High-efficiency polymerization reactor

A polymerization reactor and reactor technology, applied in the field of high-efficiency polymerization reactors, can solve the problems of difficult processing of the shell of the polymerization kettle, difficult processing of tube bundles, low heat removal efficiency, etc. Small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

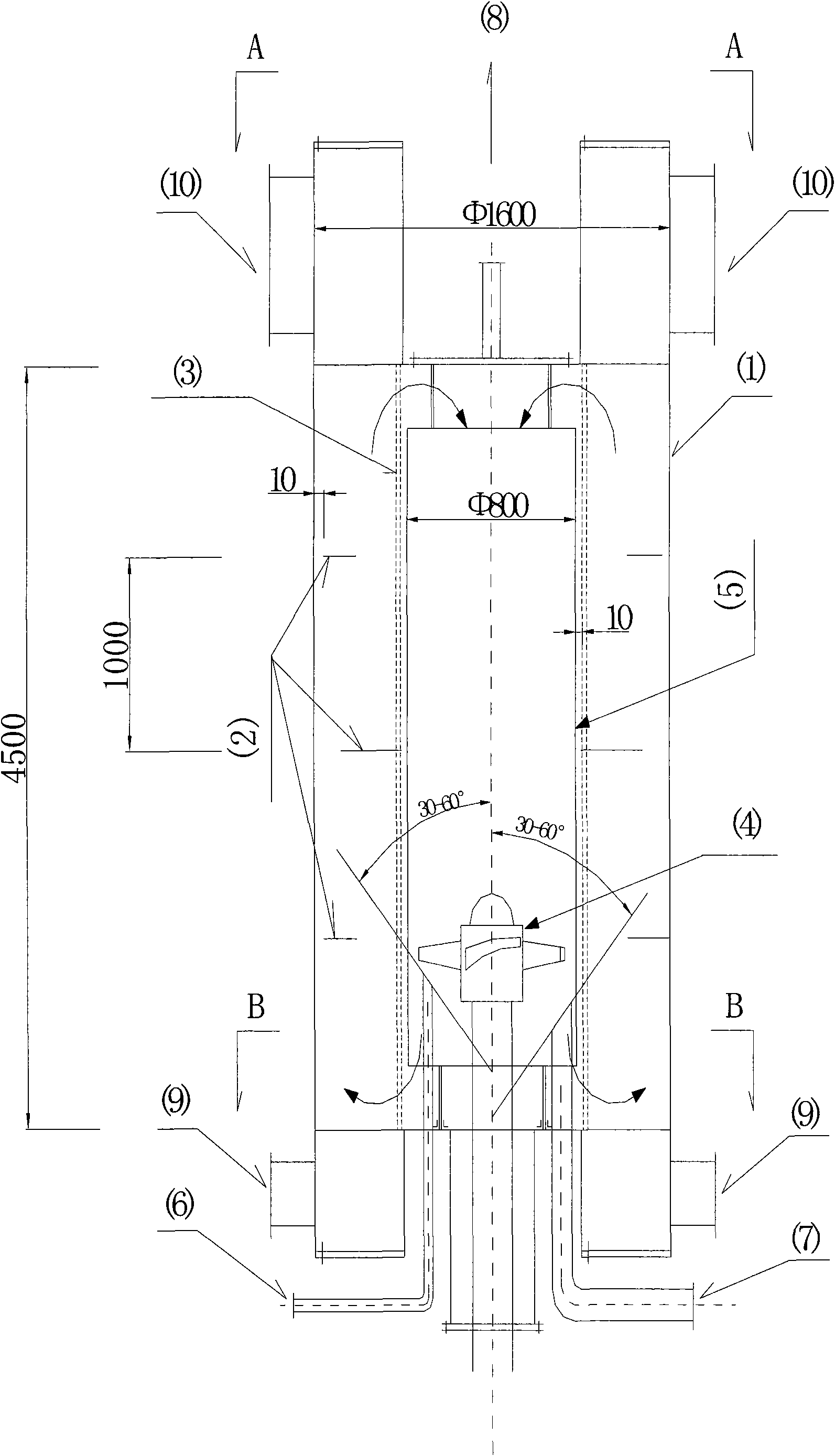

[0032] Such as figure 1 As shown,

[0033] The high-efficiency polymerization reactor of the present invention includes a reactor barrel [1], a heat exchange tube [3], an axial flow pump [4], a catalyst inlet [6], a raw material inlet [7], and a reaction product outlet [8], Cooling and heating agent inlet [9] and cooling and heating agent outlet [10], where:

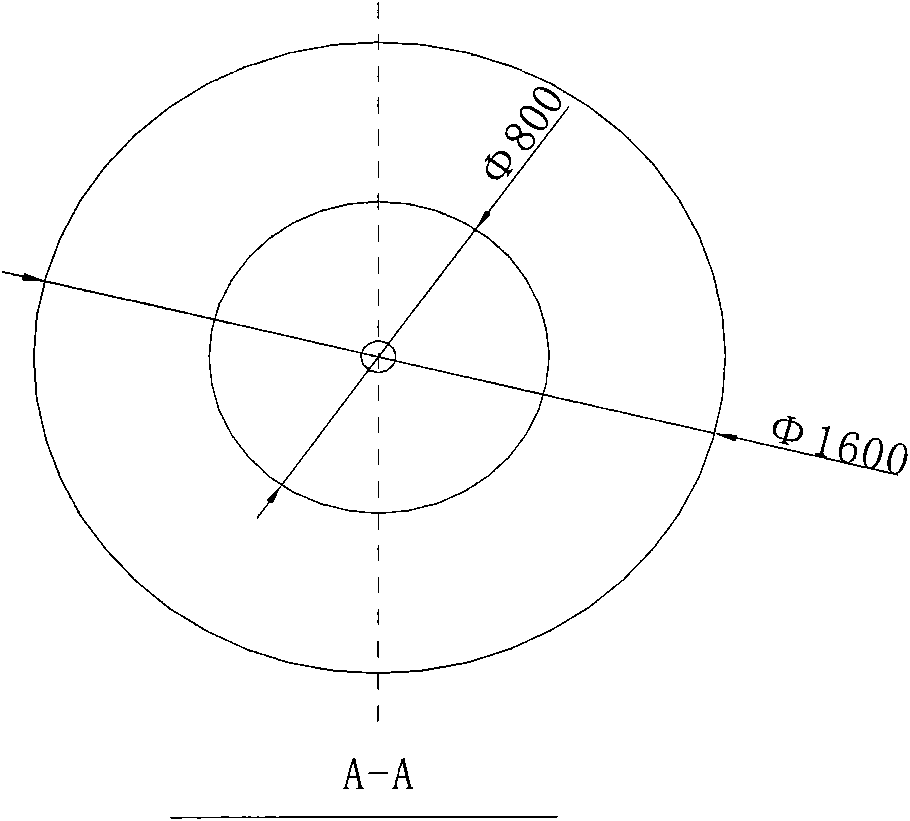

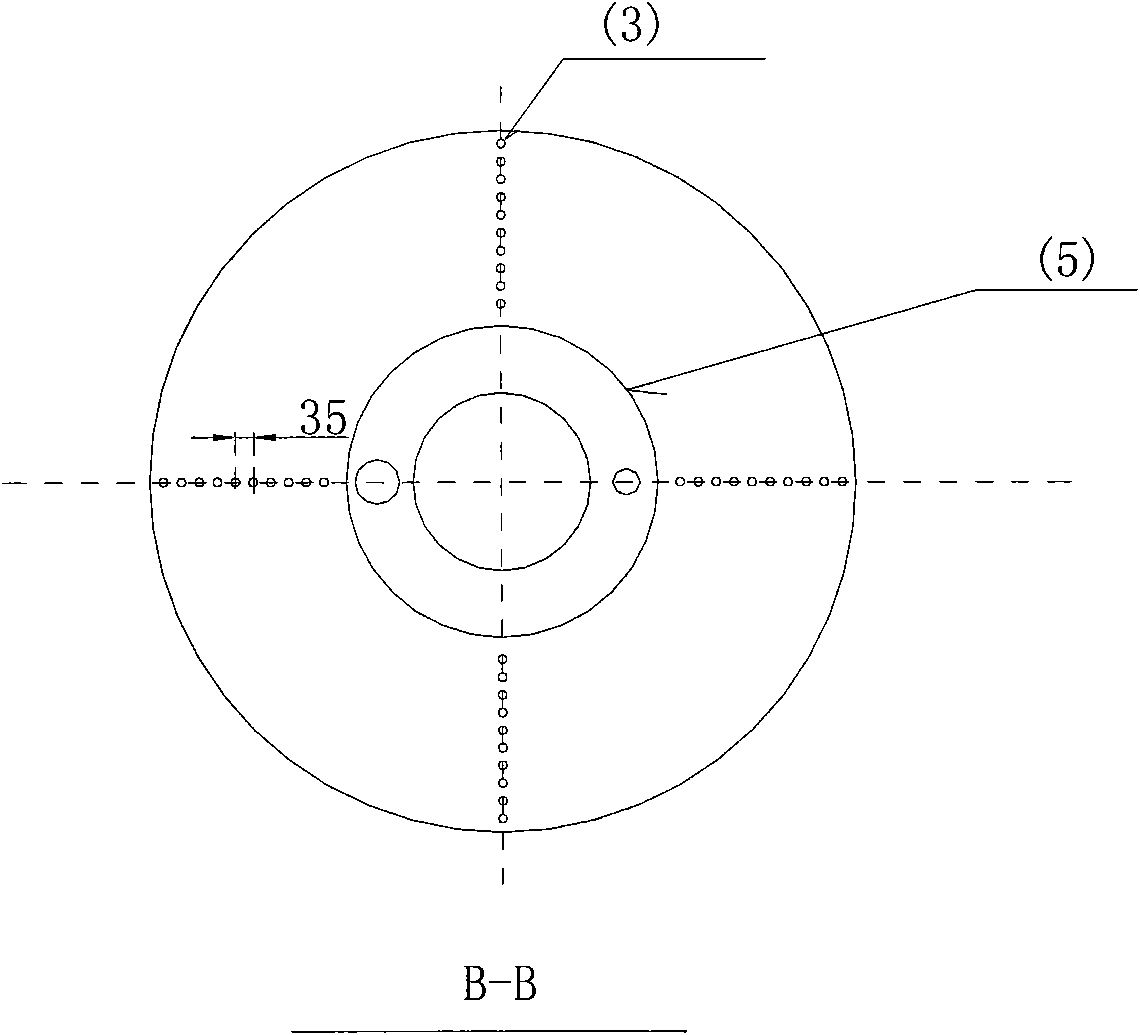

[0034] The axial flow pump [4] is arranged at the bottom of the high-efficiency polymerization reactor; a set of annular baffle plates [2] are arranged in the high-efficiency polymerization reactor; The heat exchange tube [3] and the flow guide tube [5] are arranged; the ratio of the diameter of the flow guide tube [5] to the diameter of the reactor cylinder body [1] is 0.5.

[0035] The upper and lower heads of the high-efficiency polymerization reactor are flat plates; the diameter of the reactor barrel [1] is 1600 mm, and the height is 4500 mm; the baffle plate [2] is arranged on the guide tube [5] Outside, the gap between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com