Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Uniform volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

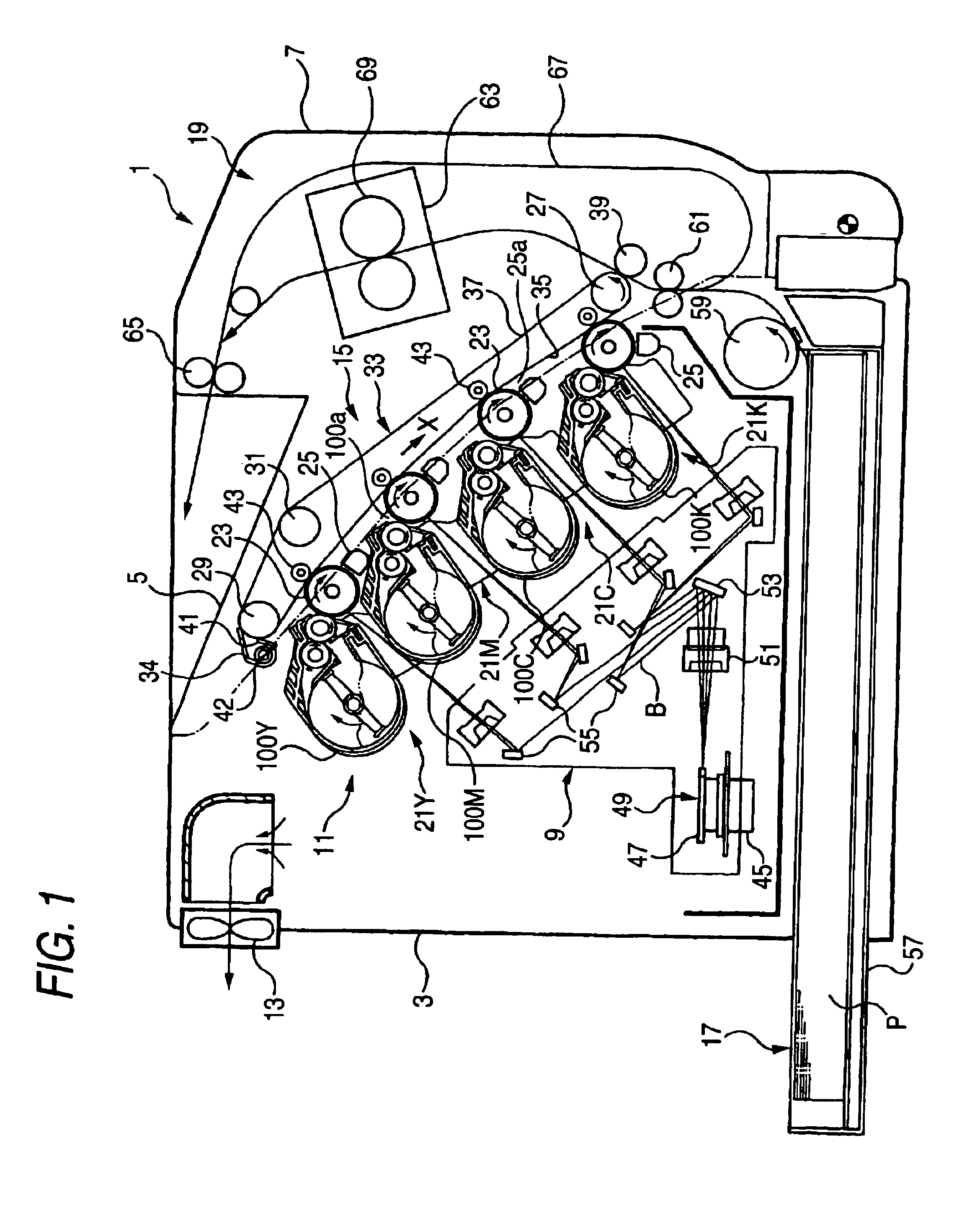

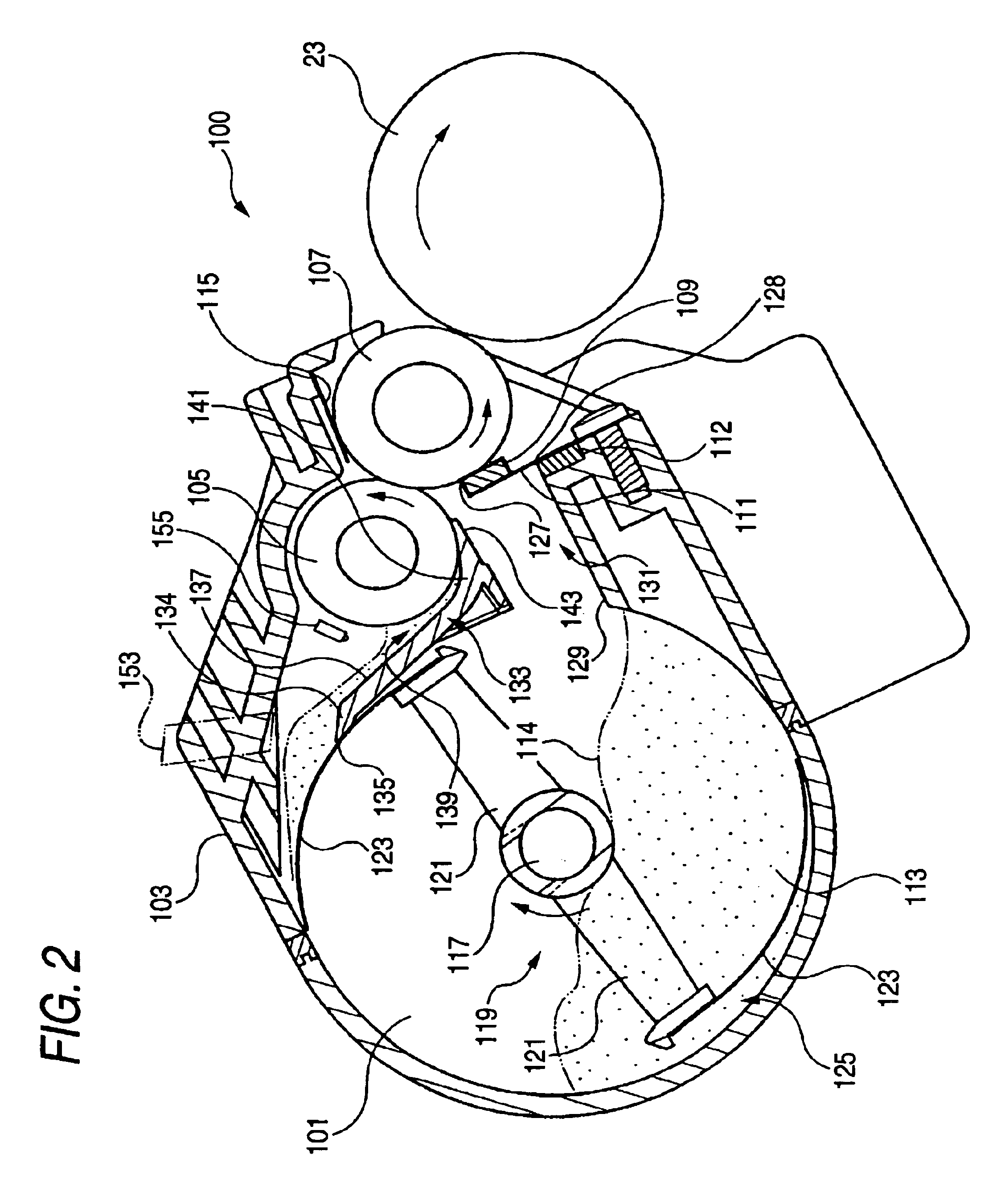

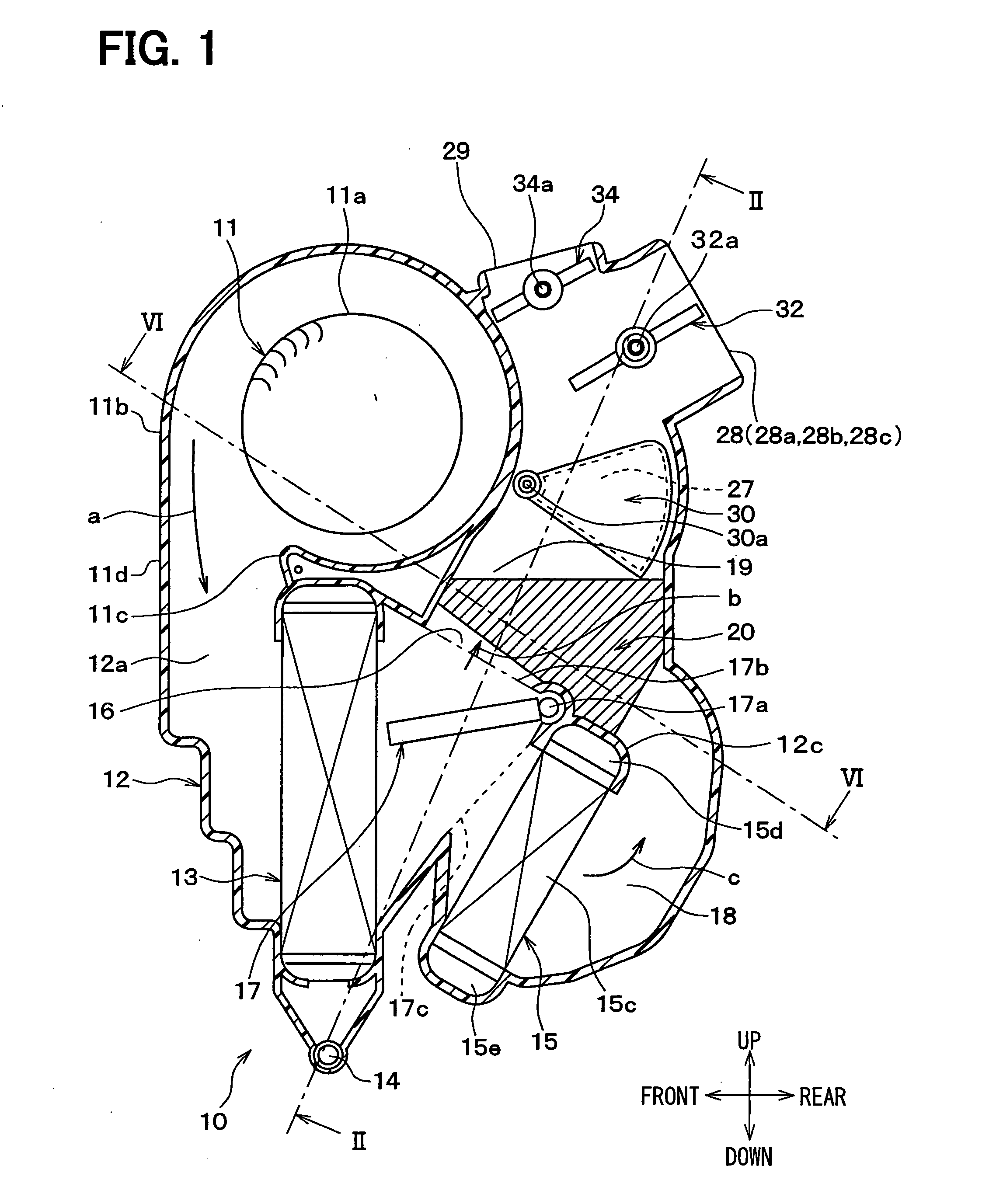

Developing device and image forming apparatus incorporating the same

InactiveUS6907215B2Improve image qualityReduce mechanical stressElectrographic process apparatusDevelopersImage formationEngineering

Owner:SEIKO EPSON CORP

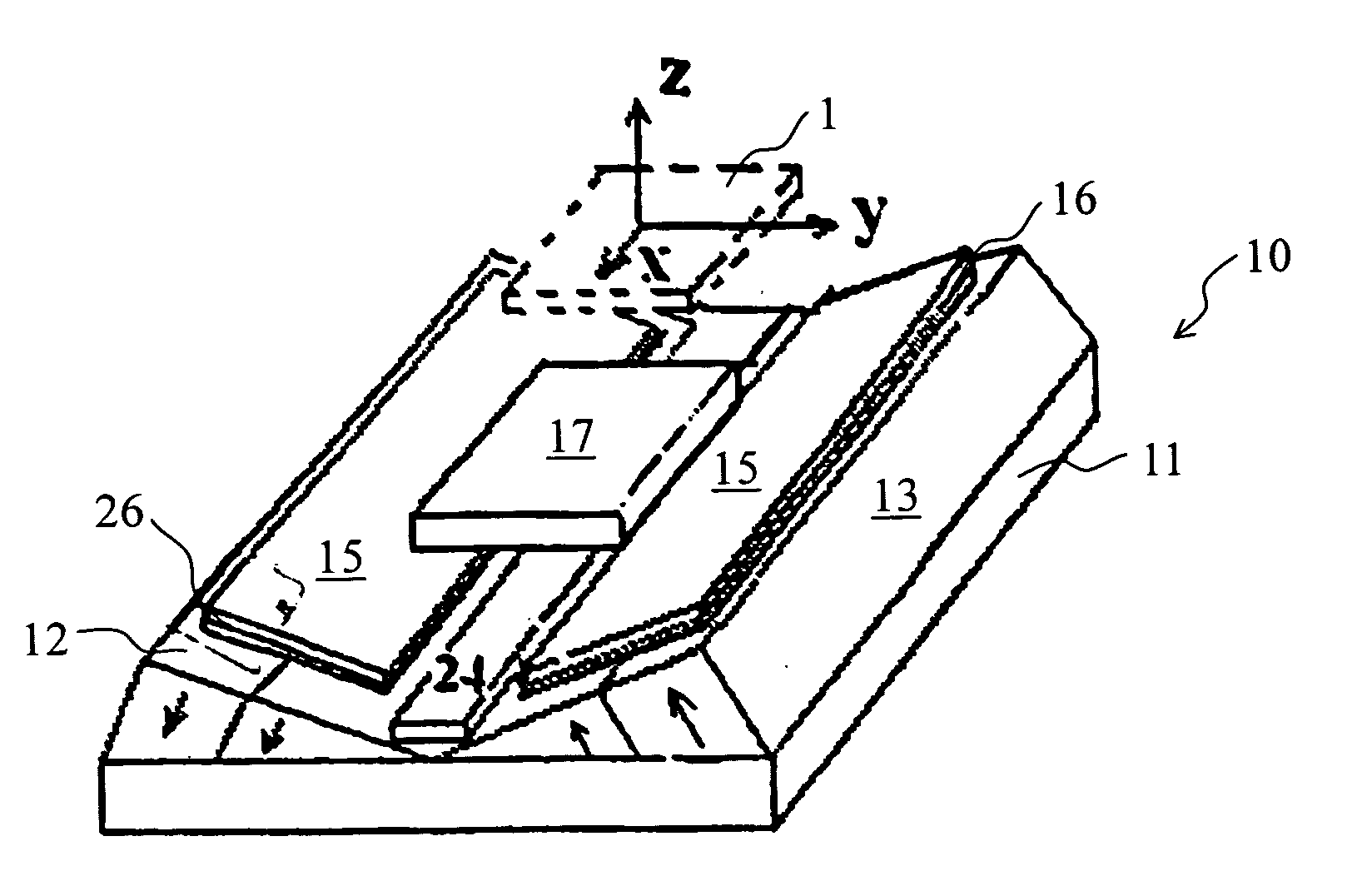

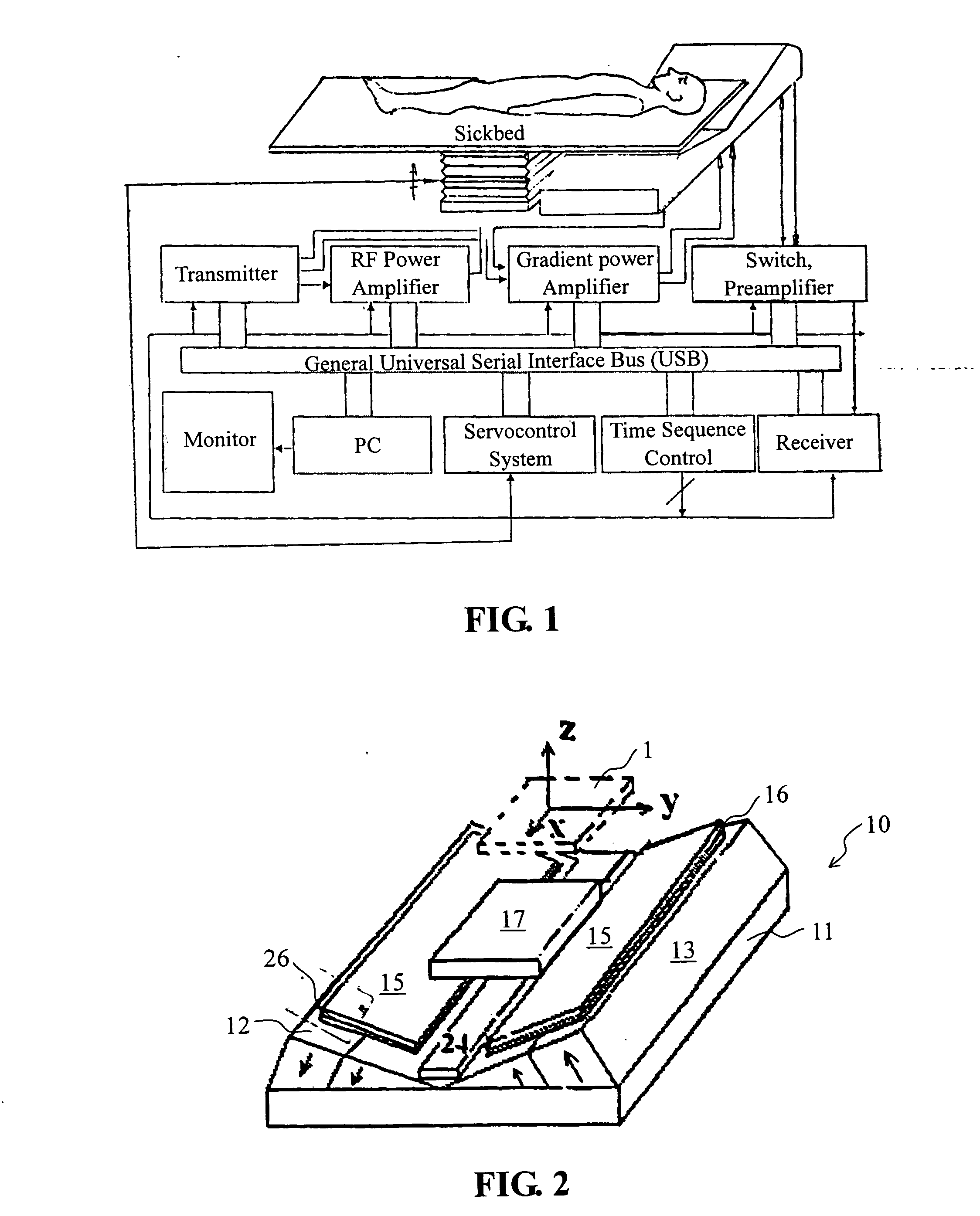

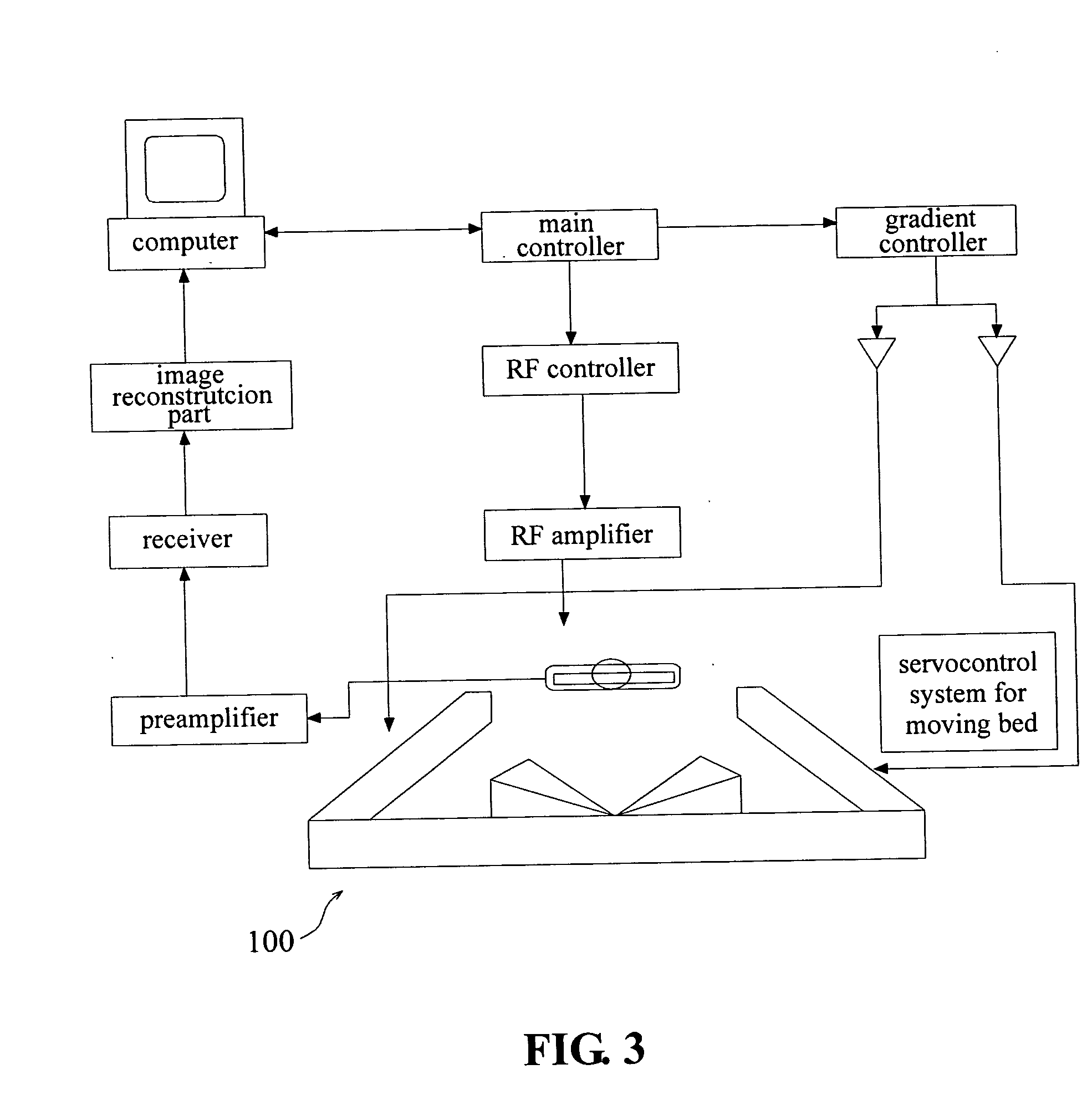

Magnet and method of forming uniform magnetic field for MRI system

InactiveUS20050258924A1High degree of opennessLarge uniform field volumePermanent magnetsMagnetic materialsMagnetMagnetic field

The present invention relates to the magnetic apparatus for magnetic resonance imaging system and method for forming uniform magnetic field. The magnetic apparatus comprises a field yoke for forming flux path, a first member of permanent magnet, provided on one end of the field yoke, free end of which is inclined inwardly, a second member of permanent magnet, provided on the other end of the field yoke in symmetry with the first member of permanent magnet, having reverse polarity with the first member of permanent magnet, an adjusting block, provided on the center of the field yoke for extruding magnetic field formed by the first and second members of permanent magnet. The adjusting block in the present invention can form a magnetic field for adjusting to extrude the basic magnetic field in order to provide a parallel magnetic field. The present invention can be applied in the MRI system and make the system have a high open degree for operations. The MRI system can be made compact, movable and inexpensive.

Owner:BEIJING TAIJIE MAGNETO ELECTRIC INST

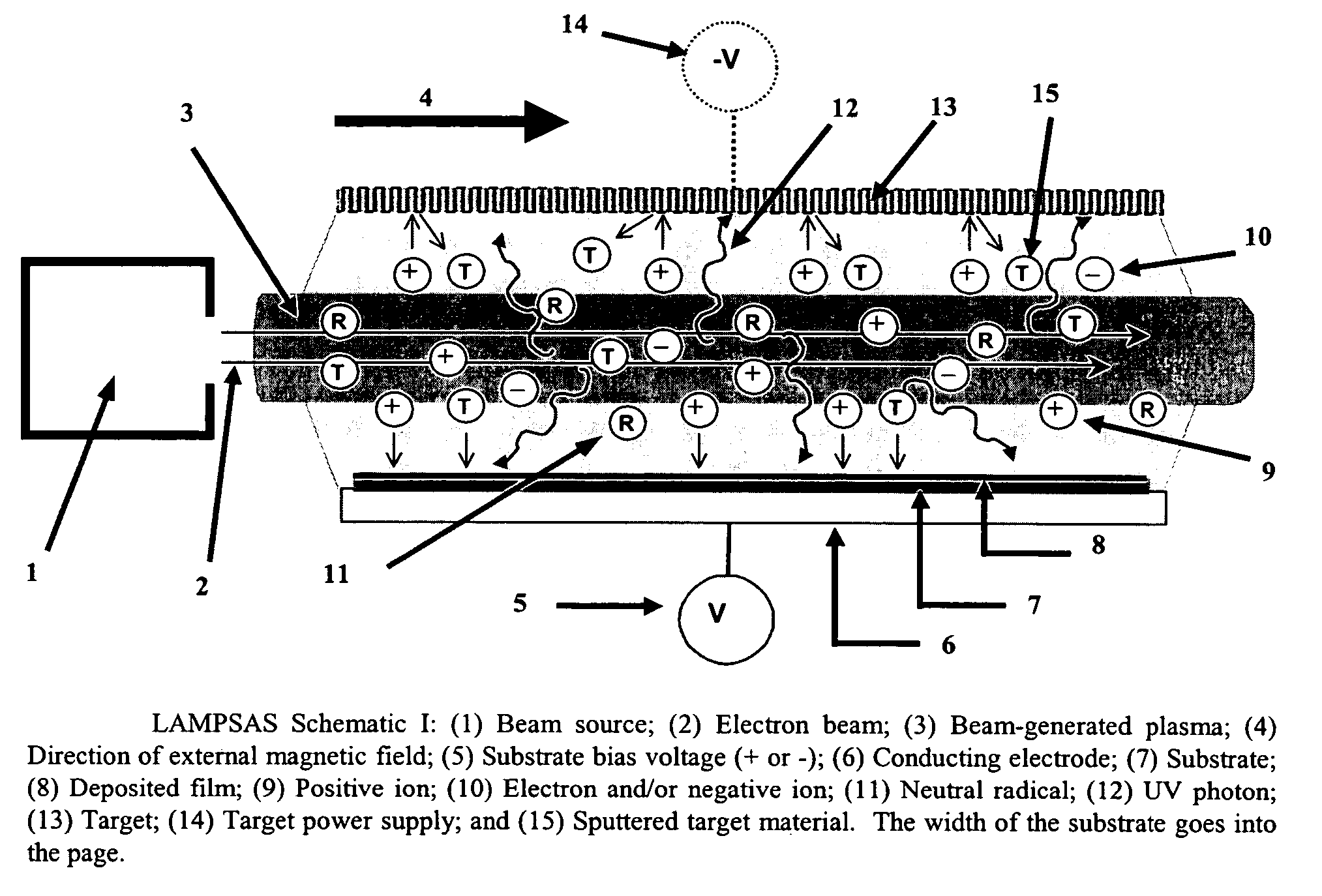

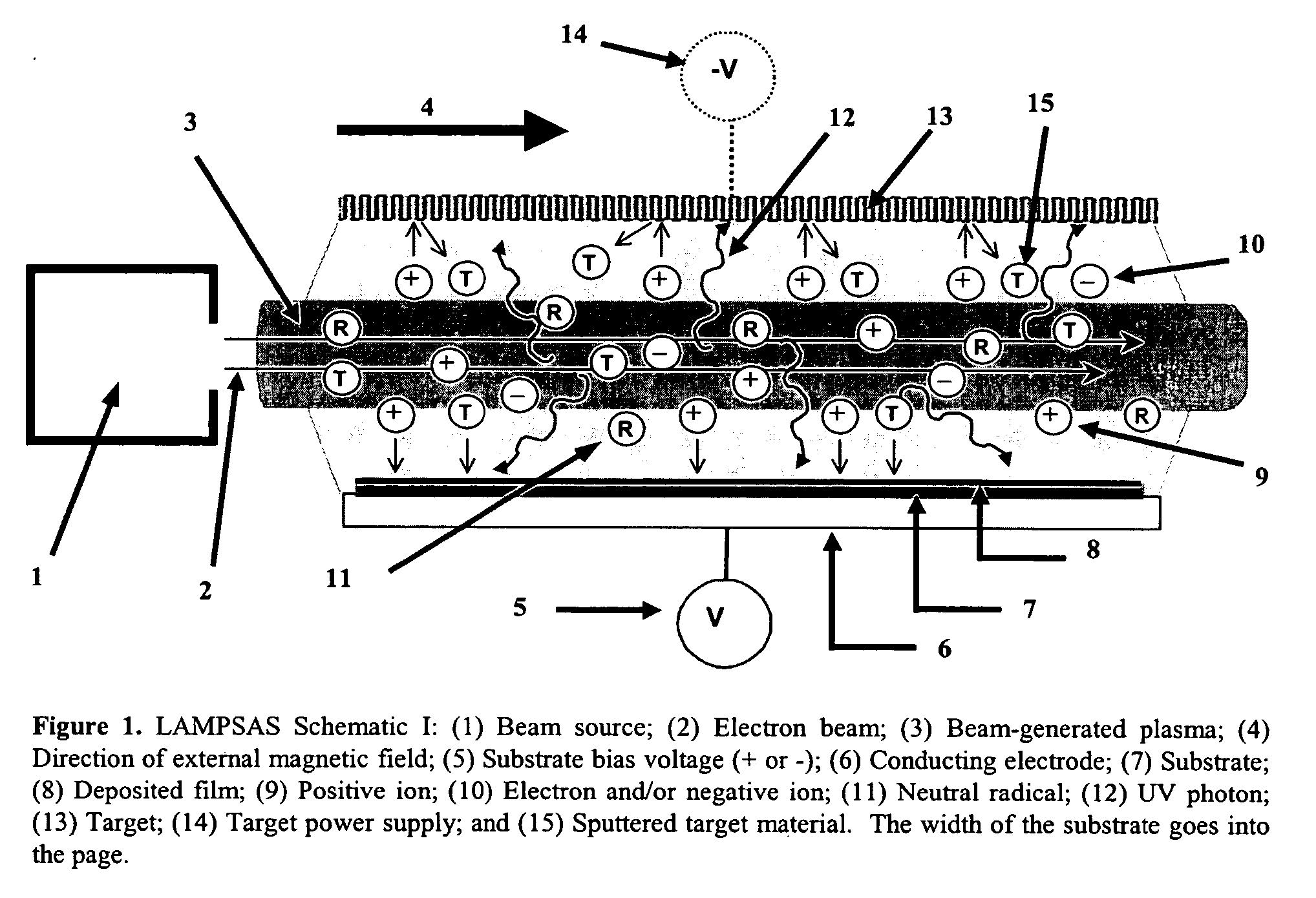

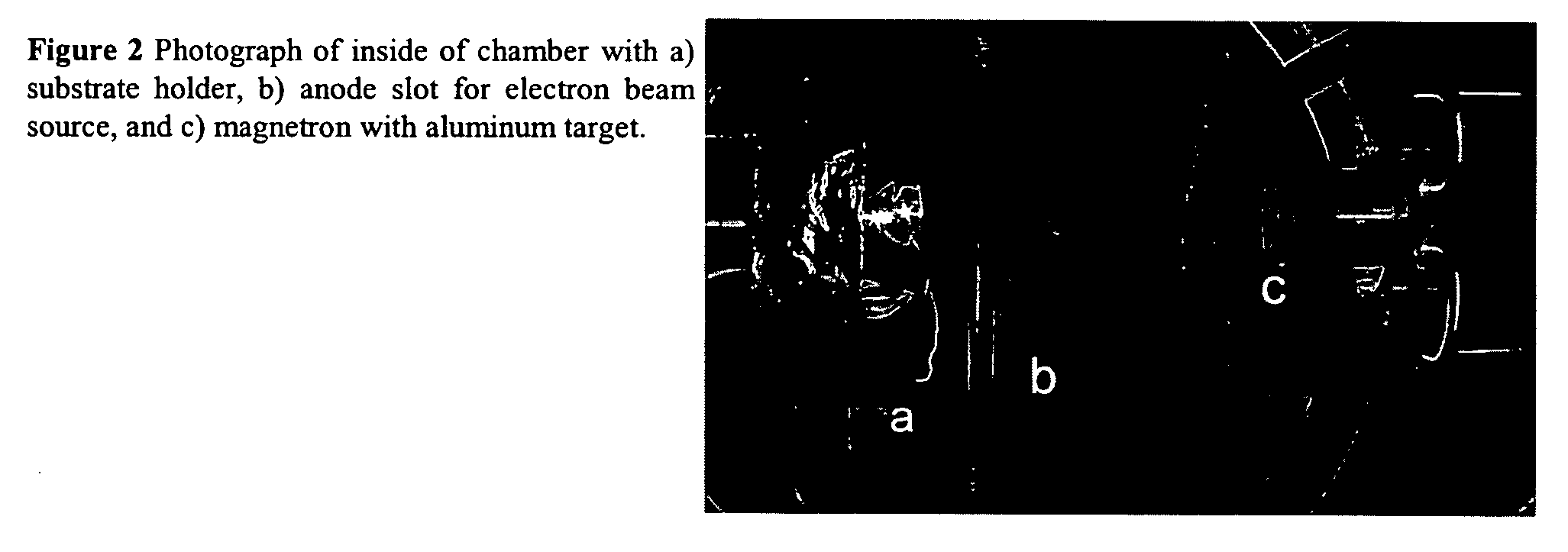

Large area metallization pretreatment and surface activation system

ActiveUS20050230242A1Improve abilitiesImprove adhesionElectrical apparatusVacuum evaporation coatingBiological activationSurface structure

A large area metallization pretreatment and surface activation system that uses an electron beam-produced plasma capable of delivering substantial ion and radical fluxes at low temperatures over large areas of an organic plastic or polymer material. The ion and radical fluxes physically and chemically alter the surface structure of the organic plastic or polymer material thereby improving the ability of a film to adhere to the material.

Owner:THE U S A AS REPRESENTED BY THE SEC OF THE NAVY

Composite for electrode active material and secondary battery comprising the same

ActiveUS20100243964A1High battery life characteristicHigh control capabilityConductive materialOxide conductorsLithiumMetal

Disclosed are a composite which can be used as an electrode active material for a secondary battery, and the secondary battery comprising the same. The composite includes: a first material selected from the group consisting of metals and metalloids capable of being reversibly alloyed with lithium; a second material selected from the group consisting of metals incapable of being alloyed with lithium, compounds containing the metals, and compounds containing metals or metalloids capable of being irreversibly alloyed with lithium; and a third material which is at least one kind of metal having a higher electrical conductivity than the second material, wherein a content of the third material ranges from 10 to 10,000 ppm based on the total weight of the composite. In the composite, the third material increases the electrical conductivity, thereby forming an electrical conducting path between materials within the composite. This allows the volume of a battery to be uniformly changed during the charge / discharge. Thus, when the composite is used as an electrode active material for a secondary battery, it is possible to improve a life characteristic of the battery, and minimize a change in a thickness of the electrode.

Owner:LG ENERGY SOLUTION LTD

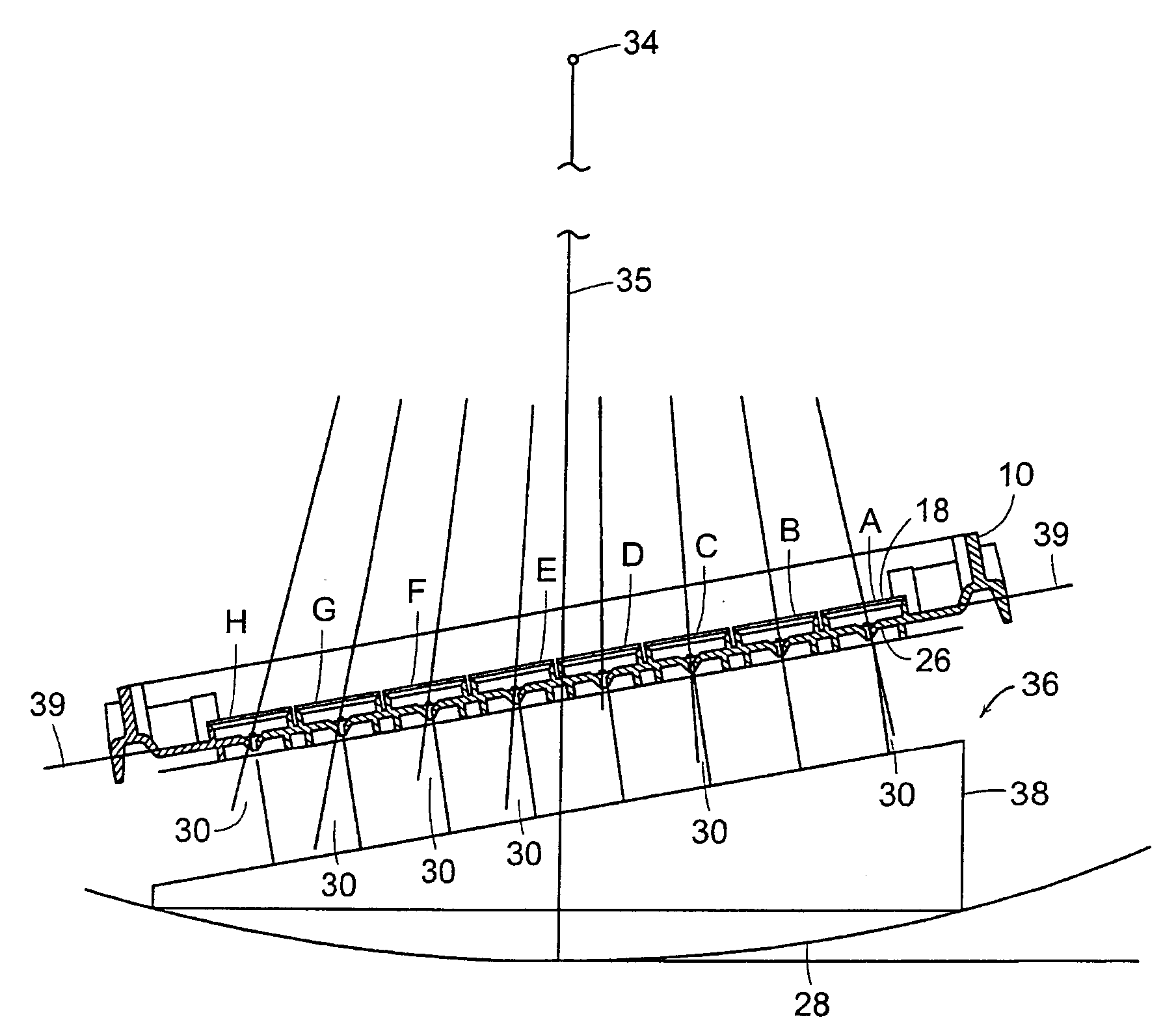

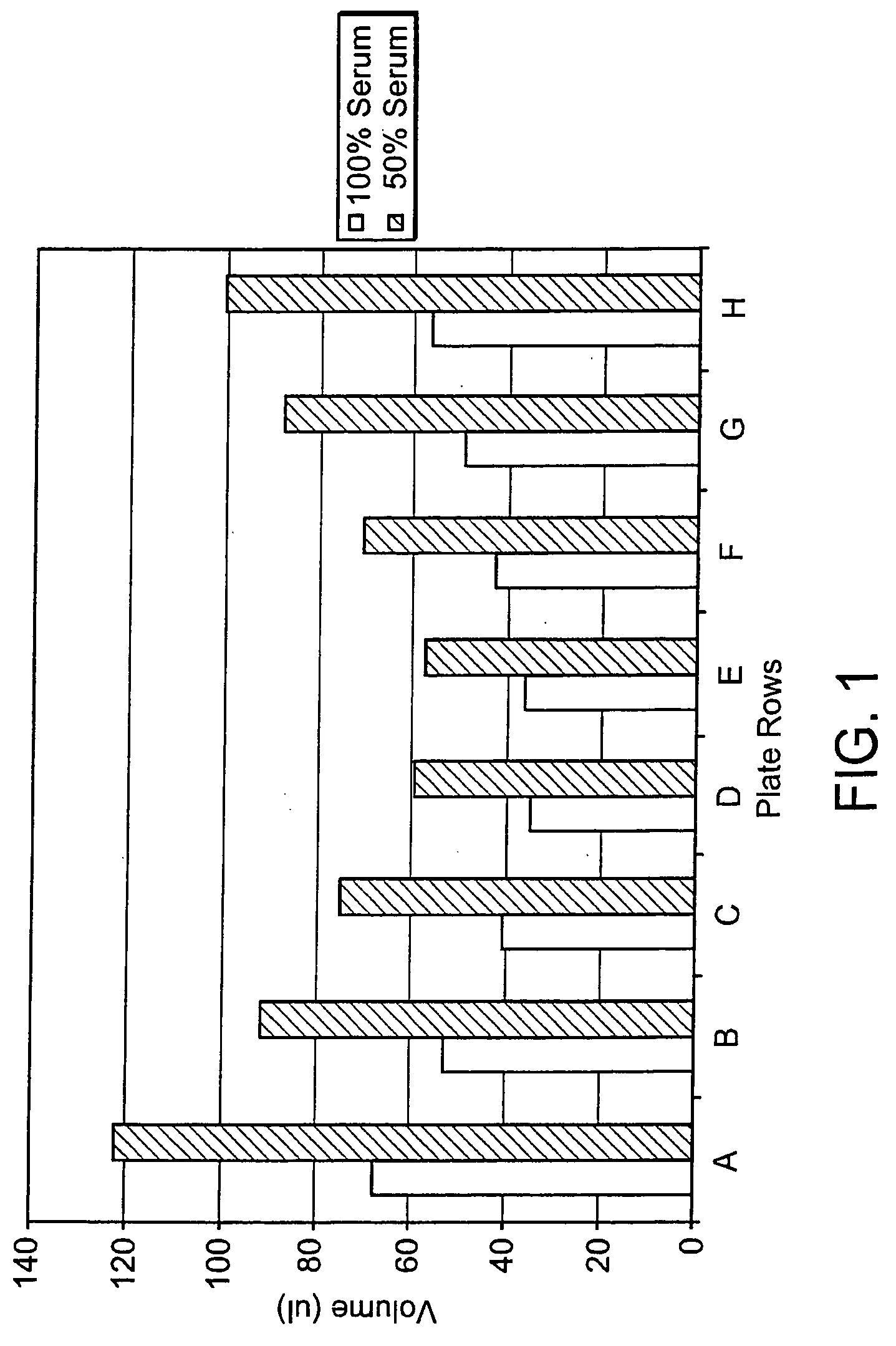

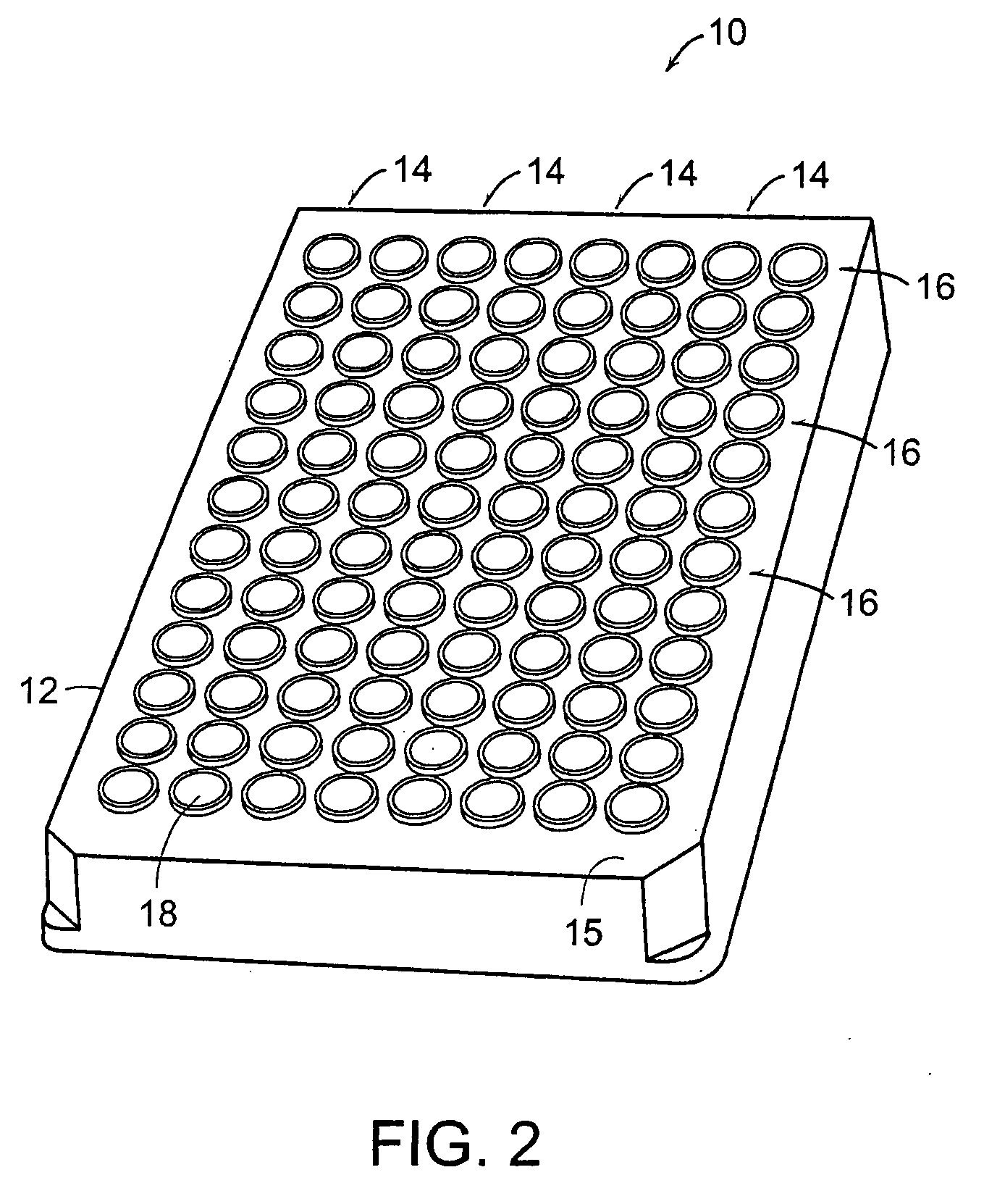

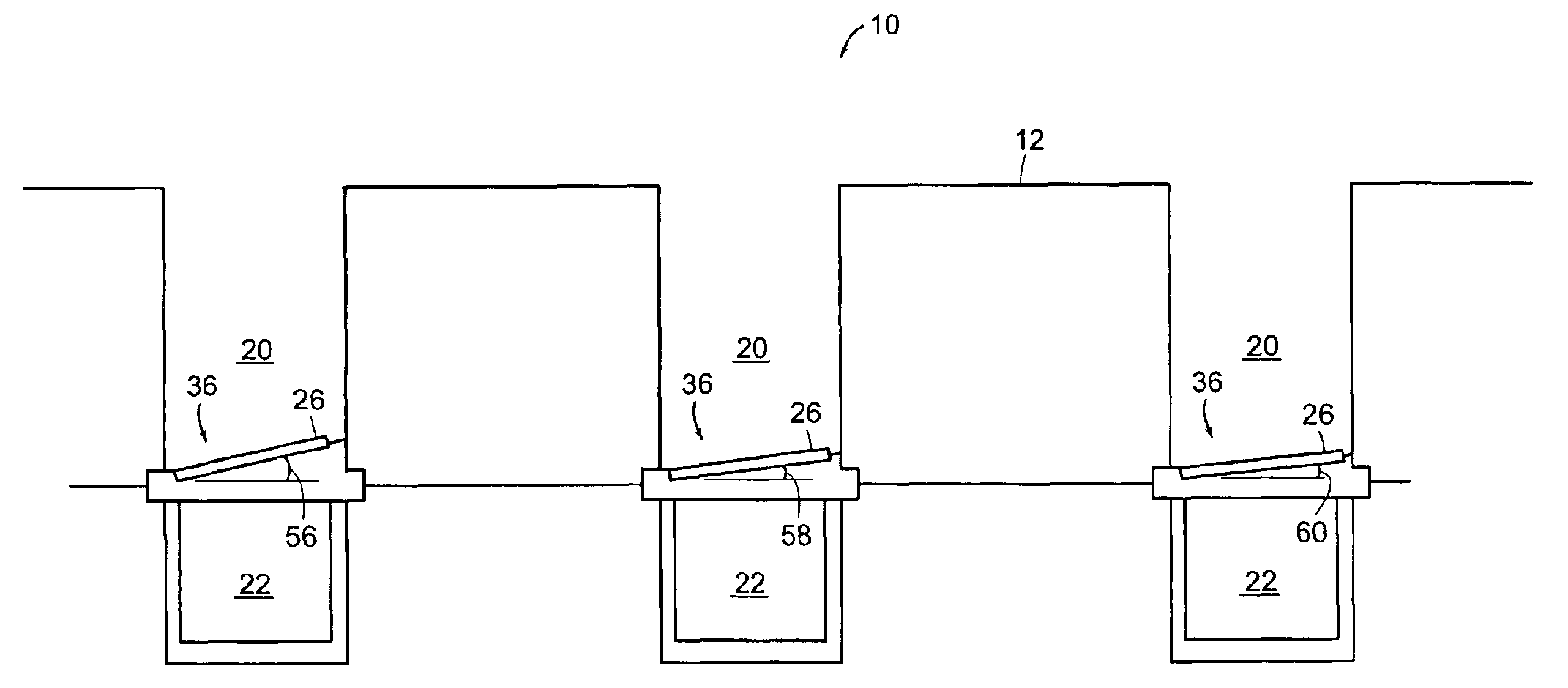

Methods for filtering fluids

InactiveUS20050161400A1Prevent rotationIncrease volumeWater/sewage treatment by centrifugal separationUltrafiltrationEngineeringMembrane configuration

A fluid filtering device includes a plurality of filtering wells and an angling mechanism which adjusts the angle of the membranes within the filtering wells relative to a line of a centrifuge where the line is perpendicular to the axis of rotation of a centrifuge and passes through the center of a major plane of the filtering device. The angling mechanism can include a wedge located between the center of rotation of a centrifuge and a swinging bucket of the centrifuge. The angling mechanism can also be located within each filtering well and can provide individually specified angles for each membrane, relative to the line of the centrifuge.

Owner:MILLIPORE CORP

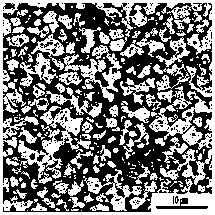

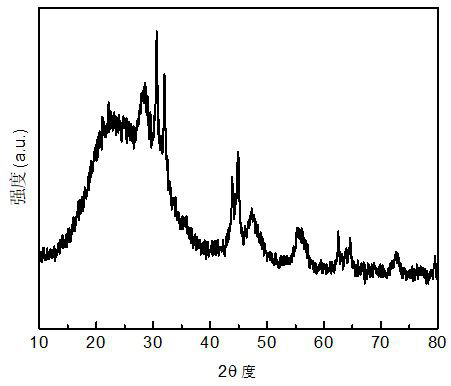

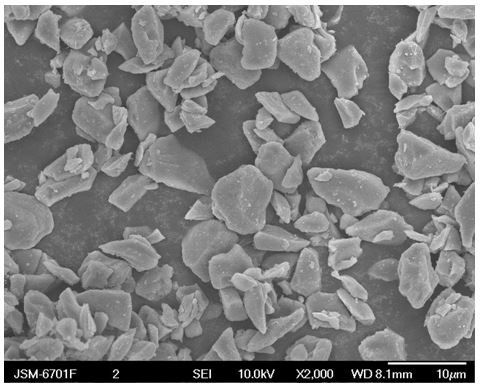

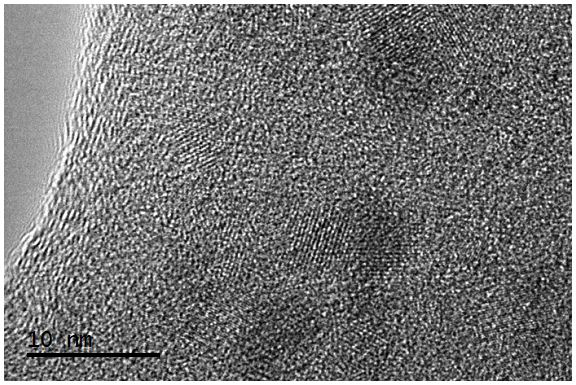

Composite rare-earth oxide strengthened tungsten-base high-specific-gravity alloy composite material and preparation method thereof

The invention provides a composite rare-earth oxide strengthened tungsten-base high-specific-gravity alloy composite material and a preparation method thereof. The composite material is composed of tungsten alloy base powder and 0.1-1.0wt% of composite rare-earth oxide particles, wherein composite rare-earth oxides are two or more of CeO2, DyO2, Y2O3 and Nd2O3. The preparation method for the composite rare-earth oxide strengthened tungsten-base high-specific-gravity alloy composite material mainly comprises steps of raw material pre-mixing, primary ball-milling, secondary ball-milling, activating and sintering and the like. Before the activating and sintering step, a mode of combining composite rear-earth oxide adding with secondary ball-milling is adopted, so that added substances can befined and homogenized, and uniform distribution and volume fraction of a bonding phase also can be improved, and therefore, the alloy has an excellent microscopic structure, a smaller W crystalline grain size and compactness of 98% or more; and the composite material is improved in comprehensive performance, and is of great significance on development and application of a high-toughness ultrafine-grain tungsten alloy.

Owner:ZOLTRIX MATERIAL GUANGZHOU

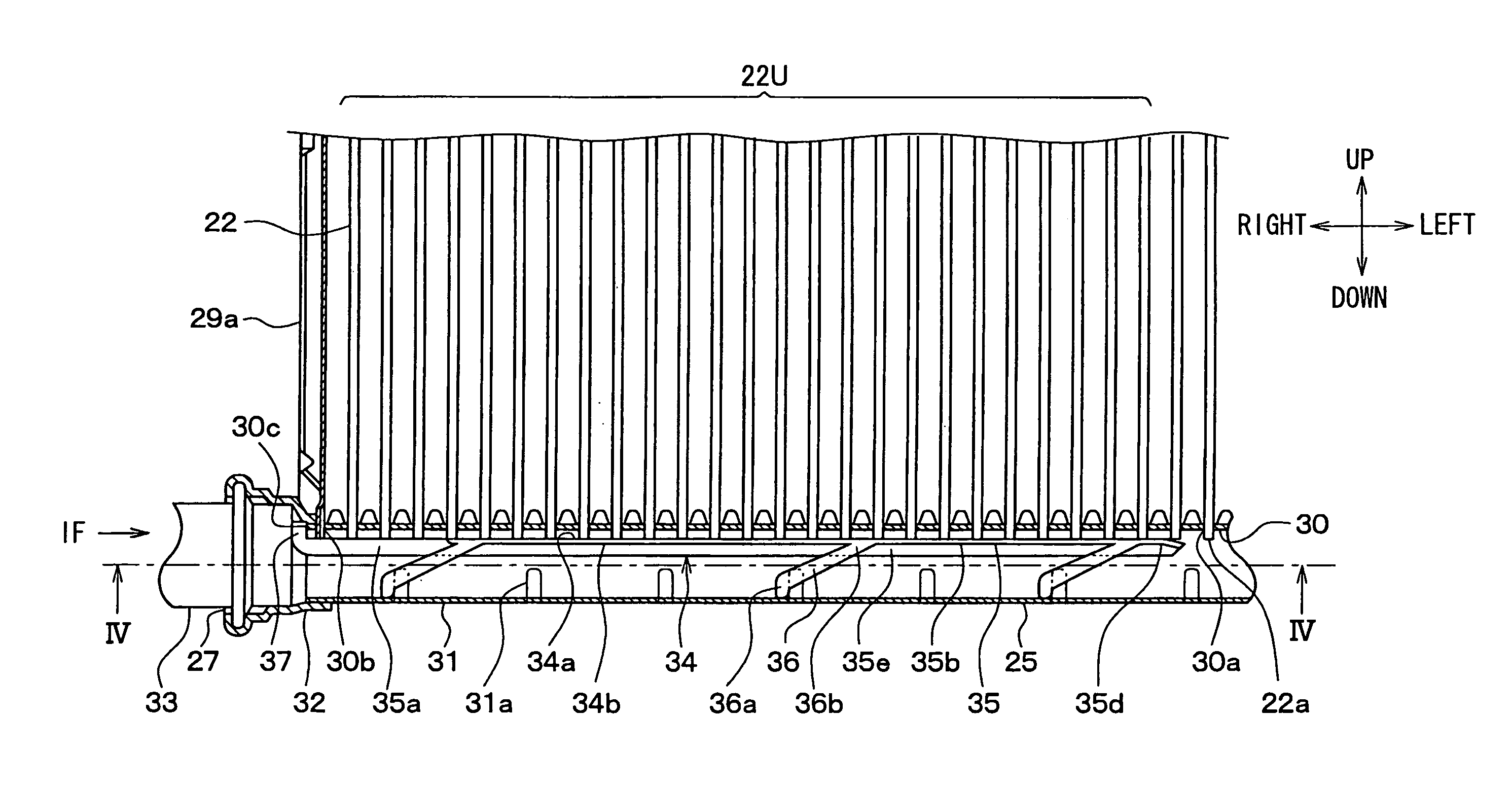

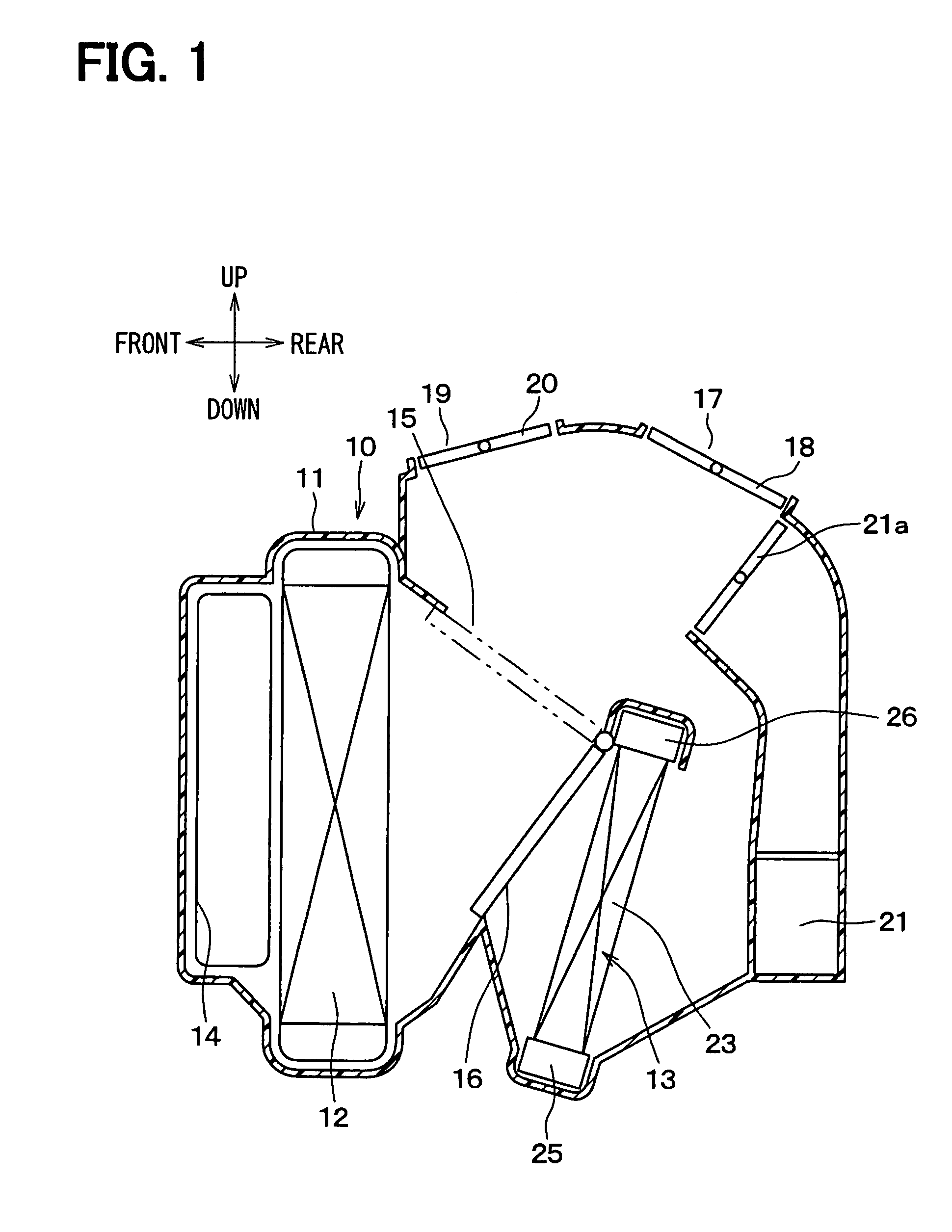

Air conditioning apparatus for vehicle

InactiveUS20080083241A1Uniform volumeReduce unevennessAir-treating devicesDomestic cooling apparatusEngineeringAir conditioning

An air conditioning apparatus for a vehicle has a unit case, a heat exchanger for generating a heated air, a bypass passage through which a bypass air flows while bypassing the heat exchanger, and a baffle member having first passages and second passages. The unit case has openings for introducing a conditioned air into a passenger compartment. The openings are aligned in an alignment direction across a width of the unit case. The first passages and second passages are alternately arranged in the alignment direction. One of the bypass air and the heated air has an uneven distribution of a flow speed in the alignment direction at a position upstream of the baffle member, and flows in the first passages. Widths of the first passages are varied according to the distribution of the flow speed.

Owner:DENSO CORP

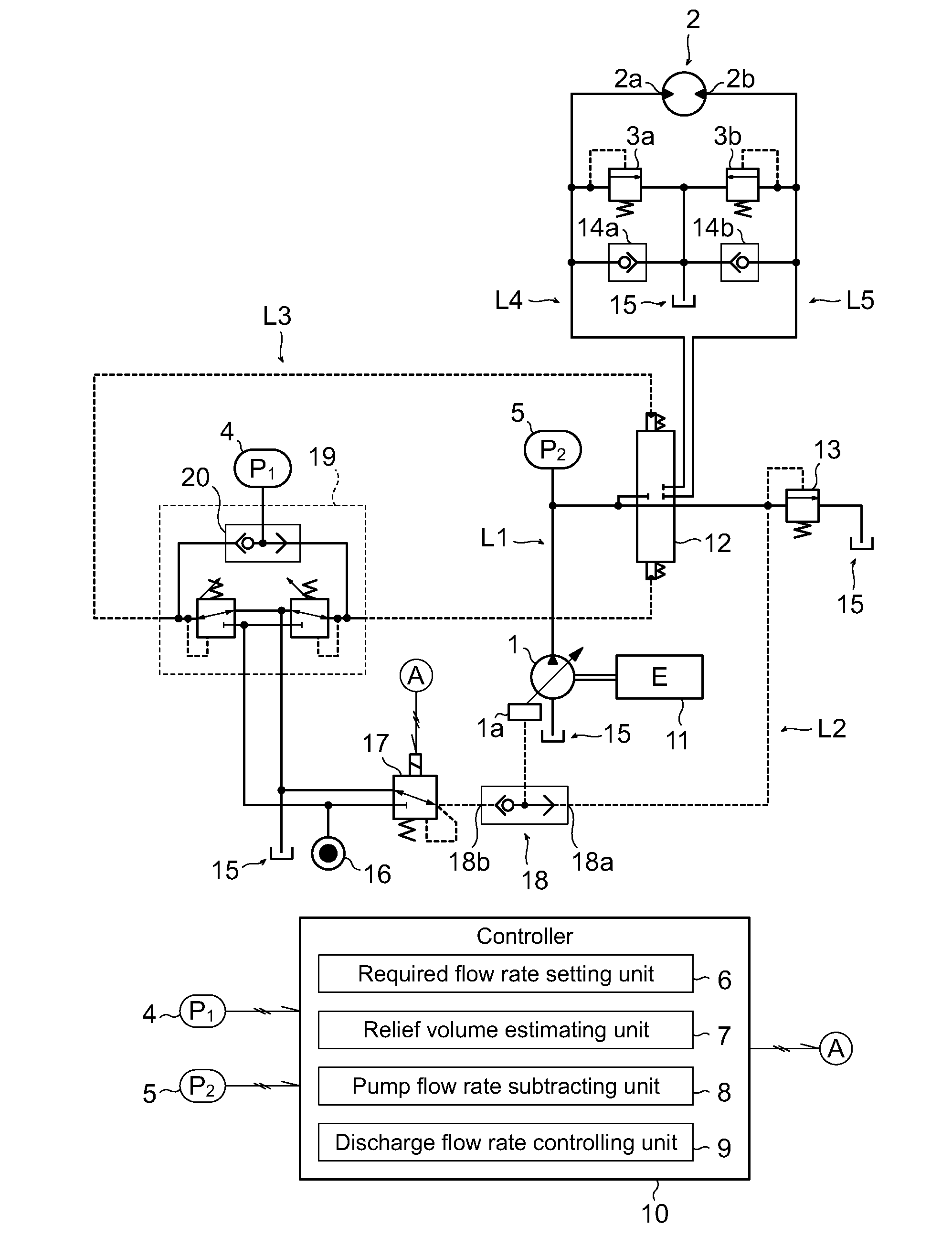

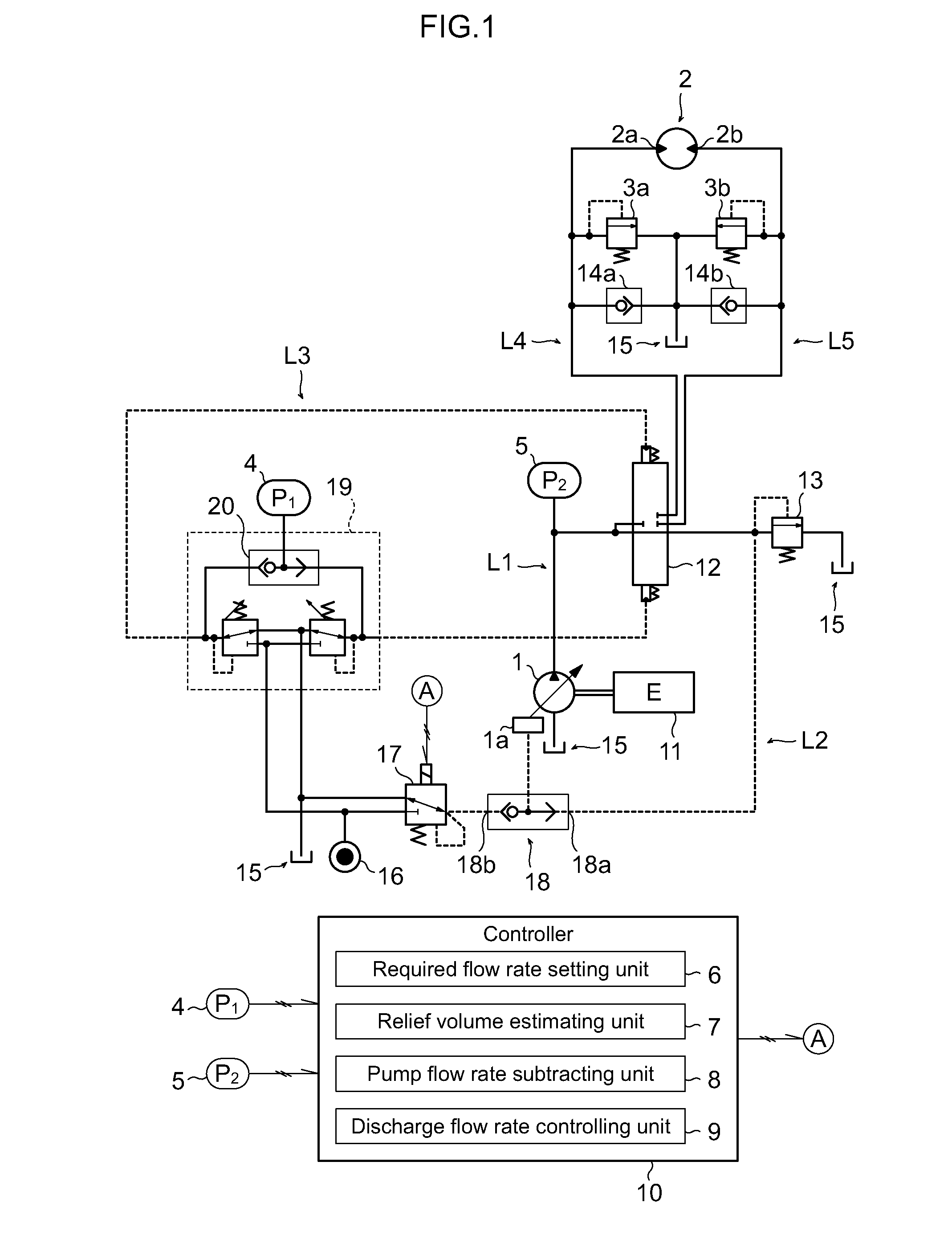

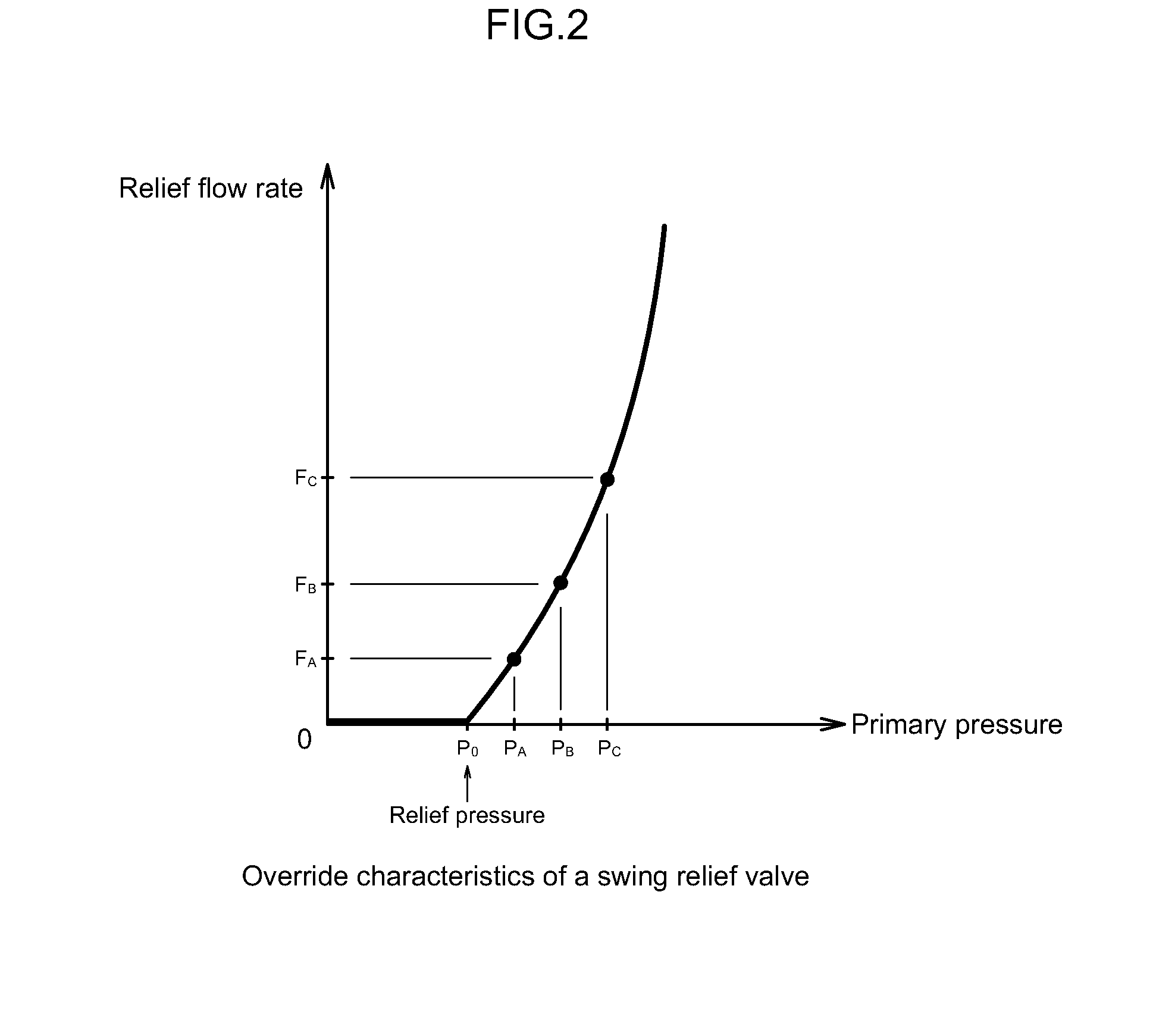

Hydraulic swing-controlling apparatus of work machine

ActiveUS20120131913A1Reduce relief lossEnhanced efficiencyFluid couplingsServomotorsRelief valveEngineering

In a work machine including a hydraulic pump (1), a swing motor (2), and swing relief valves (3a and 3b), the amount of the swing operation (P1) related to the swing motion of the swing motor (2) is detected, and the hydraulic pressure (P2) supplied from the hydraulic pump (1) to the swing motor is also detected. Additionally, the required flow rate (FR) of hydraulic oil required for the swing motor (1) is set based on the amount of the swing operation (P1). In addition, the volume of relief (FE) is estimated from the hydraulic pressure (P2) based on the override characteristics of the swing relief valves (3a and 3b). The discharge flow rate of the hydraulic pump (1) is controlled based on the value obtained by subtracting the volume of relief (FE) from the required flow rate (FR).

Owner:KEJTERPILLAR R L

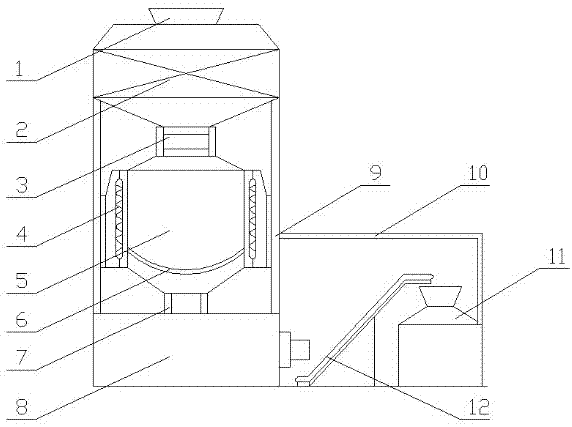

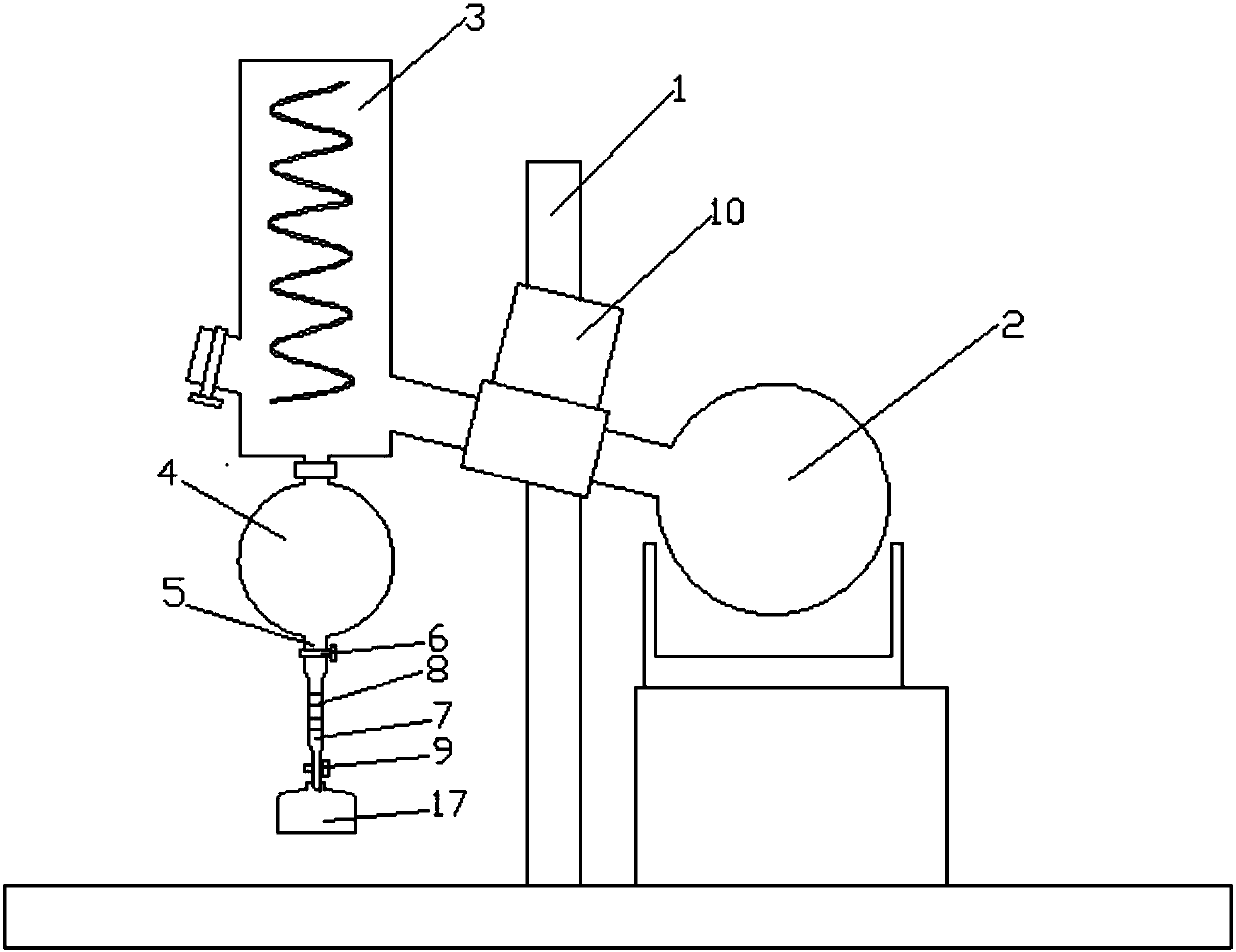

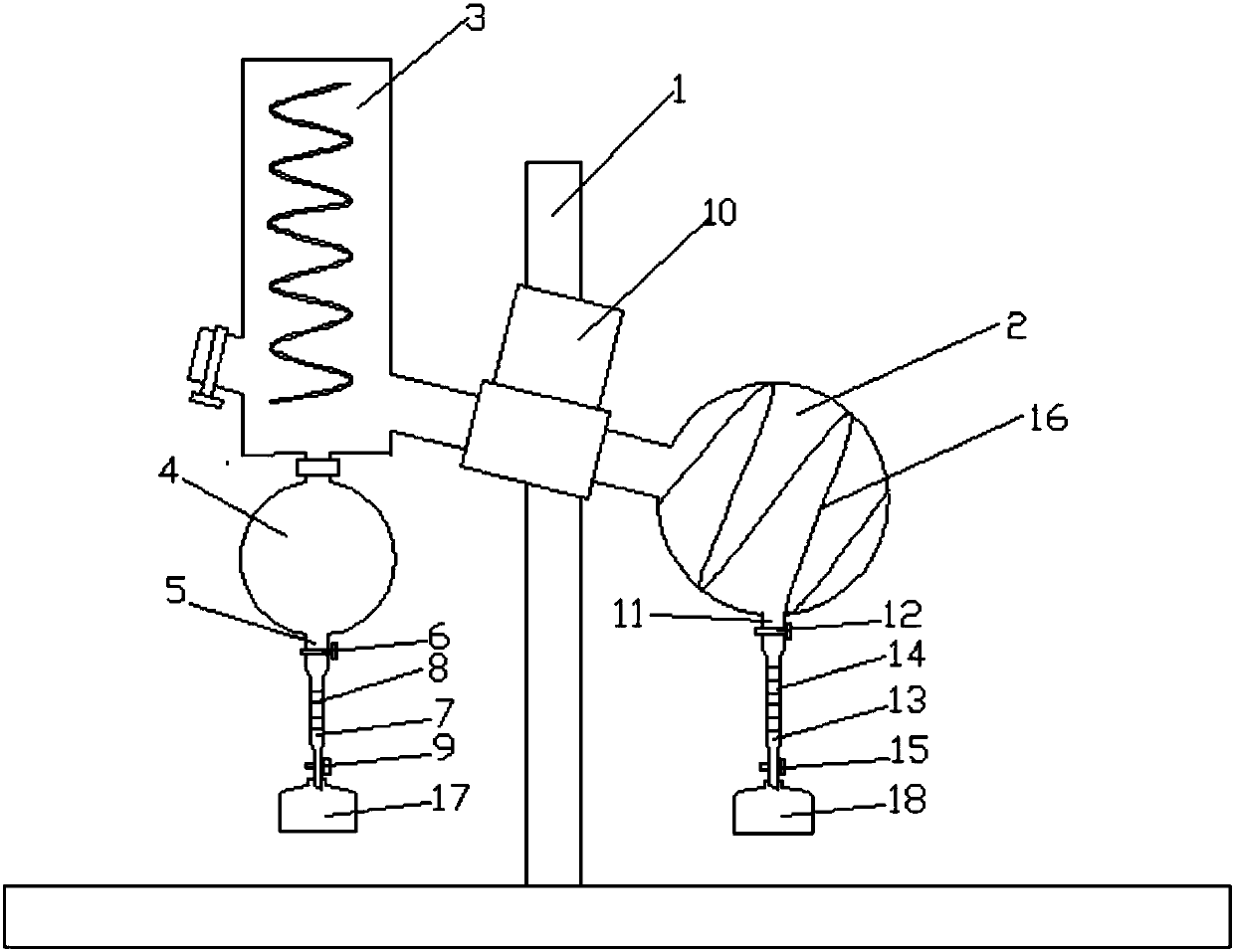

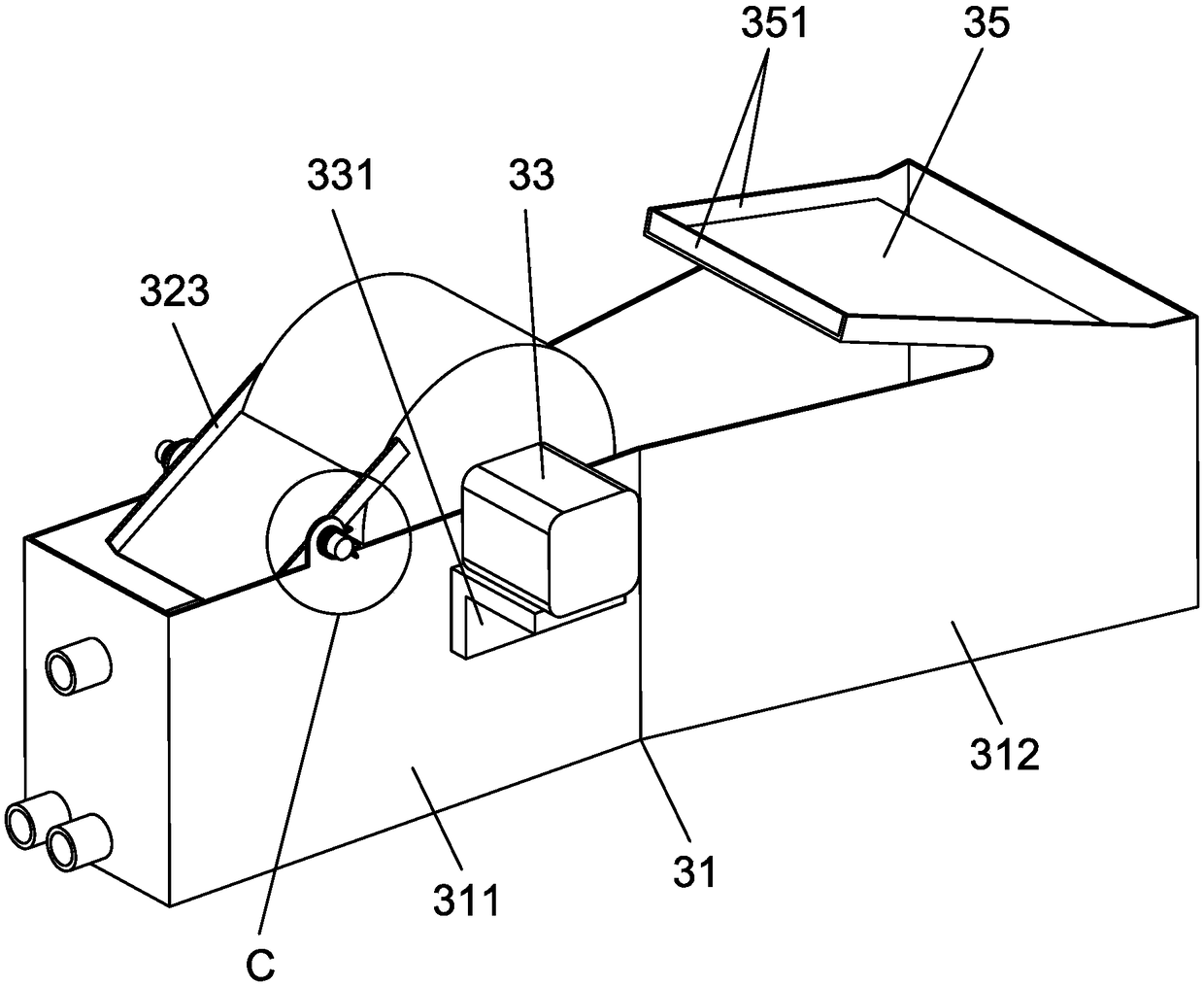

Recycled plastic recycling equipment

InactiveCN106915009AUniform volumeAvoid contaminationPlastic recyclingMechanical material recoveryCrusherElectromagnetic heating

The invention discloses recycled plastic recycling equipment. The recycled plastic recycling equipment is characterized by comprising a feeding hopper, a coarse crusher, a heat-insulating transfer path, electromagnetic heating tubes, a melting room, a filter screen, an extruder hopper, a single-screw extruder, a bracket, a dustproof cover, a fine grinding mill and a material lifter, wherein the feeding hopper is mounted above the coarse crusher; the heat-insulating transfer path is mounted below the coarse grinder; the melting room is arranged below the heat-insulating transfer path; the filter screen is mounted on the bottom of the melting room; and the electromagnetic heating tubes are mounted at the two sides of the melting room. The recycled plastic recycling equipment disclosed by the invention is used for performing coarse grinding on waste plastic, and then melting and filtering the waste plastic; after being filtered, the plastic is extruded through the single-screw extruder, and is fed into the fine grinding mill; the dustproof cover can prevent the plastic from being contaminated by impurities such as dust in a transmitting process, and the fine grinding mill is used for performing fine grinding on the plastic, so that plastic extruded by the extruder can be directly added into the fine grinding mill to perform fine grinding, and does not need to be crushed.

Owner:天津思迈德高分子科技股份有限公司

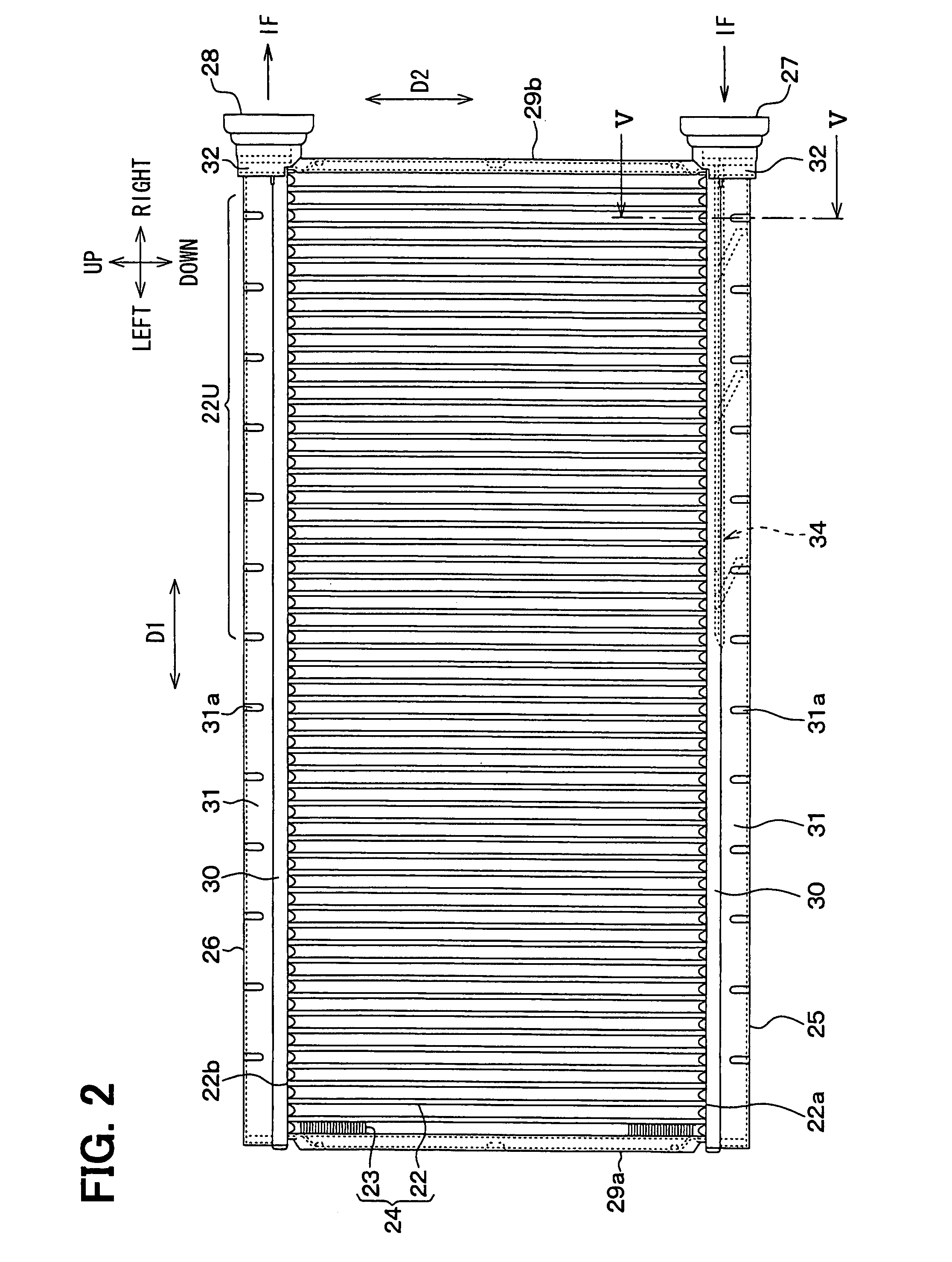

Heat exchanger

ActiveUS7841393B2Increase the internal volumeReduce internal volumeStationary conduit assembliesHeat exchanger casingsWaste managementHeat exchanger

Owner:DENSO CORP

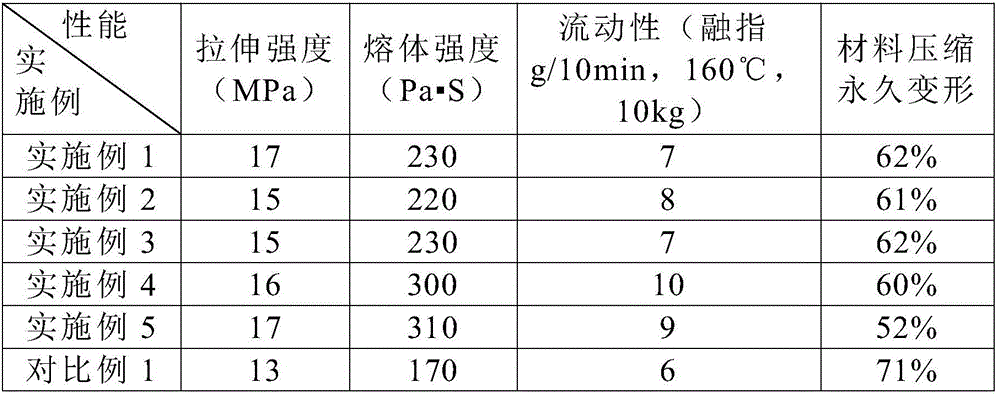

Injection molding grade PVC composite material high in mobility and melt strength

The invention relates to an injection molding grade PVC composite material high in mobility and melt strength and belongs to the technical field of macromolecules. The composite material comprises, by weight parts, 30-60 parts of low molecular weight PVC resin powder, 5-20 parts of crosslinking PVC resin powder, 10-30 parts of main plasticizer, 10-20 parts of secondary plasticizer, 0.5-20 parts of nano calcium carbonate, 0.5-2 parts of high melt strength processing agent, 0.4-1.5 parts of lubricant, 0.5-4 parts of heat stabilizer, 0.1-1 part of light stabilizer, 0.1-0.3 part of antioxidant and 1-3 parts of other auxiliaries. Melt strength and mechanical properties of the PVC composite material are improved while high mobility is guaranteed. The injection molding grade PVC composite material can adapt to injection molding products of various sizes and shapes and can meet requirements of low plastic temperature and short plastic cycle.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

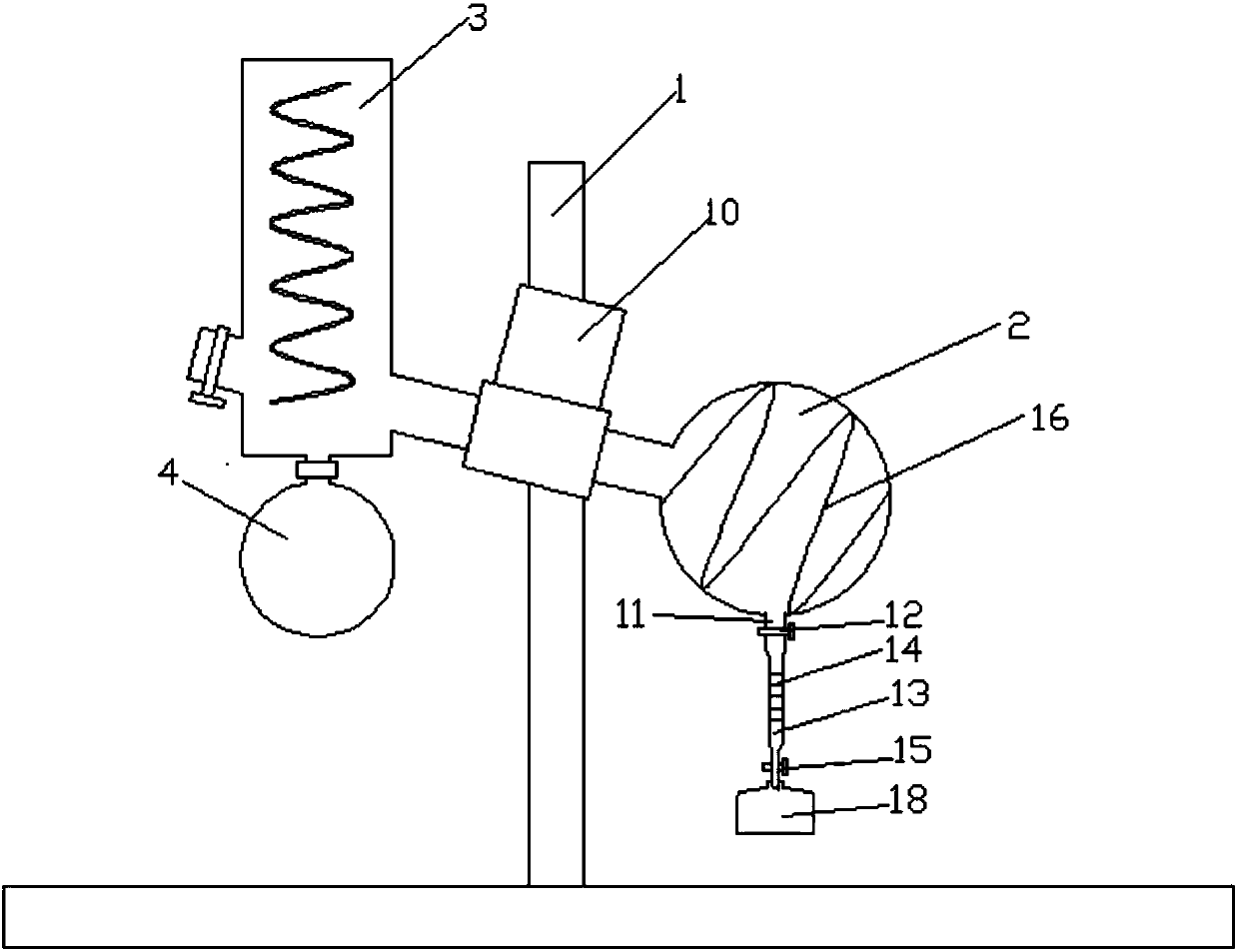

Rotary evaporator capable of accurately achieving fraction quantification

ActiveCN108043058AReduce volumeReduce heating water consumption and oil consumptionDistillation regulation/controlDistillation in rotating vesselsRotary evaporatorDistillation

The invention relates to the technical field of chemical experiment equipment, in particular to a rotary evaporator and in particular to a rotary evaporator capable of accurately achieving fraction quantification. The invention provides the rotary evaporator capable of accurately achieving fraction quantification. According to the rotary evaporator, a conventional spherical collection bottle is improved into a structure that a liquid discharge hole is formed in the bottom of the collection bottle, so that a fraction liquid can be discharged under a condition that the collection bottle is not detached down; meanwhile, due to a metering tube with scales in the position of the liquid discharge hole, variations of fraction quantities can be visibly observed, distillation can be immediately stopped when a fraction meets a designed accurate quantity, the precisely quantified fraction can be accurately discharged, components of fractions and indexes for reflecting quality of the fractions canbe tested, property differences of fractions of a same distillation sample at different distillation stages can be studied, and unification of detection standards can be achieved.

Owner:BEIJING NORMAL UNIVERSITY

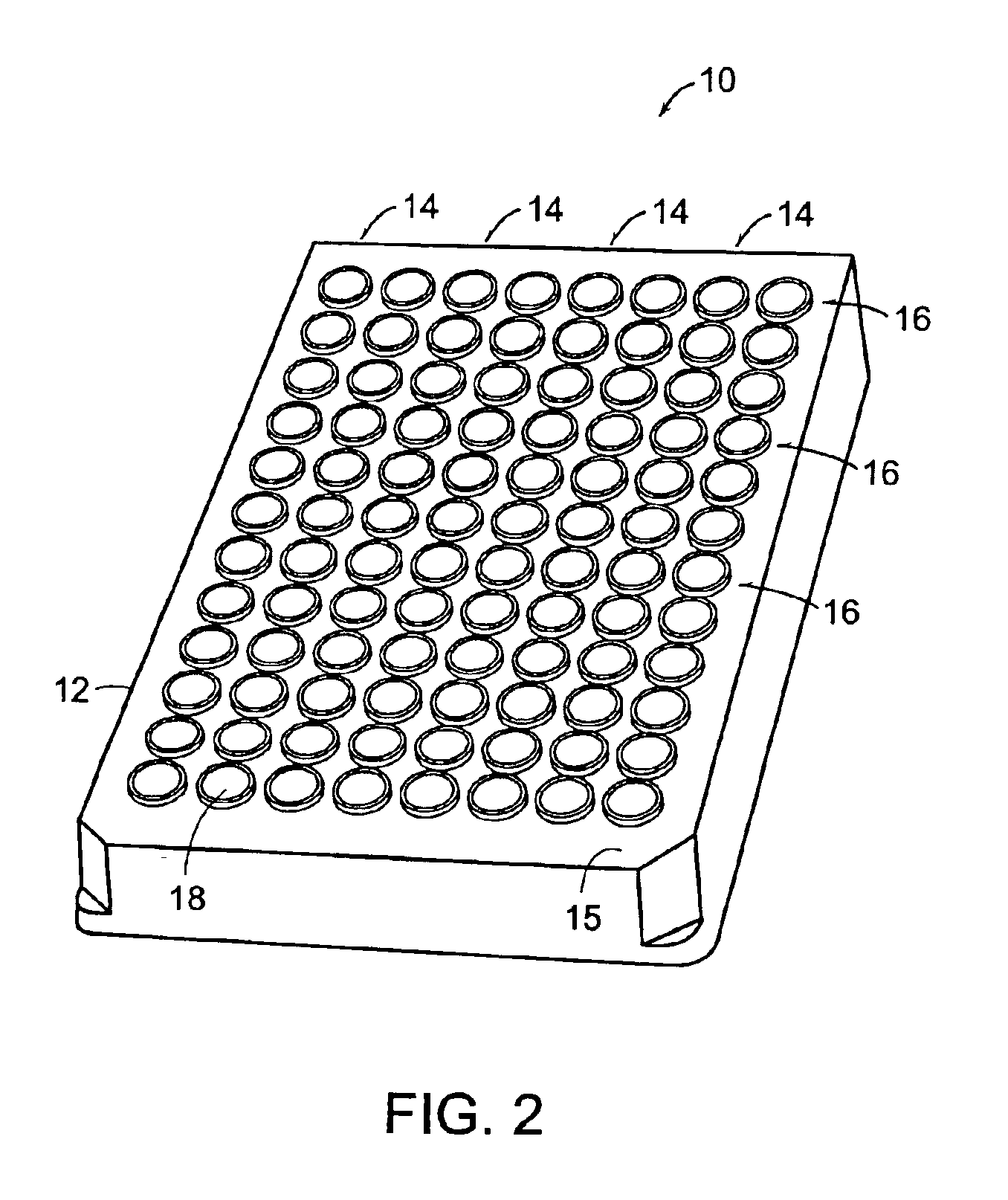

Fluid filtering device

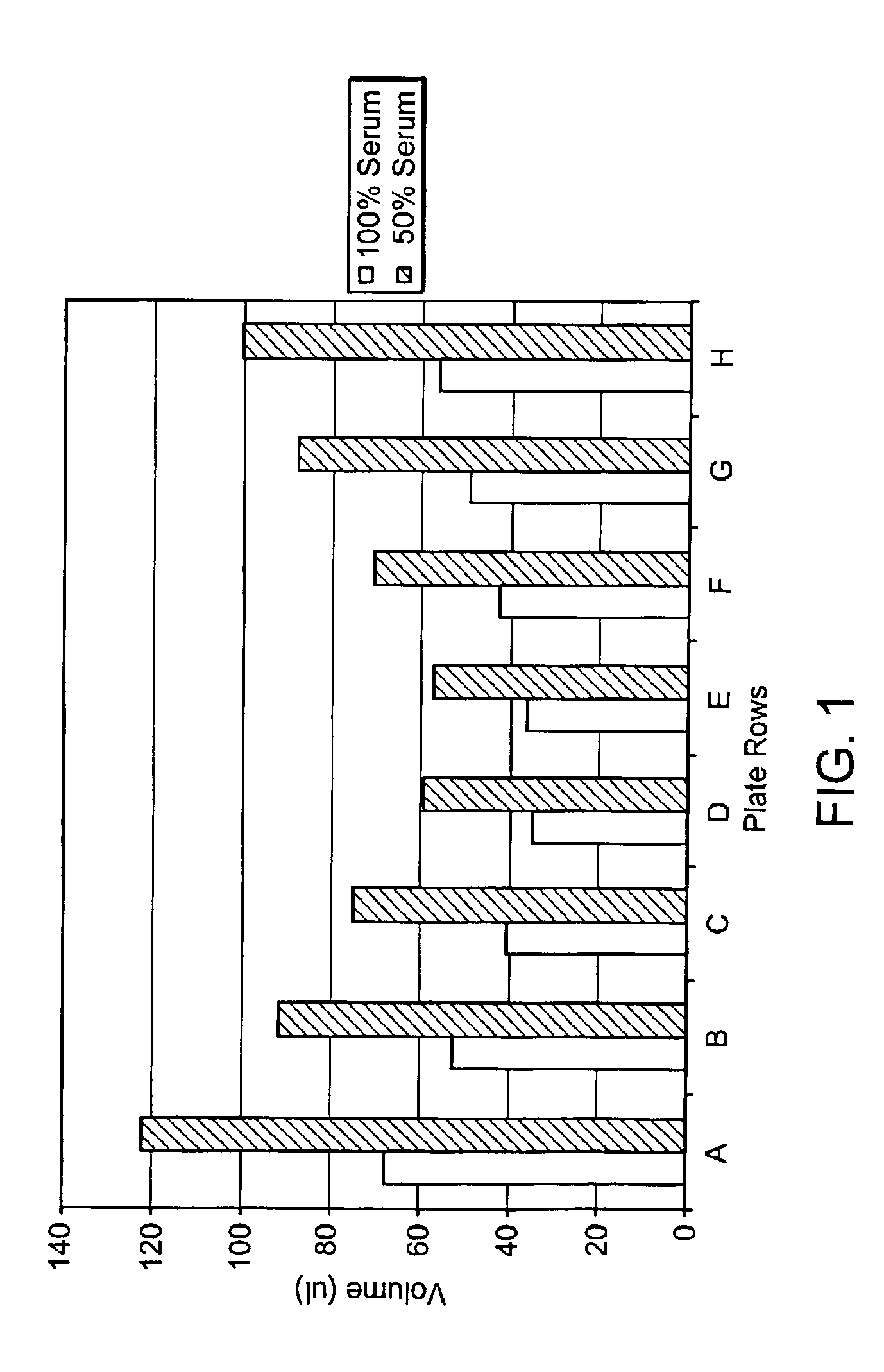

InactiveUS6899810B1Increase volumeLittle well-to-well filtrate volume variabilityWater/sewage treatment by centrifugal separationUltrafiltrationRotational axisLine tubing

A fluid filtering device includes a plurality of filtering wells and an angling mechanism which adjusts the angle of the membranes within the filtering wells relative to a line of a centrifuge where the line is perpendicular to the axis of rotation of a centrifuge and passes through the center of a major plane of the filtering device. The angling mechanism can include a wedge located between the center of rotation of a centrifuge and a swinging bucket of the centrifuge. The angling mechanism can also be located within each filtering well and can provide individually specified angles for each membrane, relative to the line of the centrifuge.

Owner:MILLIPORE CORP

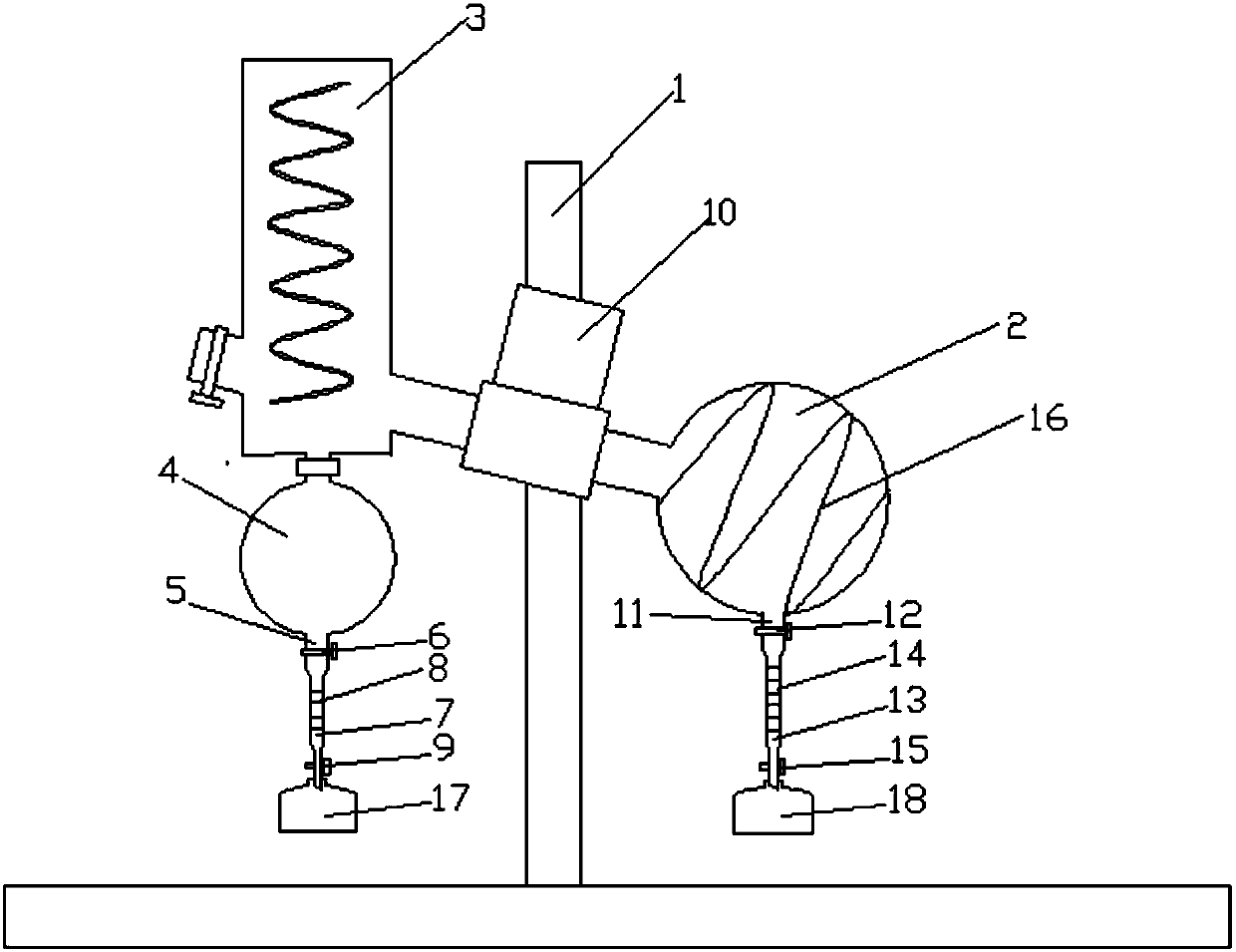

Rotary evaporator capable of accurately achieving quantification of concentrated liquid

ActiveCN108043059AQuantitatively accuratePrecision releaseDistillation regulation/controlDistillation in rotating vesselsRotary evaporatorDistillation

The invention relates to the technical field of chemical experiment equipment, in particular to a rotary evaporator and in particular to a rotary evaporator capable of accurately achieving quantification of a concentrated liquid. According to the rotary evaporator capable of accurately achieving quantification of the concentrated liquid, a distillation bottle is improved into a structure that a liquid discharge hole is formed in the bottom, so that a concentrated liquid can be discharged on premise that the distillation bottle is not detached and the negative pressure inside a distillation system is not greatly affected; meanwhile, due to a metering tube with scales in the position of the liquid discharge hole, variations of quantities of the concentrated liquid can be visibly observed, distillation can be immediately stopped when the quantity of the concentrated liquid meets a designed accurate quantity, the precisely quantified concentrated liquid can be accurately discharged, indexes such as reaction yield can be tested, unification of detection standards can be achieved, properties of different concentrated liquids of same yield and properties of a same sample of different concentration degrees can be studied and compared.

Owner:BEIJING NORMAL UNIVERSITY

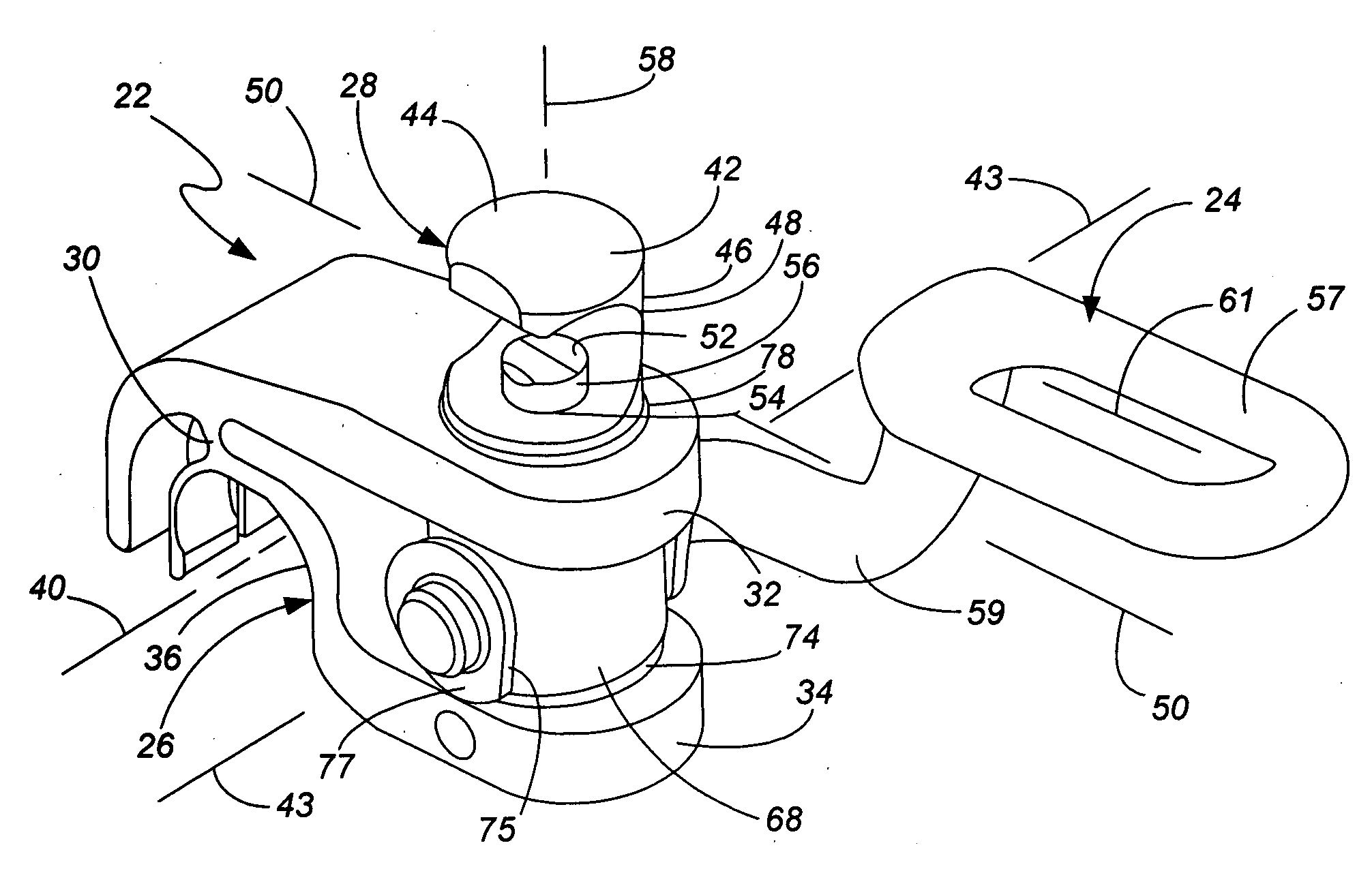

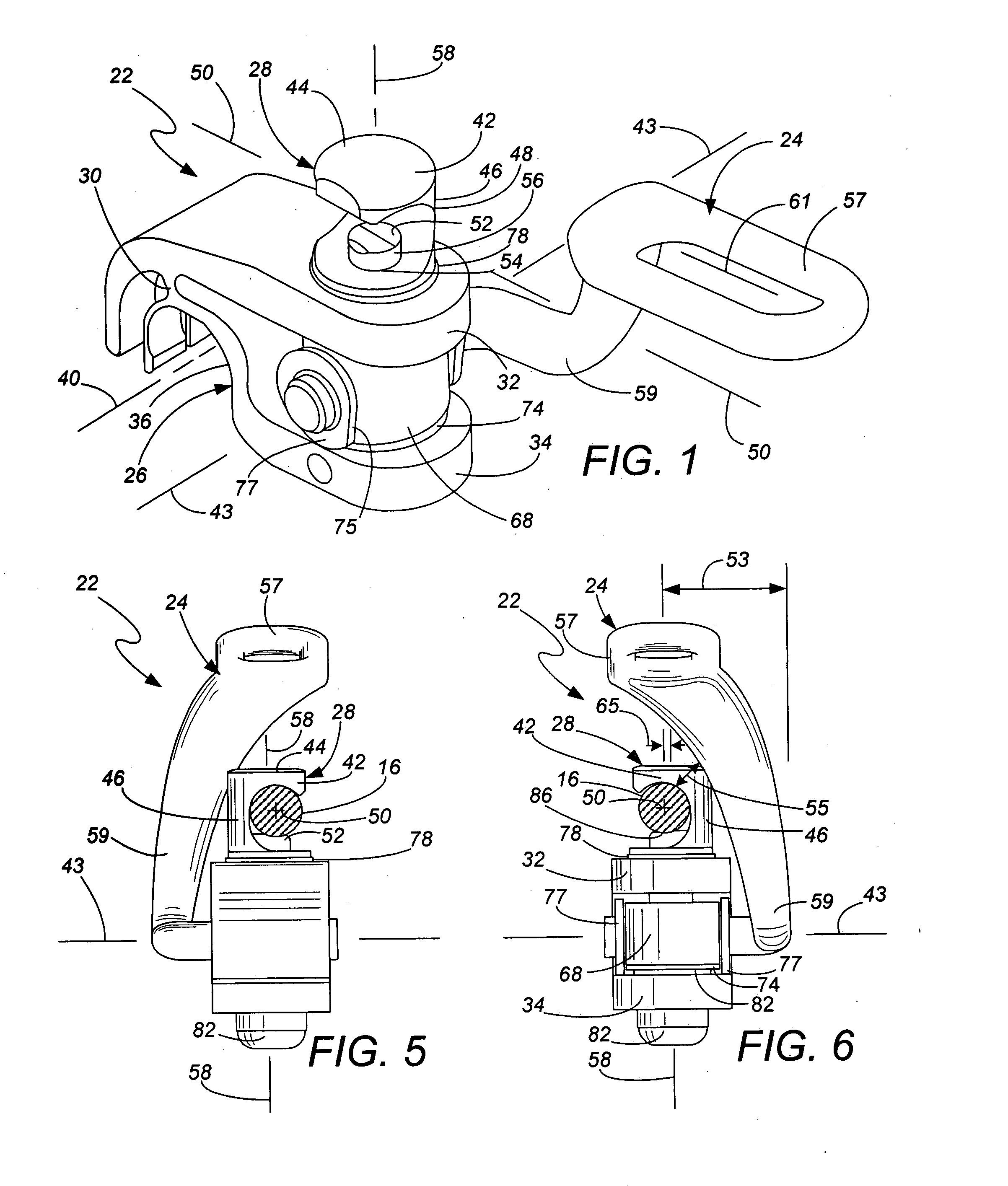

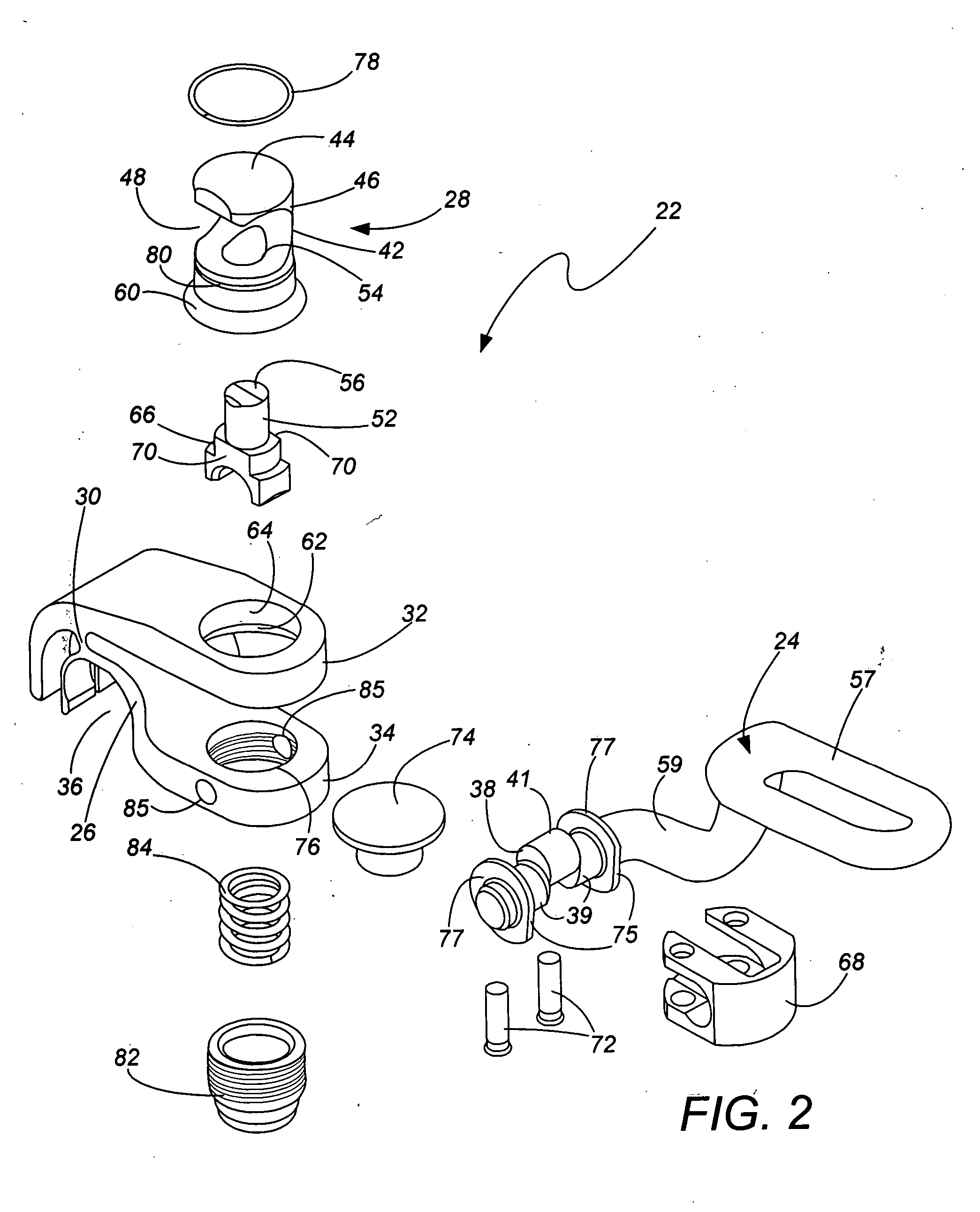

Method of making a surgical clamp

InactiveUS20070191686A1Avoiding non-uniform shrinkageUniform thicknessDiagnosticsSurgical instrument supportSurgical ClampsEngineering

A surgical clamp includes a support frame clamp member, a retraction shaft clamp member and a handle linked to the support frame clamp member and the retraction shaft clamp member for moving the clamp members between loosened and tightened positions. The handle includes a cam, and the handle / cam is unitarily formed by metal injection molding. The handle includes relatively uniform thickness throughout to better accept the shrinkage induced by the metal injection molding process. The base used for a bottom position of the cam is adjustable and spring loaded, to better support a wider range of manufacturing tolerances on the cam as well as the other components of the clamp without over stressing the metal injection molded handle during use. The handle includes a gripping portion with a planar portion inducing alignment of the clamping force as desired for best operation of the clamp.

Owner:MINNESOTA SCI

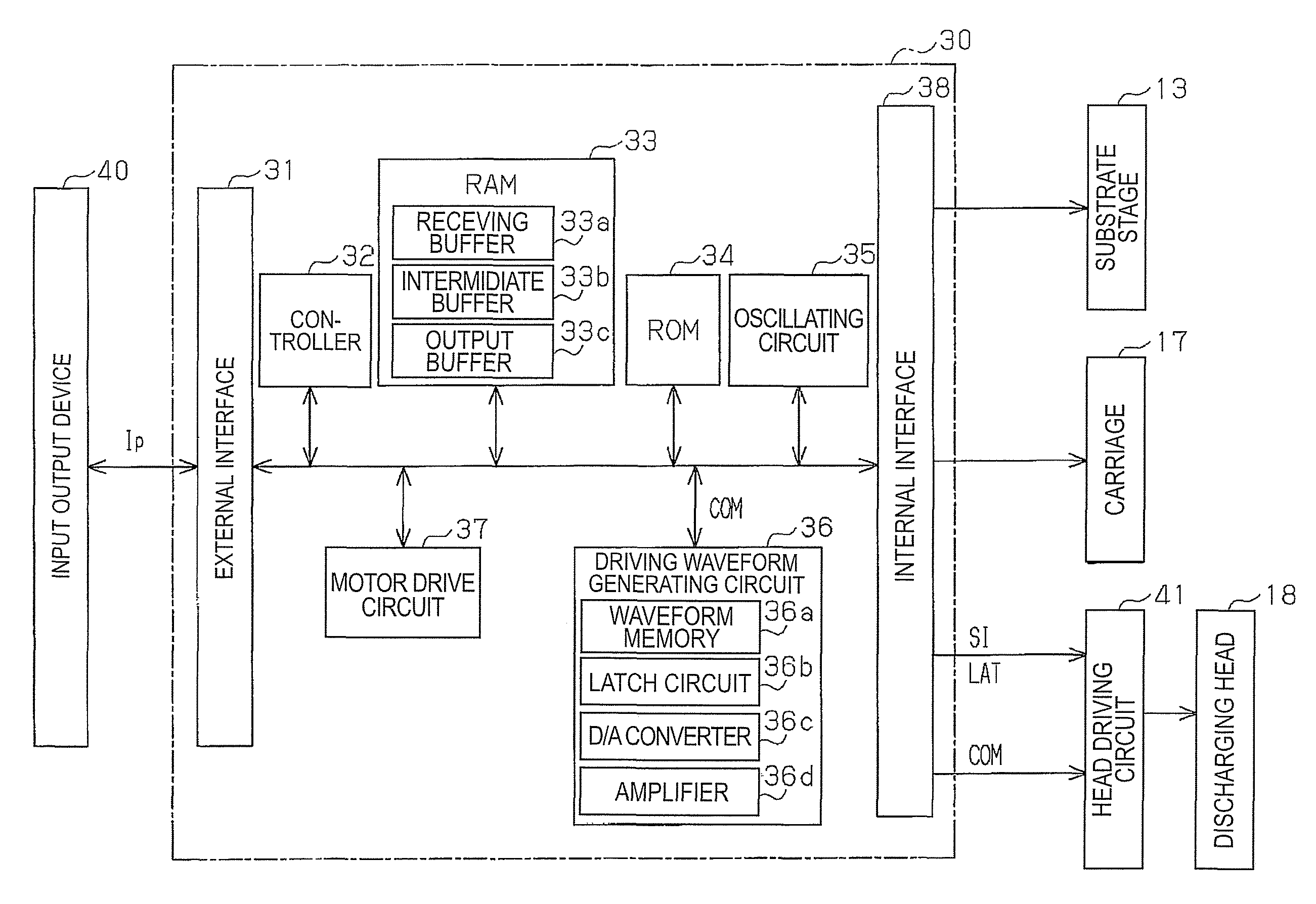

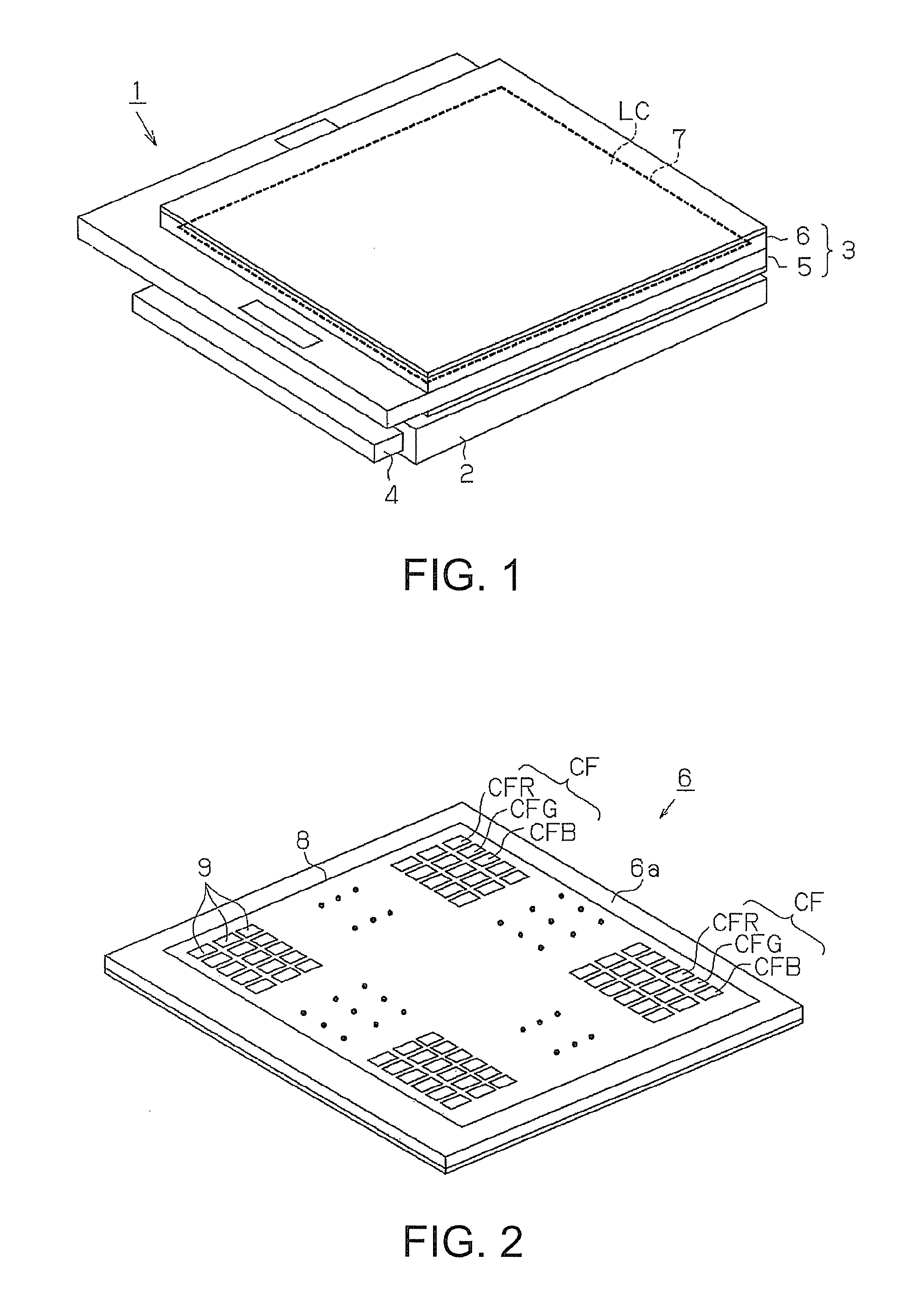

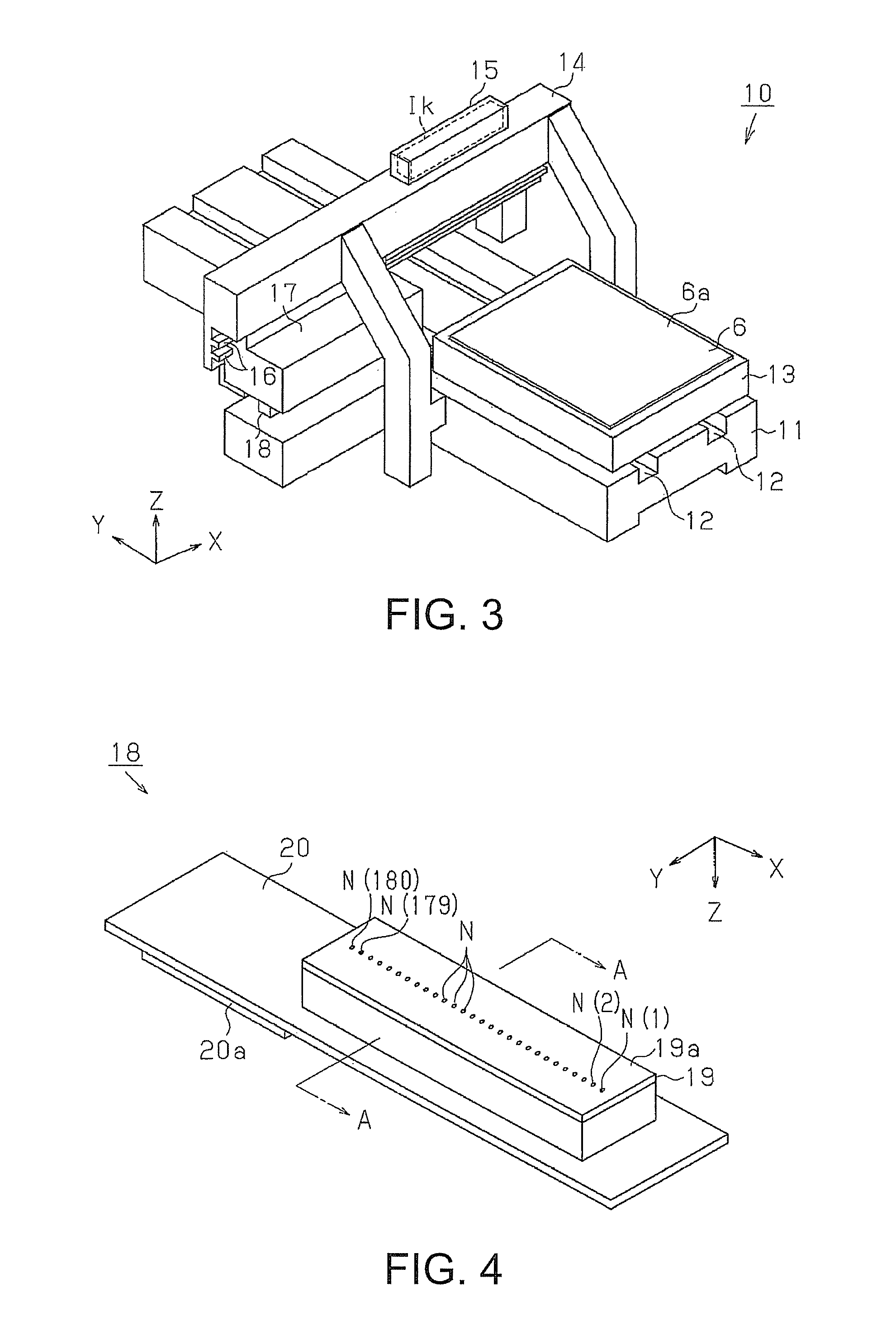

Liquid discharging device and electro optic device

InactiveUS7963622B2Improve thickness uniformityShorten discharge timeElectroluminescent light sourcesOther printing apparatusSpray nozzleEngineering

A liquid droplet-discharging device comprises: a droplet-discharging head having a plurality of nozzles that are arranged in a predetermined direction and discharge liquid droplets; a scanning unit for relatively moving the droplet-discharging head and a substrate toward a scanning direction: a memory memorizing pattern data corresponding to driving nozzles that are selected from the plurality of nozzles in each of a plurality of discharged regions, by partitioning a drew region of the substrate into the plurality of discharged regions every discharging frequency along a scanning direction of the substrate; a transferring unit for developing the patterned data memorized by the memory into a plurality of data to be divided and transferring the divided data to the liquid droplet-discharging head in order; and an output unit for outputting a driving signal that drives a driving nozzle selected by the divided data to discharge the liquid droplets. The patterned data are data that allocates the plurality of nozzles to a plurality of blocks and corresponds each of the plurality of blocks to each of the plurality of discharging regions.

Owner:SEIKO EPSON CORP

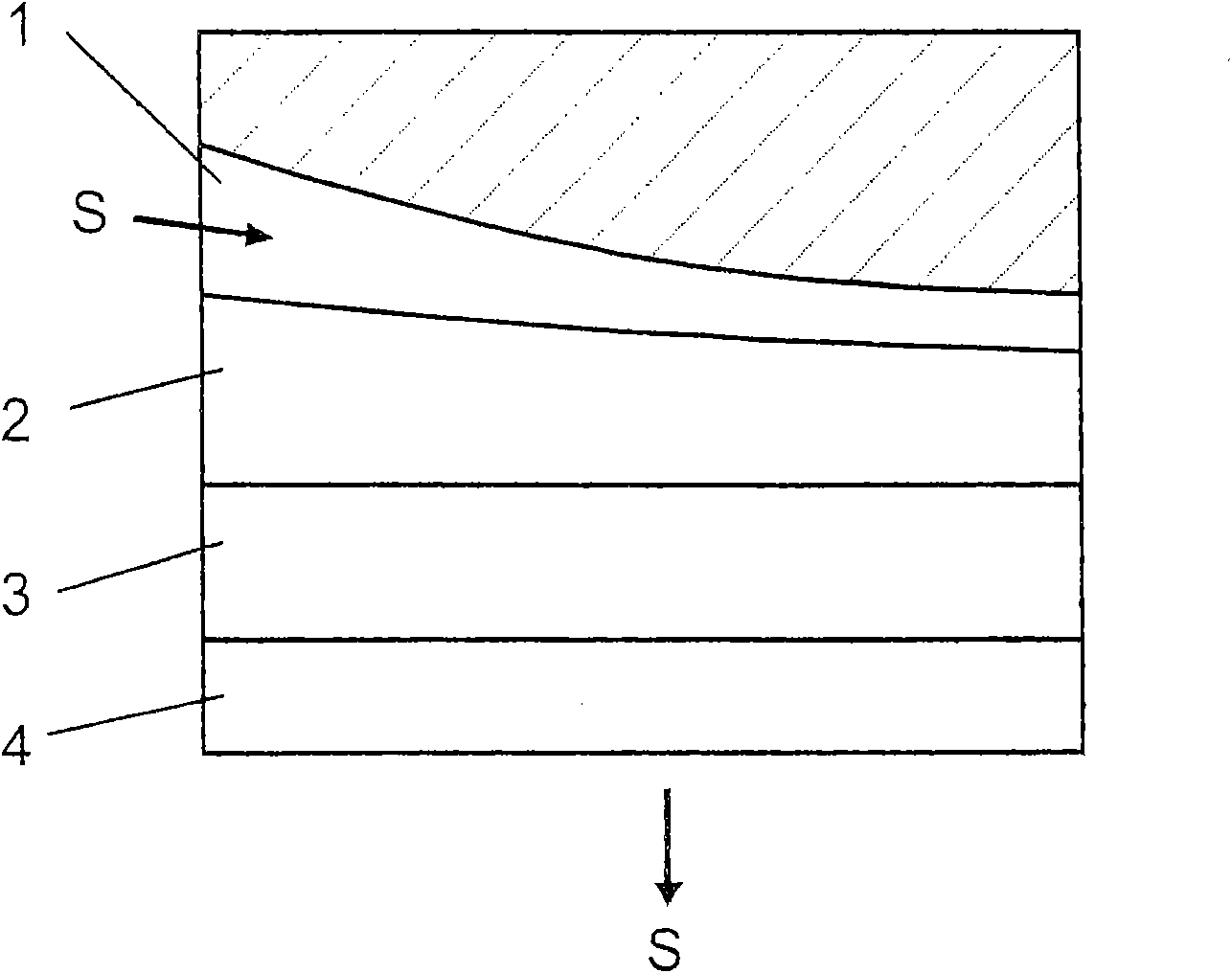

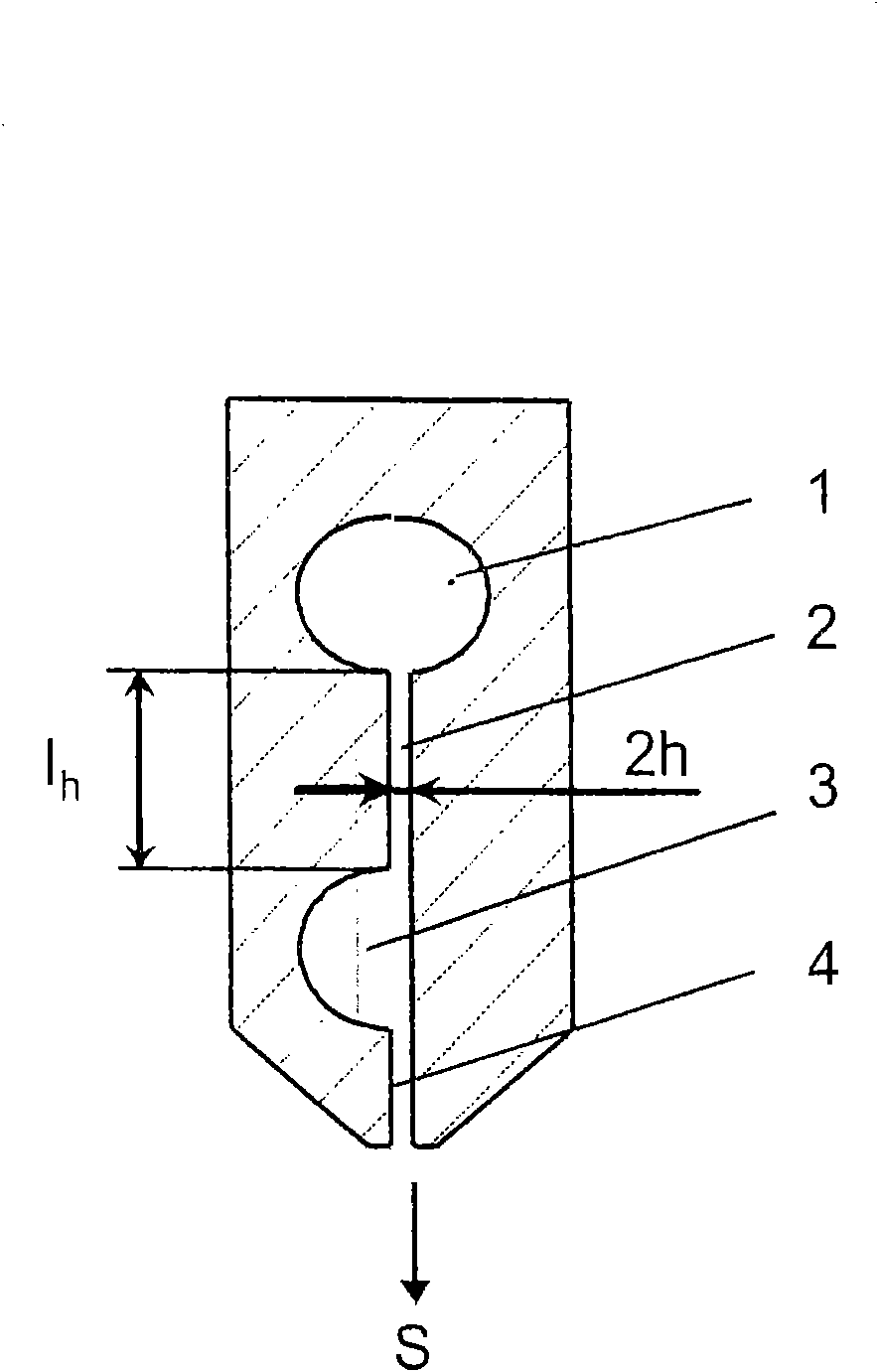

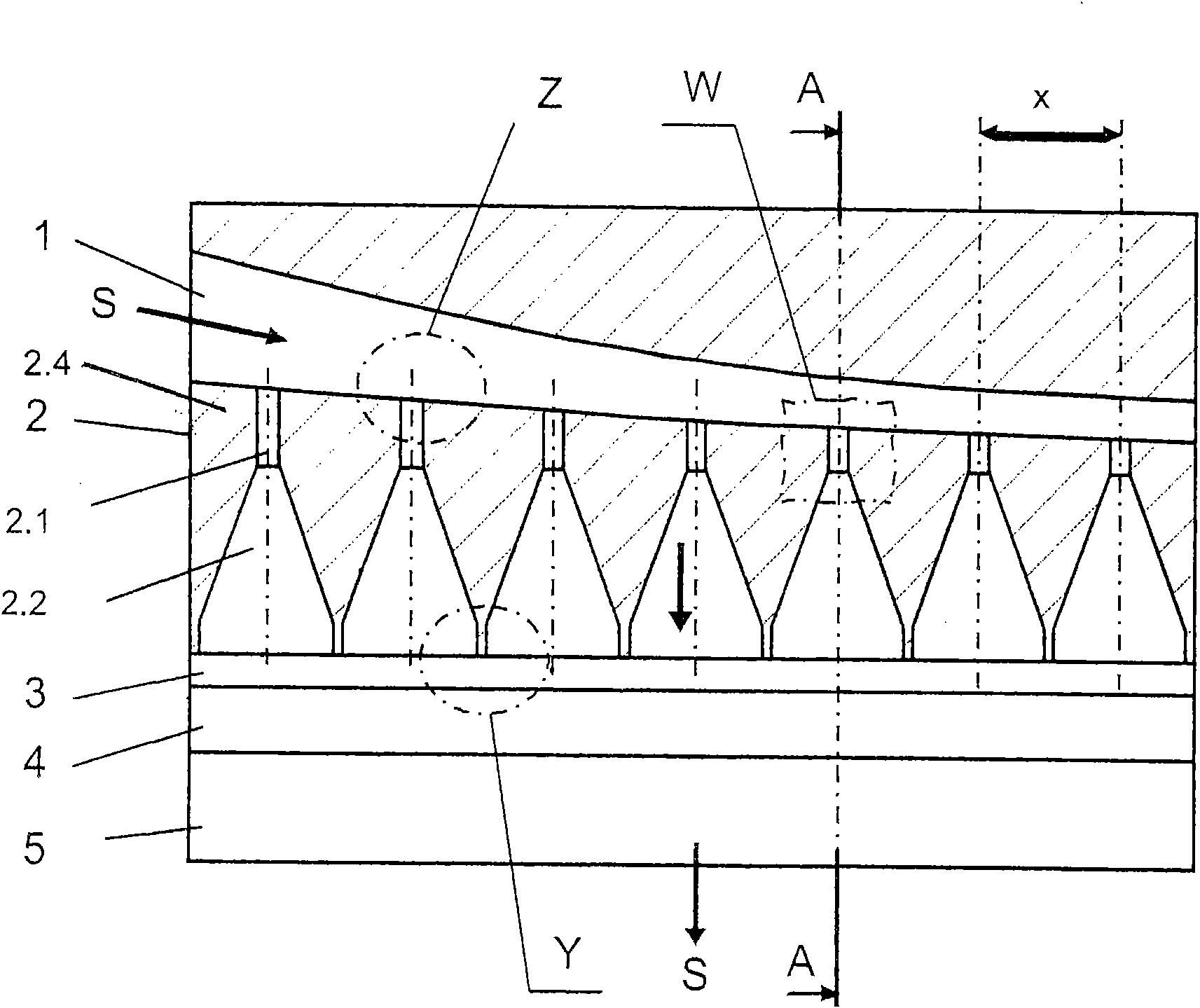

Curtain coater

InactiveCN101992173AUniform pressureUniform volumeLiquid surface applicatorsPaper/cardboardEngineeringEqualization

A curtain coater is used for discharging a coating medium to a movable paper or plate in a form of a movable curtain by weight approximately. the curtain coater includes: a storage device having a first chamber extending in a discharging width and a metering channel for discharging the coating medium as a curtain by a feeding line, wherein the metering channel (2) is divided into multiple individual guide channels, which abut against the first chamber (1) through spaced pipe sections (2.1) on an inlet side and along the discharging width, the lengths and aperture widths of the pipe sections (2.1) are selected for equalization of the flow resistance along the discharging width. Furthermore, in a flow direction (S), the pipe sections (2.1) are replaced by diffusers (2.2) respectively for guiding split flows from the guide channels together on an outlet side.

Owner:ANDRITZ KUESTERS GMBH & CO KG

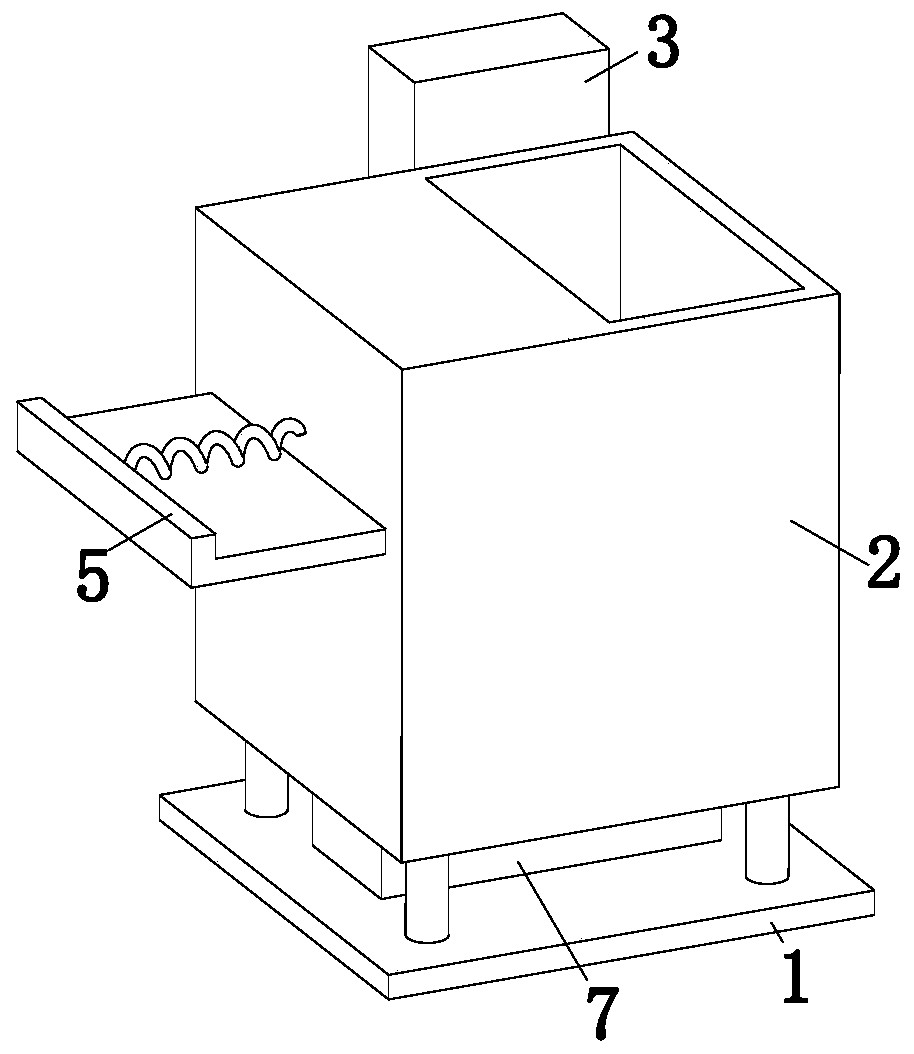

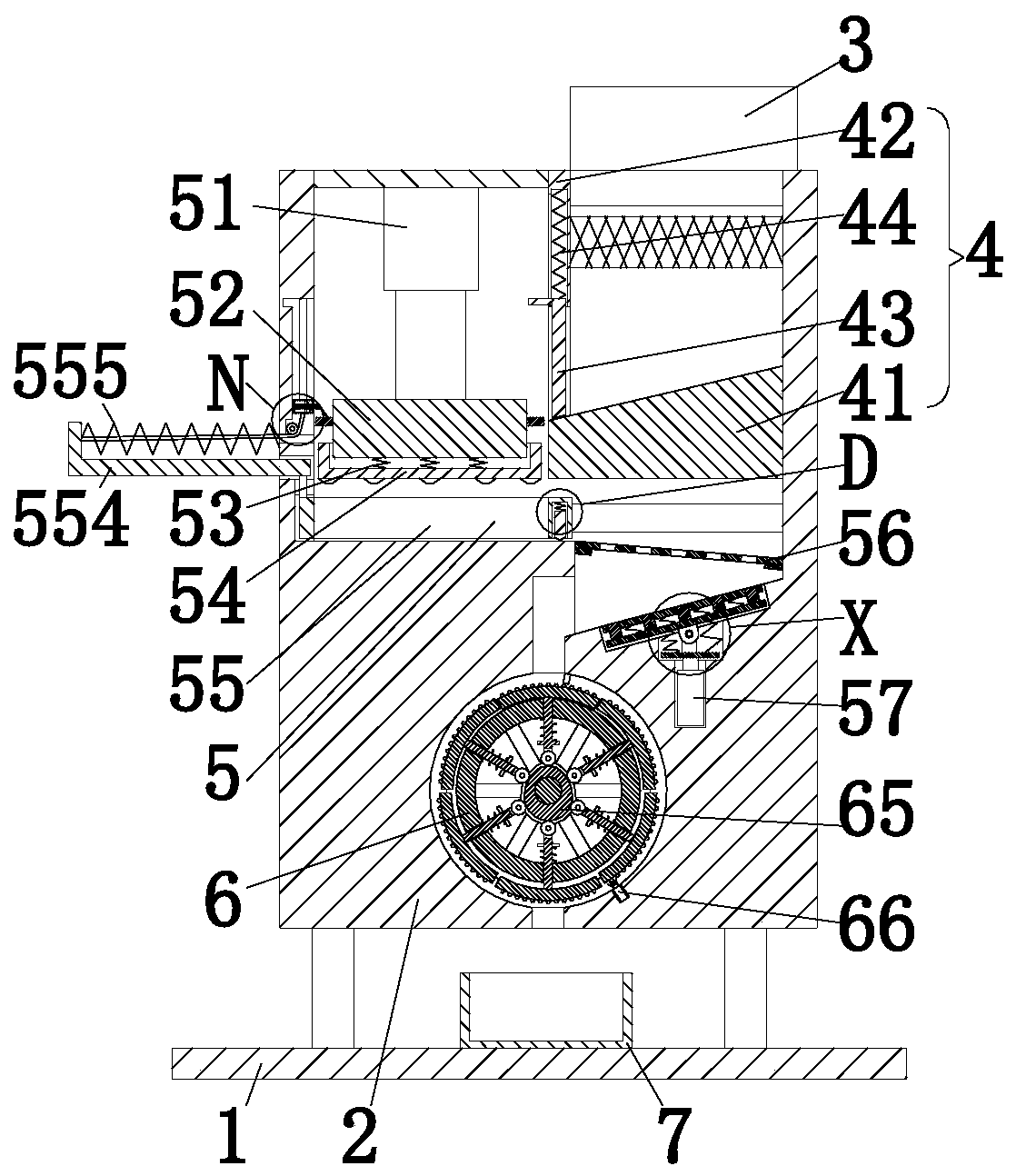

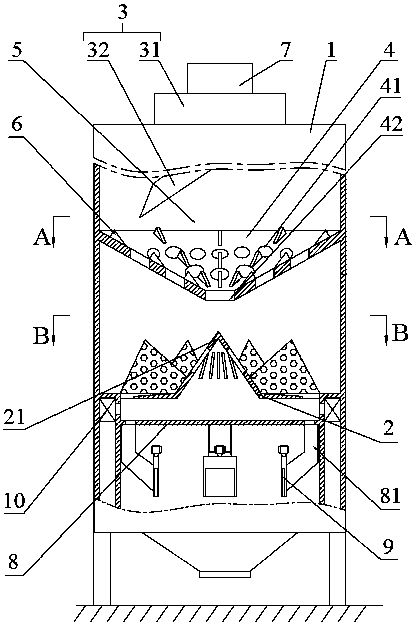

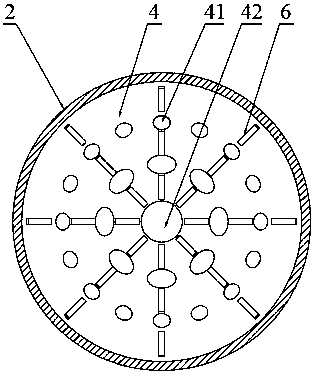

Dispersion machining treatment system for cement preparing and method

ActiveCN111318350AUniform volumeThere will be no jammingGrain treatmentsMechanical engineeringMachining

The invention relates to a dispersion machining treatment system for cement preparing and a method. The system comprises a bottom plate, a decomposing frame, a screening frame, a feeding opening, a breaking device, a grinding device, and a receiving frame. The upper end of the bottom plate is provided with the decomposing frame through a supporting column, the rear end of the decomposing frame isprovided with the screening frame, a rectangular groove is formed in the upper end of the decomposing frame, and the problems that in an existing device, when blocked cement is dispersed, cement blocks which are large in size after breaking cannot be repeatedly broken, the breaking effect is reduced, cement sticking easily appears, cement stacking is caused, the device is damaged, production costis increased, the breaking efficiency is reduced, meanwhile, multi-stage dispersion cannot be carried out, the dispersed cement is large in size, and is not uniform, the dispersion effect is low, thecement remaining in the device cannot be removed, the material waste is caused, and the cement dispersion efficiency is reduced can be solved.

Owner:邯郸中材建设有限责任公司

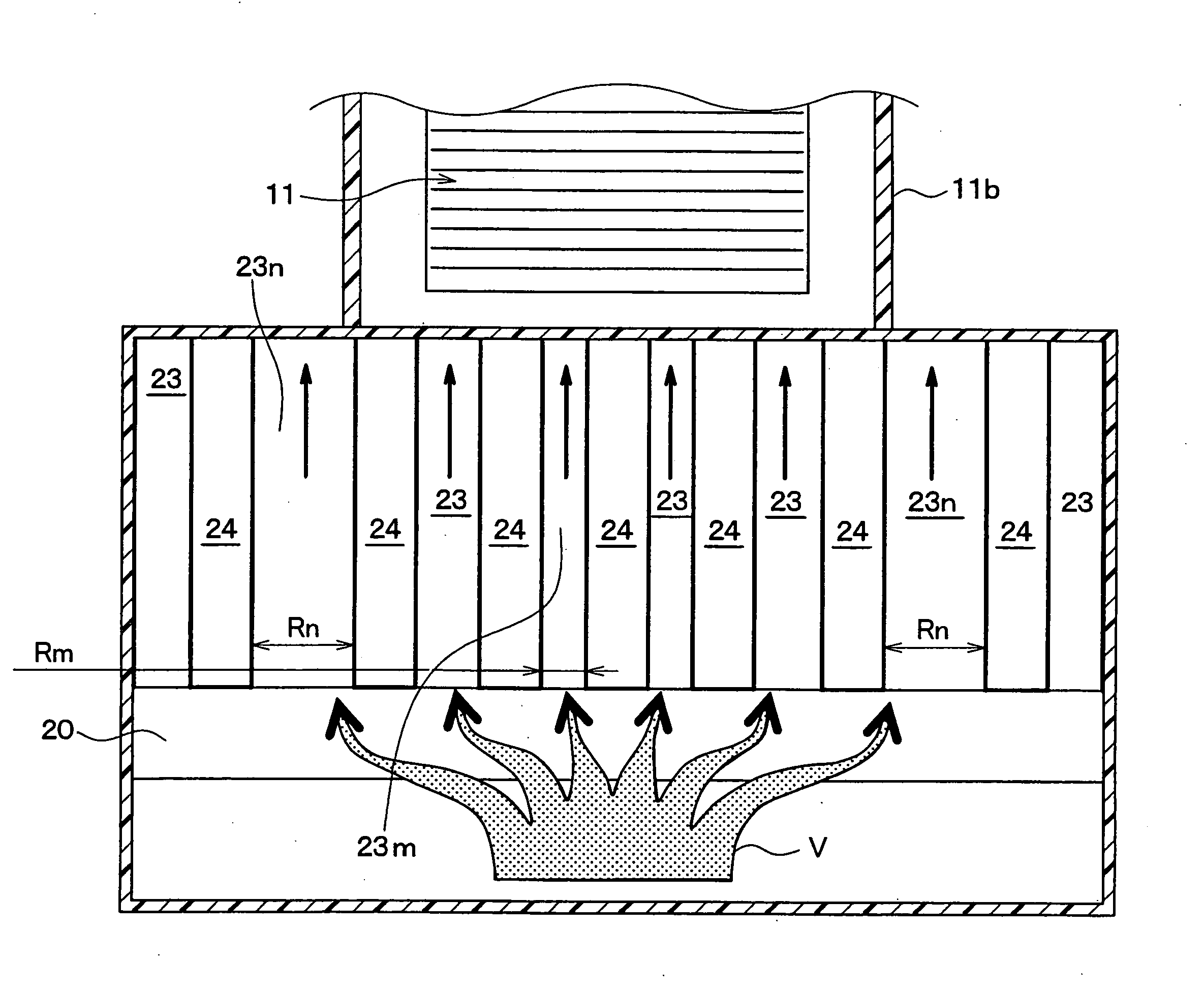

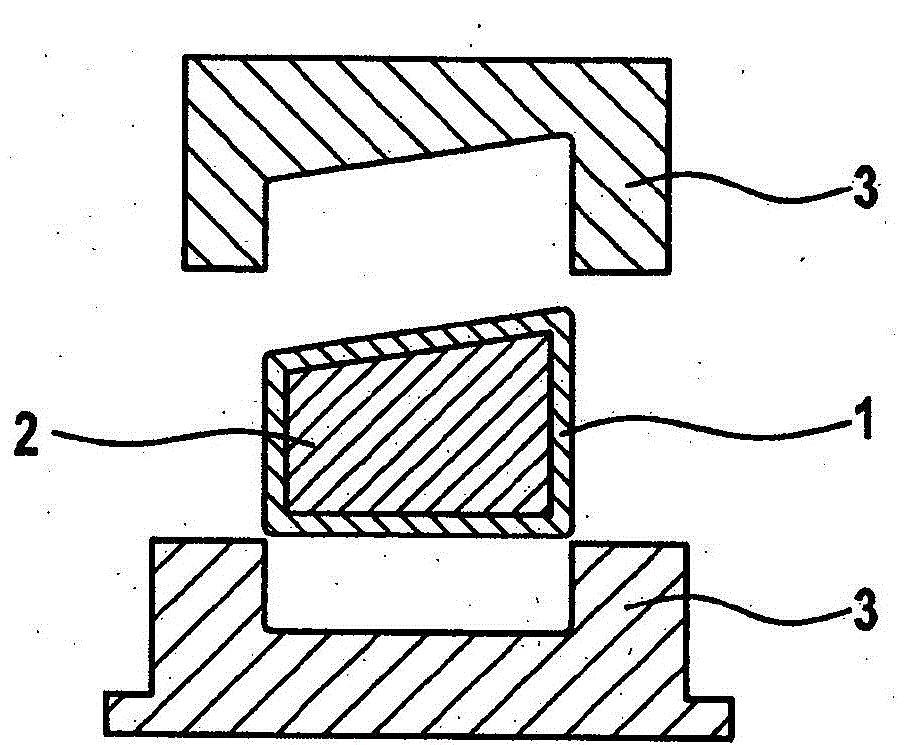

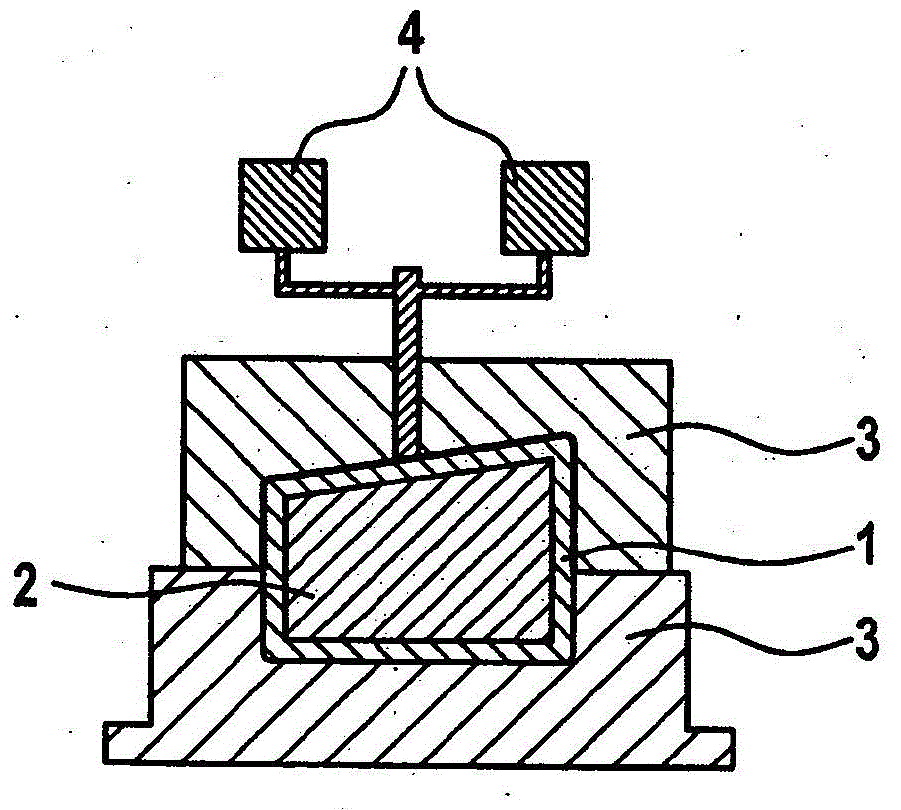

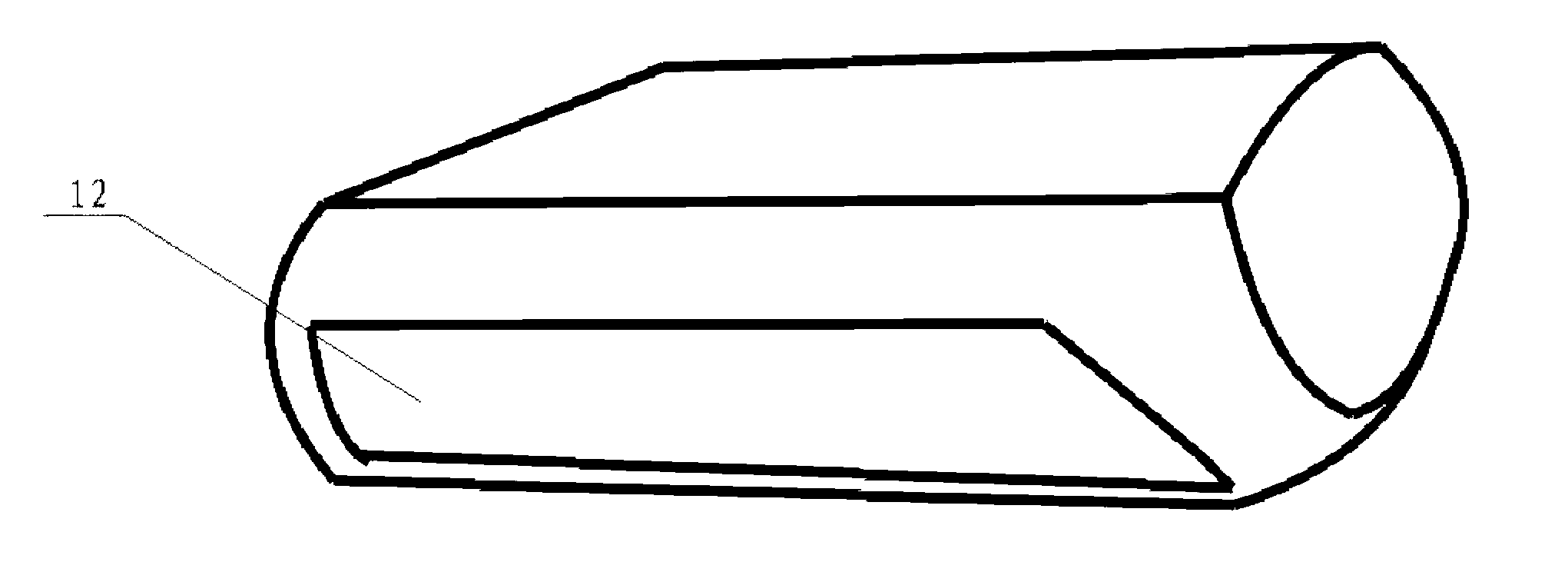

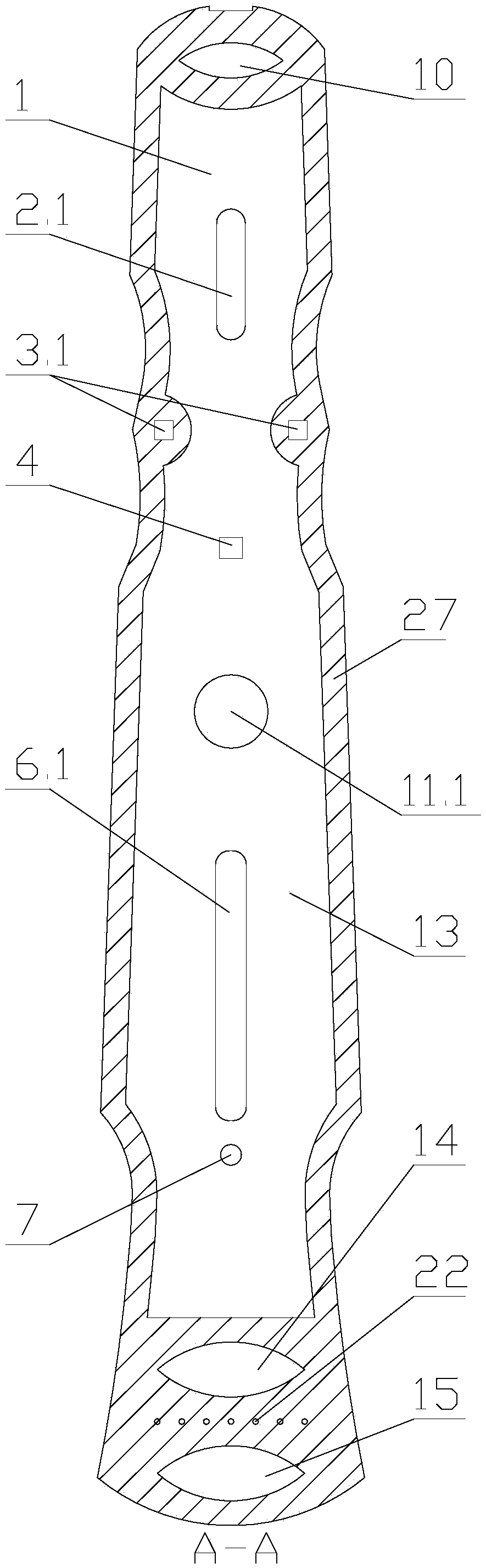

Method for manufacturing fiber enhancement hollowed section bar

ActiveCN104802424AEasy to manufactureShorten the production cycleMaterials scienceFiber reinforcement

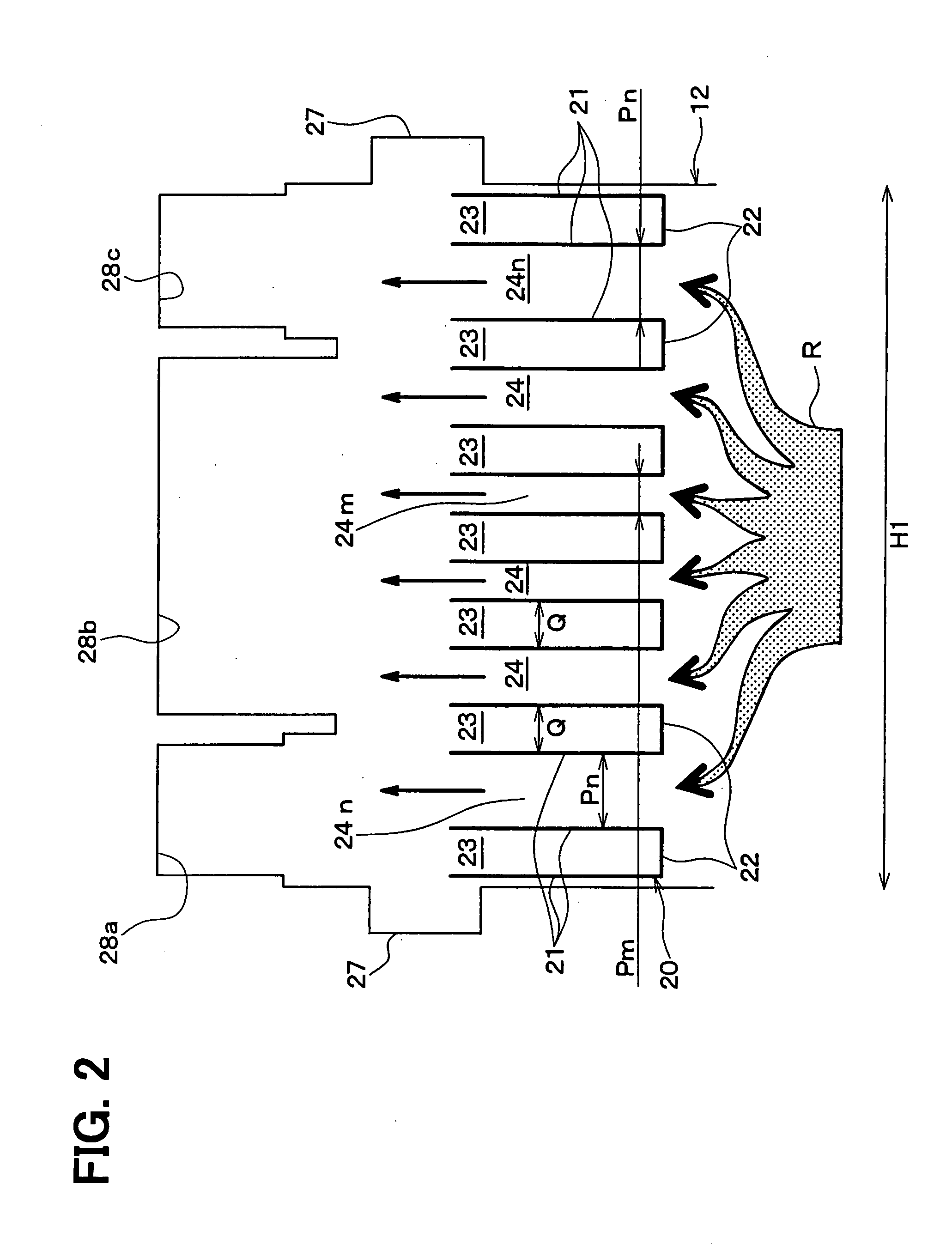

The invention relates to a method for manufacturing fiber enhancement hollowed section bar. This method is the following steps: fiber (22) applied to profile on the body (20); Will be described in the section on the body (20), together with the body in the profile of the fiber (22) in mould (10); Closed die (10) will be stated, until in the mold (10) and fiber pre qualified cavity formed between (22) (24). The matrix materials (28) mentioned in injection mould (10) and described the cavity (24); And that described pre qualified cavity (24).

Owner:BAYERISCHE MOTOREN WERKE AG

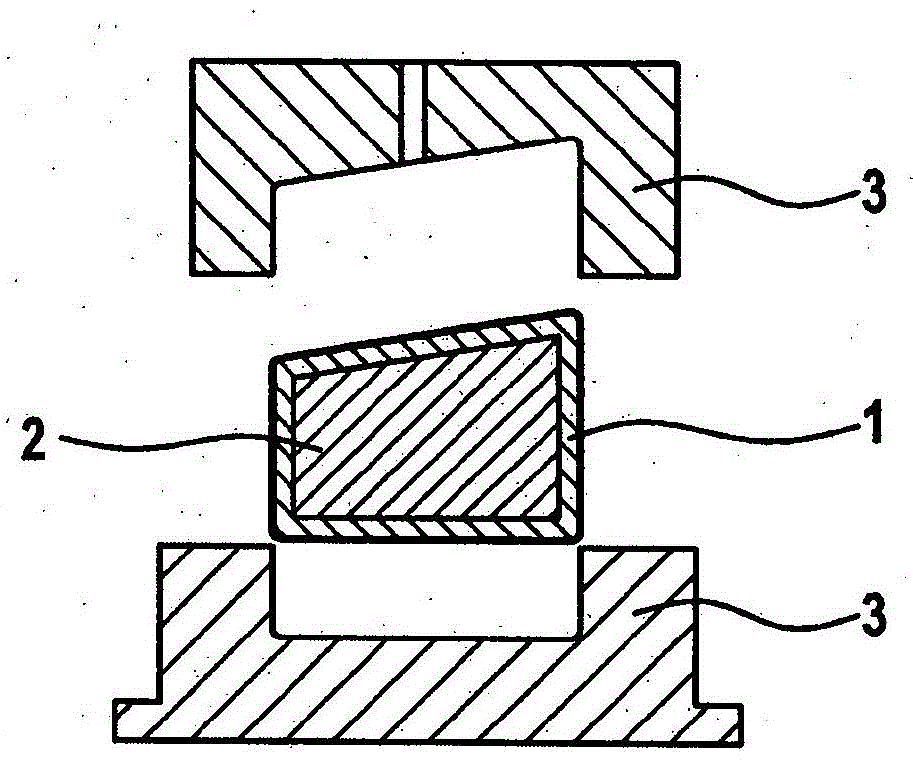

Pre-machining process of spinning hub

The invention relates to a pre-machining process of a spinning hub. After traceable hitting and carving are conducted on a rough material, the rough material is firstly pre-machined, the size of a wheel ring is controlled, and preheating and spinning are conducted. According to the pre-machining process of the spinning hub, mechanical properties of the hub are improved, the thickness of a hub rim can be appropriately reduced, raw materials are saved, production efficiency is promoted, and production cost is lowered. The hub is more accurately positioned on a mold.

Owner:盛旺汽车零部件(昆山)有限公司

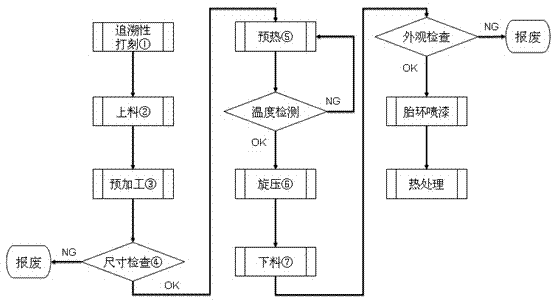

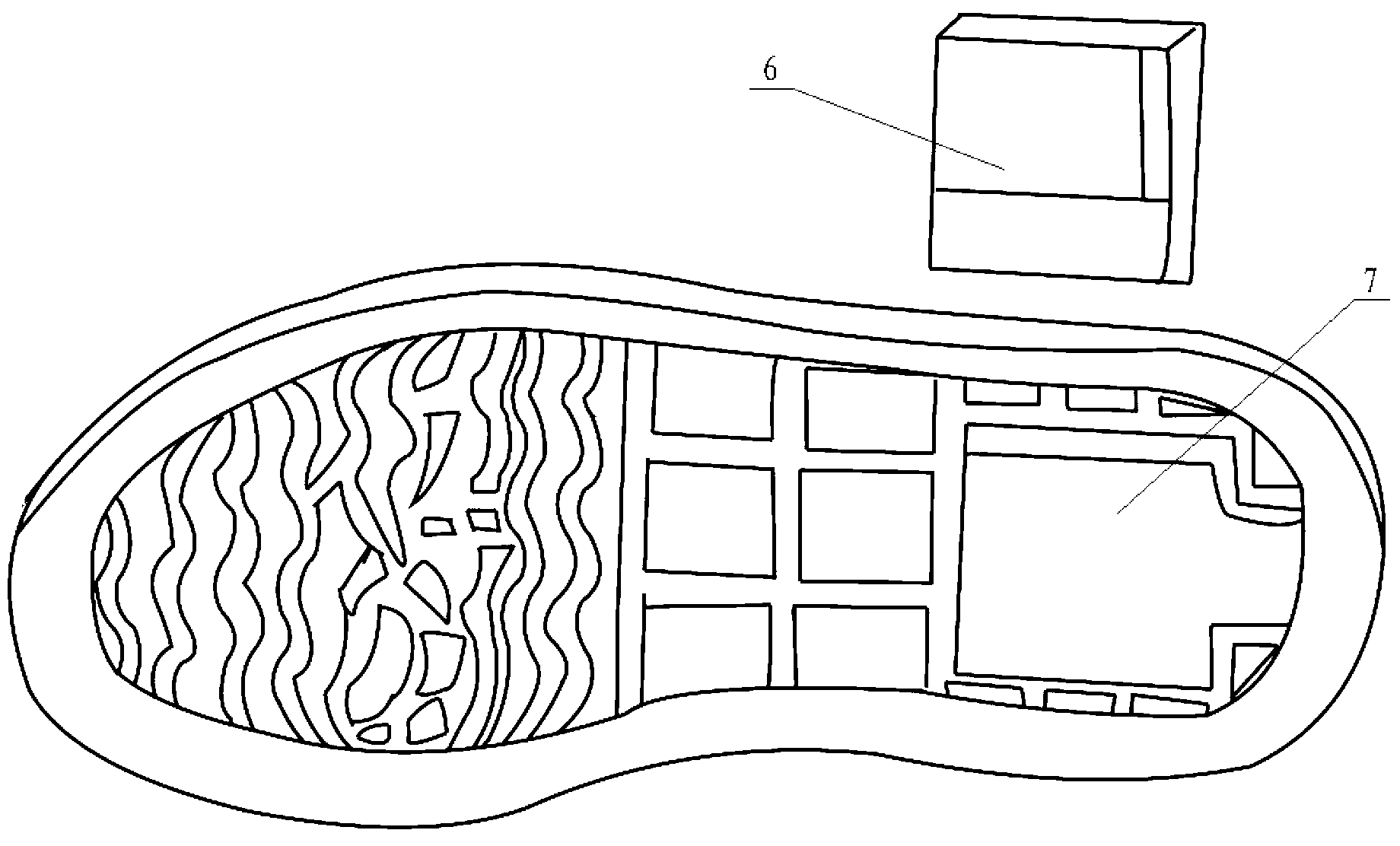

Wireless charging positioning smart shoes

InactiveCN103315439ASolve the problem of small size and difficult to install wireless modulesUniform volumeSolesElectrical batteryComputer module

A pair of wireless charging positioning smart shoes comprises a first shoe body and a second shoe body. A wireless emission device and a wireless current receiving device are arranged in a heel of the first shoe body and are connected. A battery and a wireless current emission device are arranged in a heel of the second shoe body. Electric energy of the battery is emitted by the wireless current emission device and received by the wireless current receiving device, and the wireless current receiving device receives currents of the battery and provides the currents for the wireless emission device to be used. Compared with the prior art, the wireless charging positioning smart shoes have the advantages that the wireless devices and the power supply device are arranged in the pair of shoes, the wireless emission device is mounted in one shoe, the power supply device is mounted in the other shoe, and the electric energy of the power supply device is transmitted to the wireless emission device through the wireless current emission device and the wireless current receiving device, accordingly, the problem that wireless modules cannot be mounted easily as shoe soles of children's shoes are small in size is solved, and the pair of shoes are balanced in size and comfortable to be worn.

Owner:WENLING TAIPING SENIOR VOCATIONAL SCHOOL

High-yield and energy-saving mixing type lime kiln

The invention relates to the field of lime production, in particular to a high-yield and energy-saving mixing type lime kiln. The high-yield and energy-saving mixing type lime kiln comprises a kiln body, a fire grate is arranged in the kiln body, a distributing mechanism is arranged above the fire grate, a dividing plate is further arranged between the distributing mechanism and the fire grate andobliquely arranged, a plurality of through holes used for passing of raw materials are formed in the dividing plate, the through holes are gradually enlarged in the oblique direction of the dividingplate, thus the raw materials guided into the kiln body by the distributing mechanism are screened by the dividing plate and then fall into the fire grate for calcination treatment, the raw materialsfalling onto the fire grate are treated distinctively according to the different sizes, large-size fuel and large-size limestone make contact, small-size fuel and small-size limestone make contact, the fuel and the limestone which make contact are adaptive in size, the calcination process is carried out smoothly and advantageously, the fuel consumption is decreased, waste of resources is avoided,and the production efficiency is improved.

Owner:四川马氏窑技术发展有限公司

High-efficiency polymerization reactor

ActiveCN101920182AIncrease the heat exchange areaReduce volumeChemical industryChemical/physical/physico-chemical processesAxial-flow pumpChemical industry

The invention provides a high-efficiency polymerization reactor, belonging to the field of chemical industry. The reactor comprises a reactor cylinder body, a guide cylinder, an annularly arranged ring heat pipe, a special deflection baffle, an axial-flow pump and a feed port with special charging. The reactor can solve the problem of uniform and quick heat exchange of a polymerization reaction, changes the heat exchange mode of the traditional reactor, has the advantages of high yield in unit volume, uniform heat exchange, no dead angle low energy consumption, low investment and simple and convenient operation, greatly reduces the size of the reactor by improving the heat exchange efficiency and is applicable to all polymerization processes, in particular to rubber production.

Owner:CHINA PETROCHEMICAL CORP +1

Food waste processing device

ActiveCN109226178AImplement Assisted AggregationOvercoming aggregate throwWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesOil waterFood waste

The invention provides a food waste processing device. The food waste processing device comprises a stander, a crushing device, a dehydration device and an oil-water separation device, wherein the crushing device, the dehydration device and the oil-water separation device are arranged on the stander; the oil-water separation device comprises a collection tank, the collection tank comprises an oilextraction section and a collection section, the width of the collection section gradually decreases towards the oil extraction section, and an oil collection tank is formed in the end part of the oilextraction section; a roller is arranged between two side walls of the oil extraction section, and a third quadrant and a fourth quadrant of the roller are located in the oil extraction section; scraping plate seats are arranged above two side walls of the oil collection tank, a swingable scraping plate is hinged between the two scraping plate seats, one end of the scraping plate abuts against and is in contact with an outer column wall of a second quadrant of the roller, and the other end of the scraping plate downwards extends into the oil collection tank; and an oil baffle is arranged in the oil extraction section and is located between the side wall of one side, close to the oil collection tank, of the oil extraction section and the roller. According to the food waste processing device, the thickness of an oil surface during the oil-water separation can be effectively improved, the oil-water separation efficiency can be improved, and the rapid oil-water layering can be realized.

Owner:WENZHOU HAOBANGSHOU ELECTROMECHANICAL

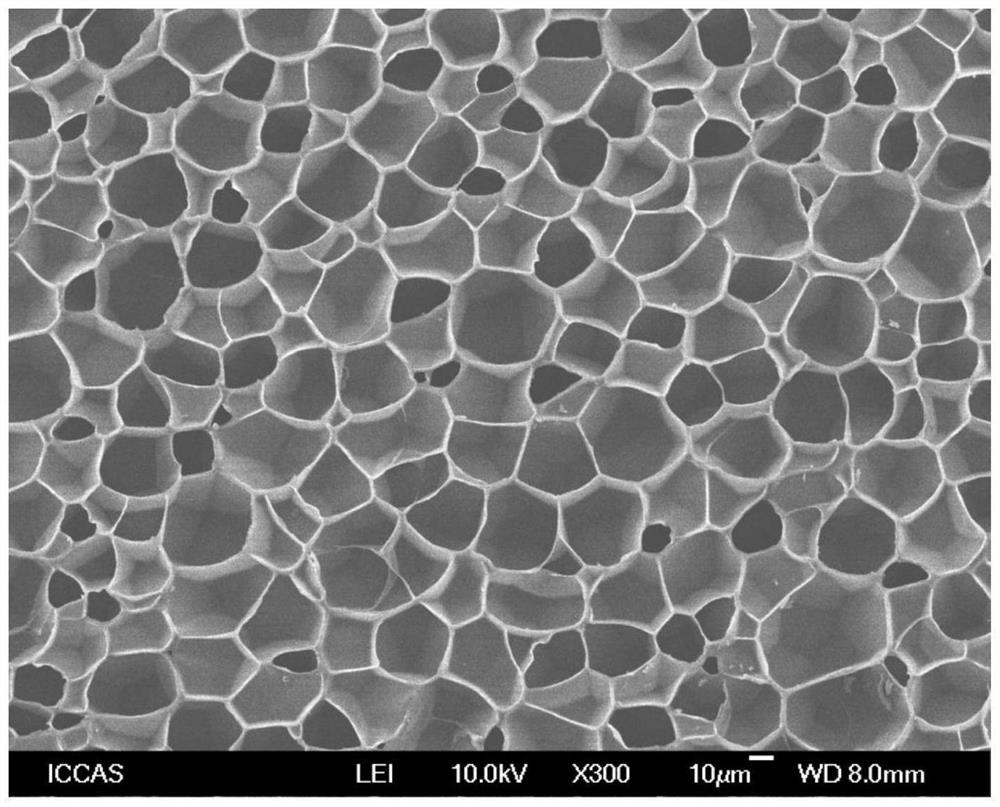

Process for the Powder Metallurgy Production of Metal Foam and of Parts Made from Metal Foam

InactiveUS20080314546A1Uniform volumeHigh degreeTransportation and packagingMetal-working apparatusPowder metallurgyWork in process

A method for a powder-metallurgical production of metal foamed material and of parts made of metal foamed material includes mixing a pulverulent metallic material including at least one of a metal and a metal alloy; pressing, under mechanical pressure, the mixed pulverulent metallic material so as to form a dimensionally stable semi-finished product; placing the semi-finished product into a chamber that is configured to be sealed pressure-tight; sealing the chamber; heating the semi-finished product to a melting or solidus temperature of the pulverulent metallic material; once the melting, or solidus temperature has been reached, reducing tile pressure in the chamber from an initial pressure to a final pressure so that the semi-finished product foams so as to form a metal foam; and lowering the temperature of the metal foam so as to solidify the metal foam.

Owner:HELMHOLTZ ZENT BERLIN FUER MATERIALIEN & ENERGIE GMBH

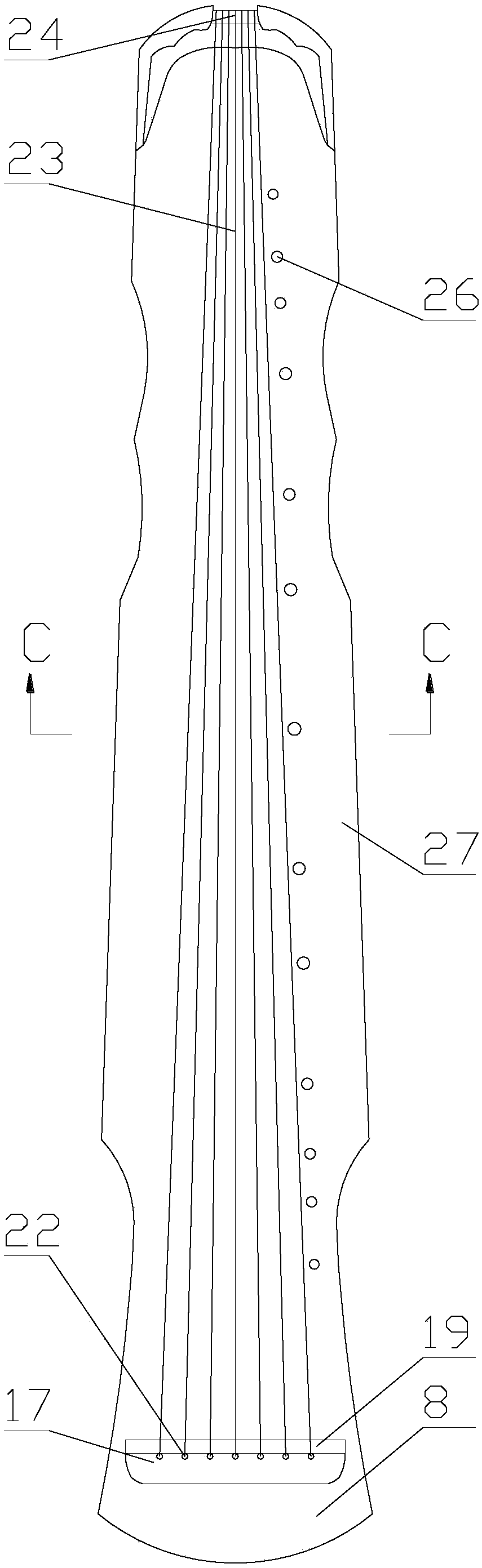

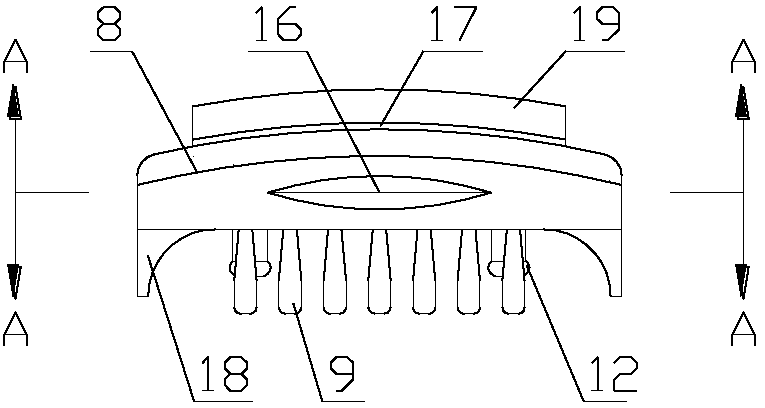

Installation of a pond resonance qin

InactiveCN108597477ALoud volumeIncrease volumeStringed musical instrumentsInternal pressureEngineering

The installation of a pond resonance qin comprises the following steps of: firstly, digging a small Cao Fu, a large Cao Fu, a Yun Zhao, a Sheng Chi, a Feng Su and a Zu Chi on the downward face of a panel and reserving a small Na Yin, a large Na Yin and a drum Na Yin; bonding a Tian Zhu and a Tian Zhu; installing the emblem on the upward face of the panel; loading he upward face of the panel with aChenglu and a Yue Shan; digging out a Long Chi and a Feng Zhao on the bottom plate; digging a foot hole on the bottom plate; digging a drum hole on the bottom plate; the outer pressure ring is adhered to the drum hole to soak the skin in warm water to soften and expand, glue is applied to one edge of the softened and expanded skin, the inner pressure ring is buckled, and the edge of the other side of the skin is coated with glue, and a skin which is bonded with the inner pressure ring is embedded in the outer pressure ring; bonding the panel to the bottom plate; drilling a string eye; painting Hui Tai and dyeing on the dried qin; installing a Yan Zu and qin sting The musical instrument qin has the advantages of large volume, long aftertaste and uniform overall volume.

Owner:薛应东

Lithium ion battery silicon-based composite negative electrode material and preparation method thereof

ActiveCN113506861AImprove ionic conductivityImprove electronic conductivitySilicaNegative electrodesSilicon monoxideSilicon oxide

The invention provides a lithium ion battery silicon-based composite negative electrode material and a preparation method thereof. The silicon-based composite negative electrode material is composed of silicon, silicon oxide, doped metal and a carbon material, the silicon and the doped metal are dispersed in a substrate formed by the silicon oxide, the surface of material particles is evenly coated with the carbon material, and the negative electrode material is in-situ nanoscale bulk phase doped metal; the doped metal is selected from one or more of fourth and fifth period transition metal elements and / or fourth and fifth main group metal elements; and the total mass of the silicon-based composite negative electrode material is 100%, the mass ratio of the doped metal is 3-12%, and the mass ratio of the carbon material is 1-10%. The metal is doped in the silicon monoxide, a part of lithium in the buffer layer is released through a reverse conversion reaction, agglomeration and growth of a silicon crystal region in a circulation process are inhibited, and the first coulombic efficiency, the multiplying power and the circulation performance of the negative electrode material are improved.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD +1

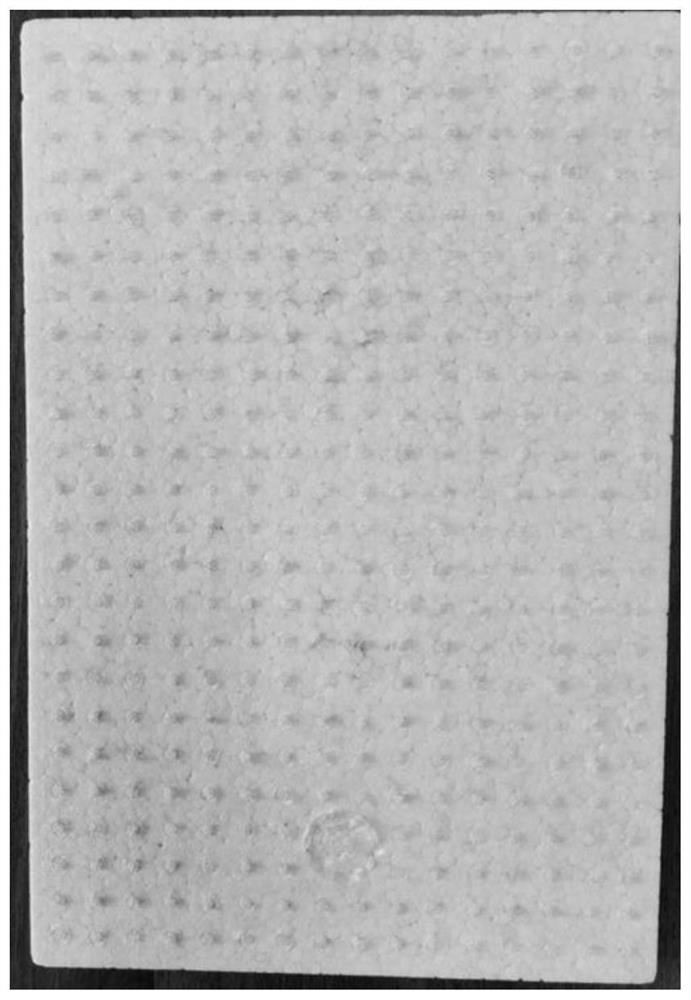

Low-shrinkage long-carbon-chain polyamide elastomer foamed bead as well as preparation method and application thereof

ActiveCN114316345ARaise the crystallization temperatureFast crystallization rateBulk chemical productionElastomerPolymer science

The invention provides a low-shrinkage long-carbon-chain polyamide elastomer foamed bead as well as a preparation method and application thereof. According to the preparation method, the foamed bead is prepared from a long-carbon-chain polyamide elastomer formed by polycondensation of a polyamide hard segment and a polyether soft segment, wherein the carbon atom number of diamine and the carbon atom number of binary acid are 2N2 (N + 1) types. The binary acid aliphatic chain and the diamine aliphatic chain of the polyamide hard segment structure of the 2N2 (N + 1) type long carbon chain polyamide elastomer prepared by the method have the same methylene number, so that spatial arrangement in which methylene chain segments are completely symmetrical can be formed, and more regular hydrogen bond interaction is formed between amido bonds. Therefore, the long-carbon-chain polyamide elastomer has higher crystallization temperature and higher crystallization rate, and the foamed beads of the long-carbon-chain polyamide elastomer are low in shrinkage rate and good in structural stability. The foaming material prepared from the foaming bead has the characteristics of soft texture, good damping property, high resilience, small permanent deformation, low density and the like, and can be widely applied to the fields of high-grade shoe materials, damping packaging and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Saline-alkaline removing method for saline-alkaline waste residue with low permeability

ActiveCN108906852AStorage takes up less spaceShort processing timeSolid waste disposalIonElectric field

The invention discloses a saline-alkaline removing method for saline-alkaline waste residue with low permeability, and belongs to the technical field of waste residue treatment. The saline-alkaline removing method is characterized in that a plurality of electrodes with characteristics of electric conduction and water permeation are horizontally arranged to form electrode groups, and the electrodegroups and waste residue layers are stacked alternately; the polarity of a direct current power source connected to any one of the electrodes is opposite to the polarity of a direct current power source connected to at least one of the electrodes surrounding the any one electrode; an appropriate amount of a liquid containing appropriate components is injected through the electrodes; direct currentis applied through the electrodes to generate an electric field in the waste residue; and under the action of the electric field, the soluble ions contained in the saline-alkaline in the waste residue migrate to the electrodes with the opposite polarity, and are carried out by the appropriate liquid through the water permeation pipelines of the electrodes so as to remove the saline-alkaline fromthe waste residue. According to the present invention, the saline-alkaline removing method can perform saline-alkaline removing on a large amount of waste residue, and further has characteristics of short treatment time and small construction occupation area.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

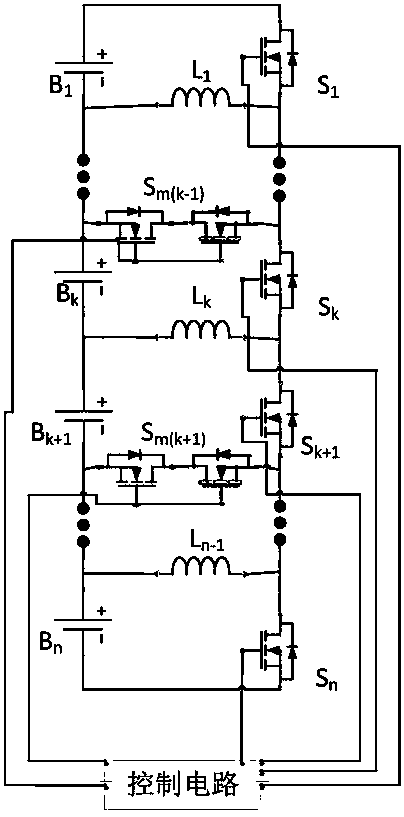

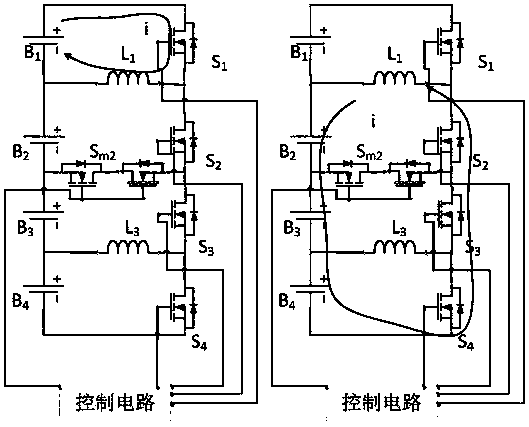

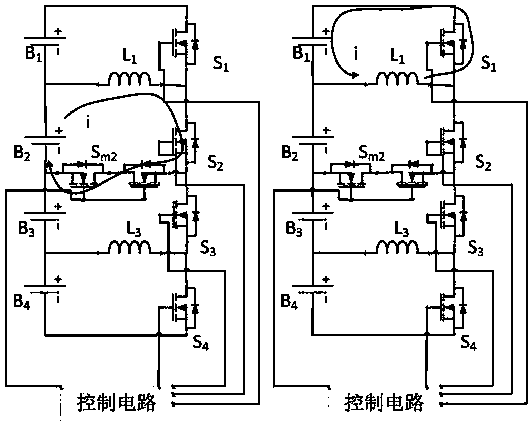

Lossless equalization improvement circuit for energy storage battery pack based on inductors and equalization method thereof

InactiveCN108306352ACell balanceReduce imbalancesCharge equalisation circuitCharging managementMOSFETElectrical battery

The invention discloses a lossless equalization improvement circuit for an energy storage battery pack based on inductors and an equalization method thereof, which reduces the number of energy storageelements in the equalization improvement circuit and simplifies and the equalization improvement circuit. The lossless equalization improvement circuit comprises a battery pack, wherein the battery pack is formed by sequentially connecting batteries B1, B2...Bn in series. The number of energy storage inductors L in the equalization improvement circuit is n / 2, and the energy storage inductors L are respectively L1, L3...Ln-1 from top to bottom. Each energy storage inductor L is connected between a negative electrode of the corresponding battery and a source electrode S of an MOSFET (Metal Oxide Semiconductor Field Effect Transistor) at the right end. The lossless equalization improvement circuit adopts the anti-parallel MOSFETs to replace the energy storage elements, the phenomenon of being unbalanced of the battery pack is improved through controlling on-off of the MOSFETs in the equalization improvement circuit and an energy storage effect of the inductors, the available capacity ofthe battery pack is improved, the maintenance and replacement cycle of the battery pack is reduced, and the service life of the battery pack is prolonged.

Owner:DONGGUAN DRN NEW ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com