Diamond inner circle cutting blade and preparation method thereof

A diamond and circular cutting technology, which is applied in the field of tools for cutting precious gemstones, can solve the problems of short service life of diamond internal circular cutting blades, and achieve the effects of improving service life, increasing the number of layers arranged, and reducing the thickness of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Diamond inner circle cutting blade

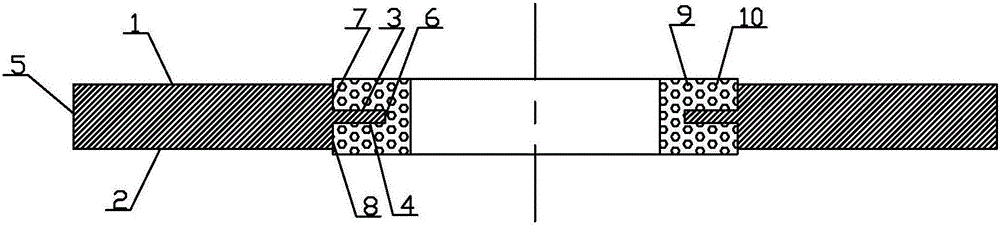

[0039] like figure 1 As shown, the diamond inner circular cutting blade according to the present invention includes a circular base body, and the circular base body has a symmetrical structure with its axis as the center line, wherein:

[0040] The circular base includes a first main surface 1, a second main surface 2 opposite to the first main surface 1, a third main surface 3, a fourth main surface 4 opposite to the third main surface 3, and an outer circumference a first side surface 5 of the edge and a second side surface 6 at the inner peripheral edge;

[0041] The third main surface 3 and the fourth main surface 4 are respectively formed by extending a certain distance outward from the upper and lower ends of the second side surface 6 toward the direction of the first side surface 5, and the third main surface 3. The width in the radial direction of the circular base is equal to the width of the fourth main surface...

Embodiment 2

[0047] Embodiment 2: the preparation method of diamond inner circle cutting blade described in the present invention

[0048] 1) Select a circular substrate, which is made of high-strength stainless steel with a thickness of 0.12mm, has a first main surface 1, a second main surface 2 opposite to the first main surface 1, and a The first side surface 5 and the second side surface 6 located at the inner peripheral edge;

[0049] 2) Extend 2 mm outwards from the upper and lower ends of the second side surface 6 toward the direction of the first side surface 5 by laser engraving to form a third main surface 3 and a fourth main surface opposite to the third main surface 3, respectively. The main surface 4, that is, the width of the third main surface 3 and the fourth main surface 4 in the radial direction of the circular base is 2mm; wherein, the third main surface 3 and the first main surface 1 pass through the first ring The side 7 is connected, and the first annular side 7 is p...

Embodiment 3

[0064] Embodiment 3: the preparation method of diamond inner circle cutting blade described in the present invention

[0065] Repeat Example 2, the difference is:

[0066] In step 3.1):

[0067] The composition of the first electrochemical coating agent is: NiCl 2 ·6H 2 O 250g / L, NiSO 4 ·7H 2 O 260g / L, concentrated hydrochloric acid 175g / L;

[0068] The process of the first coating is: the current density is 8A / dm 2 , the temperature is 35°C, and the time is 2min;

[0069] In step 3.2):

[0070] The composition of the second electrochemical coating agent is: Ni(NH 2 SO 3 ) 2 4H 2 O 320g / L, NiCl 2 ·6H 2 O20g / L, H 3 BO 3 30g / L, C 12 h 25 SO 4 Na 0.04g / L;

[0071] The process of the second coating is: the current density is 0.1A / dm 2 , the temperature is 35°C, and the time is 4min;

[0072] In step 3.3):

[0073] The composition of the second electrochemical coating agent is the same as step 3.2).

[0074] The process of the third coating is: the current de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com