Dual-cutter dual-angle fixed-length crank cutting device

A cutting device, dual-angle technology, applied in metal processing and other directions, can solve the problems of low cutting efficiency, material waste, environmental pollution, etc., and achieve the effect of improving cutting efficiency, avoiding pollution, and ensuring cutting accuracy and cutting surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following describes the present invention in further detail in conjunction with the embodiments of the drawings:

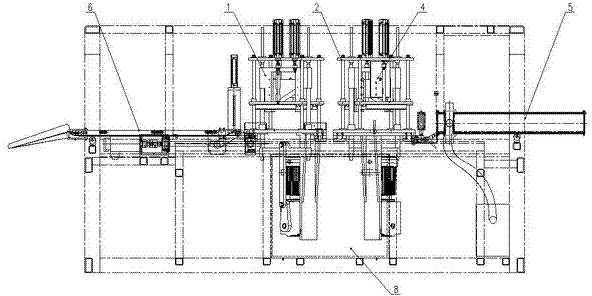

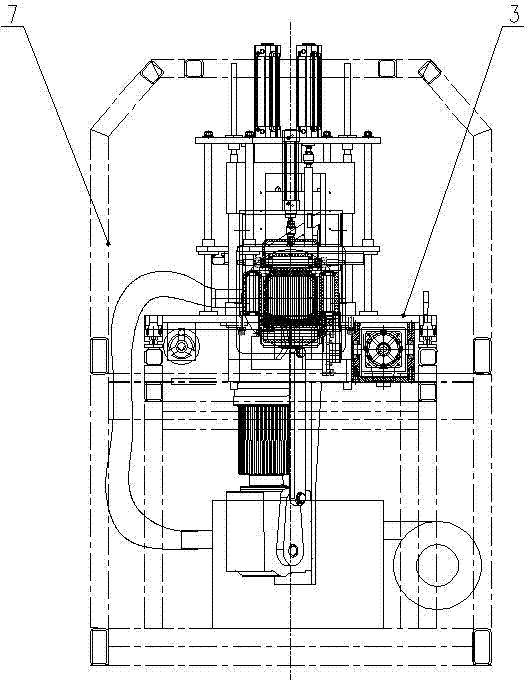

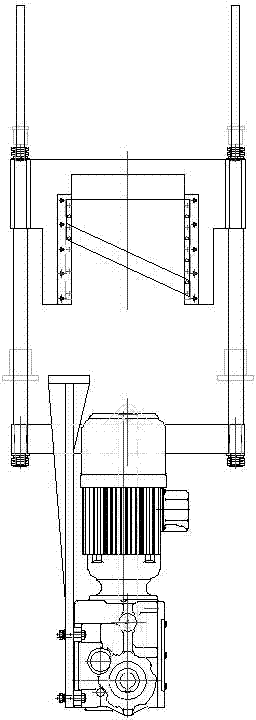

[0031] Such as figure 1 -14 shows a double-knife double-angle fixed-length crank cutting device, consisting of a cutting unit 1, a pressing unit 2, a synchronously moving work table 3, a tool heating unit 4, a preheating unit 5, a conveying unit 6, and a frame 7 and the control unit 8. The cutting unit 1 is installed on the movable table 33, guided by a linear bearing fixed at the mounting hole 334, and supported by a clamping guide rod fixed at the mounting hole 332 connected to the cylinder fixing plate 22. The pressing unit 2 is installed on the front and rear sides of the cutting unit 1. The cutter heating unit 4 is fixedly connected to the cylinder fixing plate 22 of the pressing unit 2. The synchronous moving workbench 3 is composed of a synchronous servo drive device 31, a pitch adjusting device 32 and a moving table 33. A synchronous servo dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com