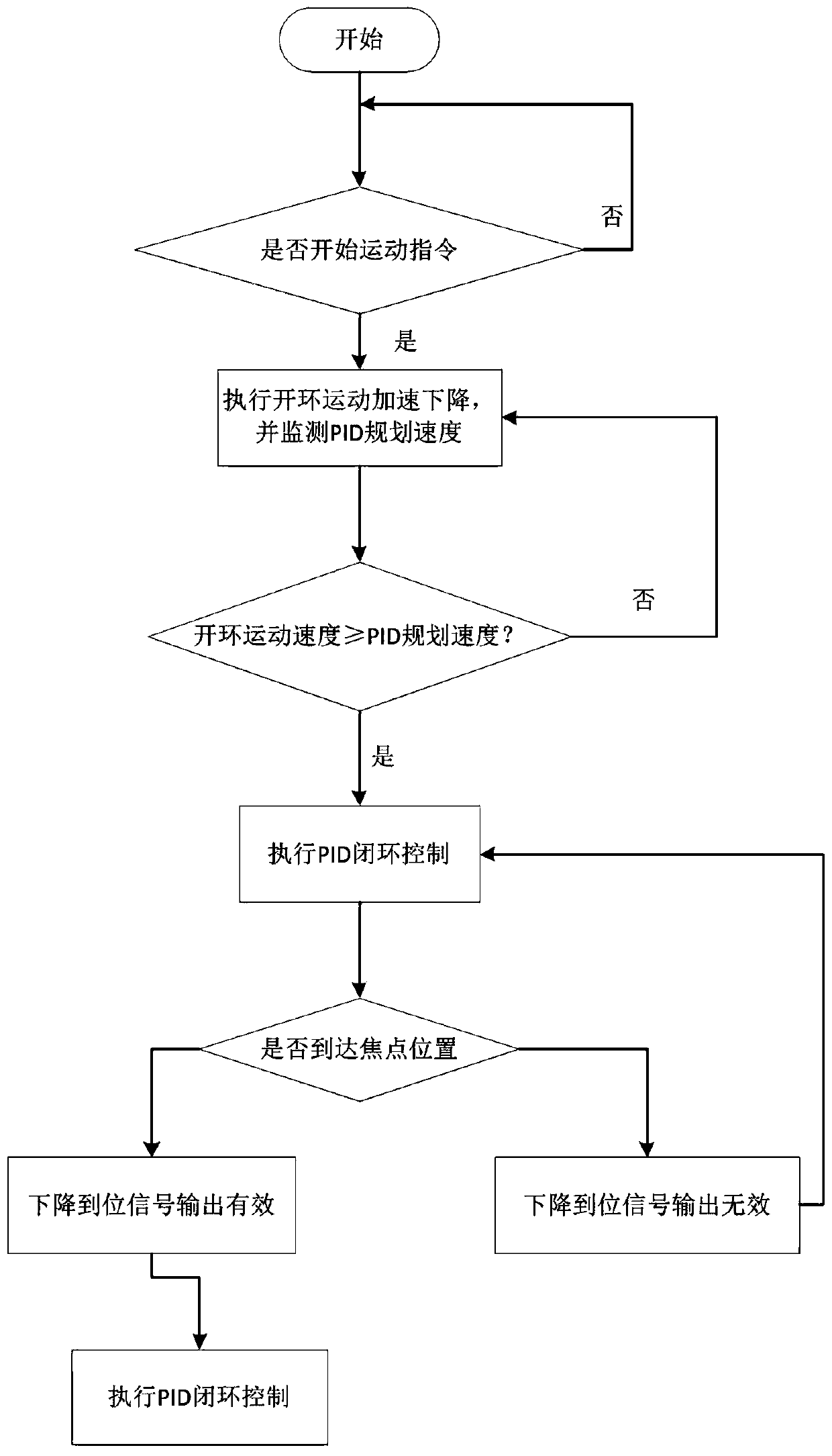

Automatic height adjusting device based on laser displacement sensor and control method thereof

PendingCN110202273ALong detection distanceHigh precisionLaser beam welding apparatusLaser cuttingWhole systems

The invention discloses an automatic height adjusting device based on a laser displacement sensor. The device comprises a Z-axis motor executing mechanism, a height adjusting controller and the laserdisplacement sensor. The automatic height-adjusting device is simple in structure. The laser displacement sensor examines the position of a workpiece and feeds back a distance signal, and the height adjusting controller then adjusts the height position of a laser cutting head according to a measurement feedback result. According to the device, the laser displacement sensor of Panasonic HG-C1100 model is adopted preferably, so that the detection precision is high. In addition, in the process of adjusting the height of the laser cutting head, the distances from positions of measuring spots of the laser displacement sensor to the cut workpiece are kept consistent, so that a purpose that a laser focusing point does not deviated from the cut workpiece. The invention also provides a control method of the automatic height adjusting device based on the laser displacement sensor. By collecting information of points in real time, the automatic height adjusting device carries out real-time control, so that the control precision is improved effectively and the operating efficiency of the whole system is improved.

Owner:深圳市睿达科技有限公司

Continuous paper covering cutting device for battery continuous pole plates

PendingCN110459734AImprove efficiencyGuaranteed cutting accuracyLead-acid accumulator electrodesEngineeringSingle plate

The invention discloses a continuous paper covering cutting device for battery continuous pole plates. The device includes a first conveyor belt used for conveying the continuous pole plates conveyedin a vertical connection bar conveying direction, a queuing mechanism used for limiting and arranging the positions of the continuous pole plates in the vertical conveying direction and the size of intervals between the adjacent connected plates, a paper covering mechanism used for covering the coated paper on upper and lower sides of the lined connected pole plates respectively, and a cutting mechanism used for cutting the continuous pole plates after paper covering into single plates. The device is advantaged in that the continuous pole plates are limited and arranged through the queuing mechanism, the upper and lower sides of the continuous pole plates are covered by the coated paper through the paper covering mechanism and then are cut by the cutting mechanism, cutting is performed after continuous paper covering, efficiency is improved, and pole plate paper covering and cutting accuracy are further guaranteed.

Owner:ZHEJIANG TIANNENG POWER ENERGY

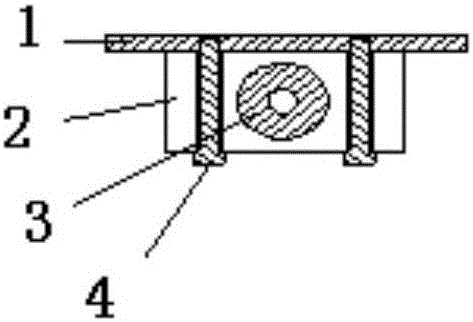

Servo supporting and blanking device used for laser pipe cutting machine

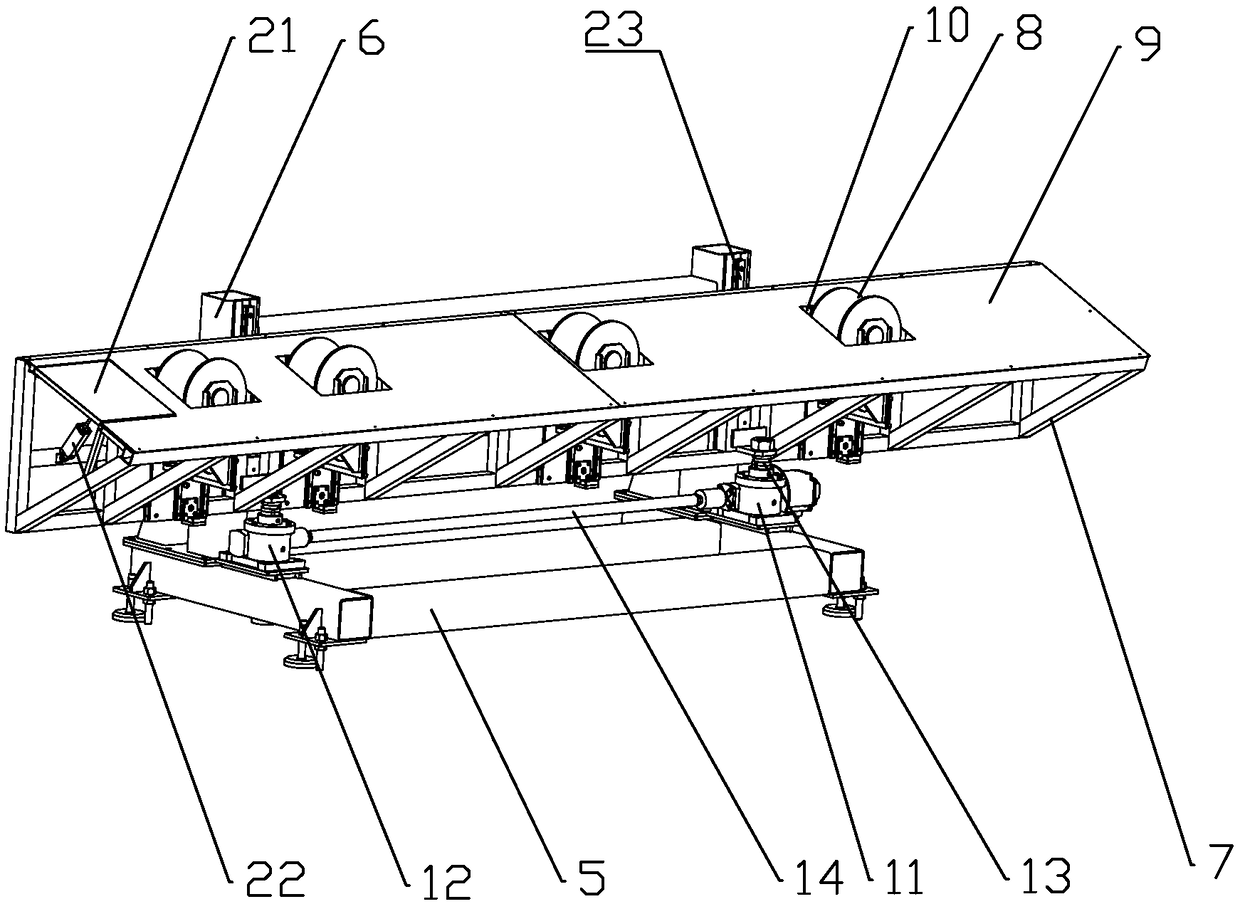

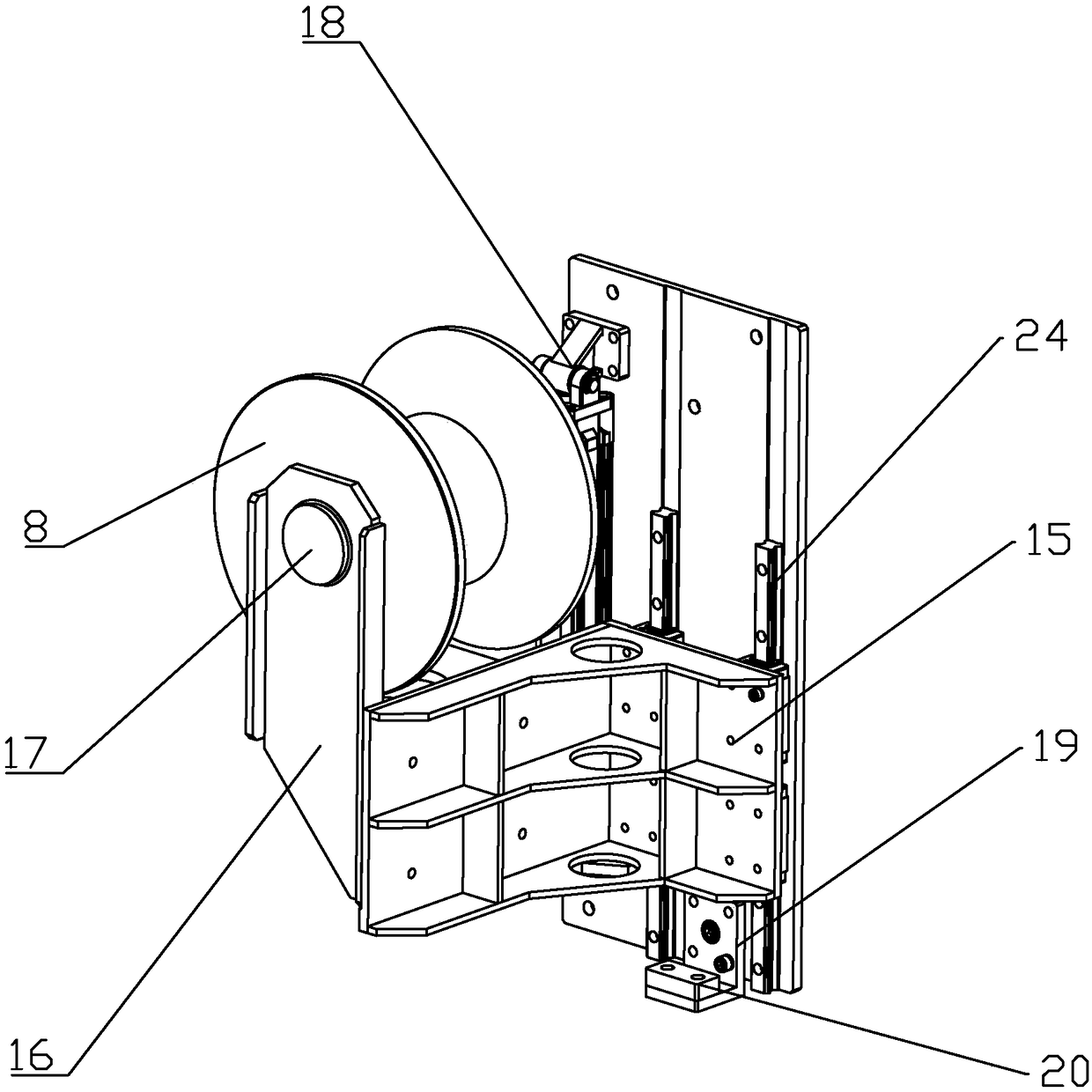

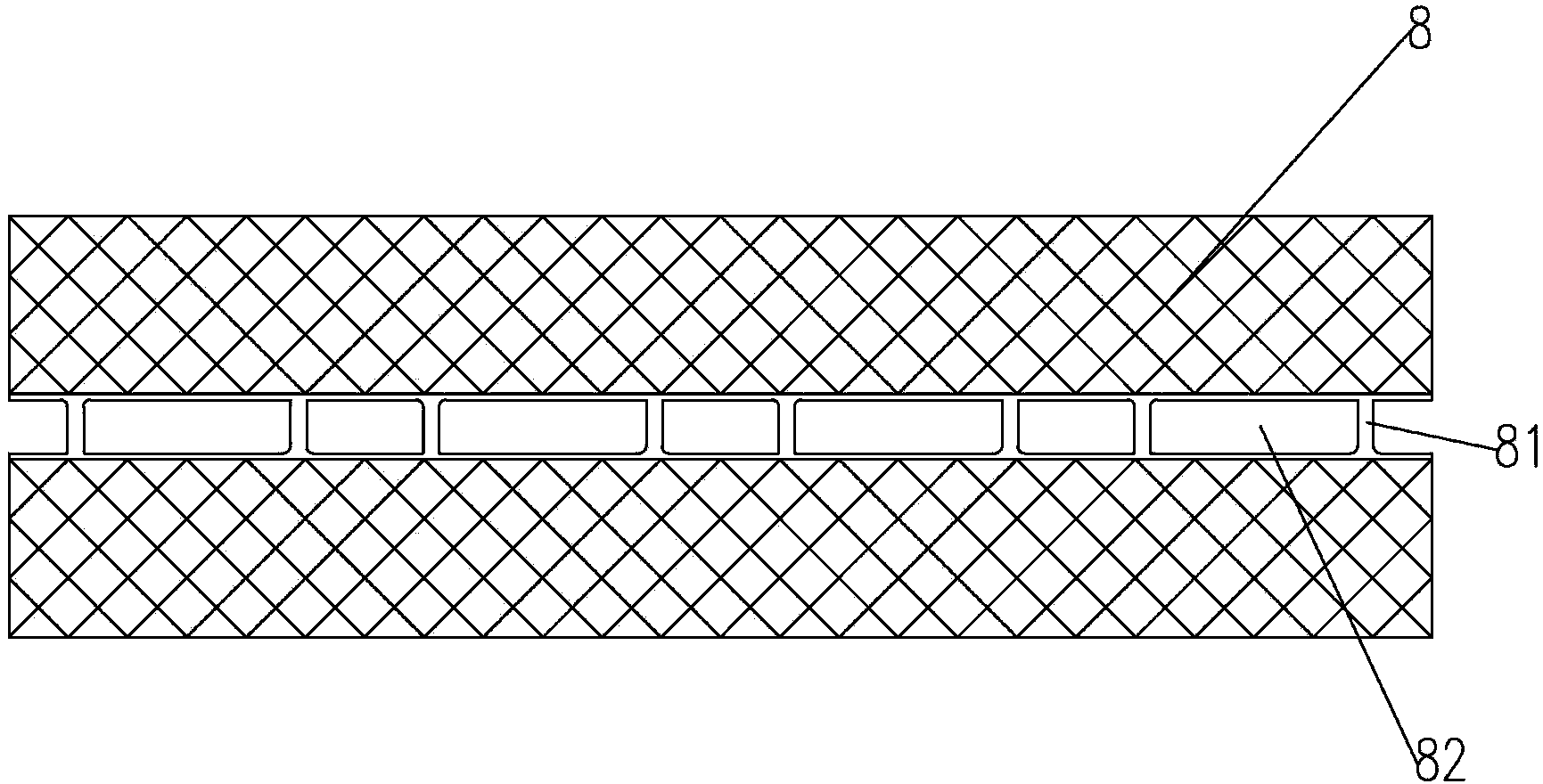

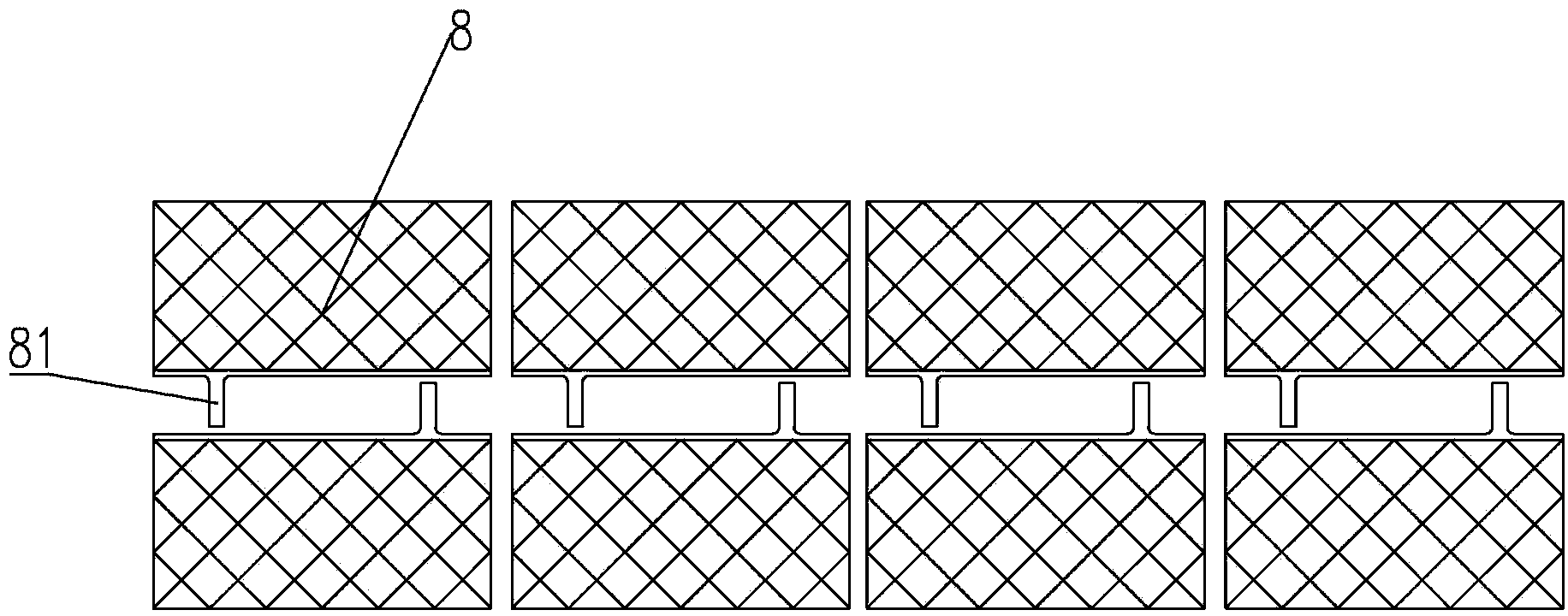

PendingCN108213740AReduce swingGuaranteed cutting accuracyWelding/cutting auxillary devicesAuxillary welding devicesControl theoryLaser

The invention provides a servo supporting and blanking device used for a laser pipe cutting machine. The servo supporting and blanking device used for the laser pipe cutting machine comprises a base frame. A fixed support is vertically arranged on the base frame. A blanking frame is movably arranged on the fixed support and connected with a servo driving device arranged on the base frame. A plurality of lifting carrier roller assemblies are arranged on the blanking frame at intervals in the length direction of the blanking frame. Carrier rollers of the lifting carrier roller assemblies are aligned in position. By adoption of the structure, the servo supporting and blanking device used for the laser pipe cutting machine is reasonable in design; through the design of the blanking frame, theamplitude of swing of steel pipes in the rotating process is decreased; and the blanking frame is driven by the servo driving device to move, when steel pipes with large differences between sectionallengths and sectional widths to rotate, the heights of the steel pipes relative to the round can be changed, and the servo driving device can adjust the height of the blanking frame at any time according to the height of the steel pipes relative to the ground, so that it is ensured that the steel pipes make contact with the carrier rollers all the time, and servo supporting is achieved.

Owner:SHANDONG LEIMING CNC LASER EQUIP CO LTD

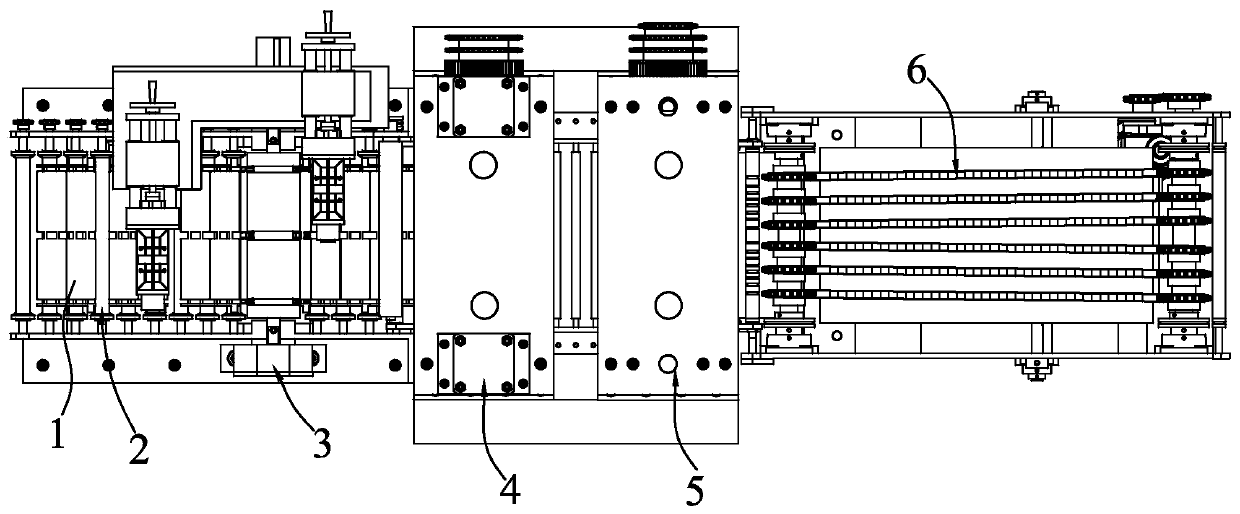

Continuous polar plate slitter machine and use method thereof

ActiveCN103962625AGuaranteed qualityGuaranteed cutting accuracyShearing machinesShearing control devicesMechanical engineeringAcceleration Unit

The invention discloses a continuous polar plate slitter machine which comprises a machine base, two machine frames, a material guide mechanism, a front conveying roller mechanism, a speed measuring device, a detection switch device, a longitudinal cutting mechanism, a rear conveying roller mechanism, a transverse cutting mechanism and a servo system, wherein the two machine frames are fixed to opposite sides of the machine base respectively, the material guide mechanism, the front conveying roller mechanism, the speed measuring device, the detection switch device, the longitudinal cutting mechanism, the rear conveying roller mechanism and the transverse cutting mechanism are sequentially arranged between the two machine frames, and the servo system is connected with the longitudinal cutting mechanism and the transverse cutting mechanism and is used for controlling the longitudinal cutting mechanism and the transverse cutting mechanism. The speed measuring device and the detection switch device feed back detected speed and lug position signals to the servo system. The servo system carries out compensation operation on the detected signals and preset parameters through a servo controller, and adjusts a slitter variable acceleration curve for compensation and modification. The invention further discloses a use method of the continuous polar plate slitter machine. The servo controller outputs corresponding execution instructions by changing input parameters, a slitter mechanism executes the variable acceleration curve and carries out compensation and modification according to the instructions, and accordingly the situation that continuous polar plates of different specifications are automatically switched for splitting is achieved.

Owner:SHENZHEN CENT POWER TECH

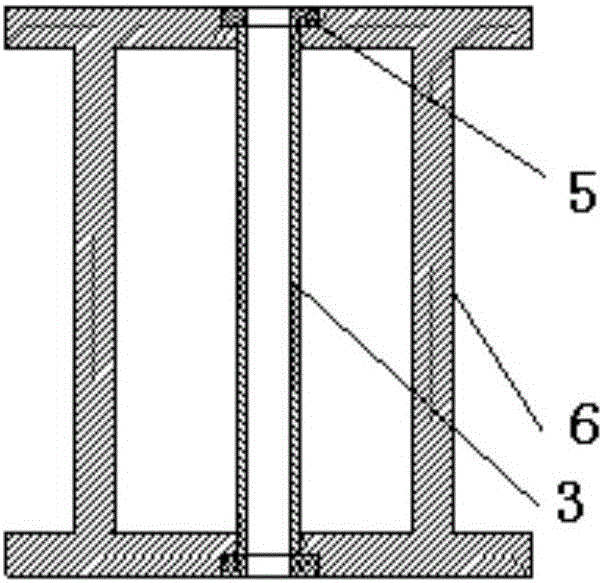

Double-lathe-head full-automatic numerically-controlled lathe

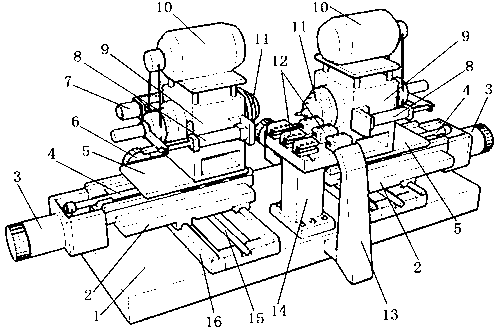

InactiveCN103170653AReduce manual loading and unloadingReduce turnover timesAutomatic/semiautomatic turning machinesMechanical equipmentEngineering

The invention discloses a double-lathe-head full-automatic numerically-controlled lathe and relates to mechanical equipment used for machining of workpieces. The double-lathe-head full-automatic numerically-controlled lathe is mainly composed of a lathe body, lathe heads, a guide rail, an X-direction moving drag plate, a Z-direction moving drag plate, a knife rest and the like. The lathe heads are of a double-lathe-head structure which allows bidirectional moving and machining at the same time, the knife rest is fixedly arranged between the two lathe heads, a double-face knife rest structure is adopted, and therefore the machining method is that the workpieces can rotate automatically and move along the X-direction and the Z-direction with the lathe heads. The structural change breaks an original structural form and machining method of a traditional lathe, machining process is simple and labor-saving, especially great convenience is brought to parts needing double-head machining, work efficiency is improved greatly, in addition, times of manual assembling and disassembling and turnover are reduced, damage on the workpieces is avoided, and machining accuracy can be effectively guaranteed.

Owner:盛焕君

Electrotype splicing method

The invention relates to an electrotyping technology in holographic anti-counterfeiting printing, in particular to an electrotype splicing method, in which a large-area holographic nickel plate with high positioning precision and an optional area is formed by unit nickel plates through splicing. The unit nickel plates are obtained through replication, and medium viscosity protective film is adhered to the front surface of each unit nickel plate; any two opposite edges of each unit nickel plate are evenly cut by a plate cutter according to identical specifications; the cut edges are spliced linearly by hand, and the joints are connected through adhesive tape, so as to form a unit group; the other pair of opposite edges of each unit group is cut by the plate cutter according to the identical specifications, so that the upper and the lower edges of each unit group are evenly cut, and a large plate can be formed by the unit groups through splicing; and the plate joints on the back of the large plate are pasted through special electrotyping tape, the medium viscosity protective film is torn off, and the large plate is connected through electrotyping. The electrotype thickness is required to be above 100 microns, the connection strength is guaranteed, the splicing quality and efficiency are improved, effects from human factors are reduced, the edge cutting is controlled, fixed reserved edges are kept, and the cutting precision is ensured.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

Collector for processing sealing rubber strip

InactiveCN102431059AEasy to operateGuaranteed cutting accuracyMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of machinery, and provides a collector for processing a sealing rubber strip. The collector comprises a working table and a control box which is arranged in the working table, wherein the working table is provided with a feeding mechanism, a turning mechanism, a conveying mechanism and a material receiving mechanism respectively; the control box is used for controlling work of the feeding mechanism, the turning mechanism, the conveying mechanism and the material receiving mechanism; the feeding mechanism is used for conveying the sealing rubber strip to be cut to the turning mechanism; the sealing rubber strip is turned by the turning mechanism after being cut, so that the cut sealing rubber strips fall on the conveying mechanism and are conveyed to the material receiving mechanism through the conveying mechanism to temporarily store a received material; and when a certain number of sealing rubber strips are achieved, the material receiving mechanism is turned to fall products into a collection trolley for collection. The collector has the advantages that: the controller is easy to operate; automatic feeding can be realized, and the cut material can also be put into the collection trolley; meanwhile, the cutting accuracy can also be guaranteed; the influence of manual operation on the quality of the processed product is reduced; and the working efficiency is increased.

Owner:宁波市胜源技术转移有限公司

Measurement-adjustable woodworking push table saw

InactiveCN106064406AGuaranteed cutting accuracyGuaranteed accuracyCircular sawsSawing componentsInstabilityEngineering

The invention discloses a measurement-adjustable woodworking push table saw, and belongs to the technical field of woodworking machinery. The measurement-adjustable woodworking push table saw comprises a push table frame, and a dividing ruler and a saw blade positioned on the push table frame; a left push plate and a right push plate are slidingly arranged on two sides of the saw blade; a finger corresponding to the dividing ruler is arranged at the end part of the left push plate; a support block is fixed in the slide direction of the left push plate, and is in threaded connection with a push rod; one end of the push rod is rotationally arranged with the left push plate, and a handle is arranged at the other end; a stopper is arranged in the slide direction of the right push plate; a slide rod is slidingly arranged on the stopper; and the slide rod is fixedly connected with the side surface of the right push plate, and is coated with a spring. The measurement-adjustable woodworking push table saw solves the problems of a traditional push table saw incapable of accurately positioning boards to be machined and weaker cutting quality of the boards caused by instability in the machining process.

Owner:武侯区华聚家私经营部

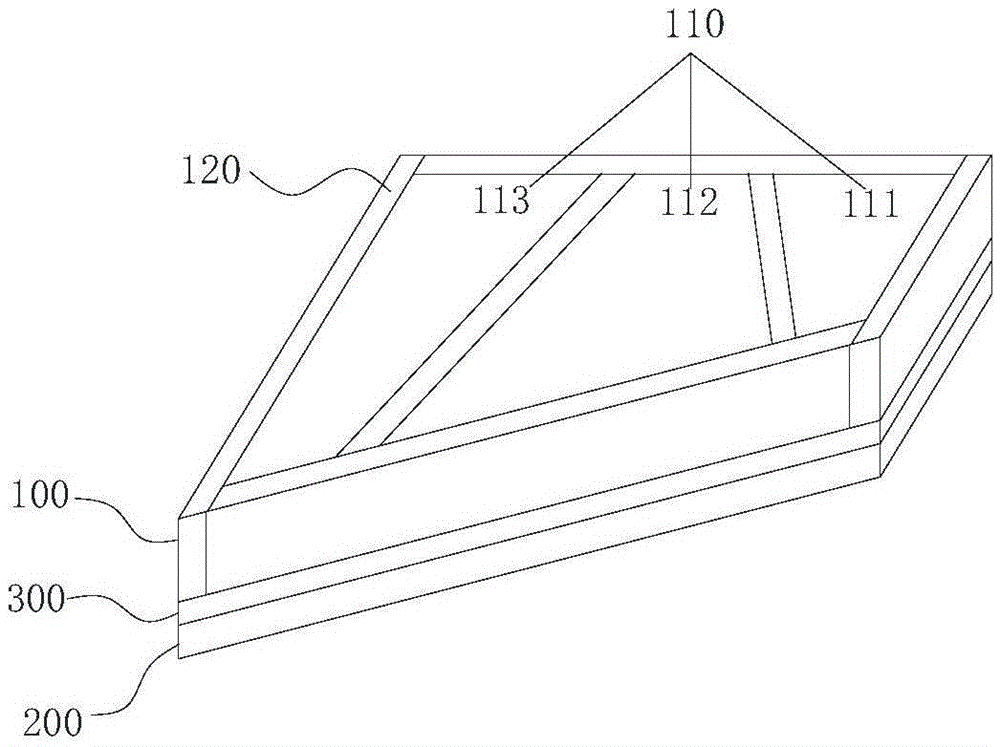

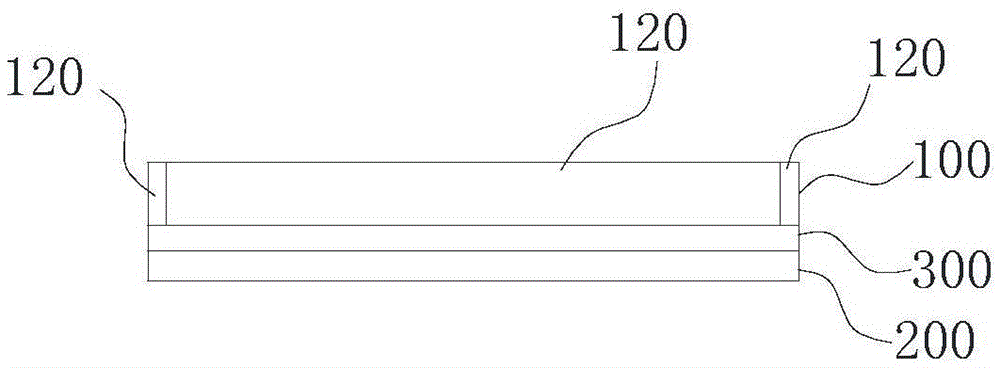

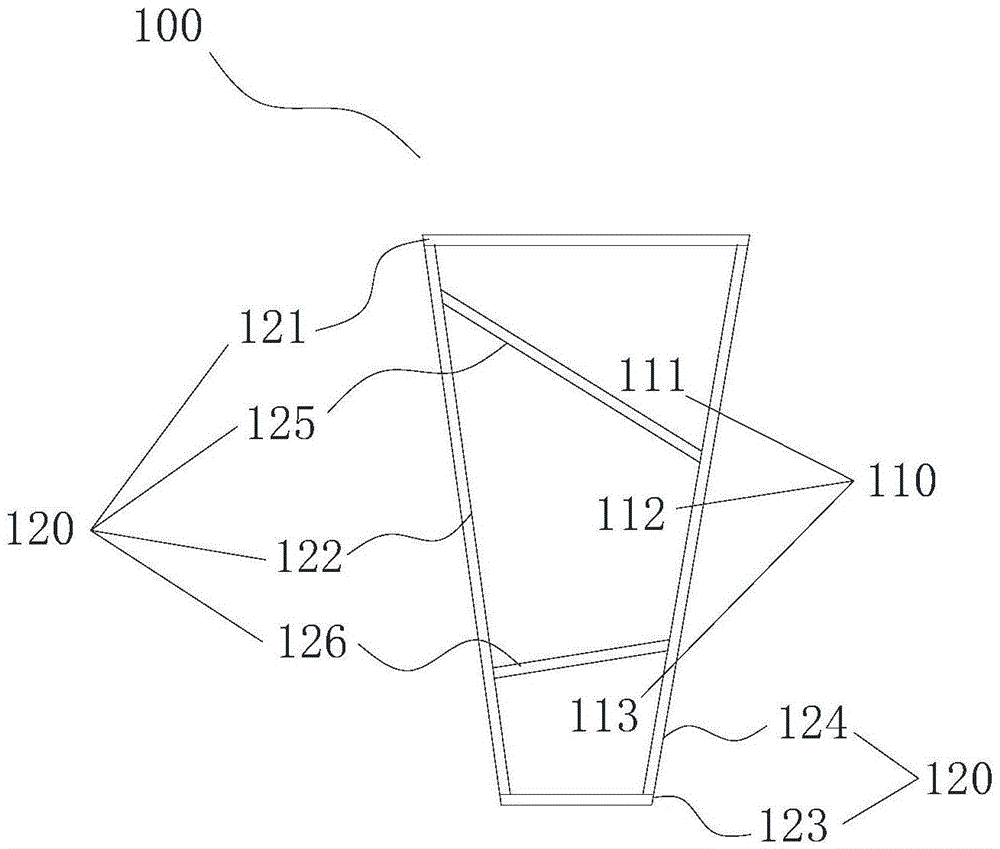

Preparation method of cell string

ActiveCN110649126AImprove cutting efficiencyGuaranteed cutting accuracyFinal product manufacturePhotovoltaic energy generationLap jointSolar battery

The invention discloses a preparation method of a cell string, comprising the following steps: (1) arranging cells; (2) lapping a cell string; and (3) welding the cell string. The cutting efficiency of connecting pieces can be greatly improved, the cutting precision of the connecting pieces can be guaranteed, the lap joint efficiency of the cell string can be improved, the welding efficiency of the cell string can be improved, the preparation efficiency of the cell string can be improved, and the productivity of the cell string and a solar cell module can be improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

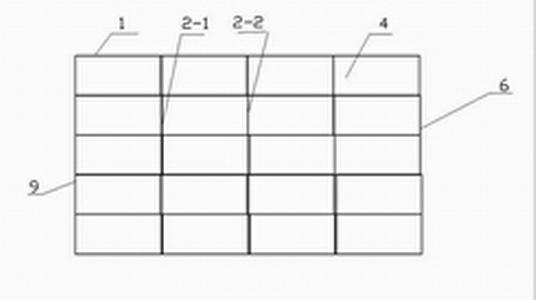

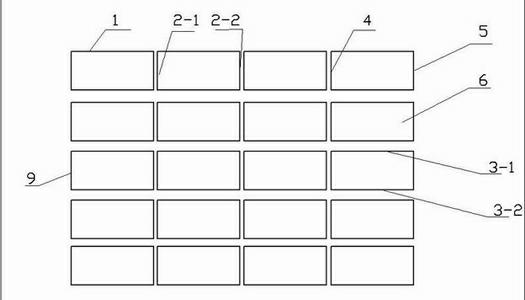

Geometric art inlaid wall and floor decorative plate and manufacturing method thereof

The invention provides a geometric art inlaid wall and floor decorative plate, and belongs to the field of architectural ornament and decoration. The decorative plate comprises a stone decorating layer, metal inlaid strips, a binding layer and a compound layer, wherein the decorating layer is formed by fixedly arraying multiple geometric decorative blocks and the metal inlaid strips according to a preset type version. According to the technical scheme, the individual unit decorative plate product can be produced in a factory-like and industrial mode, and decorative schemes meeting various individual requirements can be realized conveniently and fast just by simply changing the shapes and arrangement of the metal inlaid strips and the decorative blocks in the preset type version. Moreover, the decorative plate has a more stable structure and a high-flatness decorative face, and decoration site splicing quality and efficiency are improved. Meanwhile, the invention further provides a manufacturing method of the geometric art inlaid wall and floor decorative plate. The decorative plate manufactured by adopting the method has the advantages of being provided with individual decorative art members, and being capable of being machined industrially in a factory, high in flatness and integrity, convenient to splice and the like.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Plate cutting apparatus

InactiveCN105751172AAvoid severe deformationGuaranteed cutting accuracyWork benchesTelescopic cylinderDimensional precision

The invention discloses a plate cutting apparatus, comprising a basic support, a cutting rack, a feeding platform, a discharging platform, a cutting unit mount and a plurality of cutting units; wherein all the cutting rack, the feeding platform, the discharging platform and the cutting unit mount are fixed on the basic support; a plurality of descending telescopic cylinders are discretely distributed at the top of the basic support; a plurality of ascending telescopic cylinders are discretely distributed on the cutting rack; the ascending telescopic cylinders and the descending telescopic cylinders are in one-to-one correspondence and are used for clamping the top and bottom of a plate, respectively; the multiple cutting units are mounted on the cutting unit mount to cut the plate. The plate cutting apparatus can be used to solve the problem that an existing plate cutting apparatus has low dimensional precision of produced plates.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Jade cutting device

InactiveCN106827265AStable positionAvoid shakingWorking accessoriesFine working devicesGear wheelElectric machinery

The invention relates to a jade cutting device. A telescopic air cylinder is arranged at the bottom of a bracket; a bottom plate is connected onto the telescopic air cylinder; guide sliding rails are arranged on two sides of the bottom plate; gears are meshed in the guide sliding rails and are connected through a moving rod; a transmission mechanism is arranged on the moving rod and is connected with a cutting rack; a second motor is arranged on the cutting rack; a rotary end of the second motor is fixedly connected with the transmission mechanism; a conveying device is connected onto the cutting rack; a working table is arranged on the conveying device; an insection meshed with the conveying device is arranged at the bottom surface of the working table; a pasting plate is arranged on the working table; jade material is pasted on the pasting plate; a feeding device and a discharging device are arranged on two sides of the conveying device; a cutting piece is arranged above the working table; a suction hood is arranged out of the cutting piece and is connected with a negative pressure cabin through a connecting pipe; and the negative pressure cabin is connected with a negative pressure pump. The jade cutting device is accurate in cutting, saves time and labor, can cut jade in a multidirectional manner, and has the dust collection function.

Owner:天津市山友玉石纽扣有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com