Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223results about "Non-printed masks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

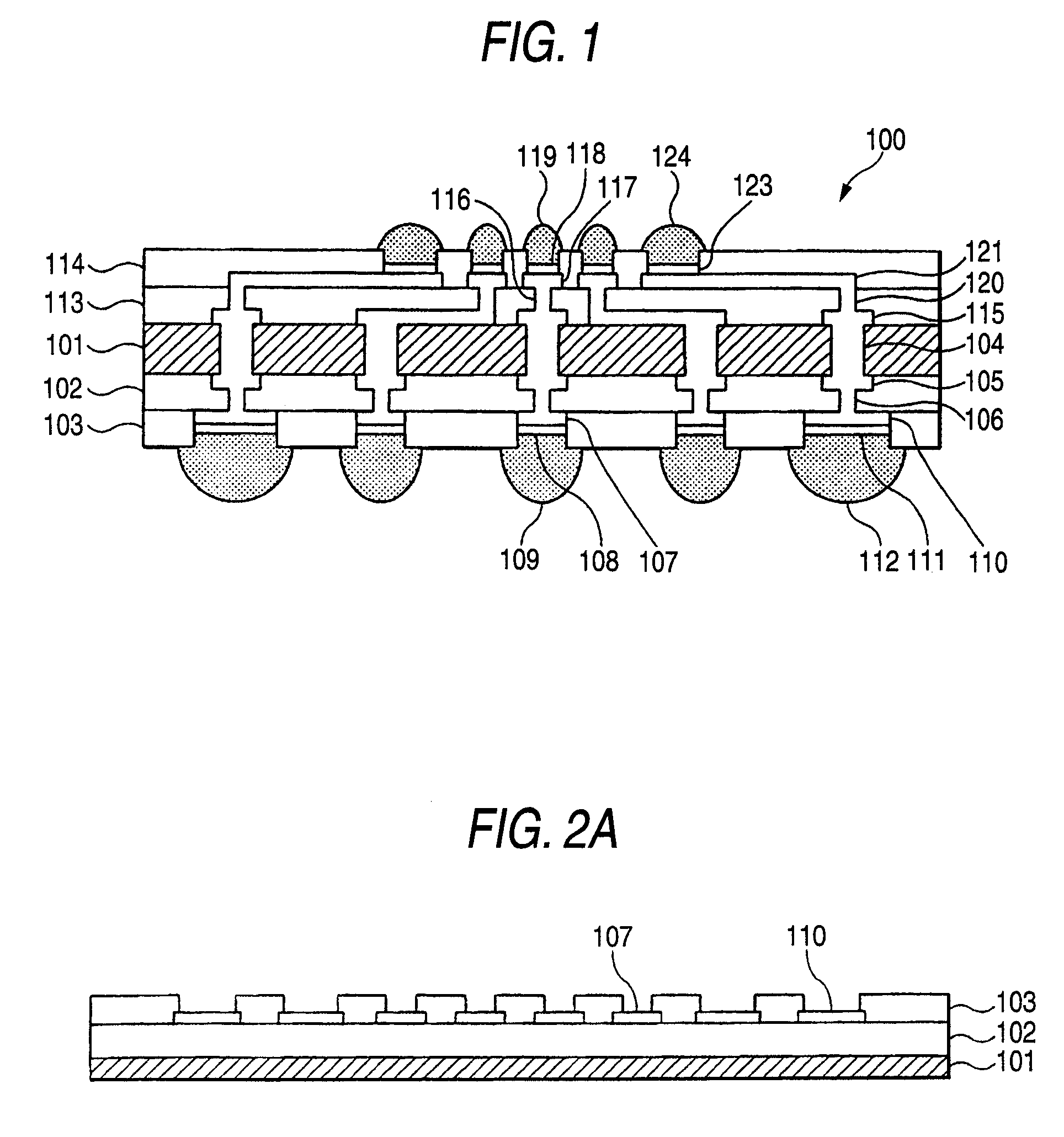

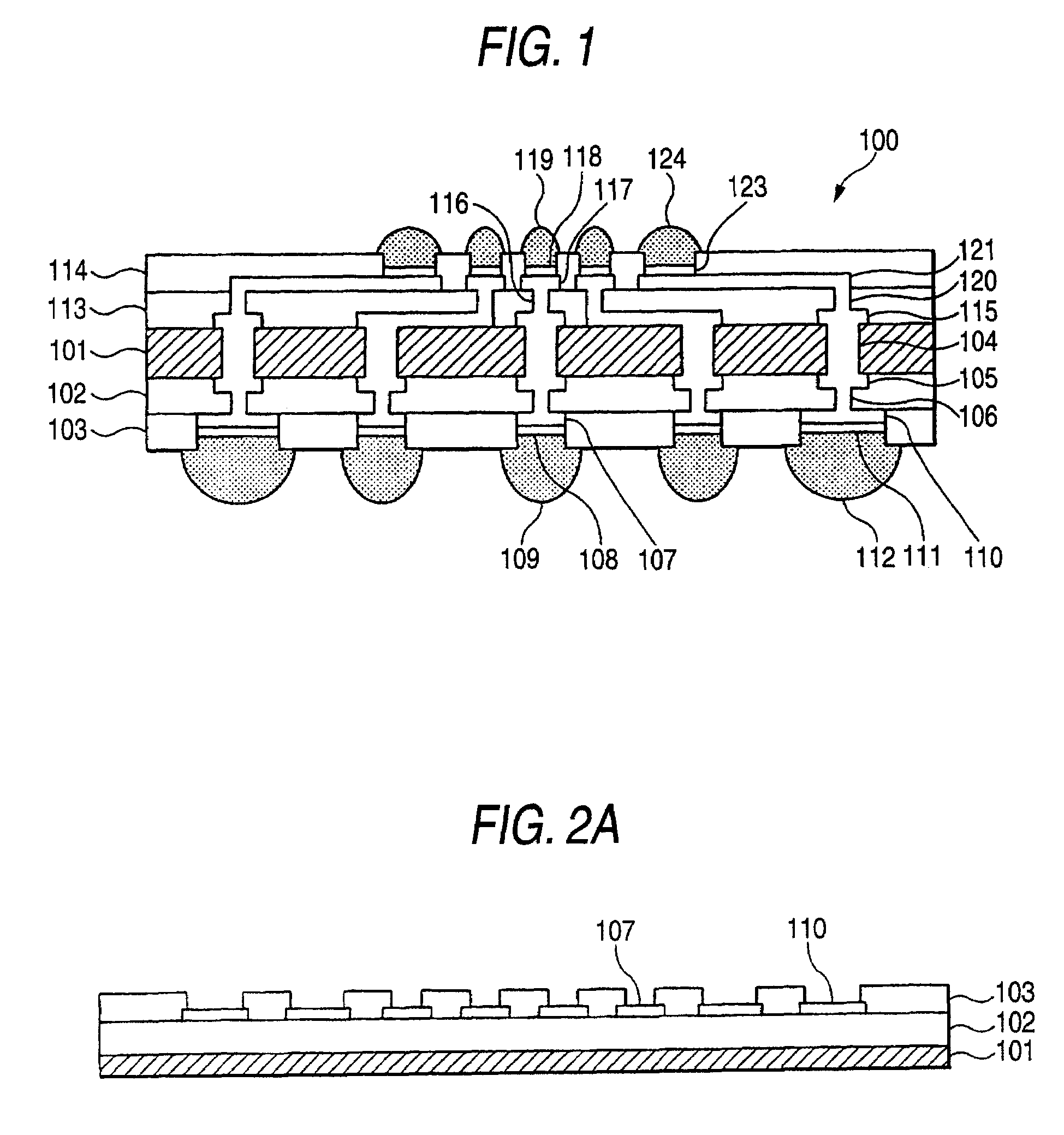

Printed wiring board

ActiveUS20070096327A1Rough surfaceSmall surface roughnessPrinted circuit assemblingSemiconductor/solid-state device detailsResistElectrical conductor

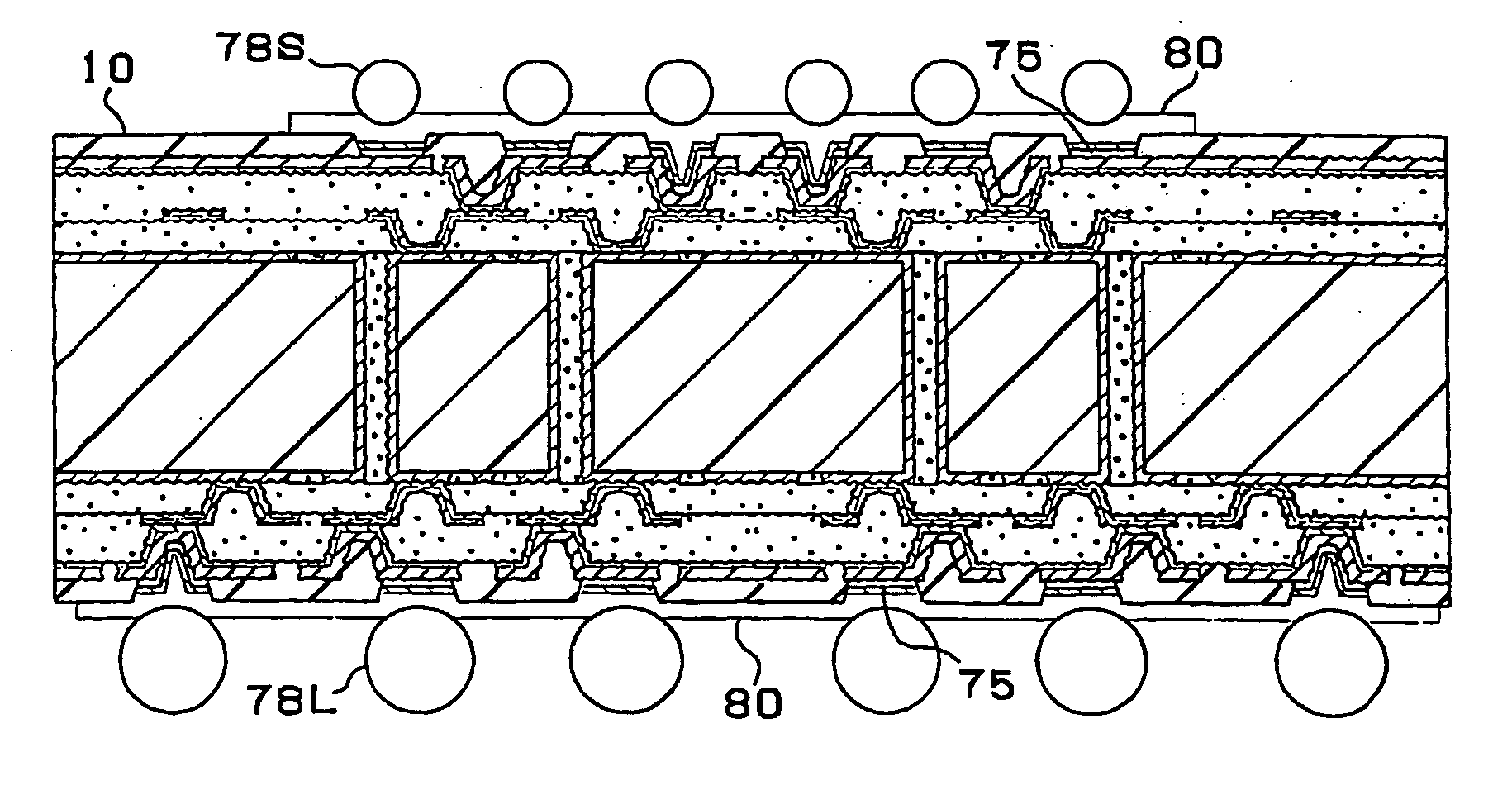

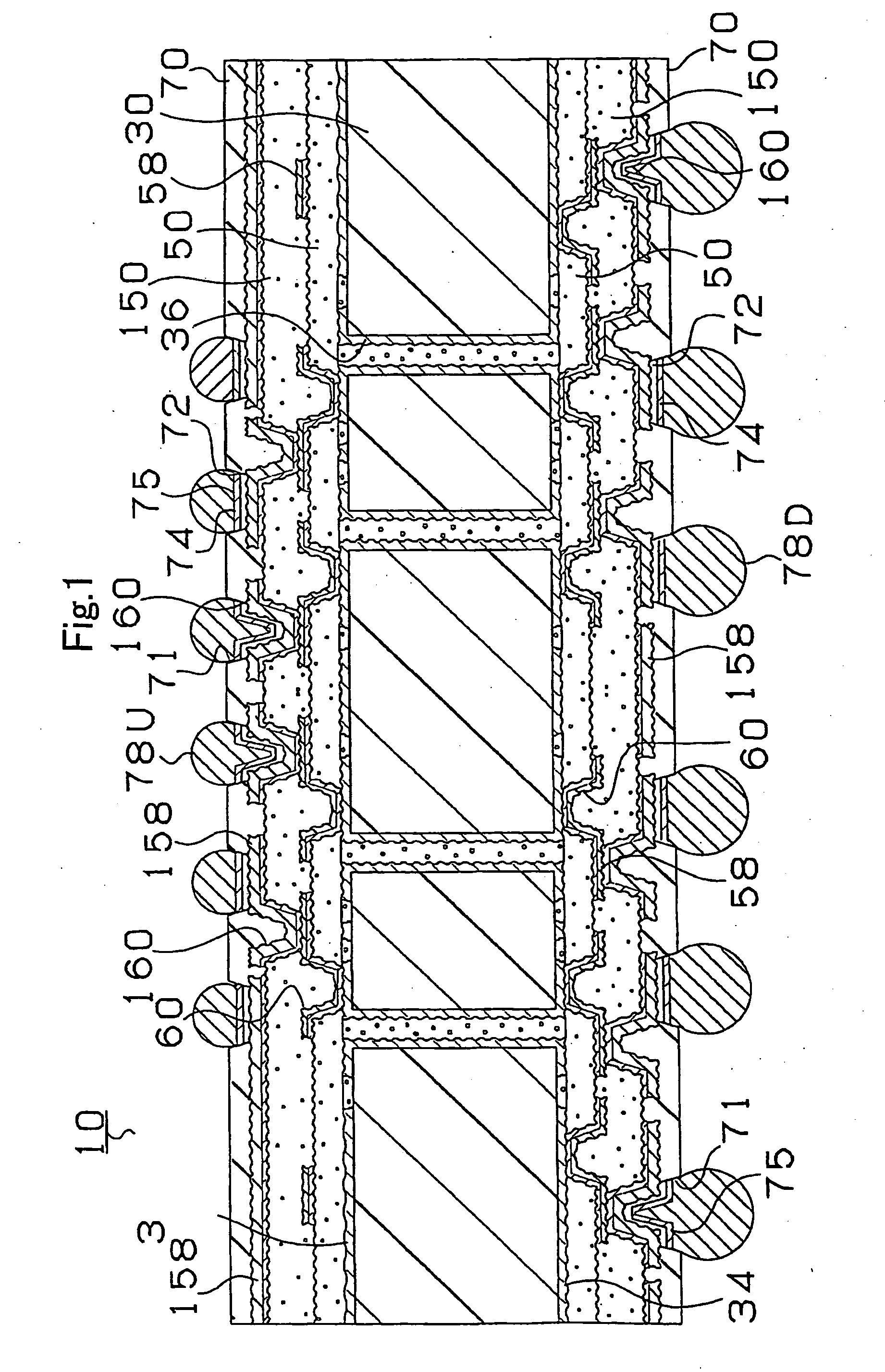

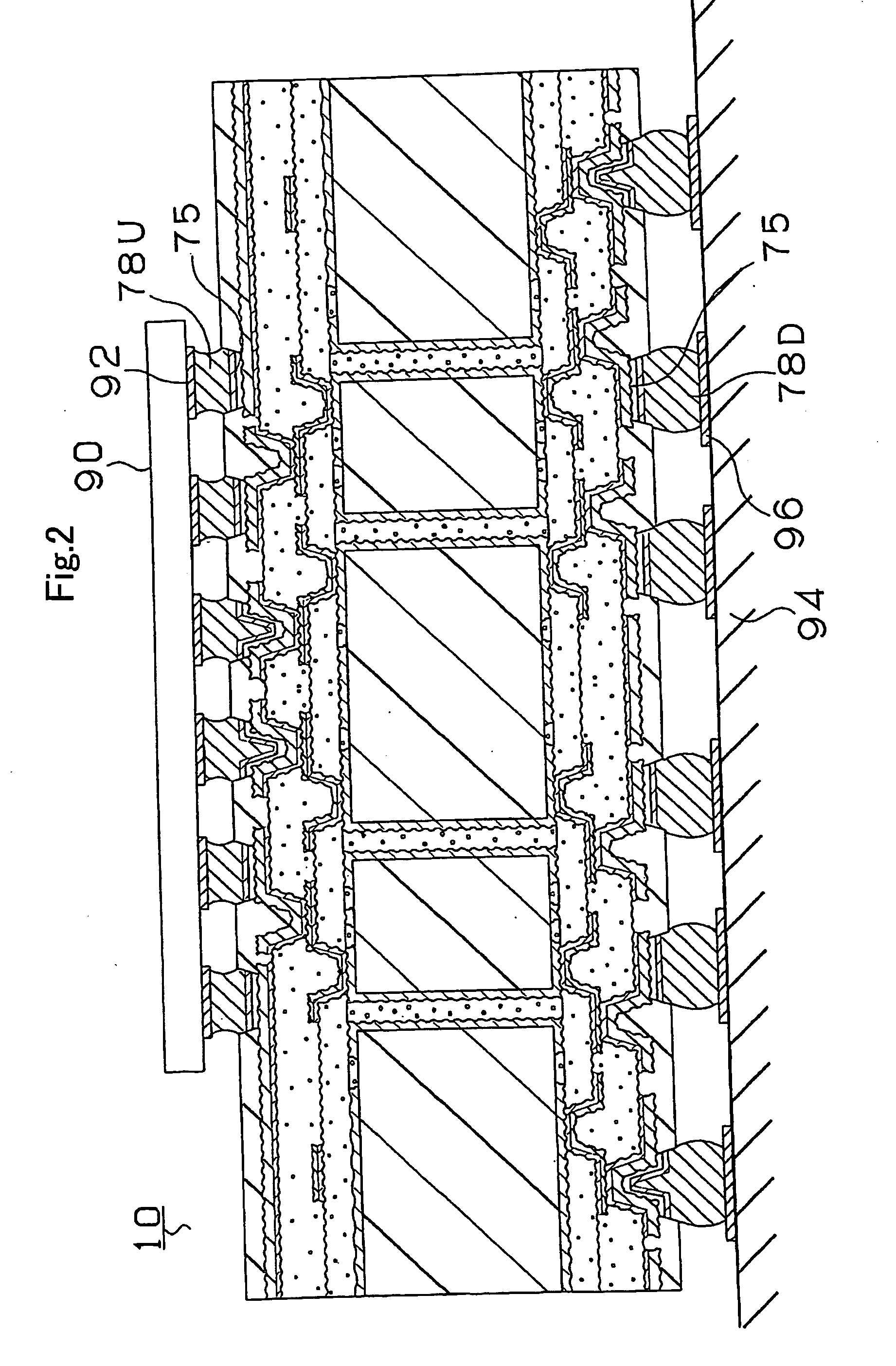

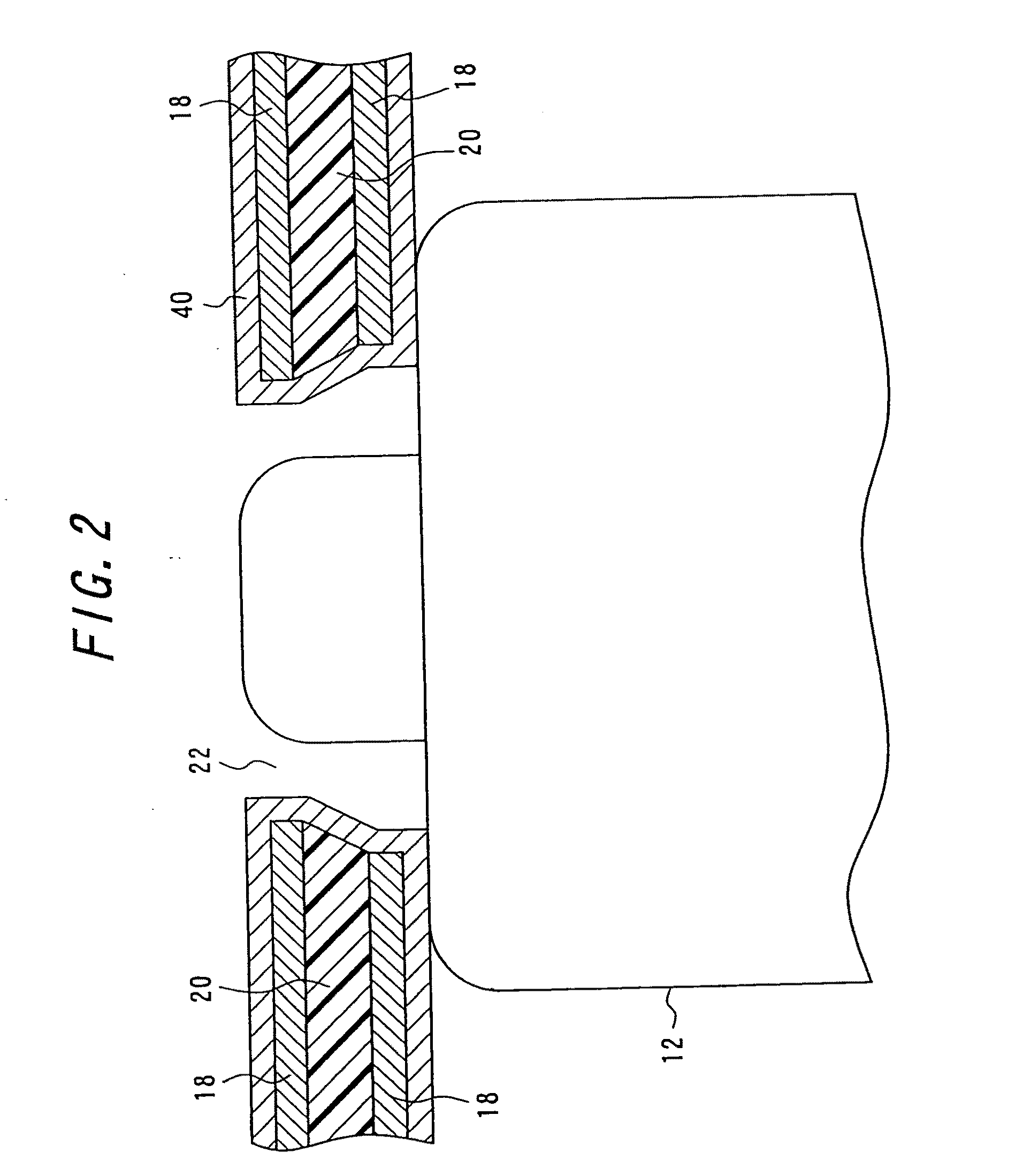

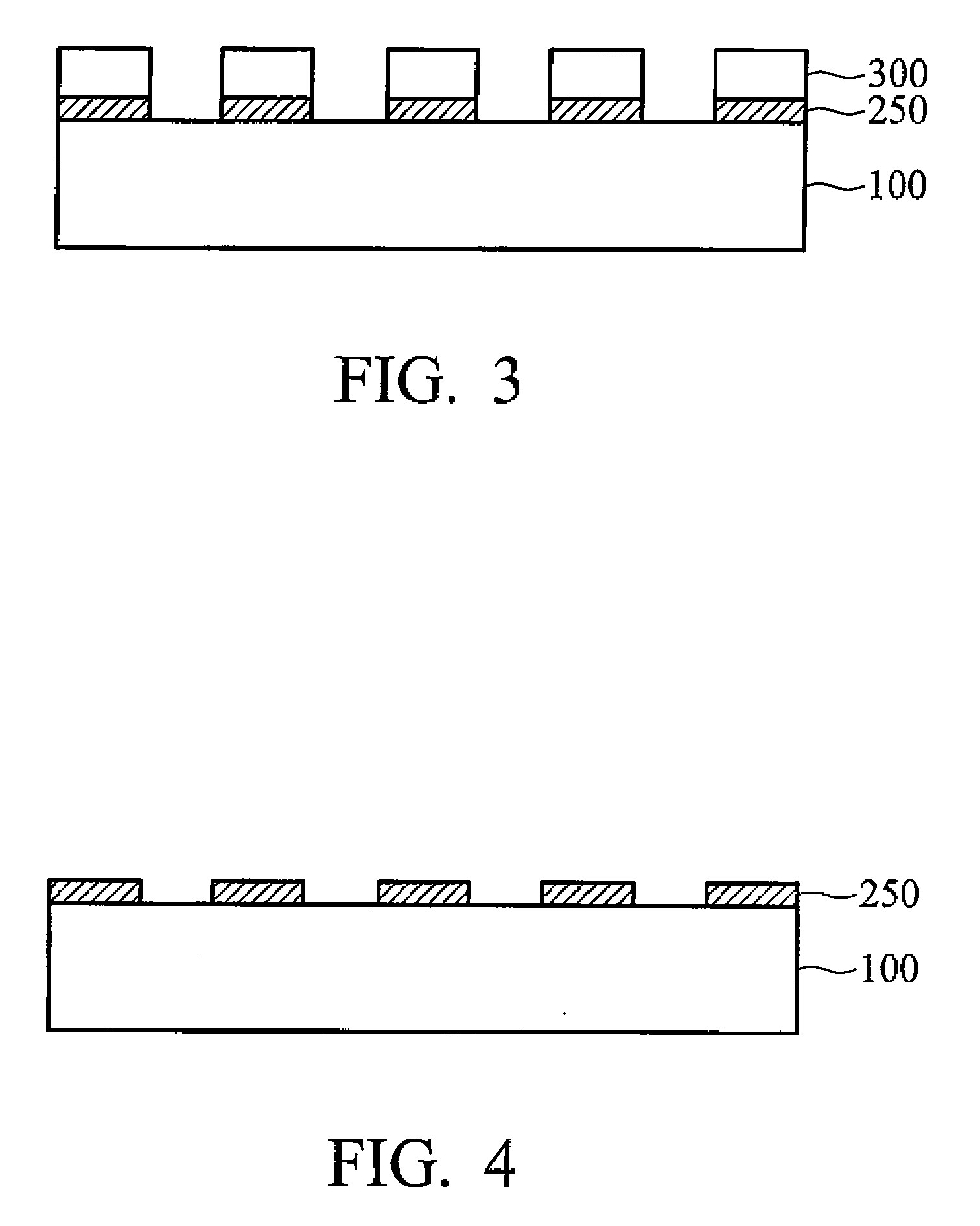

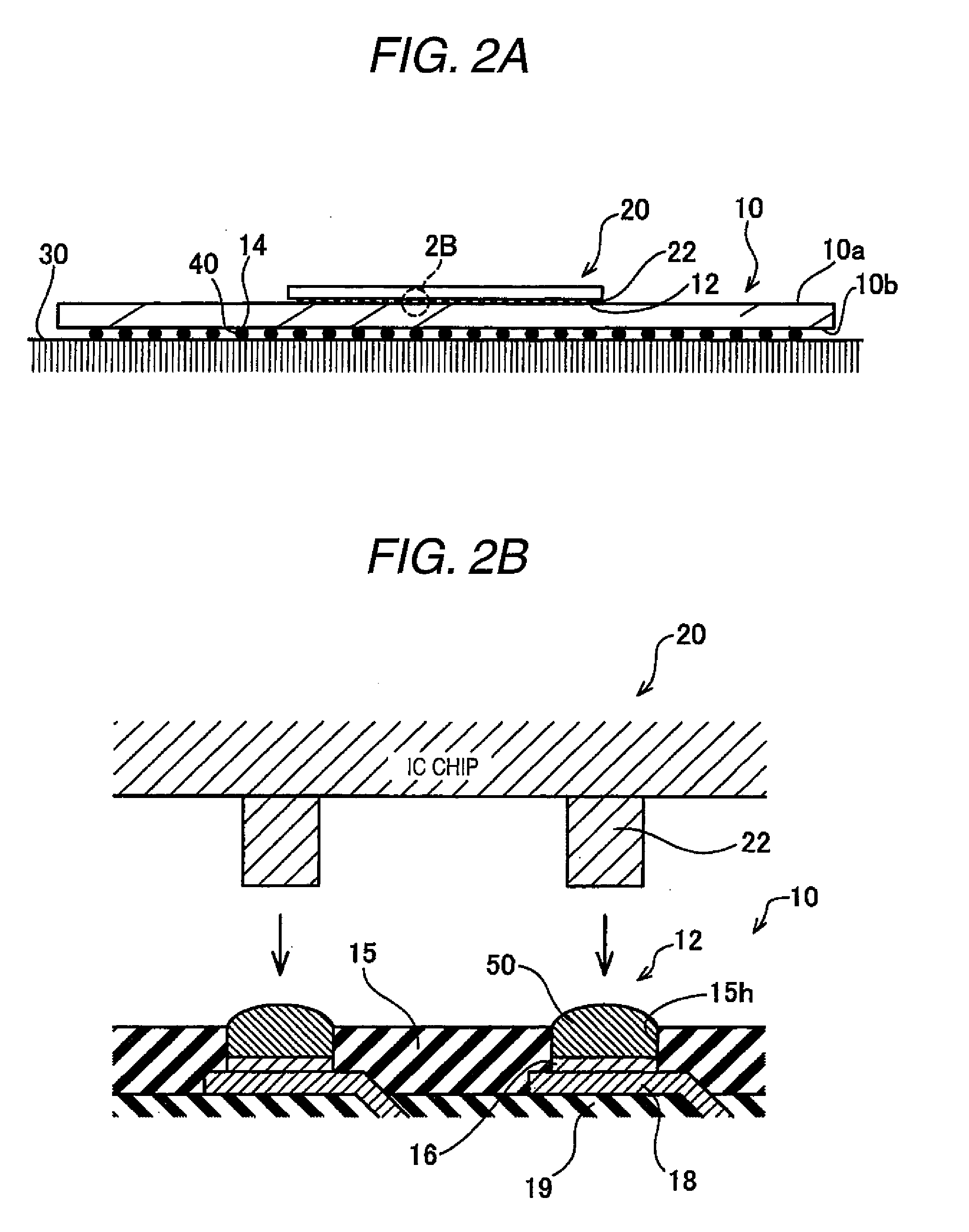

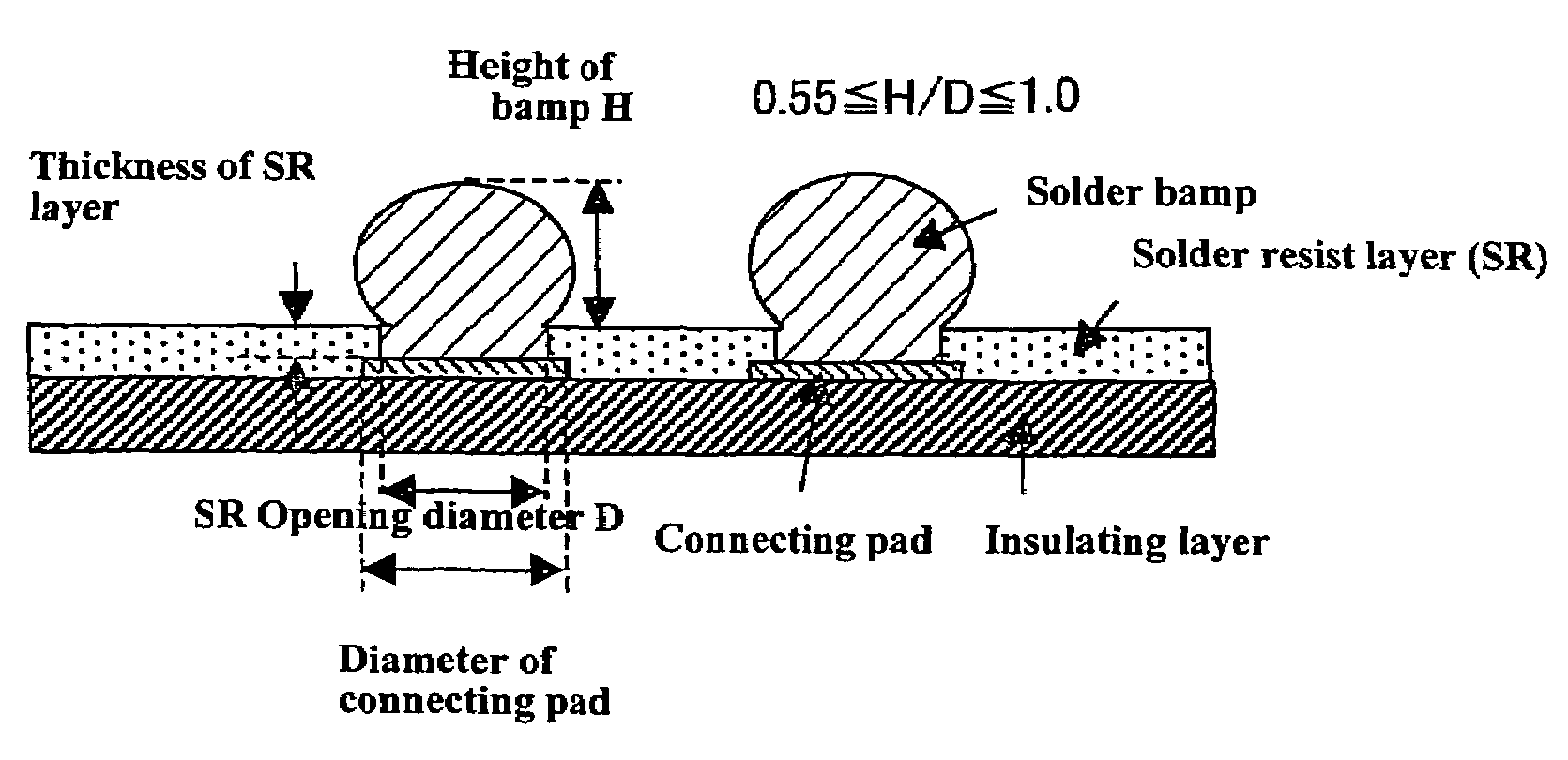

A printed wiring board comprises a wiring substrate provided with at least one conductor circuit, a solder resist layer formed on the surface of the wiring substrate, covering the at least one conductor circuit, conductor pads formed on a part of the at least one conductor circuit exposed from respective openings provided in the solder resist layer for mounting electronic parts, and solder bumps formed on the respective conductor pads. Connection reliability and insulation reliability are easily improved by making the ratio (H / D) of a height H from solder resist layer surface the solder bump to an opening diameter of the opening about 0.55 to about 1.0 even in narrow pitch structure under the pitch of the opening provided in the solder resist layer of about 200 μm or less.

Owner:IBIDEN CO LTD

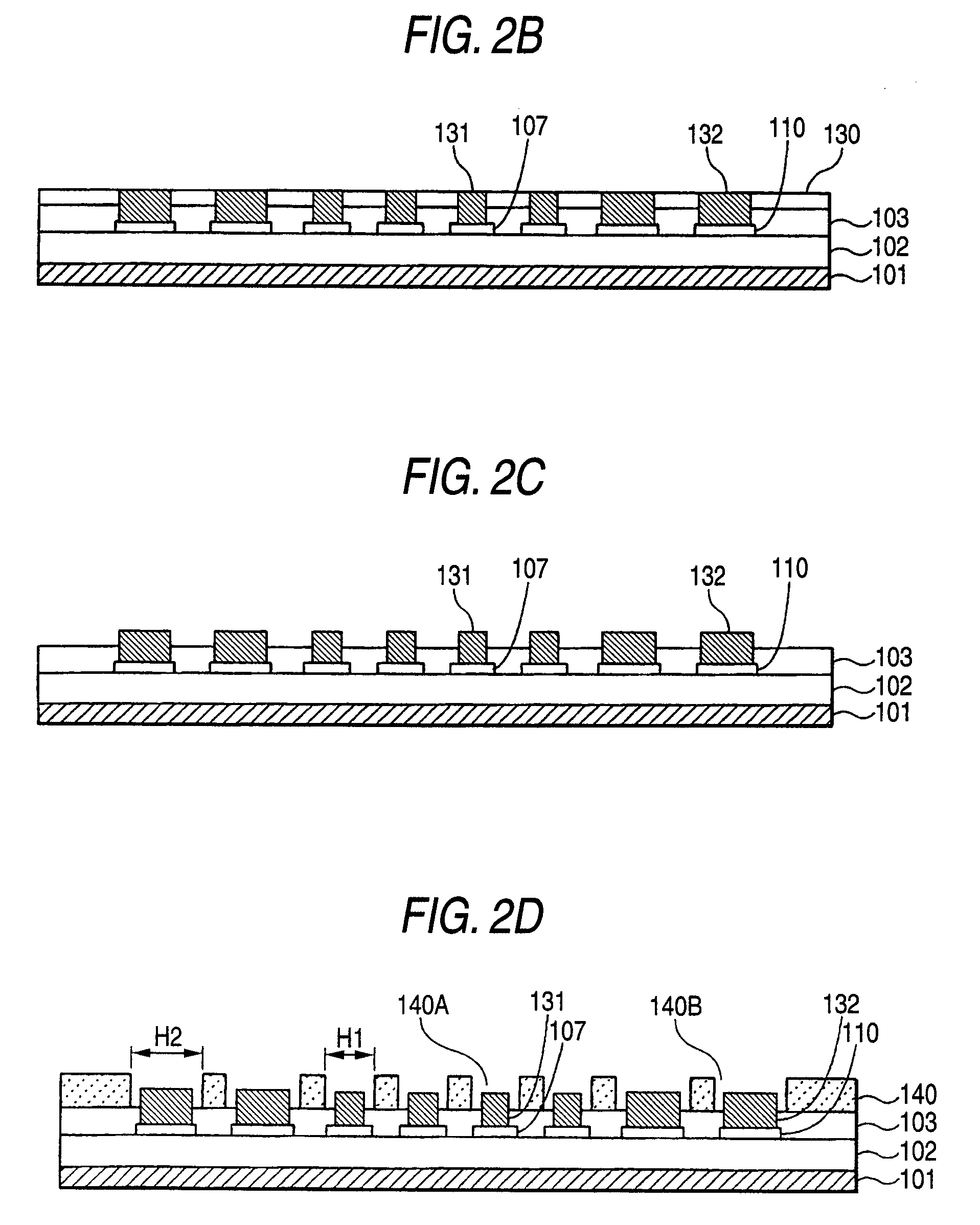

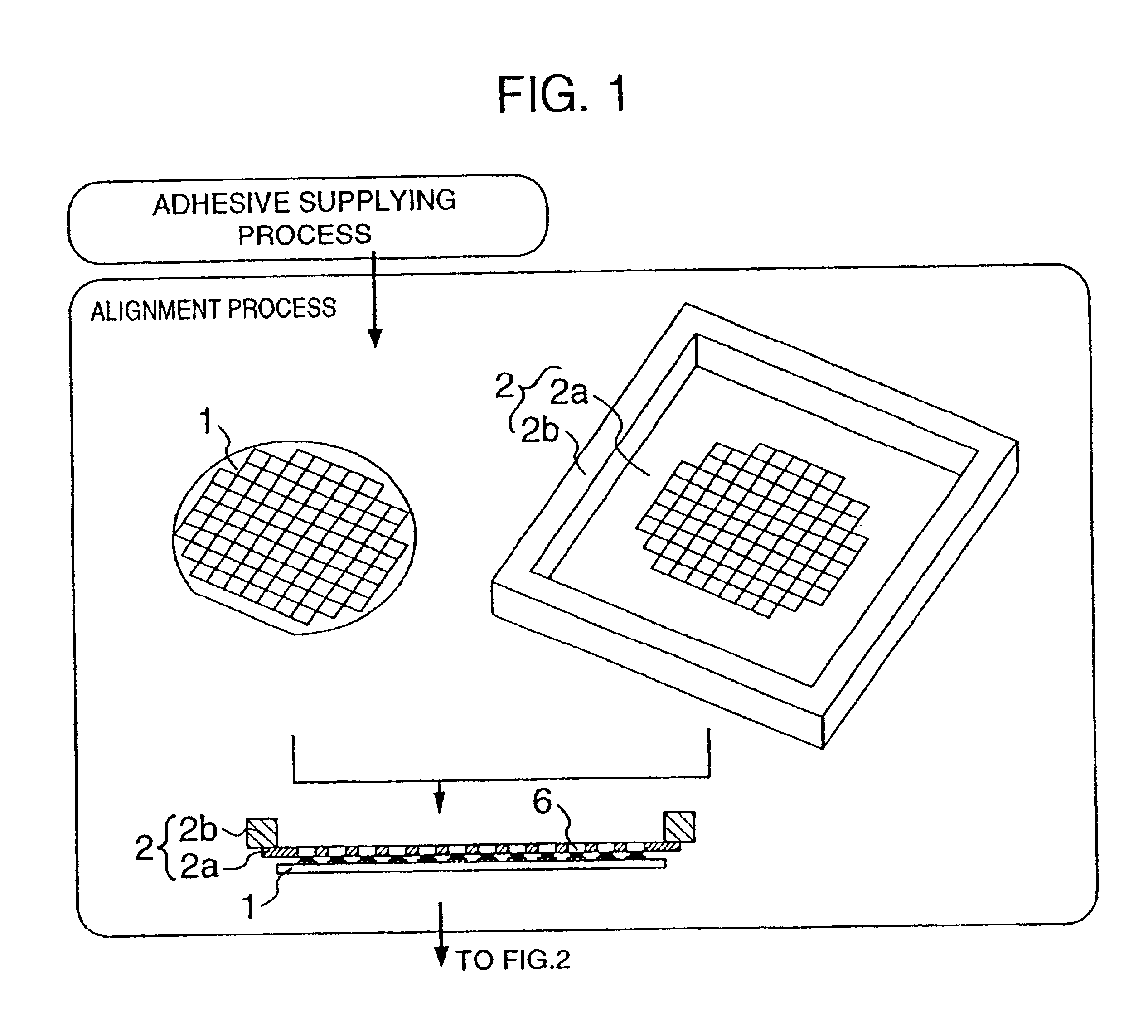

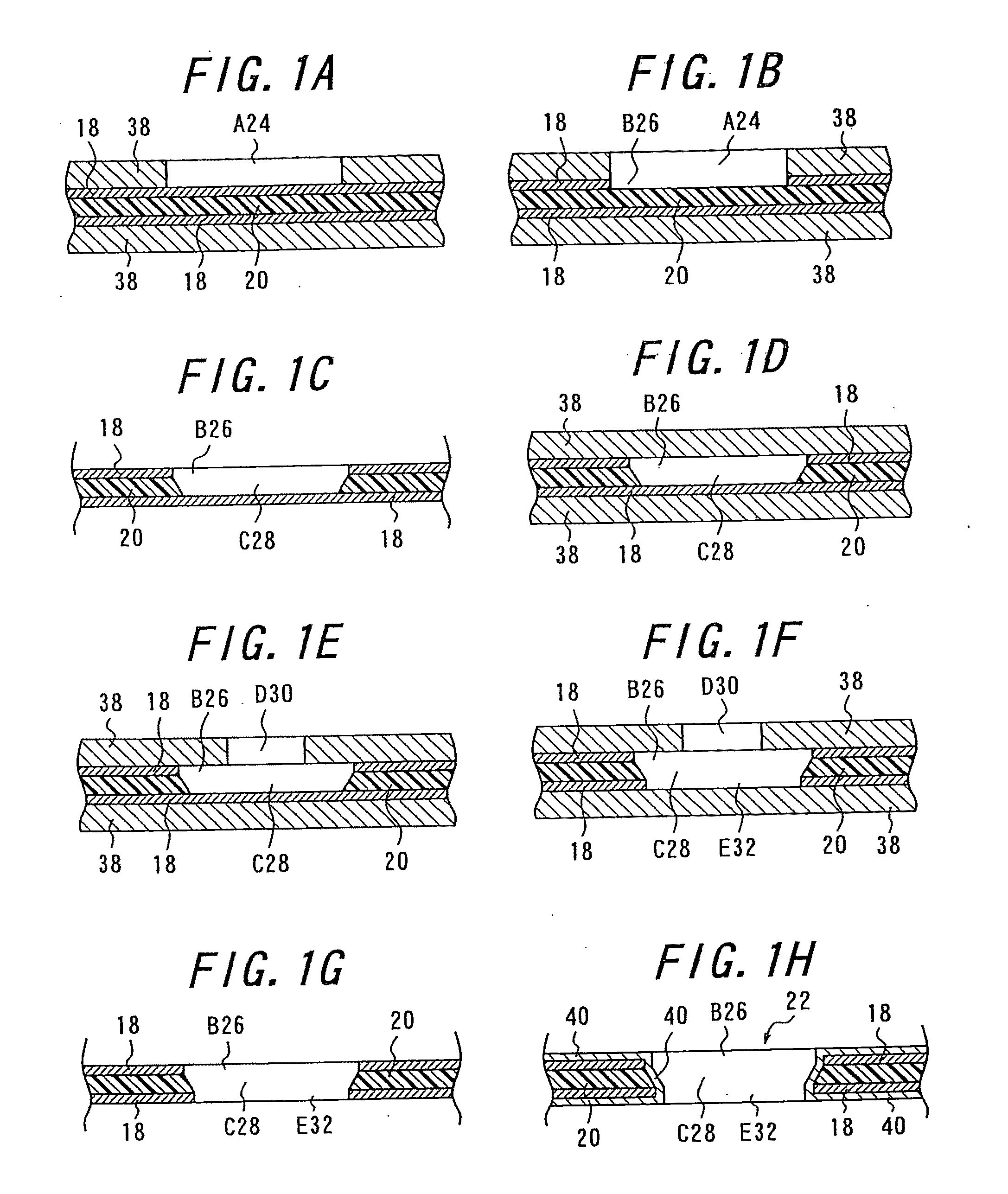

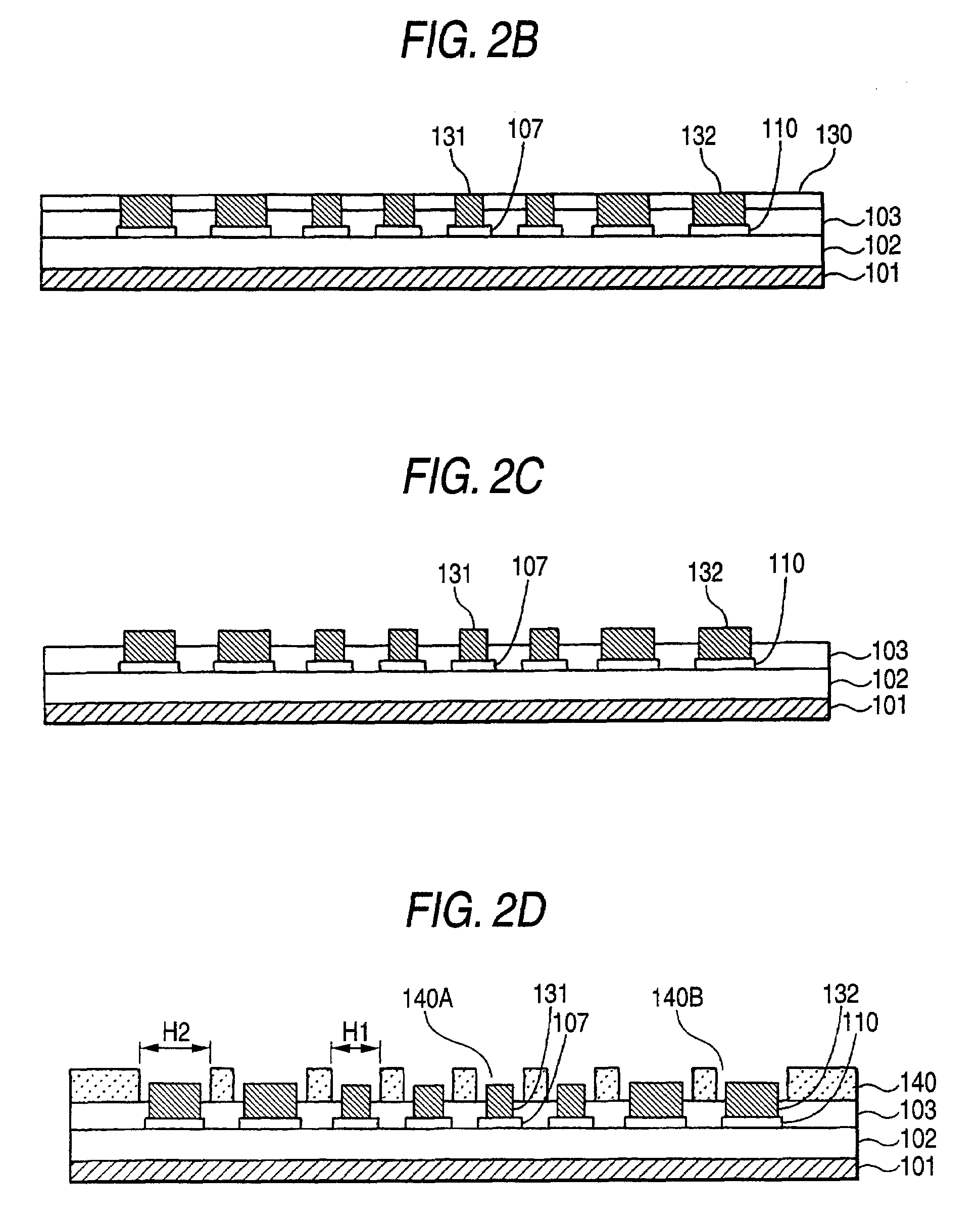

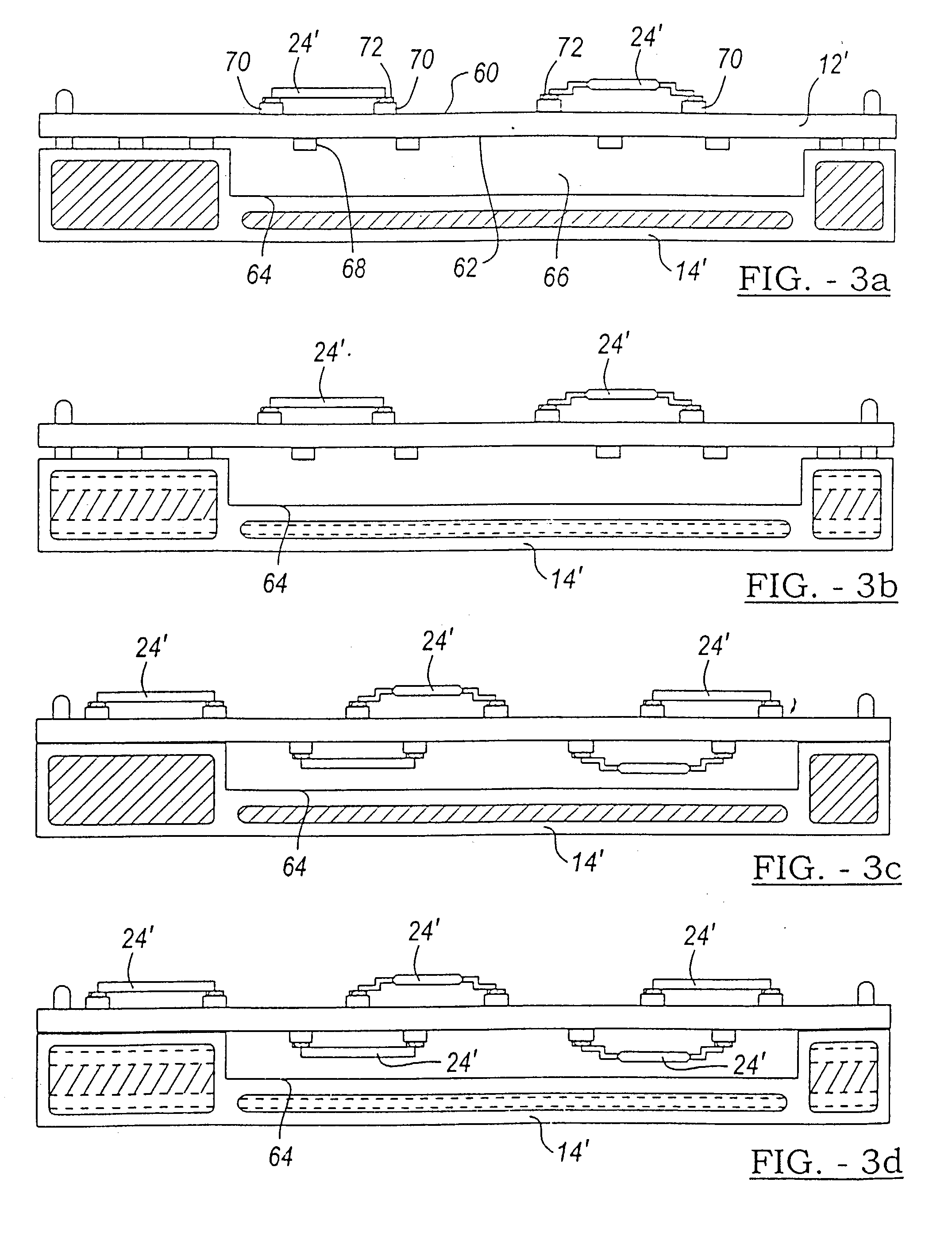

Method of forming solder connection portions, method of forming wiring substrate and method of producing semiconductor device

ActiveUS20070234563A1Improve reliabilitySemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor

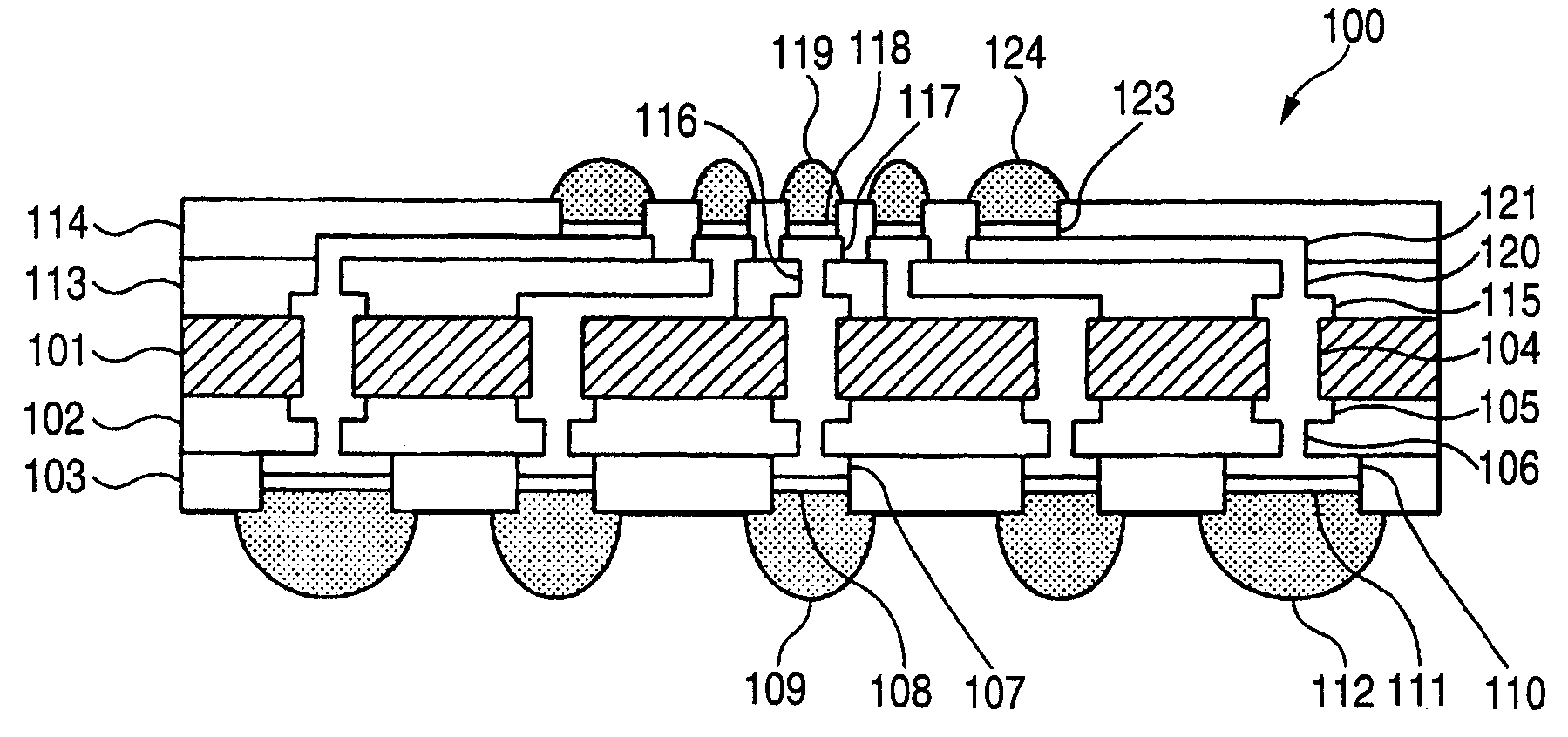

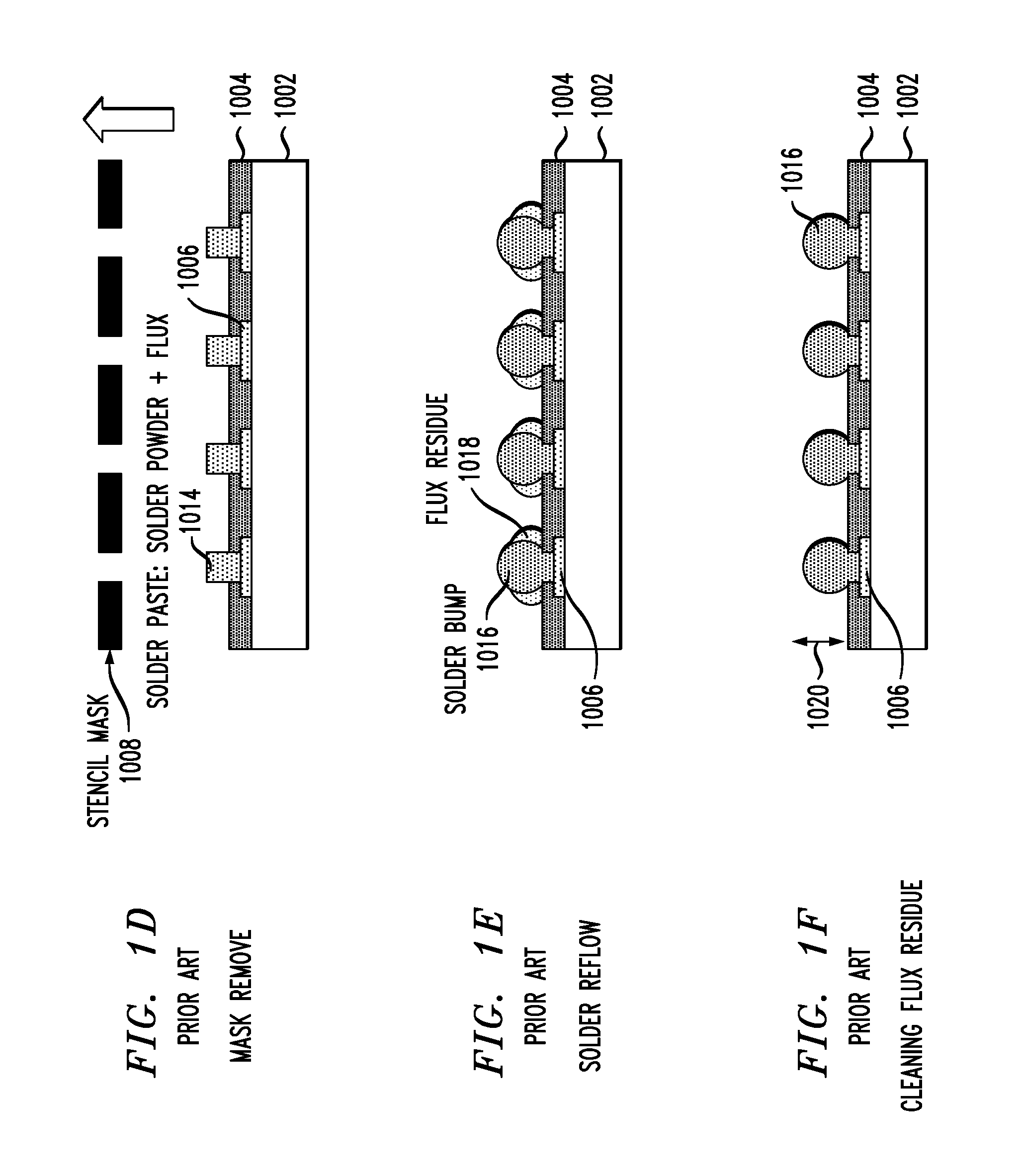

A method of forming solder connection portions on first electrode pads and on second electrode pads, comprises a first step of arranging solder balls on the first electrode pads by arranging a first mask on a base mask; a second step of arranging solder balls on the second electrode pads by arranging a second mask on the base mask; and a third step of melting the solder balls. The base mask has first opening portions corresponding to the first electrode pads and second opening portions corresponding to the second electrode pads and having a size different from that of the first opening portions. The first mask has opening portions corresponding to the first opening portions and covering the second opening portions. The second mask has opening portions corresponding to the second opening portions and covers the first opening portions.

Owner:SHINKO ELECTRIC IND CO LTD

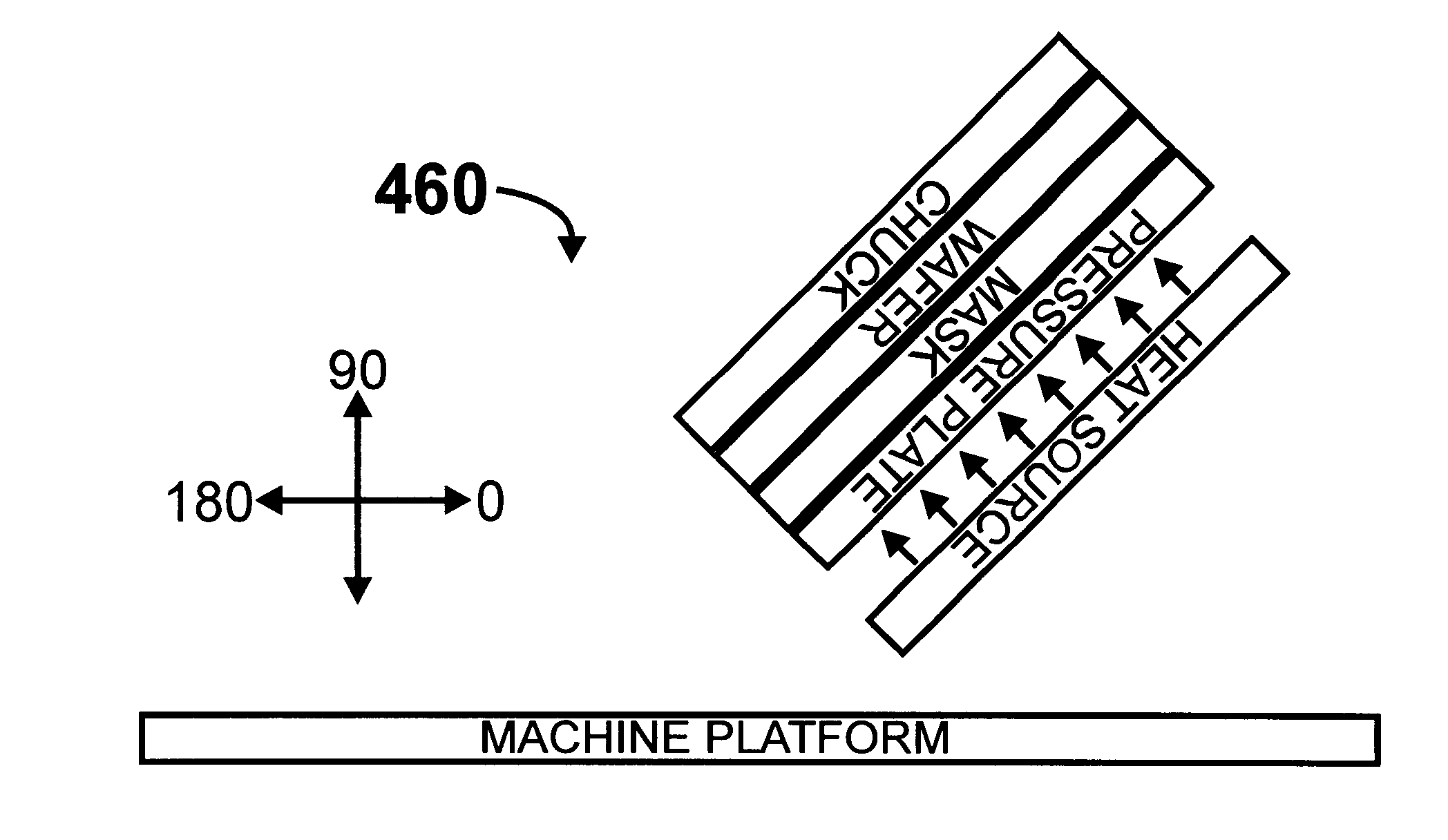

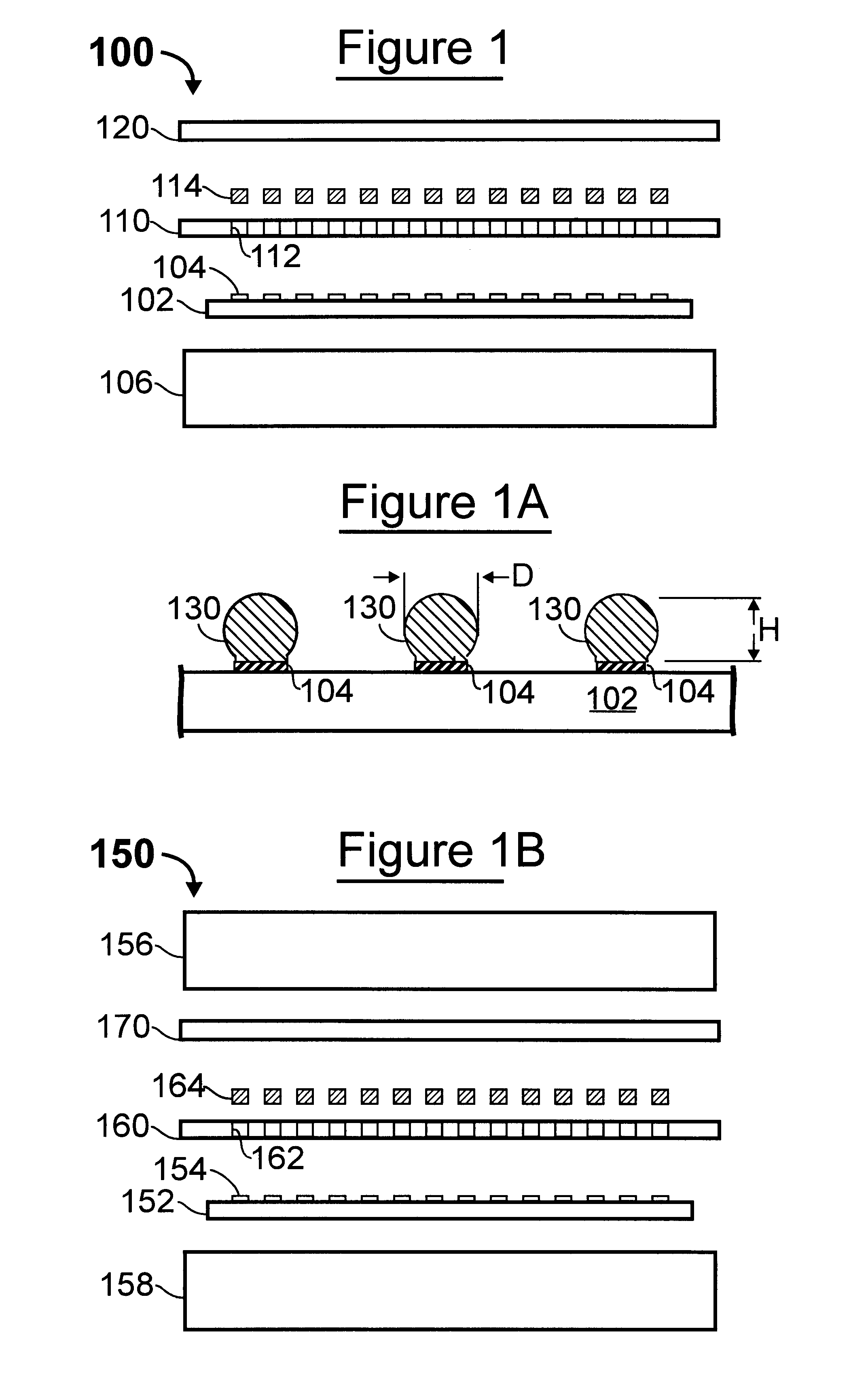

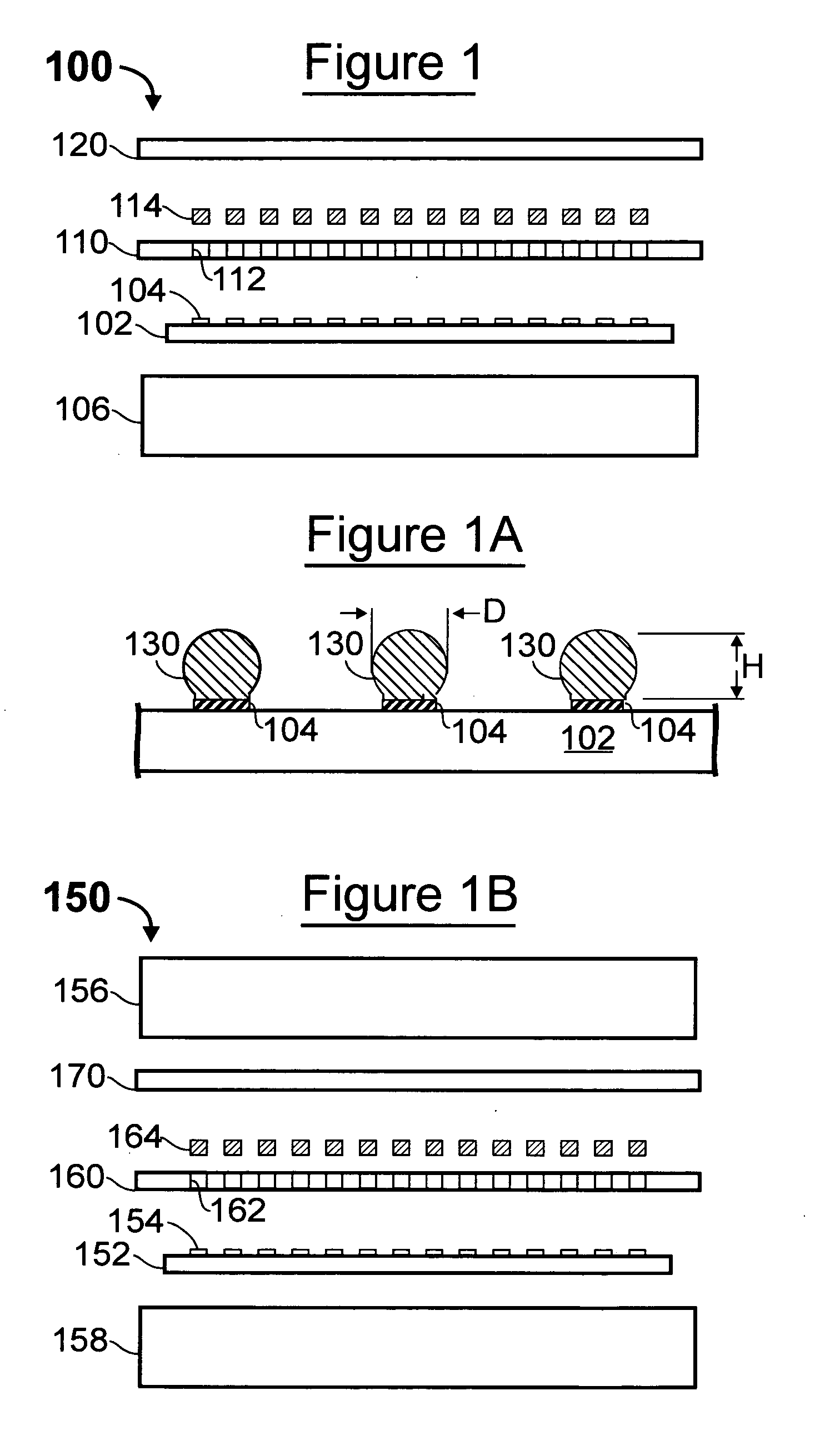

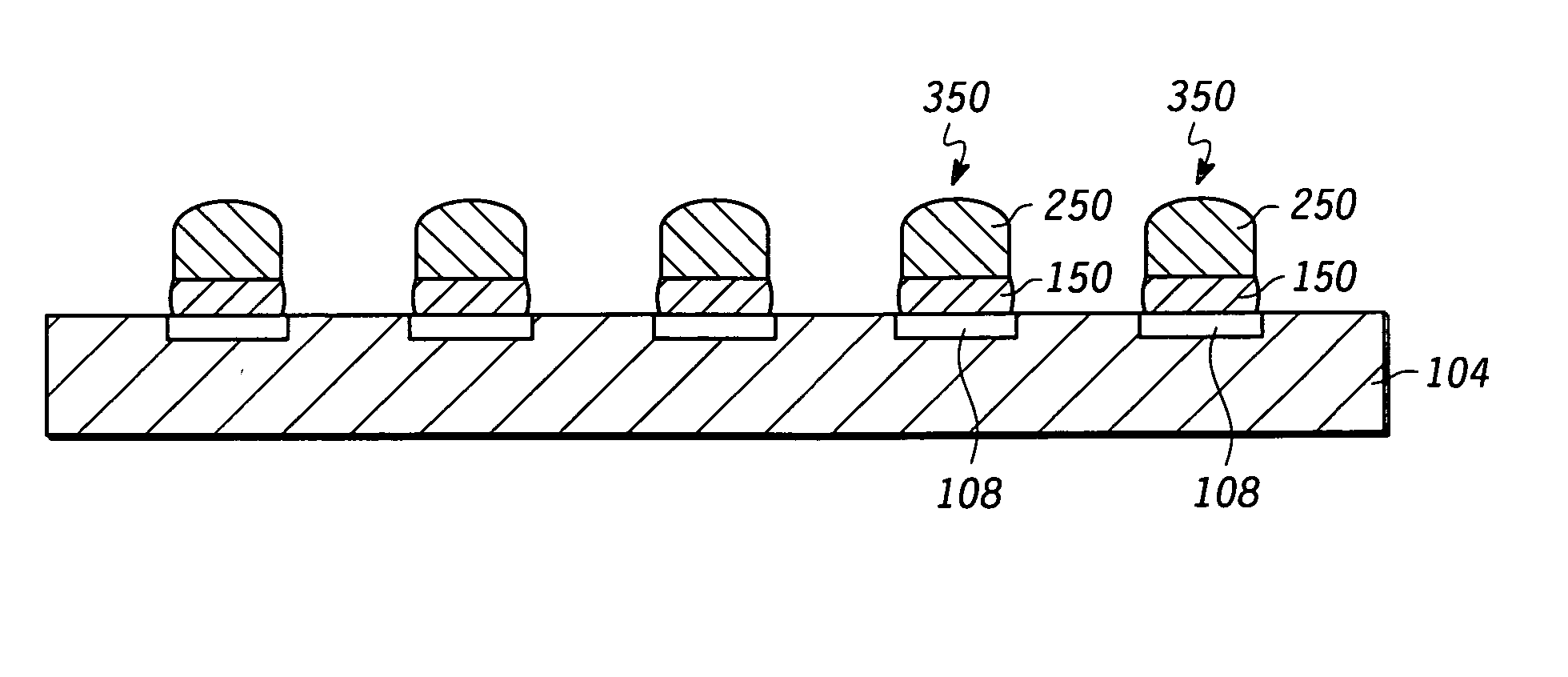

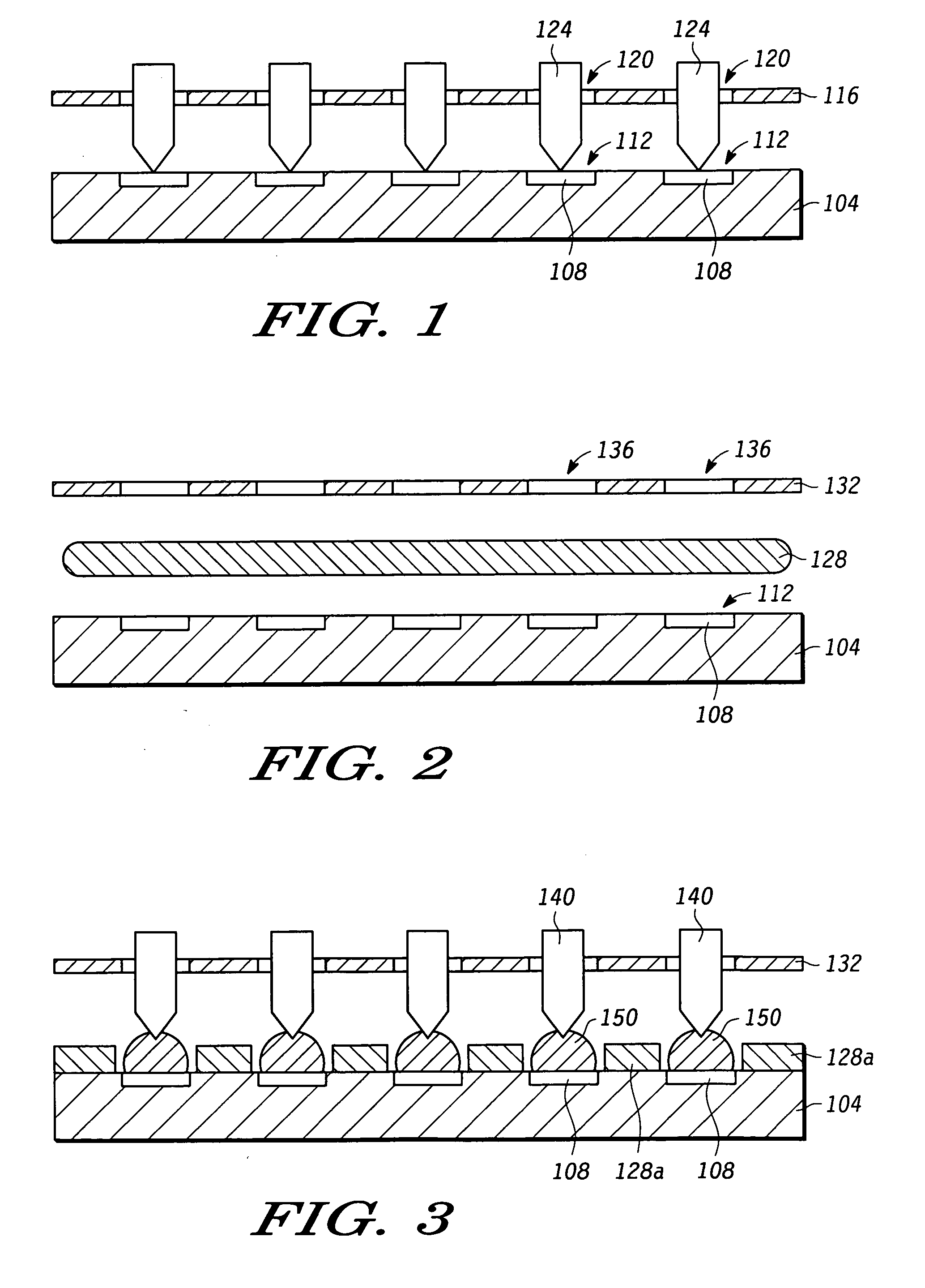

Methods for forming solder balls on substrates

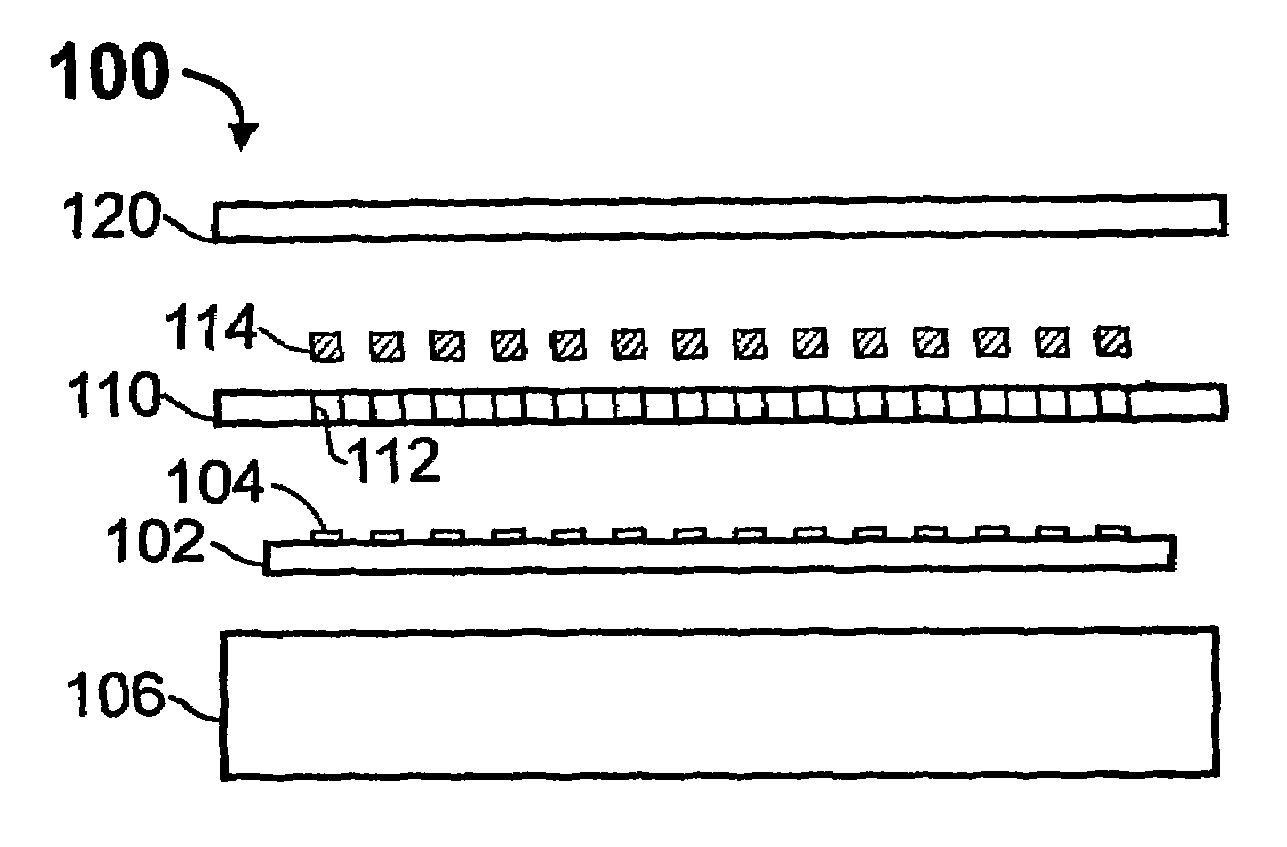

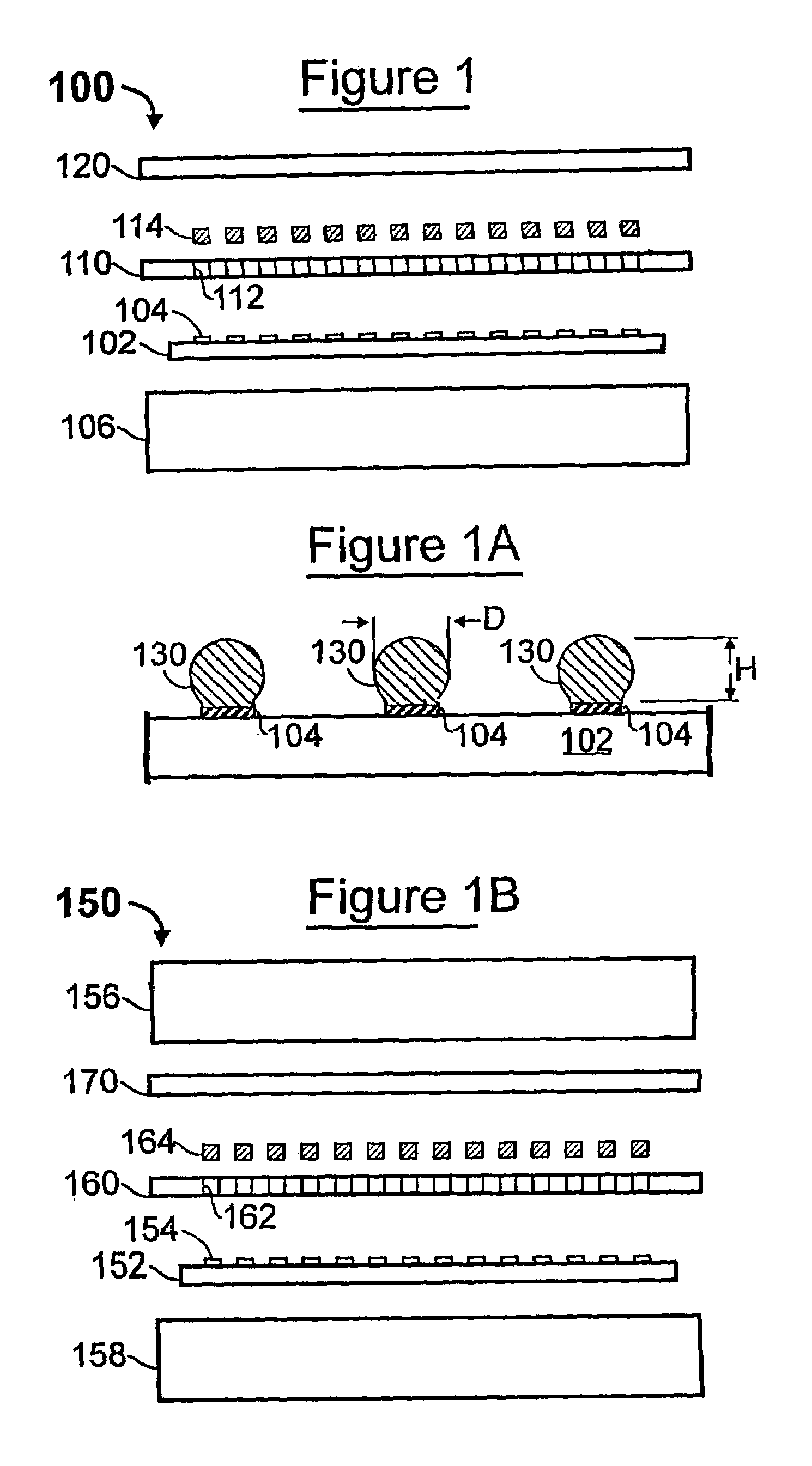

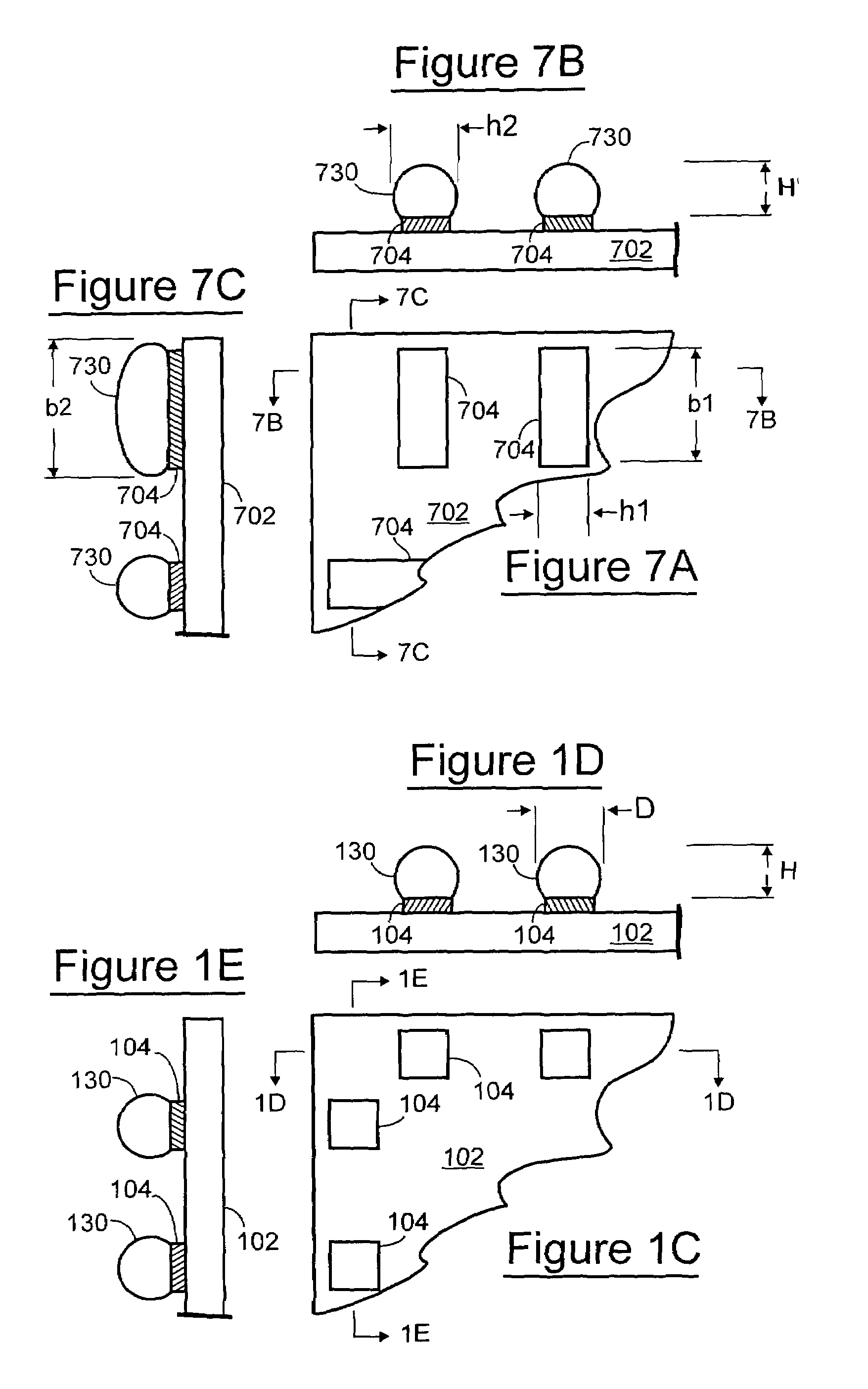

InactiveUS6293456B1Reduce effective thermal massPromote wettingPrinted circuit assemblingPrinted circuit aspectsSolder ballMechanical engineering

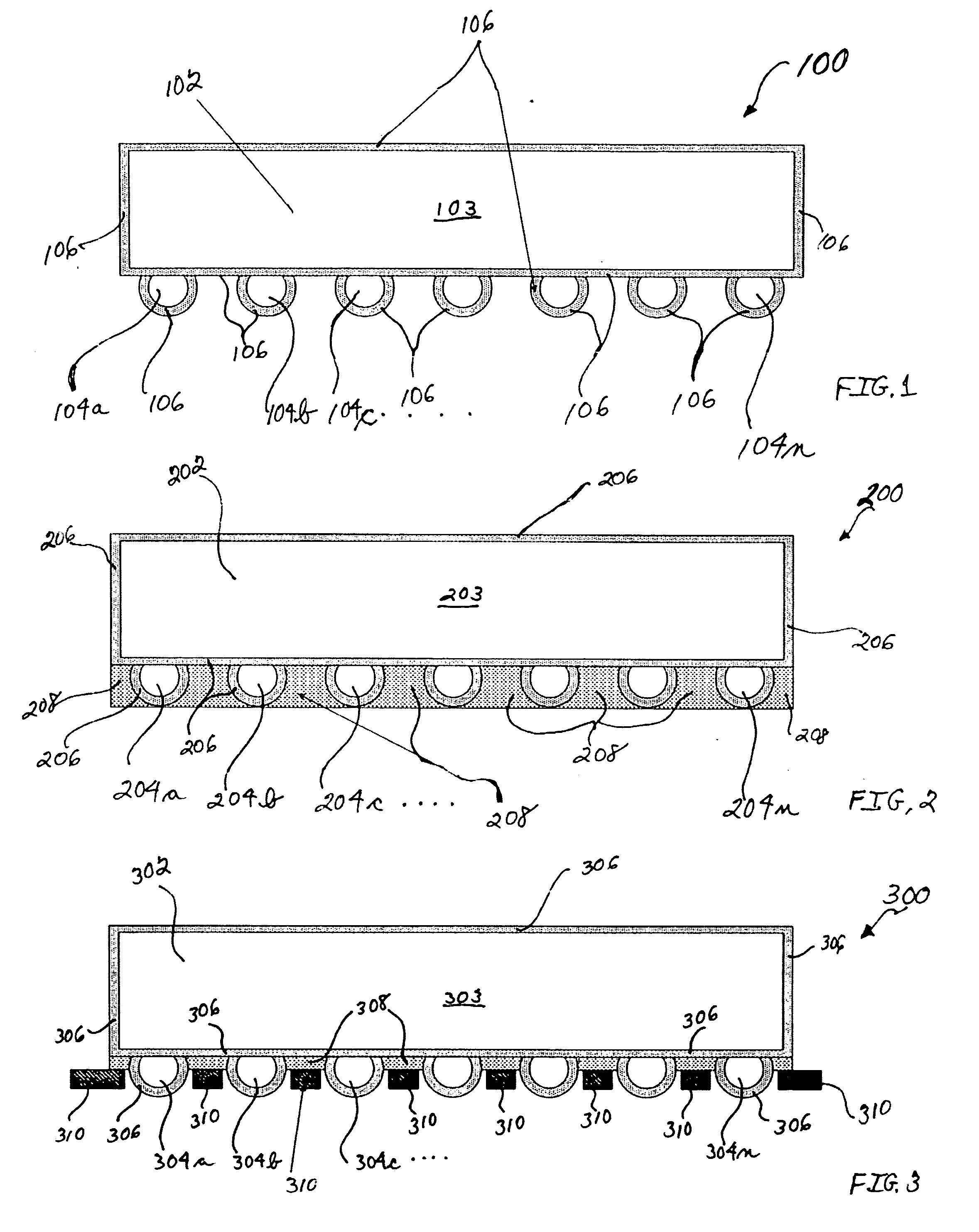

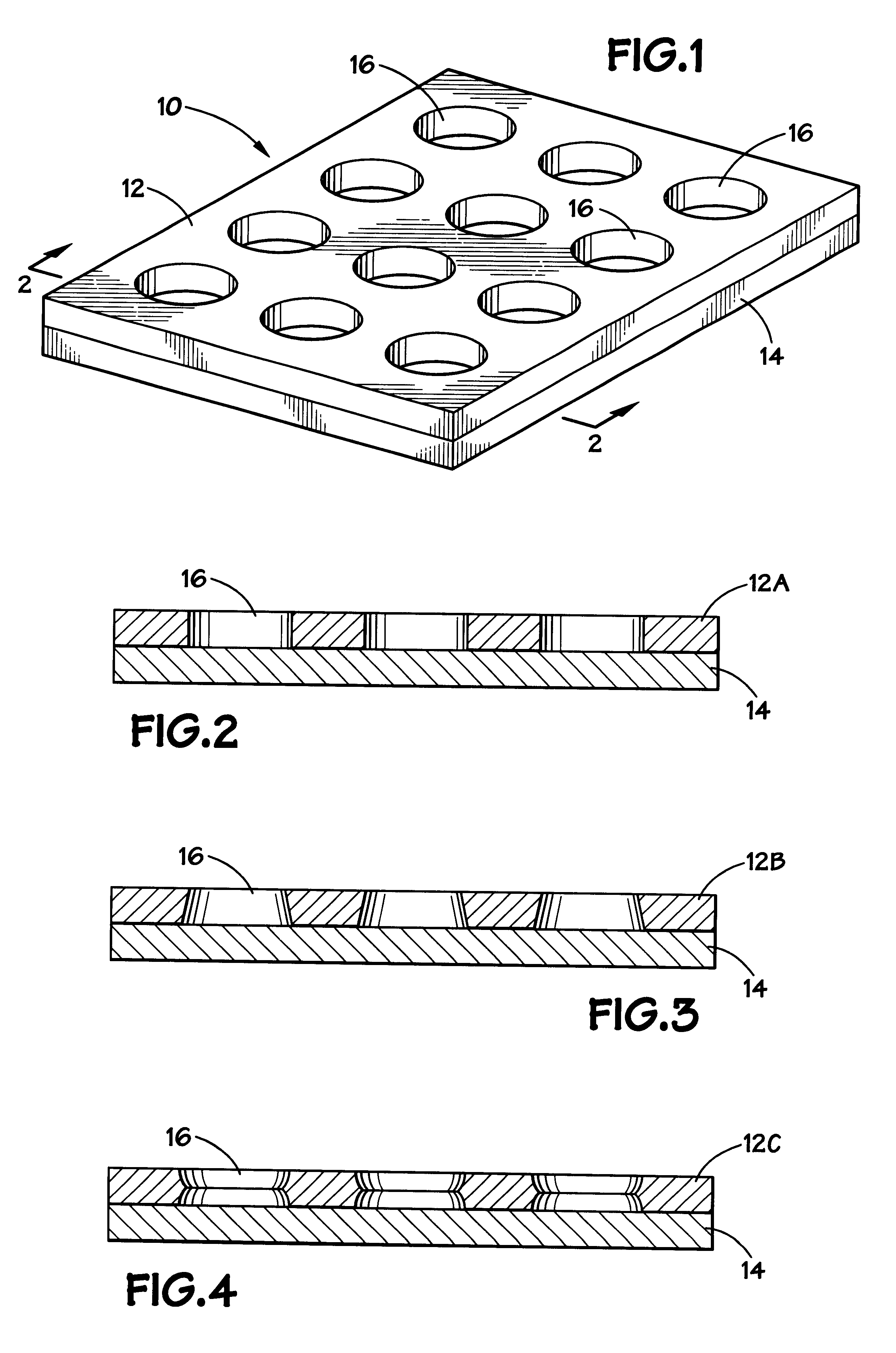

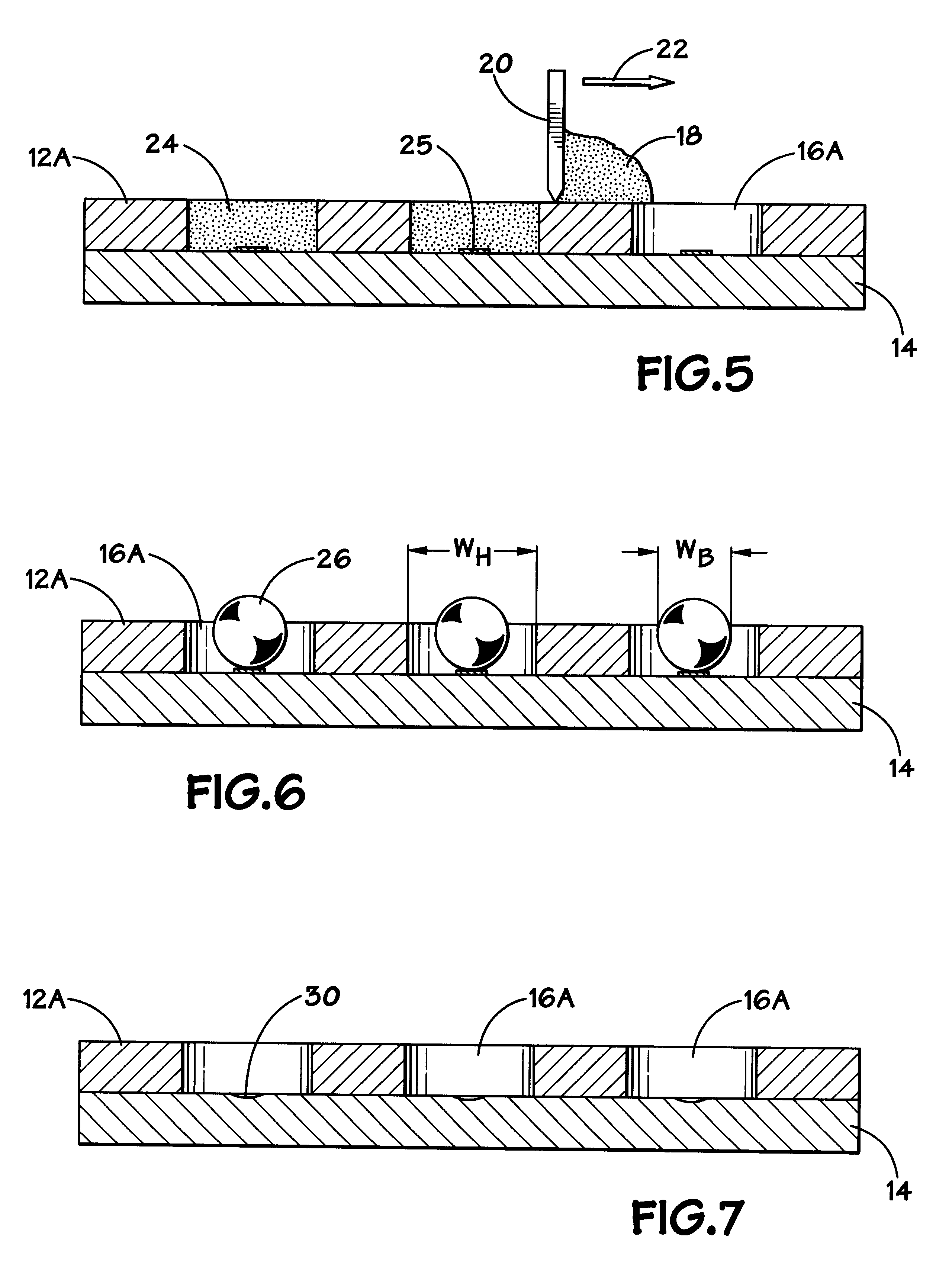

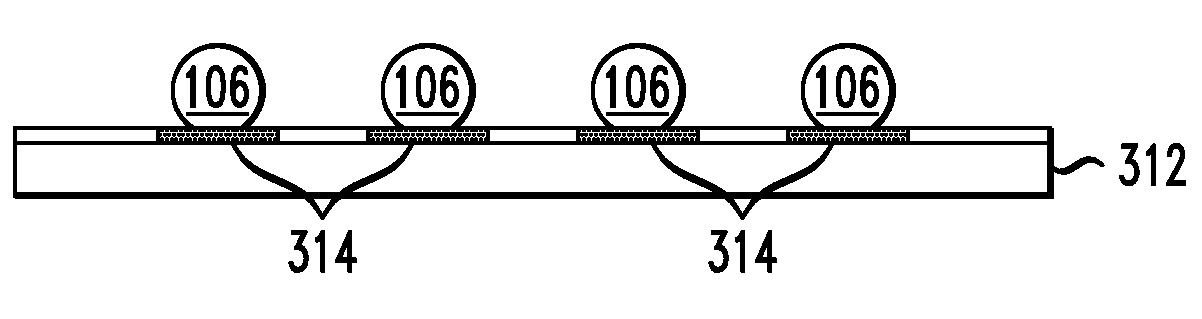

A mask (110; see also 160, 210, 260, 310, 408, 500, 702, 802, 904) having a plurality of openings (cells) is disposed on, or nearly on, the surface of a substrate (102), the openings (112) of the mask being aligned over a corresponding plurality of pads (104) on the substrate. The openings in the mask are filled with solder material (114). A pressure plate (120) is disposed over the mask to capture the solder material in the cells. Heat is directed at the mask (through the pressure plate) to reflow the solder. This is done in an inverted or partially inverted orientation. The stackup (assembly) of substrate / mask / pressure plate may be un-inverted prior to cooling. Mask configurations, methods of mounting the masks, and solder material compositions are described. The methods are robust, and are well suited to fine pitch as well as coarse pitch ball bumping of substrates.

Owner:SEMIPAC INC

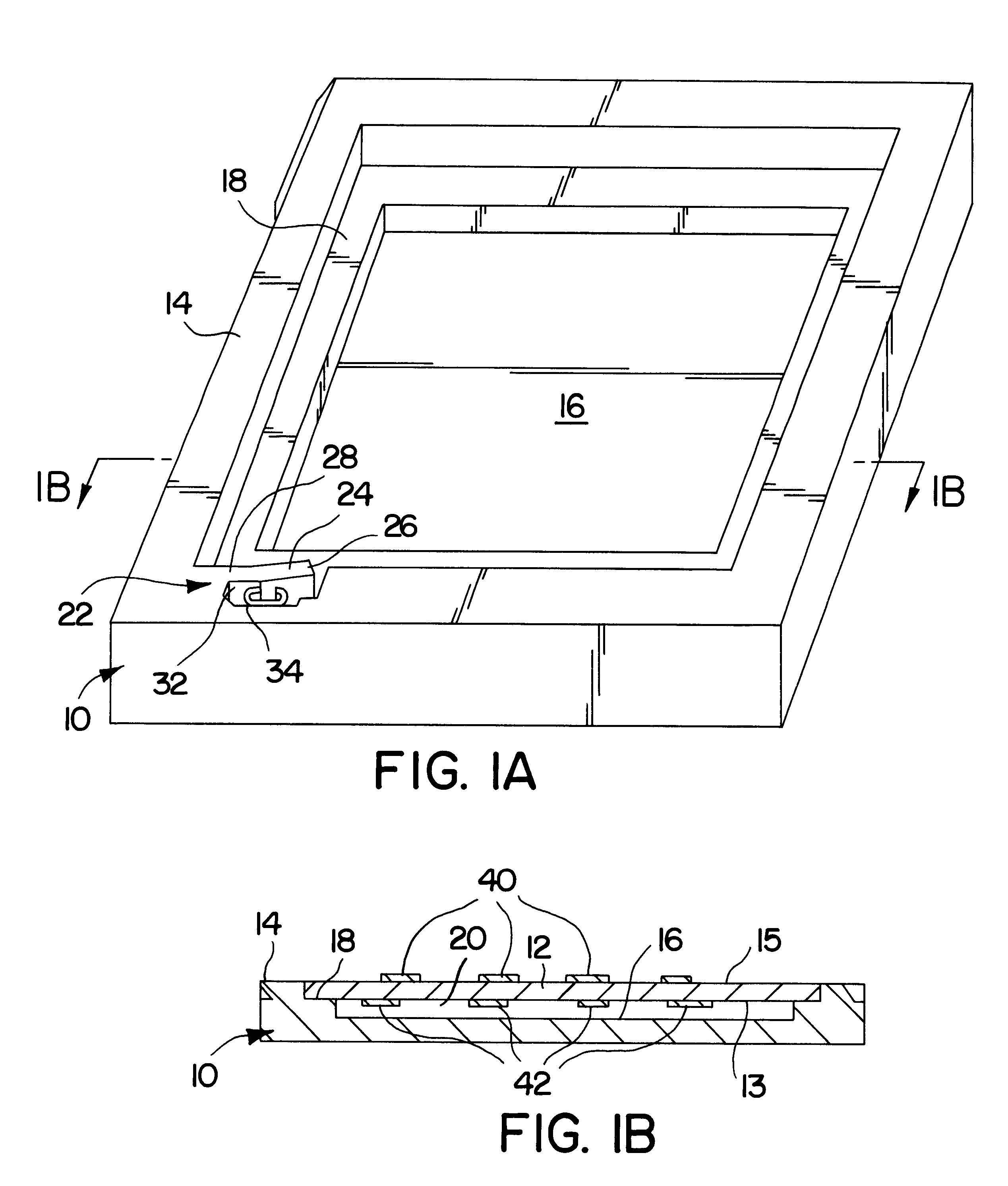

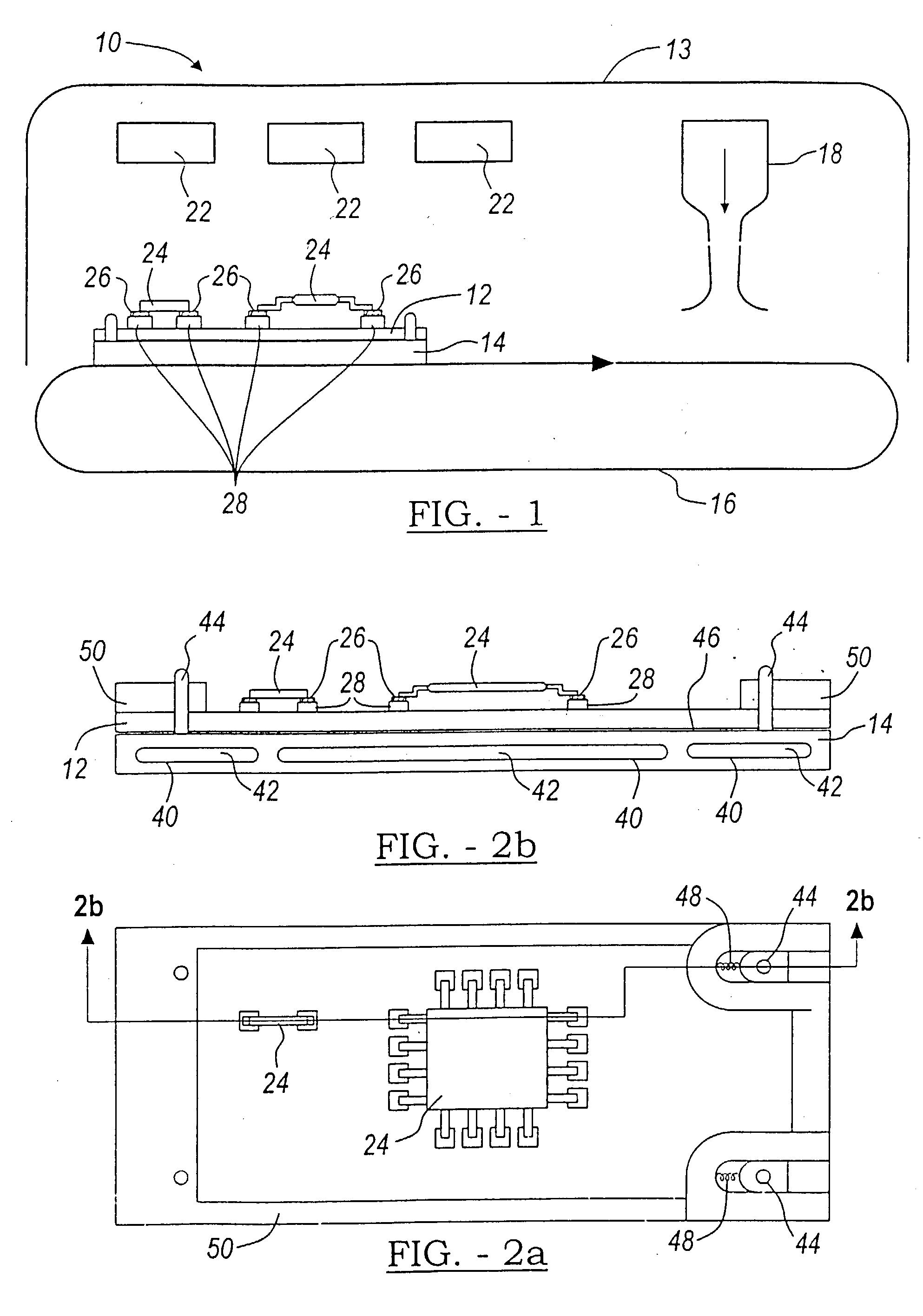

Pallet for combined surface mount and wave solder manufacture of printed ciruits

InactiveUS6267288B1Even heat distributionMinimize warpagePrinted circuit assemblingFinal product manufactureSurface mountingEngineering

A pallet for mounting components on a double sided PCB including a fab (panel) having a frame area surrounding a depression. A shoulder around the depression is dimensioned to support the fab. The fab is laid on the shoulder with the a group of components mounted in a previous reflow operation in the space between the depression and a first area of the fab. The print, pick and place and reflow operations are performed to mount a second group of components on the opposite side of the fab. The first area of the fab is shielded from the heat of the oven so that the first components do not separate from the fab during the second reflow step. Standoffs in the depression prevent sagging of the board. Another area of the pallet has a recessed area with cutouts for wave soldering components located on the third area of the fab.

Owner:CHUNG HENRY

Method and apparatus for applying external coating to grid array packages for increased reliability and performance

InactiveUS20060278971A1Improve electrical performanceImprove reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsParylene coatingEngineering

A method and apparatus are disclosed for selective removal of a conformal coating from the solder balls of grid array packages such that the benefits of the coating are realized. An ancillary benefit of the invention is improved process-ability of the grid array package by improving the mechanical containment of the solder during the reflow process and improved electrical isolation between the individual solder attachment points. For example, a method for coating a ball grid array is provided, which includes coating the ball grid array with a thin layer of parylene. Next, the solder ball side of the part is butter smeared or squeegeed with a water soluble coating and assembled wet. A mask having holes in the same pattern as the balls in the grid, and a thickness that is about 80% of the height of the balls, is applied to the solder ball side of the part. This side of the part is then butter smeared again with the water soluble coating, and the entire assembly is allowed to dry. At this point, about 20% of each parylene-coated solder ball protrudes higher than the surface of the mask. The solder ball side of the part is then grit blasted with an abrasive material. The extent that the abrasive material removes the parylene coating from the solder balls is limited by the mask and the layer of water soluble coating. Therefore, the grit blasting removes the parylene coating from only the protruding areas (e.g., about top 20%) of the solder balls. Water is then used to remove the water soluble coating, and the parylene coated part is baked to remove moisture. Thus, a parylene coated ball grid array (or column grid array) is provided that is highly impervious to moisture, has a very high dielectric strength, and thereby improves the electrical performance and reliability of the surface mounted part.

Owner:HONEYWELL INT INC

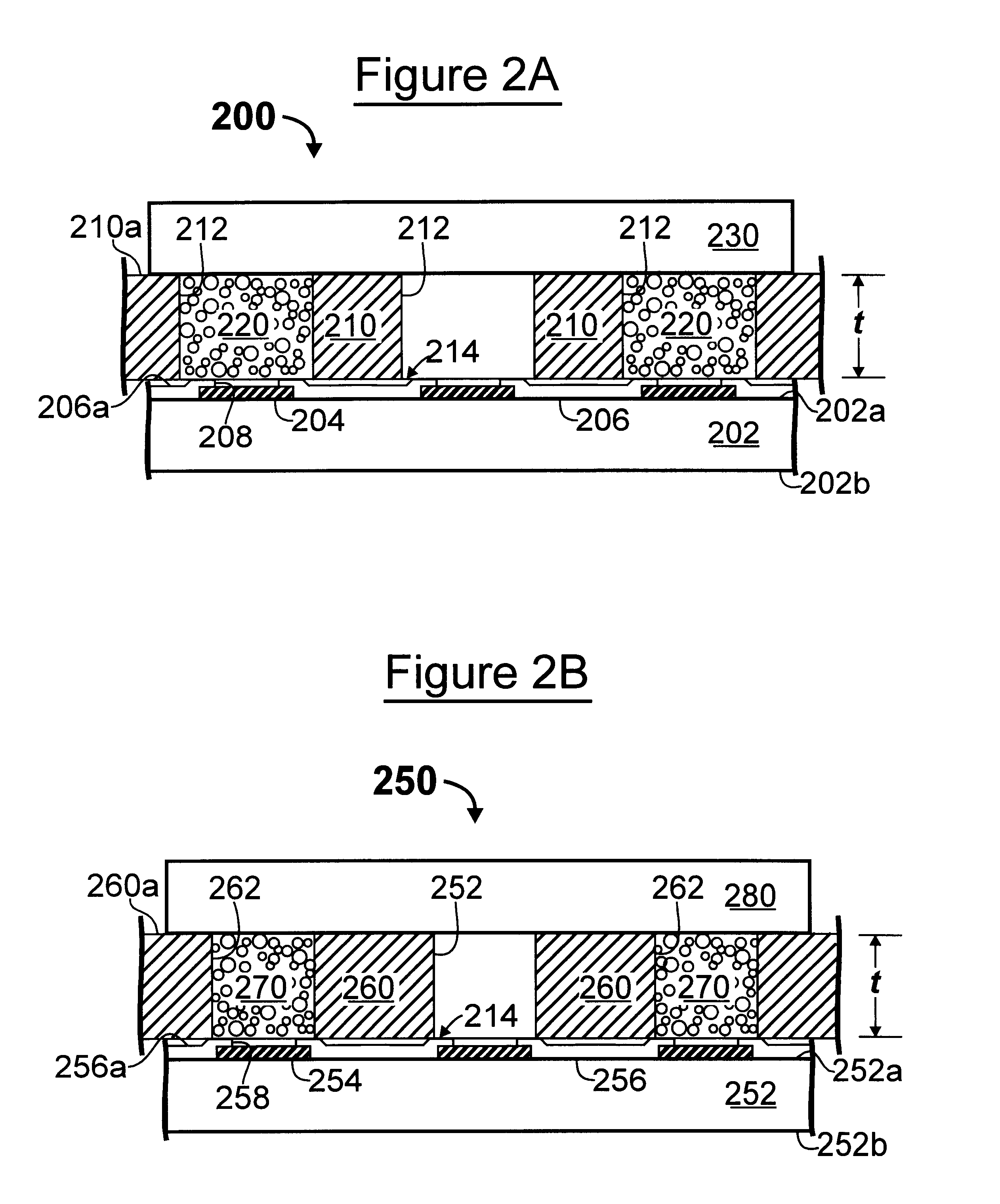

Direct IMS (Injection Molded Solder) Without a Mask for Forming Solder Bumps on Substrates

ActiveUS20110201194A1Avoid confusionSemiconductor/solid-state device detailsPrinted circuit aspectsResistForming gas

An assembly is obtained; it includes a substrate; a plurality of wet-able pads formed on a surface of the substrate; and a solder resist layer deposited on the surface of the substrate and having an outer surface. At least the solder resist layer is formed with recessed regions defining volumes adjacent the wet-able pads. Molten solder is directly injected into the volumes adjacent the wet-able pads, such that the volumes adjacent the wet-able pads are filled with solder. The solder is allowed to solidify. It forms a plurality of solder structures adhered to the wet-able pads. The substrate and the solder are re-heated after the solidification, to re-flow the solder into generally spherical balls extending above the outer surface of the solder resist layer. The volumes adjacent the wet-able pads are configured and dimensioned to receive sufficient solder in the injecting step such that the generally spherical balls extend above the outer surface of the solder resist layer as a result of the re-heating step. In an alternative approach, solder injection and solidification are carried out in a nitrogen environment or a forming gas environment, and the reflow step may be omitted.

Owner:GLOBALFOUNDRIES US INC

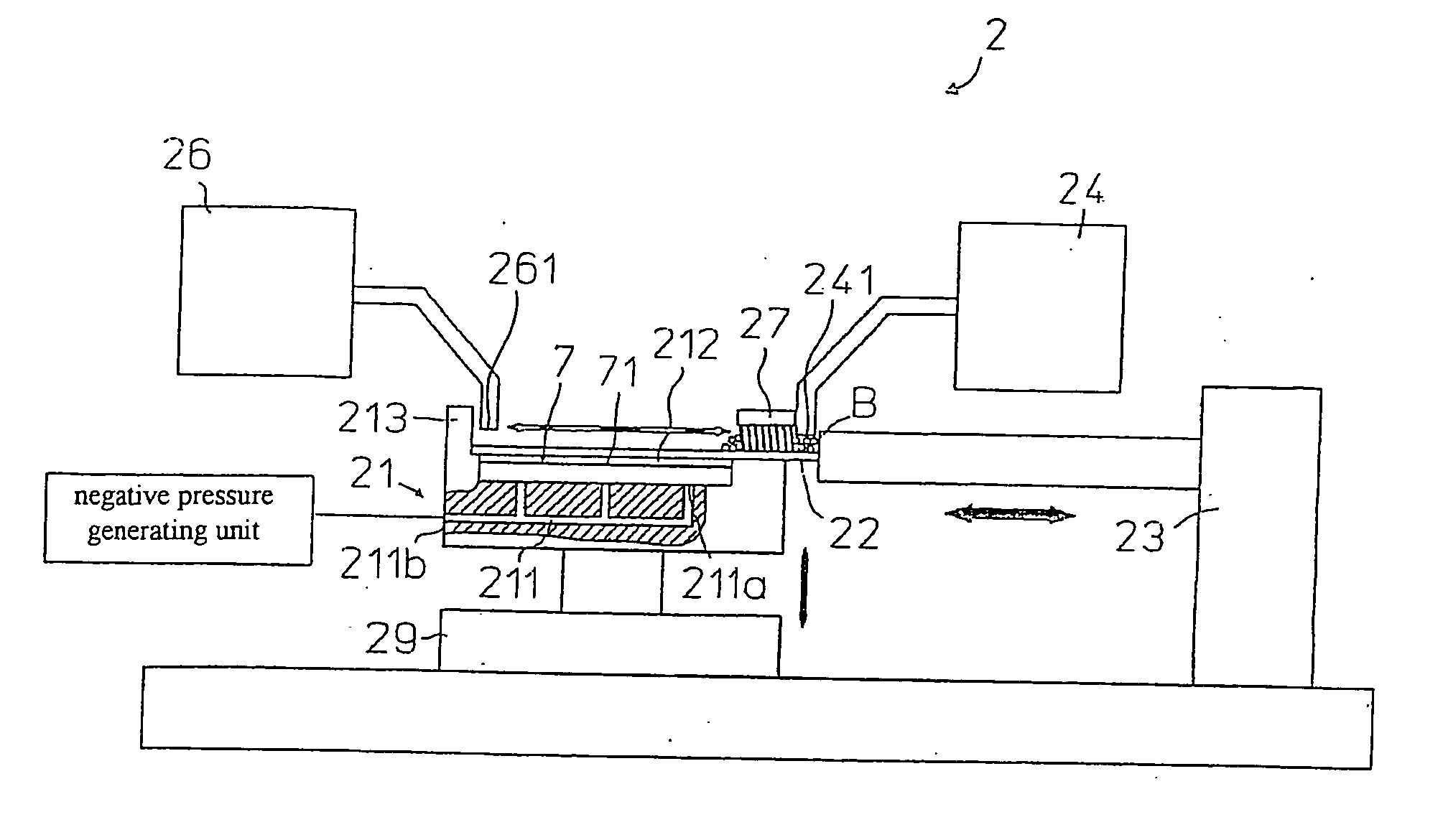

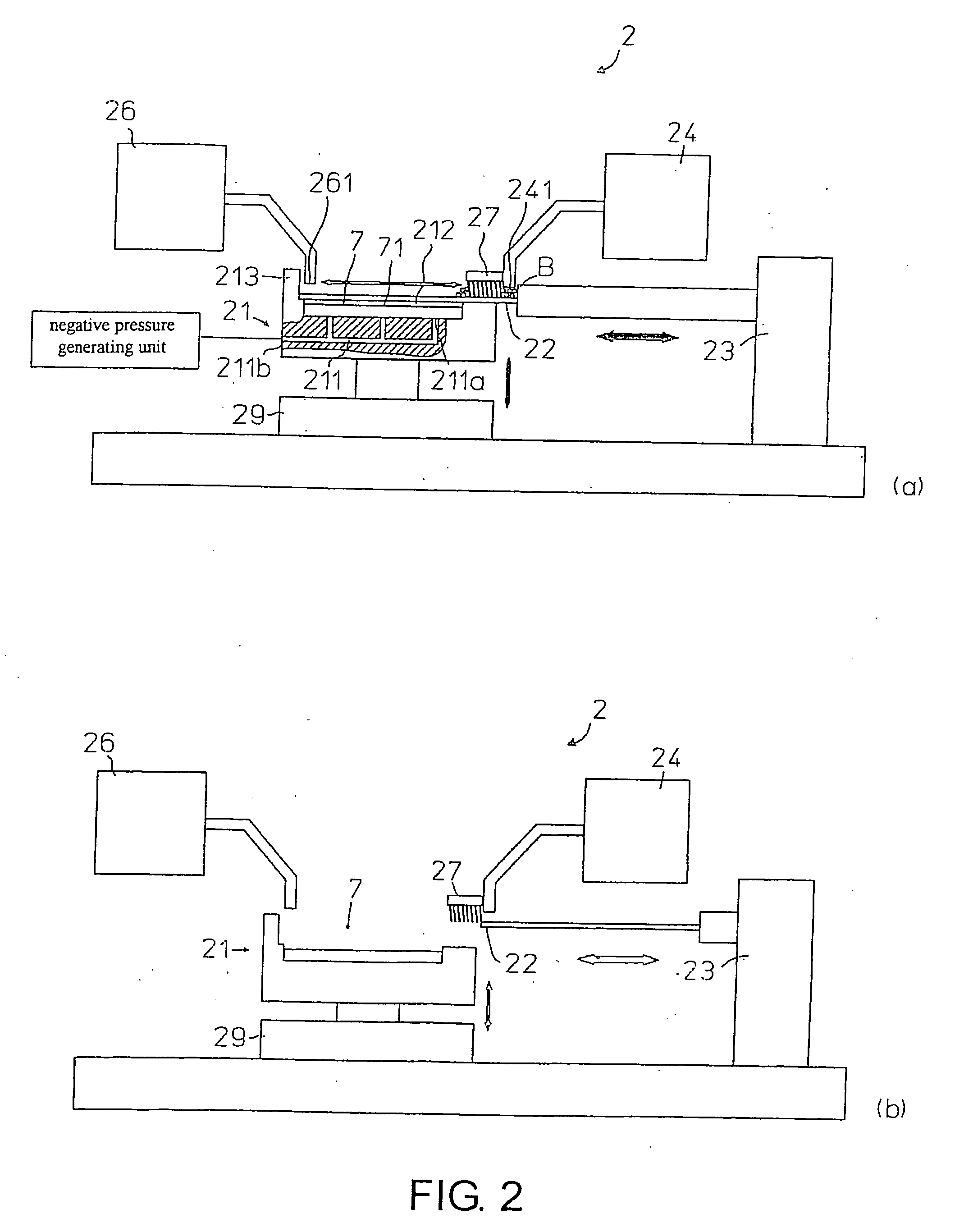

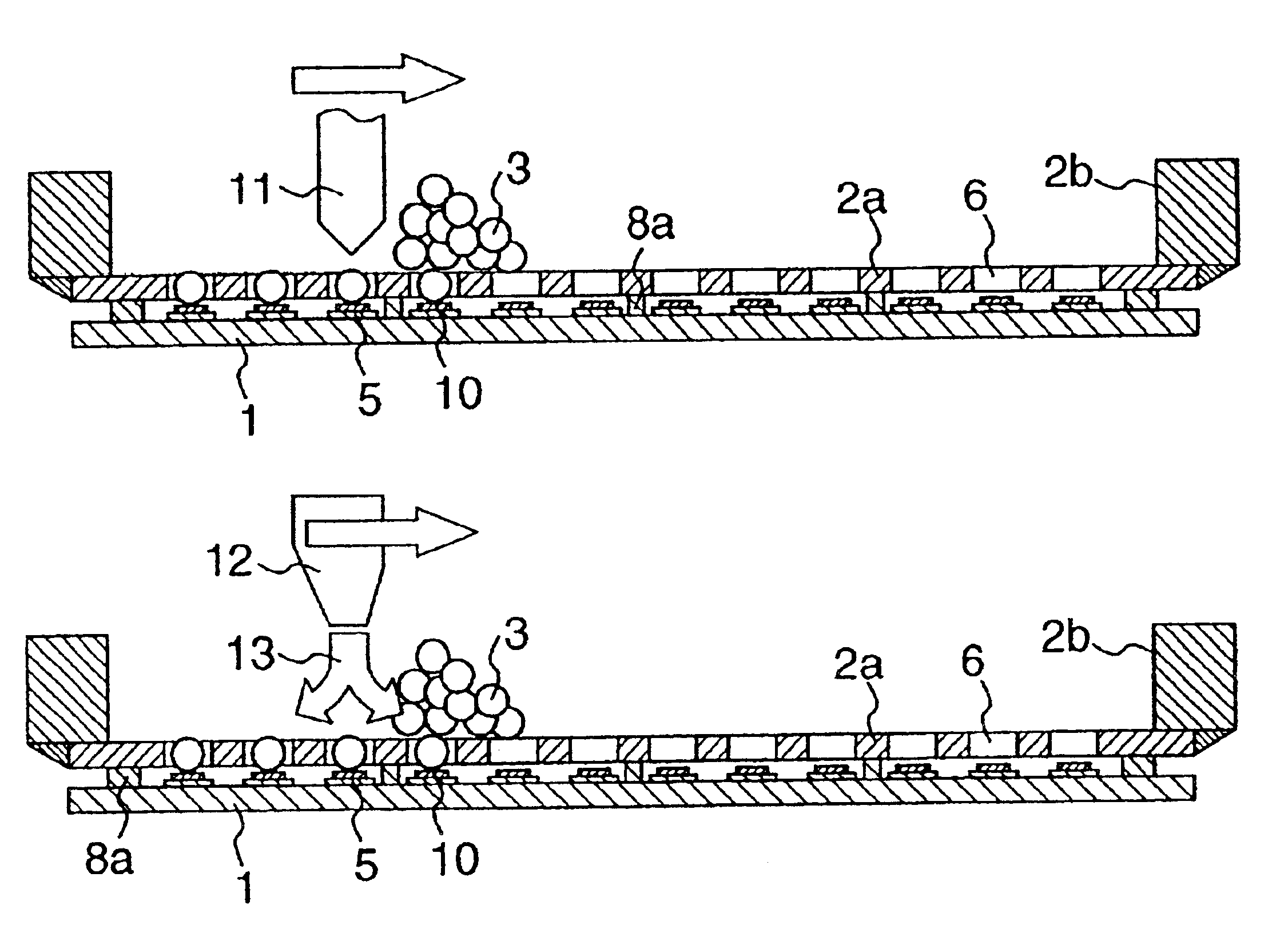

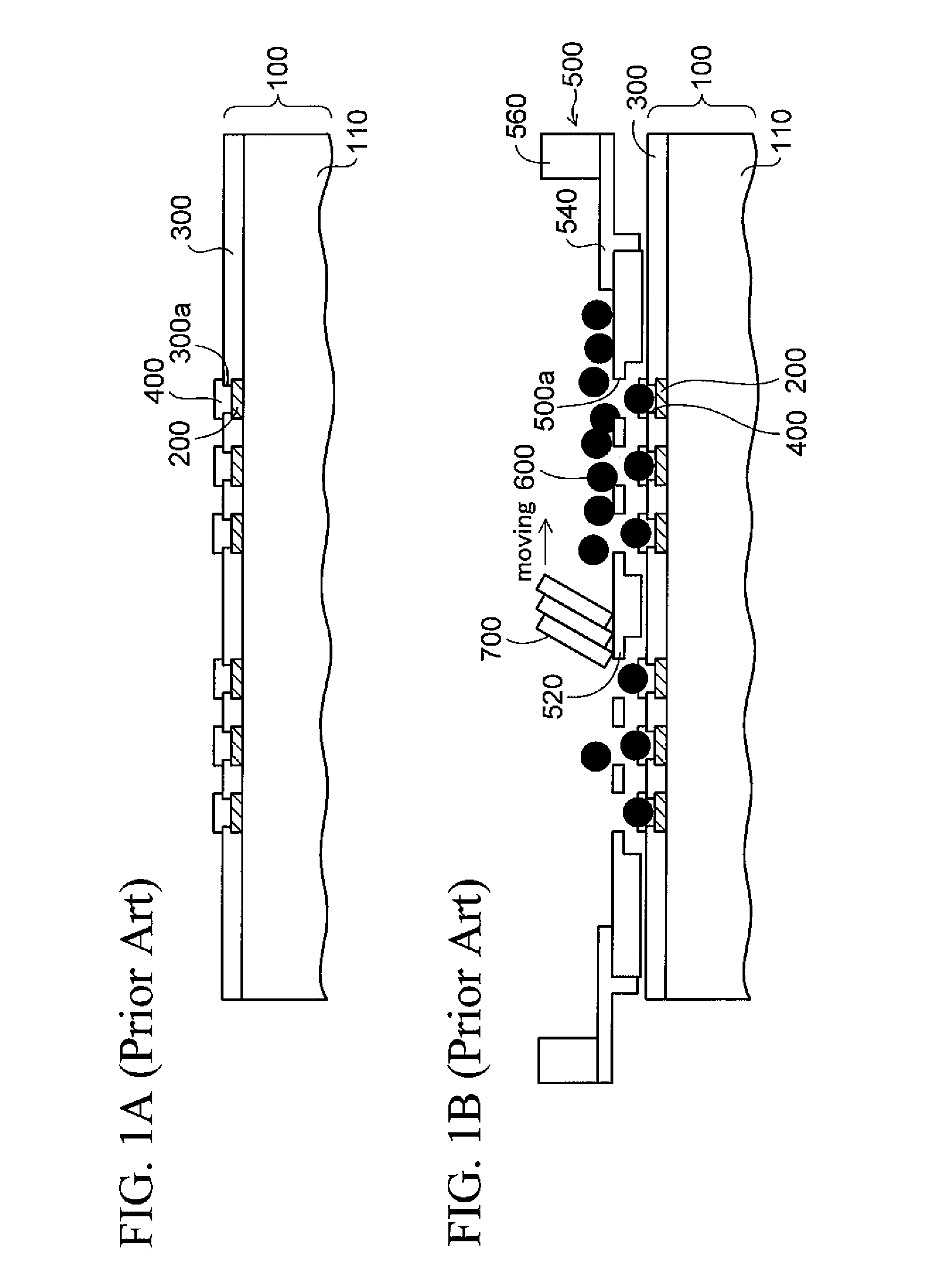

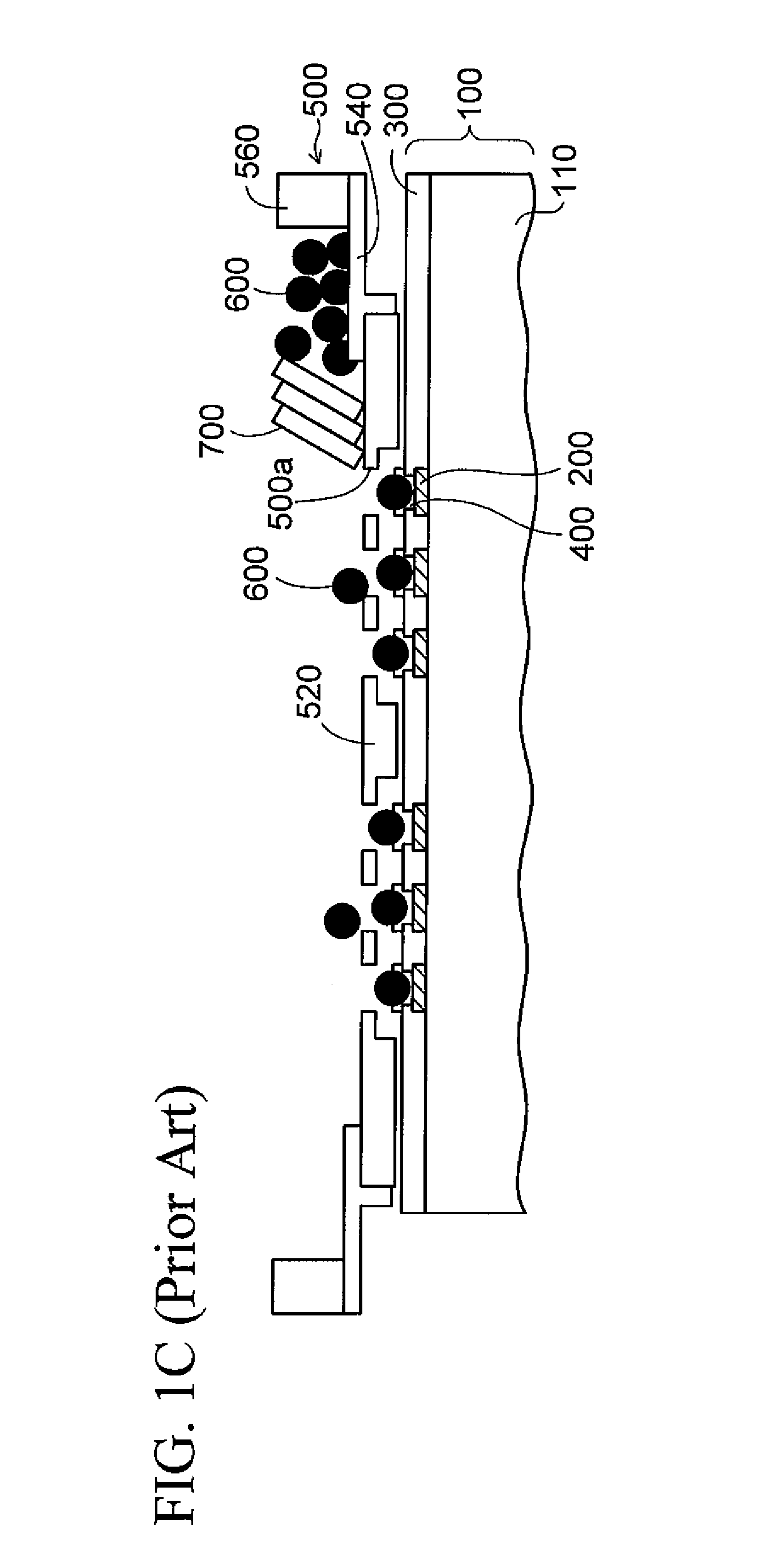

Method and apparatus for mounting conductive ball

InactiveUS20070130764A1Minimize effect of gapEasy to correctPrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

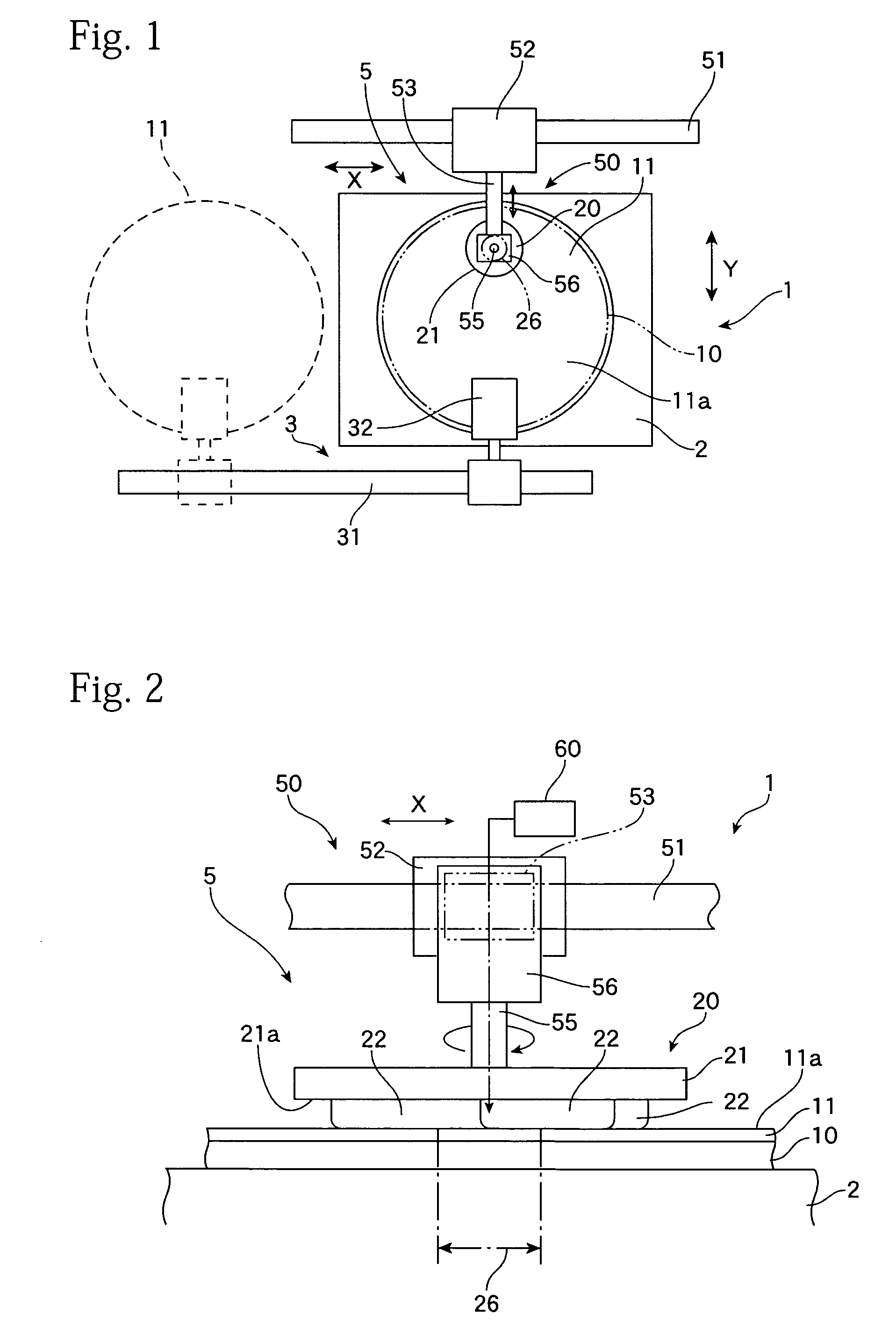

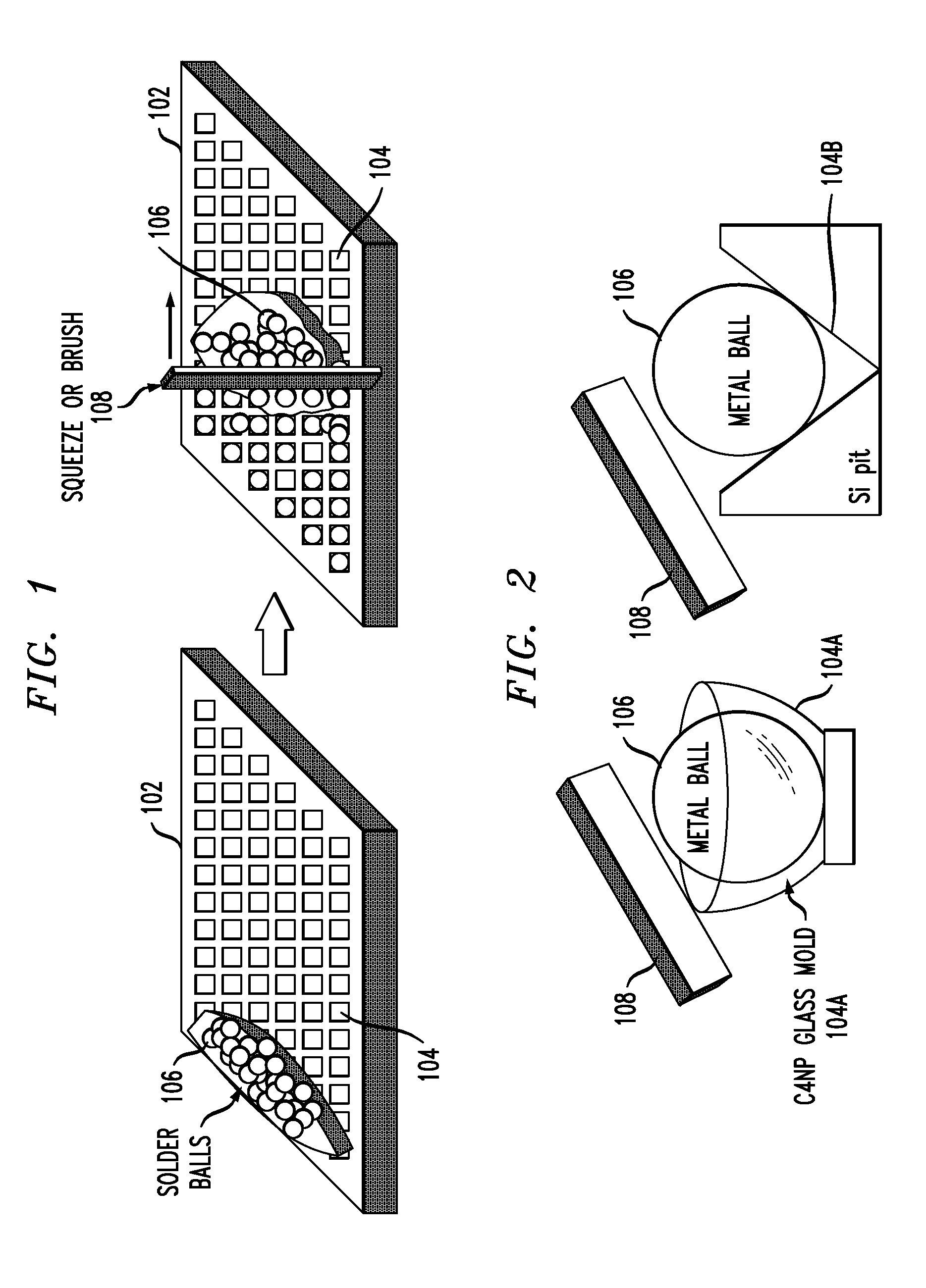

A method of mounting conductive balls comprises a step of setting, on a substrate, a mask that includes a plurality of apertures for disposing conductive balls on the substrate and a filling step. The filling step includes using a head that moves along a surface of the mask, holding a group of conductive balls in an area that is part of the surface of the mask, and moving the area so that parts of a path taken by the area overlap. By limiting the area where filling is carried out and moving the conductive balls while gathering the conductive balls in this area, it is possible to prevent losses for the conductive balls, to increase the filling efficiency, and to suppress the number of unfilled apertures.

Owner:ATHLETE FA KK

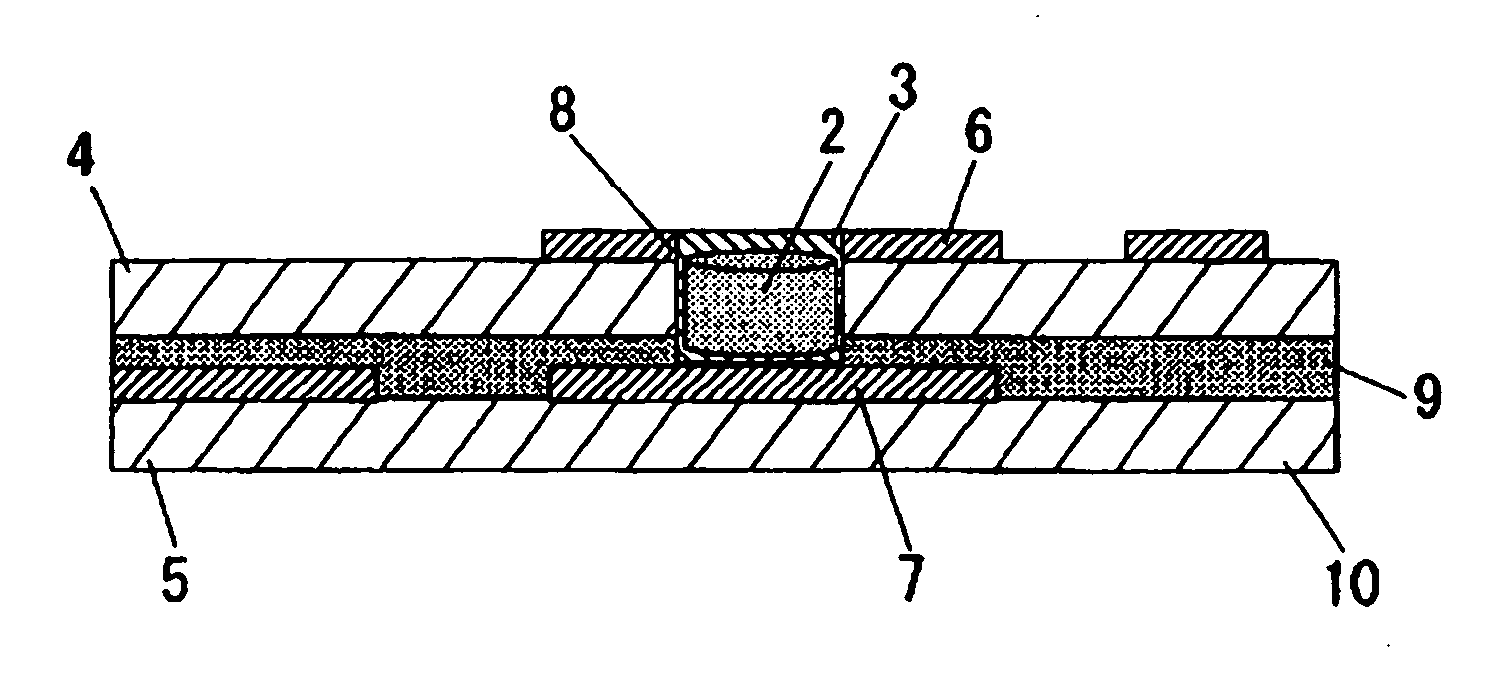

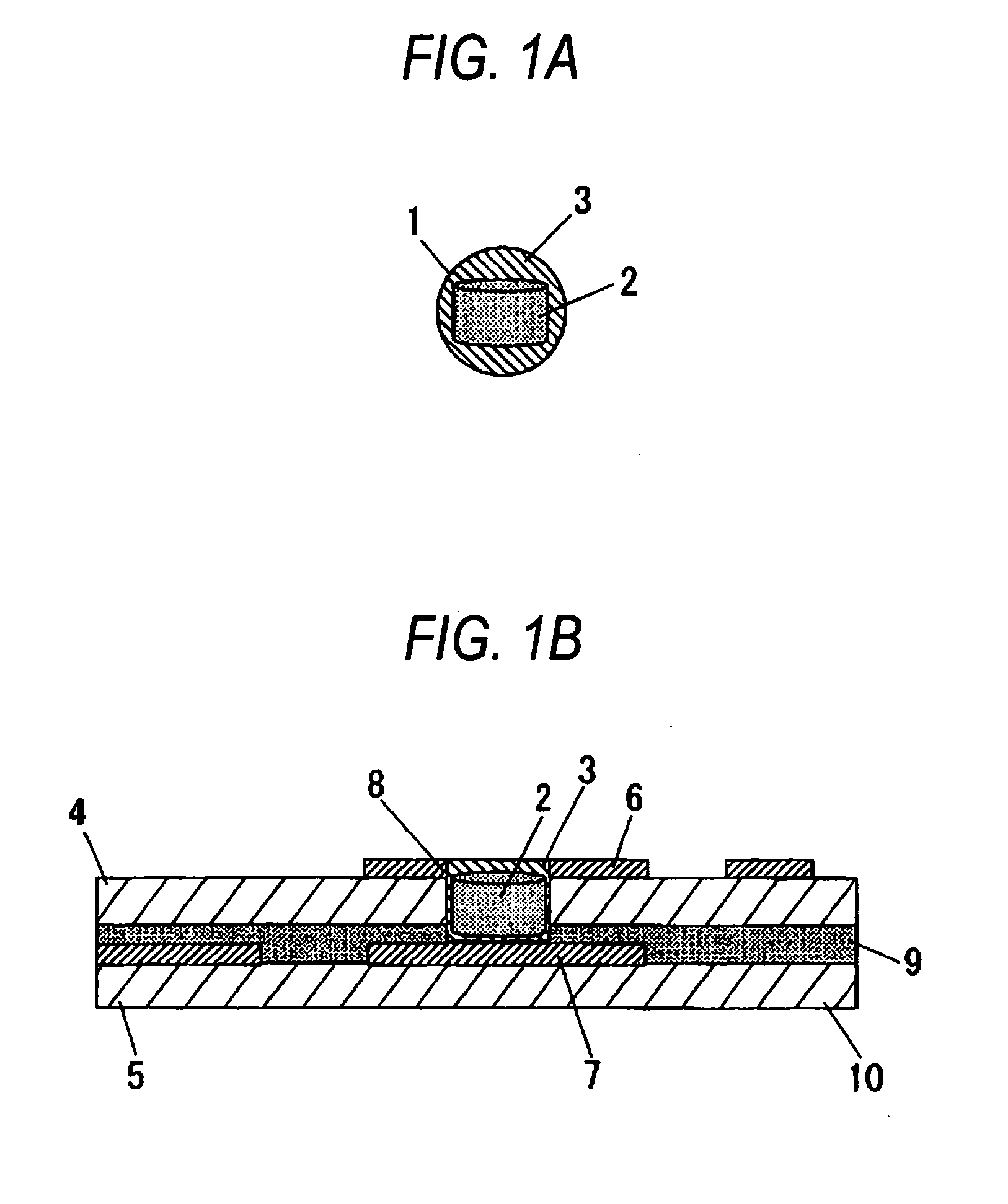

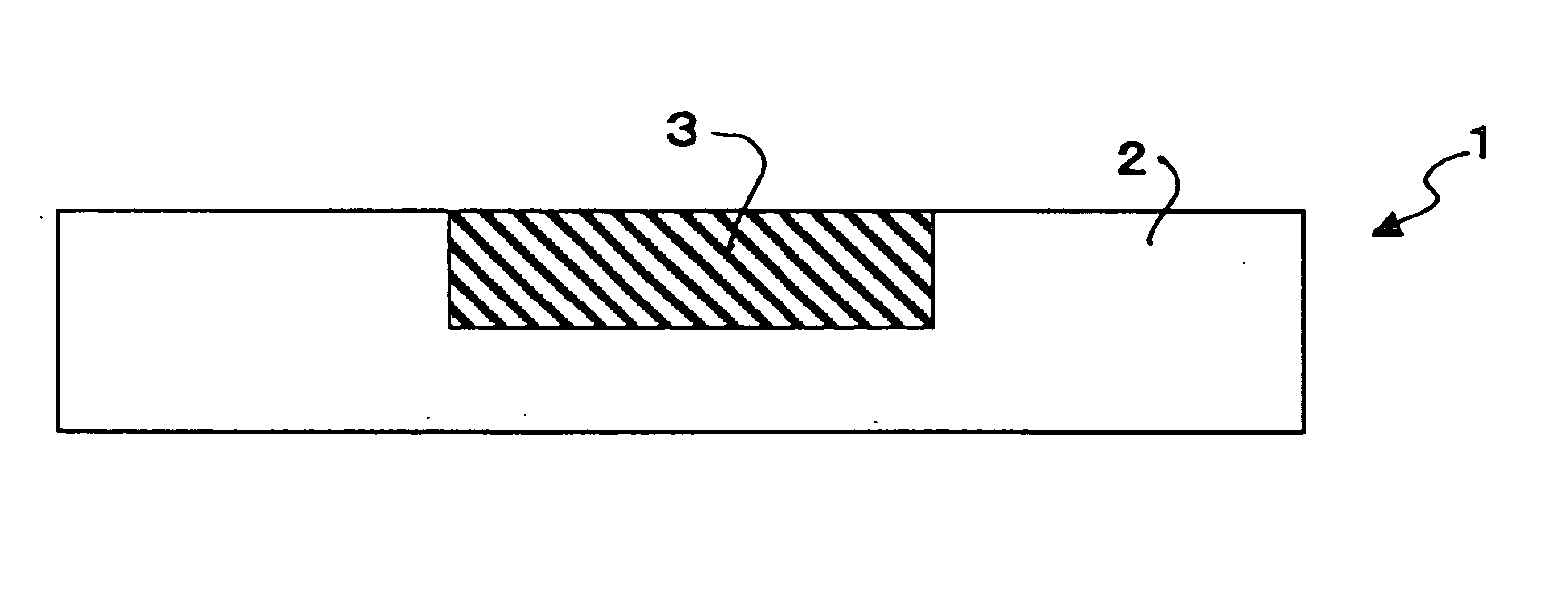

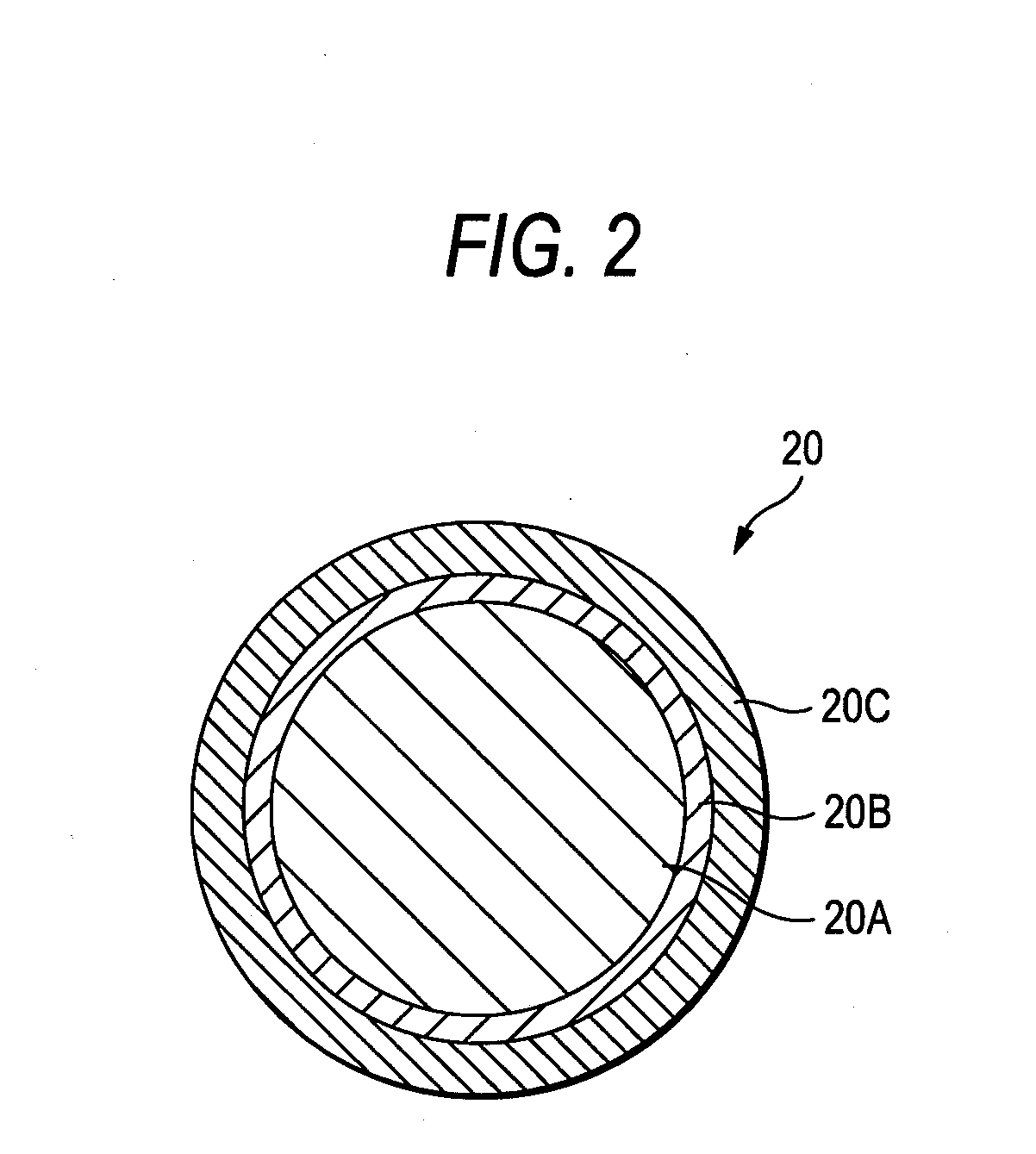

Interlayer connection conductor and manufacturing method thereof

InactiveUS20060272850A1Improve connection reliabilityUniform volumePrinted circuit aspectsPretreated surfacesElectrical conductorFlexible electronics

An interlayer connection conductor 1 is formed of a substantially spherical interlayer connector that is formed by forced in through holes 108, in a thickness direction, on a flexible printed circuit board having wiring layers 106, 107 on at leas one surface of an insulating layer The interlayer connection conductor includes a small cylindrical piece of metal core 102 formed by cutting a metal fine wire and a solder metal 103 coated around the surface of the metal core.

Owner:PANASONIC CORP

Methods and apparatus for forming solder balls

Methods and apparatus for forming a plurality of uniformly sized solder balls utilize a stencil having a plurality of holes of uniform volume disposed on a substrate. Solder is disposed in the holes of the stencil on the substrate. Typically, the solder is in the form of solder paste which is distributed into the holes using a squeegee. While within the holes of the stencil on the substrate, the solder is melted to form solder balls. The stencil may then be removed to leave the solder balls on the substrate, or the solder balls may be removed while the stencil remains on the substrate.

Owner:MICRON TECH INC

Method and apparatus for placing conductive balls

InactiveUS20060086777A1Increase placement rateSolve easy adhesionContact member manufacturingSemiconductor/solid-state device detailsMechanical engineering

Owner:HITACHI METALS LTD

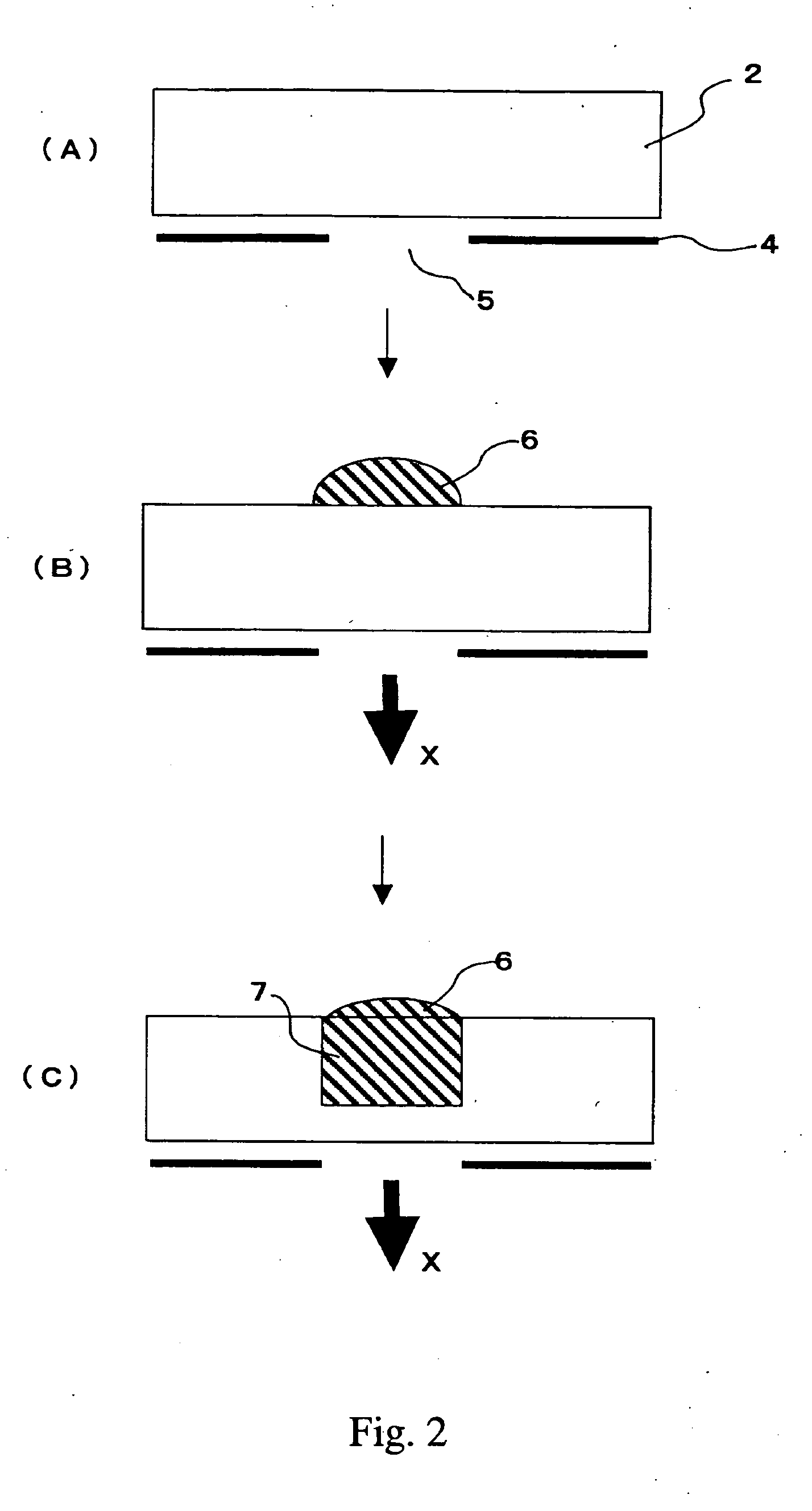

Method of forming bumps

InactiveUS6869008B2Rapid productionLow costPrinted circuit assemblingSolid-state devicesSolder ballEngineering

In the conventional bump forming method that can be applied to a semiconductor device in which a large number of bumps are required to be formed, there are various limitations on the material of which the bumps are made, due to enough cubic volume of bumps and to small scattering of the bump height. According to the invention, solder balls and a tool having a large number of through-holes are used, and under the condition that the through-holes of the tool are aligned with the pads of the semiconductor device, the solder balls are charged into the through-holes, pressed to be fixed on the pads, and then reflowed to form bumps.

Owner:RENESAS ELECTRONICS CORP

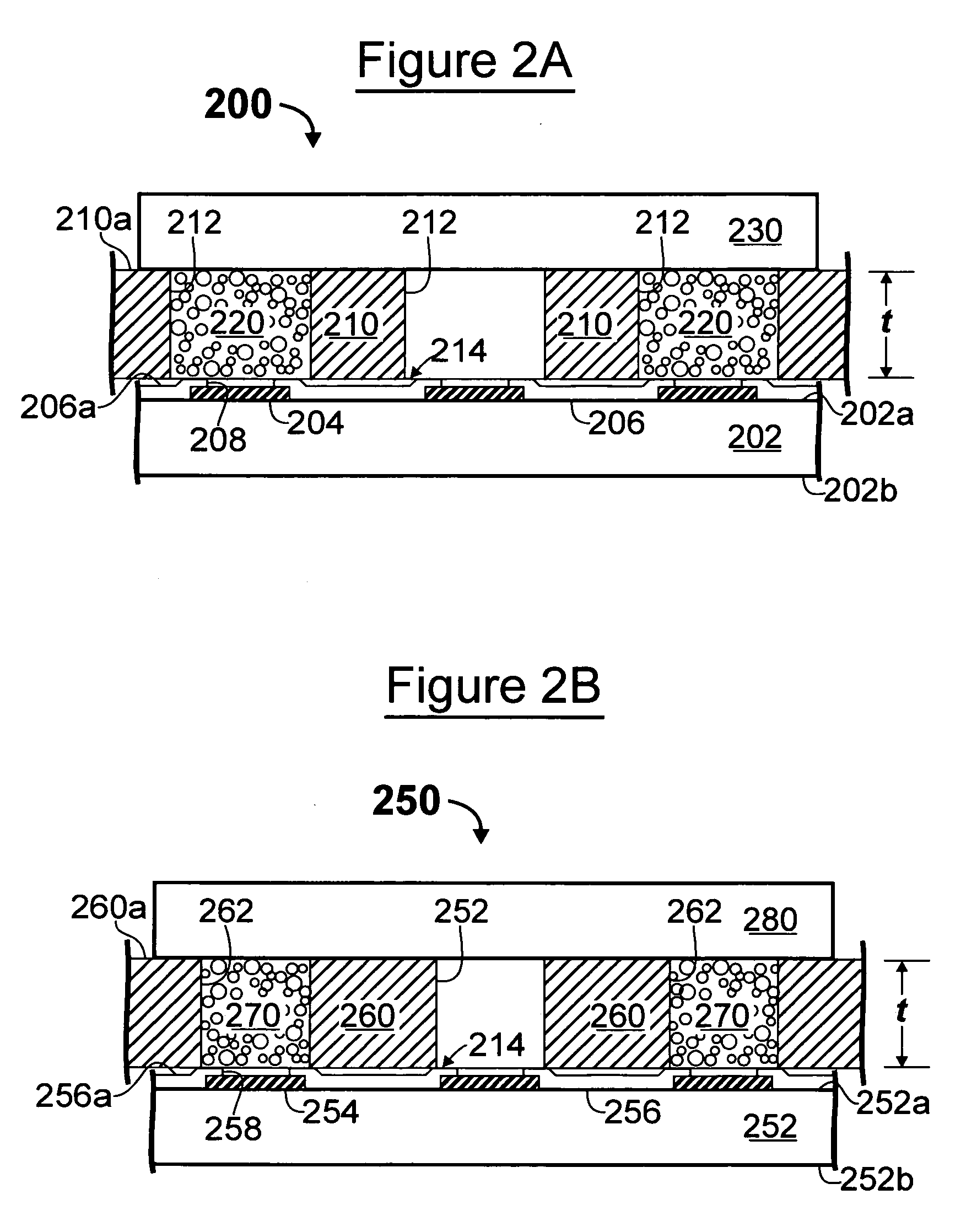

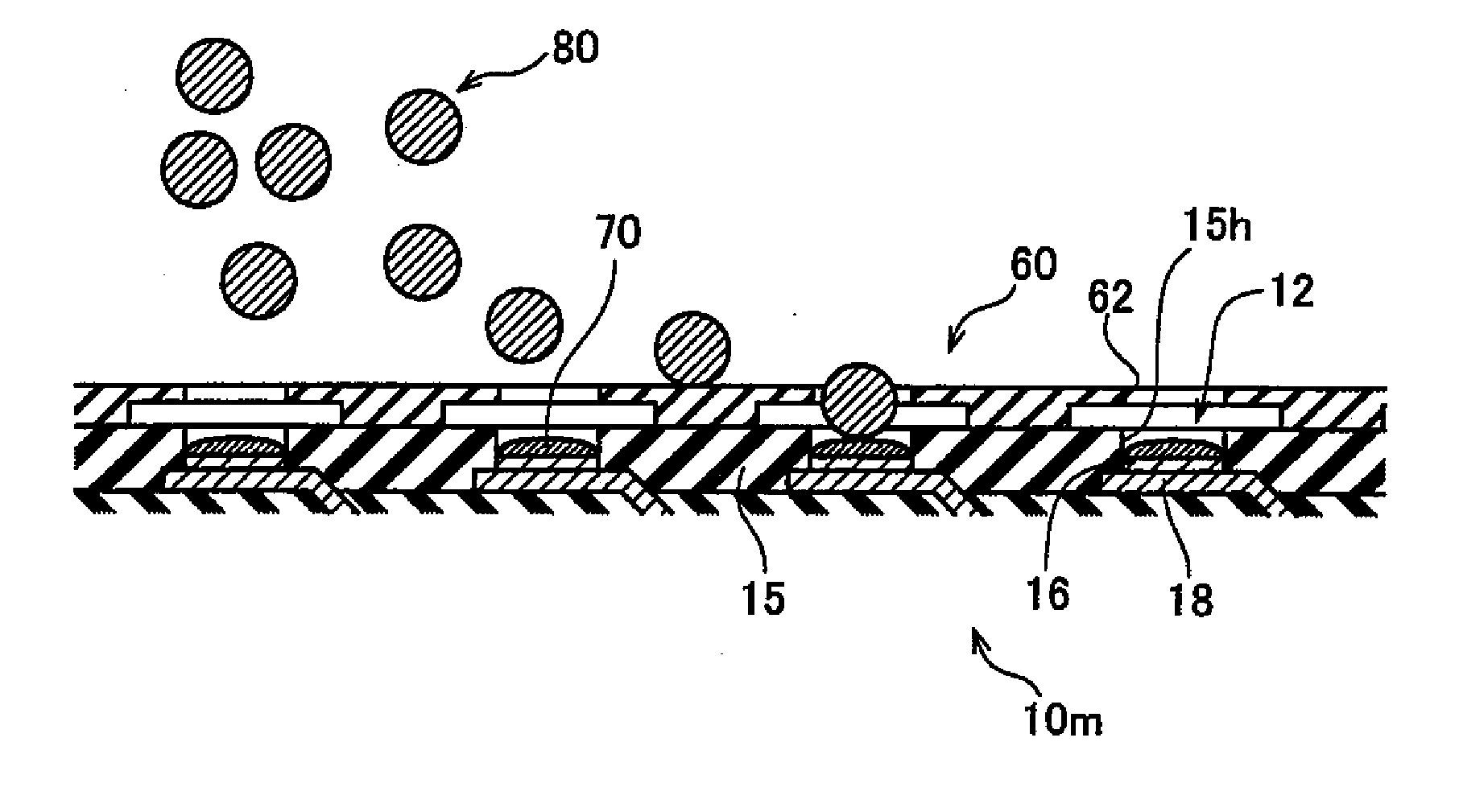

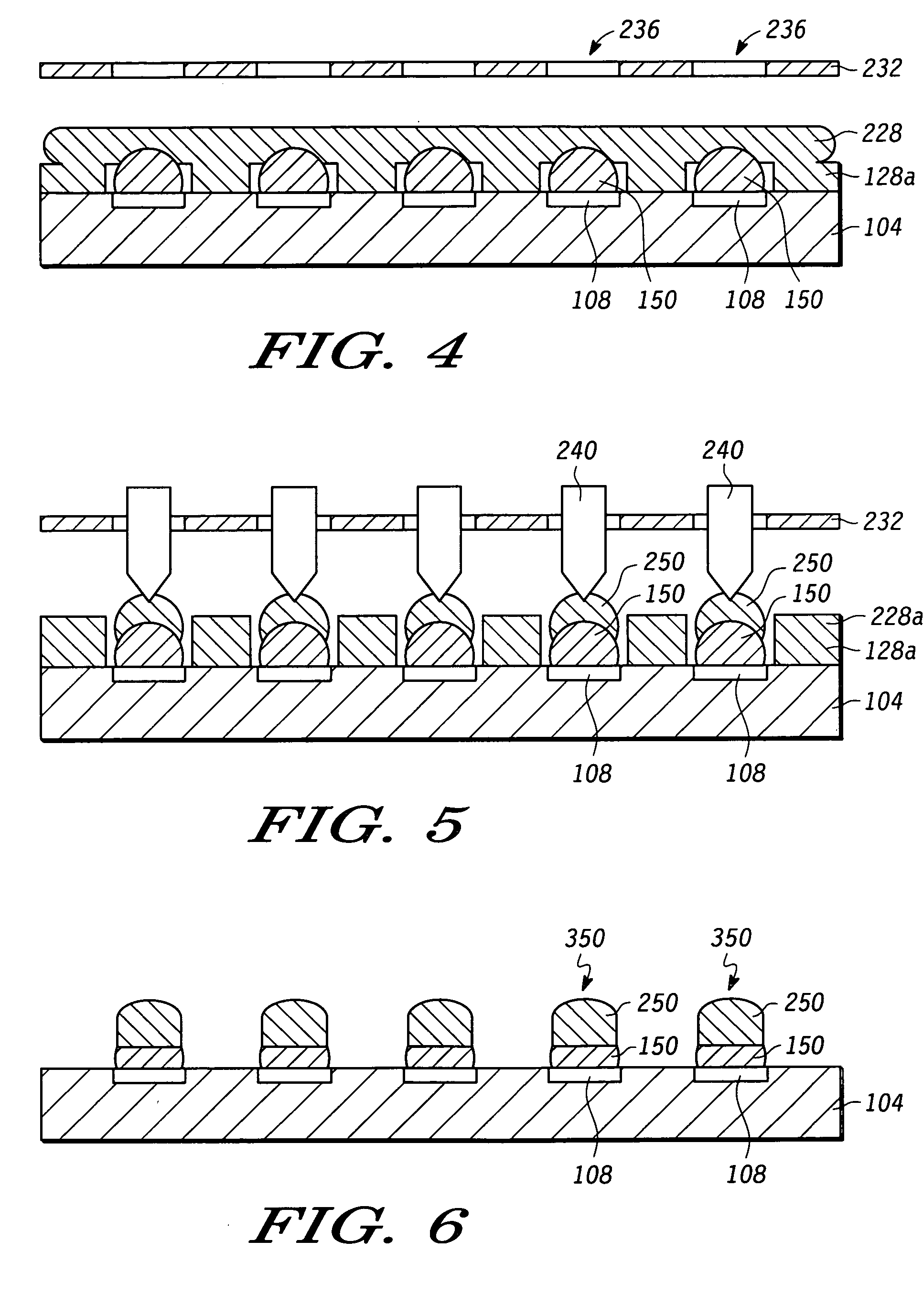

Forming solder balls on substrates

InactiveUS20060208041A1High densityImprove scalabilitySemiconductor/solid-state device detailsSolid-state devicesMetallurgySolder ball

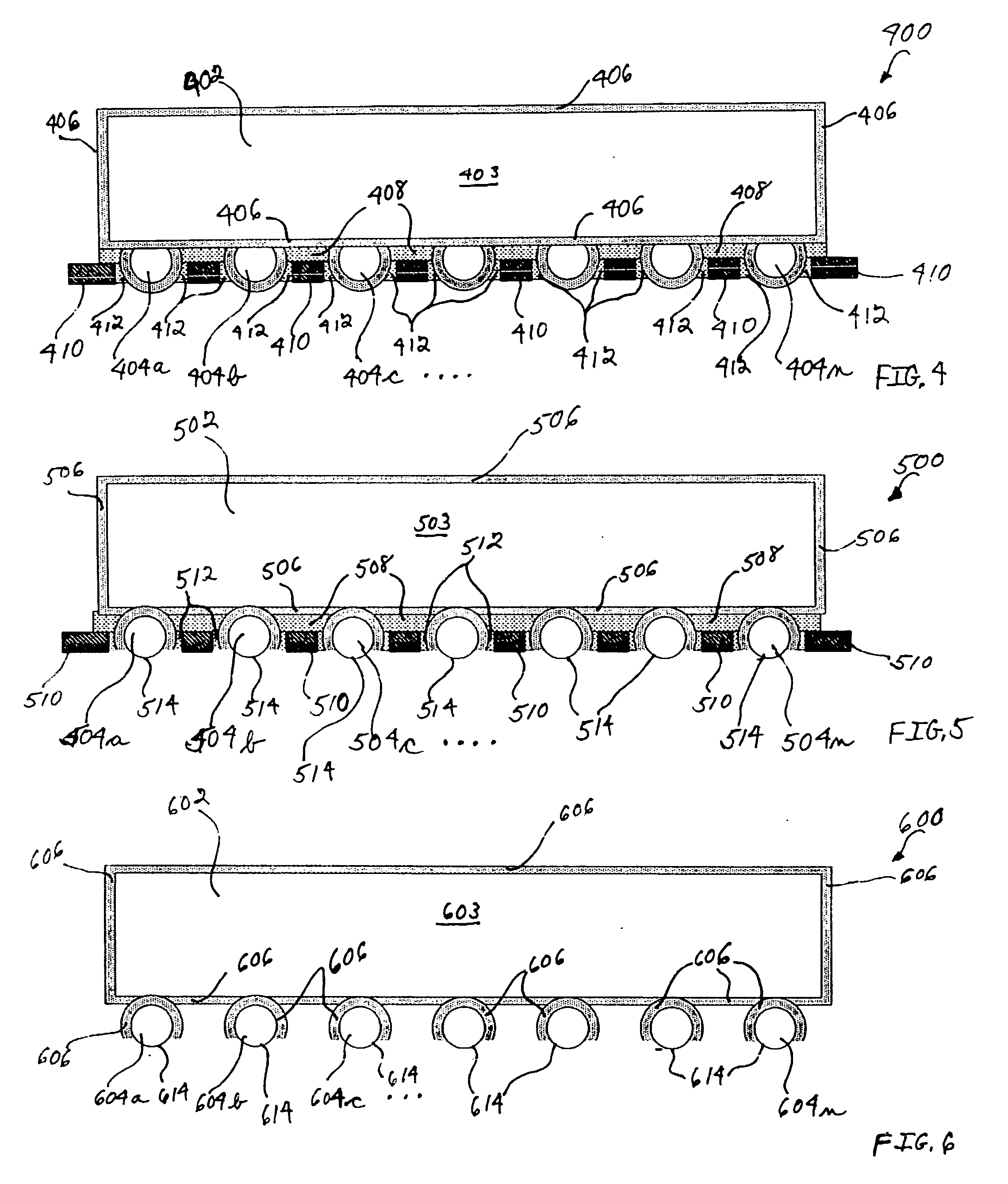

A mask (stencil) having cells (openings) is disposed on a surface of a heater stage, and is then filled (printed) with solder paste. Then a substrate is assembled to the opposite side of the mask. Then the solder paste is reflowed. This may be done partially inverted. Then the mask is separated from the substrate, either before or after cooling. Solder balls are thus formed on the substrate, which may be a semiconductor wafer. A biased chuck urges the substrate into intimate contact with the mask. A method for printing the mask with solder paste is described. Methods of forming high aspect ratio solder bumps (including balls and reflowable interconnect structures) are described.

Owner:SEMIPAC INC

Conductive material and manufacturing method thereof

InactiveUS20050255312A1Improve bending performanceLow costPorous dielectricsMaterial nanotechnologyElectrical resistance and conductanceConductive materials

Owner:NISCA KK +1

Electric contact and method for producing the same and connector using the electric contacts

InactiveUS20100096168A1Well formedPrinted circuit aspectsSolid-state devicesElectrical conductorCopper plating

Owner:OHTSUKI TOMONARI +4

Exposure device with mechanism for forming alignment marks and exposure process conducted by the same

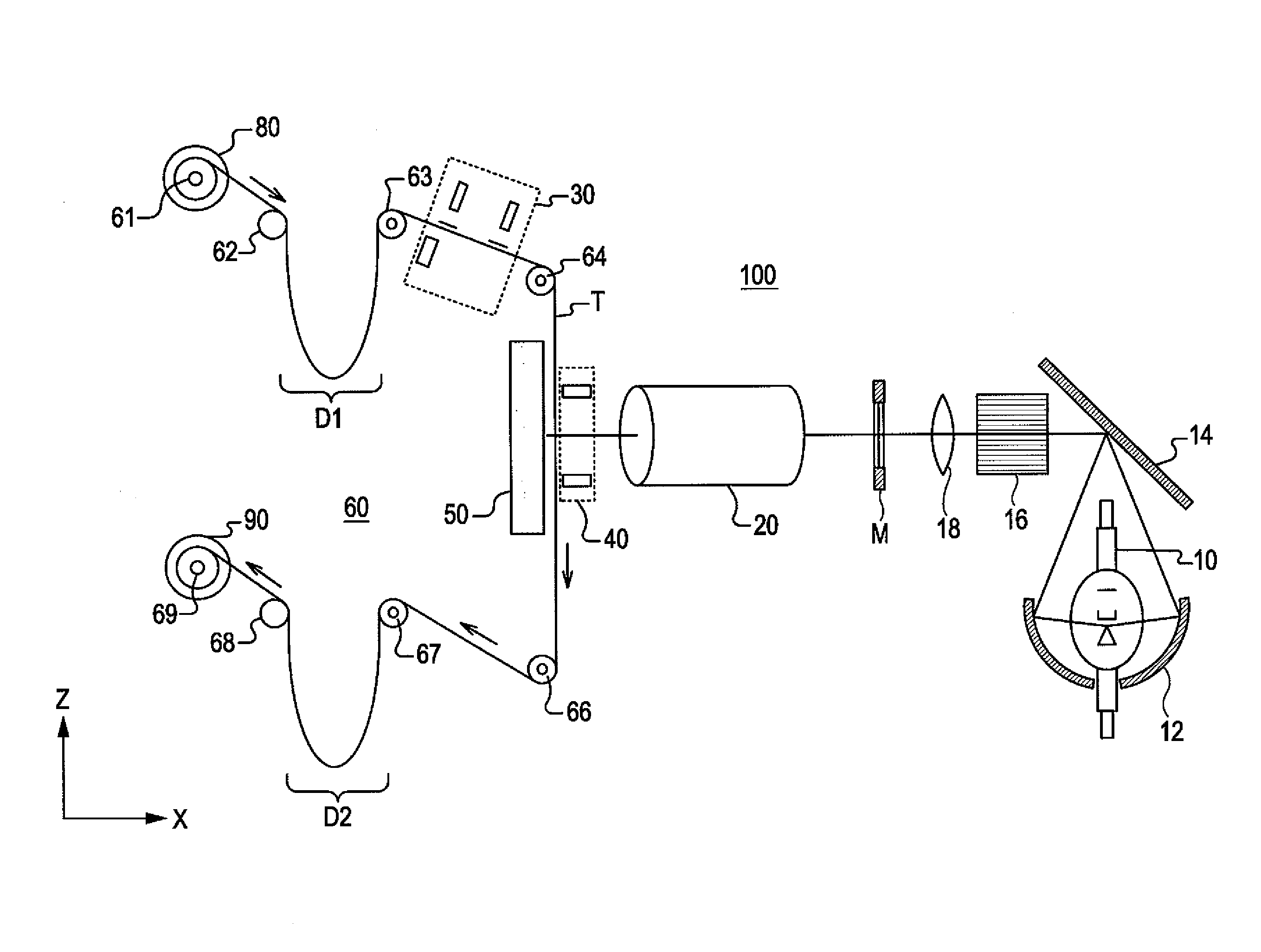

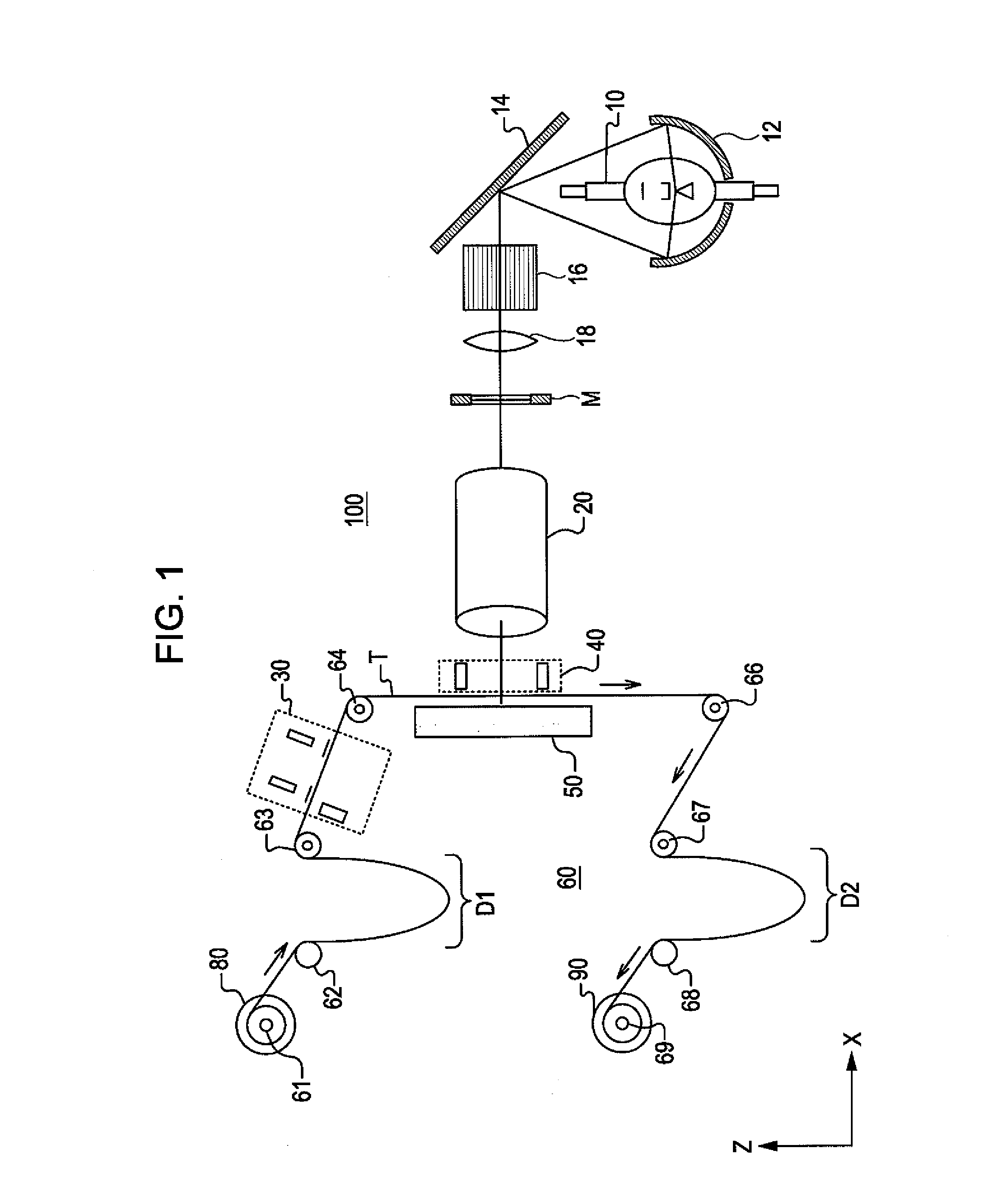

ActiveUS20090059195A1Accurate transferReduce riskPrinted circuit aspectsSolid-state devicesEngineeringRoll film

The present invention relates to an exposure device for transferring circuit patterns of a mask to a roll-film-shaped object. The exposure device includes a supply reel rotation section that is constituted by a supply reel around which the object is wound and that feeds the object by rotating the supply reel, at least one guide roller for guiding the object fed from the supply reel rotation section, an exposure stage on which the circuit patterns are transferred to the object guided by the guide roller, and an alignment mark forming section which forms, on the object, alignment marks that are used to align the mask with the object and which is positioned between the guide roller and the exposure stage.

Owner:ORC MFG

Apparatus and method for arranging magnetic solder balls

InactiveUS20090072012A1Avoid it happening againAvoid damageLiquid surface applicatorsSolid-state devicesSolder ballEngineering

An apparatus for arranging magnetic solder balls includes: a stage for placing and fixing the substrate thereon; a magnet which is incorporated in the stage and is movable in parallel with a lower surface of the placed and fixed substrate so as to cause a magnetic force to act in an upward direction of the stage; and a mask frame capable of being positioned above the stage. An arranging method using this arranging apparatus is also provided. An apparatus for arranging magnetic solder balls includes: a stage for placing and fixing the substrate thereon; a mask frame capable of being positioned above the stage; and a magnetic generator which is movable above the mask frame and causes a magnetic force to act on the stage. An arranging method using this arranging apparatus is also provided.

Owner:SHINKO ELECTRIC IND CO LTD

Off-center solder ball attach assembly

InactiveUS6870267B2Printed circuit assemblingSemiconductor/solid-state device detailsDielectricSolder ball

A connection component includes a dielectric element having a first surface and a second surface, and conductive pads on the first surface of the dielectric element, each conductive pad having a center. The connection component also includes conductive vias electrically connected to the conductive pads and extending toward the second surface of the dielectric element, each of the vias having an opening at one of the conductive pads. At least one of the via openings is offset from the center of at least one of the conductive pads.

Owner:TESSERA INC

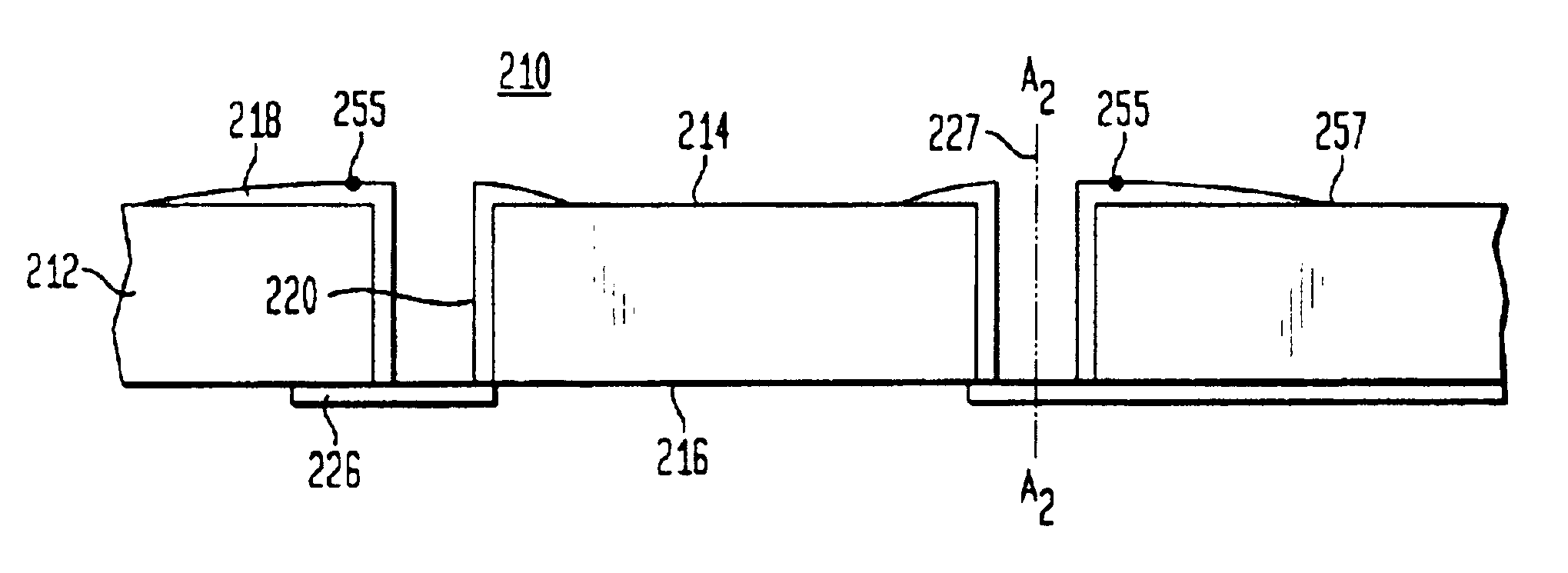

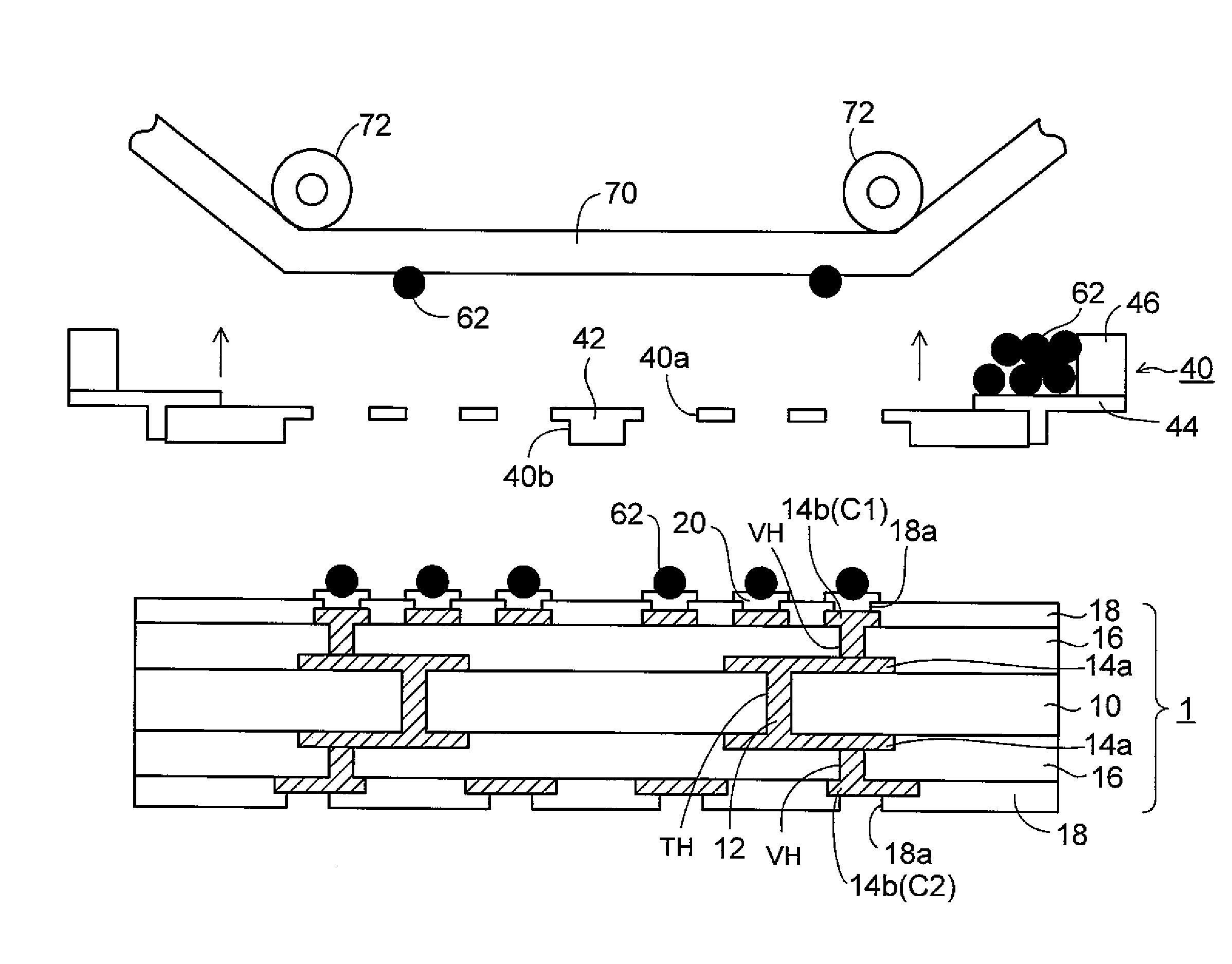

Method of forming solder connection portions, method of forming wiring substrate and method of producing semiconductor device

ActiveUS7507655B2Improve reliabilitySemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor

A method of forming solder connection portions on first electrode pads and on second electrode pads, comprises a first step of arranging solder balls on the first electrode pads by arranging a first mask on a base mask; a second step of arranging solder balls on the second electrode pads by arranging a second mask on the base mask; and a third step of melting the solder balls. The base mask has first opening portions corresponding to the first electrode pads and second opening portions corresponding to the second electrode pads and having a size different from that of the first opening portions. The first mask has opening portions corresponding to the first opening portions and covering the second opening portions. The second mask has opening portions corresponding to the second opening portions and covers the first opening portions.

Owner:SHINKO ELECTRIC IND CO LTD

Method for plugging holes in a printed circuit board

InactiveUS6954985B2Smoothly plugging a solder resist insulatingQuantity minimizationSurface layering apparatusMultilayer circuit manufactureSurface patternEngineering

A hole plugging method for a printed circuit board, a hole plugging device in accordance therewith and a manufacturing method in accordance therewith where a mask for selectively exposing a via hole, a through hole and a surface pattern of the printed circuit board is positioned on the board having the via hole and the through hole to electrically connect circuit patterns formed on the surface of the board and in the board and an insulating material is plugged in the via hole by abutting and pushing the material on the surface of the board. Therefore, the insulating material can be plugged smoothly without a void, the processing is simplified by plugging the insulating material just to the height of the circuit pattern in a space between the circuit patterns and accordingly, damage to the circuit pattern can be prevented.

Owner:LG INNOTEK CO LTD

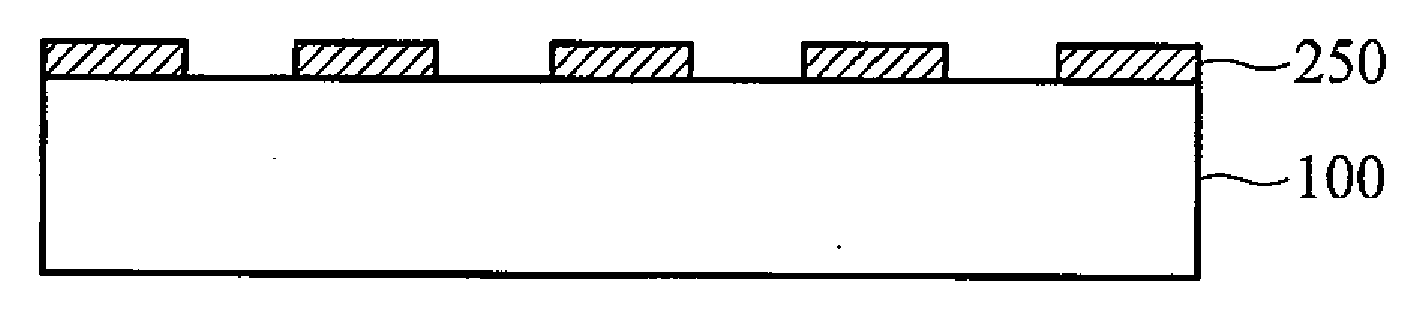

Method for fabricating conductive pattern on flexible substrate and protective ink used therein

The invention discloses a method for fabricating a conductive pattern on a flexible substrate. A flexible substrate having a conductive layer thereon is provided. A protective ink is screen printed on the conductive layer, wherein a portion of the conductive layer is exposed through the protective ink. The exposed portion of the conductive layer is removed by etching using the protective ink as a mask. The protective ink is then removed, thus providing a conductive pattern with a minimum line width of not greater than 150 μm. The invention also discloses a composition for the protective ink.

Owner:IND TECH RES INST

Forming solder balls on substrates

InactiveUS7007833B2Well formedHigh densityWelding/cutting auxillary devicesSolid-state devicesMetallurgySolder ball

A mask (stencil) having cells (openings) is disposed on a surface of a heater stage, and is then filled (printed) with solder paste. Then a substrate is assembled to the opposite side of the mask. Then the solder paste is reflowed. This may be done partially inverted. Then the mask is separated from the substrate, either before or after cooling. Solder balls are thus formed on the substrate, which may be a semiconductor wafer. A biased chuck urges the substrate into intimate contact with the mask. A method for printing the mask with solder paste is described. Methods of forming high aspect ratio solder bumps (including balls and reflowable interconnect structures) are described.

Owner:WSTP

Techniques for arranging solder balls and forming bumps

InactiveUS20090283575A1Solid-state devicesSemiconductor/solid-state device manufacturingSolder ballEngineering

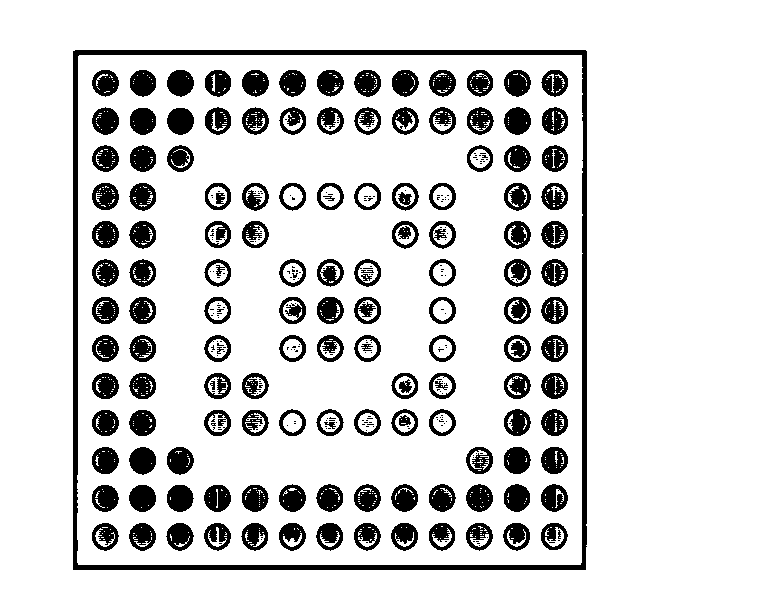

A mask having a plurality of through holes and a mold having a plurality of cavities are provided, and the through holes and the cavities are aligned. Conductive balls ale dispensed into the aligned through holes and cavities Substantially one ball is dispensed into each aligned through hole and cavity, and the mask with the holes and the cavities in the mold ale configured and dimensioned such that the balls are substantially flush with, or recessed below, an outer surface of the mask. The mask is removed, the conductive balls are aligned with pads of a semiconductor device, and the conductive balls are transferred to the pads by fluxless reflow in a formic acid environment. Vibrational, electrostatic, and direct transfer aspects are also disclosed.

Owner:ULTRATECH INT INC

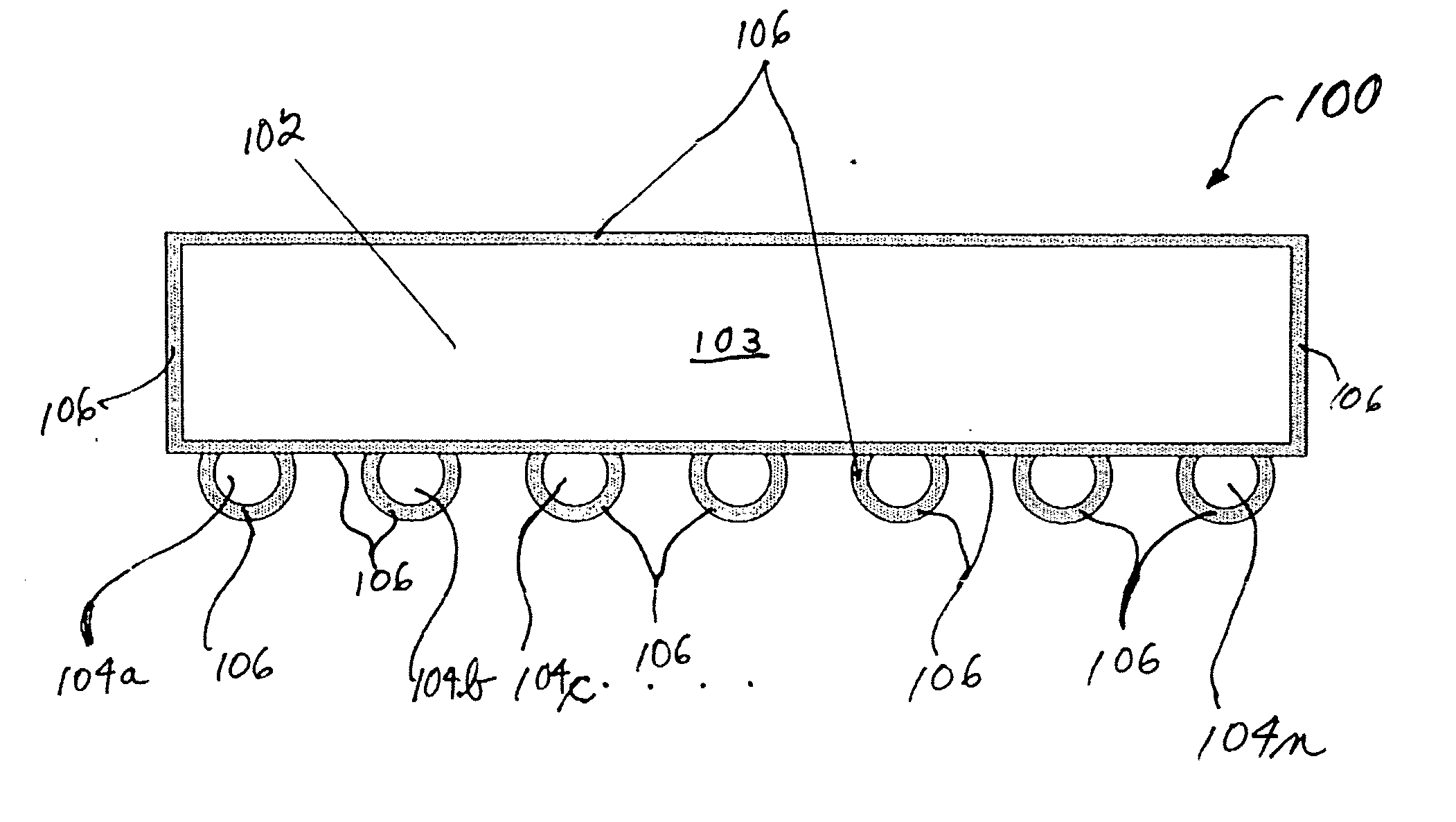

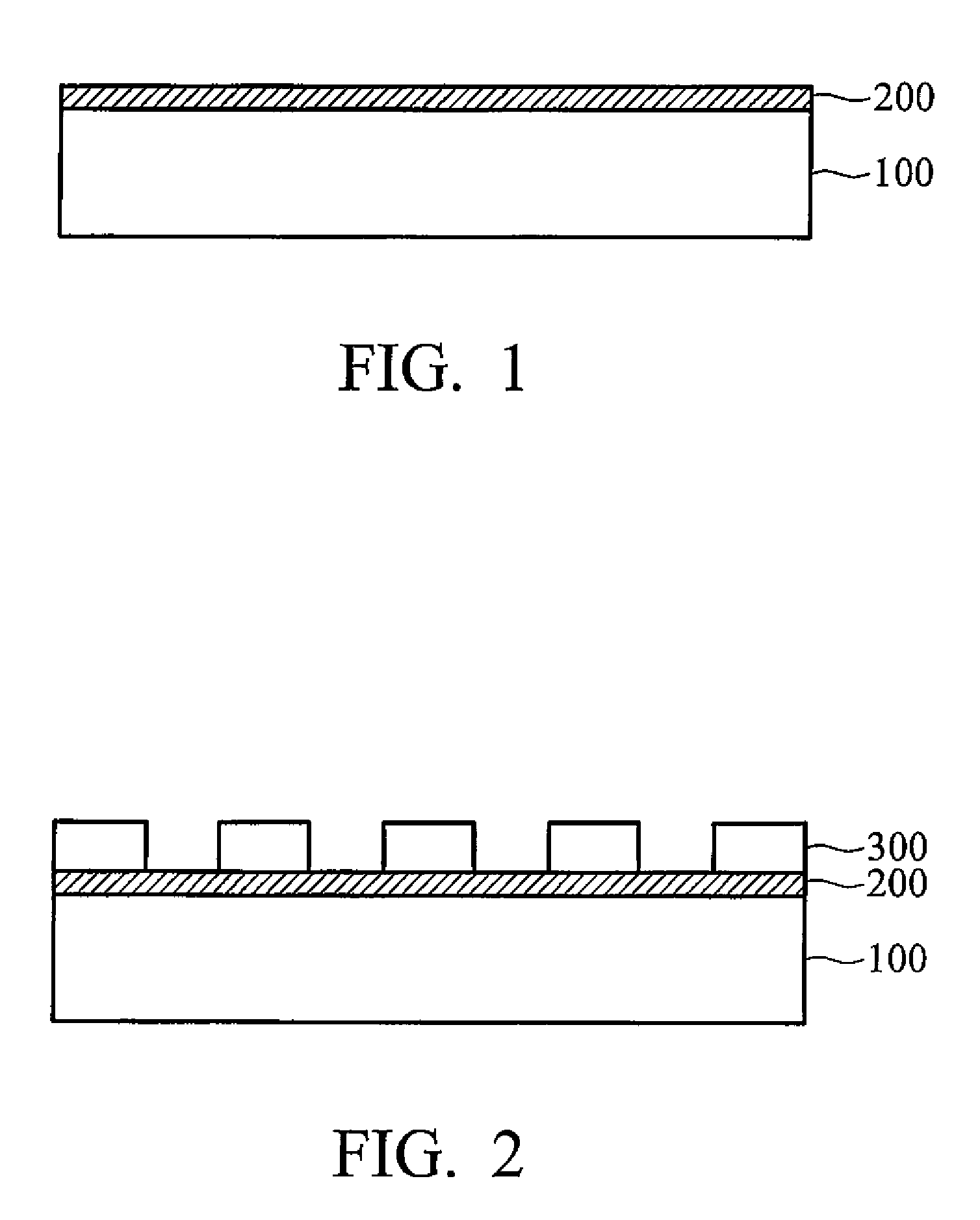

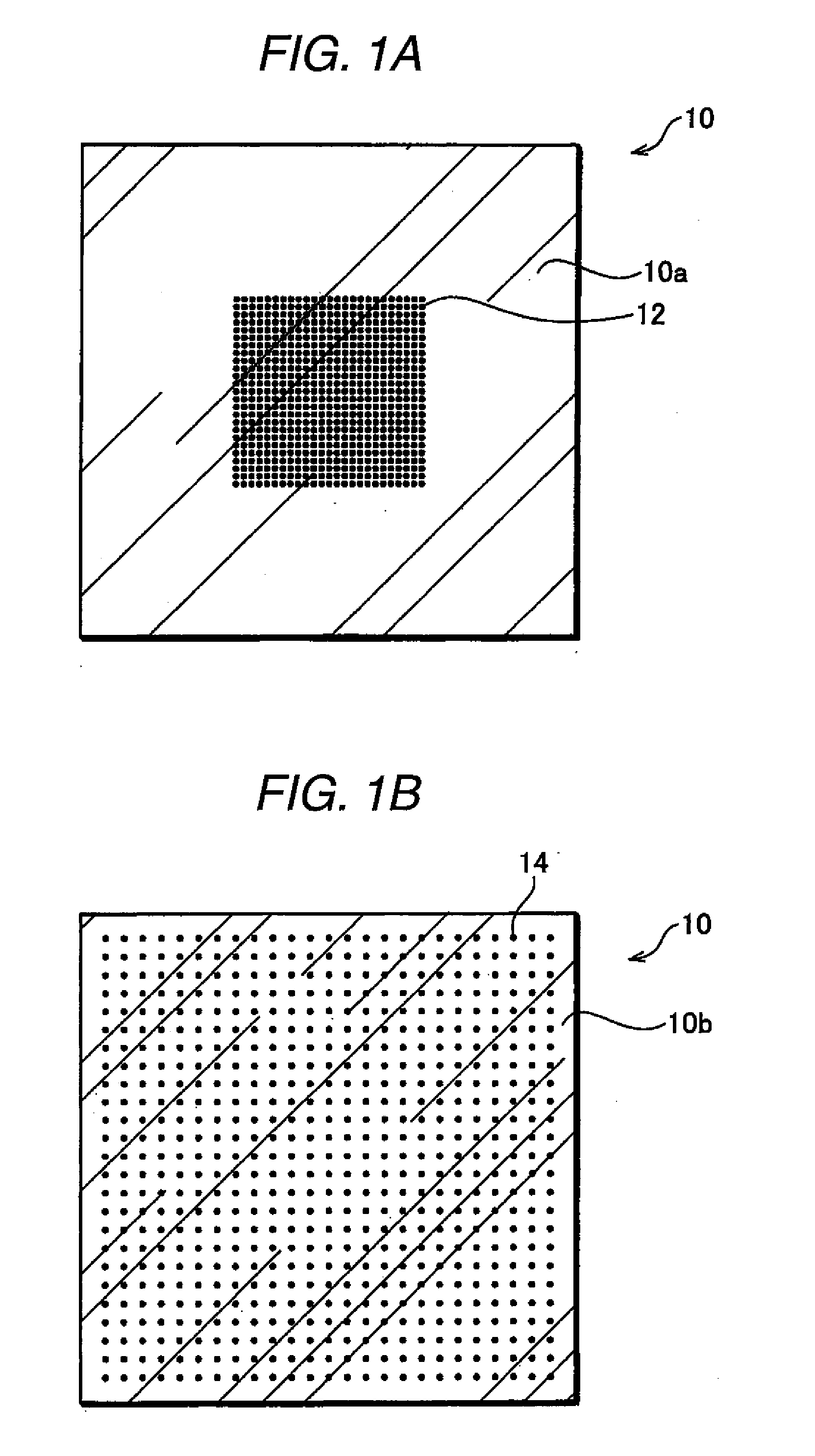

Device packages

InactiveUS20090042382A1Easily and precisely locatedLow costSemiconductor/solid-state device manufacturingNon-printed masksSolder ballEngineering

Low volume production of electronic devices having ball attachments, e.g. solder ball arrays, is advantageously achieved using a specific method. In particular a stencil having holes in, for example, the ball grid array pattern is formed by laser ablation of the holes in materials such as paper and polymers. The stencil holes are aligned with corresponding pads on the electronic device. Balls such as solder balls are introduced into the holes and heated to induce adhesion of the balls to the corresponding pads.

Owner:AGERE SYST INC

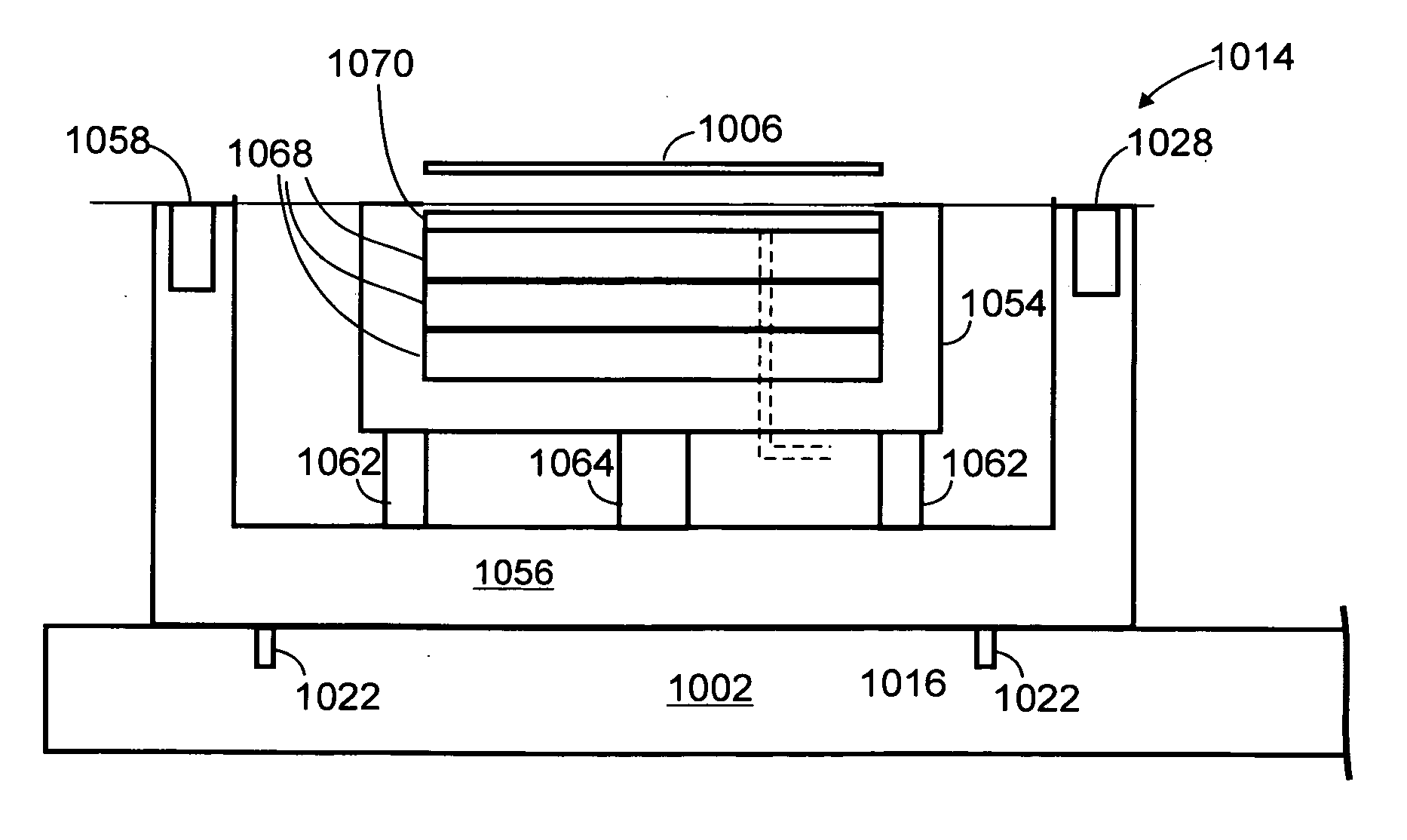

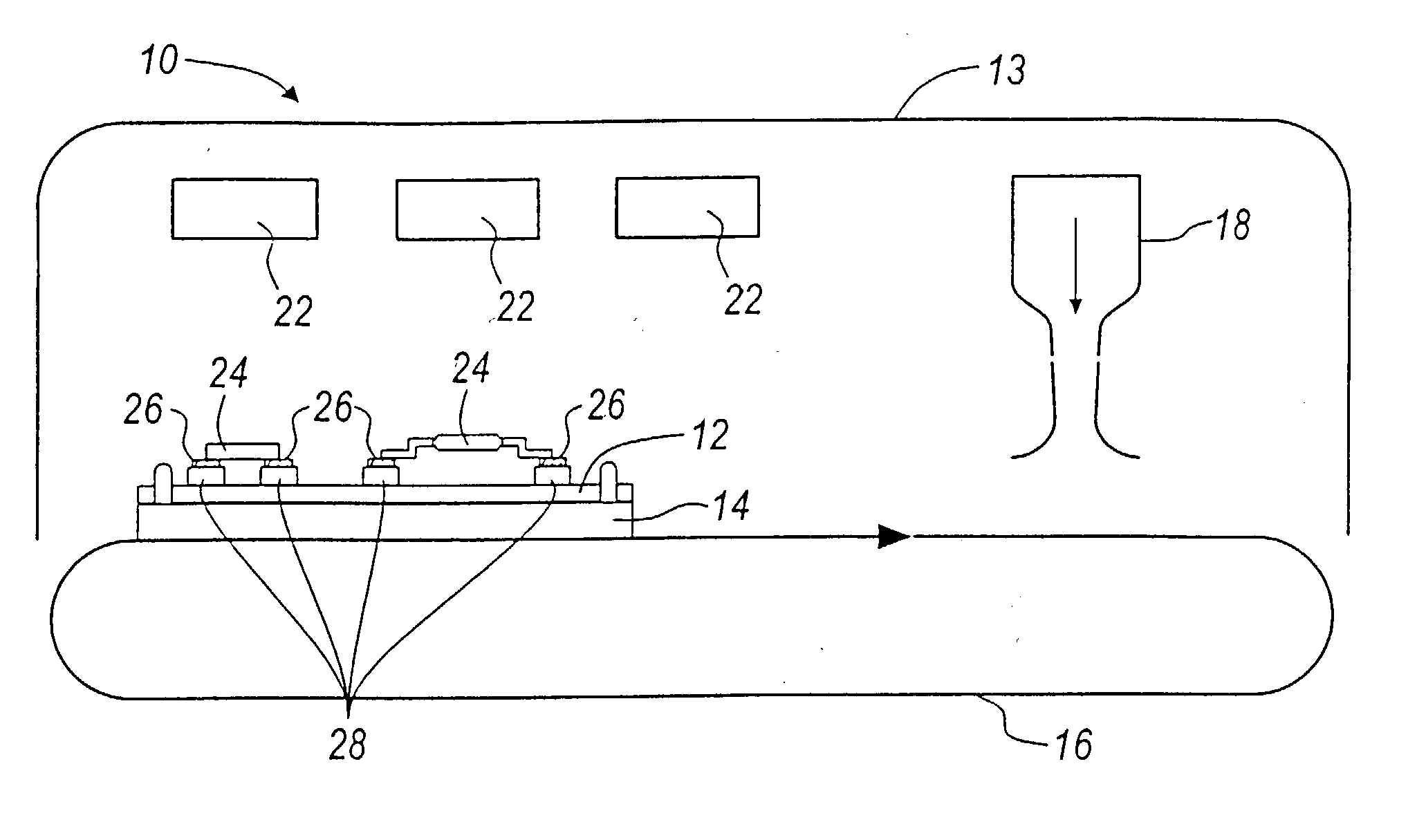

Vector transient reflow of lead free solder for controlling substrate warpage

InactiveUS20050001019A1Improve usabilityPrinted circuit assemblingMuffle furnacesEngineeringElectronic component

A system and method for reflowing lead-free solder to interconnect a plurality of electronic components to a substrate is disclosed. The system includes an oven for preheating the substrate and the plurality of electronic components disposed thereon, and a supplemental heat source disposed in the oven for providing additional heat energy to reflow the solder.

Owner:SYNAPTICS INC

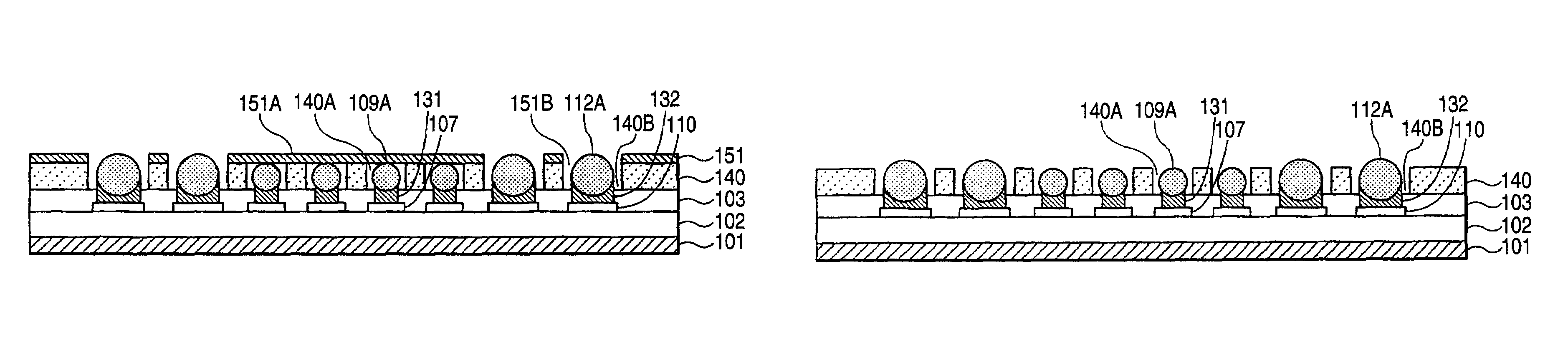

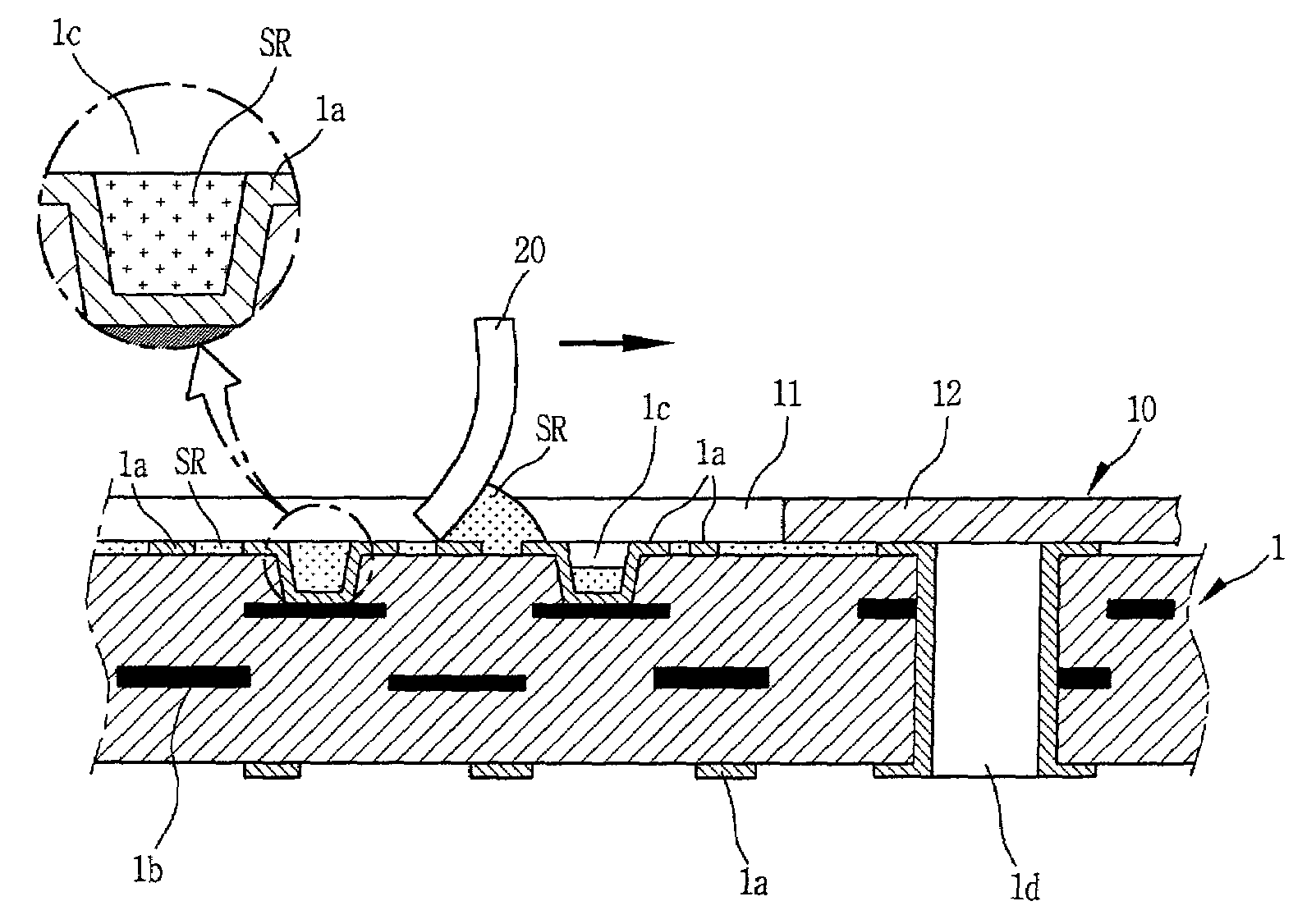

Solder ball mounting apparatus and wiring board manufacturing method

InactiveUS20090283574A1Inhibition defectReduce connection failuresSemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

A wiring board includes an insulating layer having a plurality of through holes formed therein, a base substrate layer positioned below the insulating layer, and a plurality of electrodes disposed on the base substrate layer, each electrode having an exposed surface exposed from a respective through hole, each exposed surfaces being coated with a flux. A plurality of solder balls are disposed on the fluxes in the through holes, respectively. An apparatus for mounting the solder balls on the plurality of electrodes includes: a solder ball removing unit configured to remove a first plurality of solder balls located other than in the through holes; and a solder ball pressing unit configured to press a second plurality of solder balls individually disposed in the through holes towards respective electrodes and into respective flux.

Owner:NGK SPARK PLUG CO LTD

Printed wiring board

ActiveUS7714233B2Printed circuit assemblingSemiconductor/solid-state device detailsResistSolder mask

A printed wiring board including a wiring substrate provided with at least one conductor circuit, a solder resist layer formed on the surface of the wiring substrate, covering the at least one conductor circuit, conductor pads formed on a part of the at least one conductor circuit exposed from respective openings provided in the solder resist layer for mounting electronic parts, and solder bumps formed on the respective conductor pads. The ratio (H / D) of a height H of the solder bumps from solder resist layer surface to an opening diameter of the openings are made to be about 0.55 to about 1.0 with the pitch of the openings provided in the solder resist layer of about 200 μm or less.

Owner:IBIDEN CO LTD

Method for forming multi-layer bumps on a substrate

InactiveUS20070099413A1High standoffImprove joint reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsCompound (substance)Metal powder

A method for forming multi-layer bumps on a substrate includes depositing a first metal powder on the substrate, and selectively melting or reflowing a portion of the first metal powder to form first bumps. A second metal powder is then deposited on the first bumps, and melted to form second bumps on the first bumps. A masking plate is disposed over the substrate to select the portions of the metal powders that are melted and the metal powders are melted via an irradiation beam. The multi-layer bump is formed without the need for any wet chemicals.

Owner:NXP USA INC

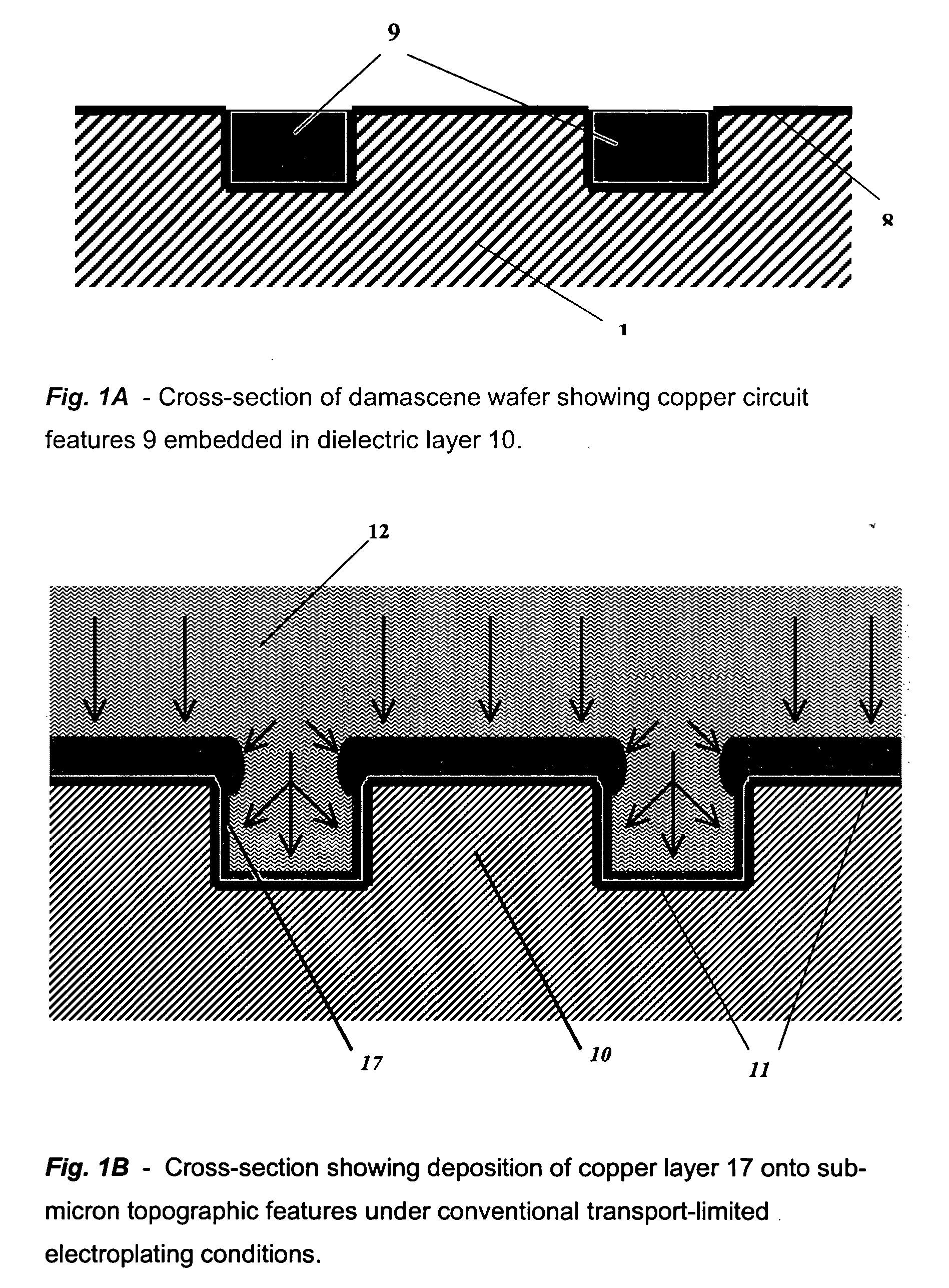

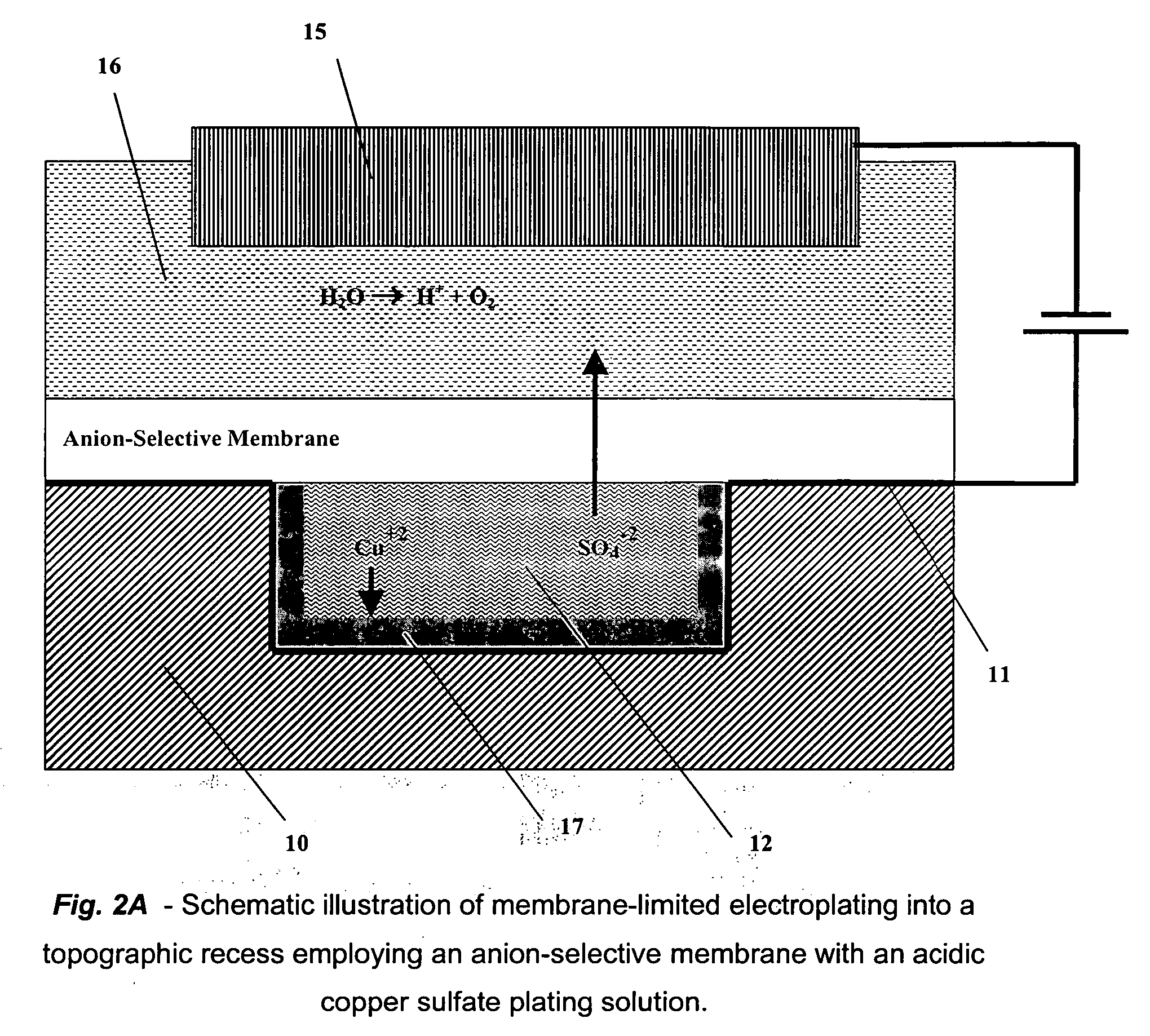

Membrane-limited selective electroplating of a conductive surface

This invention relates to processes and apparati for selectively electroplating a metal layer or layers into recessed topographic features on a conductive surface. The processes and apparati of the invention are useful for fabricating metal circuit patterns, for example for creating copper interconnects between integrated circuit elements embedded in a thin layer of dielectric material on the surface of a semiconductor wafer.

Owner:EI DU PONT DE NEMOURS & CO

Method of mounting conductive ball and conductive ball mounting apparatus

ActiveUS20090072011A1Improve reliabilityEfficient removalSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

A method of mounting a conductive ball according to the present invention includes the steps of, disposing a mask on a substrate including connection pads, the mask having opening portions corresponding to the connection pad, supplying conductive balls on the mask, arranging the conductive balls on the connection pad of the substrate through the opening portions of the mask by moving the conductive balls to one end side of the mask by ball moving member (a brush), and removing excess conductive balls remaining on a region of the mask where the opening portions are provided, by bonding the excess conductive balls to a ball removal film (adhesive film).

Owner:SHINKO ELECTRIC IND CO LTD

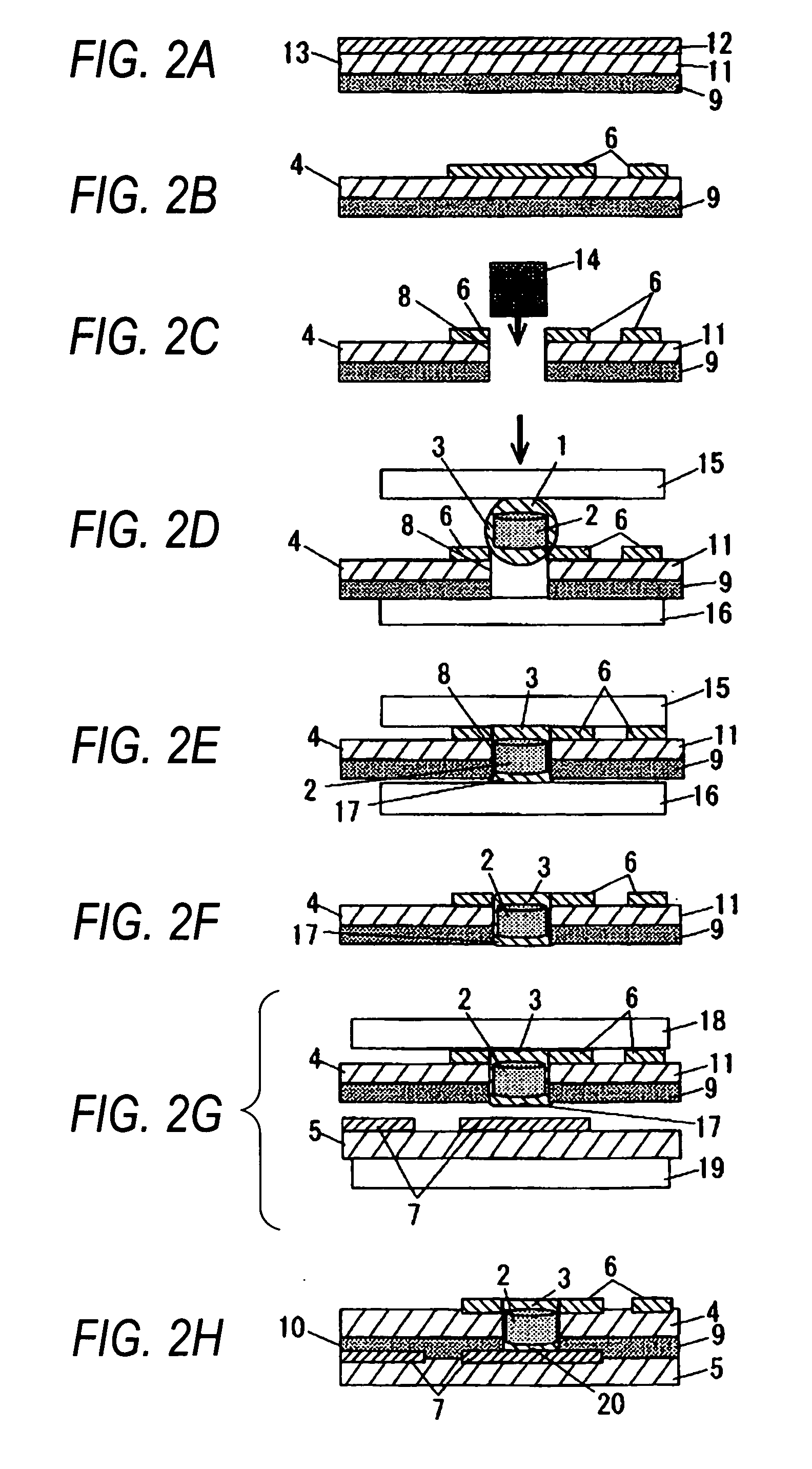

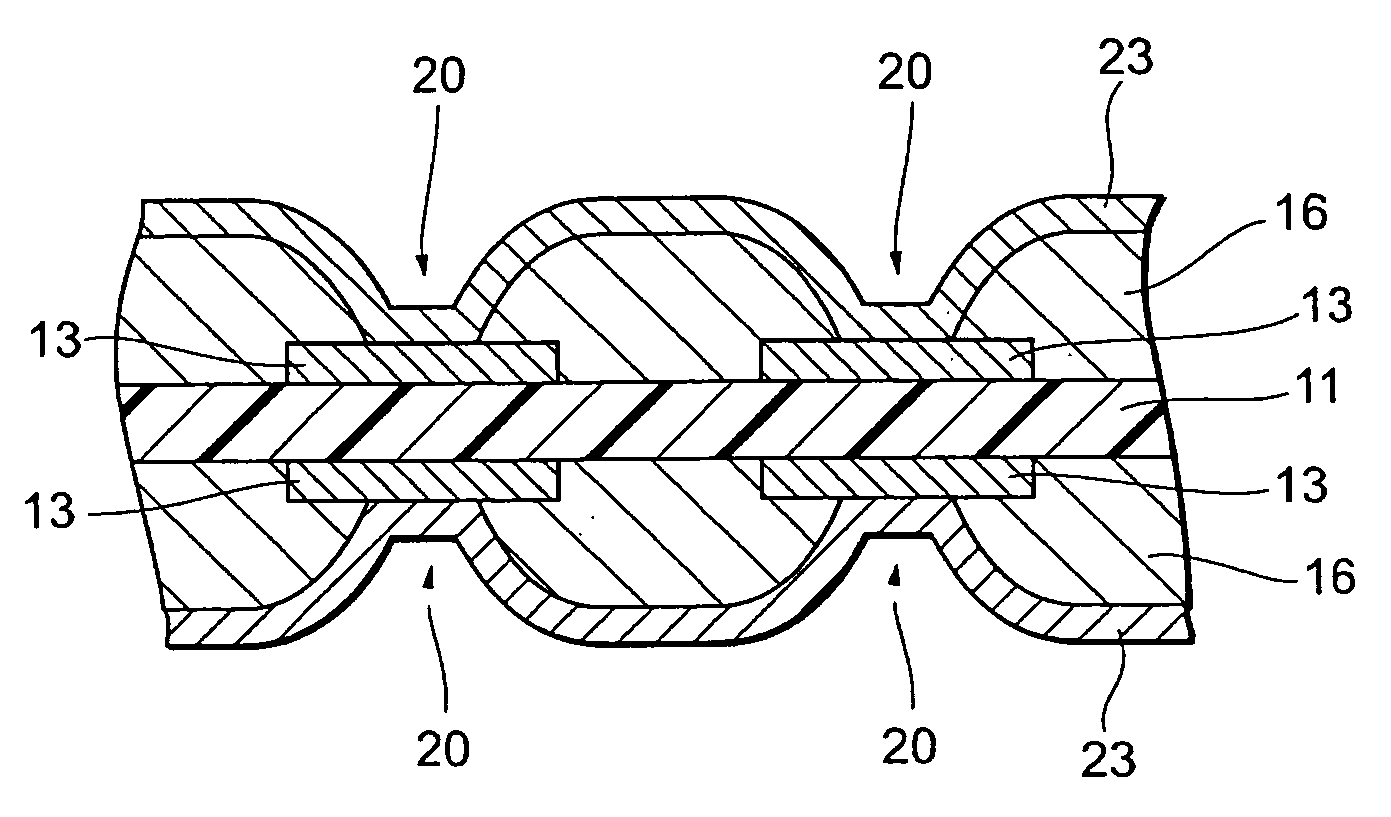

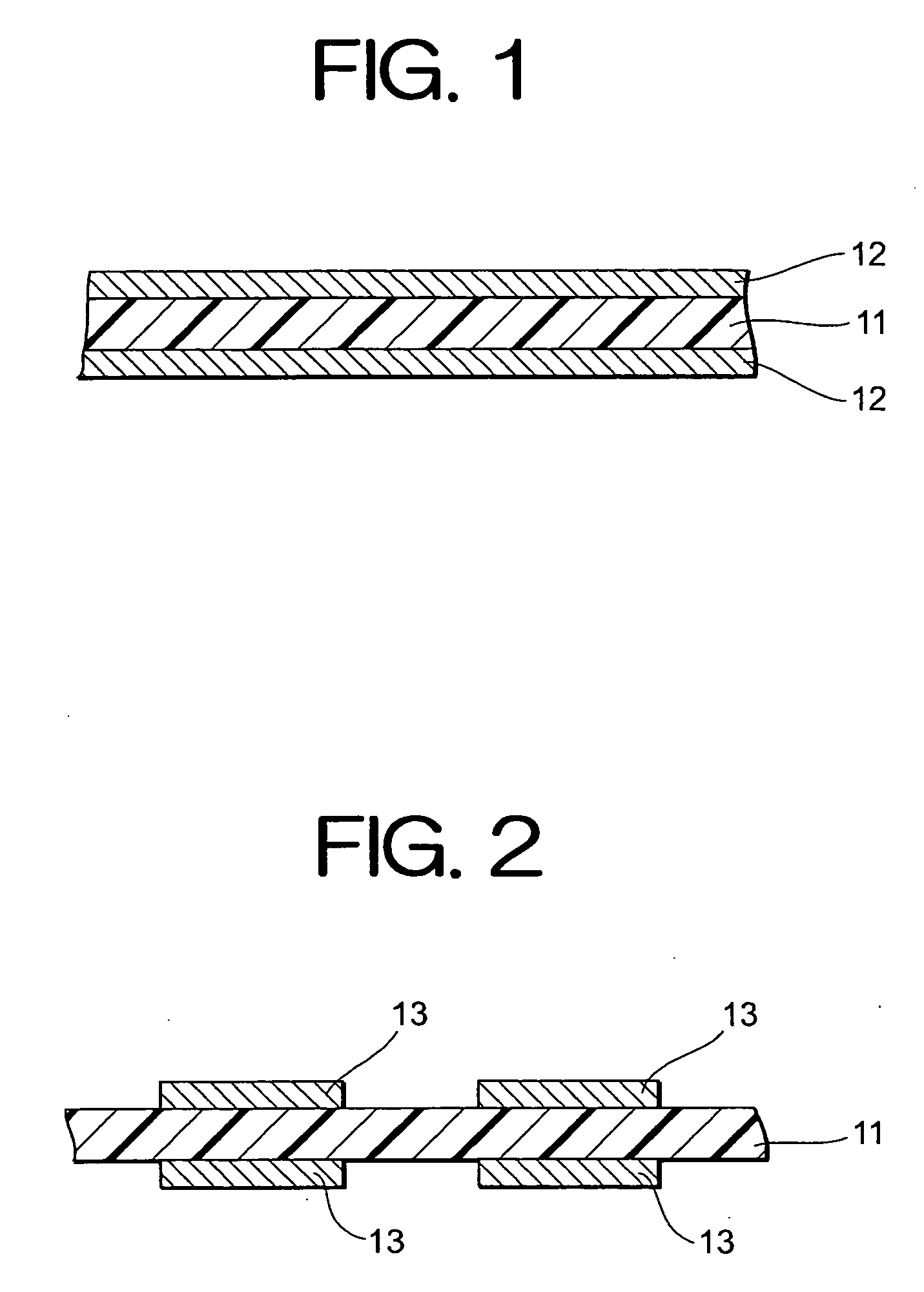

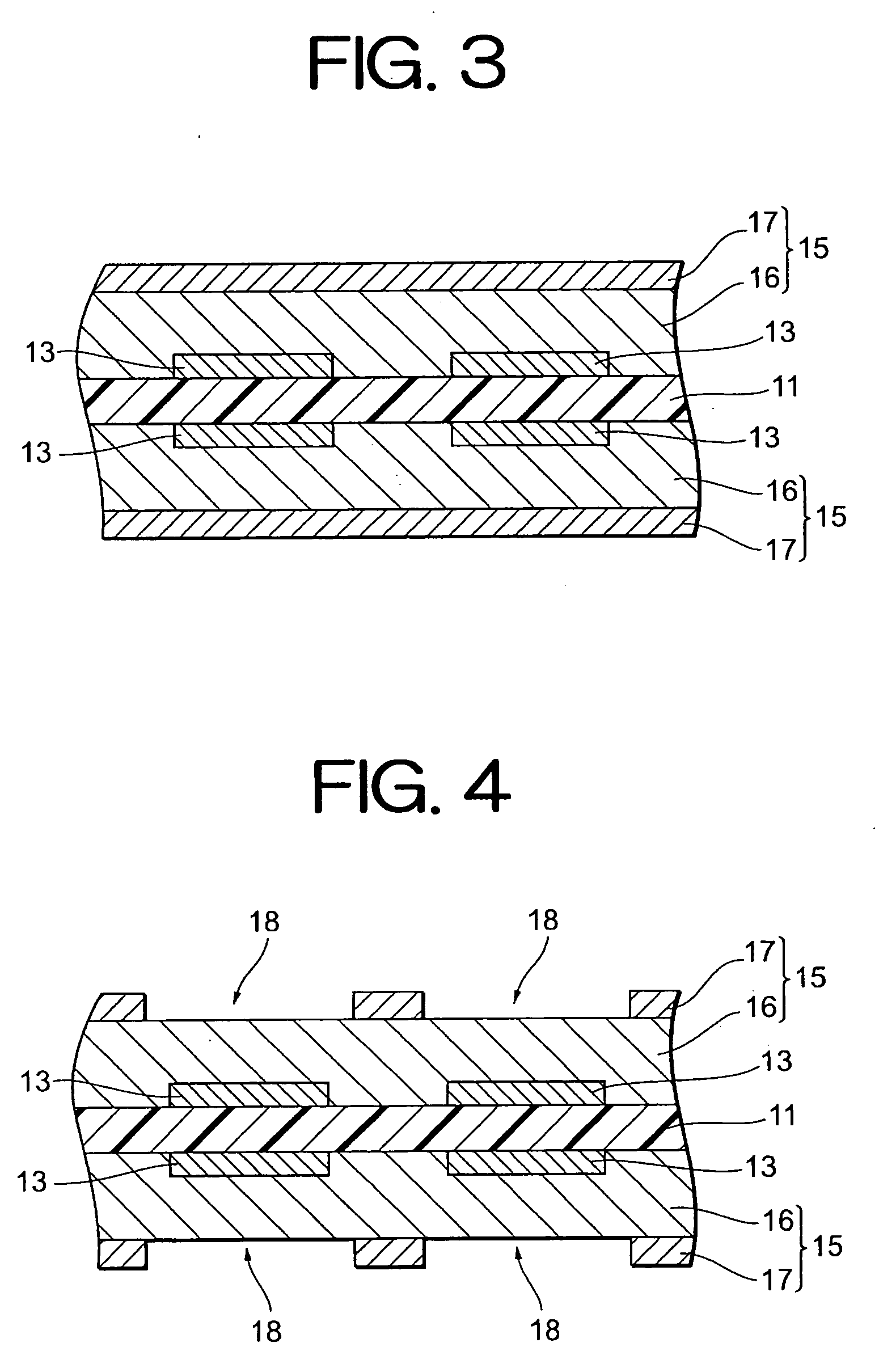

Printed wiring board and manufacturing method therefor

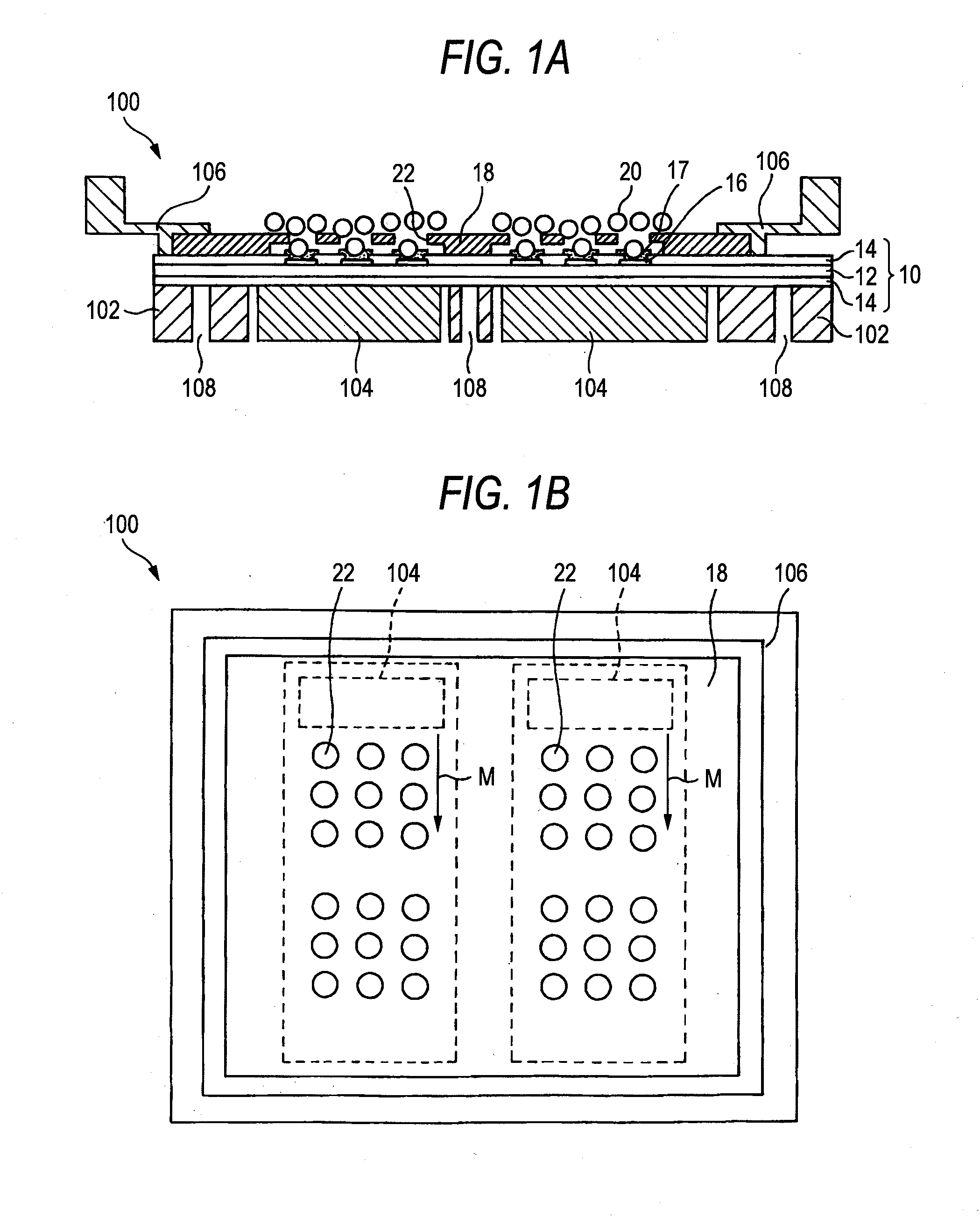

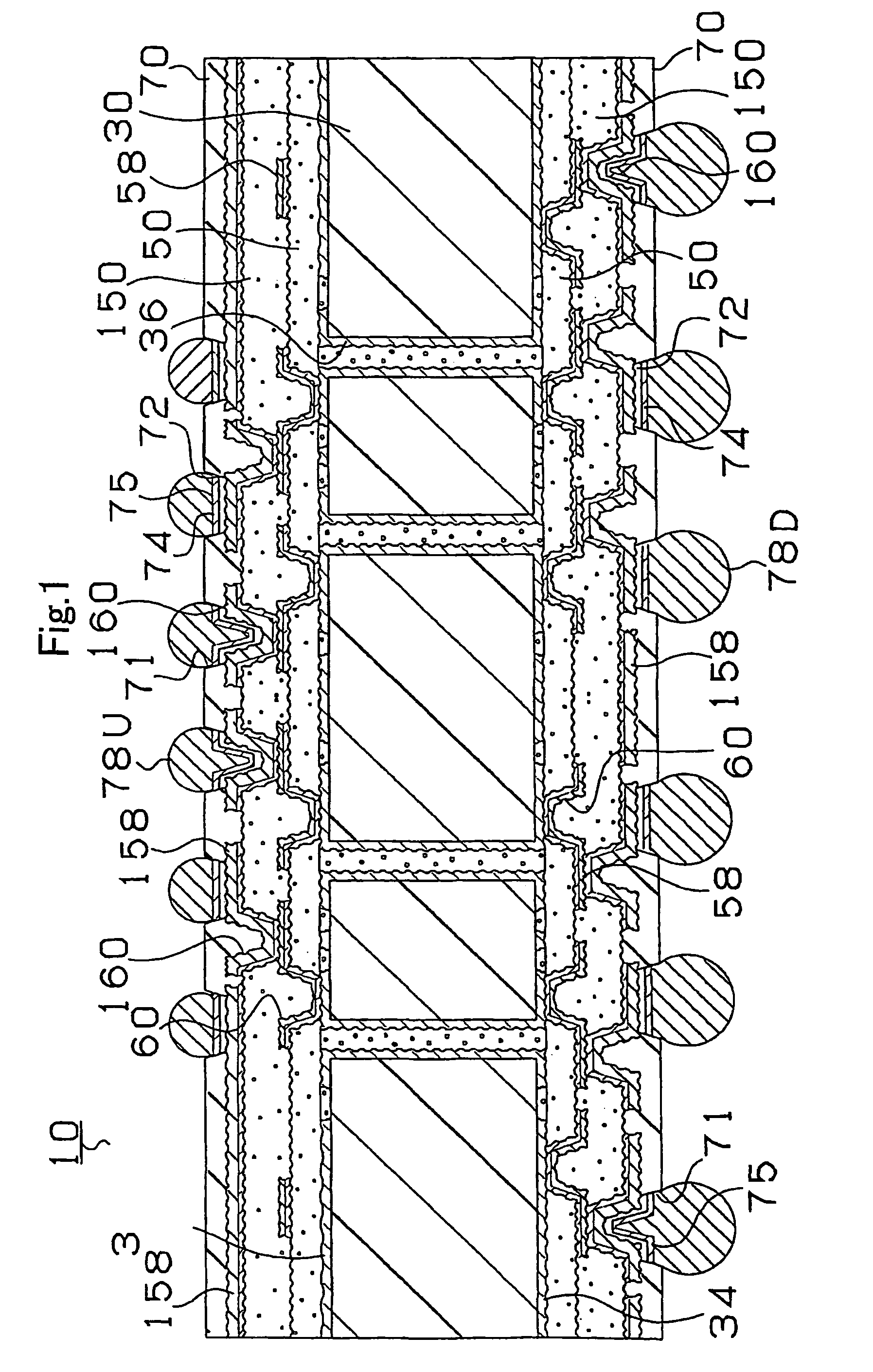

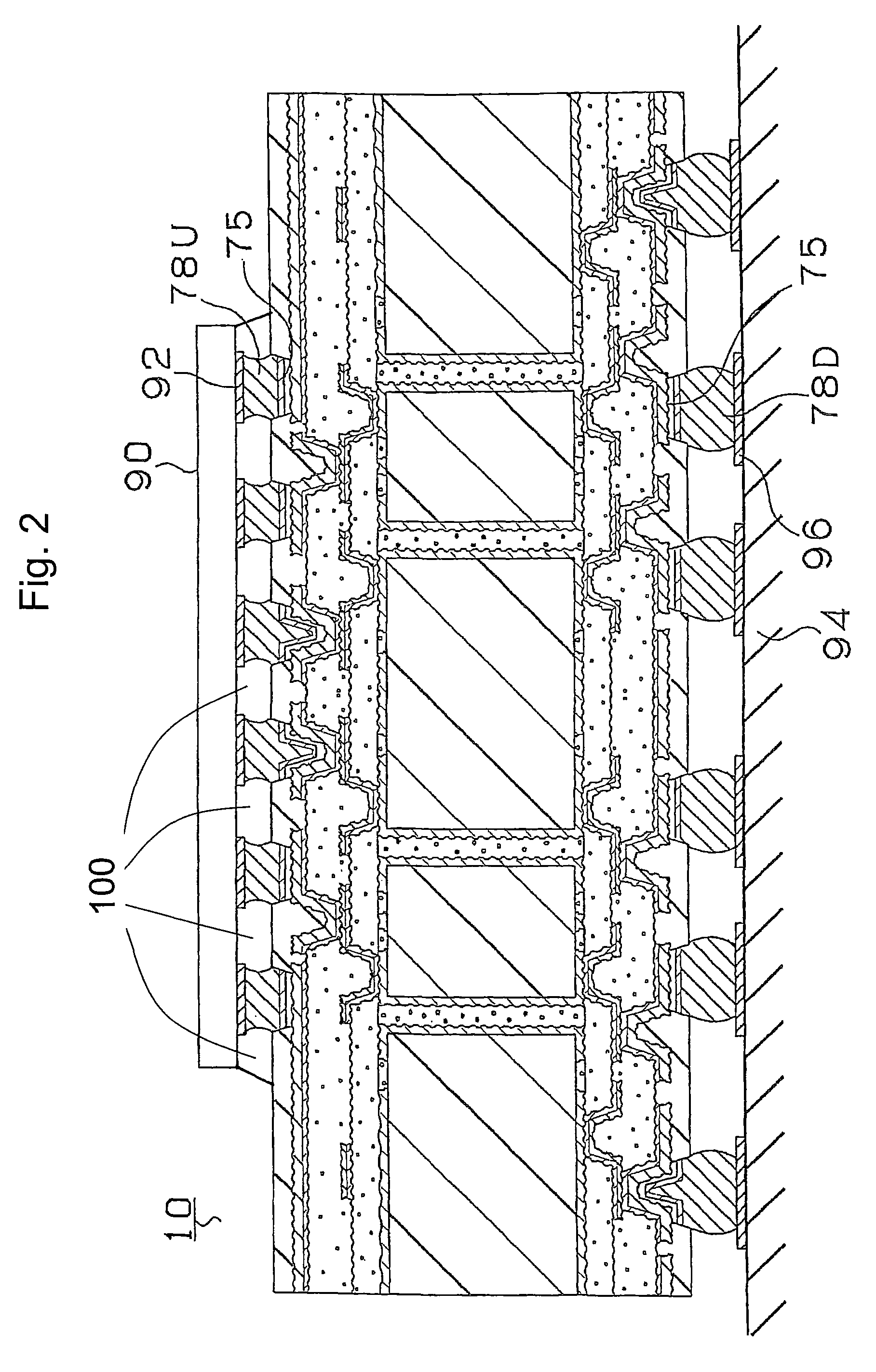

ActiveUS20090211799A1Improve connection reliabilityHigh densityDecorative surface effectsPrinted circuit aspectsElectrical conductorInsulation layer

The present invention provides a printed wiring board which can prevent a plating failure in a connection hole such as a via to be formed in the printed wiring board, thereby can enhance the connection reliability and a manufacturing method therefor. The printed wiring board 100 includes a thermosetting resin sheet 16 (insulation layer) having a via hole 20 (through hole) constituted by inner wall parts having different taper angles from each other, a copper foil 17 (conductor layer) provided on the thermosetting resin sheet 16, and a wiring pattern 13 (wiring layer) which is provided so as to be exposed from the via hole 20 and is electrically connected with the copper foil 17 through the via hole 20.

Owner:TDK CORPARATION

Popular searches

Printed electric component incorporation Electrical connection printed elements Non-metallic protective coating application Semiconductor devices Electrically conductive connections Stacked resist layers Metal working apparatus Welding apparatus Solder feeding devices Welding/cutting media/materials

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com