Recycled plastic recycling equipment

A technology for recycling and reusing plastics, which is applied in recycling technology, plastic recycling, mechanical material recycling, etc. It can solve the problems of easy inclusion of impurities, low quality of plastic powder, and decline in plastic quality, so as to improve processing efficiency and achieve uniform volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

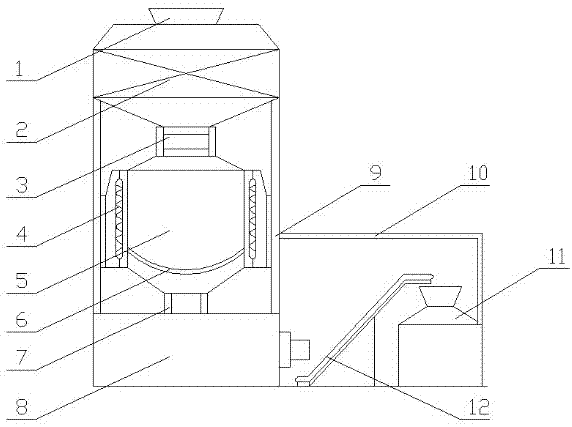

[0009] A processing and reuse equipment for recycled plastics, characterized in that it includes a hopper 1, a coarse crusher 2, a heat-insulated feeding channel 3, an electromagnetic heating tube 4, a melting chamber 5, a filter screen 6, an extruder hopper 7, a single Screw extruder 8, bracket 9, dust cover 10, fine pulverizer 11, material hoist 12; the hopper 1 is installed above the coarse crusher 2, and the heat-insulating material passage 3 is installed below the coarse crusher 2, and the heat-insulated transmission A melting chamber 5 is set under the feed channel 3, electromagnetic heating tubes 4 are installed on both sides of the melting chamber 5, brackets 9 are installed on one side of the electromagnetic heating tube 4, a filter screen 6 is installed at the bottom of the melting chamber 5, and an extruder hopper 7 is installed under the melting chamber 5 , a single-screw extruder 8 is installed below the extruder hopper 7, a material hoist 12 is installed on one si...

Embodiment 2

[0011] Put the recycled plastic into the hopper 1, and the coarse crusher 2 will roughly crush it, and then fall into the melting chamber 5, and the electromagnetic heating tube 4 will run to heat the plastic to make it into a molten state, and the filter screen 6 will melt The impurities in the plastic are filtered, and the molten plastic enters the extruder hopper 7 after filtering, the single-screw extruder 8 extrudes the molten plastic and cools it naturally, and the material elevator 12 sends the extruded plastic to the fine pulverizer 11 Carry out fine crushing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com