Patents

Literature

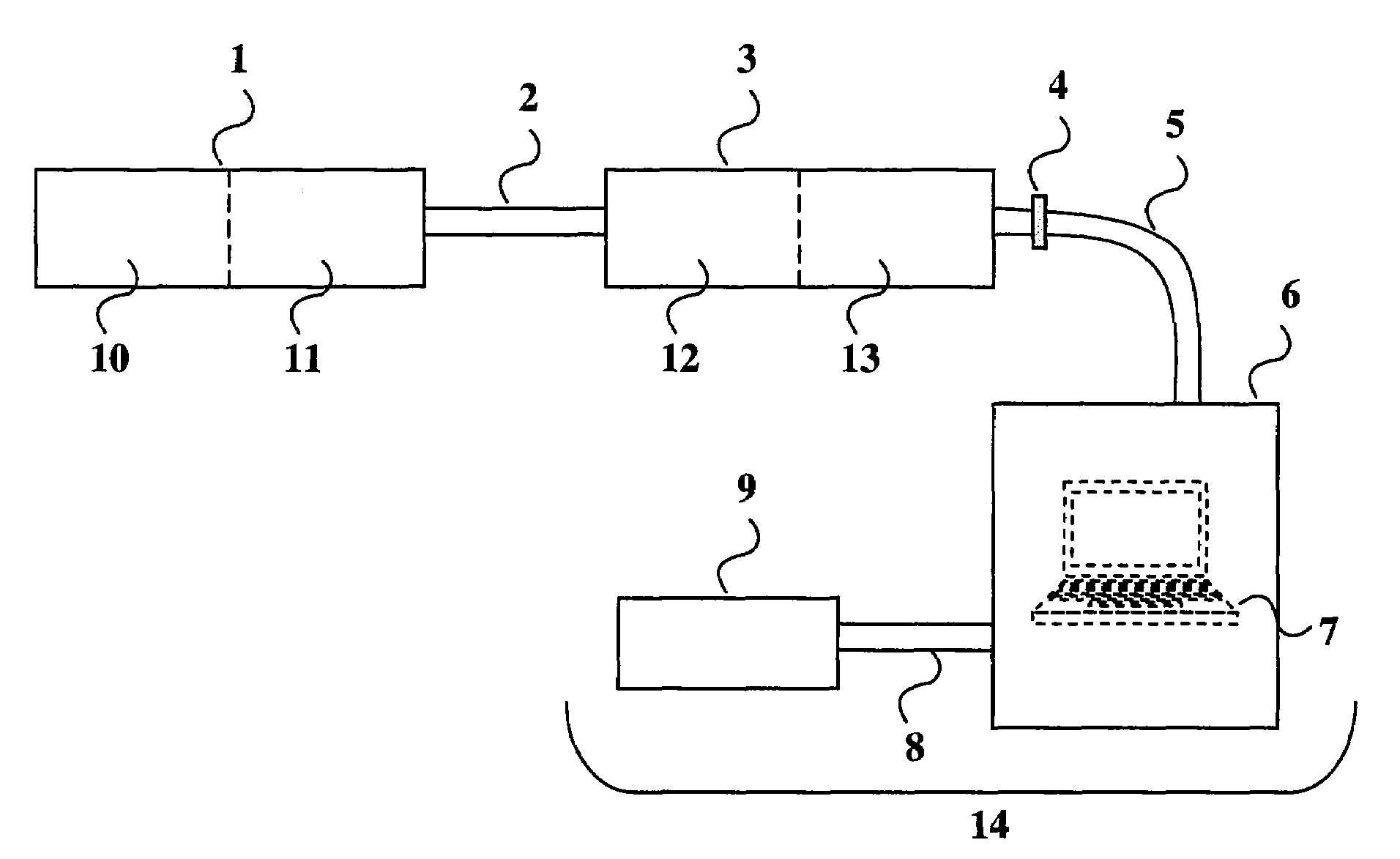

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70 results about "Parylene coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

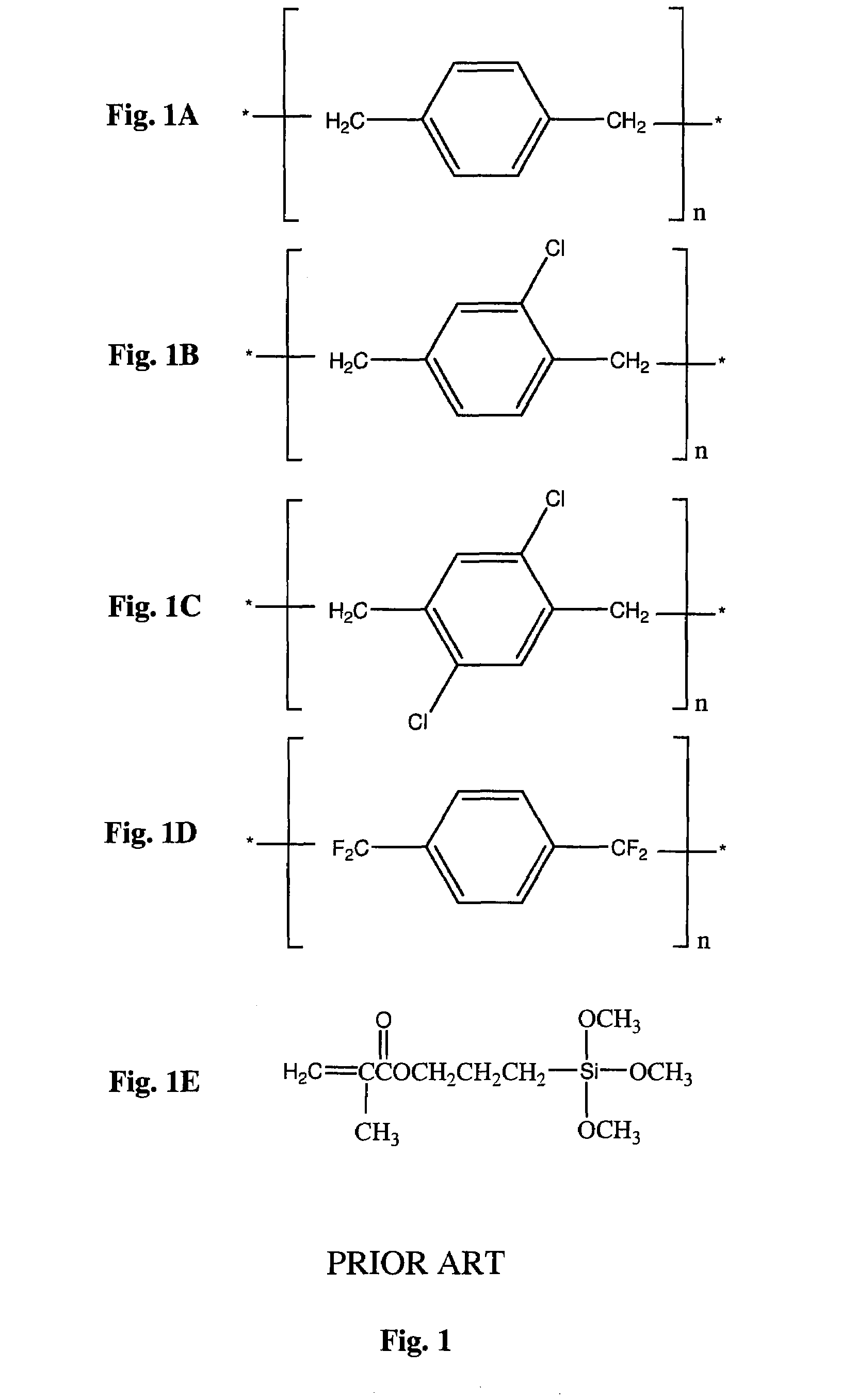

Parylene has become the protective coating of choice for challenging electronics, aerospace and medical applications. Conformal coatings are generally liquid in nature, while Parylene is formed on surfaces from a high purity powder known as a dimer with no liquid stage.

Sutures and surgical staples for anastamoses, wound closures, and surgical closures

InactiveUS8016881B2Improve featuresControlled release rateSuture equipmentsStentsSurgical stapleMicroparticle

The invention relates to sutures and surgical staples useful in anastomoses. Various aspects of the invention include wound closure devices that use amphiphilic copolymer or parylene coatings to control the release rate of an agent, such as a drug or a biological material, polymerizing a solution containing monomers and the agent to form a coating, using multiple cycles of swelling a polymer with a solvent-agent solution to increase loading, microparticles carrying the agent, biodegradable surgical articles with amphiphilic copolymer coatings, and sutures or surgical staples the deliver a drug selected from the group consisting of triazolopyrimidine, paclitaxol, sirolimus, derivatives thereof, and analogs thereof to a wound site.

Owner:MIRUS LLC

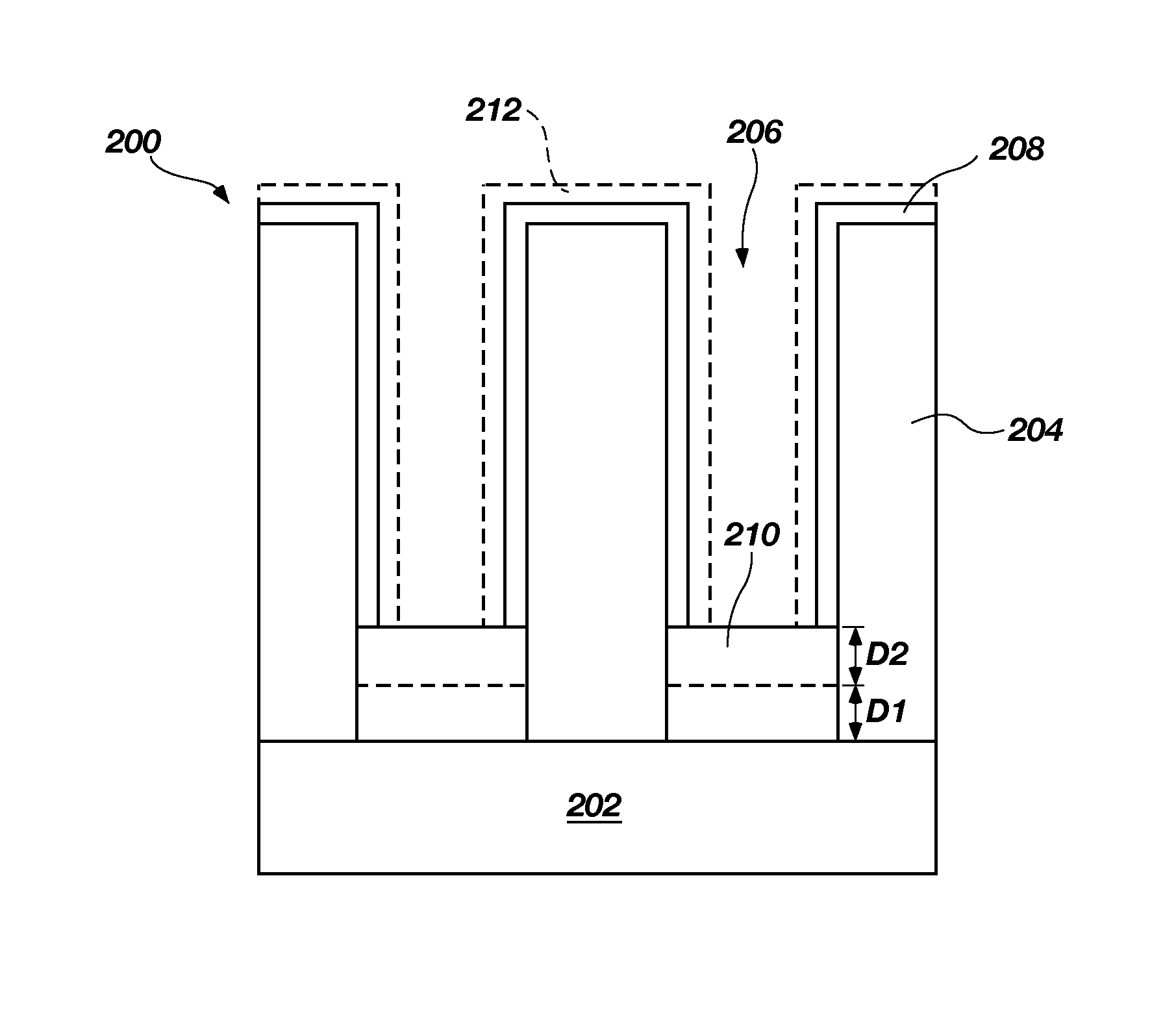

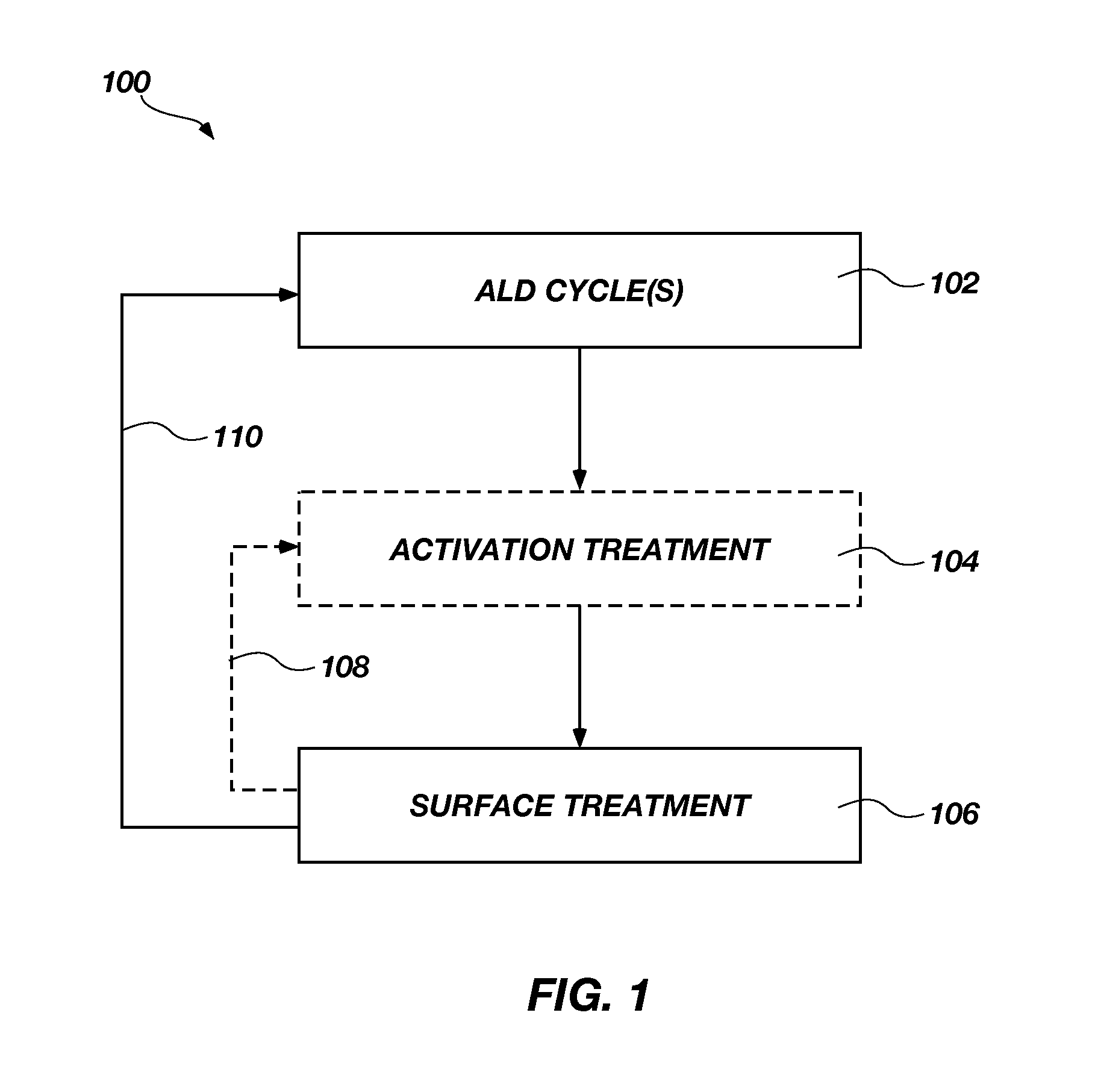

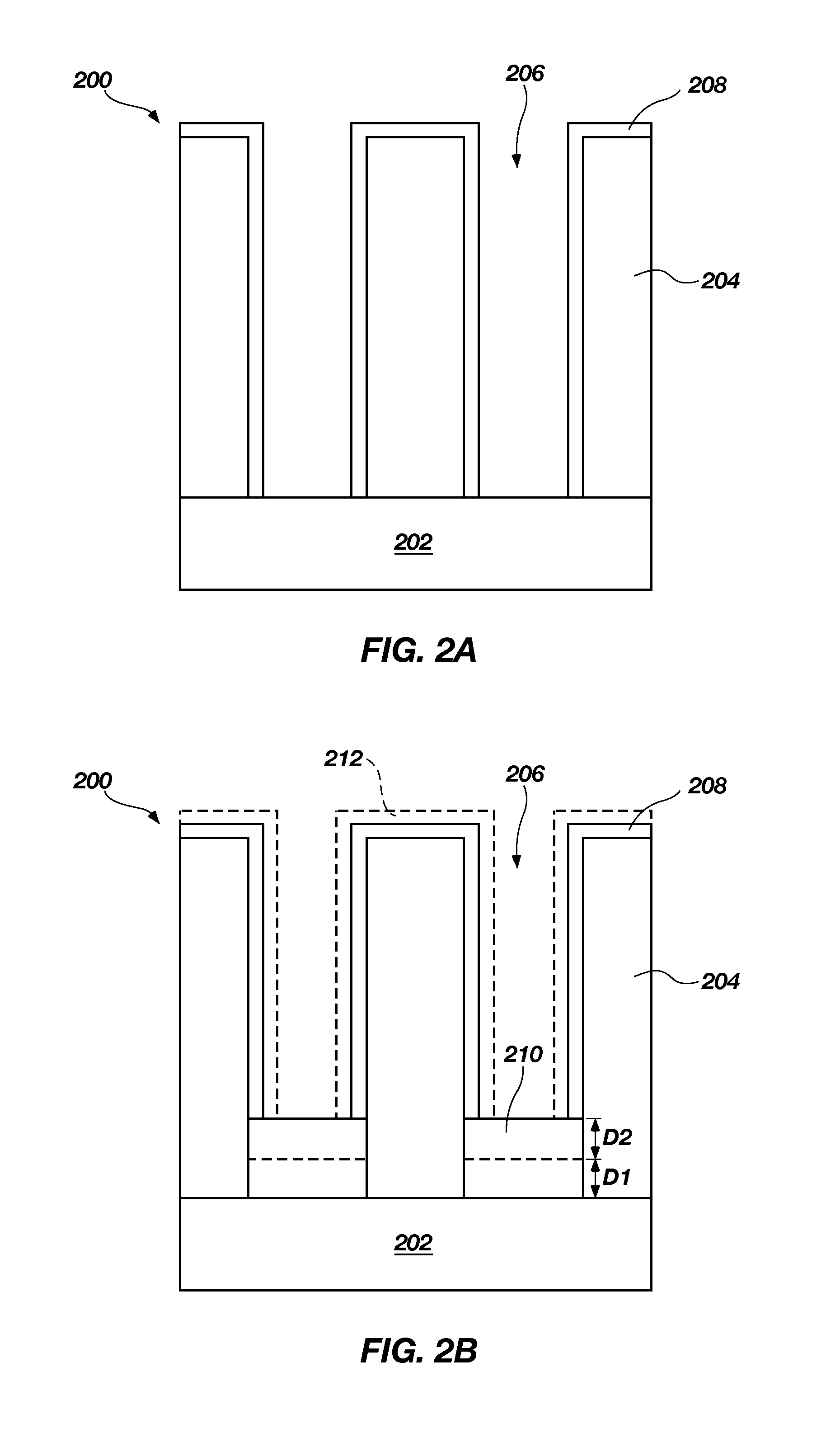

Methods of selectively forming a material using parylene coating

ActiveUS8945305B2Polycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor structureSelective deposition

Methods for depositing a material, such as a metal or a transition metal oxide, using an ALD (atomic layer deposition) process and resulting structures are disclosed. Such methods include treating a surface of a semiconductor structure periodically throughout the ALD process to regenerate a blocking material or to coat a blocking material that enables selective deposition of the material on a surface of a substrate. The surface treatment may reactivate a surface of the substrate toward the blocking material, may restore the blocking material after degradation occurs during the ALD process, and / or may coat the blocking material to prevent further degradation during the ALD process. For example, the surface treatment may be applied after performing one or more ALD cycles. Accordingly, the presently disclosed methods enable in situ restoration of blocking materials in ALD process that are generally incompatible with the blocking material and also enables selective deposition in recessed structures.

Owner:MICRON TECH INC

Sutures and surgical staples for anastamoses, wound closures, and surgical closures

ActiveUS20050038472A1Good storage stabilityRemove moistureSuture equipmentsPowder deliverySurgical stapleMicroparticle

The invention relates to sutures and surgical staples useful in anastomoses. Various aspects of the invention include wound closure devices that use amphiphilic copolymer or parylene coatings to control the release rate of an agent, such as a drug or a biological material, polymerizing a solution containing monomers and the agent to form a coating, using multiple cycles of swelling a polymer with a solvent-agent solution to increase loading, microparticles carrying the agent, biodegradable surgical articles with amphiphilic copolymer coatings, and sutures or surgical staples the deliver a drug selected from the group consisting of triazolopyrimidine, paclitaxol, sirolimus, derivatives thereof, and analogs thereof to a wound site.

Owner:MIRUS LLC

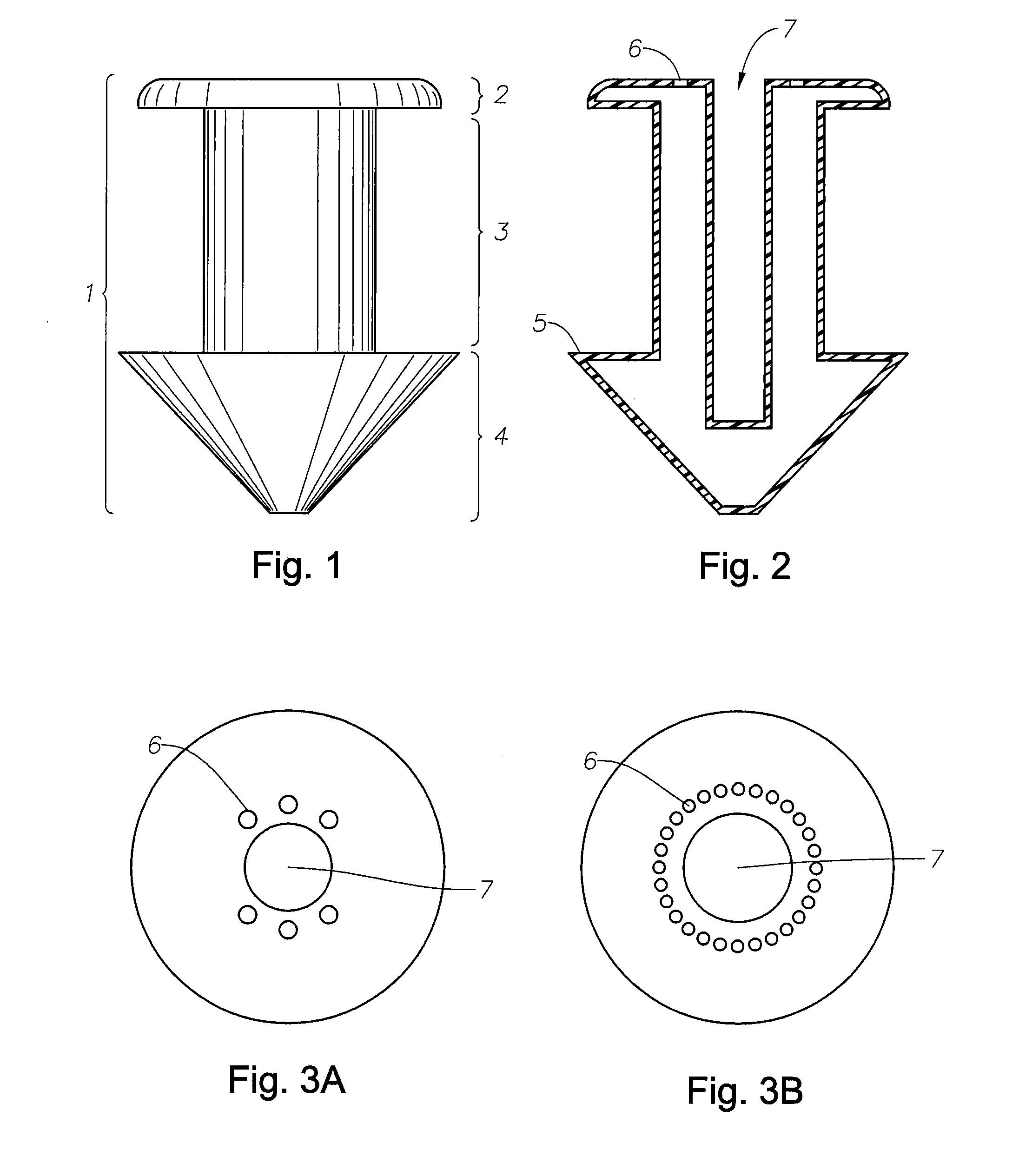

Punctal Plugs and Methods of Delivering Therapeutic Agents

ActiveUS20080181930A1High retention rateIncrease stiffnessBiocideSenses disorderCollagen Punctal PlugsParylene coating

The present invention concerns implantable ocular devices for the sustained release of medication to the eye, and methods for manufacturing and using such devices. In one embodiment, the present invention provides a device comprising: (a) a body comprising a matrix of a prostaglandin and a silicone; (b) a parylene coating on the outer surface of the body; and (c) one or more pores extending from the outer surface of the parylene coating to the outer surface of the body.

Owner:NOVARTIS AG

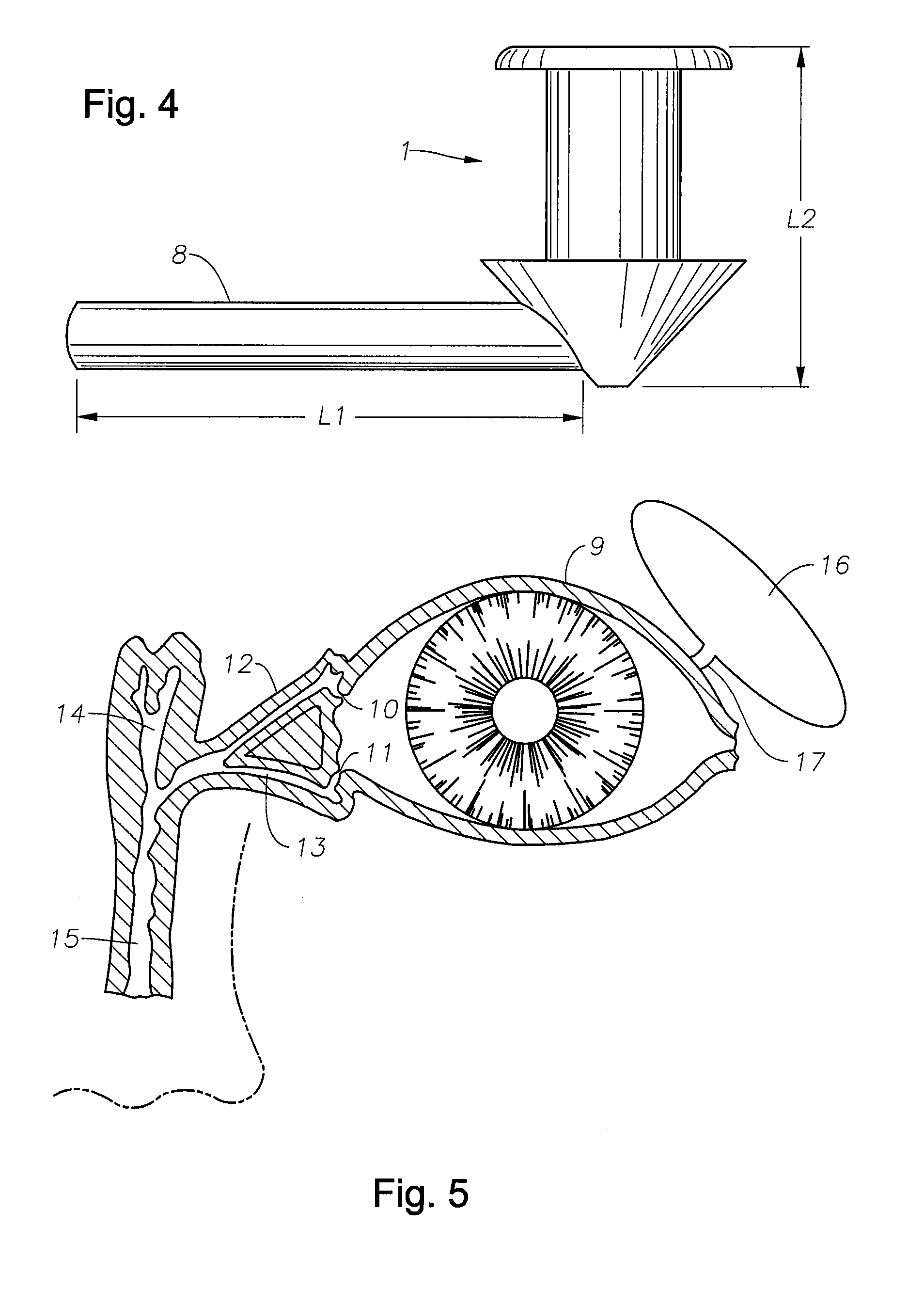

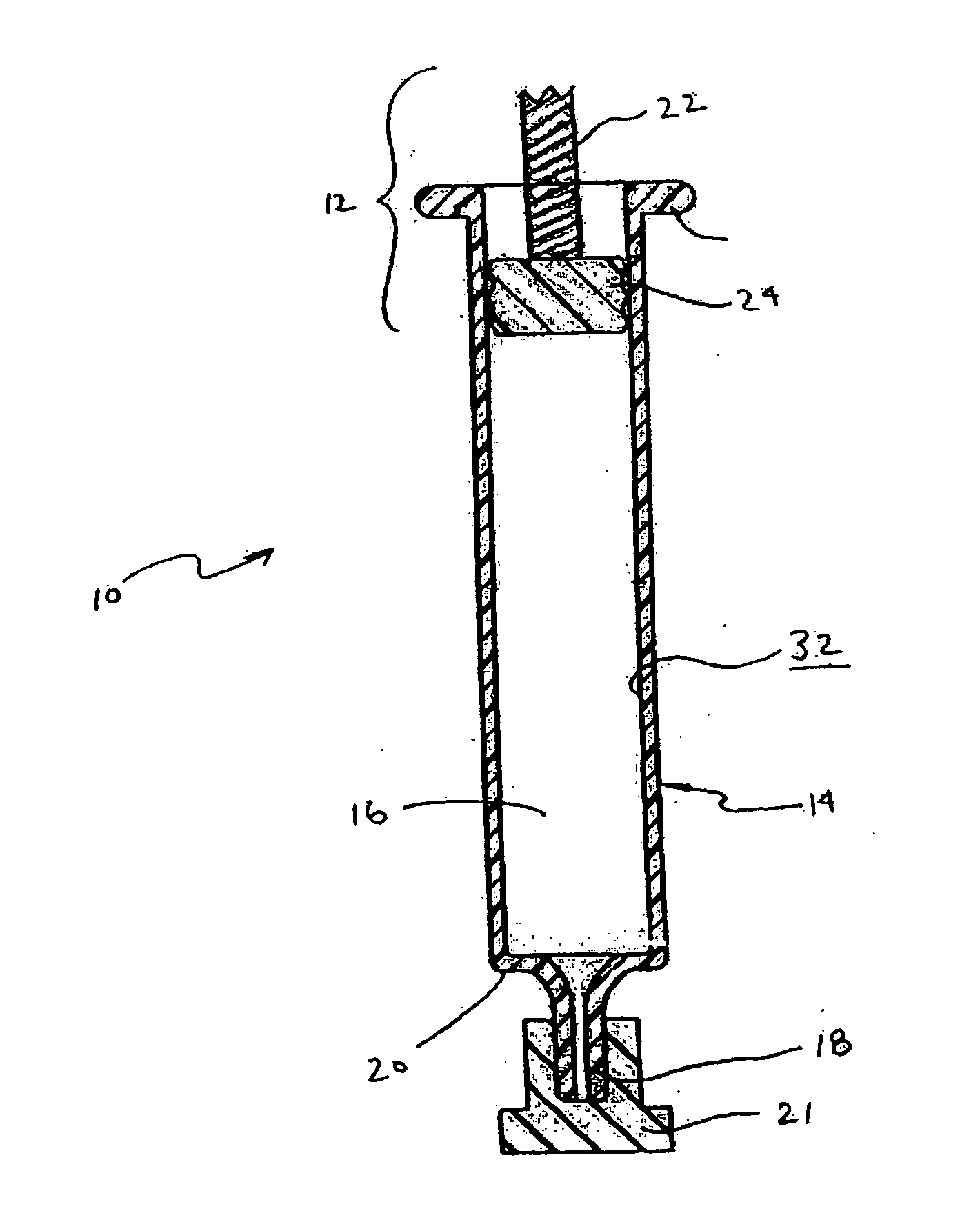

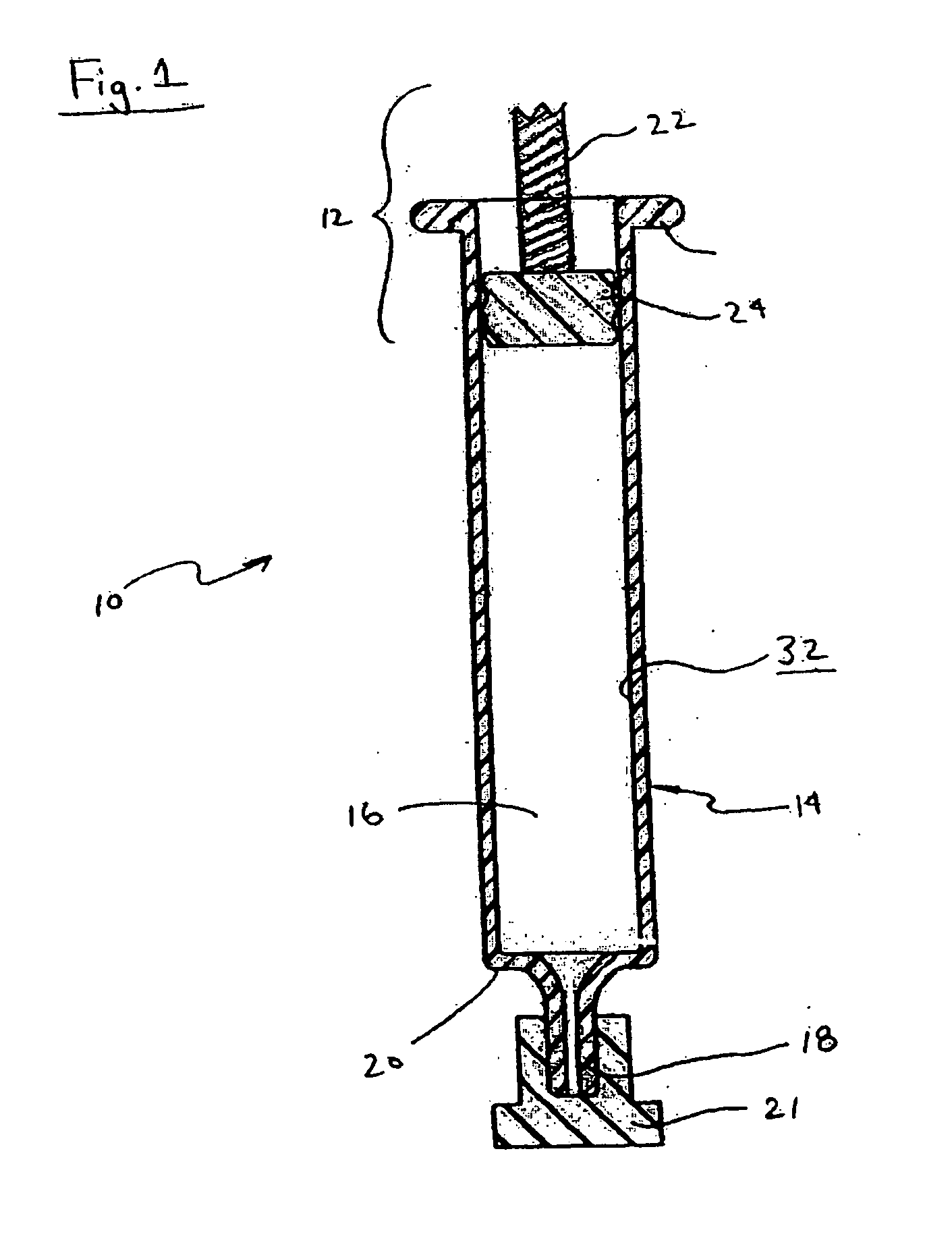

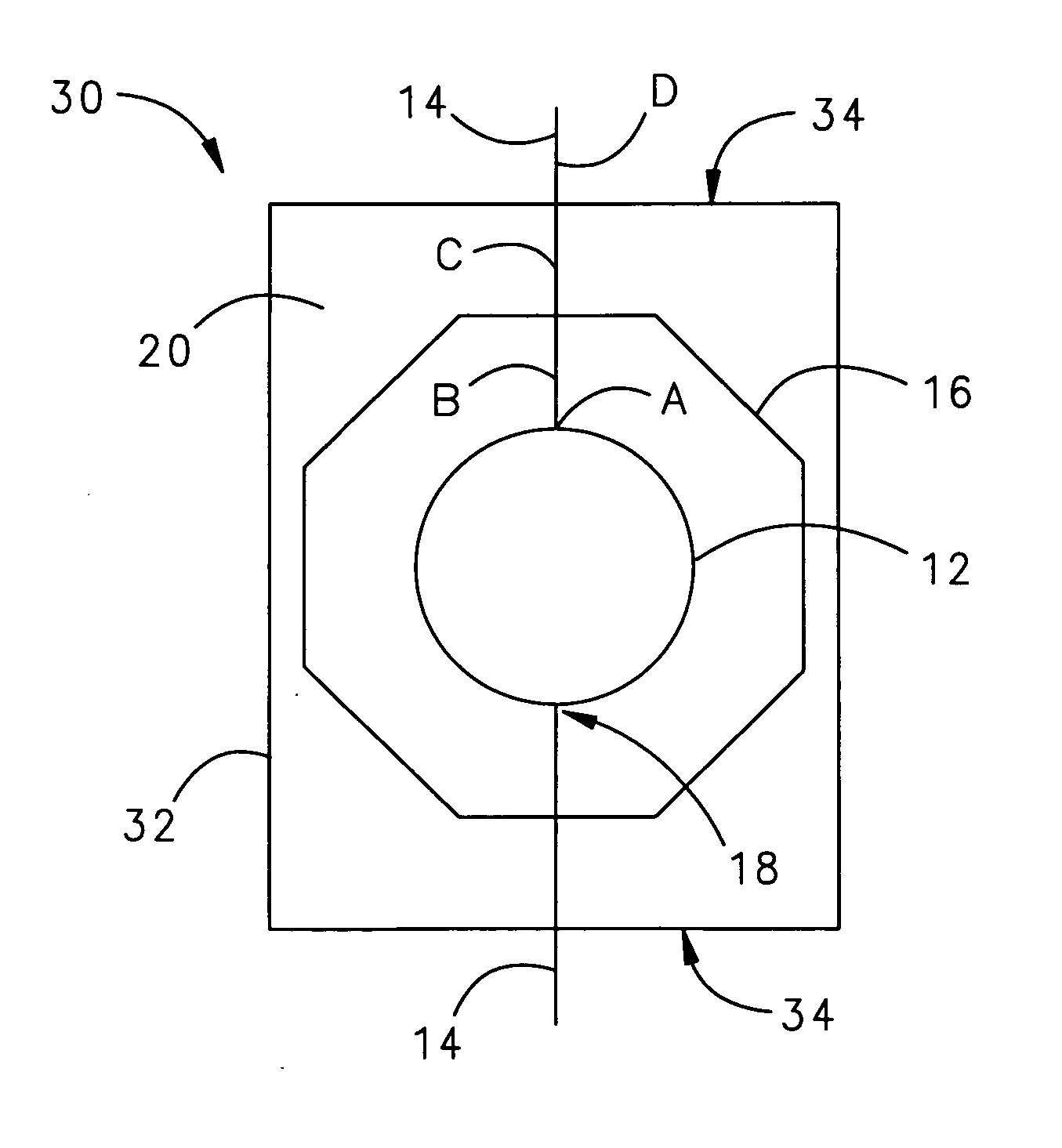

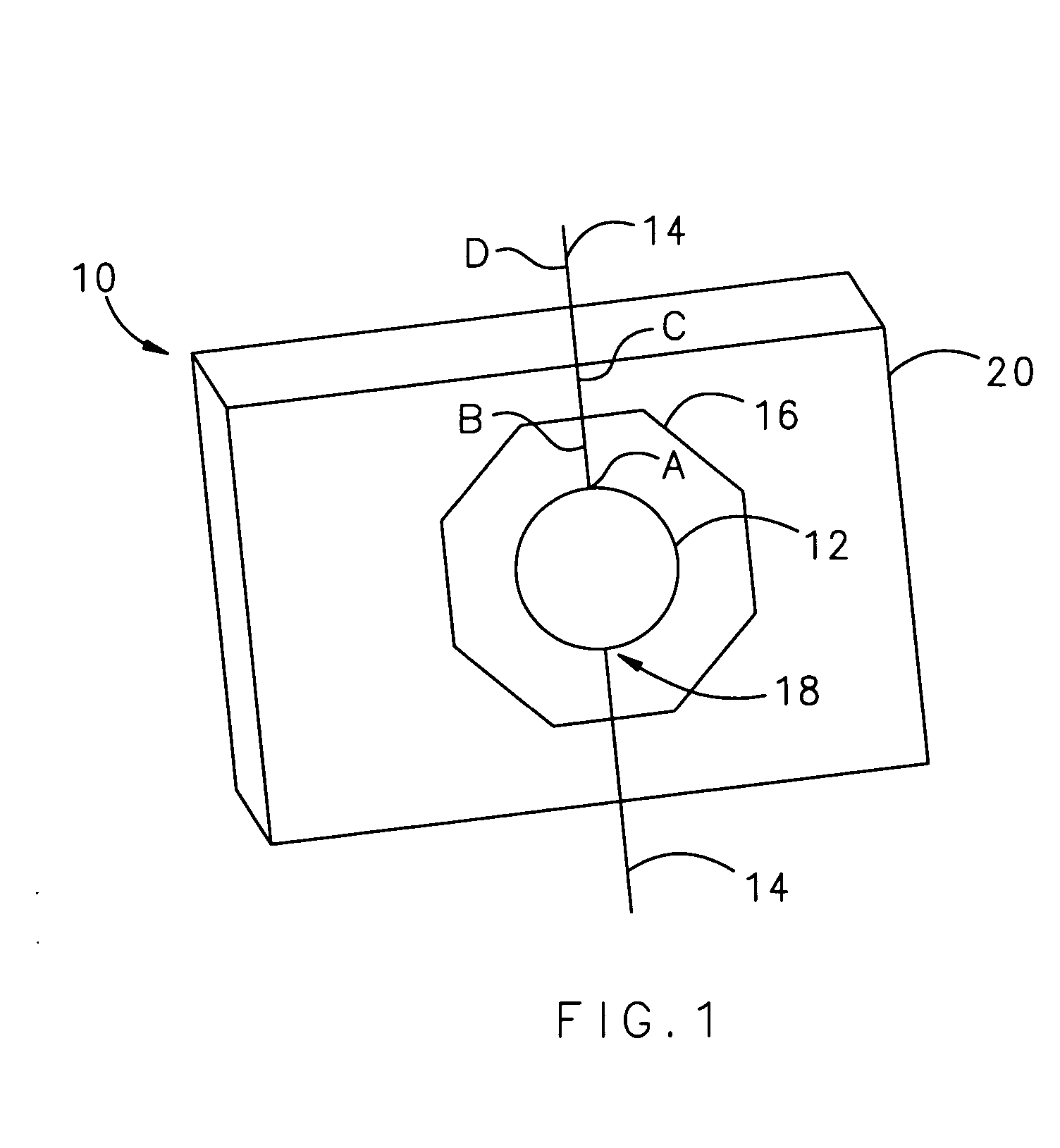

Piston assembly for syringe

InactiveUS20050010175A1Reduce connectionsReduce chanceIntravenous devicesEngineeringParylene coating

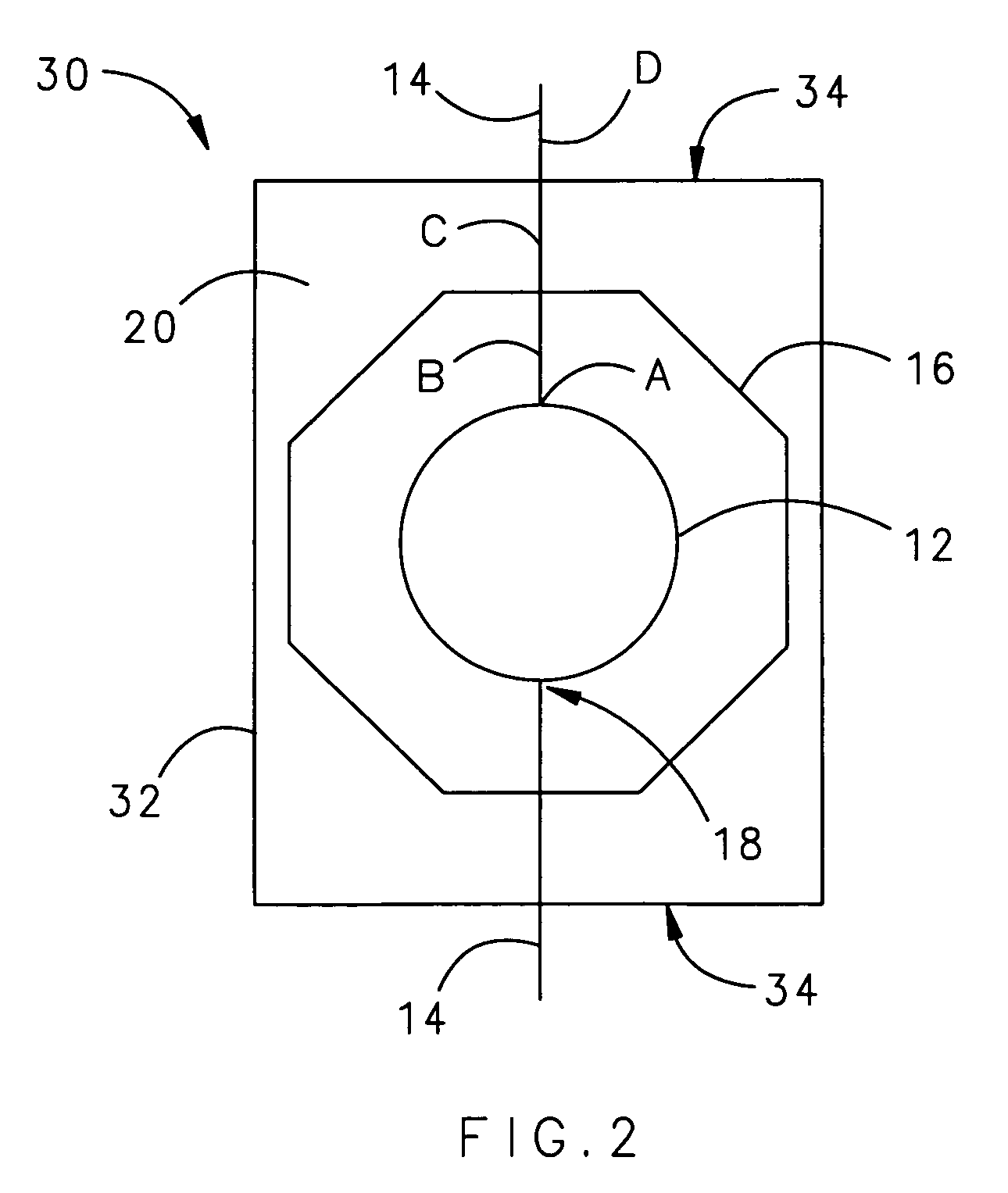

A piston assembly (10) for a flowable materials container having a barrel (14) defining a fluid containing chamber (16). The barrel (14) is made of a body of a cyclic olefin containing polymer or a bridged polycyclic olefin containing polymer. An elastomeric piston (24) is slidably attached to the barrel (14) and provides a seal of the chamber. The piston (24) has a parylene coating on an outer surface thereof to reduce the necessary break away force. A plunger (22) is also provided and has a second mating member (42) removably connecting the plunger to a first mating member (44) of the piston. The first mating member (44) has a series of threads having a major diameter and a minor diameter, and the second mating member (42) has a series of threads having a major diameter and a minor diameter. The major and minor diameters of the second mating members (42) is appreciably smaller than the major and minor diameters of the other of the first mating member (44) to provide ease of connection.

Owner:BAXTER INT INC

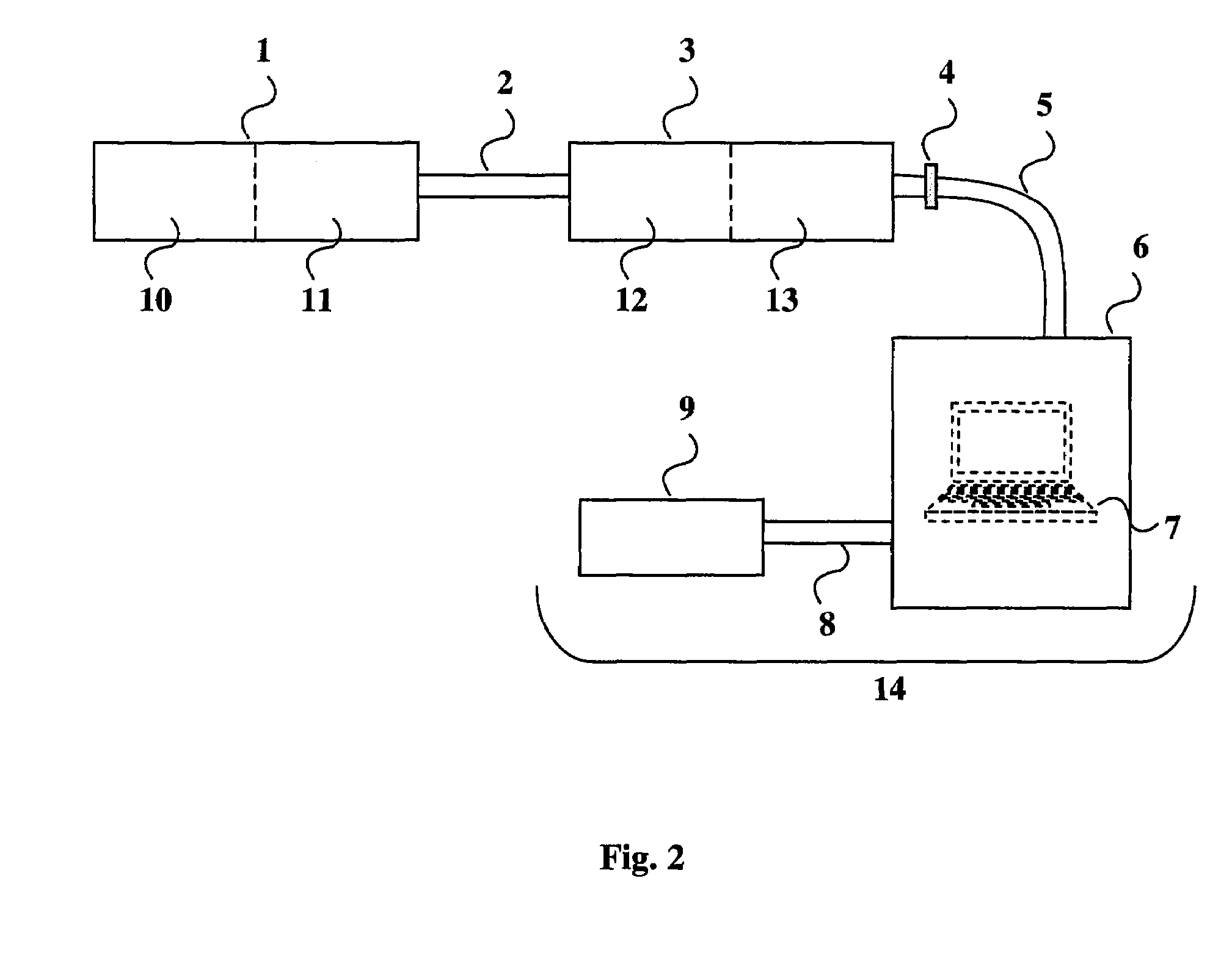

Method and apparatus to coat objects with parylene

InactiveUS20090263641A1Liquid surface applicatorsSynthetic resin layered productsGas phaseParylene coating

The present invention provides a novel method to apply Silquest to an object as a vapor, a related method to coat objects with Parylene and Silquest, and objects coated by these methods. The invention further provides an vapor deposition apparatus with multi-temperature zone furnaces that is useful for applying a Parylene coating to objects. The invention further provides objects coated with Silquest and polymers, including Parylene, where the objects are incompatible with immersion in water.

Owner:HZO INC

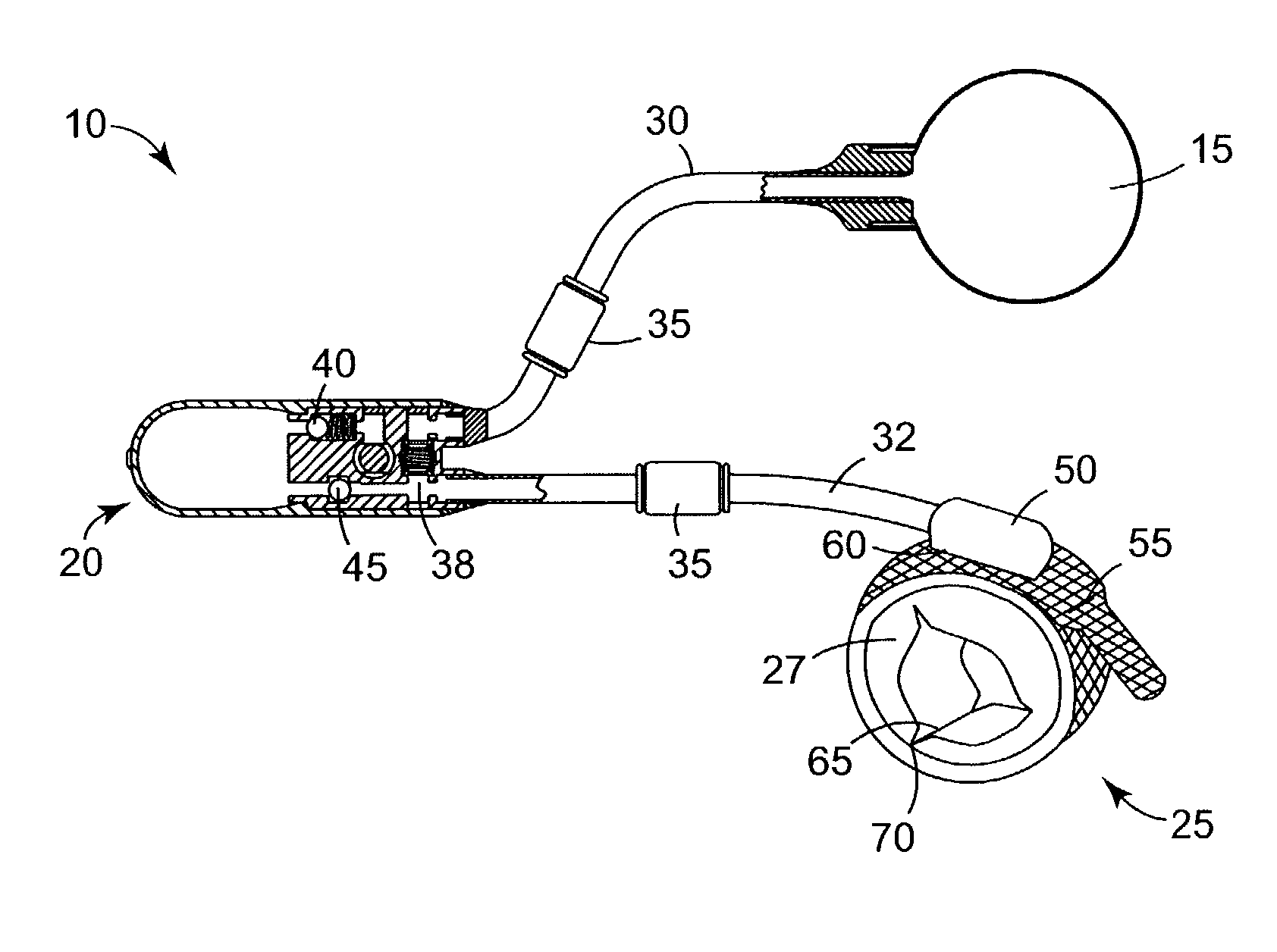

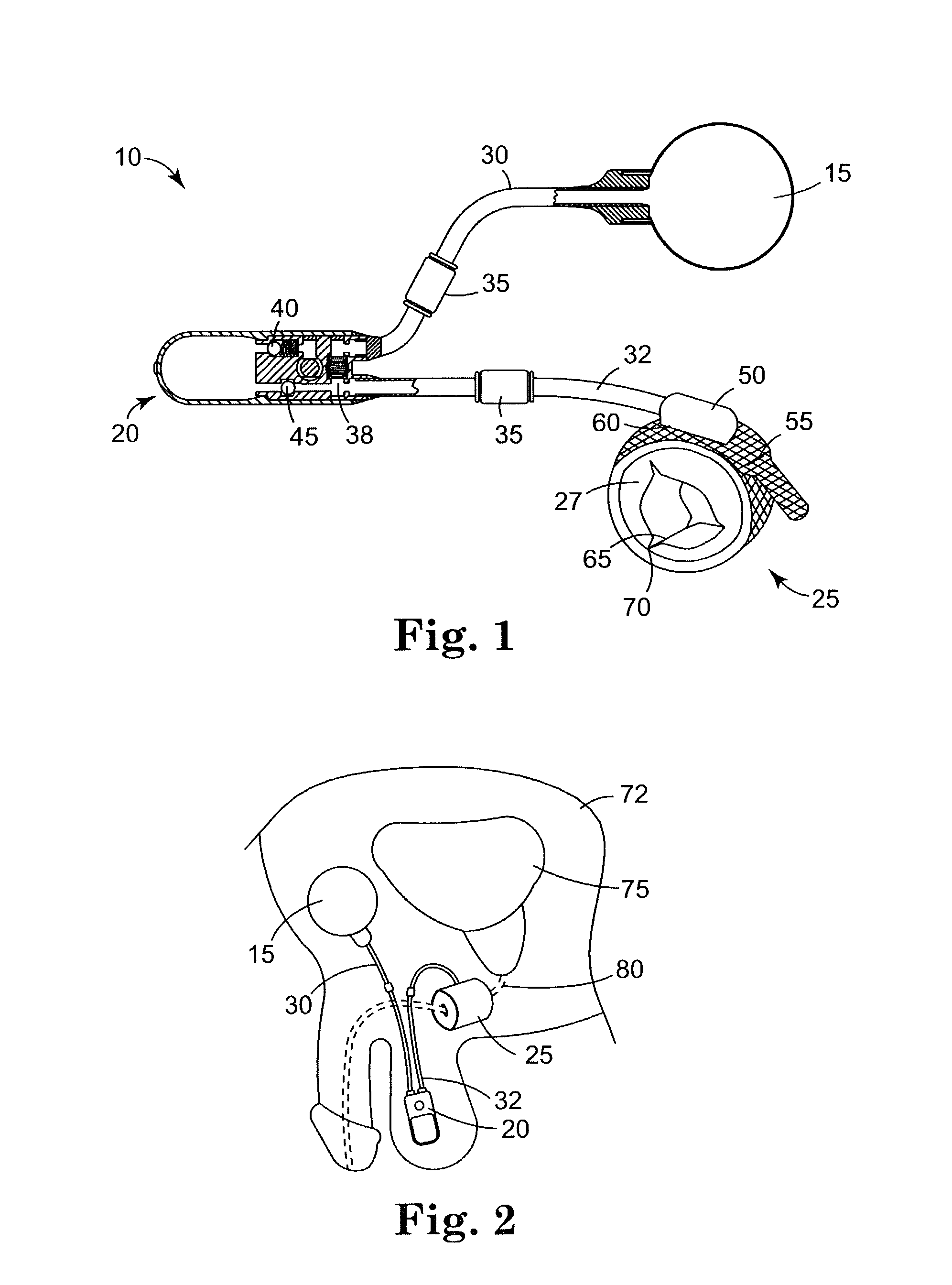

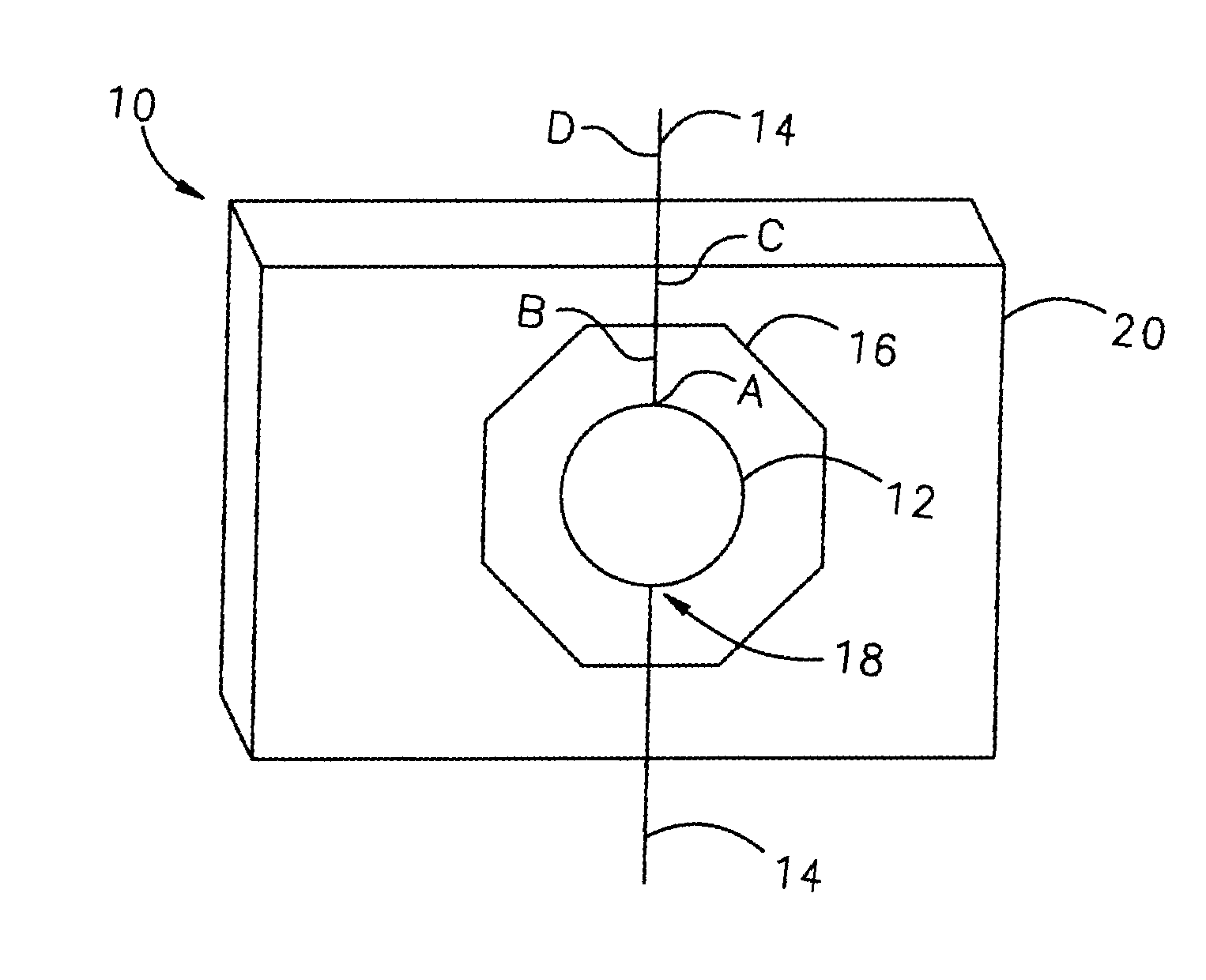

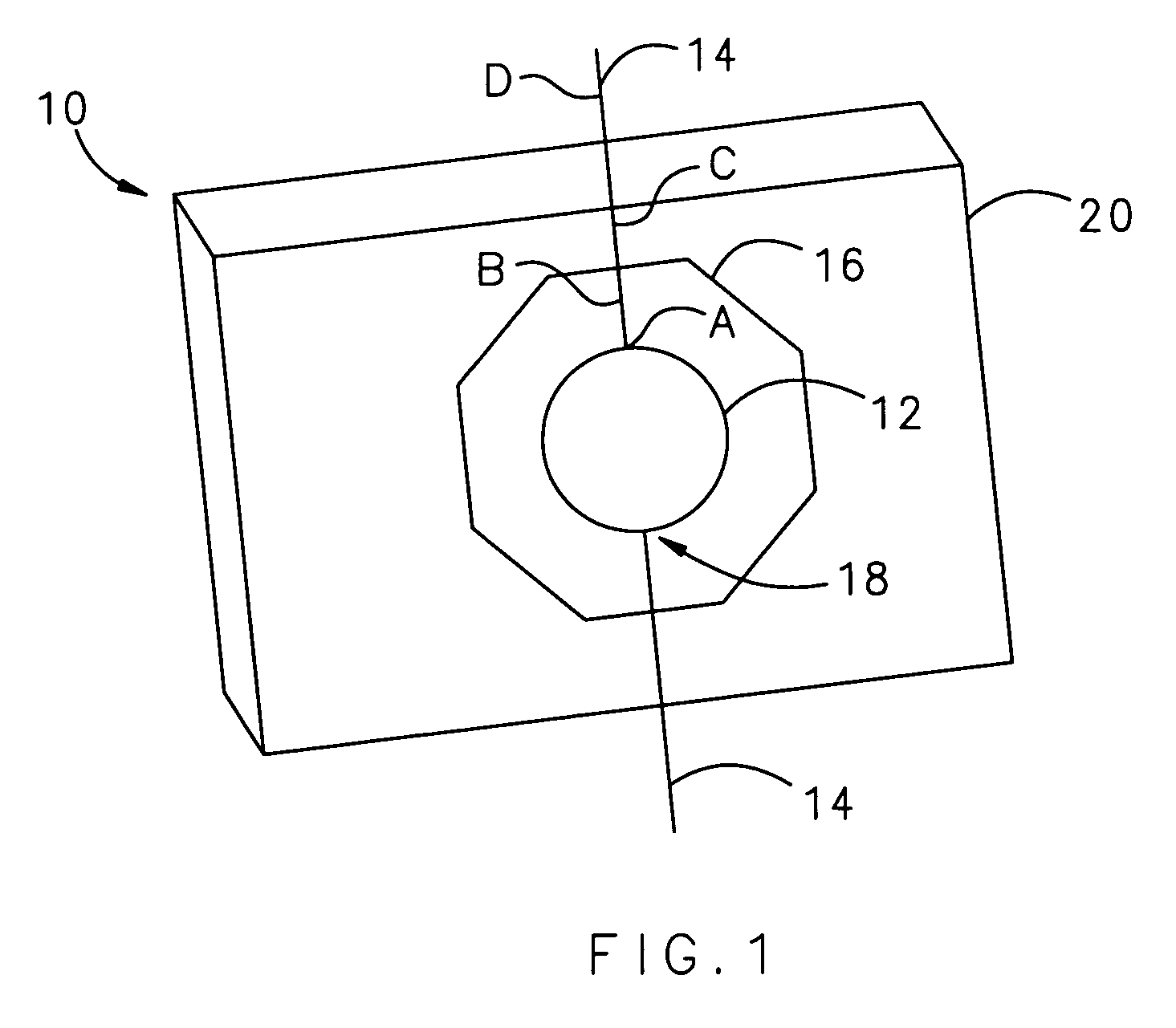

Parylene coated components for artificial sphincters

InactiveUS7011622B2Prevent and inhibit wearPrevent and inhibit and abrasionAnti-incontinence devicesSurgeryParylene coatingVacuum chamber

This invention provides an artificial sphincter including a component coated on at least one contacting surface with a polymeric material, the polymeric coating adapted to expand and return to an original configuration and to prevent or inhibit wear or abrasion of the contacting surface. The polymeric material is parylene in some embodiments. The component adapted for inflation and deflation may be a cuff formed from silicon and adapted to surround a urethra or a rectum. Also provided by the present invention is a method of depositing a coating to a surface of an inflatable component by providing a vacuum chamber system having an inner chamber positioned within an outer chamber. At least one coating material is introduced into at least one of the inner and outer chambers to deposit a coating onto an exposed surface of the component. This invention also provides methods of masking portions of surfaces of an inflatable component to prevent a coating from being deposited on the masked portion.

Owner:BOSTON SCI SCIMED INC

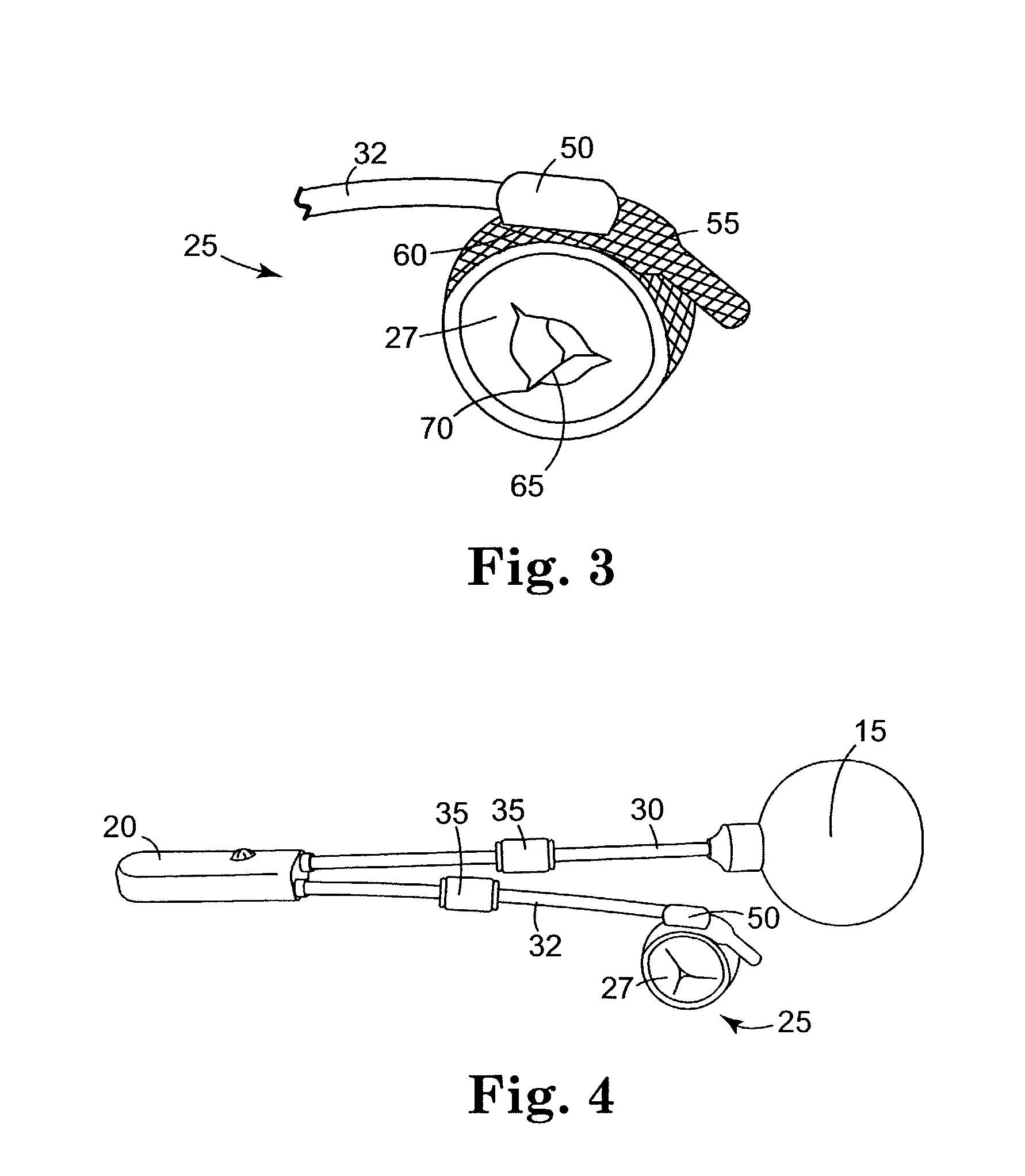

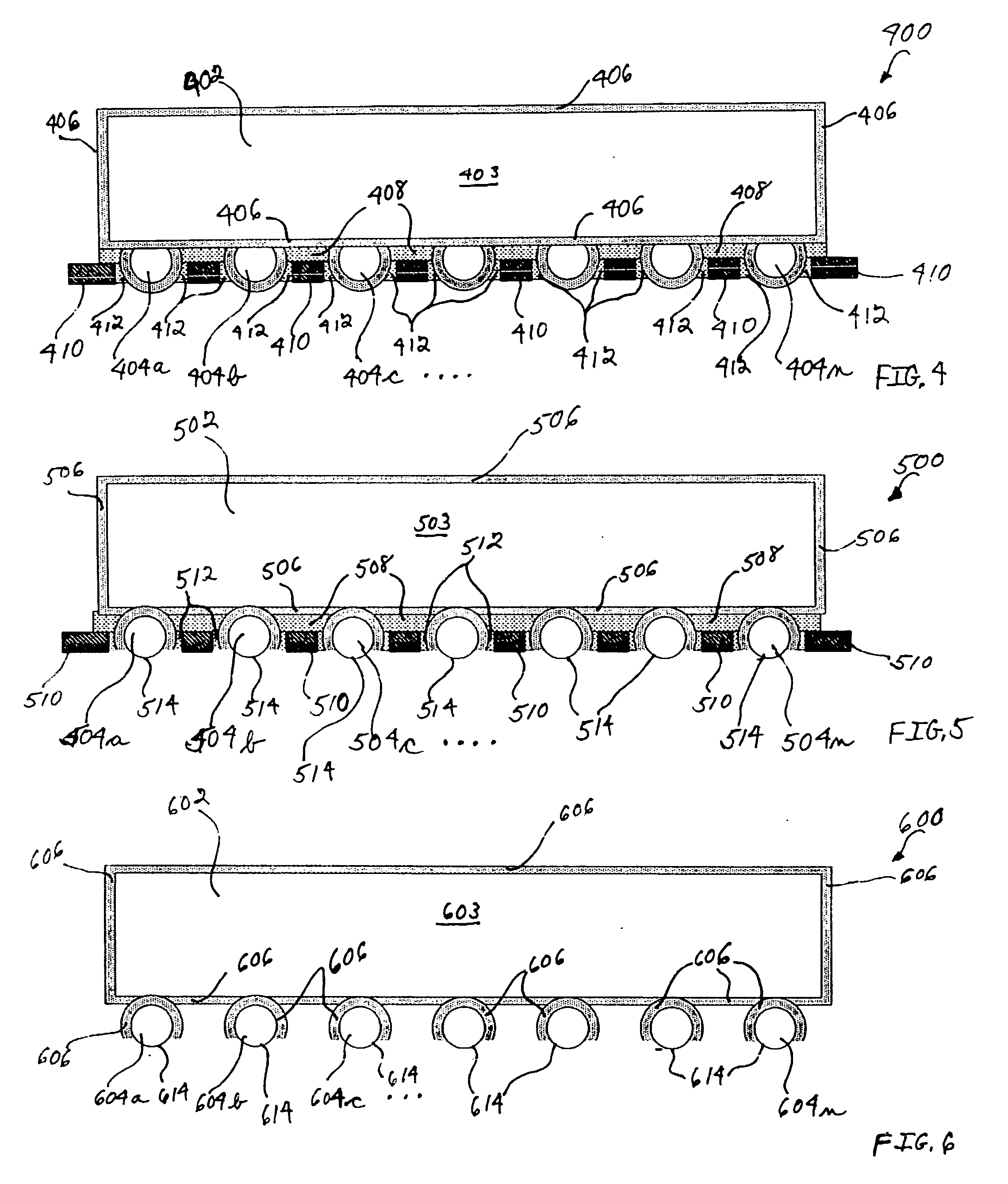

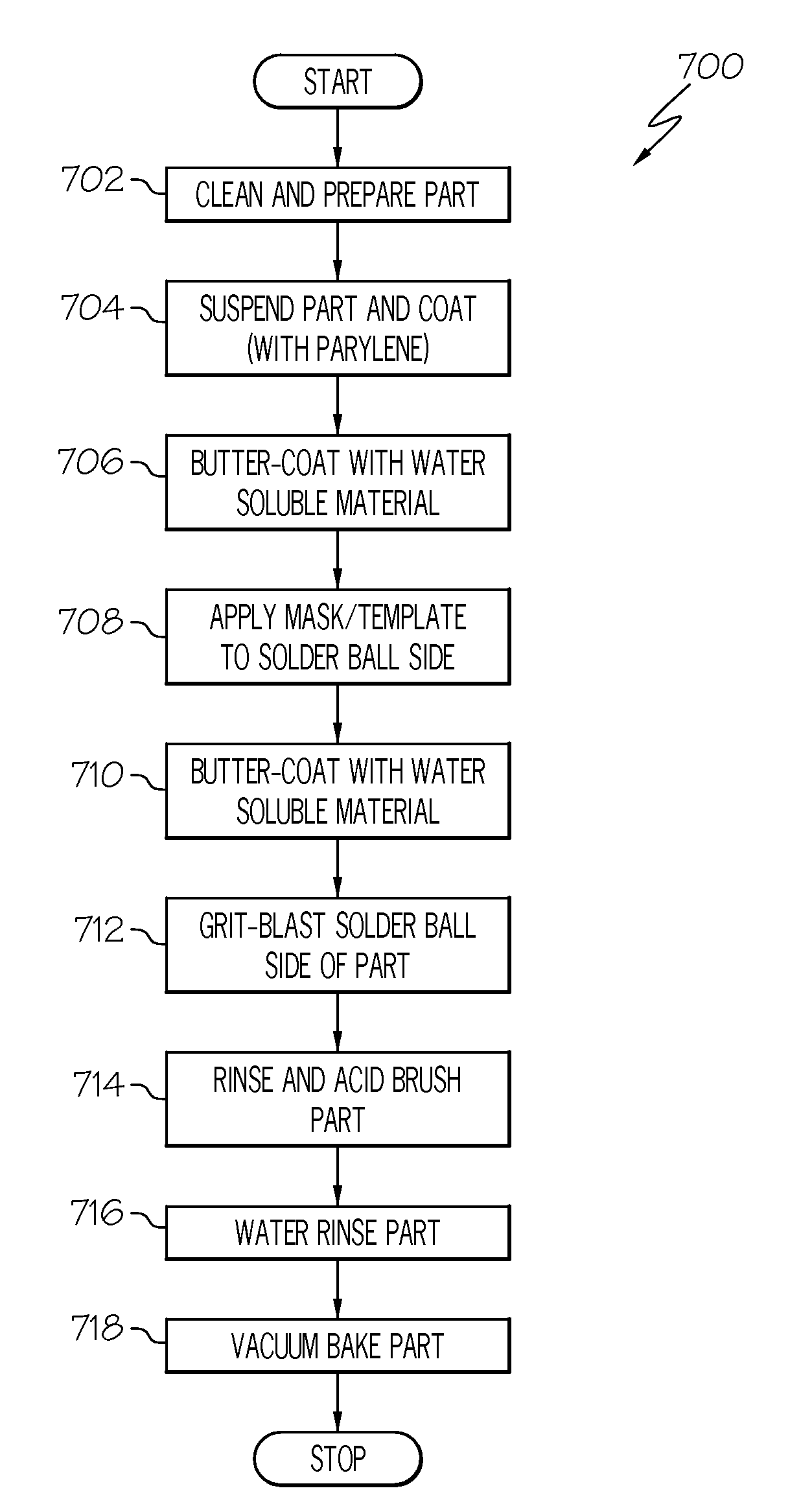

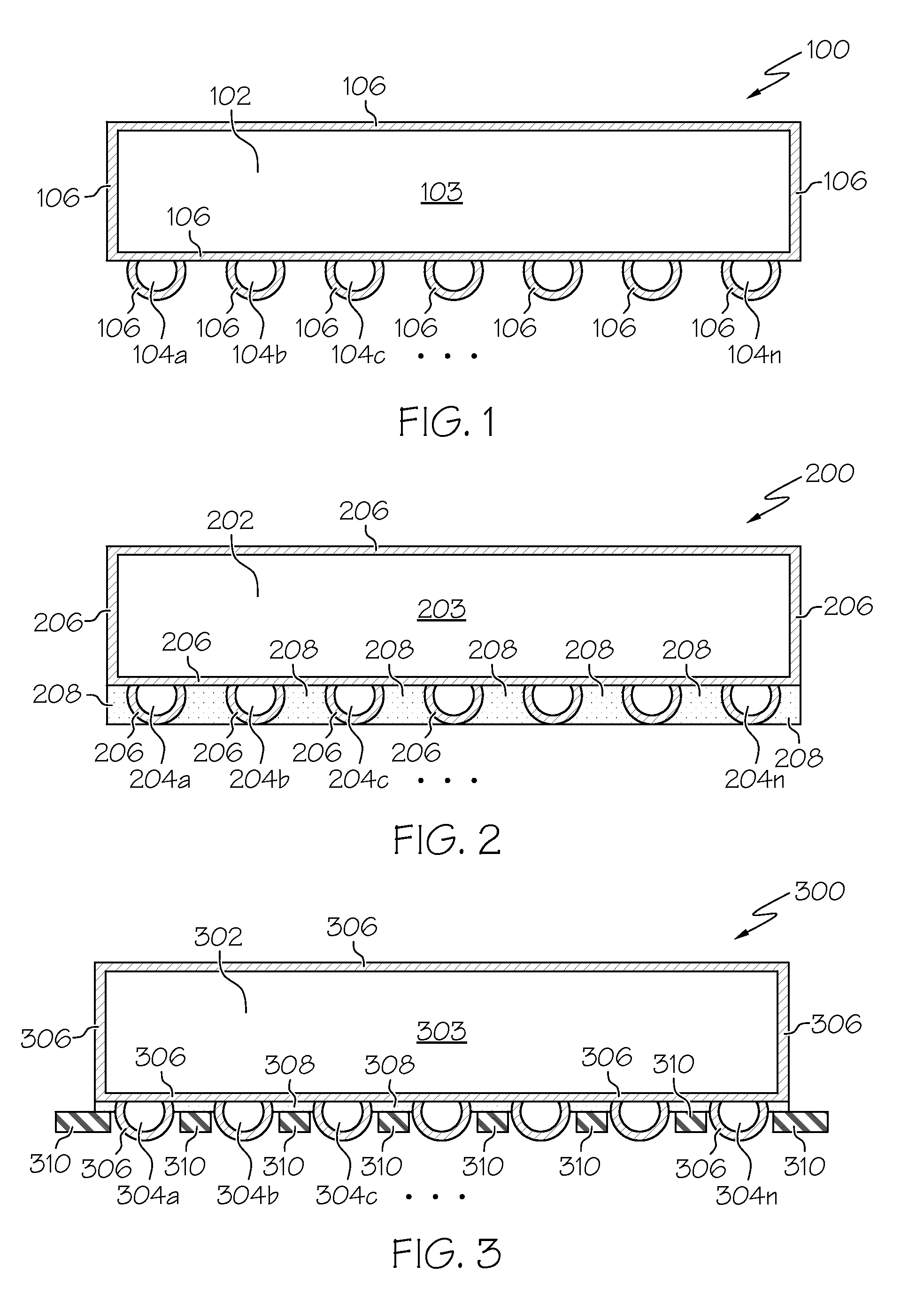

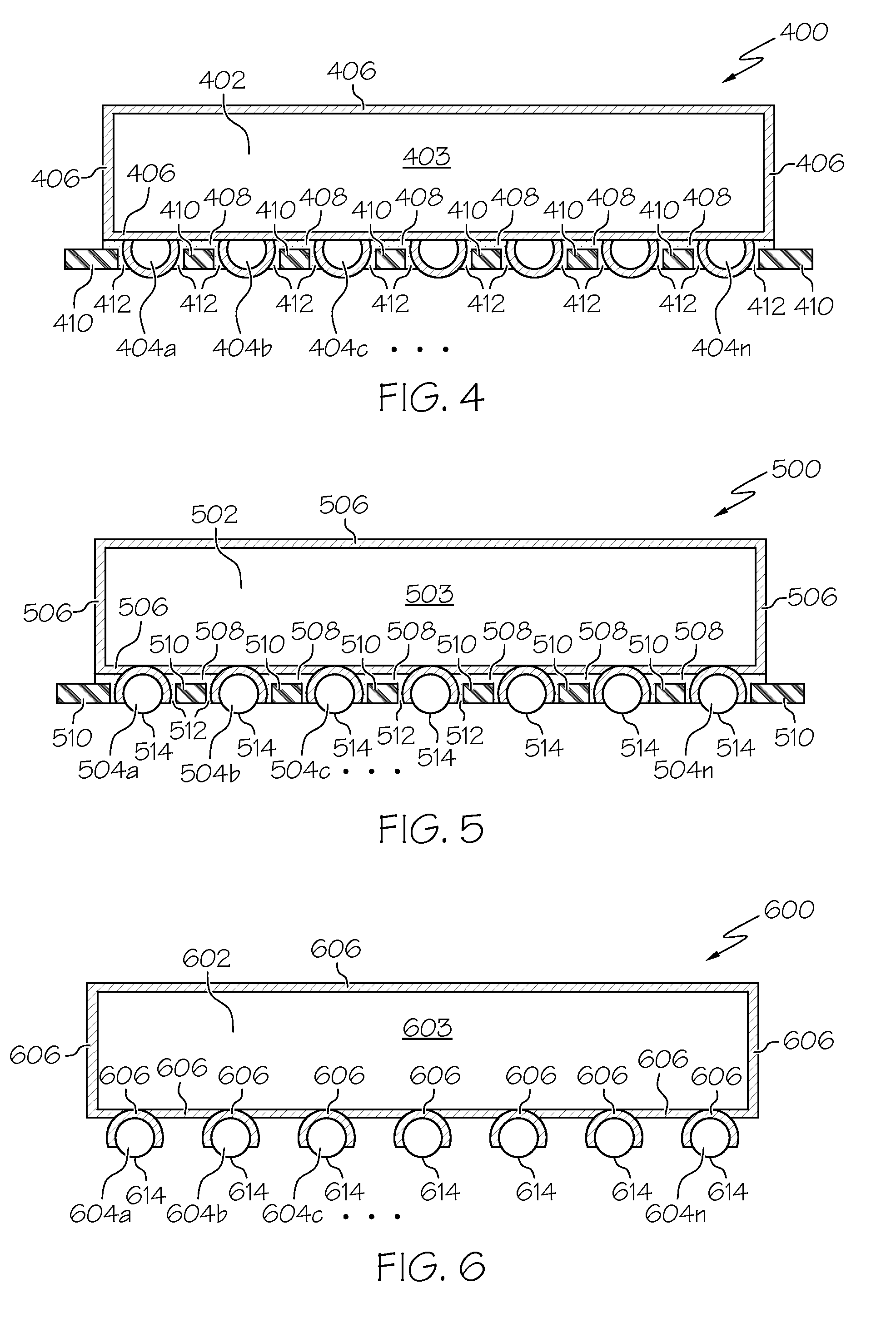

Method and apparatus for applying external coating to grid array packages for increased reliability and performance

InactiveUS20060278971A1Improve electrical performanceImprove reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsParylene coatingEngineering

A method and apparatus are disclosed for selective removal of a conformal coating from the solder balls of grid array packages such that the benefits of the coating are realized. An ancillary benefit of the invention is improved process-ability of the grid array package by improving the mechanical containment of the solder during the reflow process and improved electrical isolation between the individual solder attachment points. For example, a method for coating a ball grid array is provided, which includes coating the ball grid array with a thin layer of parylene. Next, the solder ball side of the part is butter smeared or squeegeed with a water soluble coating and assembled wet. A mask having holes in the same pattern as the balls in the grid, and a thickness that is about 80% of the height of the balls, is applied to the solder ball side of the part. This side of the part is then butter smeared again with the water soluble coating, and the entire assembly is allowed to dry. At this point, about 20% of each parylene-coated solder ball protrudes higher than the surface of the mask. The solder ball side of the part is then grit blasted with an abrasive material. The extent that the abrasive material removes the parylene coating from the solder balls is limited by the mask and the layer of water soluble coating. Therefore, the grit blasting removes the parylene coating from only the protruding areas (e.g., about top 20%) of the solder balls. Water is then used to remove the water soluble coating, and the parylene coated part is baked to remove moisture. Thus, a parylene coated ball grid array (or column grid array) is provided that is highly impervious to moisture, has a very high dielectric strength, and thereby improves the electrical performance and reliability of the surface mounted part.

Owner:HONEYWELL INT INC

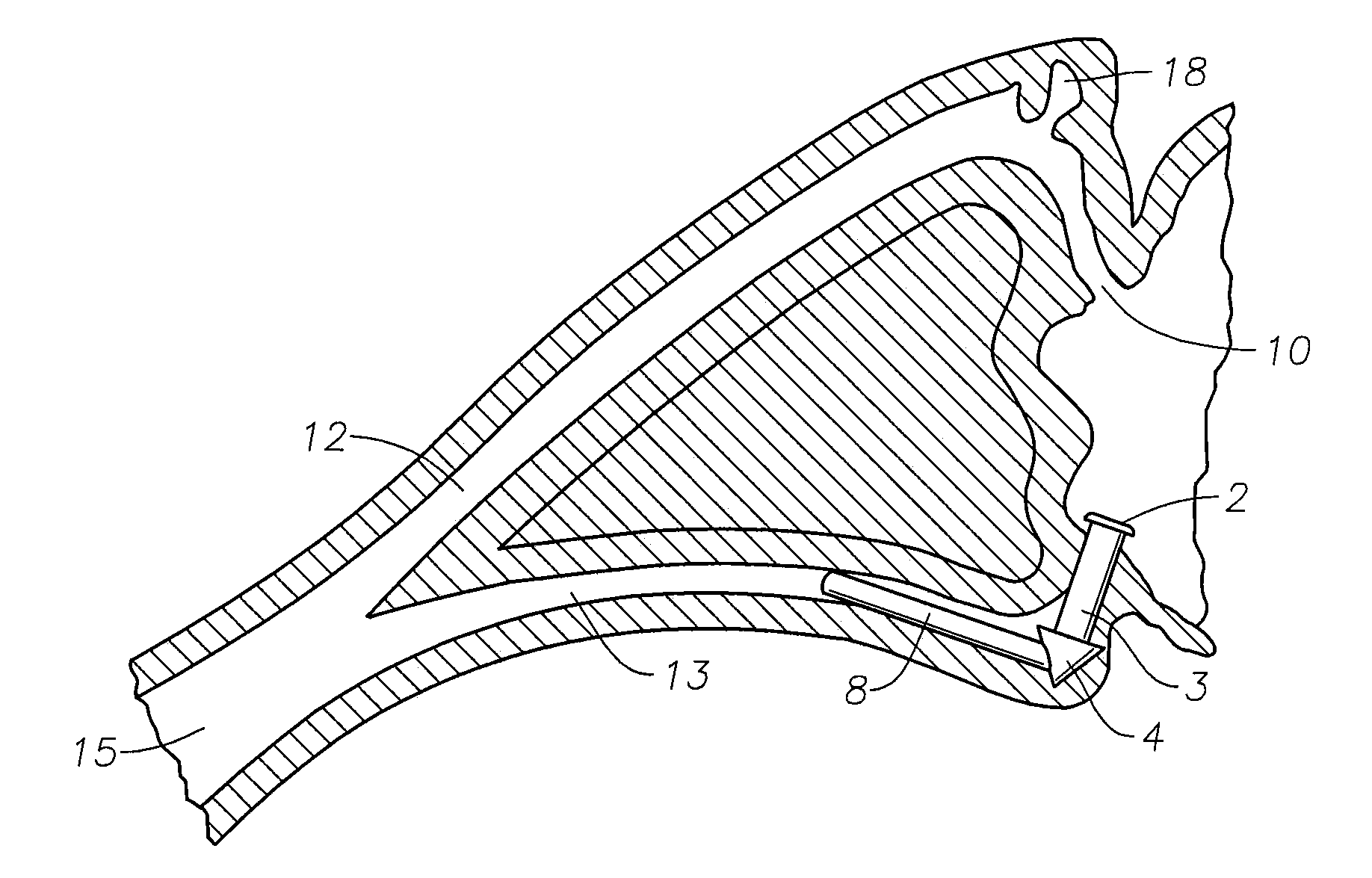

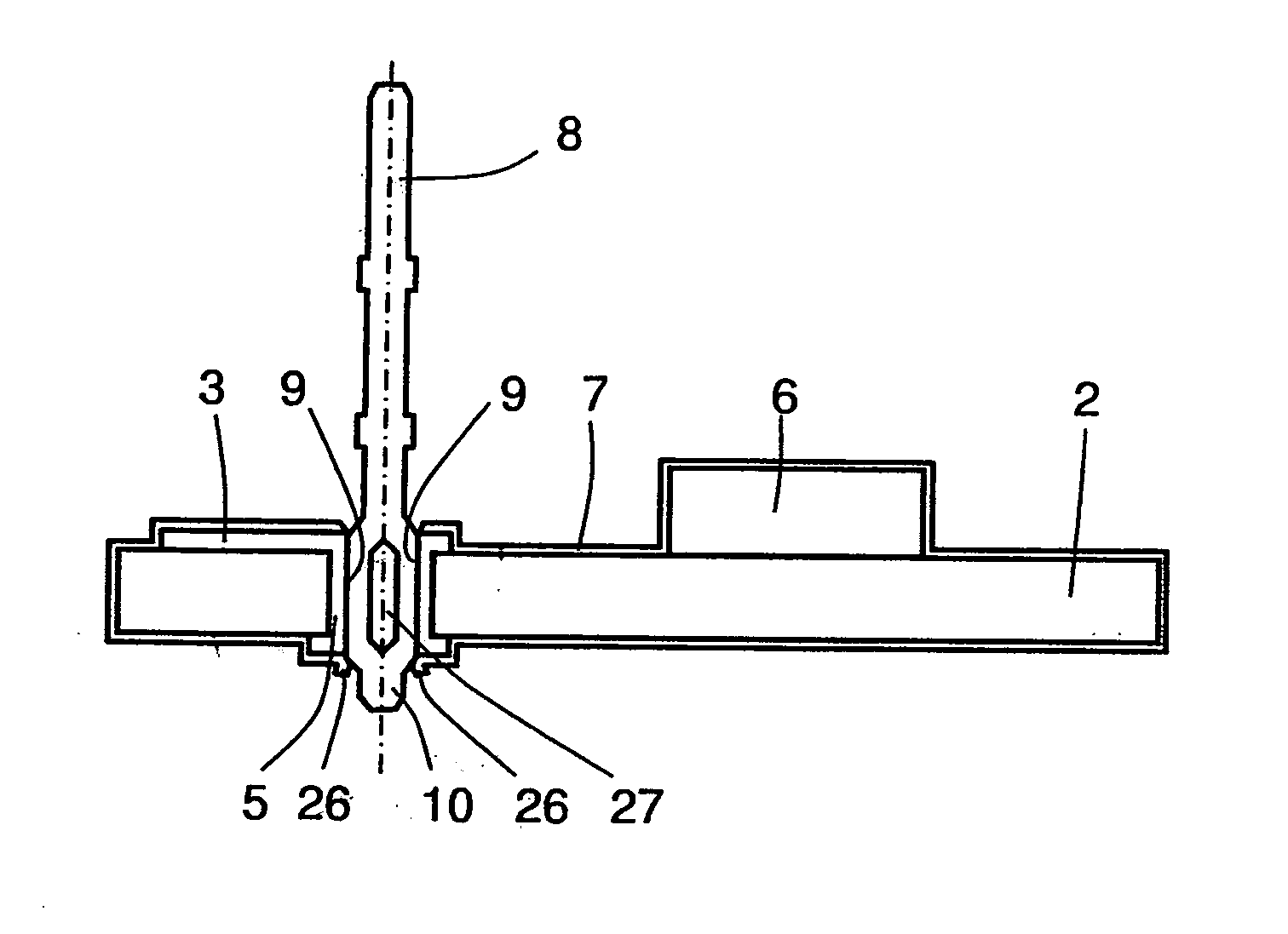

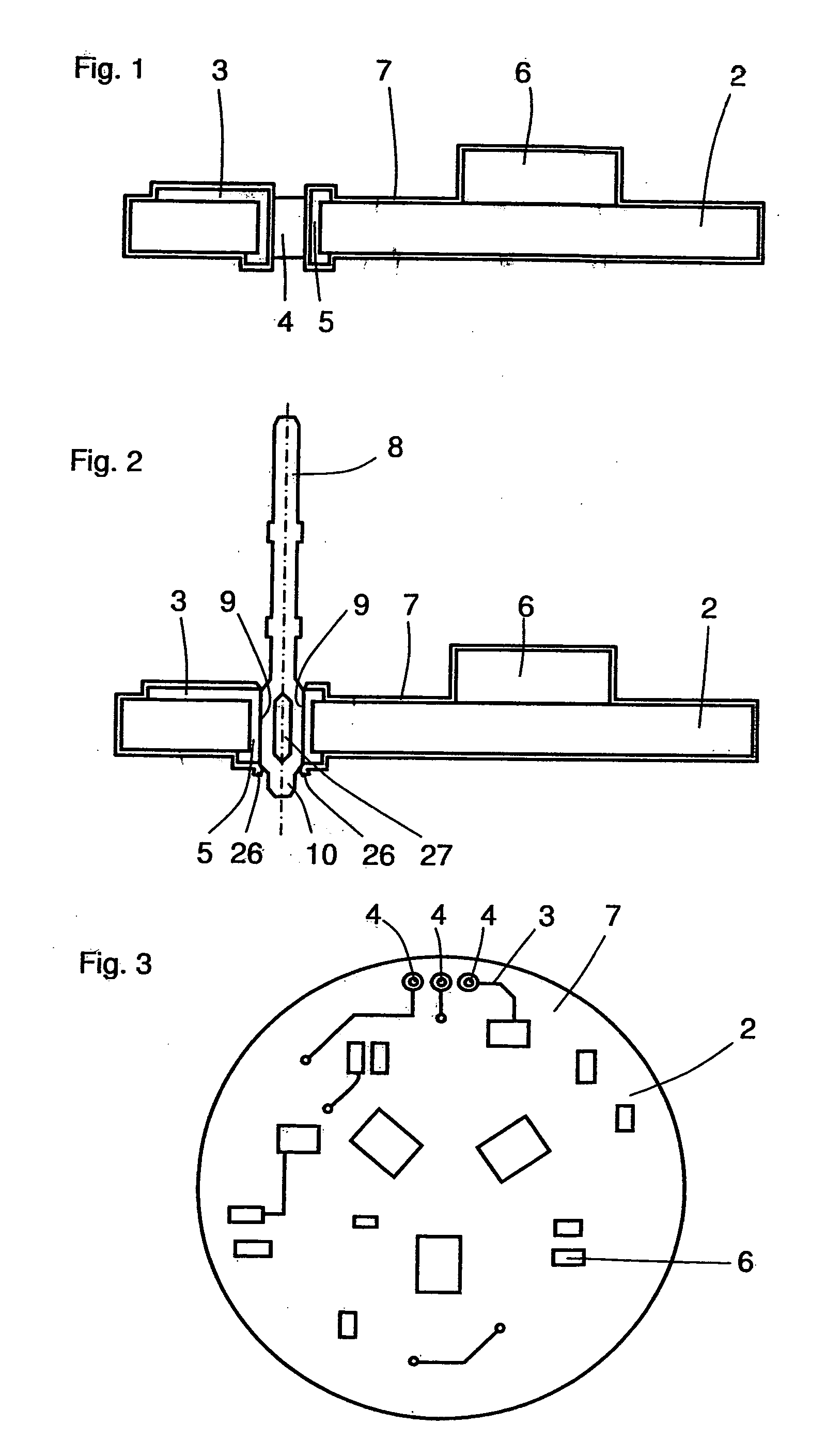

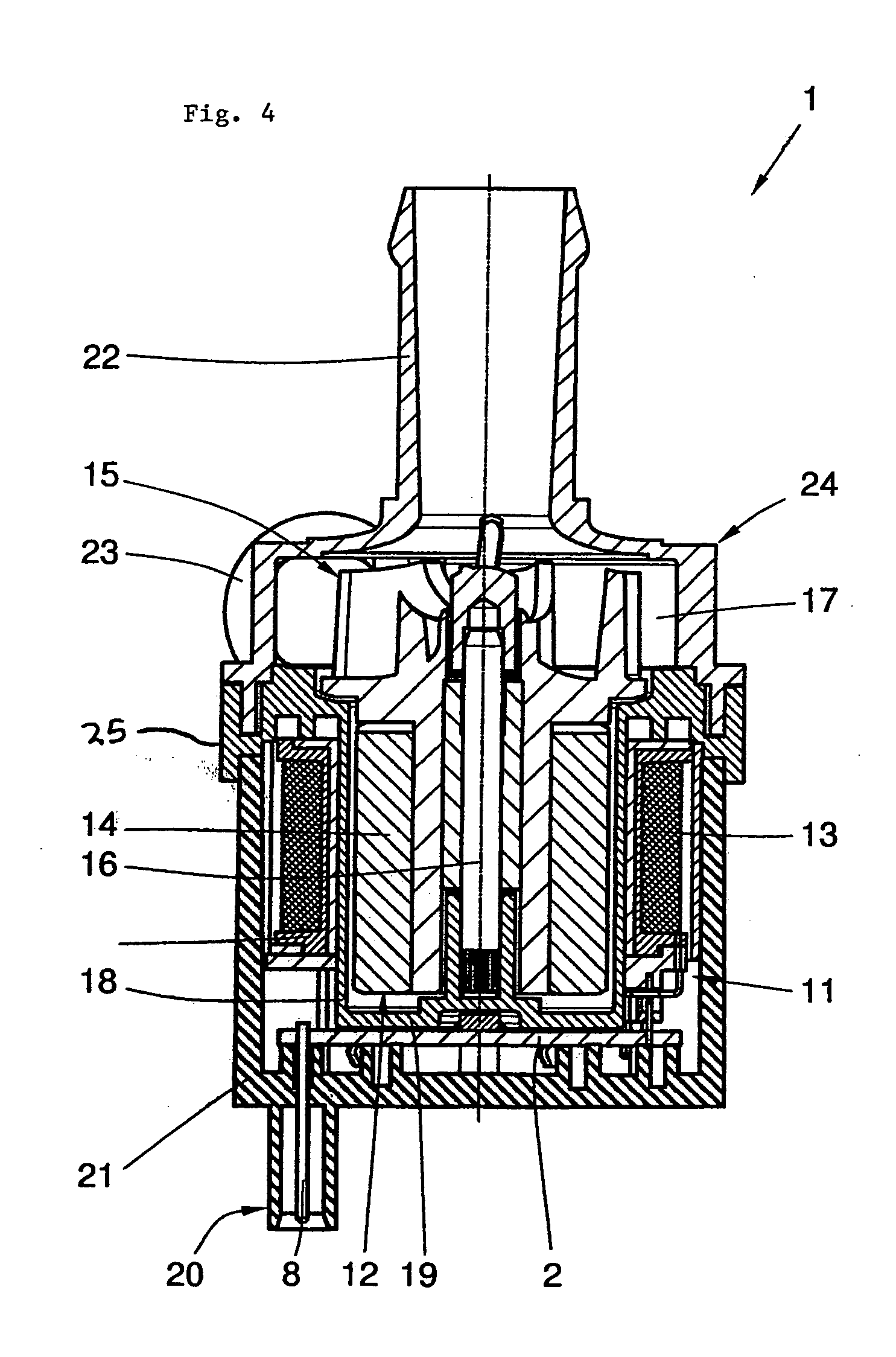

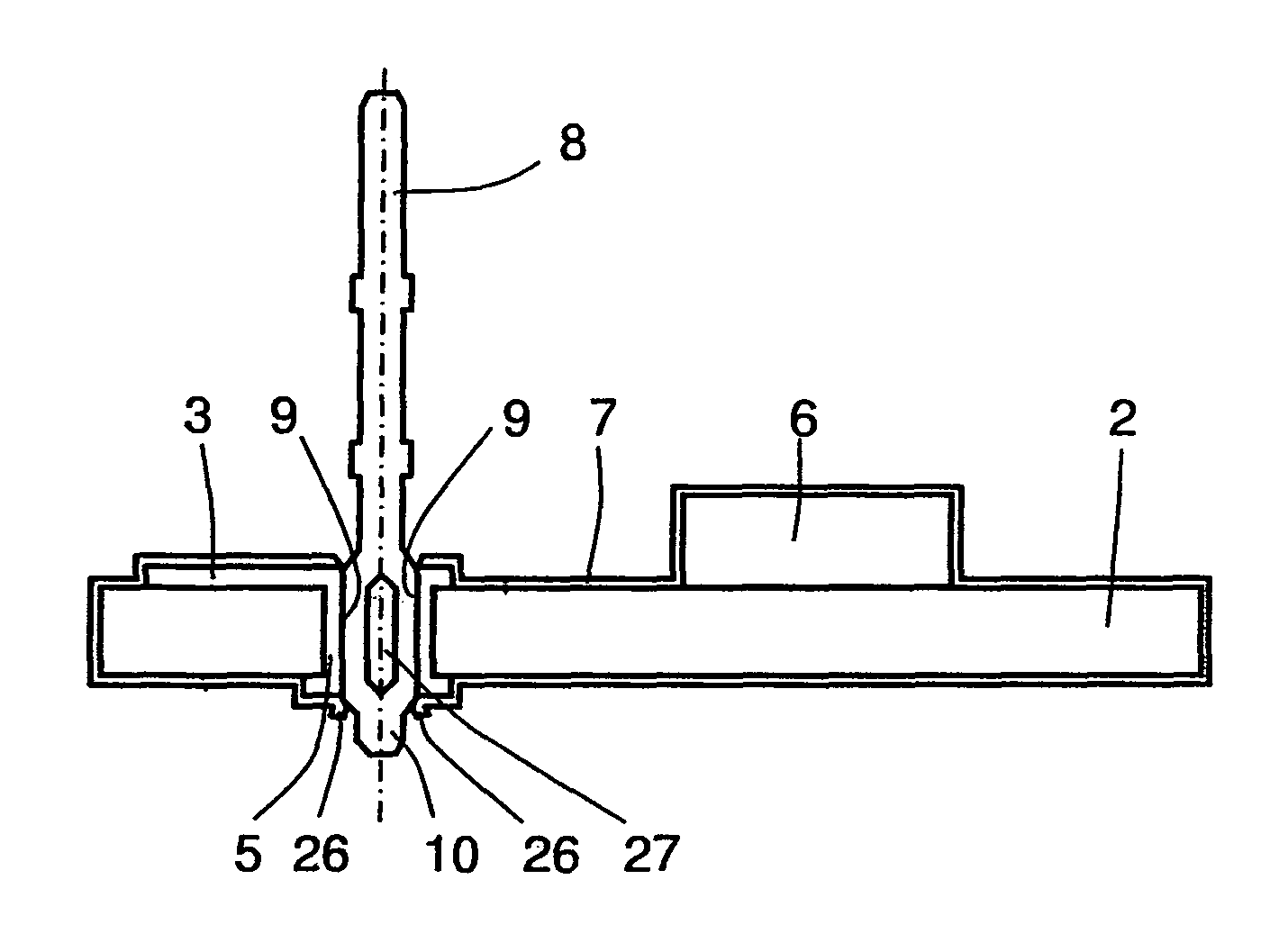

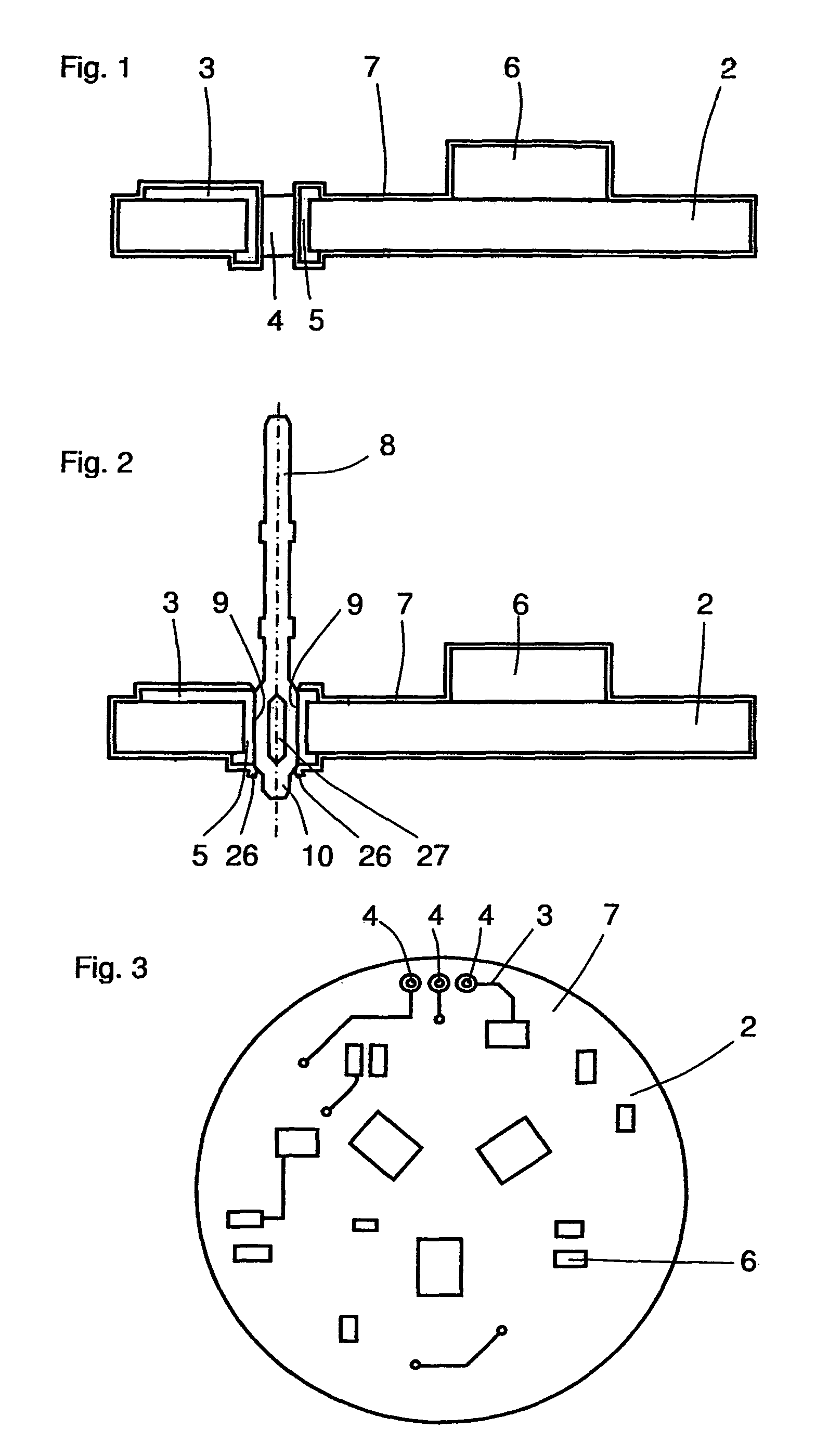

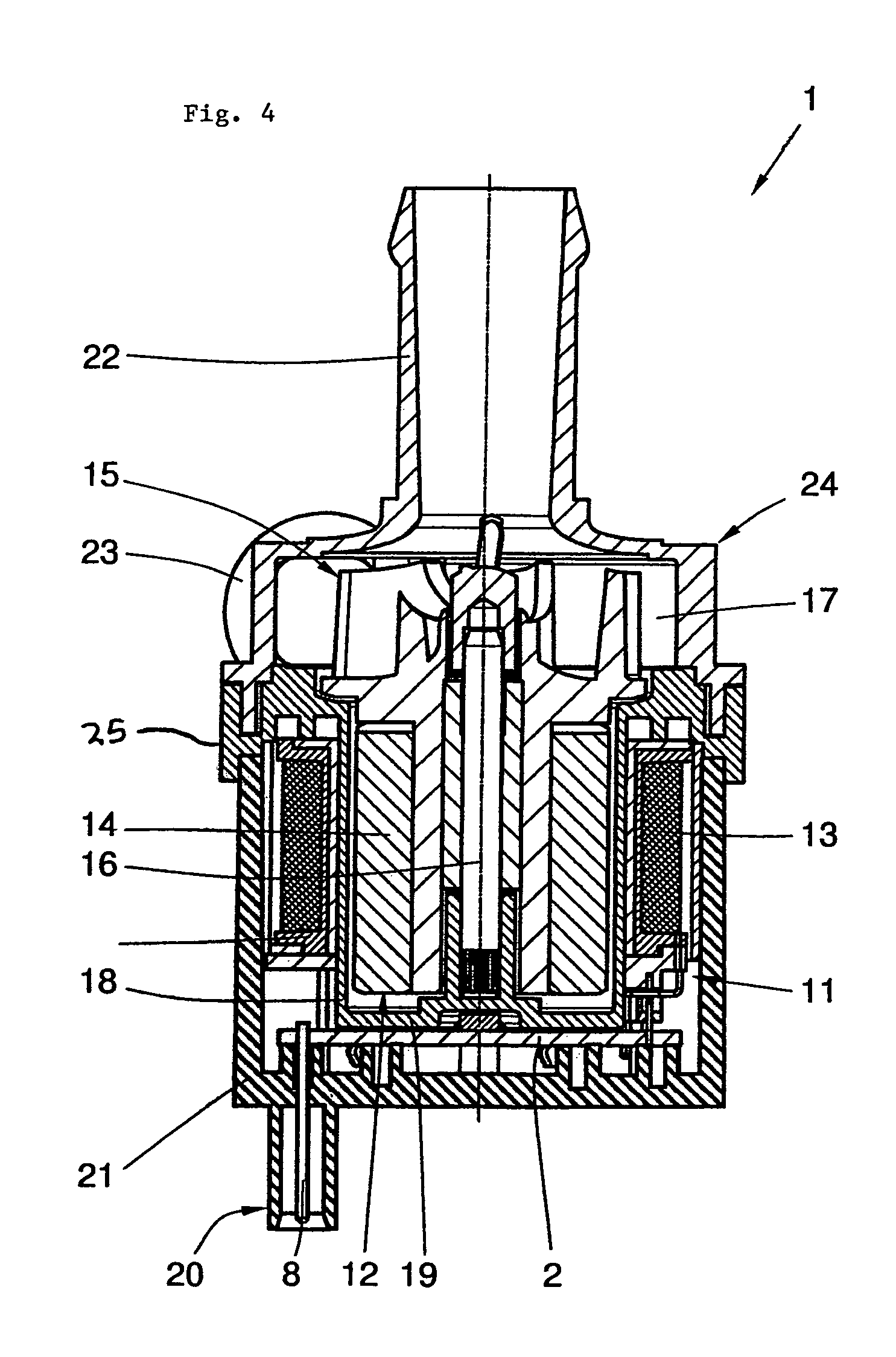

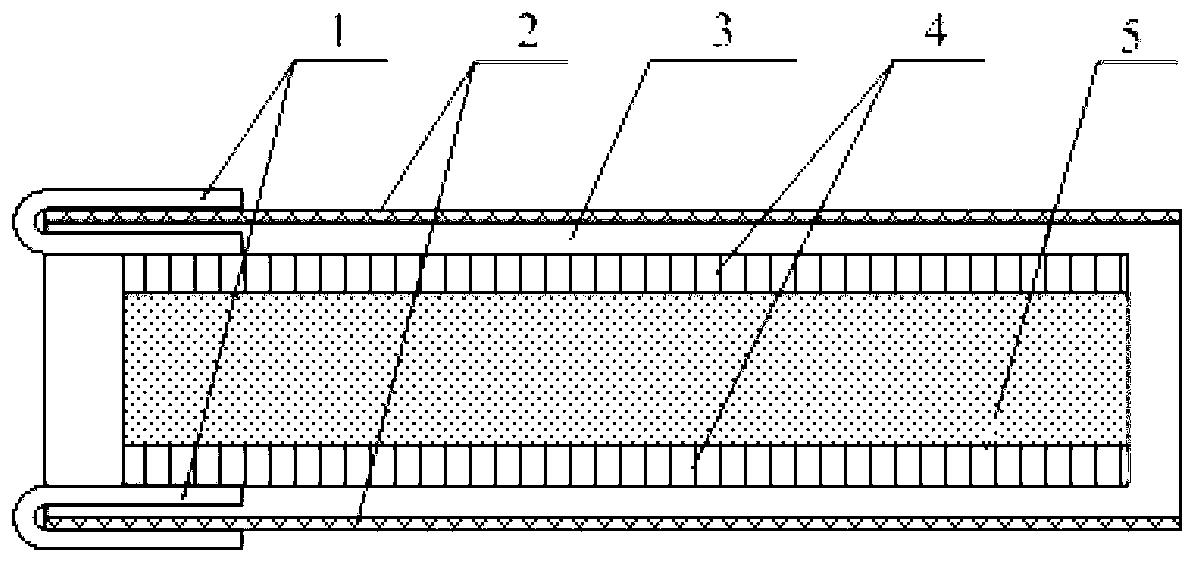

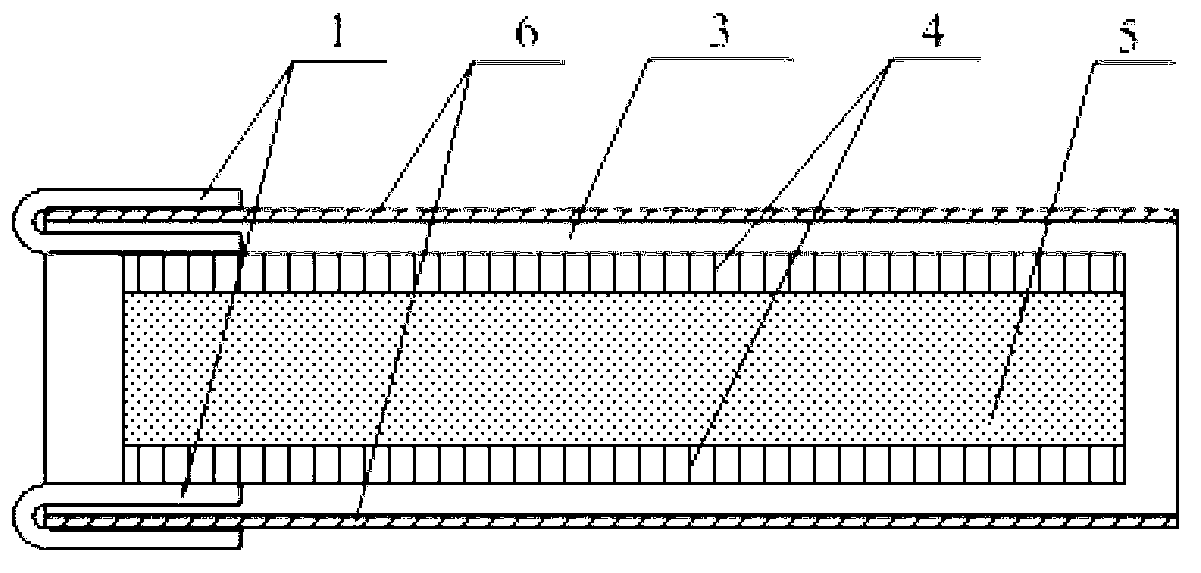

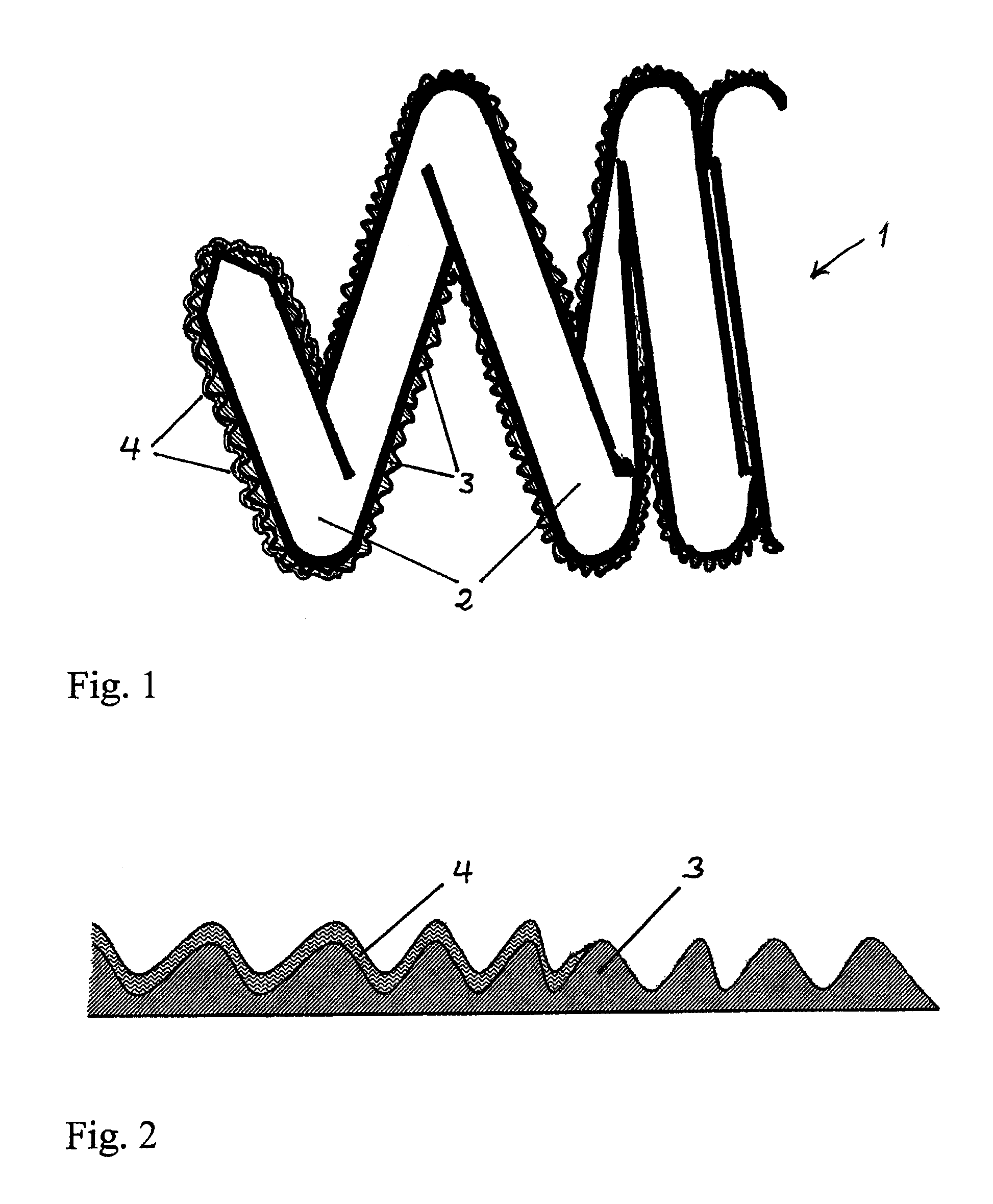

Electric drive with a circuit board

ActiveUS20100118503A1Improve protectionPrinted circuit assemblingElectrically conductive connectionsElectrical conductorEnvironmental effect

An electric drive (1) with a circuit board (2), having conductor tracks (3) and contact openings (4) with plated through-holes (5) and equipped with electronic components (6), the circuit board (2) being coated with a protective layer (7) of insulating material, and press-fit contacts (8) are inserted into the contact openings (4) and in electrical contact areas (9) within the contact openings (4) electrical contact exists between a press-fit contact (8) and the plated through-hole (5) of the contact opening (4). The task of the invention is to reliably protect circuit boards of electric drives exposed to moisture and other chemical environmental effects and contact them economically. This task is solved according to the invention in that the protective layer (7) is a parylene coating, which covers the circuit board (2), the electronic components (6) and the surface areas of the contact openings (4) and circuit board (2) directly connected to the contact areas (9) between at least one press-fit contact (8) and at least one contact opening (4).

Owner:BUHLER MOTOR GMBH

Preparation method for high-insulation hard nanometer protection coating of composite structure

ActiveCN107587119AHigh hardnessImprove insulation performanceChemical vapor deposition coatingPlasma technologyWear resistant

The invention provides a preparation method for a high-insulation hard nanometer protection coating of a composite structure, belonging to the field of plasma technology. According to the method, a reaction cavity is vacuumized and inert gas is introduced to allow a substrate to move, so organosilicon monomers with low dipole moment and high chemical inertia are screened out; the free volume and compactness of a coating are regulated and controlled through multifunctionality monomers, so the coating is allowed to have insulating properties and excellent protection performance and wear resistance at the same time; and an organosilicon coating is deposited on the coating with high insulating properties, and surface hard treatment is carried out so as to form a hard coating with a compact structure. The high-insulation hard nanometer protection coating provided by the invention has more excellent protection performance, insulating properties and wear resistance compared with conventionalcoatings such as parylene under the condition of same thickness. The preparation method provided by the invention overcomes the problems of poor wear resistance, too great thickness, low production efficiency and the like of conventional parylene coatings; and through hard treatment, a composite wear-resistant silica structure is increased in the coating, and the hardness and wear resistance of the coating are effectively improved.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

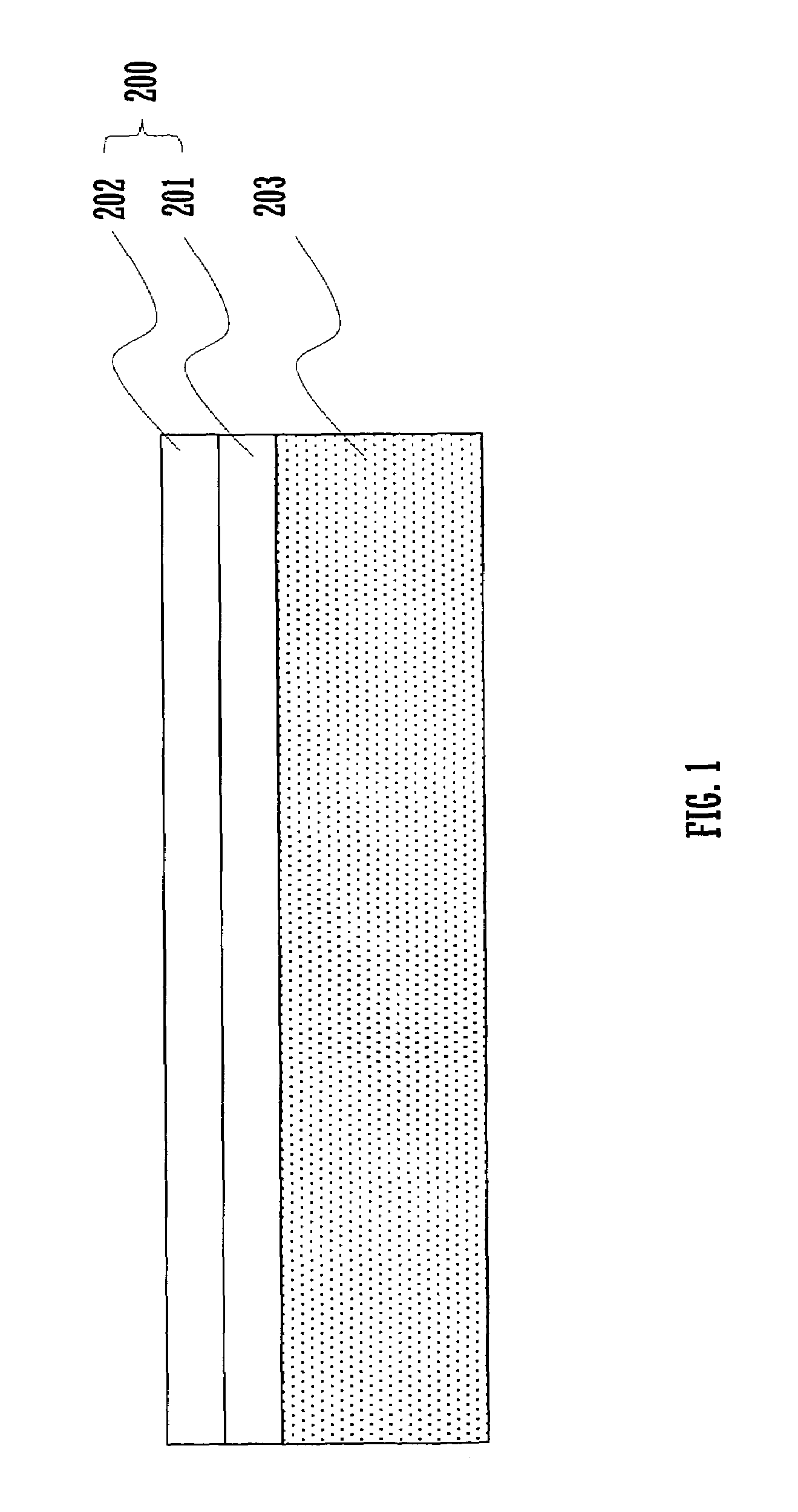

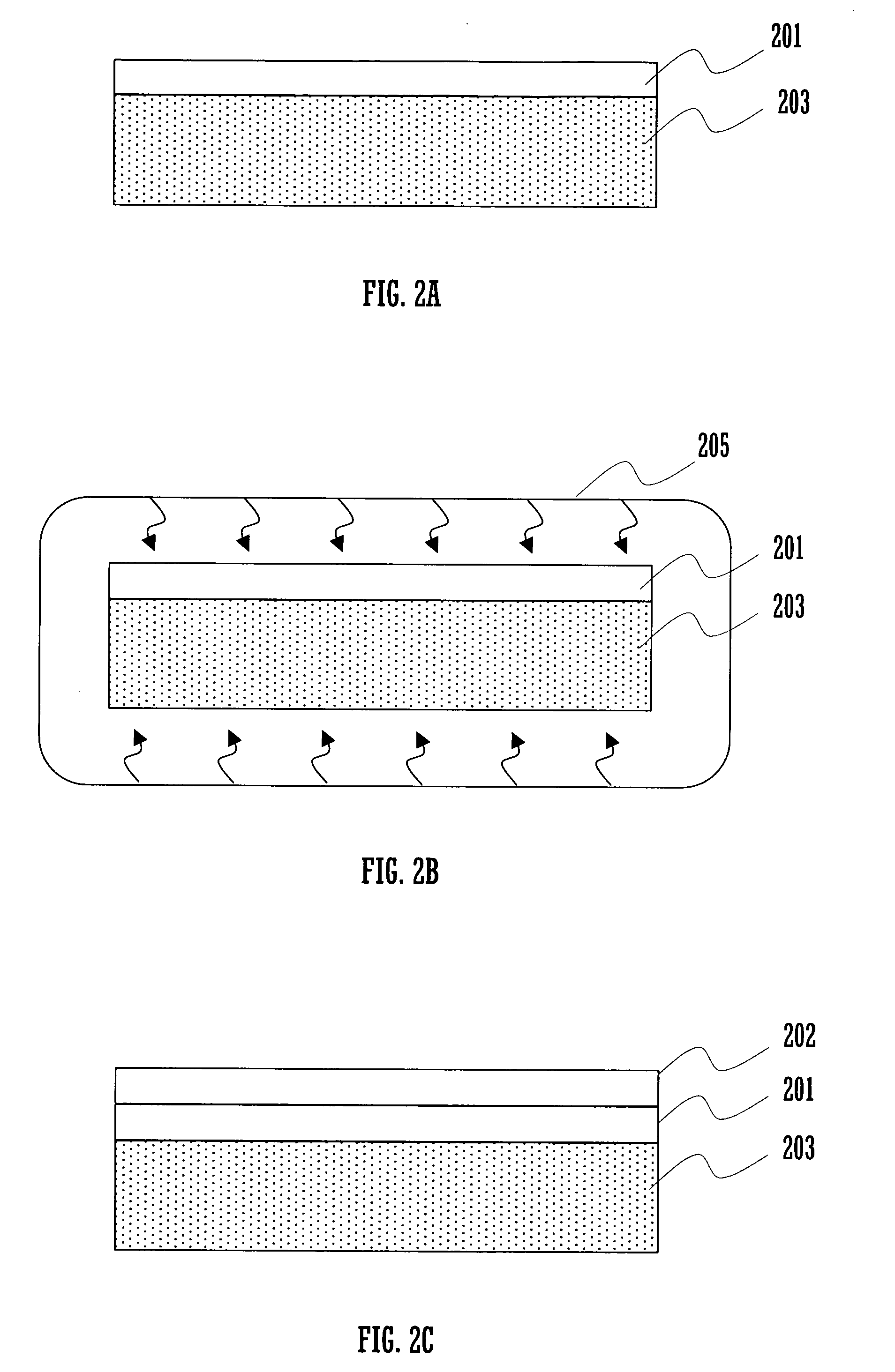

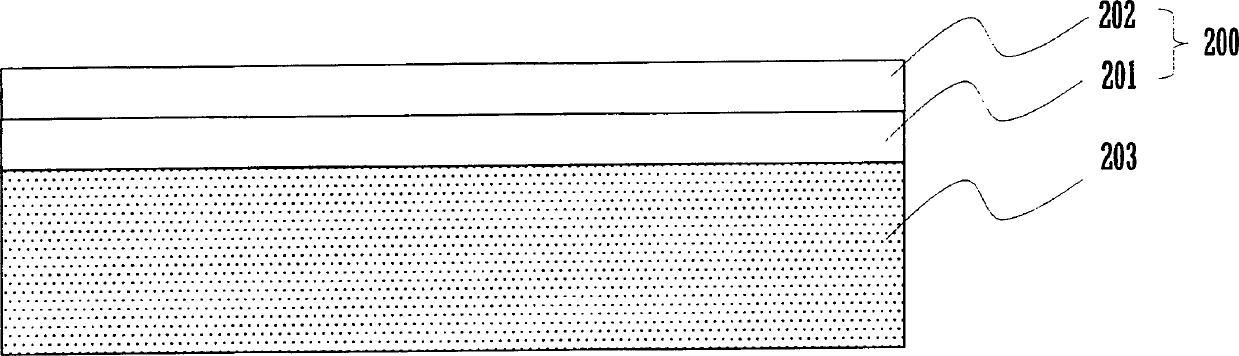

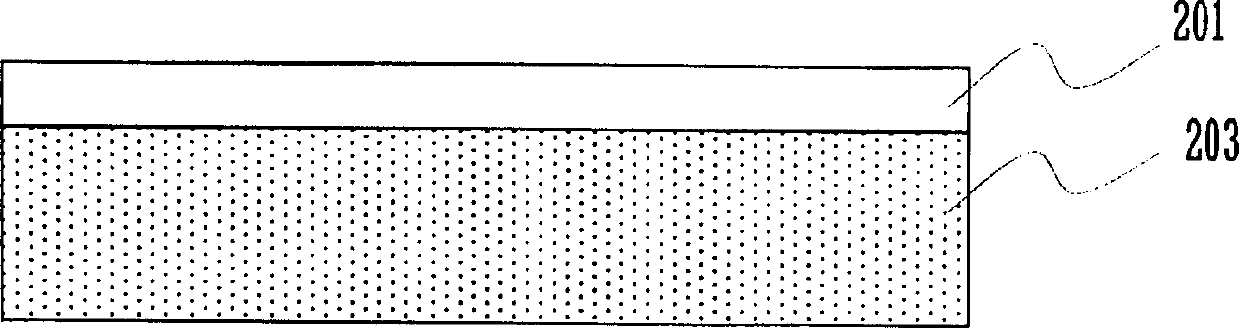

Method for producing organic insulating coating and ink-jet printhead produced according to the method

ActiveUS7066582B2Improve insulation performanceAvoid it happening againPretreated surfacesCoatingsParylene coatingHeat treated

An organic insulating coating formed on a substrate is composed of two layers of a first parylene coating and a second parylene coating. Heat treatment is performed to at least the first parylene coating after being formed, at a temperature below 125° C. for two hours. Then the second parylene coating is formed on the first parylene coating. Occurrence of pinholes is thus prevented at least in one of the two layers of the organic coatings, with the result that insulating properties of the coatings are improved.

Owner:SHARP KK

Method of protecting a capacitor

ActiveUS7350281B2Low gasLess expensive or unsealedPrinted circuit assemblingLine/current collector detailsEpoxyMoisture permeability

An electric device includes an electric element, such as a wound film capacitor, with power input and output leads. The electric element includes a coating layer of parylene that provides moisture resistance and low gas and moisture permeability to protect the electric element from short and long term moisture degradation effects. A known case layer is located adjacent to the coating layer. The case layer is a metal, epoxy-based, silicone-based, or polymer material that encapsulates the coating layer and the electric element to protect the coating layer and electric element from physical damage.

Owner:HAMILTON SUNDSTRAND CORP

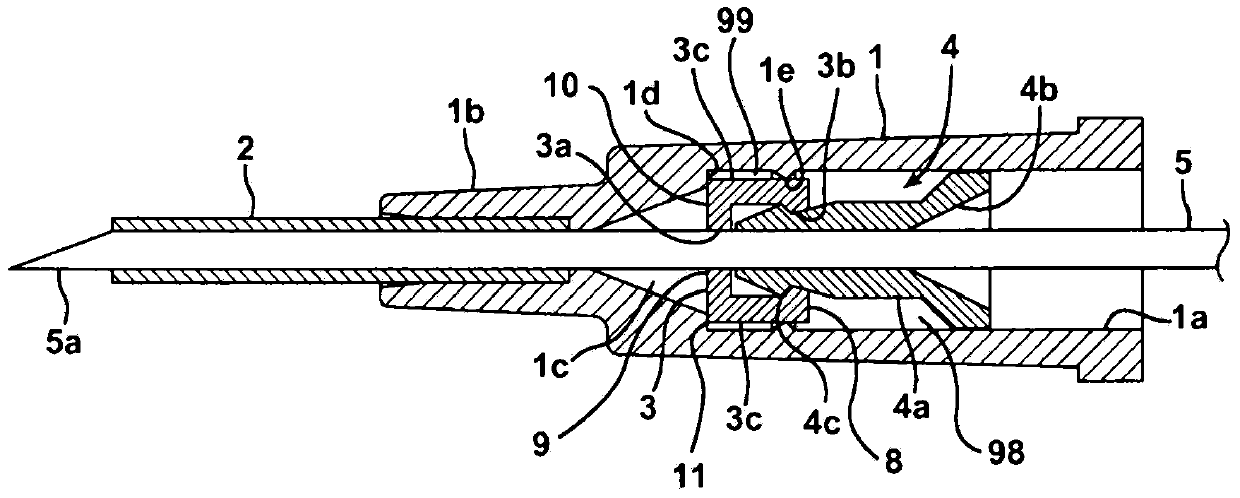

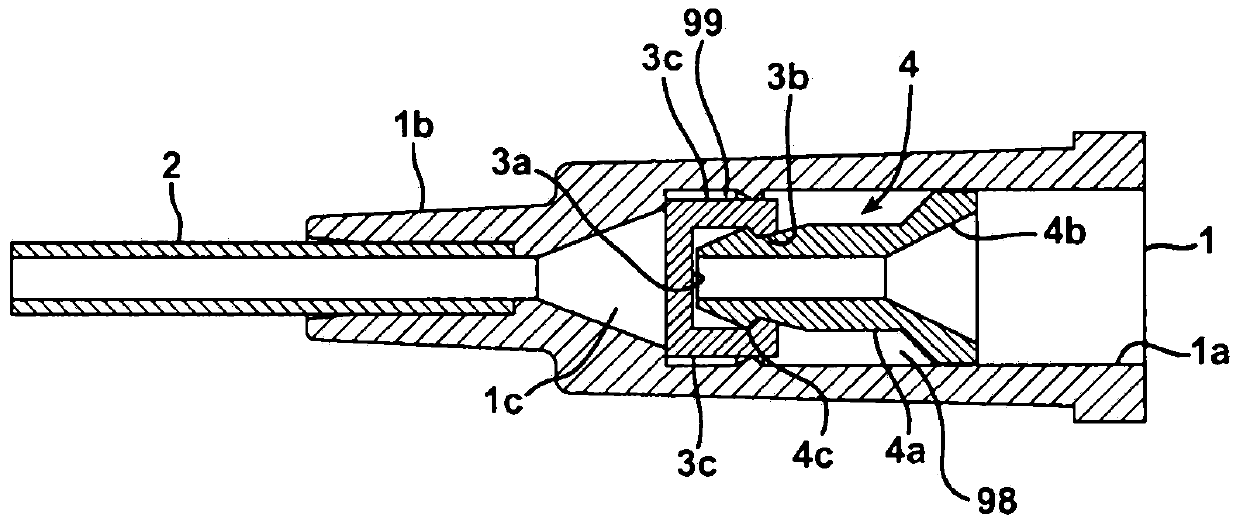

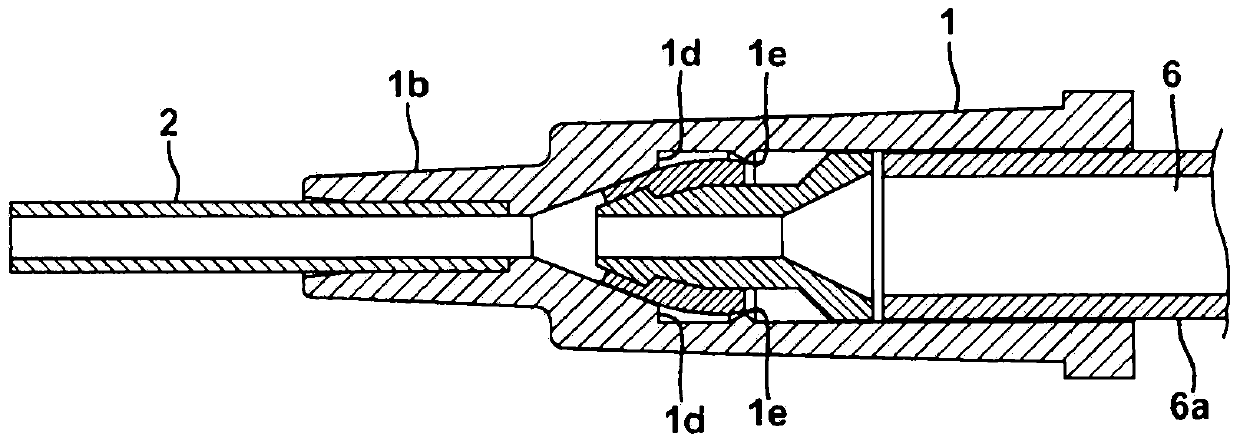

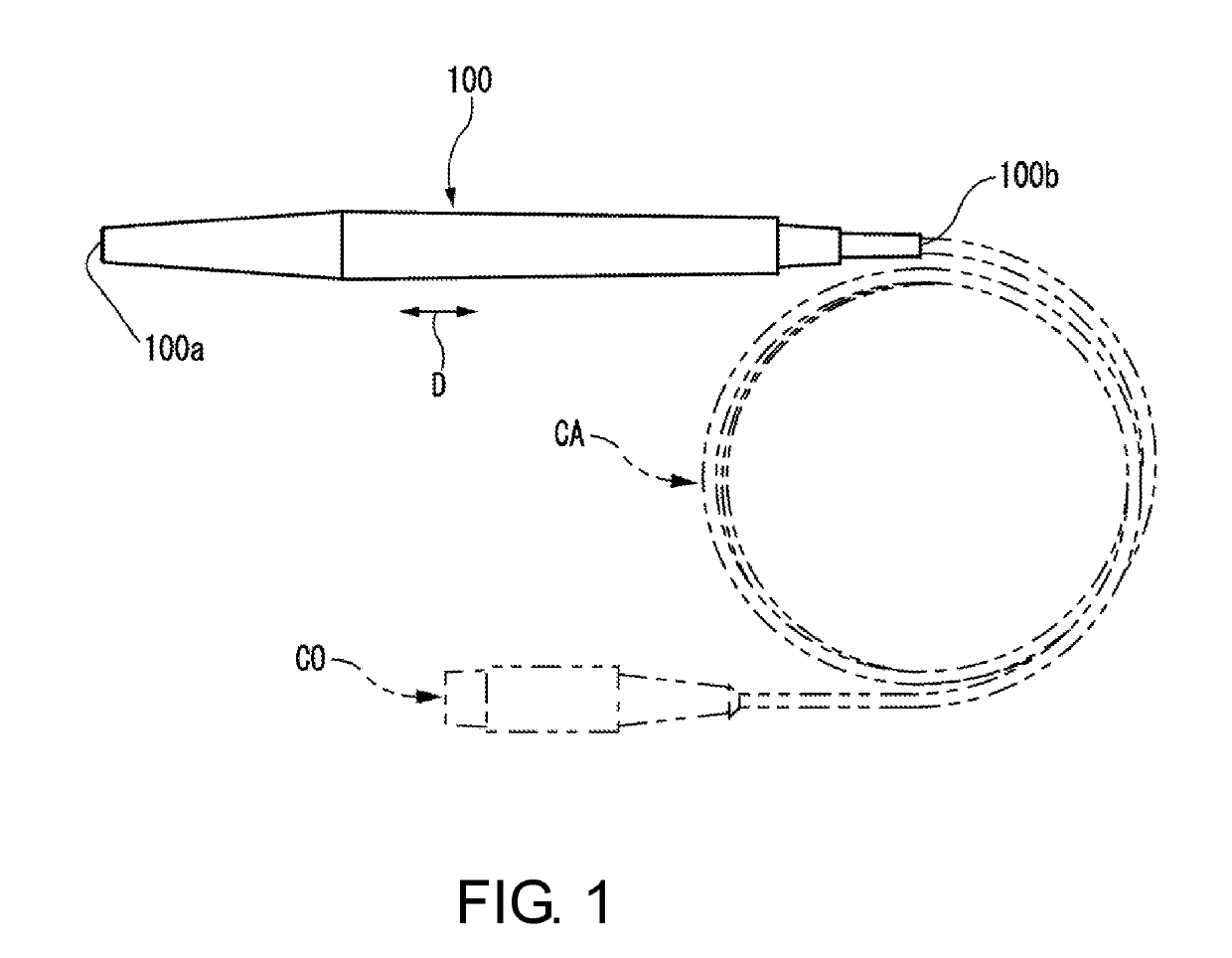

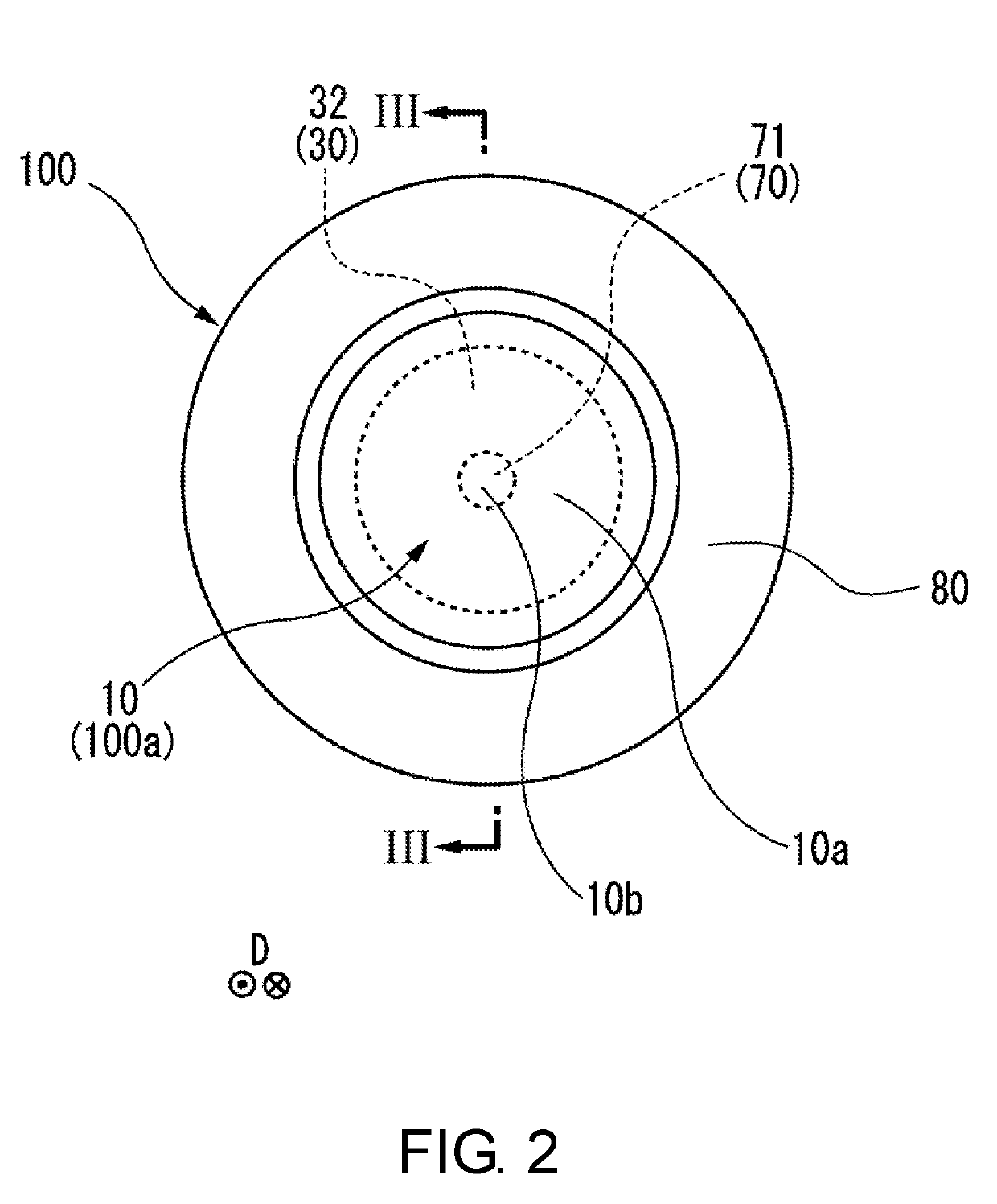

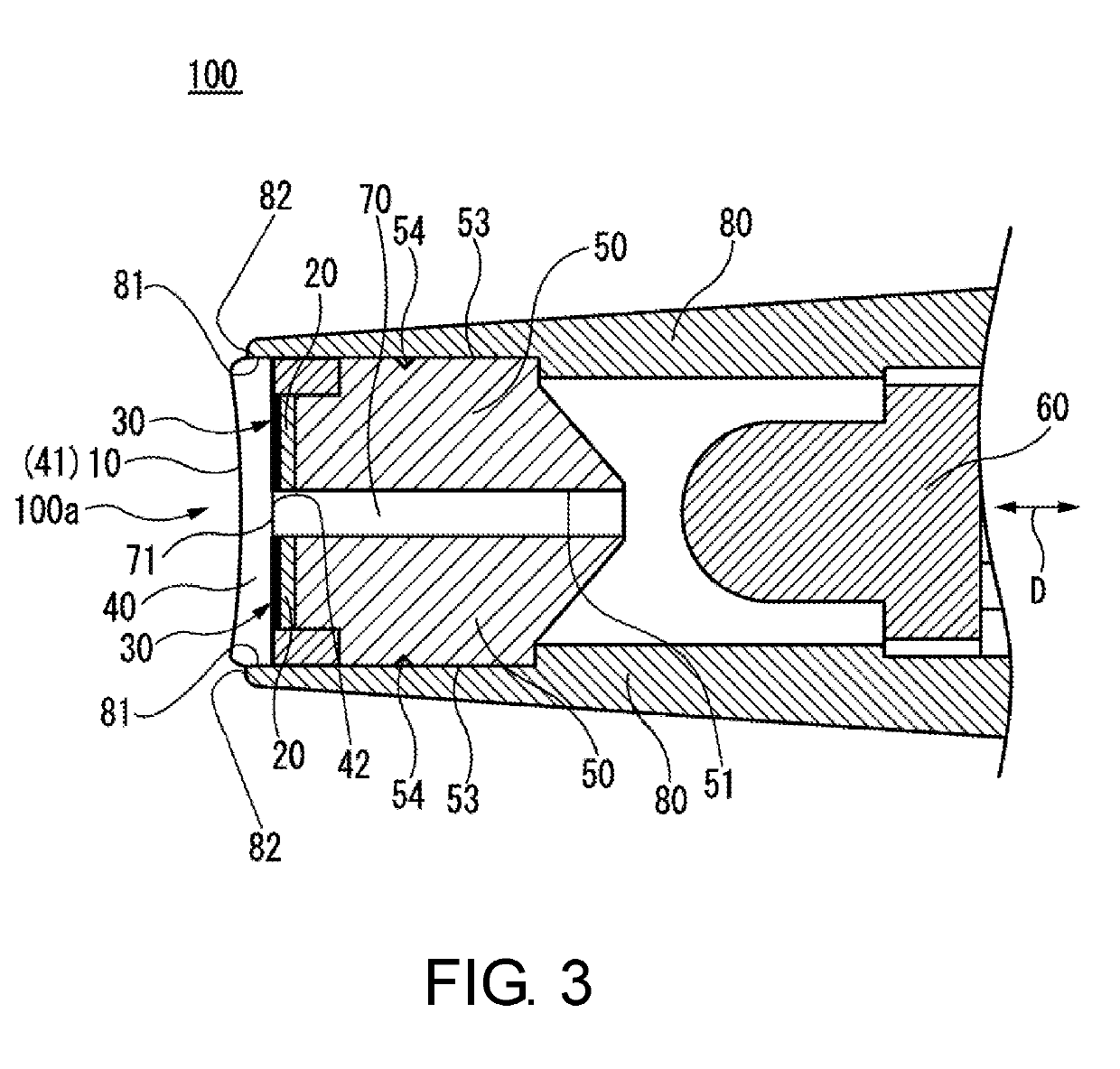

Systems and methods for providing a catheter assembly

A system for controlling fluid flow in a catheter assembly ( 101 ) is disclosed herein. An intravenous catheter assembly has a catheter adapter ( 14 ) and a needle hub, and the catheter adapter has an inner lumen. A septum ( 50 ) is disposed within a portion of the inner lumen, and a slit ( 56 ) is formed through the septum. A Parylene coating is disposed within the slit of the septum, the Parylene coating has a thickness of between approximately 0.00005 to 0.0005 millimeters. An introducer needle has a first end coupled to the needle hub and the second end extending through the inner lumen of the catheter adapter. A middle portion of the introducer needle is positioned within a portion of the septum.

Owner:BECTON DICKINSON & CO

Method for producing organic insulating coating and ink-jet printhead produced according to the method

An organic insulating coating formed on a substrate is composed of two layers of a first parylene coating and a second parylene coating. Heat treatment is performed to at least the first parylene coating after being formed, at a temperature below 125 DEG C. for two hours. Then the second parylene coating is formed on the first parylene coating. Occurrence of pinholes is thus prevented at least in one of the two layers of the organic coatings, with the result that insulating properties of the coatings are improved.

Owner:SHARP KK

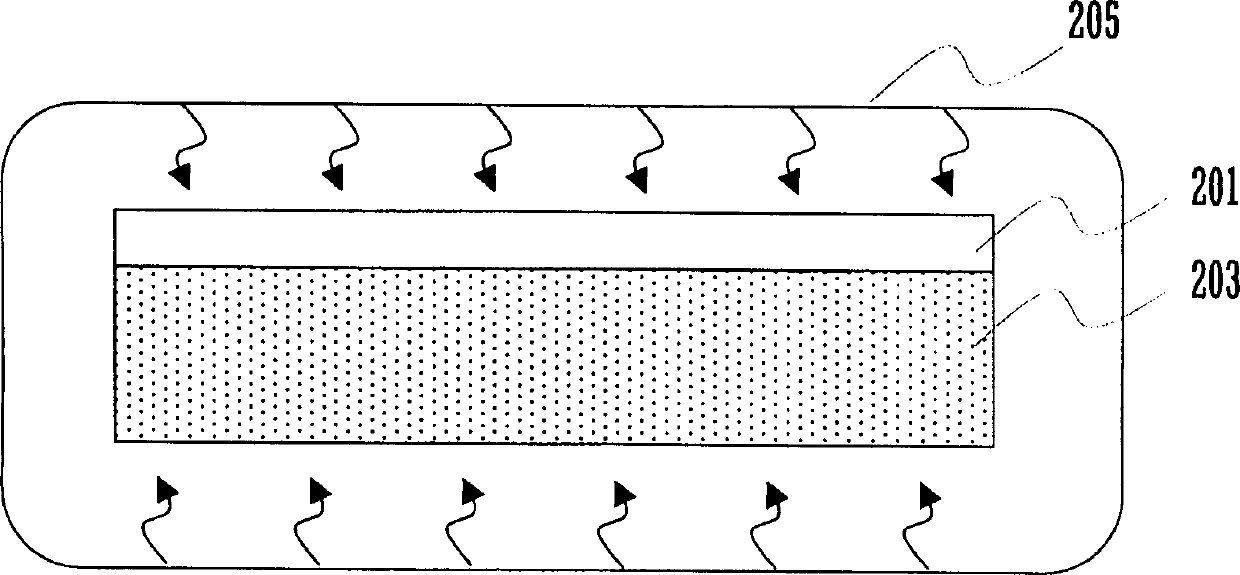

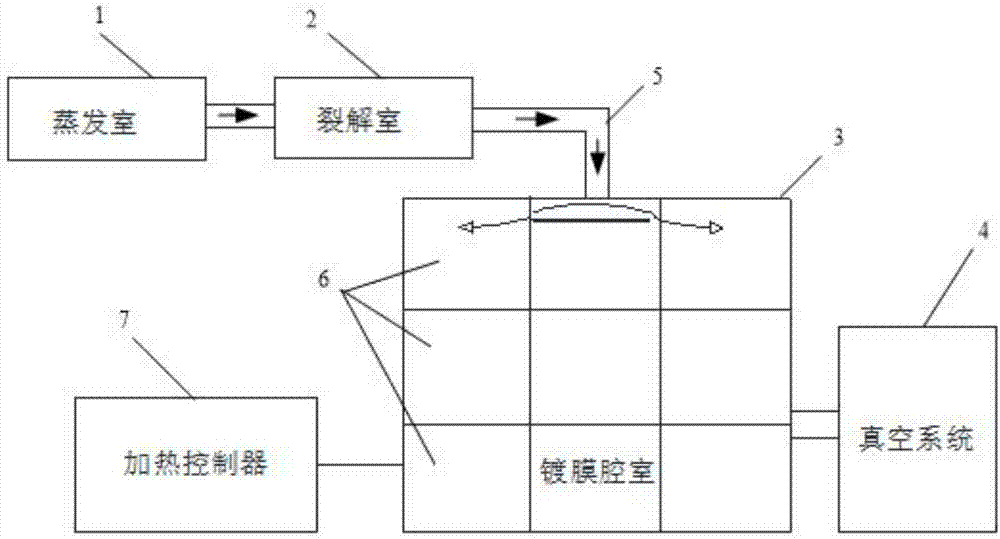

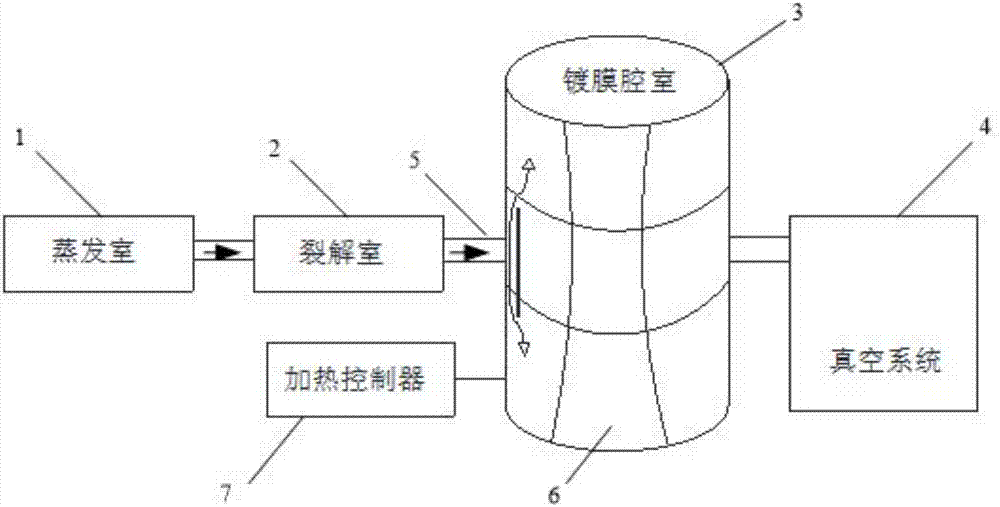

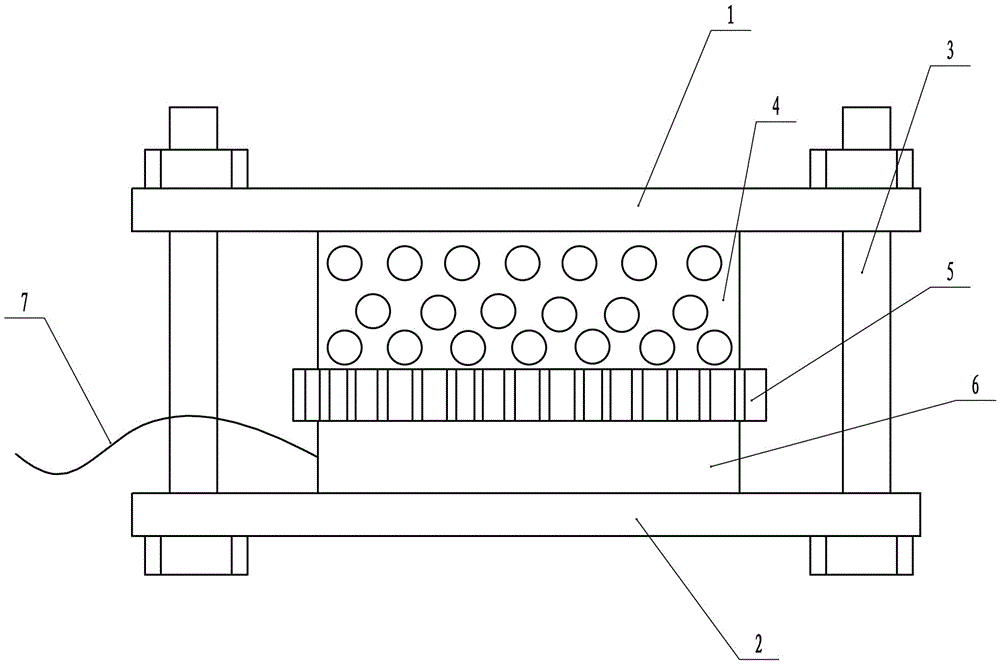

Heating control device and method for chemical vapor deposition

PendingCN107964653AIncrease crystallization rateImprove uniformityChemical vapor deposition coatingGas phaseParylene coating

The invention provides a heating control method for chemical vapor deposition equipment. The heating control method comprises the steps that a film coating chamber is arranged into multiple lattices which are arranged vertically and horizontally, each lattice is internally provided with a heat-emitting body and further internally provided with a temperature feedback device, and the heat emitting bodies and the temperature feedback devices are all connected with a heating controller; 2, the film coating chamber is sealed, and vacuum extraction is conducted to reach 0.01-1 Torr through a vacuumsystem; 3, the heat-emitting bodies and the temperature feedback devices are utilized to be connected with the heating controller, and the temperature of the area where the lattices are located is controlled to be within the range from 30 DEG C to 100 DEG C; and 4, a parylene material is put into an evaporation chamber to be heated and gasified, after a cleavage reaction is conducted through a cleavage chamber, gas is formed, the gas enters the film coating chamber, and in the gas introduction process, the temperature of the area where the lattices are located is maintained to be 30-100 DEG C,so that a thin film material is obtained. According to the heating control method, area division is conducted through the lattices; independent heating is conducted for temperature control; and the crystallization rate of parylene film coating is increased, and uniformity of parylene film coating is improved.

Owner:XIA YU NANO TECH (SHENZHEN) CO LTD

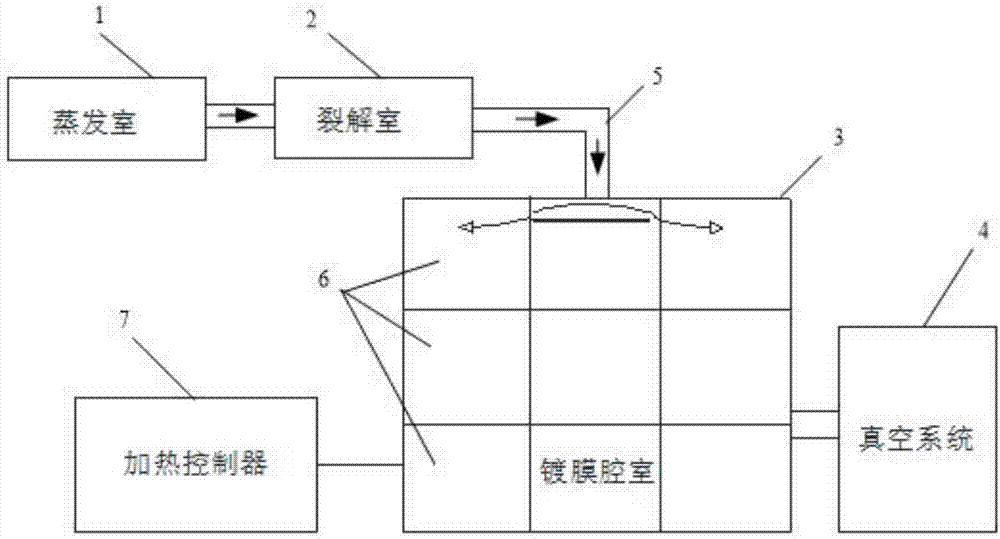

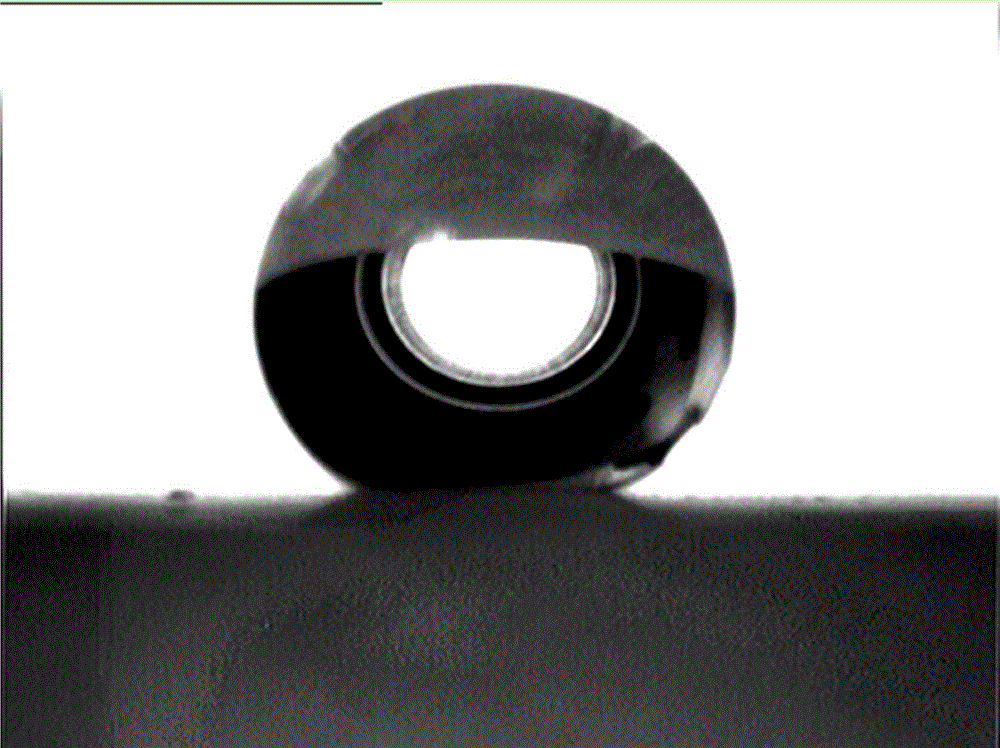

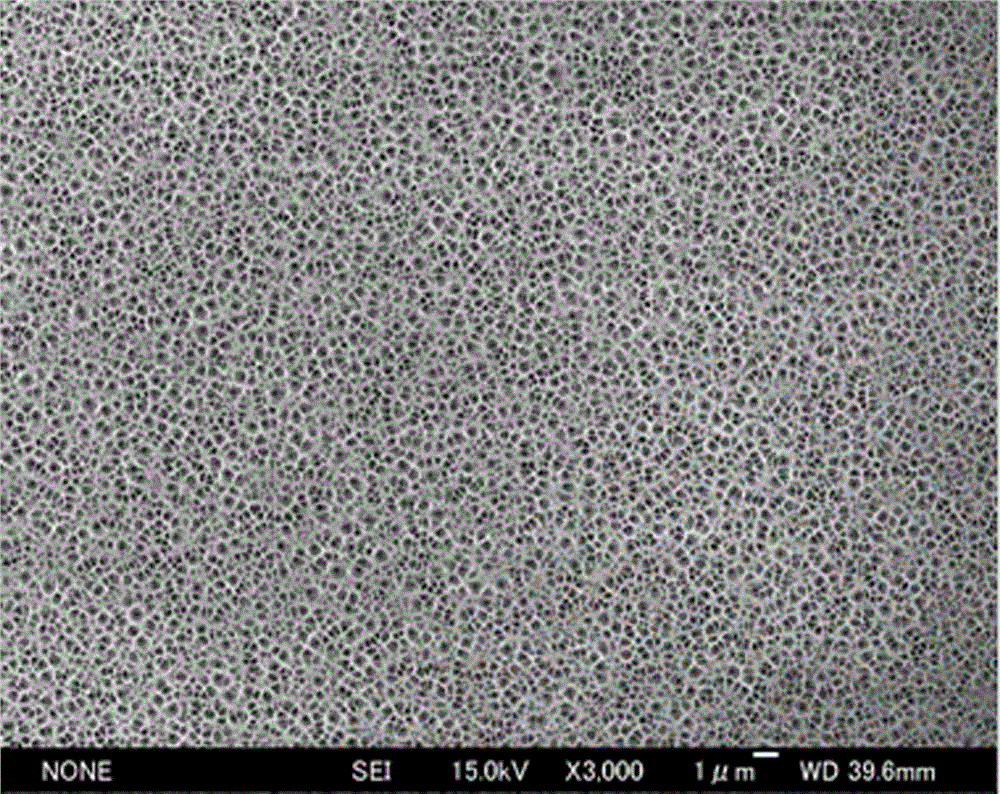

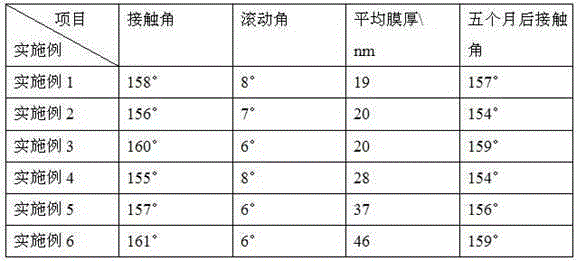

Preparation method for super-hydrophobic aluminum surface

ActiveCN105401200AImprove hydrophobicityImprove stabilityAnodisationChemical vapor deposition coatingEvaporationPhosphoric acid

The invention provides a preparation method for the super-hydrophobic aluminum surface. The preparation method comprises the following steps that (1) an aluminum sheet is pretreated, specifically, the aluminum sheet is sequentially placed into a detergent aqueous solution, an ethanol solution and a deionized aqueous solution for ultrasonic wave cleaning, and the aluminum sheet is subjected to electrolytic polishing treatment; (2) anodizing is conducted, specifically, the aluminum sheet is put into a phosphoric acid solution for anodizing and then put into a phosphoric acid solution for pore broadening; and (3) chemical vapor deposition (CVD) evaporation is conducted, specifically, the aluminum sheet is put into parylene coating equipment after being anodized, and even parylene evaporation is achieved by controlling the reaction conditions. According to the novel preparation method for the super-hydrophobic aluminum surface, the anodizing method and the CVD evaporation method are combined. A prepared aluminum surface thin film is good in hydrophobic property, high in stability and good in cold resistance and humidity resistance; the control over the thickness of the coating can be achieved by controlling the input amount of the parylene, and the thin film with the nano-scale thickness is obtained.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

Method for preparing super-hydrophobic copper surface by combining electro-deposition with CVD

InactiveCN105483781AExcellent superhydrophobic propertiesVacuum evaporation coatingSputtering coatingEvaporationParylene coating

The invention discloses a method for preparing a super-hydrophobic copper surface by combining electro-deposition with CVD. The method comprises the following steps: (1) copper sheet pre-treatment: sequentially placing a copper sheet into acetone solution, ethanol solution and deionized water solution, ultrasonically cleaning, and then mechanically polishing; (2) combining the copper sheet with a commercial anodic alumina template through a fixture, taking the copper sheet as a cathode, taking a platinum electrode as an anode, and taking nickel ion solution as an electrolyte for carrying out electro-deposition reaction; and (3) using small Parylene coating equipment for carrying out CVD chemical evaporation, so as to prepare the super-hydrophobic copper surface; and through a test, the obtained super-hydrophobic copper surface is excellent in super-hydrophobic performance, and capable of being used in the aspects of anti-fouling, anti-rusting and self-cleaning applications for a metallic copper surface. The method disclosed by the invention is simple to operate, short in processing time, and high in controllability.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

Use of parylene coating in an electric device

ActiveUS20060018080A1Low gasLess expensive or unsealedPrinted circuit assemblingLine/current collector detailsEpoxyElectrical devices

An electric device includes an electric element, such as a wound film capacitor, with power input and output leads. The electric element includes a coating layer of parylene that provides moisture resistance and low gas and moisture permeability to protect the electric element from short and long term moisture degradation effects. A known case layer is located adjacent to the coating layer. The case layer is a metal, epoxy-based, silicone-based, or polymer material that encapsulates the coating layer and the electric element to protect the coating layer and electric element from physical damage.

Owner:HAMILTON SUNDSTRAND CORP

Electric drive with a circuit board

ActiveUS8310838B2Improve protectionPrinted circuit assemblingElectrically conductive connectionsEnvironmental effectElectrical conductor

An electric drive (1) with a circuit board (2), having conductor tracks (3) and contact openings (4) with plated through-holes (5) and equipped with electronic components (6), the circuit board (2) being coated with a protective layer (7) of insulating material, and press-fit contacts (8) are inserted into the contact openings (4) and in electrical contact areas (9) within the contact openings (4) electrical contact exists between a press-fit contact (8) and the plated through-hole (5) of the contact opening (4). The task of the invention is to reliably protect circuit boards of electric drives exposed to moisture and other chemical environmental effects and contact them economically. This task is solved according to the invention in that the protective layer (7) is a parylene coating, which covers the circuit board (2), the electronic components (6) and the surface areas of the contact openings (4) and circuit board (2) directly connected to the contact areas (9) between at least one press-fit contact (8) and at least one contact opening (4).

Owner:BUHLER MOTOR GMBH

Manufacture method for insect specimens coated with poly-p-xylylene

InactiveCN108782540AImprove the protective effectEffective moisture-proofDead animal preservationXylyleneDecomposition

The invention relates to a manufacture method for insect specimens coated with poly-p-xylylene. The manufacture method includes increasing the temperature of poly-p-xylylene chemical material powder in an evaporation chamber to 175 DEG C before vaporization, feeding poly-p-xylylene vapor into a splitting decomposition chamber, heating the vapor to 680 DEG C, turning poly-p-xylylene vapor moleculesinto active monomer poly-p-xylylene vapor molecules after splitting decomposition, hollowing out insects, drying and dehydrating the insects in a vacuum chamber with the temperature of 25 DEG C, spraying active monomer poly-p-xylylene vapor to inner and outer surfaces of the insects in the vacuum chamber through a thin tube, evenly adsorbing and infiltrating active monomer poly-p-xylylene molecules in the vapor to the inner and outer surfaces of the insects under a vacuum state, and forming coatings 0.1-10 micrometers in thickness through polymerization and sedimentation to obtain the insectspecimens.

Owner:QIQIHAR UNIVERSITY

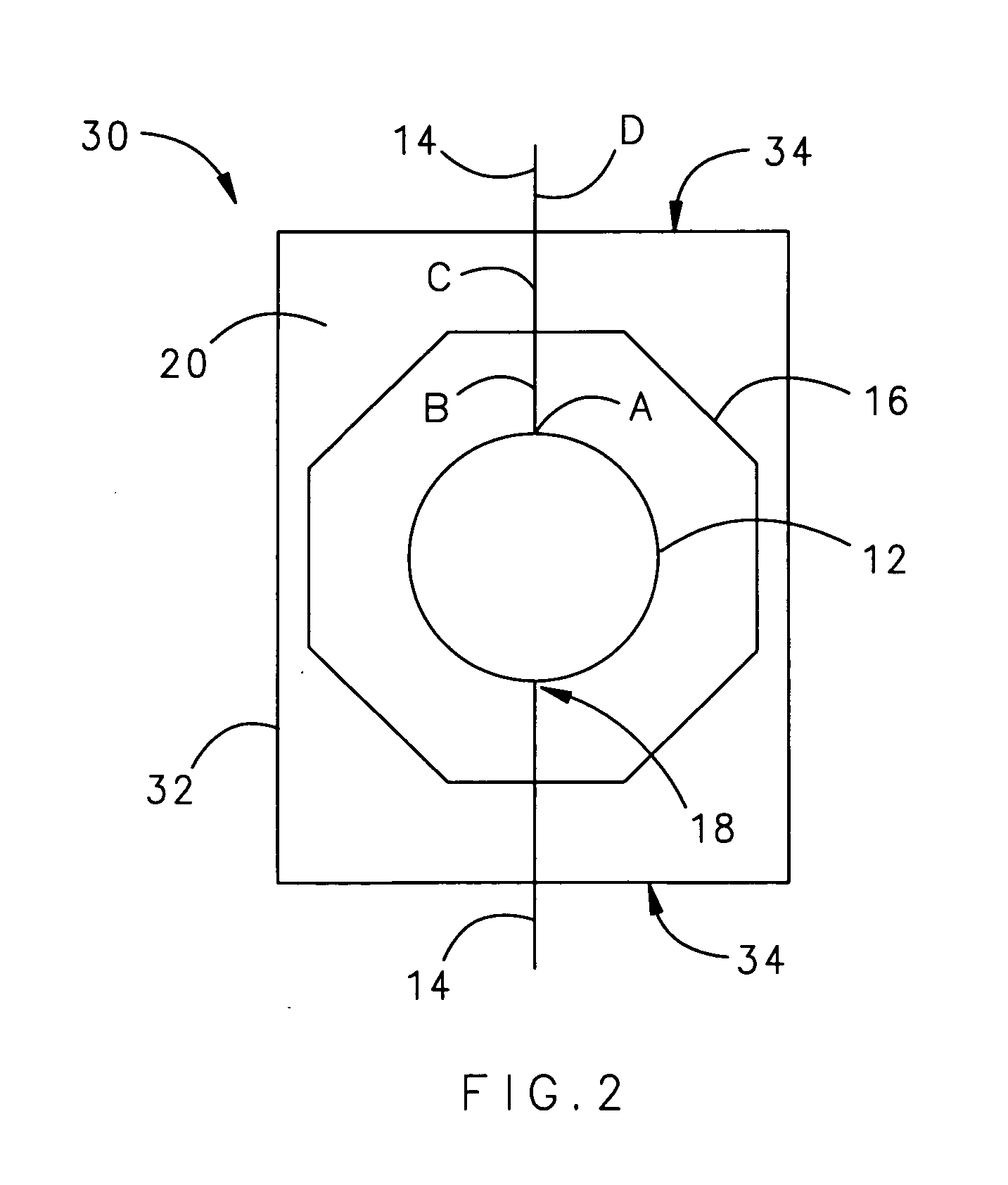

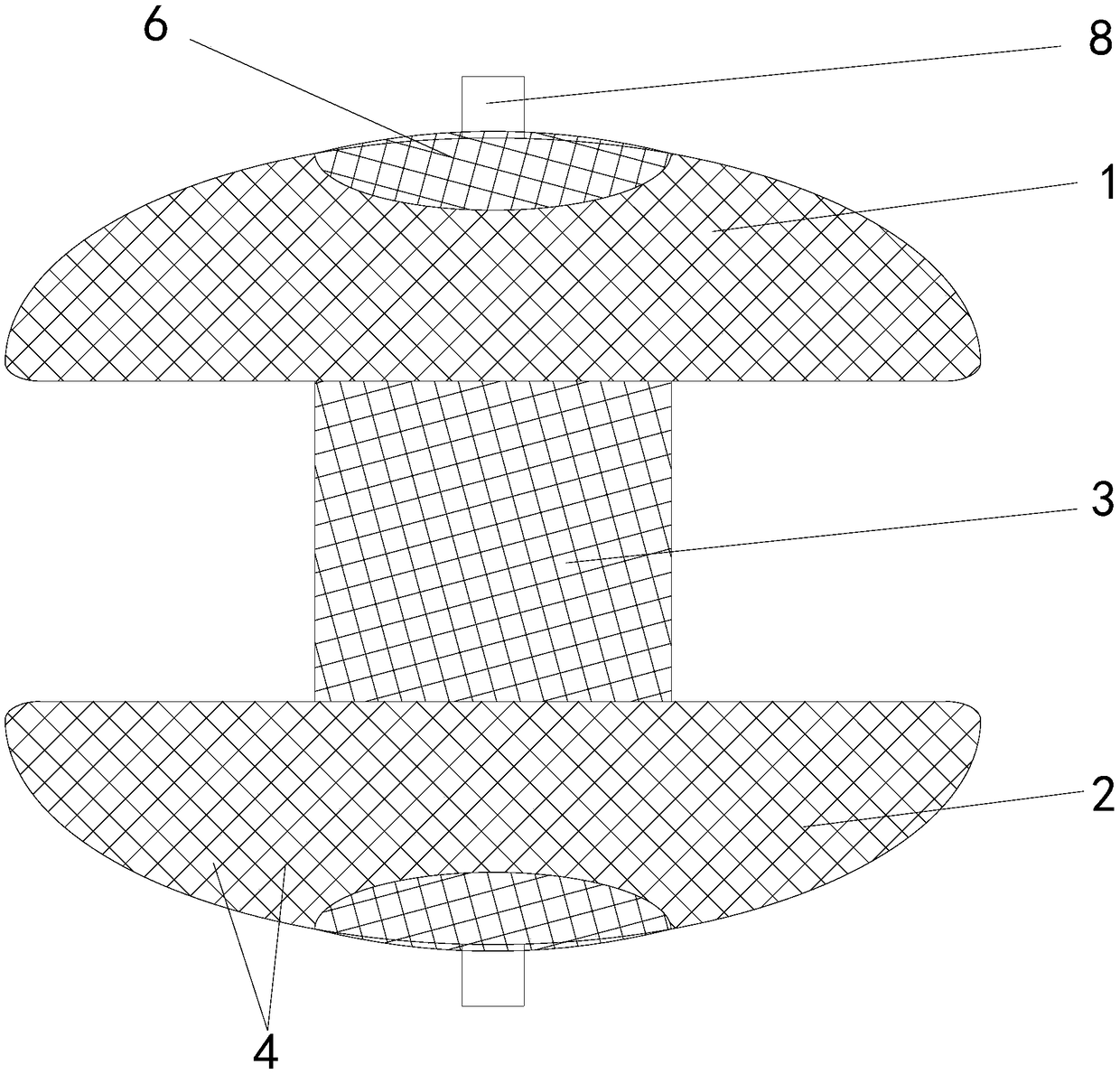

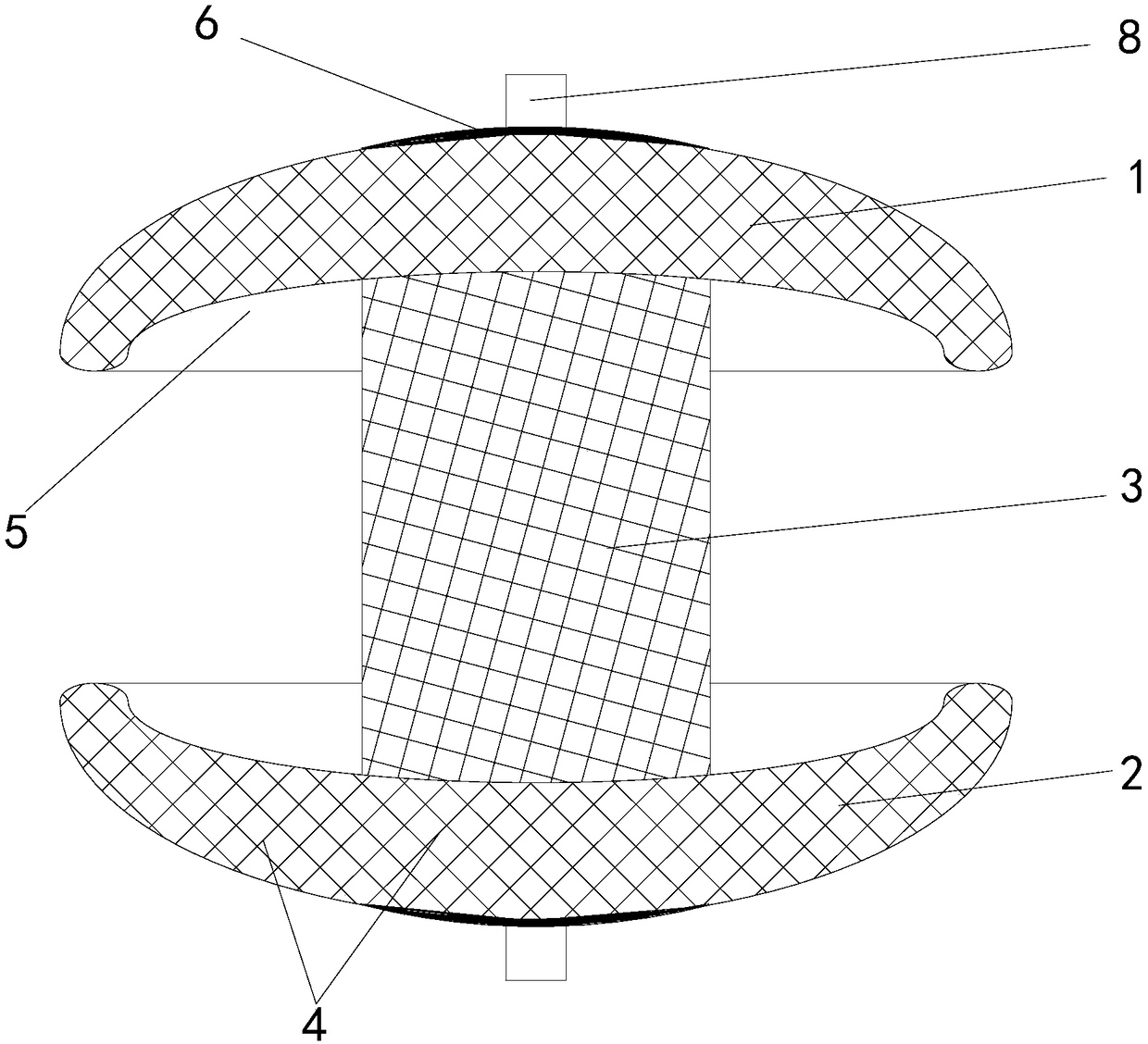

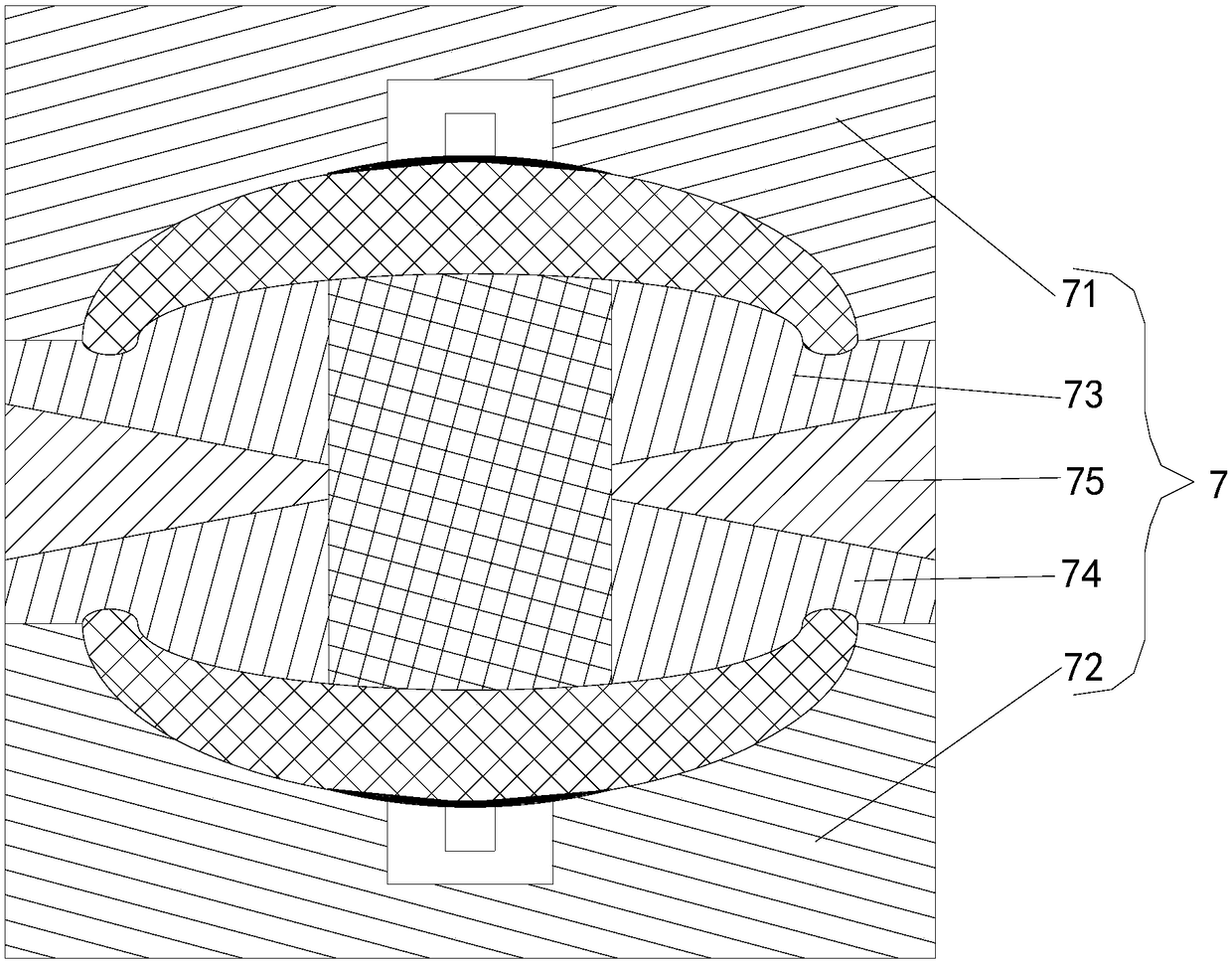

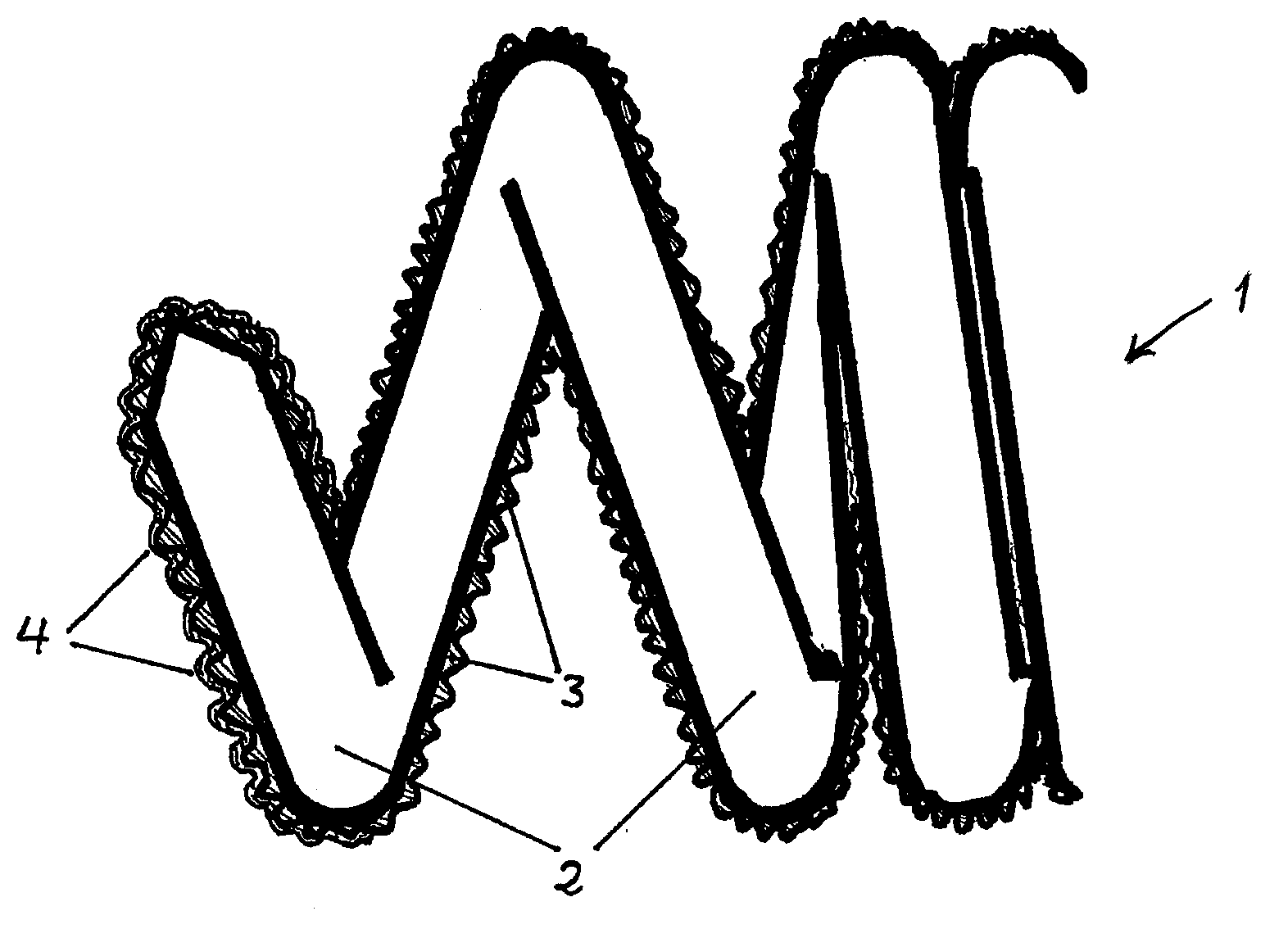

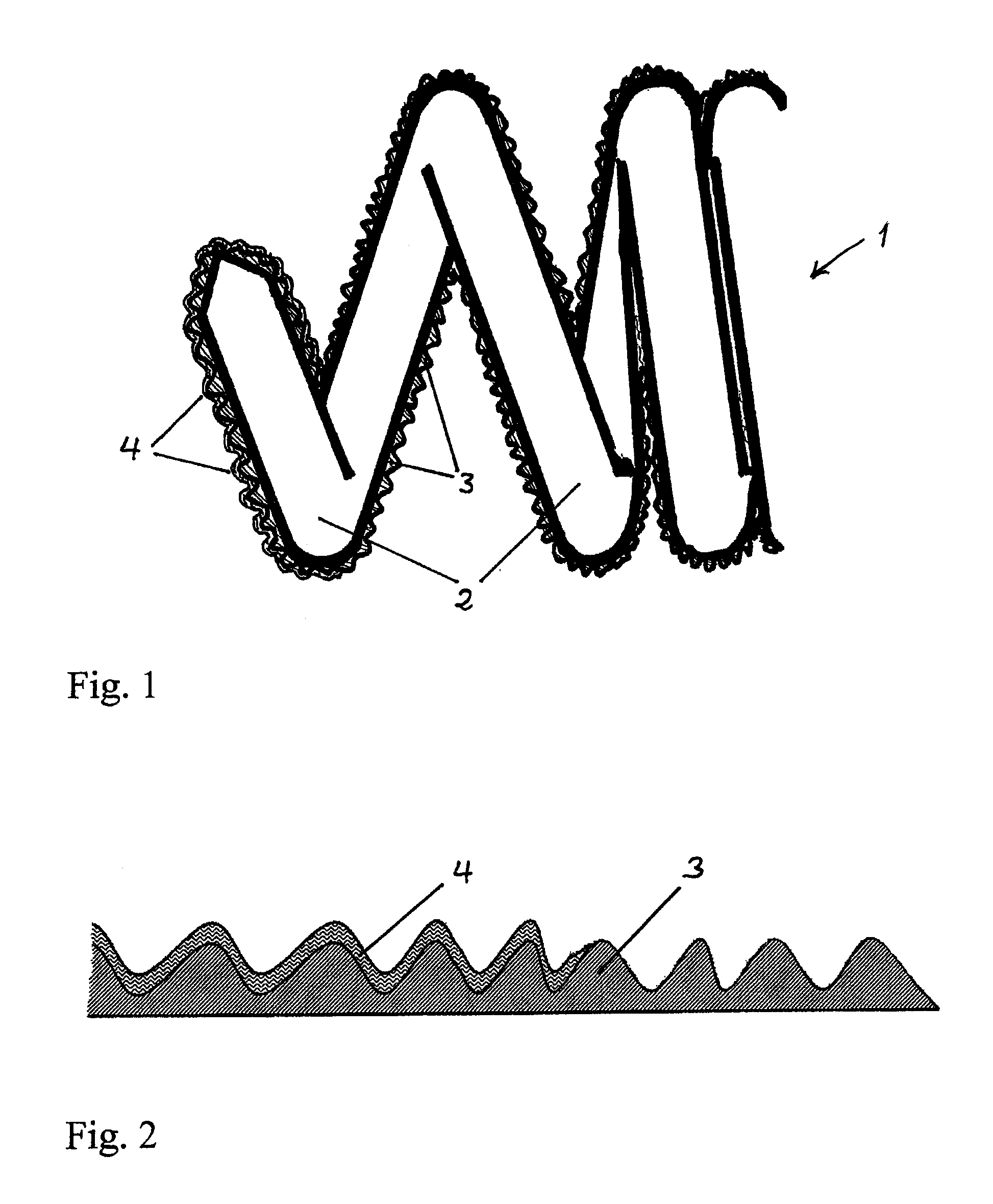

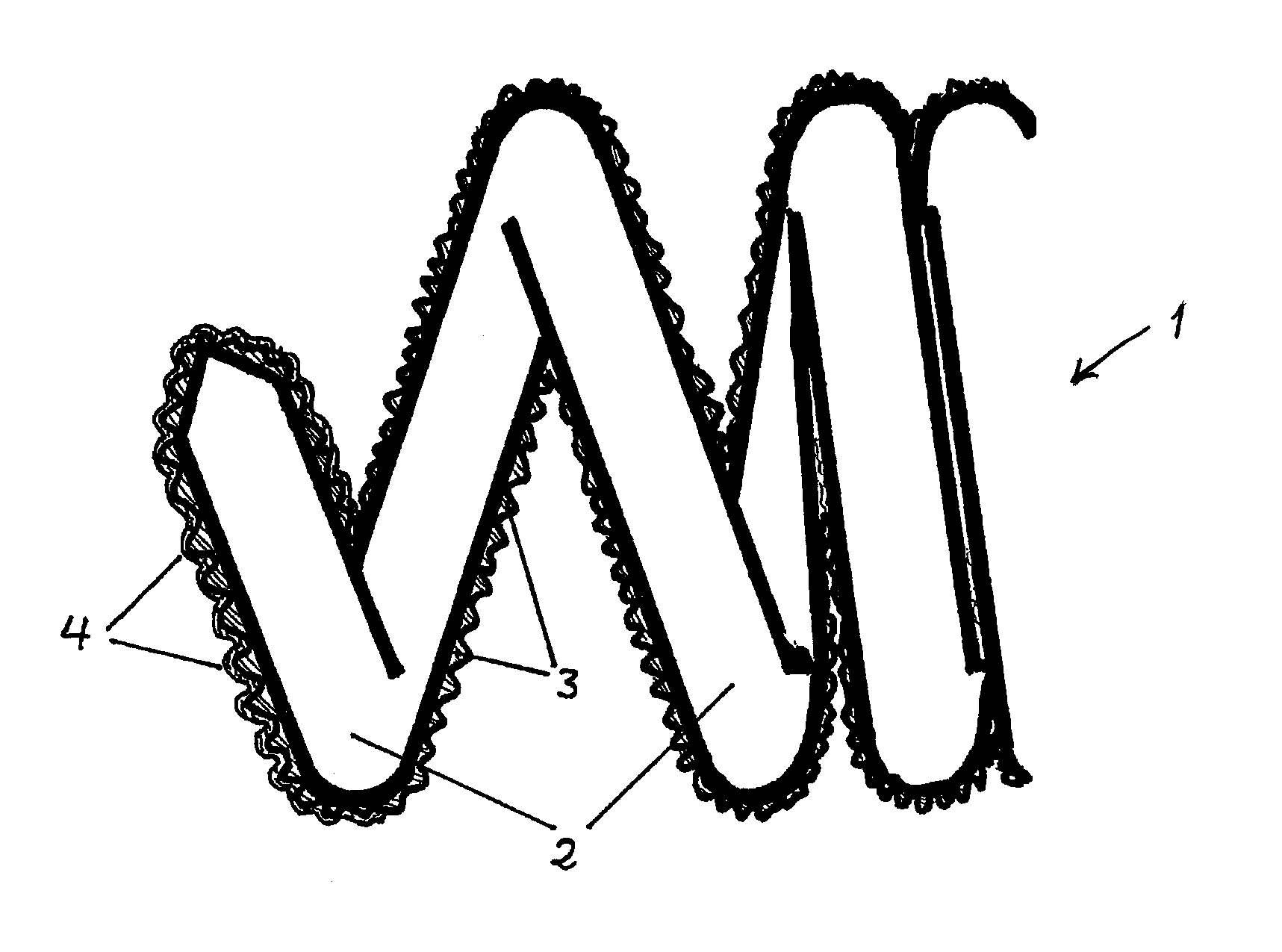

A closure device for preventing thrombosis of patent oval foramen and a preparation method

A closure device for preventing thrombosis of patent oval foramen is disclosed. The left disk, a right disk and a waist are woven with grid lines made of nickel-titanium alloy, and the surface of gridlines is coated with Parylene coating by vacuum vapor deposition process. The invention also discloses a preparation method of the closure device, which comprises the following steps: selecting a nickel-titanium alloy wire with uniform thickness as a grid line; coating the grid lines with the Parylene coatings by vacuum vapor deposition; weaving at least two group of grid lines to form a networkmanagement; weaving an expansion line in a grid between gridlines of a network management; thermally shaping the mesh tube into a left disk, a right disk and a waist through a thermally-shaped mold. As that closure device for prevent thrombosis is generated, the nickel element material of the closure device is completely isolate from the body fluid of the human body, the nickel element is not allowed to enter the human body, the health of the human body is ensured, and the application range of the closure device is enlarged.

Owner:WUHAN VICKOR MEDICAL TECH CO LTD

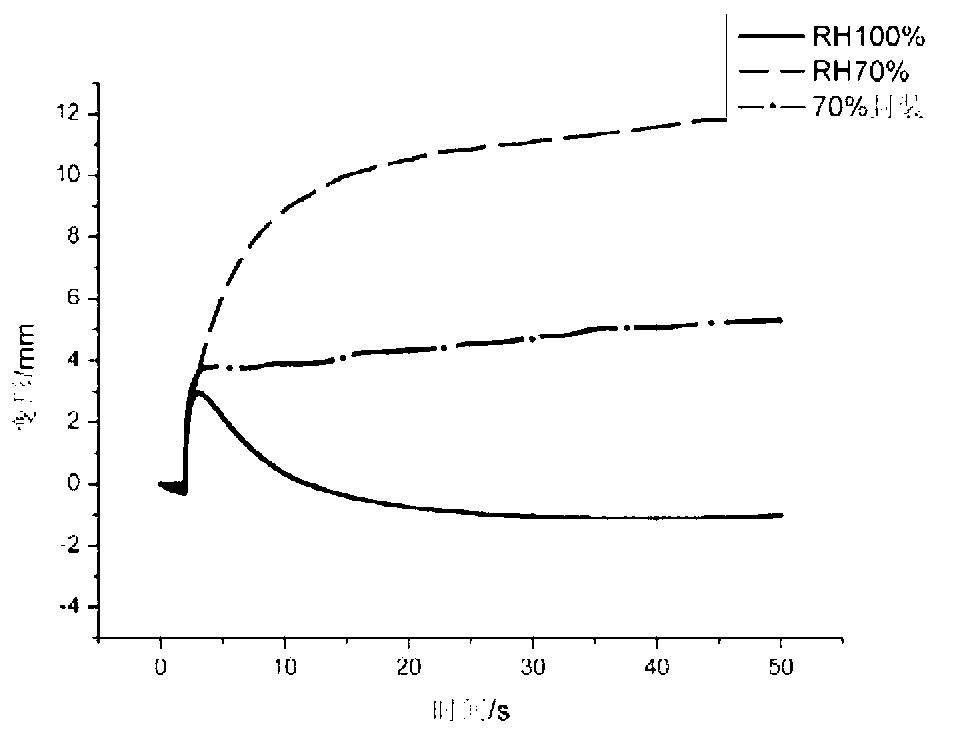

Packaging process capable of improving stability of ionic polymer metal composite (IPMC) driver

InactiveCN103280522AMoisture stableQuick bondingPiezoelectric/electrostrictive device manufacture/assemblyIonic polymer–metal compositesAdhesive

The invention discloses a packaging process capable of improving the stability of an ionic polymer metal composite (IPMC) driver. The packaging process is characterized in that the packaging process is implemented by two methods, wherein one method comprises the steps of performing pre-packaging by using an ultraviolet gluing material, and depositing a Parylene coating or a gas barrier layer such as a dense oxide gas barrier layer at normal temperature; and the other method comprises the step of adhering an IPMC surface to a high-barrier thin film material by using light curing glue as an adhesive, so that the stability of water in the material is ensured. According to the packaging process, the curing time of a packaging layer is greatly reduced; in addition, heating is not required in the whole process, so that the water in the material can be accurately controlled; and the packaging process has high practical value.

Owner:XI AN JIAOTONG UNIV

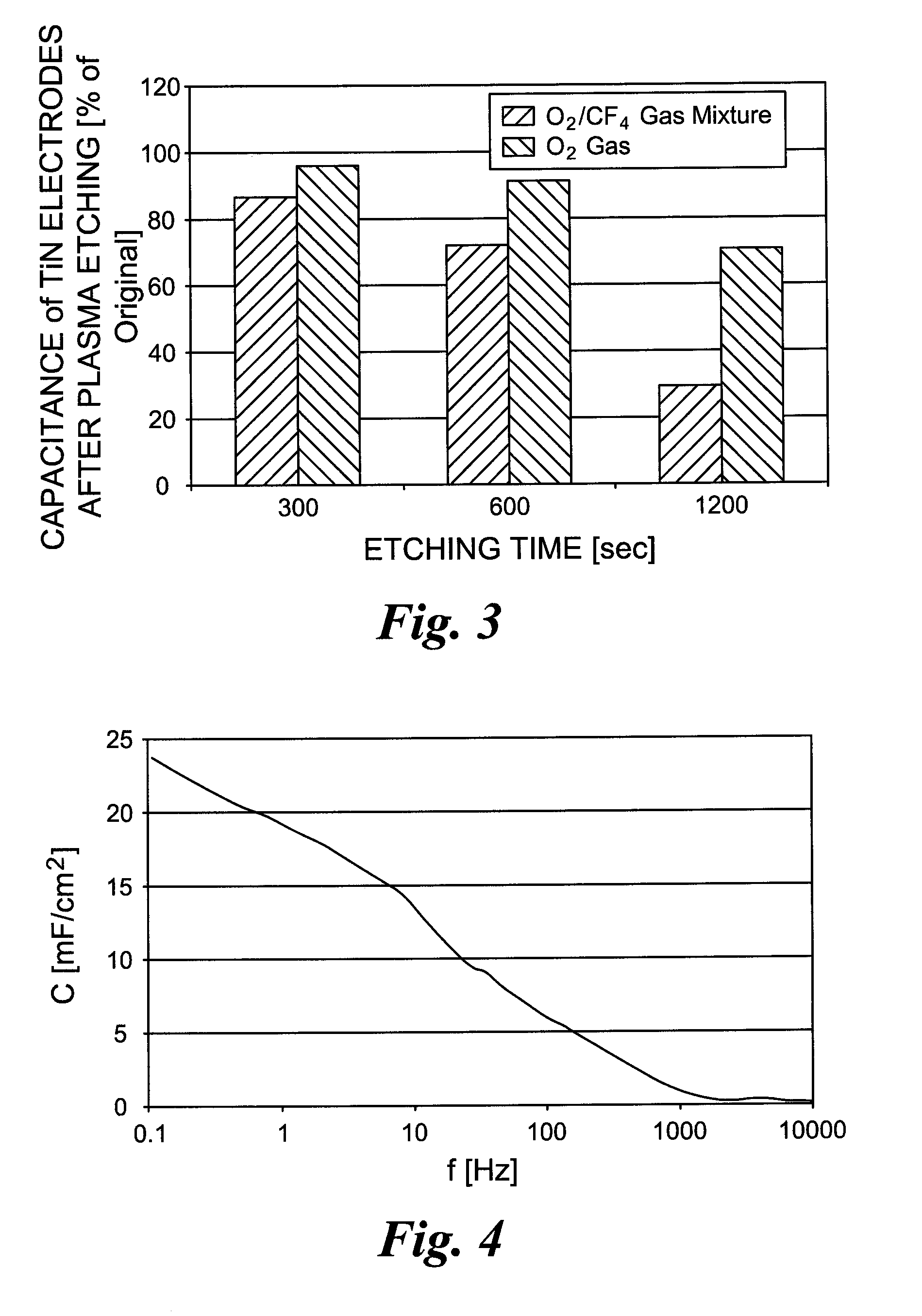

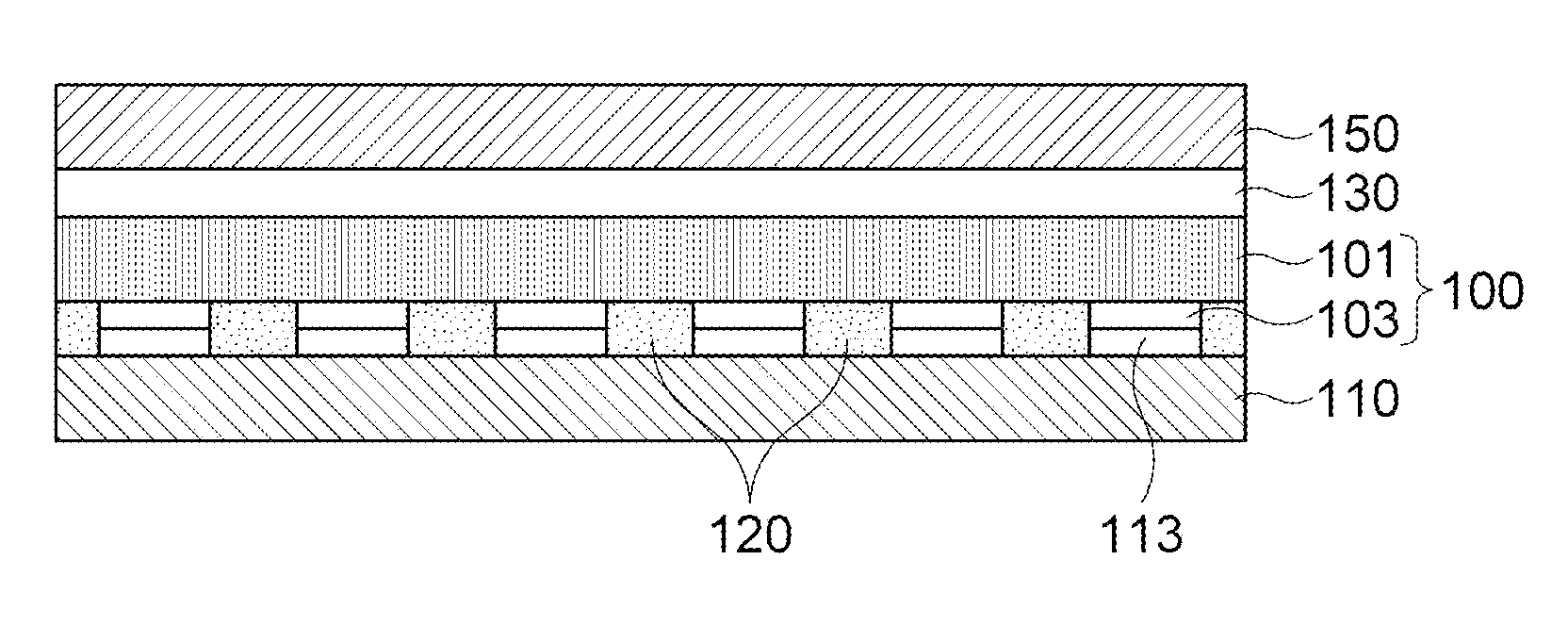

Selective parylene coating for cardiac pacemaker electrodes

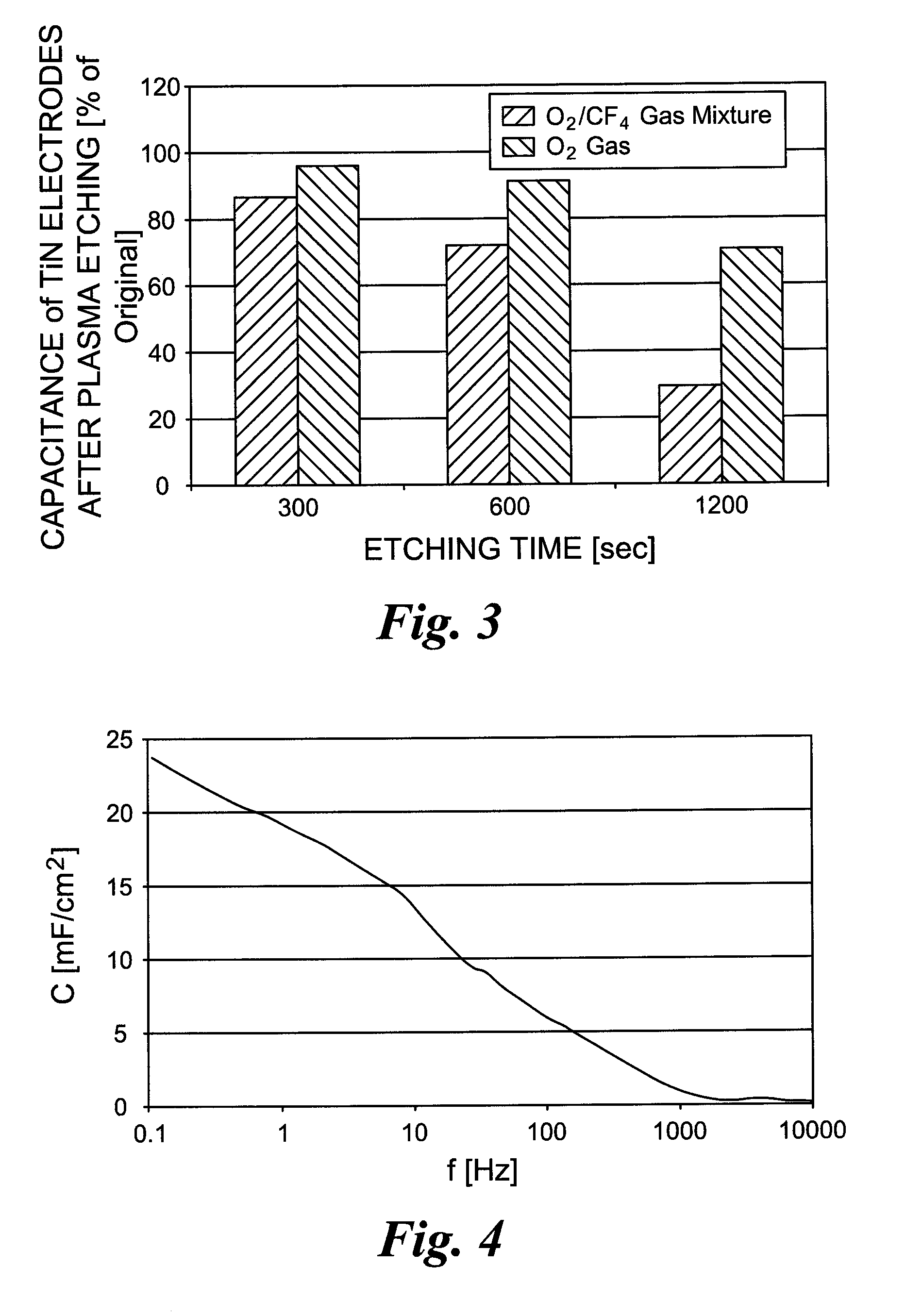

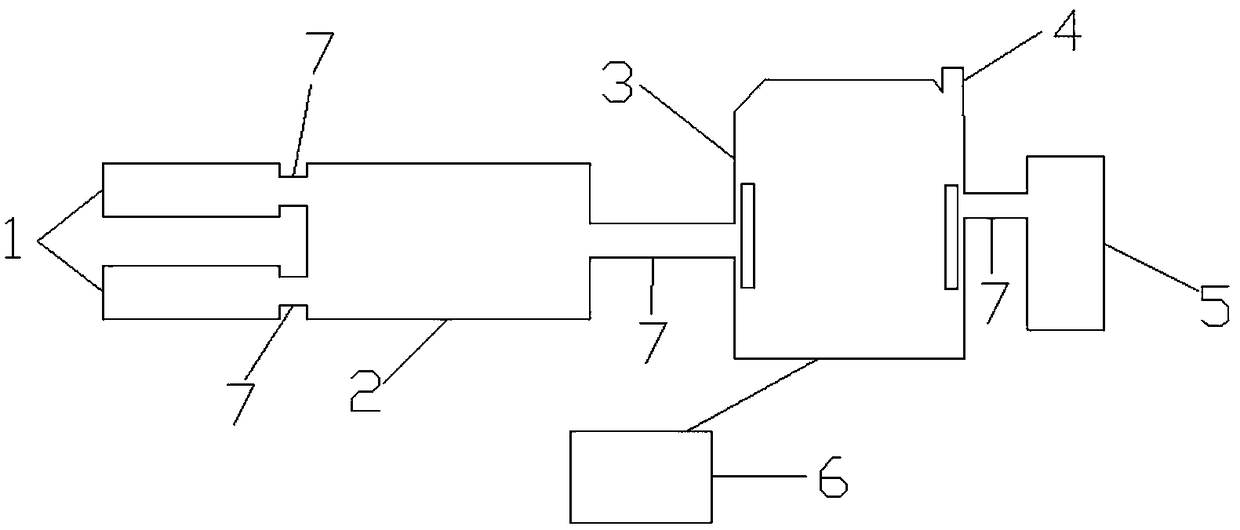

ActiveUS20090312825A1Without affecting capacitanceAvoid bleedingDecorative surface effectsInternal electrodesCapacitanceCoated surface

A stimulation electrode is produced having a porous film layer and being partially coated with an insulating parylene (polyparaxylylene) film, whose insulating film has a dielectric breakdown voltage of greater than 100 V. Parylene is deposited on the entire surface of a porous film coating and then partially removed again by plasma. After the partial removal of the parylene, this porous film still has a capacitance of greater than 15 mF / cm2 in a physiological NaCl solution at a frequency of 0.1 Hz. For the stimulation electrode, the transition from the insulating film to the porous film is formed so that the film thickness of the parylene film decreases continuously. In this way, a stimulation electrode having a porous film layer and being partially coated with an insulating parylene film is provided, whose electrode on the non-insulating parylene film-coated surface has a capacitance of greater than 15 mF / cm2 in a physiological NaCl solution at a frequency of 0.1 Hz and whose insulating film advantageously has a dielectric breakdown voltage of greater than 100 V.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Machining technology and machining device facilitating parylene coating detection

PendingCN109338334ASolve problems that are not easy to detectDetection is clear and intuitiveFluorescence/phosphorescenceChemical vapor deposition coatingDecompositionWhitening Agents

The invention discloses a machining technology and a machining device facilitating parylene coating detection, and belongs to the technical field of chemical vapor deposition. The machining technologycomprises the steps that fluorescent whitening agent powder is arranged in a sublimation cup, a vacuum deposition chamber is sealed, a vacuum system is used for conducting pumping to achieve vacuum,a cooling controller is utilized for controlling the temperature of the area of the vacuum deposition chamber, a parylene material is placed in an evaporation chamber to be heated and gasified, and gas is formed after the splitting decomposition reaction is conducted in a splitting decomposition chamber; and a sublimation cup heating switch is turned on, the heating temperature is set, the constant temperature is kept, the fluorescent whitening agent powder is deeply evaporated in the sublimation cup, a discharging valve is closed, a heating power source is turned off, the vacuum deposition chamber is opened, a machined workpiece is taken out and placed on a detection table, and an ultraviolet lamp is used for conducting irradiation detection. According to the machining technology and themachining device facilitating parylene coating detection, the fluorescent whitening agent powder is sublimated and evenly deposited on the machined workpiece, the coating protectiveness is not damaged, the ultraviolet lamp is used for irradiation for detection, and visual observation can be achieved for the machined product effect.

Owner:JIANGSU KERUN PHOTOELECTRIC TECH CO LTD

Selective parylene coating for cardiac pacemaker electrodes

ActiveUS8355802B2Avoid bleedingPrecise definitionInternal electrodesPretreated surfacesCoated surfaceCapacitance

A stimulation electrode is produced having a porous film layer and being partially coated with an insulating parylene (polyparaxylylene) film, whose insulating film has a dielectric breakdown voltage of greater than 100 V. Parylene is deposited on the entire surface of a porous film coating and then partially removed again by plasma. After the partial removal of the parylene, this porous film still has a capacitance of greater than 15 mF / cm2 in a physiological NaCl solution at a frequency of 0.1 Hz. For the stimulation electrode, the transition from the insulating film to the porous film is formed so that the film thickness of the parylene film decreases continuously. In this way, a stimulation electrode having a porous film layer and being partially coated with an insulating parylene film is provided, whose electrode on the non-insulating parylene film-coated surface has a capacitance of greater than 15 mF / cm2 in a physiological NaCl solution at a frequency of 0.1 Hz and whose insulating film advantageously has a dielectric breakdown voltage of greater than 100 V.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

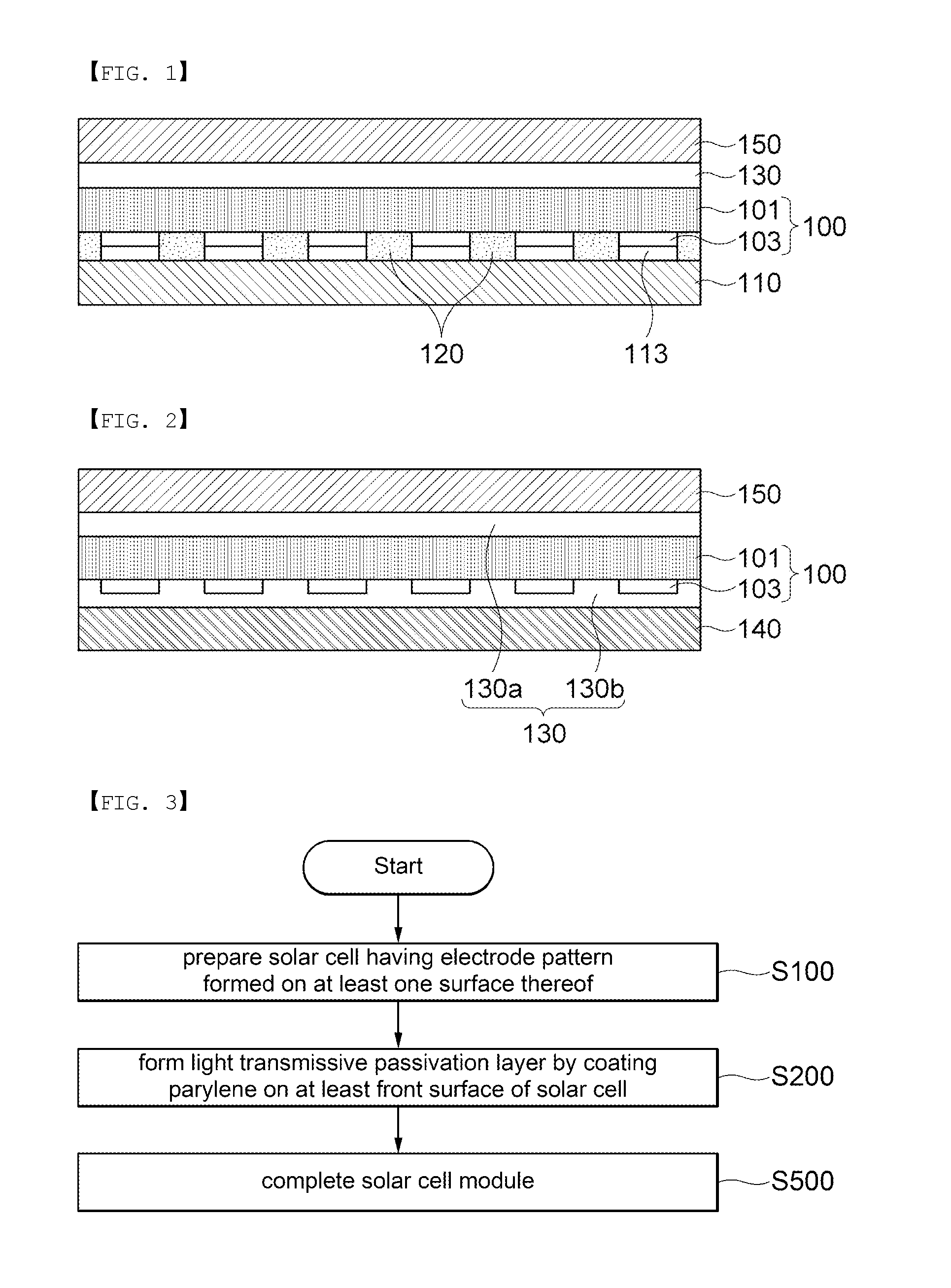

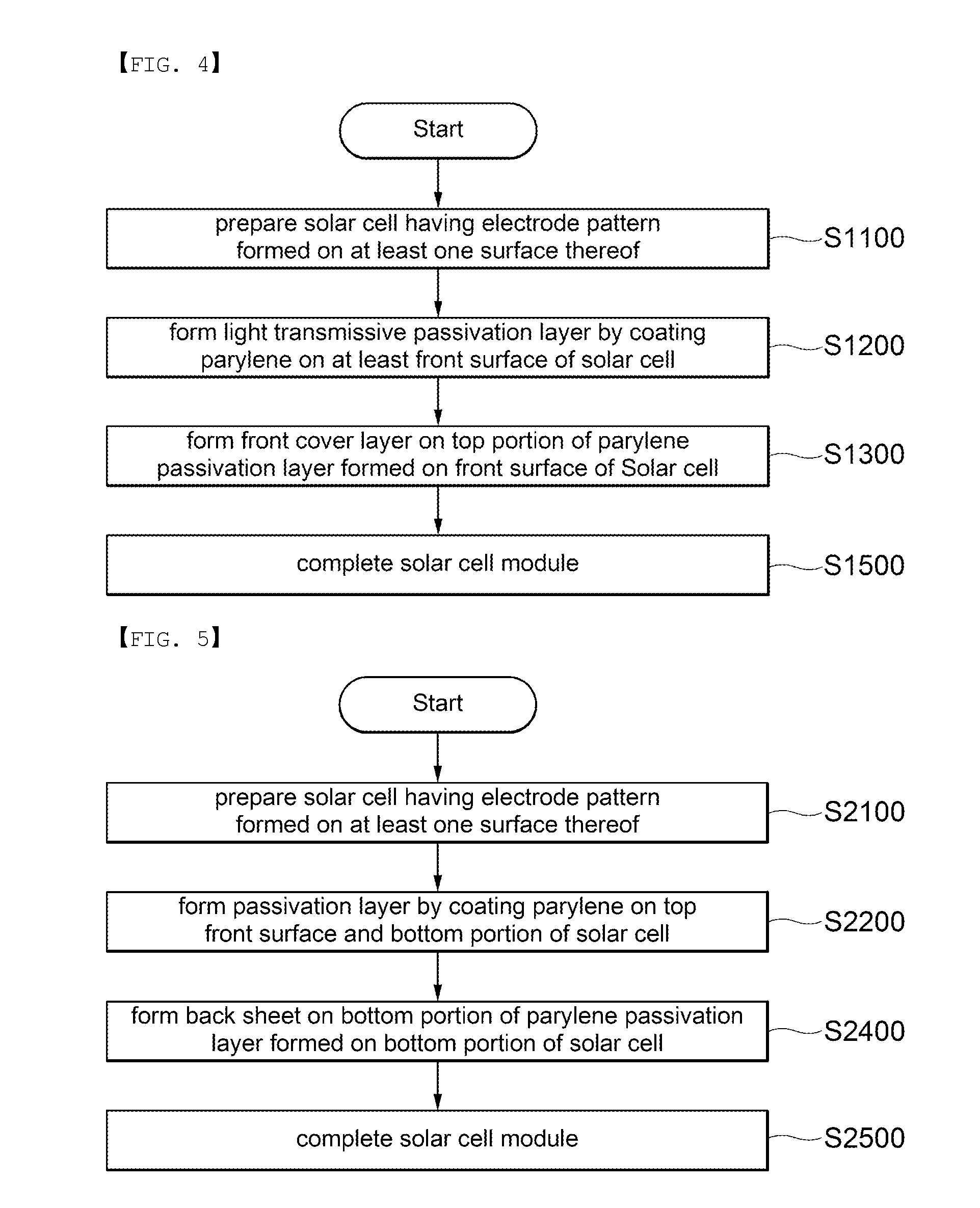

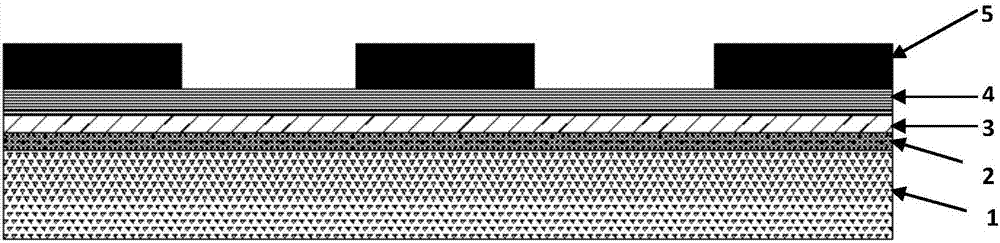

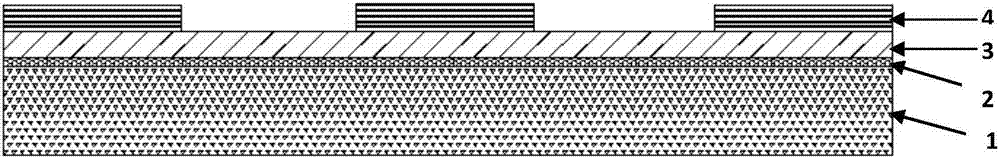

Solar cell module and method for manufacturing the same

InactiveUS20120247551A1Avoid warpingSemiconductor/solid-state device manufacturingPhotovoltaic energy generationParylene coatingEngineering

Disclosed herein are a solar cell module and a method for manufacturing the same. According to an exemplary embodiment of the present invention, there is provided a solar cell module, including: a solar cell having electrode patterns formed on at least one surface thereof; and a parylene coating layer(s) forming a light transmissive passivation layer on at least a front surface of the solar cell. According to another exemplary embodiment of the present invention, there is provided a method for manufacturing a solar cell module, including: (a) preparing a solar cell having electrode patterns formed on at least one surface thereof; and (b) forming a light transmissive passivation layer by coating parylene on at least a front surface of the solar cell.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Ultrasonic transducer

ActiveUS20190090734A1Reduce reflectionMaterial analysis using sonic/ultrasonic/infrasonic wavesInfrasonic diagnosticsParylene coatingSound wave

An ultrasonic transducer includes a piezoelectric element in round shape, an acoustic lens, and an acoustic matching layer. The piezoelectric element generates an ultrasonic sound wave. The acoustic matching layer decreases a reflection of the ultrasonic sound wave from a subject. The piezoelectric element has a center having a hole through which an optical fiber that guides a light of a light source passes. The ultrasonic transducer transmits and receives the ultrasonic sound wave while emitting the light. The acoustic lens has a material using a resin with a withstand voltage, mainly polymethylpentene. The acoustic matching layer has a thickness set to λ / 4 by not applying a polyparaxylylene coating for ensuring the withstand voltage on the acoustic matching layer. The optical fiber has a distal end configured not to pass through the acoustic lens. The piezoelectric element and the acoustic matching layer have shapes in a planar surface.

Owner:NIHON DEMPA KOGYO CO LTD

Method and apparatus for applying external coating to grid array packages for increased reliability and performance

InactiveUS7351657B2Improved process-ability of the grid array packageImprove performanceSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringParylene coating

A method and apparatus are disclosed for selective removal of a conformal coating from the solder balls of grid array packages such that the benefits of the coating are realized. An ancillary benefit of the invention is improved process-ability of the grid array package by improving the mechanical containment of the solder during the reflow process and improved electrical isolation between the individual solder attachment points. For example, a method for coating a ball grid array is provided, which includes coating the ball grid array with a thin layer of parylene. Next, the solder ball side of the part is butter smeared or squeegeed with a water soluble coating and assembled wet. A mask having holes in the same pattern as the balls in the grid, and a thickness that is about 80% of the height of the balls, is applied to the solder ball side of the part. This side of the part is then butter smeared again with the water soluble coating, and the entire assembly is allowed to dry. At this point, about 20% of each parylene-coated solder ball protrudes higher than the surface of the mask. The solder ball side of the part is then grit blasted with an abrasive material. The extent that the abrasive material removes the parylene coating from the solder balls is limited by the mask and the layer of water soluble coating. Therefore, the grit blasting removes the parylene coating from only the protruding areas (e.g., about top 20%) of the solder balls. Water is then used to remove the water soluble coating, and the parylene coated part is baked to remove moisture. Thus, a parylene coated ball grid array (or column grid array) is provided that is highly impervious to moisture, has a very high dielectric strength, and thereby improves the electrical performance and reliability of the surface mounted part.

Owner:HONEYWELL INT INC

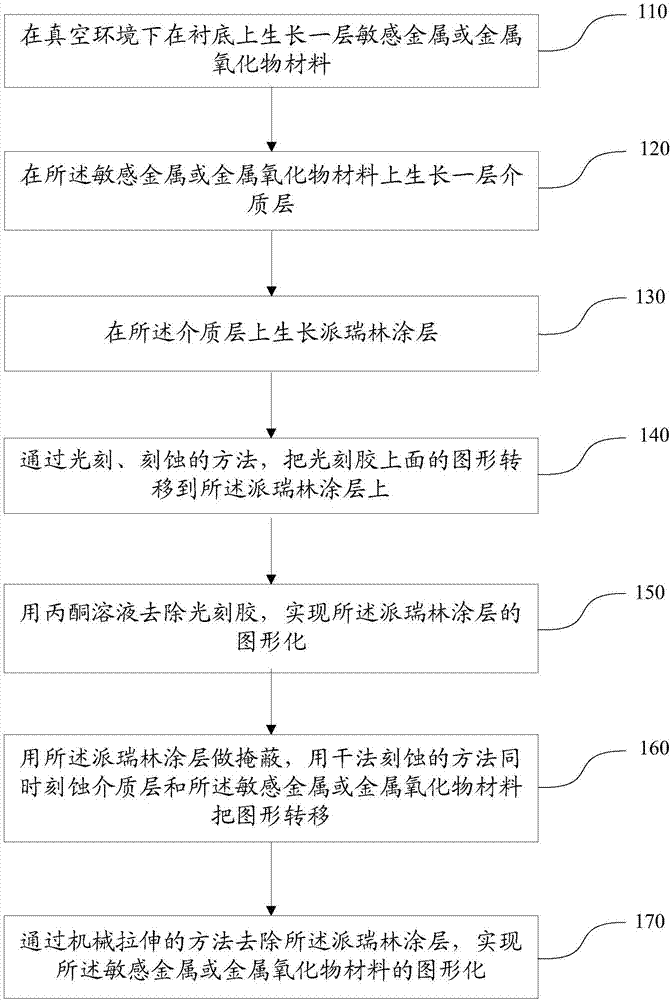

Manufacturing method for patterned sensitive metal or metal oxide material

ActiveCN106981420AAvoid contactPerformance impactSemiconductor/solid-state device manufacturingMechanical stretchingParylene coating

The invention relates to a manufacturing method for patterned sensitive metal or a metal oxide material. The manufacturing method comprises the following steps of enabling a layer of sensitive metal or metal oxide material to be grown on a substrate in a vacuum environment; enabling a layer of dielectric layer to be grown on the sensitive metal or metal oxide material; enabling a parylene coating layer to be grown on the dielectric layer; transferring a pattern on photoresist to the parylene coating layer by means of photoetching and etching methods; removing the photoresist by an acetone solution to realize patterning of the parylene coating layer; by taking the parylene coating layer as masking, etching the dielectric layer and the sensitive metal or the metal oxide material by a dry etching method at the same time to realize pattern transferring; and removing the parylene coating layer by a mechanical stretching method to realize the patterning of the sensitive metal or the metal oxide material. By adoption of the manufacturing method, contact between the sensitive metal and the metal oxide material and air can be avoided as for as possible, so that influence to the performance of the semiconductor device can be avoided.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

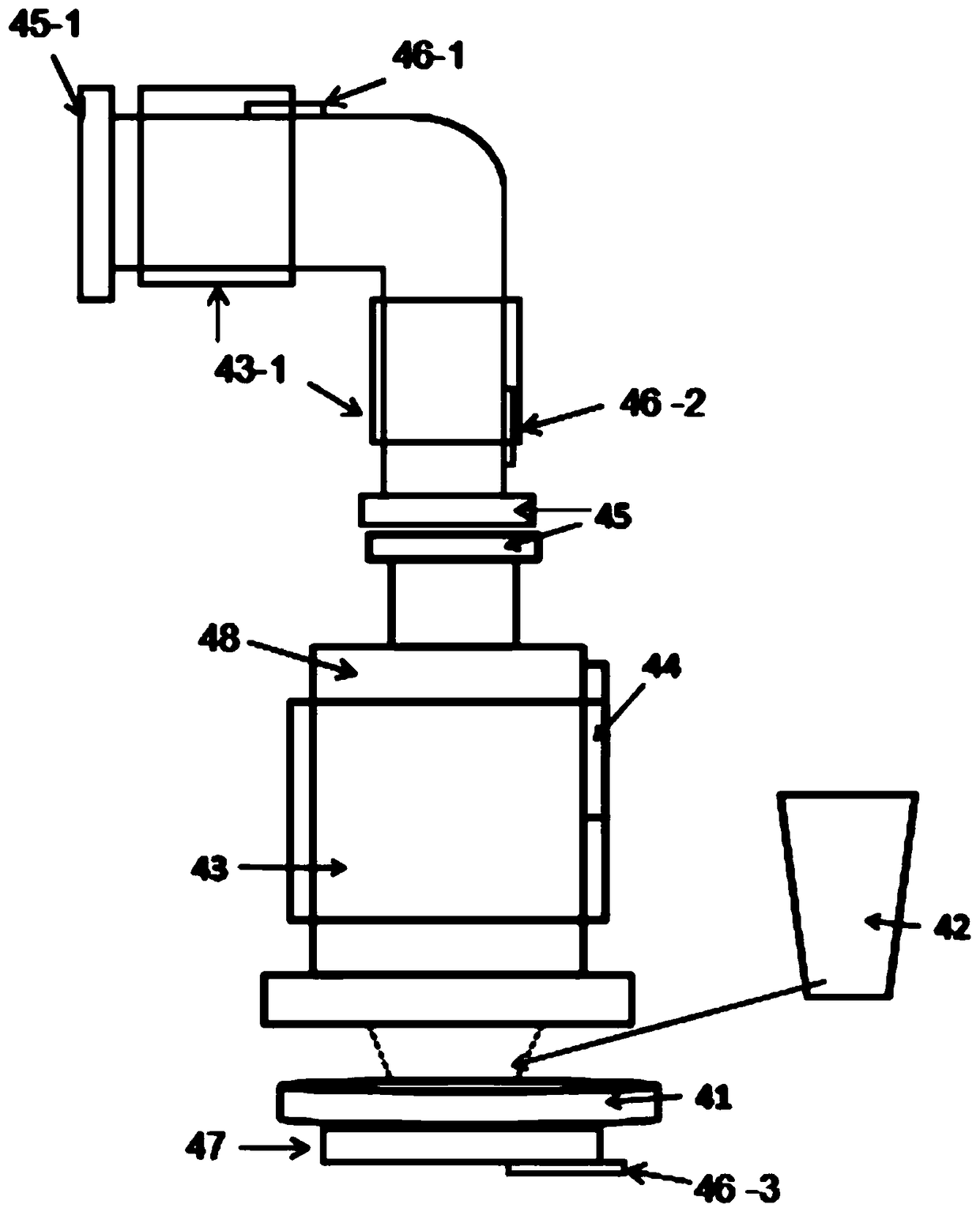

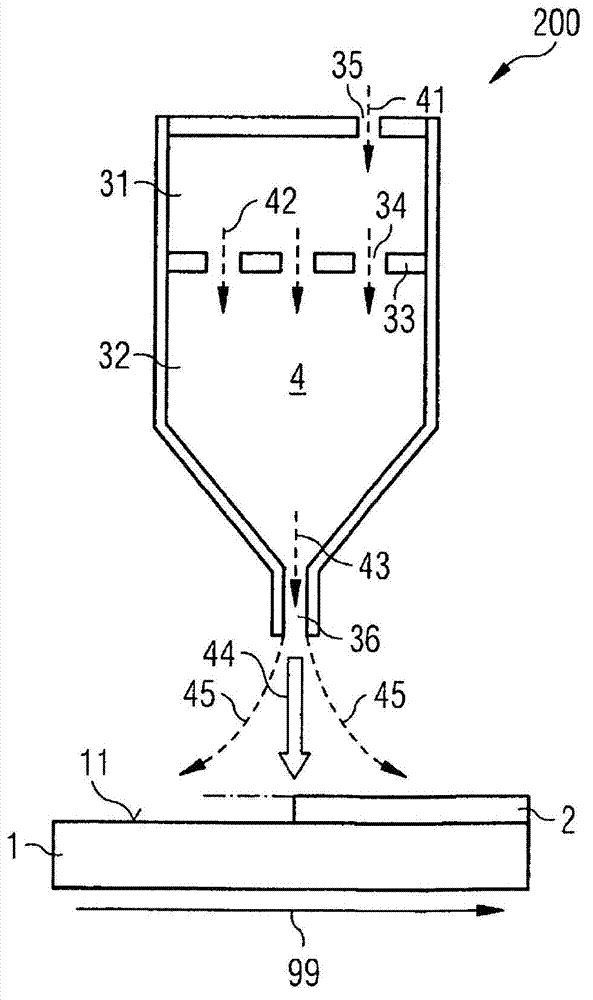

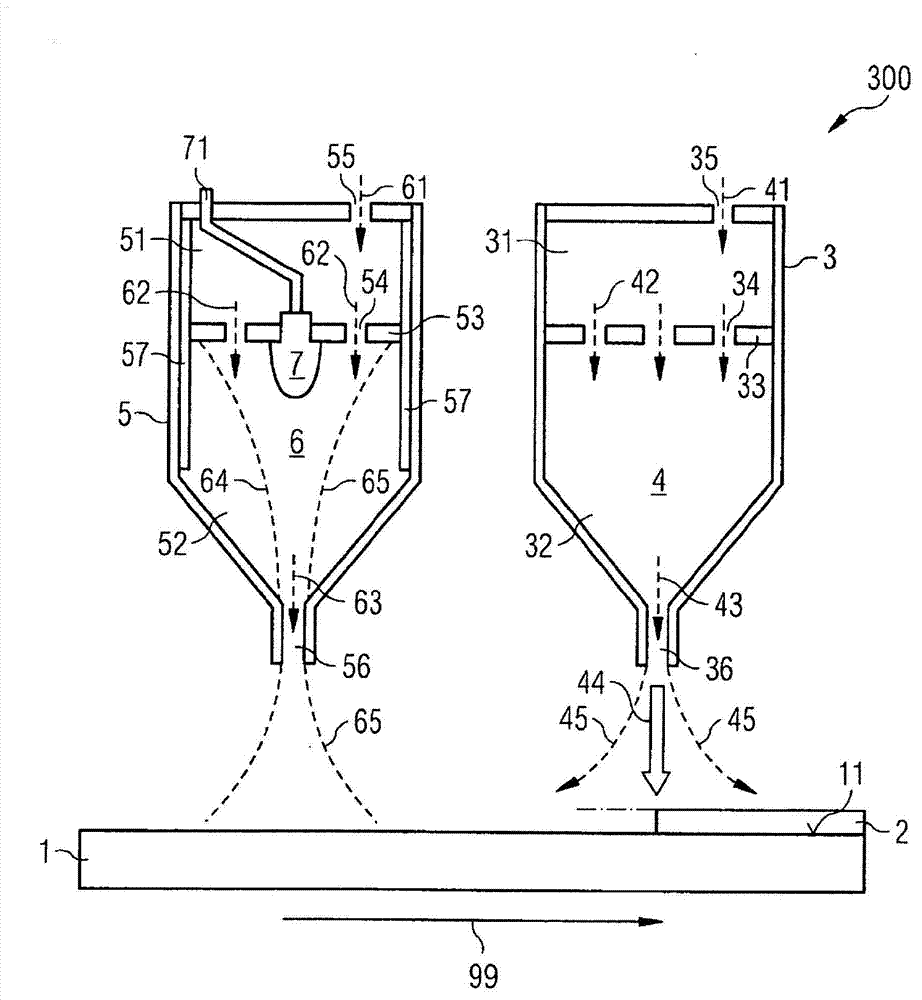

Method and device for producing a parylene coating

InactiveCN102791388AIncrease productionSolid-state devicesPretreated surfacesParylene coatingAtmospheric pressure

The invention relates to a method for producing a parylene coating (2) on at least one surface (11) of at least one component (1), in which a first gas (4) having parylene monomers is provided and the parylene monomers are deposited on the at least one surface (11) of the component (1) by feeding the first gas (4) having the parylene monomers by means of a first nozzle (3) to at least one surface (11), wherein the component (1) is disposed in an environment having atmospheric pressure. The invention further relates to a device for producing a parylene coating.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com