Etching solution composition for titanium-aluminum-titanium metal laminated membrane

A technology of composition and etching solution, which is applied in the field of etching solution, can solve the problems of high cost and limitation, and achieve the effects of reducing production cost, reducing the amount of side etching, and improving the uniformity of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0026] Titanium is deposited on a glass substrate by sputtering -aluminum -titanium the substrate.

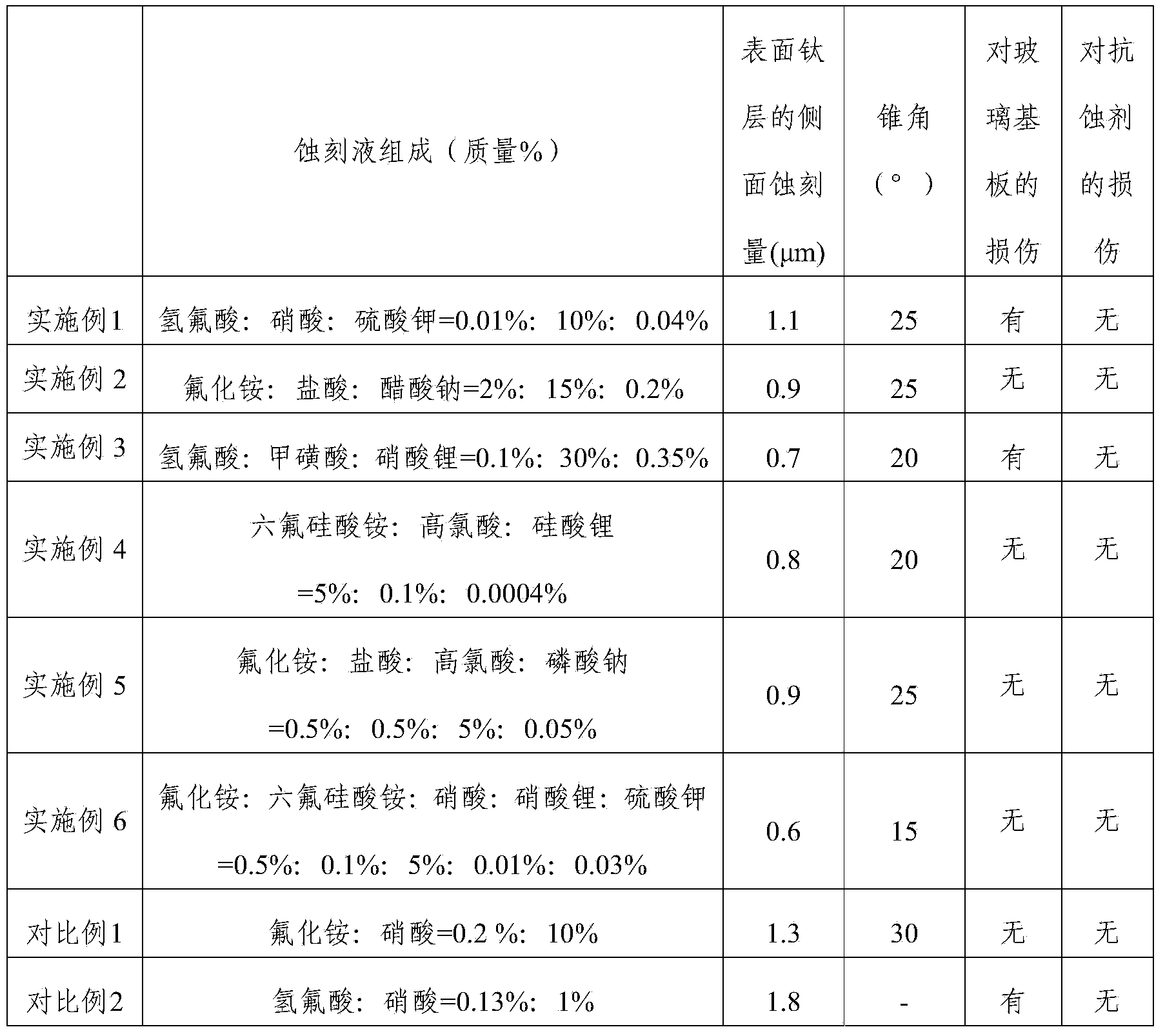

[0027] Then, the titanium-aluminum-titanium metal laminated film was patterned with a resist, and immersed in the etching solution of Examples 1 to 6 in Table 1 (etching temperature: 30° C.). Thereafter, after washing with ultrapure water and drying with nitrogen gas, the shape of the substrate was observed with an electron microscope. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com