Collector for processing sealing rubber strip

A technology of sealing rubber strips and collectors, which is applied in the field of collectors, can solve the problems that the products cannot meet the quality requirements, it is difficult to ensure the cutting accuracy, and the operation is time-consuming and laborious, so as to achieve the effects of reducing impact, simple operation, and ensuring cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

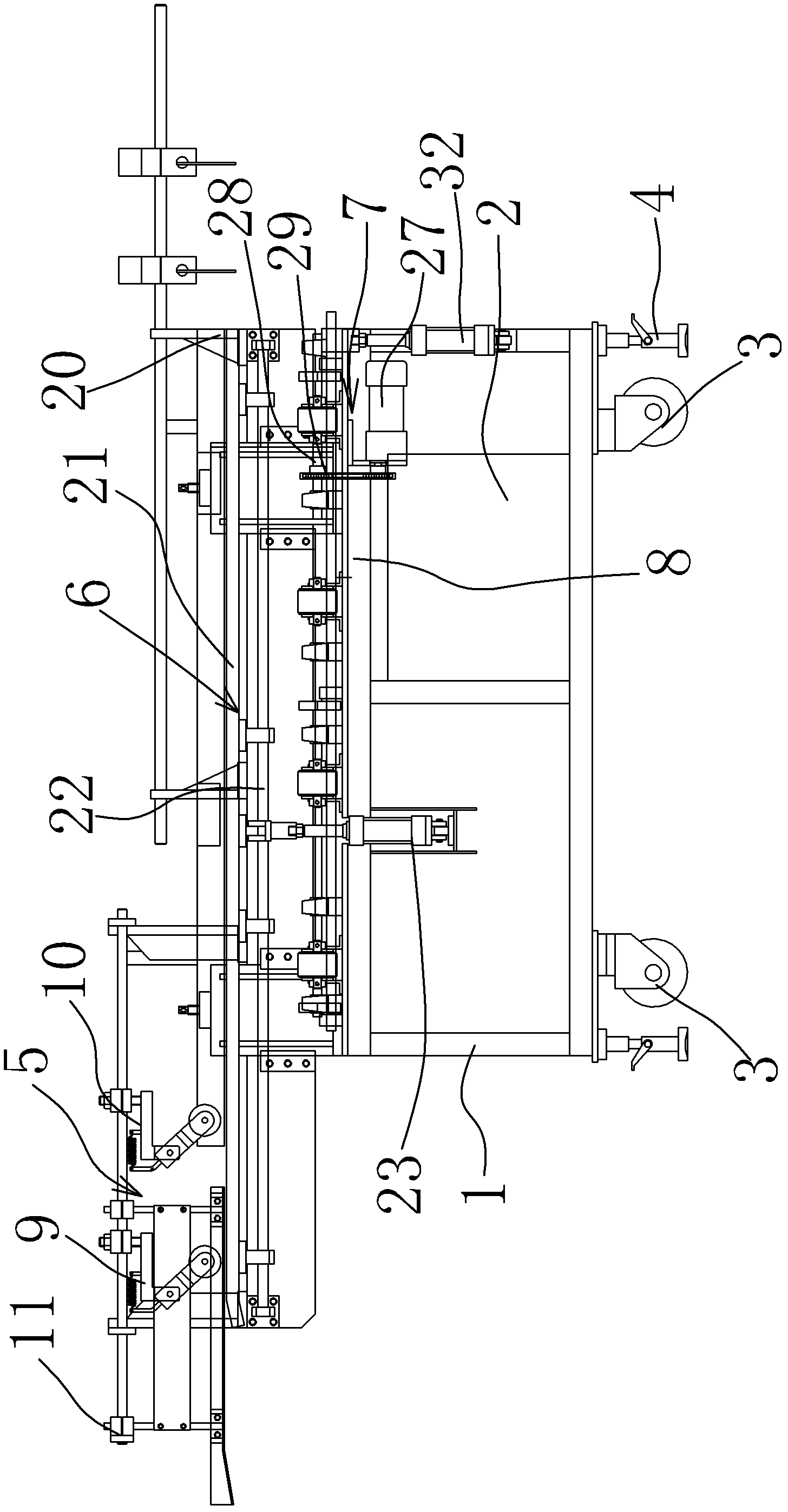

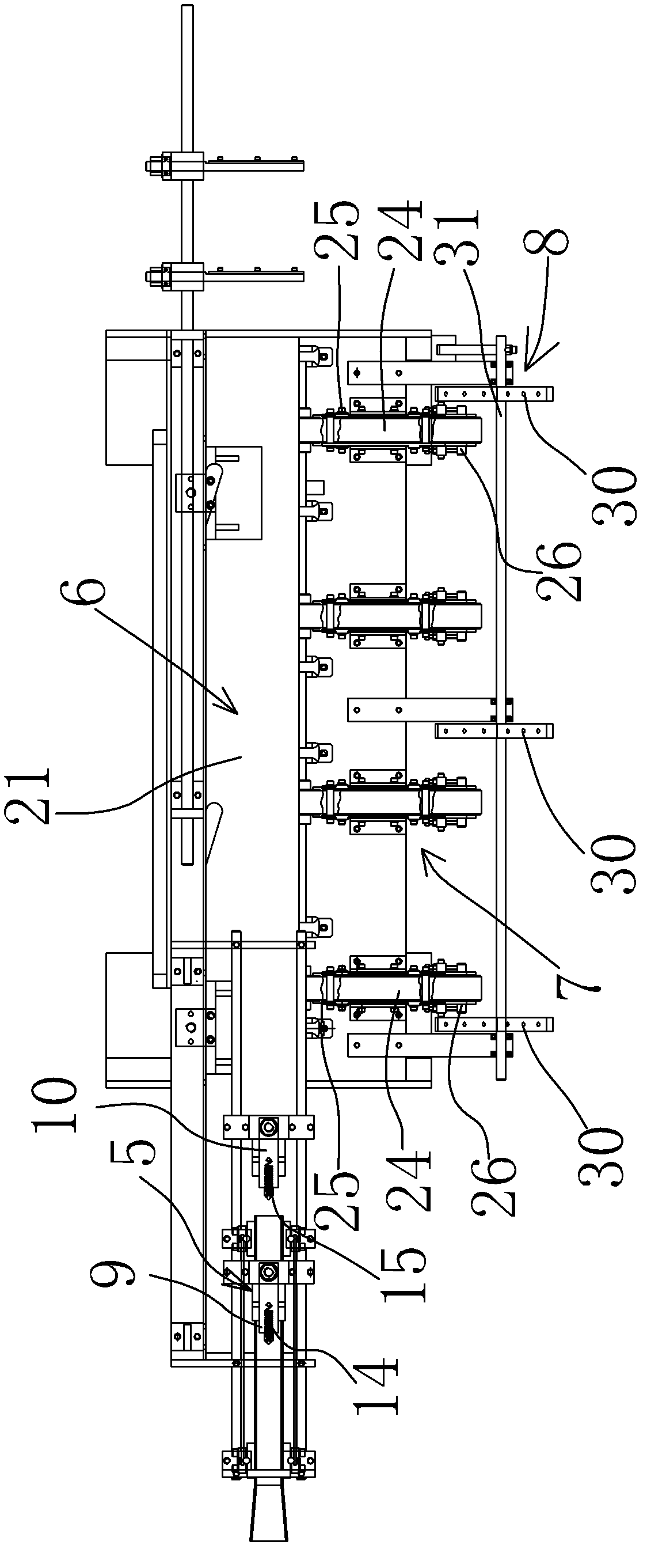

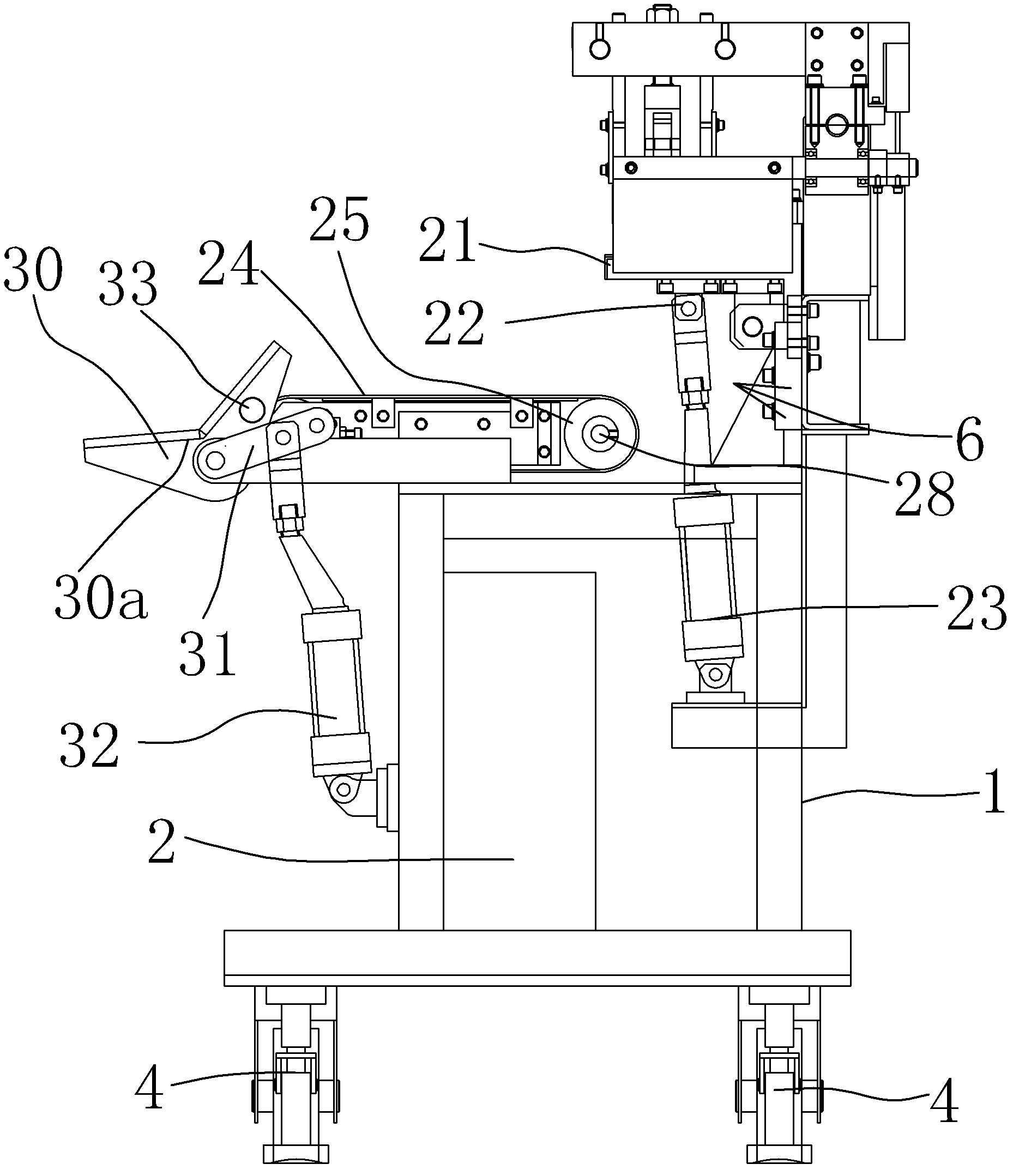

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0024] In the figure, workbench 1; control box 2; casters 3; lifter 4; feeding mechanism 5; turning mechanism 6; conveying mechanism 7; receiving mechanism 8; first feeding device 9; second feeding device 10; stroke control Switch 11; first fixed plate 12; first feeding wheel 13; first spring 14; first connecting plate 15; second fixing plate 16; second feeding wheel 17; second spring 18; Frame 20; Turning table 21; Turning shaft 22; Turning cylinder 23; Conveyor belt 24; Main conveying wheel 25; Slave conveying wheel 26; Motor 27; Shaft 31; material receiving cylinder 32; gravity sensor 33.

[0025] Such as figure 1 As shown, the collecting machine used for processing sealing rubber strips includes a workbench 1 and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com