Composite rare-earth oxide strengthened tungsten-base high-specific-gravity alloy composite material and preparation method thereof

A rare earth oxide and compound rare earth technology, applied in the field of metal materials, can solve the problems of limited strengthening effect of composite materials, unsatisfactory microstructure and mechanical properties, etc., and achieve excellent microstructure, comprehensive performance improvement, Improve the effect of element distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The invention provides a composite rare earth oxide reinforced tungsten-based high specific gravity alloy composite material and a preparation method thereof. The method is carried out according to the following steps:

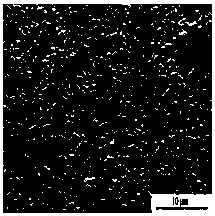

[0042]S01: Pre-mix the prepared tungsten-based high specific gravity alloy base powder and rare earth oxide powder evenly to obtain the mixed raw material, and then put the mixed raw material into a high-energy ball mill with a ball-to-material ratio of 5:1 for a ball mill. The ball milling time is 2h, the ball milling medium is anhydrous ethanol, the material of the ball milling tank is 304 stainless steel, and the rotation speed is 300r / min. Among them, the basic powder of tungsten-based high specific gravity alloy is micron-sized 93wt% tungsten powder, 4.9wt% nickel powder, 2.1wt% iron powder, and the composite rare earth oxide powder is submicron-sized Y 2 o 3 Powder and Dy 2 o 3 powder, and the addition of the rare earth oxide powder is 0.1wt% o...

Embodiment 2

[0048] The invention provides a composite rare earth oxide reinforced tungsten-based high specific gravity alloy composite material and a preparation method thereof. The method is carried out according to the following steps:

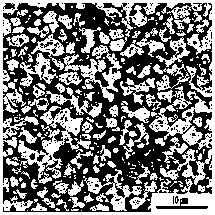

[0049] S01: Pre-mix the prepared tungsten-based high specific gravity alloy base powder and rare earth oxide powder evenly to obtain the mixed raw material, and then put the mixed raw material into a high-energy ball mill with a ball-to-material ratio of 5:1 for a ball mill. The ball milling time is 2h, the ball milling medium is anhydrous ethanol, the material of the ball milling tank is 304 stainless steel, and the rotation speed is 300r / min. Among them, the basic powder of tungsten-based high specific gravity alloy is micron-sized 93wt% tungsten powder, 4.9wt% nickel powder, 2.1wt% iron powder, and the rare earth oxide powder is submicron-sized Y 2 o 3 Powder and Dy 2 o 3 powder, and the addition of the rare earth oxide powder is 0.4wt% of the bas...

Embodiment 3

[0055] The invention provides a composite rare earth oxide reinforced tungsten-based high specific gravity alloy composite material and a preparation method thereof. The method is carried out according to the following steps:

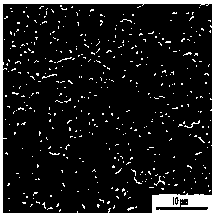

[0056] S01: Pre-mix the prepared tungsten-based high specific gravity alloy base powder and rare earth oxide powder evenly to obtain the mixed raw material, and then put the mixed raw material into a high-energy ball mill with a ball-to-material ratio of 5:1 for a ball mill. The ball milling time is 2h, the ball milling medium is anhydrous ethanol, the material of the ball milling tank is 304 stainless steel, and the rotation speed is 300r / min. Among them, the basic powder of tungsten-based high specific gravity alloy is micron-sized 93wt% tungsten powder, 4.9wt% nickel powder, 2.1wt% iron powder, and the rare earth oxide powder is submicron-sized Y 2 o 3 Powder and Dy 2 o 3 powder, and the addition of the rare earth oxide powder is 0.7wt% of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com