Geometric art inlaid wall and floor decorative plate and manufacturing method thereof

A decorative panel and wall-mounted technology, applied in the field of building decoration, can solve the problems of harsh working environment, high material loss, low efficiency of personalized decoration construction, etc., achieve good integrity, ensure flatness, and provide quality and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

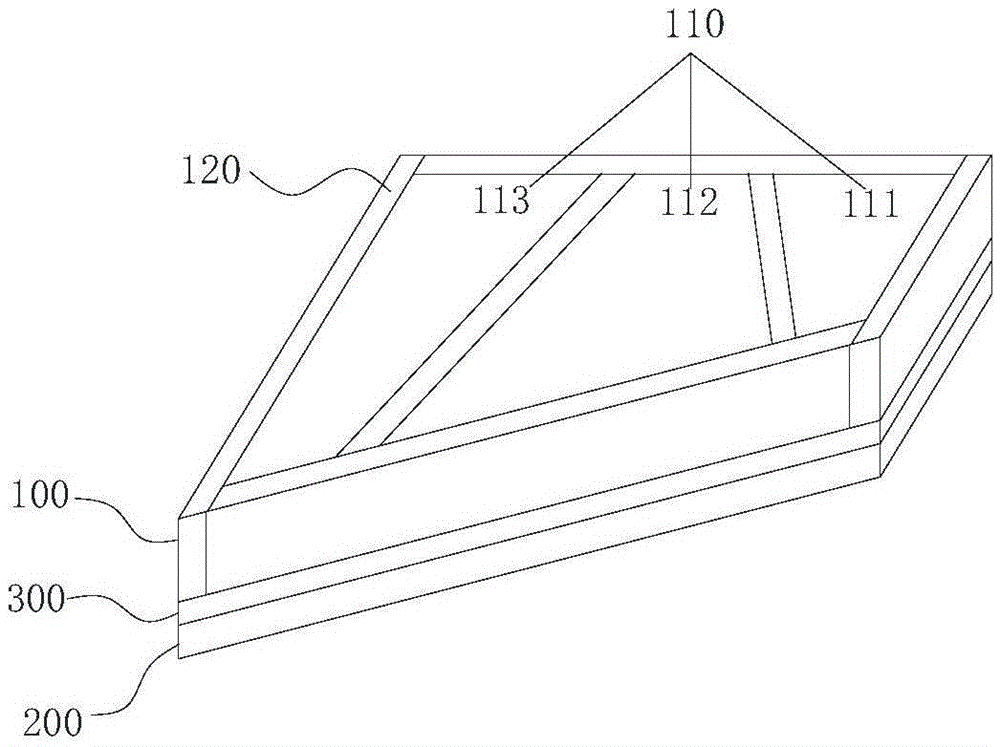

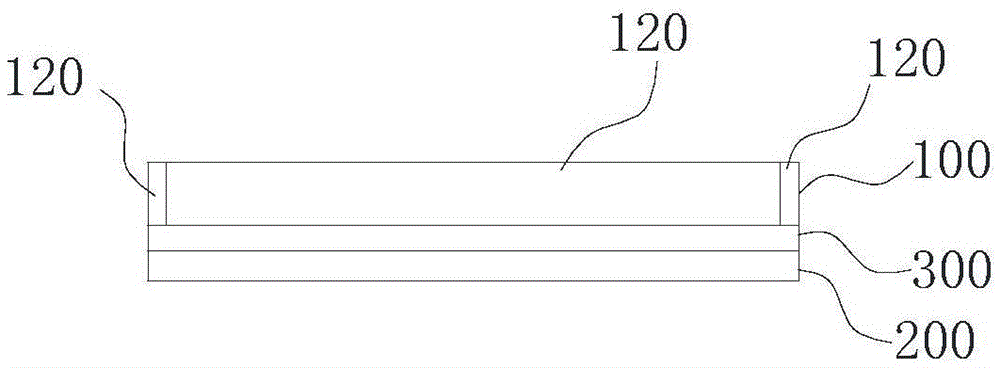

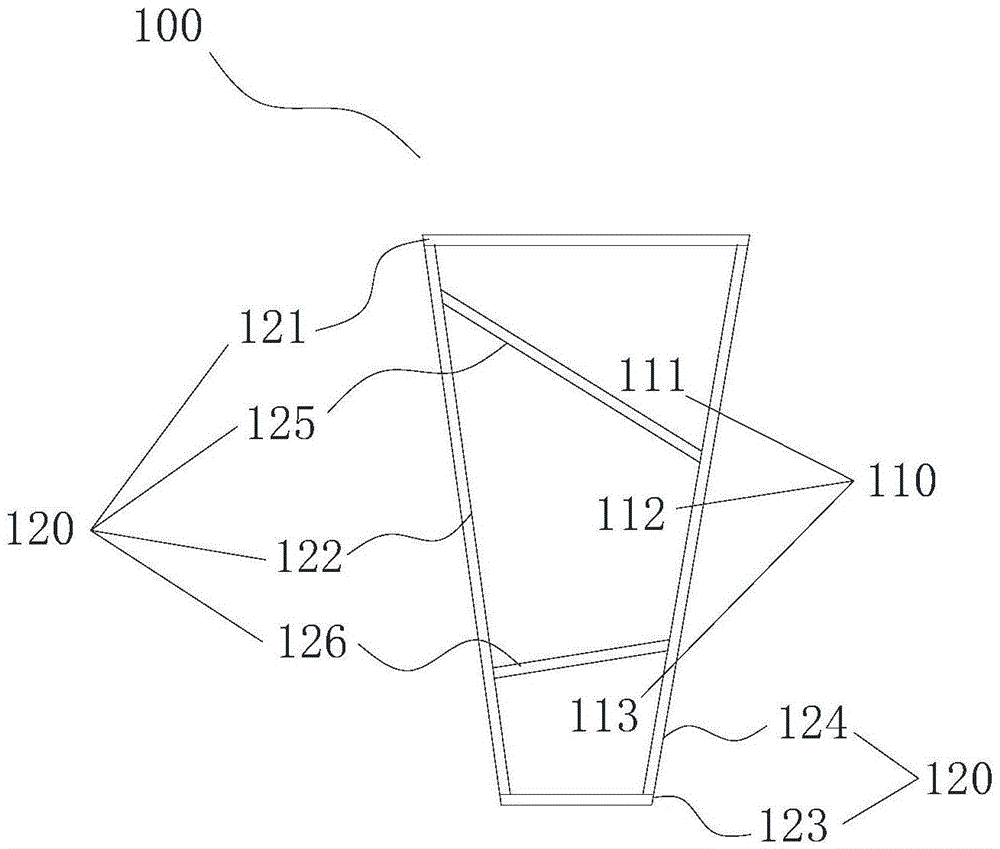

[0062] see Figure 1 to Figure 4 , figure 1 The three-dimensional schematic diagram of the geometric art inlaid wall and floor decorative board provided in this embodiment, figure 2 For a side view, image 3 For a top view, Figure 4 It is a schematic cross-sectional view of the metal mosaic strip in this embodiment. It should be noted that the "wall and floor decoration board" referred to in the present invention means that the decoration board can be used as a wall decoration material or as a floor decoration material.

[0063] In this embodiment, the geometric art inlaid wall decoration board includes: a decorative layer 100 and a composite layer 200, the composite layer 200 is arranged on the non-decorative surface of the decorative layer 100, and the composite layer 200 is connected to the decorative layer by a bonding layer 300 100 bonds. Wherein, the decorative layer 100 includes a plurality of decorative blocks 111, 112, 113 arranged according to a predetermined ...

Embodiment 2

[0073] see Figure 7 , and in conjunction with the accompanying drawings in Embodiment 1. Figure 7 It is a flow chart of the preparation method of the geometric art inlaid wall and floor decorative board provided in this embodiment. The method comprises the steps of:

[0074] S1: According to the predetermined pattern, provide decorative blocks and metal inlay strips;

[0075] Usually, the pattern of wall or floor decoration is a wall or floor design drawn by computer-aided design software. body or floor pattern. According to the design drawing of the decorative block 110 and the metal inlay strip 120 in the predetermined pattern, the required decorative block 110 and the metal inlay strip 120 are provided.

[0076] S2: Arranging the decorative block 110 and the metal inlay strip 120 in a mold according to a predetermined pattern;

[0077] In order to improve the assembly efficiency of the factory and ensure the processing accuracy of mass production, in the solution pro...

Embodiment 3

[0109] Figure 11 A schematic diagram of on-site splicing of a decorative block provided in this embodiment. Among them, decorative panel A 1 、A 2 、A 3 、A 4 、A 5 、A 6 Form a set of standard decoration unit B 1 , the first row in the figure is the standard decoration unit B 1 The strips are spliced repeatedly, and the other adjacent row is standard decorative unit B 2 The strip repeating splicing, where decorative unit B 2 by trim unit B 1 Formed by inverting 180 degrees. Decoration unit B 2 by trim unit B 1 Arranged at a certain distance. Of course, according to the difference of the predetermined version, the decorative block 110, the decorative plate A n , standard decoration unit B 1 There are different shapes, so there are many different splicing methods and splicing patterns. On-site construction personnel only need to arrange and splice the decorative panels into standard decorative units in a certain order, and then repeatedly arrange the standard deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com