Power generation device by waste heat of gas water heater

A gas water heater and waste heat power generation technology, which is applied to air heaters, fluid heaters, generators/motors, etc., can solve the problems of unsatisfactory effect and small temperature difference, so as to achieve small occupied space, no maintenance required, The effect of reducing the volume of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but some embodiments are not limited thereto.

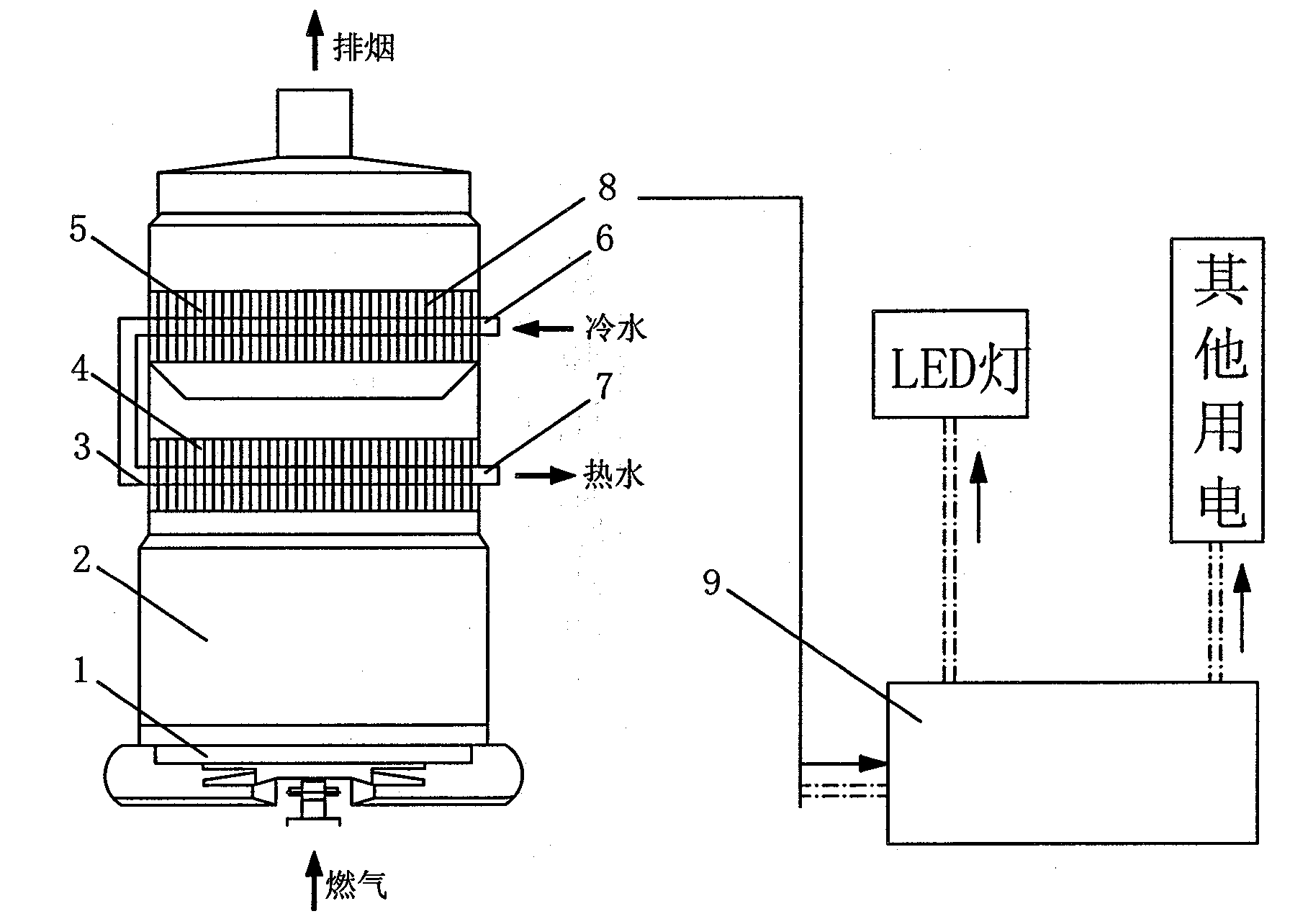

[0031] Such as figure 1 As shown, a gas water heater waste heat power generation device includes a condensing gas water heater and a thermoelectric power generation system; The heat exchanger 5, the third water inlet connecting pipe 6 and the third water outlet connecting pipe 7 are composed. The combustion chamber 2 is located under the heat exchanger 4 in the high temperature section, and the burner 1 is located under the combustion chamber 2; the heat exchanger 4 in the high temperature section is located under the heat exchanger 5 in the condensation section;

[0032] The waste heat thermoelectric power generation system mainly includes a thermochip power generation module 8 and a voltage boosting and stabilizing module 9 . Among them, the thermoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com