Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Improve infrared radiation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite graphene infrared radiation and heat conduction film and manufacturing method thereof

ActiveCN105514066AImprove infrared radiation performanceFast heat conductionSemiconductor/solid-state device detailsConjugated diene hydrocarbon coatingsOptoelectronicsHeat sink

The invention discloses a composite graphene infrared radiation and heat conduction film and a manufacturing method of the composite graphene infrared radiation and heat conduction film, and is characterized in that a substrate is provided with a composite graphene infrared radiation coating layer. According to the manufacturing method of the composite graphene infrared radiation and heat conduction film disclosed by the invention, a thin film manufactured by utilizing good infrared radiation capacity and good heat conduction capacity of a composite graphene infrared radiation material has the good heat conduction capacity in both directions which are parallel to and vertical to the substrate, so that heat can be rapidly transferred from a heating part to a heat sink device or an environment, the heat conduction efficiency is increased, local hot points in a device are removed, and temperature gradient in a heat conduction path is reduced; the composite graphene infrared radiation and heat conduction film disclosed by the invention has the advantages that the manufacturing is simple and convenient, and a powerful support is provided for high integration of electronic devices and rapid heat conduction of heating devices.

Owner:宿州晶禾科技有限公司

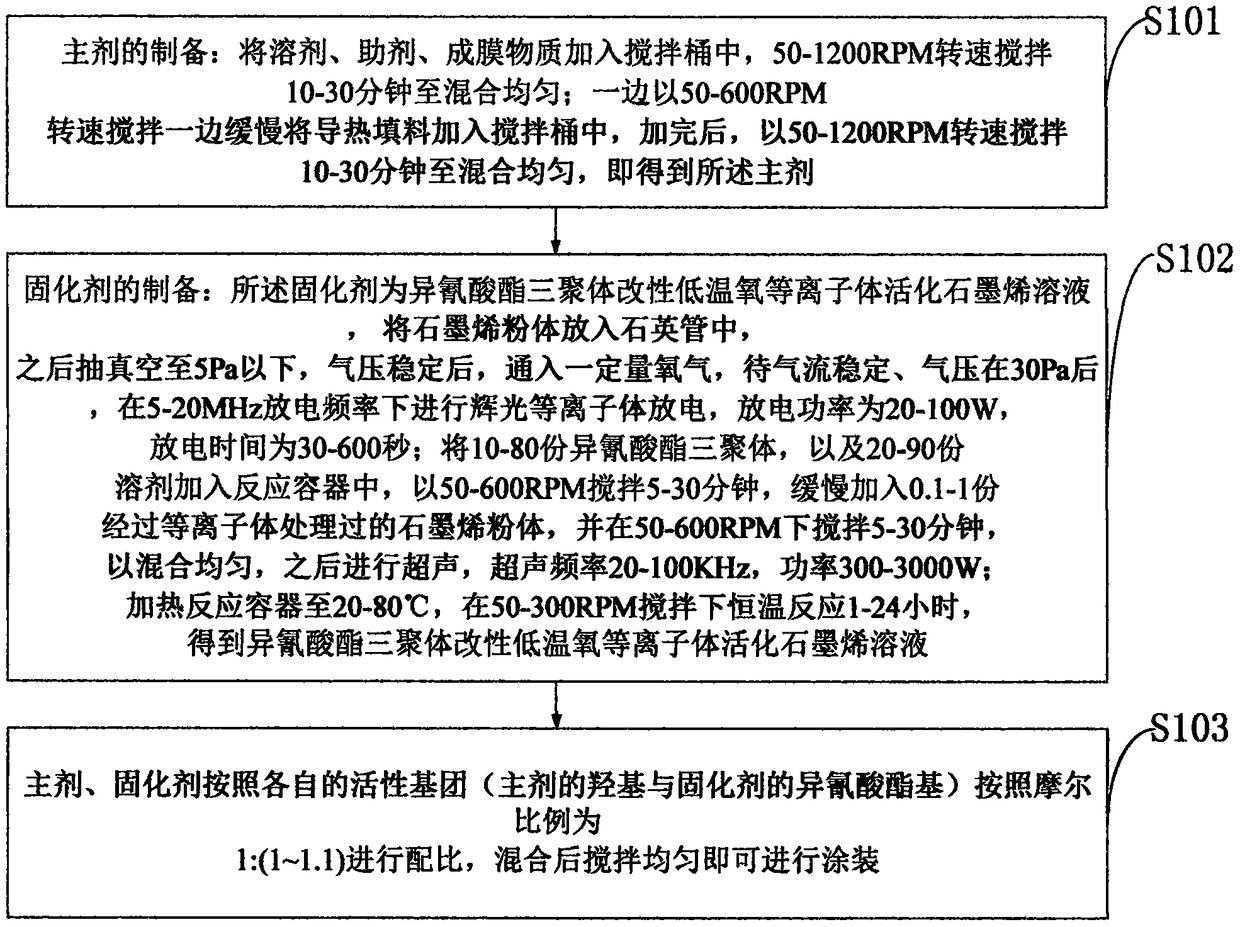

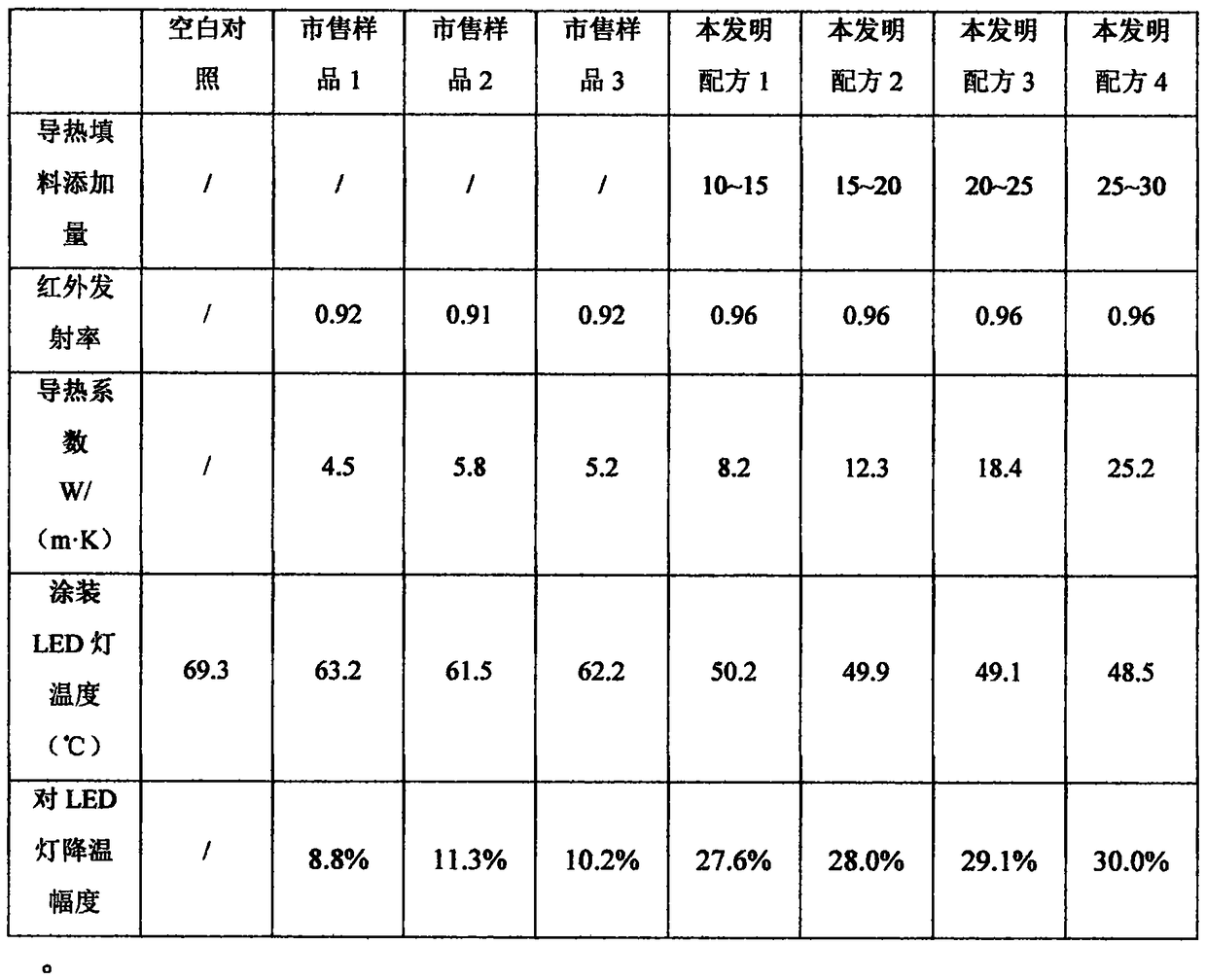

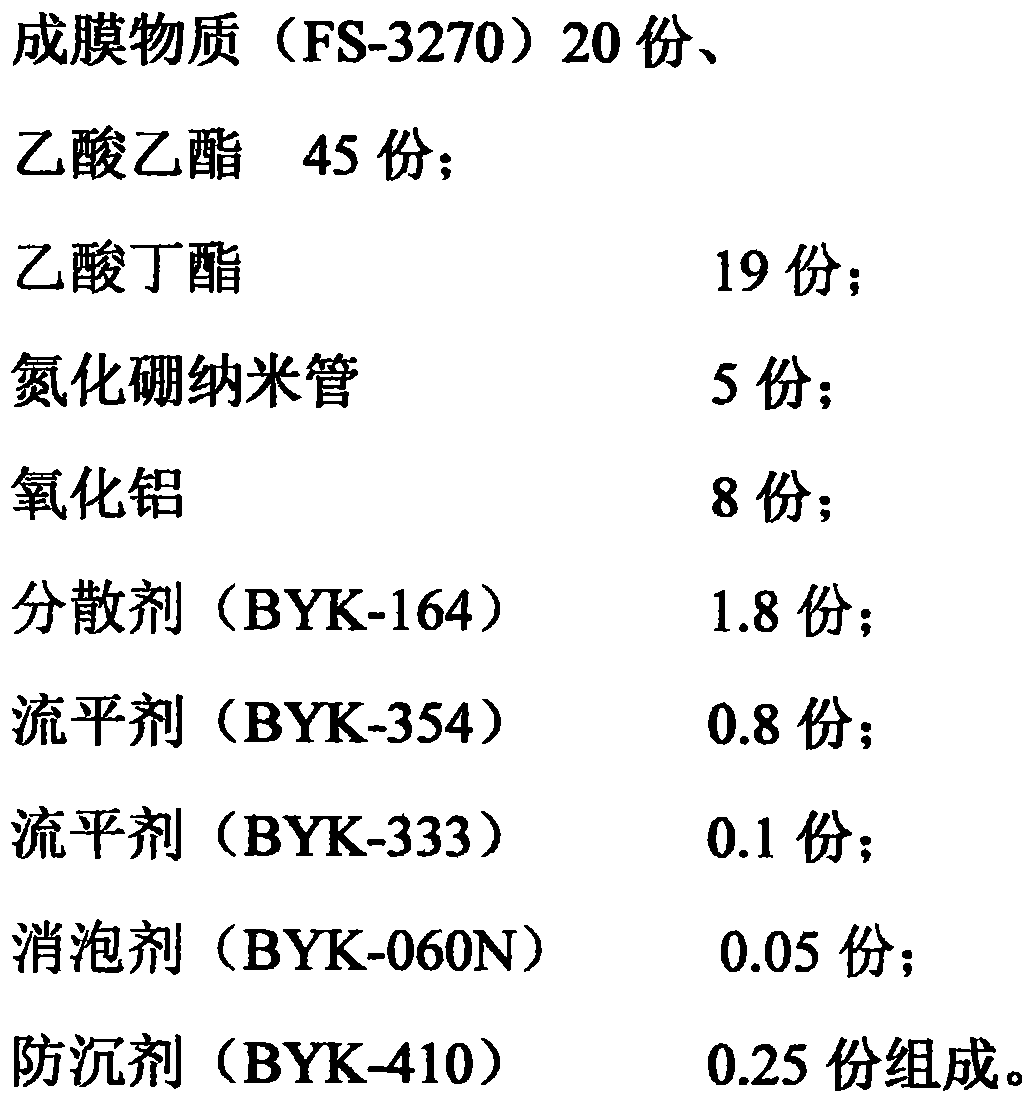

Isocyanate modified graphene containing heat-dissipating coating material and preparation method

ActiveCN109266187AEvenly dispersedCompact formAnti-corrosive paintsPolyurea/polyurethane coatingsCross-linkPolymer science

The invention belongs to the technical field of heat dissipating materials and discloses an isocyanate modified graphene containing heat-dissipating coating material and a preparation method. The heat-dissipating coating material is prepared from a main agent and a curing agent, wherein the mole ratio of hydroxyl radicals of the main agent to isocyanate radicals of the curing agent is 1: (1 to 1.1); the main agent is prepared from a film forming matter, a solvent, adjuvants and heat conducting fillers according to a mass ratio; the curing agent is an isocyanate trimer modified low-temperatureoxygen plasma activated graphene solution. The invention simultaneously discloses the preparation method. The heat-dissipating coating material disclosed by the invention has excellent heat-conductingproperty and high infrared radiance, and heat can be rapidly conducted to a whole coating and is dissipated in an infrared radiating manner; graphene is activated by plasma, the hydroxyl radicals areintroduced to the surface of the graphene under the condition of not carrying in a large number of defects, and can be subjected to a cross-linking reaction with isocyanate, and after isocyanate is grafted, the graphene still reserve original heat-conducting property.

Owner:四川恒力盛泰石墨烯科技有限公司

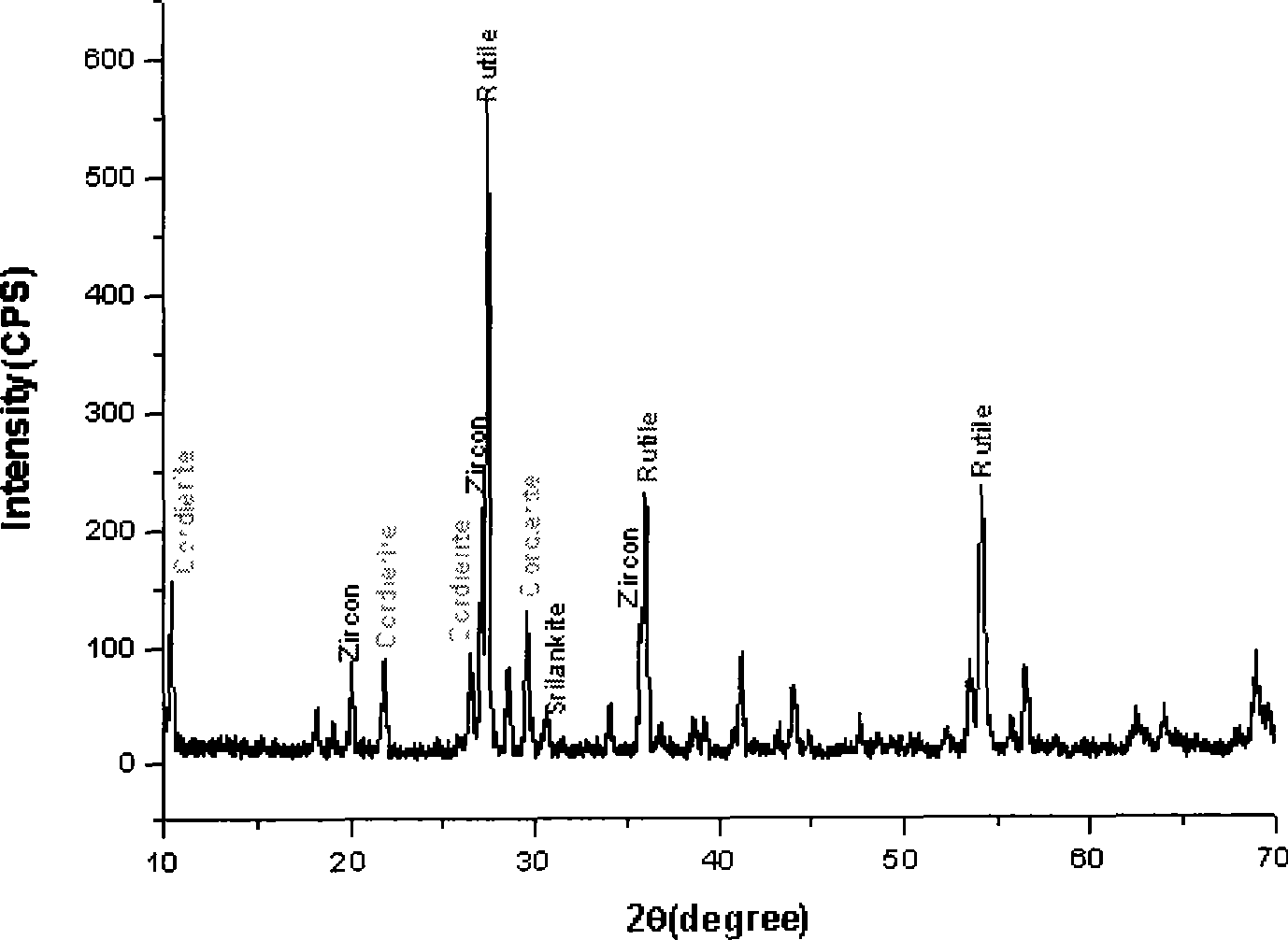

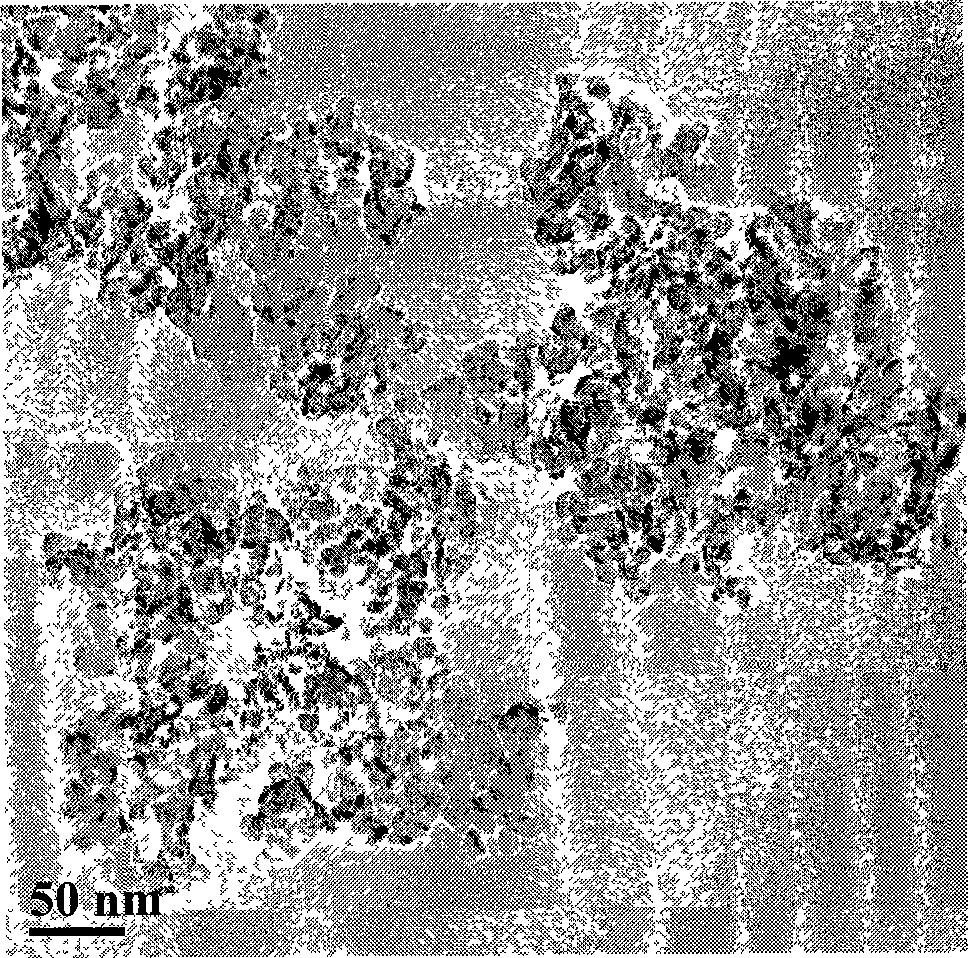

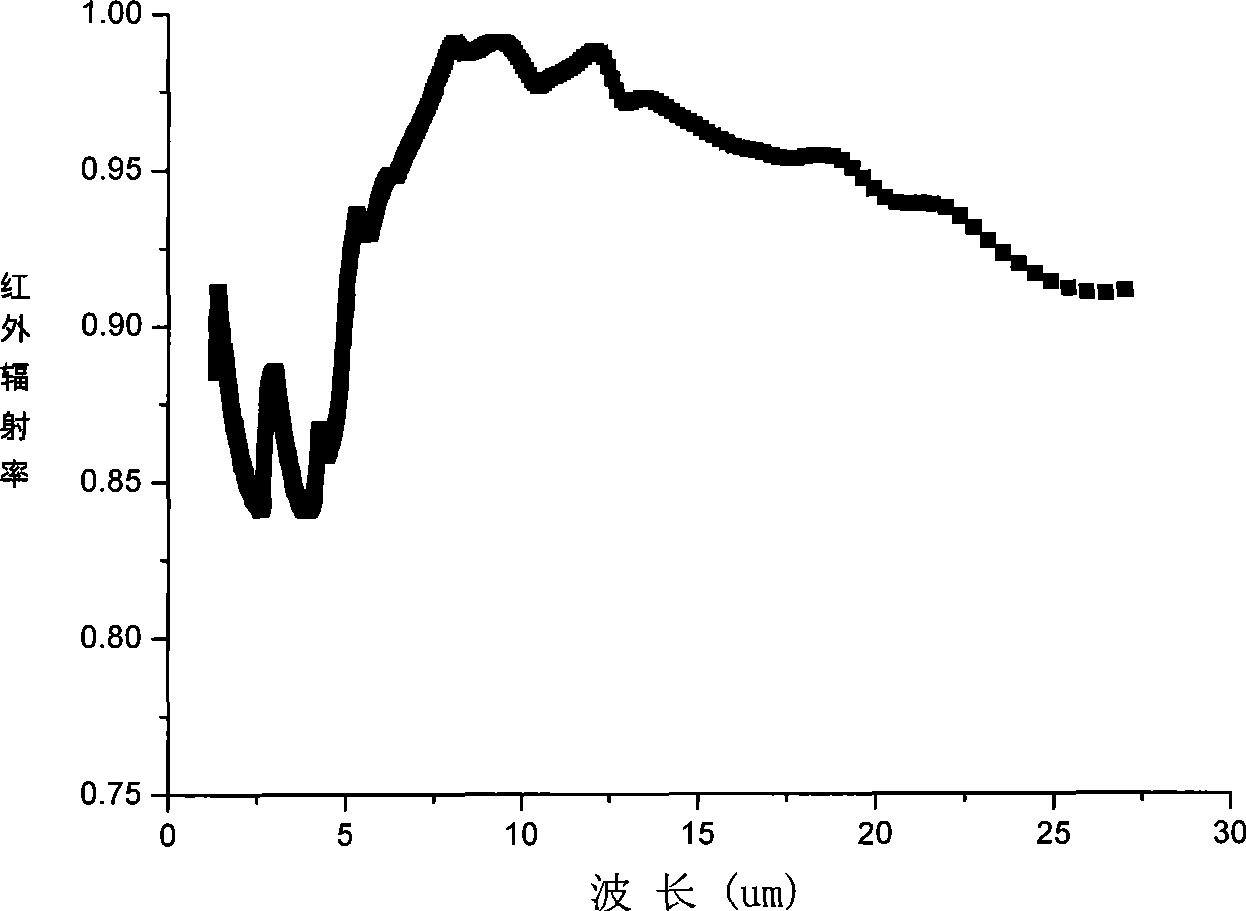

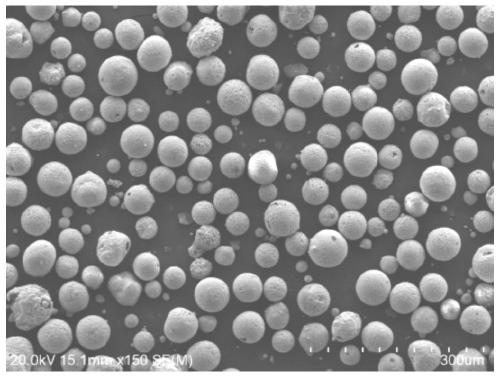

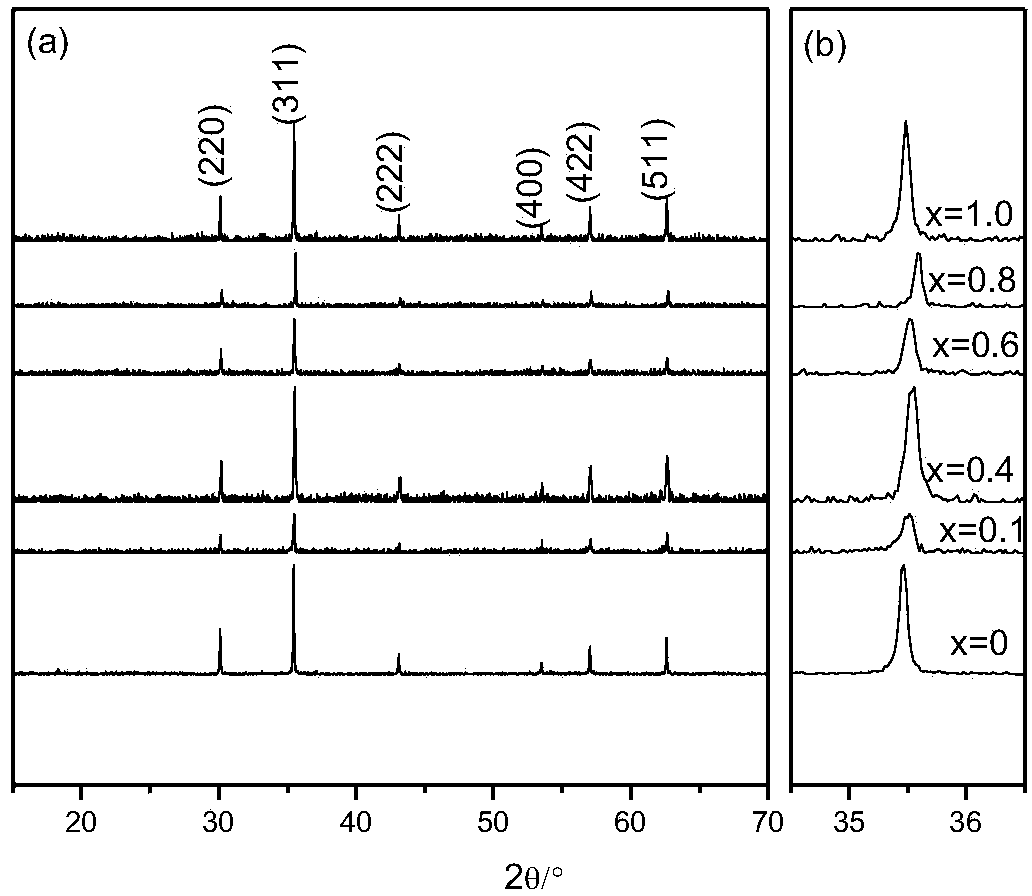

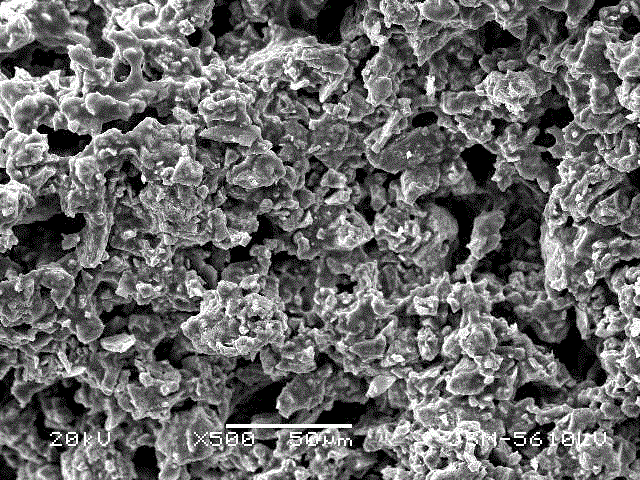

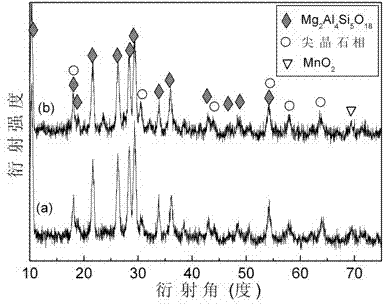

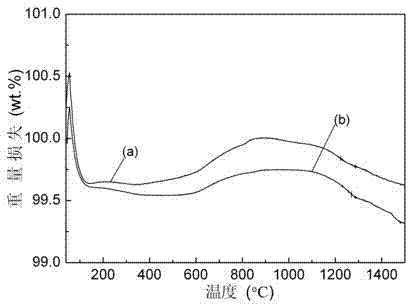

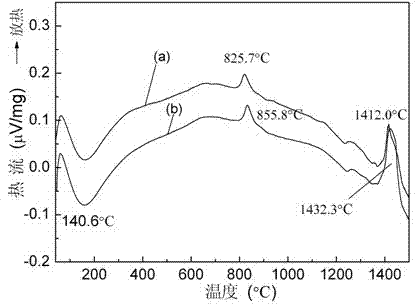

Far infrared radiation nano material and preparation thereof

InactiveCN101462869ALarge specific surface areaEnhanced anharmonic effectRare-earth elementPolyethylene glycol

The invention relates to a far-infrared radiation nano material and a preparation method thereof, and belongs to the technical field of far-infrared radiation materials. The components and the mol ratio of the nano material are as follows: (Mg1-xMx)O:Al2O3:SiO2:TiO2:ZrO2:Re2O3=1:1:(4-6):(4-5):(1-2):(0.01-0.03), wherein, M is one or two of Fe and Ni, x equals 0-0.3, and Re is one of the rare earth elements Y, La and Dy. In the method, metal alkoxide and metal inorganic salt are taken as raw materials, citric acid is taken as a complexing agent, ethylene glycol is taken as a polymerizing additive, and polyethylene glycol is taken as a dispersant, sol is formed by heating the materials in water bath, and the sol is washed with absolute ethyl alcohol and dried to obtain precursor powder. Far-infrared radiation powder with the particle diameter of 20-50nm can be obtained by calcining the precursor powder. The power obtained by the method has small and even particle diameter, and higher infrared radiation rate at normal temperature and a broader waveband scopes (2-25mum).

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

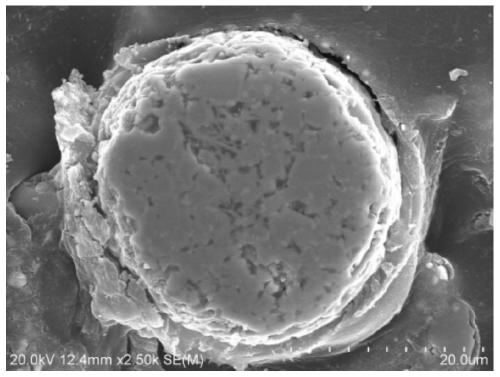

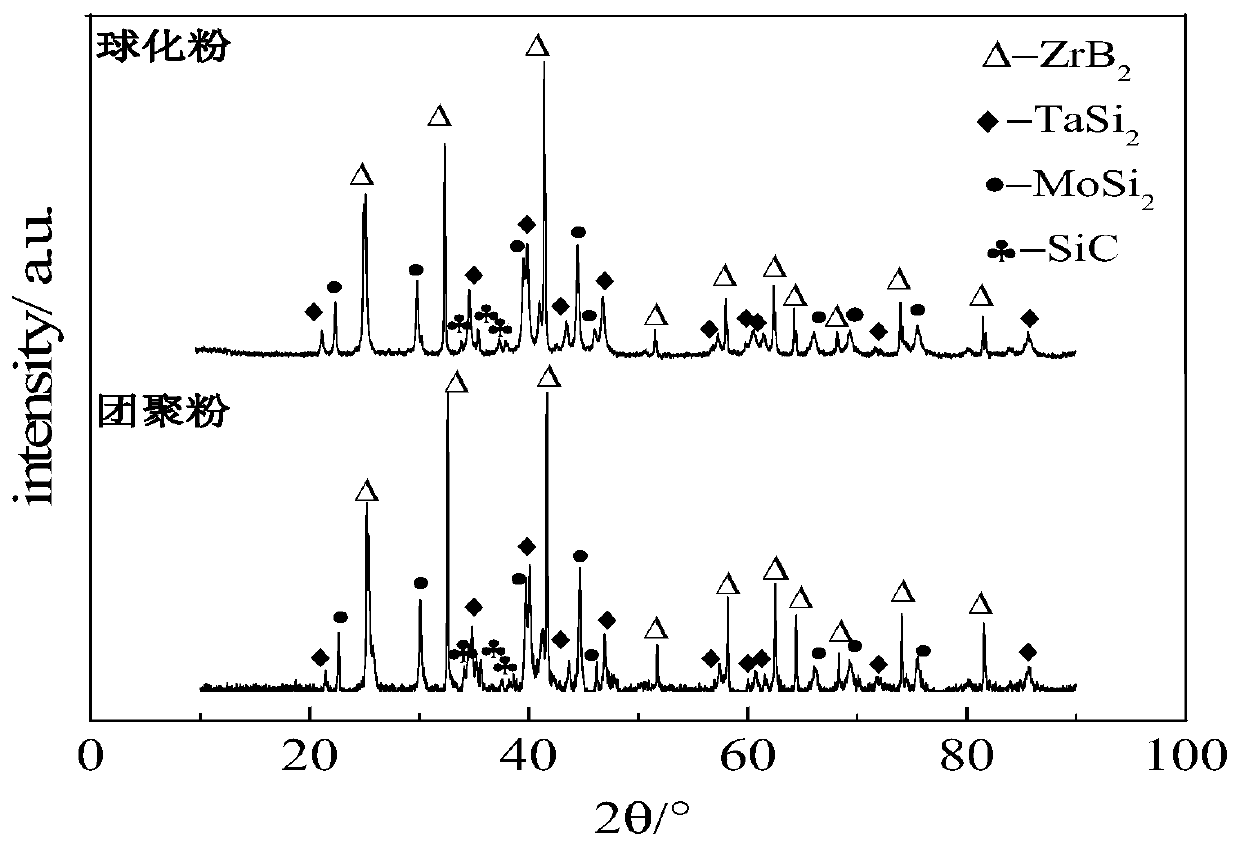

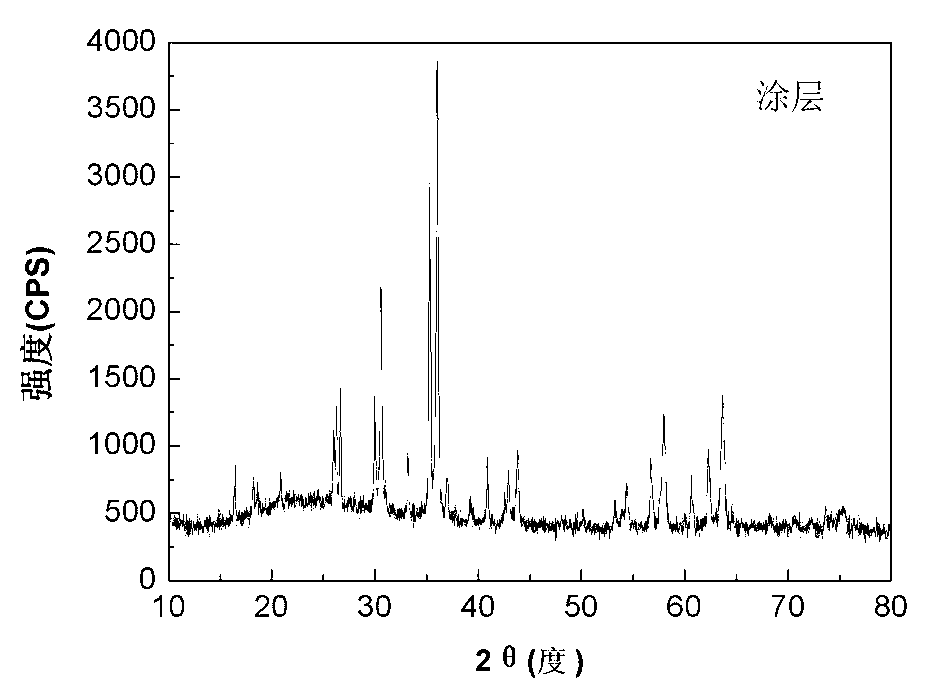

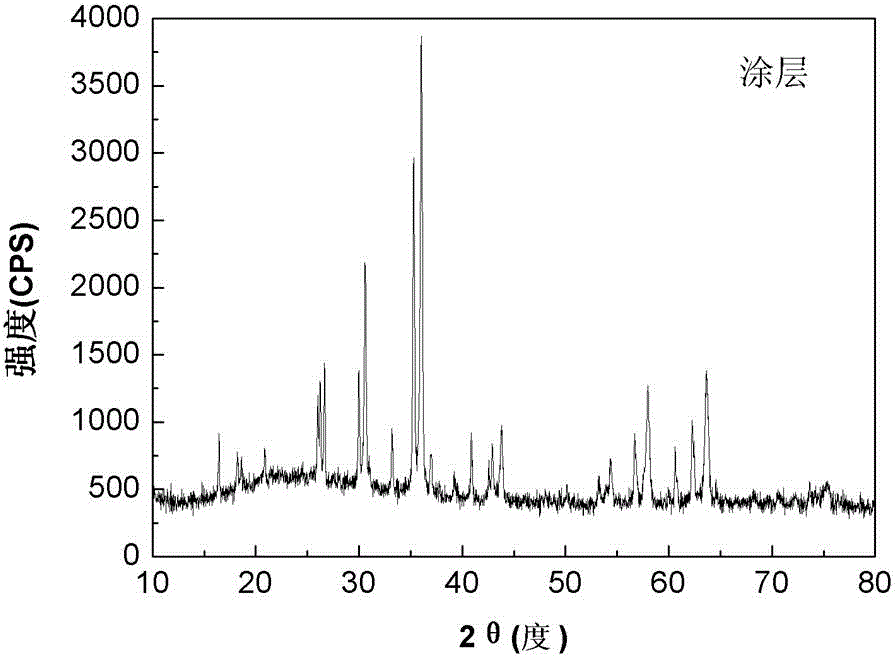

Preparation method of multi-component-doping modified zirconium diboride-silicon carbide coating

ActiveCN110396003AImprove densification performanceImprove high temperature resistanceZirconium hydrideInduction plasma technology

The invention relates to a preparation method of a multi-component-doping modified zirconium diboride-silicon carbide coating, and belongs to the technical field of composite powder and coating preparation. The method comprises the following steps: preparing ZrB2-SiC agglomerated powder doped with MoSi2 and TaSi2 through spray granulation and induction plasma spheroidization, and forming a coatingon a substrate by adopting an atmospheric plasma spraying process. By doping MoSi2 and TaSi2 at the same time, firstly, the two components serve as low-melting-point phases to fill pores and cracks in the powder, so that the compactness of the coating is improved; secondly, the two components serve as high-emissivity components to effectively radiate out heat in the coating, so that the high-temperature resistance of the coating is improved. The coating has good temperature resistance, infrared radiation performance, oxidation resistance, scouring resistance and thermal shock resistance. Thecoating can bear 300s oxyacetylene ablation examination at the surface temperature of 2000 DEG C and breaks through the technical bottleneck of 1800 DEG C.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

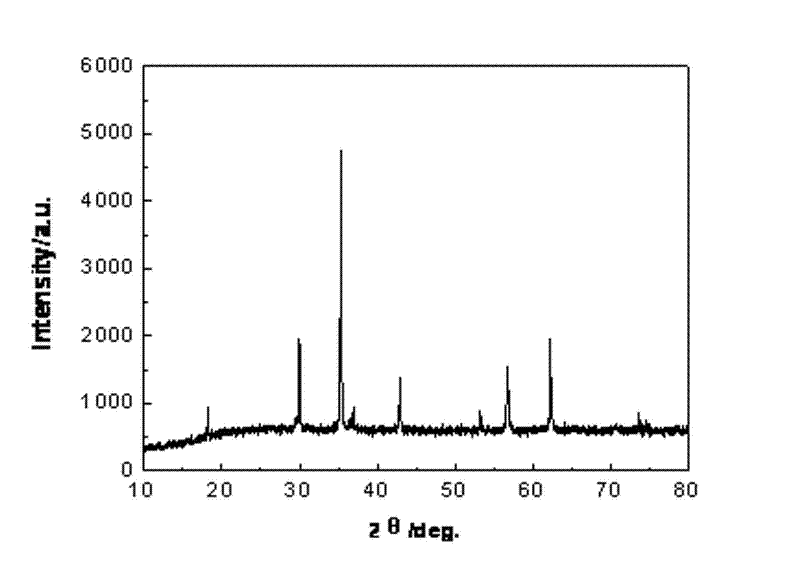

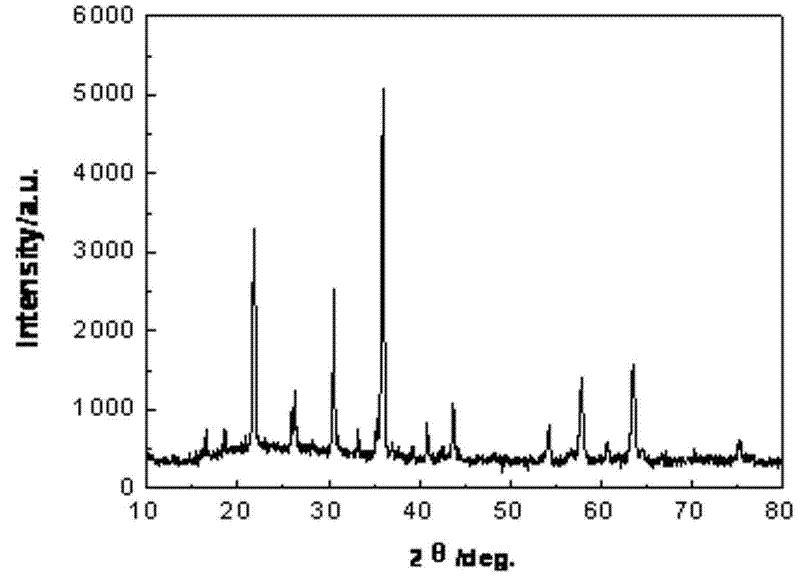

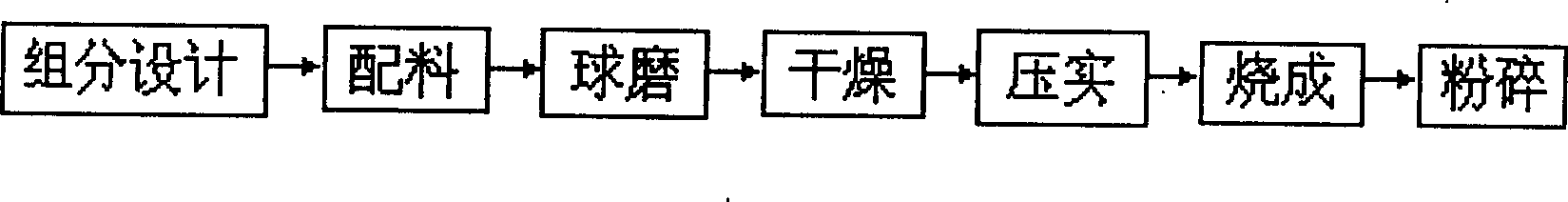

Multiphase composite system infrared radiation ceramic powder and preparation method thereof

InactiveCN102219496AImprove infrared radiation performanceSmall coefficient of thermal expansionSpinelMaterials science

The invention discloses multiphase composite system infrared radiation ceramic powder applicable to products, such as infrared radiation energy-saving coating, an infrared radiation heater and the like, of a high-temperature industrial kiln (boiler). The multiphase composite system infrared radiation ceramic powder is prepared from the following raw materials in percentage by mass: 20 to 80 percent of spinel type solid melt ceramic powder, 6 to 60 percent of Al2O3, 5 to 56 percent of SiO2, 0 to 10 percent of MgO, 0 to 3 percent of BaO, 0 to 3 percent of CaO and 0 to 6 percent of TiO2, whereinthe spinel type solid melt ceramic powder is prepared from the following raw materials in percentage by mass: 0 to 60 percent of Fe2O3, 0 to 60 percent of MnO2, 0 to 12 percent of CuO, 0 to 10 percent of Co2O3, 0 to 6 percent of Mo2O3, 0 to 6 percent of NiO, 0 to 5 percent of V2O5 and 0 to 5 percent of WO3. The invention also discloses a preparation method of the multiphase composite system infrared radiation ceramic powder. All the raw materials are the common raw materials with wide sources; a spinel-silicate multiphase composite system has a stable structure, excellent infrared radiation property, can adjust the structure and the property of the materials easily by controlling the components, and has a wide application prospect.

Owner:KING STRONG MATERIAL ENG LTD +1

Ceramic powder with infrared radiation and bacteria inhibiting function and its preparing method

The present invention relates to one kind of solid solution cordierite series ceramic powder with infrared radiation and bacteriostasis functions and its preparation process. The ceramic powder has the main components of Al2O3, SiO2, MgO and ZnO, which are prepared into white solid solution cordierite series ceramic powder through ceramic making process. The ceramic powder has normal whole waveband radiance of 0.87-0.90, 8-25 micron waveband radiance of 0.90-0.94, 8-14 micron waveband radiance of 0.88-0.94 and 14-25 micron waveband radiance of 0.91-0.94. The bacteriostasis function test shows that the ceramic powder has obvious inhibiting effect on urea sarcin and Staphylococcus aureus, with bacteriostasis rate reaching 84.1-100 %. The present invention has simple process, low cost and wide application range.

Owner:WUHAN UNIV OF TECH

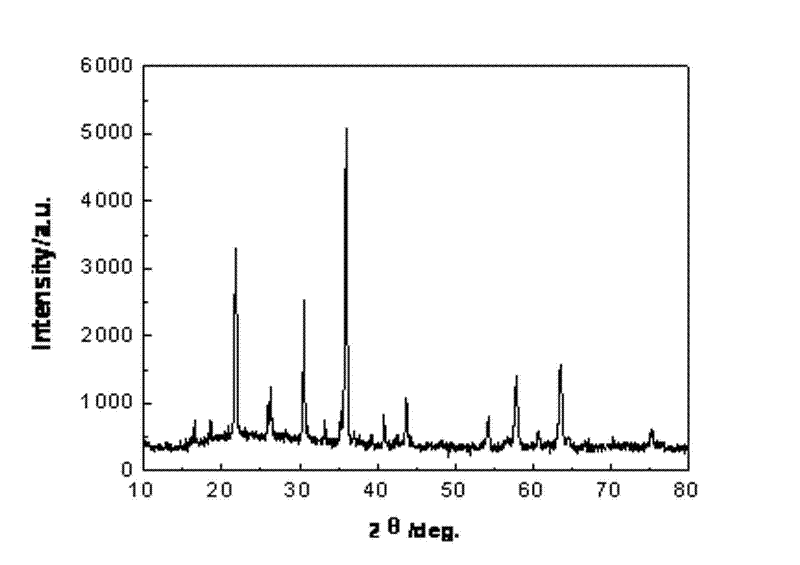

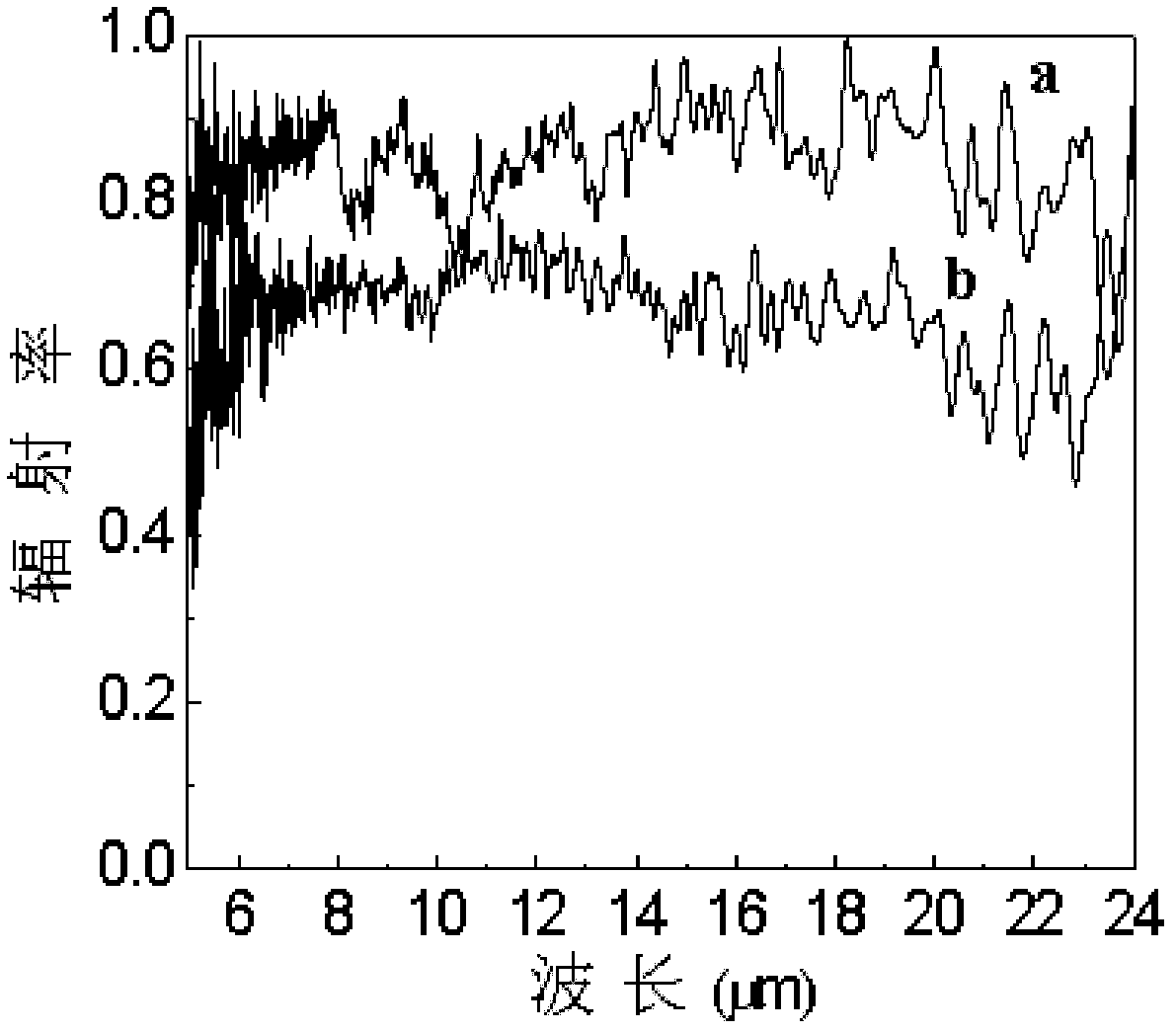

Powder material with high infrared radiance in broadband and preparation method of power material

InactiveCN102633494AImprove infrared radiation performanceLarge lattice distortionAir atmosphereBrick

The invention discloses a powder material with high infrared radiance in a broadband and the preparation method of the powder material. The powder material is of a cordierite material doped with Ba<2+> or / and Fe<3+>. The preparation method of the powder material comprises the steps of: firstly dissolving pioneer raw materials and doped raw materials which form the cordierite into an alcohol-water mixture solvent, stirring, drying, and then prefiring at the temperature of 600-1,000 DEG C under air atmosphere; and forging at the temperature of 1,150-1,350 DEG C; and finally cooling to room temperature along with a furnace. The powder material disclosed by the invention has radiance higher than 0.8 in the infrared waveband of 5-24mu m when being heated to 100 DEG C, especially, the most of infrared radiance is higher than 0.9 in the waveband of 14-20mu m and obviously higher than that of cordierite matrix, thus meeting application requirements in the fields of infrared interior wall insulating coating, infrared ceramic glazed bricks, industrial furance insulating coating and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ceramic powder with infrared radiation and bacteria inhibiting function and its preparing method

Owner:WUHAN UNIV OF TECH

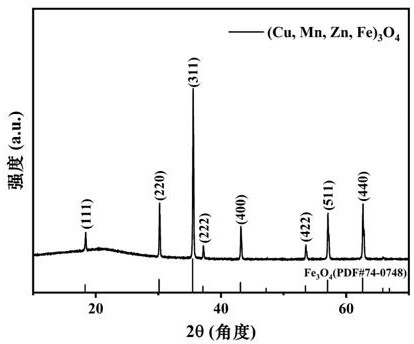

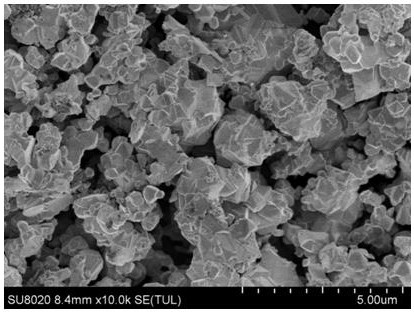

Preparation method of high-entropy oxide with good infrared radiation performance

The invention discloses a preparation method of a high-entropy oxide with good infrared radiation performance, wherein the preparation method comprises the steps: by taking any four of CuO, MnO2, Fe2O3, Cr2O3, Co3O4, TiO2, ZnO and MgO powder as raw materials, carrying out ball-milling mixing, drying and grinding, then carrying out high-temperature calcination in an air atmosphere, and cooling and grinding a product to obtain the high-entropy oxide with a spinel structure. The high-entropy oxide is prepared by combining a mechanical wet grinding method and a solid-phase synthesis method, metal elements can be guaranteed to be sufficiently and uniformly mixed, the method has the advantages of simple preparation technology, high repeatability, high production efficiency, suitability for industrial production and the like, and the prepared high-entropy oxide is single in phase, high in purity, small in particle size, uniform in element distribution, has high infrared emissivity and good thermal stability, and is used as an infrared radiation material in the field of infrared radiation heating and heat dissipation materials.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

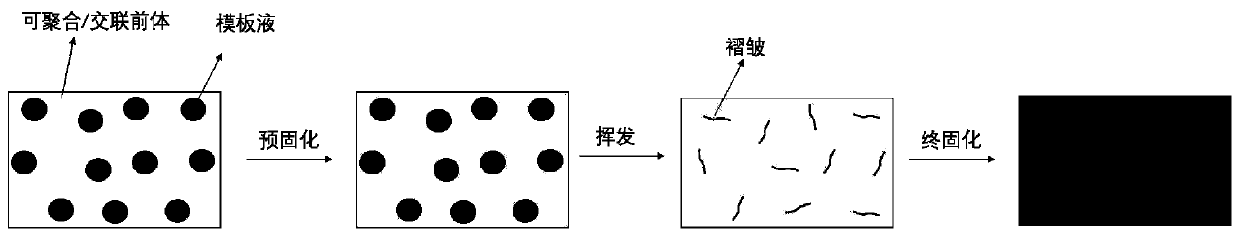

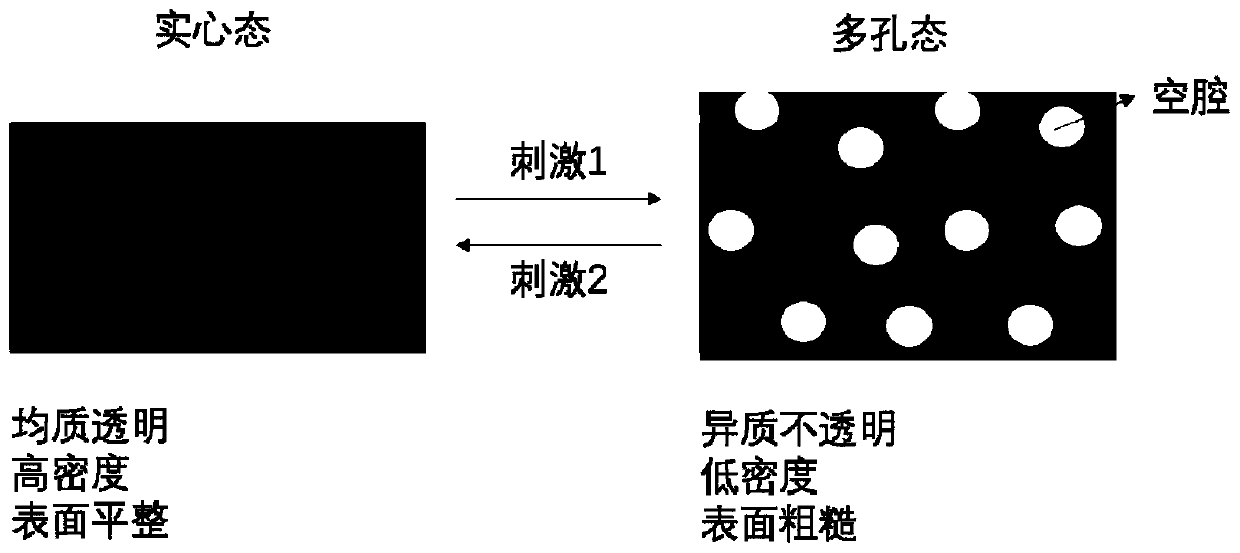

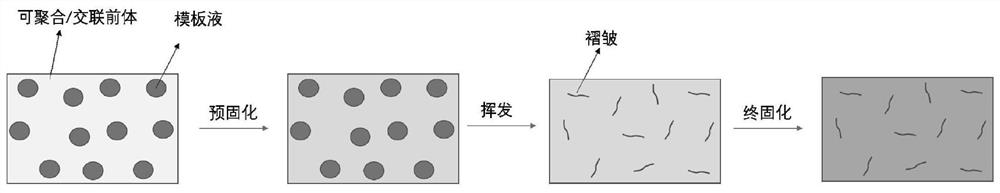

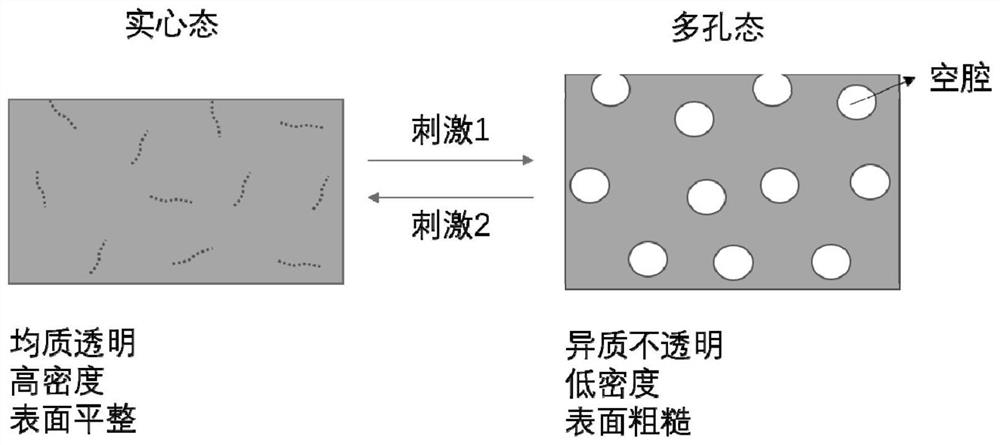

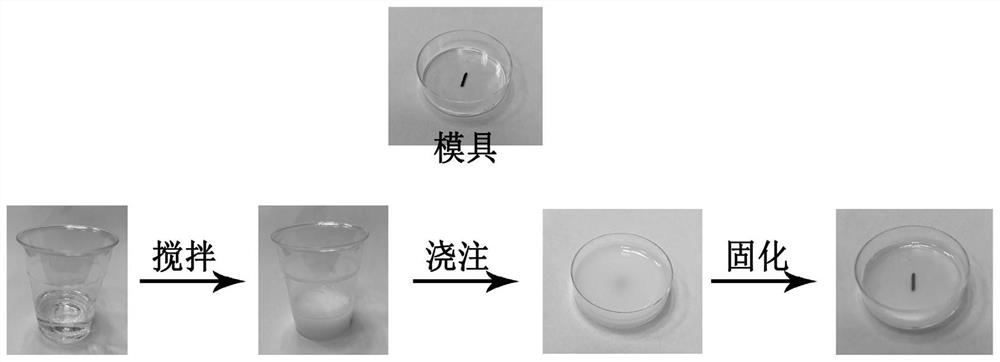

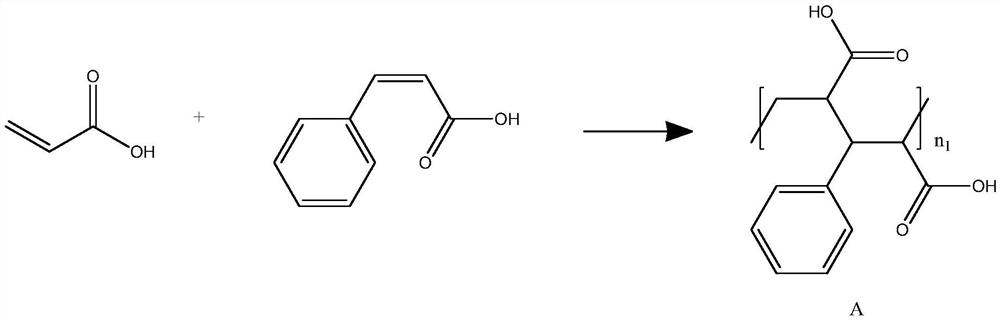

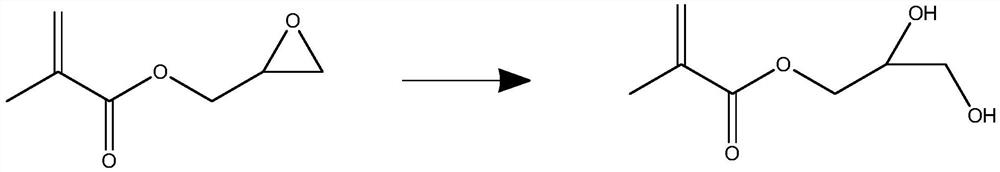

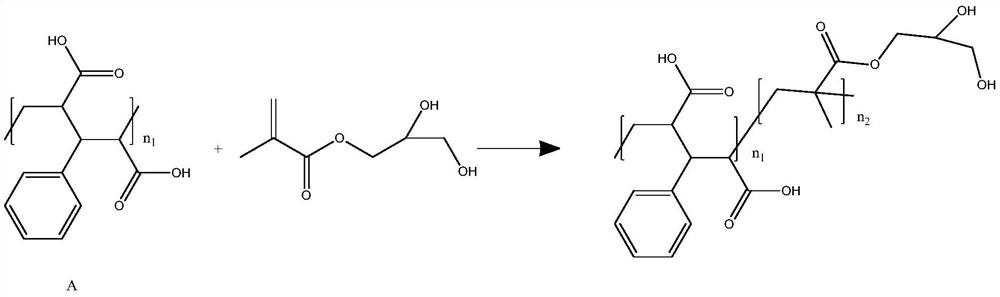

Reversible dynamic macroporous elastomer polymer material and preparation method and applications thereof

ActiveCN110922629AAdjustable pore structureImprove reflective effectEnvironmentally friendlyPolymer chemistry

The invention discloses a reversible dynamic macroporous elastomer polymer material and a preparation method and applications thereof. A polymerizable precursor (or a crosslinkable polymer precursor)and a template liquid that is insoluble in the precursor are mixed and evenly stirred, and the prepared emulsion is cured to obtain the reversible dynamic macroporous elastomer polymer material. The synthesis technology is simple, green, and environmentally friendly, is easy to perform and popularize, and has a high yield and a low preparation cost. The reversible dynamic macroporous elastomer polymer material has an adjustable reversible multilayer porous structure, has a good convertible sunlight reflection performance, an infrared irradiation performance, a strong liquid storage performance, and adjustable surface roughness, belongs to macroporous polymer materials, and has a wide application prospect in fields such as radiation refrigeration, solar heating, intelligent interface, and the like.

Owner:CHENGDU YUPING TECH CO LTD

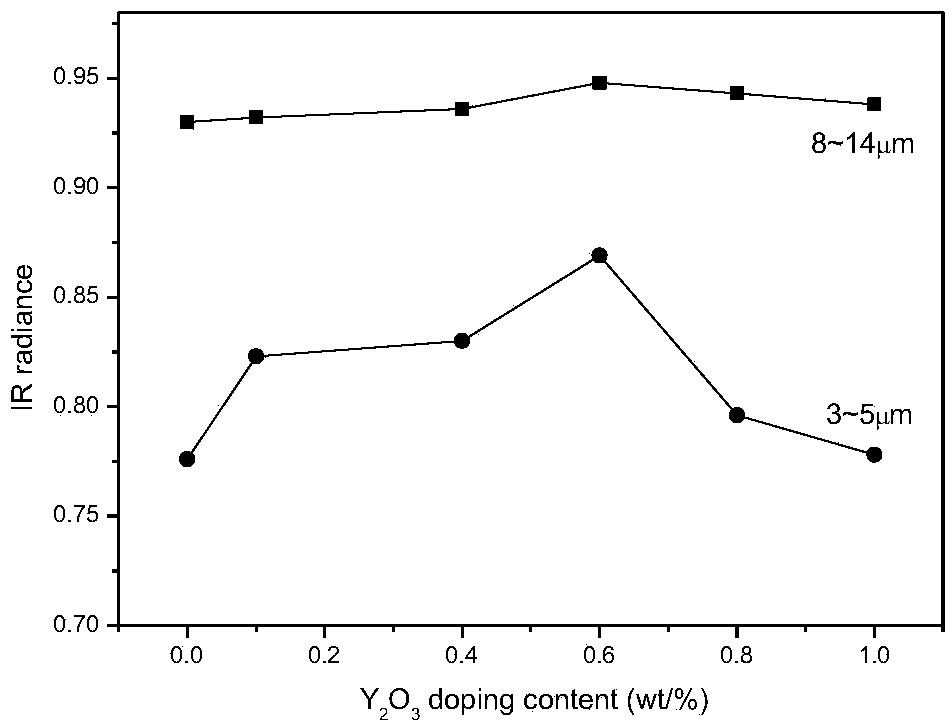

Energy-saving inner surface high-temperature radiation coating of high-temperature furnace

The invention discloses an energy-saving inner surface high-temperature radiation coating of a high-temperature furnace. The coating comprises infrared radiation powder, a bonding agent, a suspending agent and a deflocculation agent, and is characterized in that the infrared radiation powder comprises the following components in percentage by mass: 55%-70% of Cr2O3, 10%-22% of NiO, 0%-4% of TiO2, 0%-3% of SiO2, 0%-3% of Y2O3, 0%-6% of ZrO2, 1%-3% of Fe2O3 and 2%-5% of Nb2O3; the coating is 0.2-3 mm in thickness. The agglomerated infrared radiation powder is prepared by a paste spray-drying and milling process, and then the energy-saving inner surface high-temperature radiation coating of the high-temperature furnace is prepared by a plasma spraying process. The prepared coating is stable in performance, overcomes the shortcoming of instable performance of a conventional brushing coating at high temperature, and is good in infrared radiation performance at full waveband, high in strength of bonding with a metal base body on the surface of the high-temperature furnace and unlikely to cause cracks and drop in the using process.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

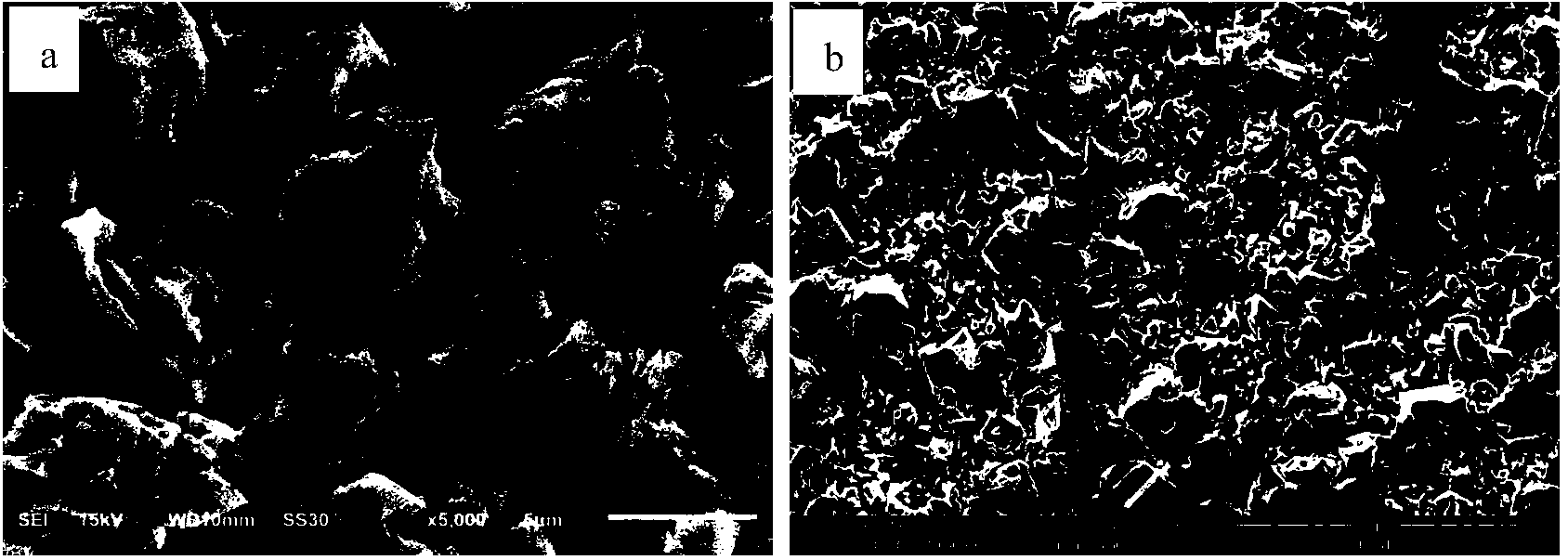

Spinel ceramic material with infrared radiation function and preparation method of spinel ceramic material

The invention provides a spinel ceramic material with an infrared radiation function and a preparation method of the spinel ceramic material. The material comprises the following raw materials in percentage by mass: 62%-83% of Fe2O3, 5%-22% of a transition metal oxide A, 12%-33% of MgO, and 0%-10% of a rare-earth oxide B, wherein the transition metal oxide A is one or a mixture of more of Ni2O3, Co2O3 and MnO2; and the rare-earth oxide B is one or a mixture of Gd2O3, La2O3, Sm2O3, Y2O3, Pr6O11 and Dy2O3. The preparation method comprises the following steps: putting the Fe2O3, the transition metal oxide A, the MgO and the rare-earth oxide B into a ball milling jar, adding deionized water and carrying out ball-milling treatment; drying and pre-sintering; and then carrying out ball-milling treatment, secondary drying and ball milling, sieving, tabletting and calcining. The infrared radiation ceramic prepared by the method is stable in structure, and compared with other infrared radiation materials, the infrared radiation property at a waveband of 3-5 microns is excellent.

Owner:NANJING UNIV OF SCI & TECH

Infrared radiation coating capable of forming coating with low conductivity factor

InactiveCN102702808AImprove bindingLow thermal conductivityAlkali metal silicate coatingsPhysical chemistryRefractory

The invention discloses infrared radiation coating capable of forming coating with low heat conductivity factors. The infrared radiation coating is prepared by the following raw materials by weight percentage: 30-50% of spinel-silicate multiphase composite system infrared radiation powder materials, 3-15% of pore-creating agents, 0-20% of hexa-potassium titanate, 25-50% of sodium silicate, 5-15% of water, 1-10% of inorganic combination auxiliary, 0-2% of anti-settling agents, 0-3% of dispersing agents, 0-1% of defoaming agents and 0-1% of flatting agents. After the coating is dried and cured, the coatings of porous structures are formed in the using process, have excellent infrared radiation performance and low conductivity factors, can be firmly combined with a fireproof material base body, do not crack when used for a long time under the high temperature of 500-1300 DEG C, do not fall off, and are corrosion resisting and excellent in thermal shock resistance.

Owner:WUHAN UNIV OF TECH

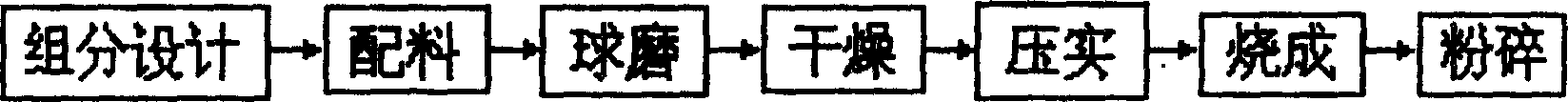

Preparation method of cordierite infrared radiation multiphase ceramic

InactiveCN109095911AImprove infrared radiation performanceQuality improvementThermal expansionCordierite

The invention relates to a preparation method of cordierite infrared radiation multiphase ceramic. The preparation method comprises the following steps: (1) weighing 35% of Fe2O3, 45% of MnO2, 10% ofCo2O3 and 10% of CuO in percentage by weight and preparing ferrite through a gel method; (2) weighing 10% of ferrite, 87% of cordierite and 3% of calcined kaolin calculated in percentage by weight, grinding and uniformly mixing the raw materials with an agate mortar to obtain powder for later use; (3) adding a binder solution which accounts for 3% of the total weight of the powder to granulate andaging for 24 to 36 hours, (4) pressing the powder into a shape and drying to obtain a ceramic blank; (5) firing the ceramic blank to obtain the cordierite infrared radiation multiphase ceramic. The preparation method of the cordierite infrared radiation multiphase ceramic disclosed by the invention adopts ferrite composite cordierite with high radiation performances and the calcined kaolin, so that the prepared infrared radiation ceramic is lower in thermal expansion coefficient, good in thermal shock resistance and higher in infrared radiation properties.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

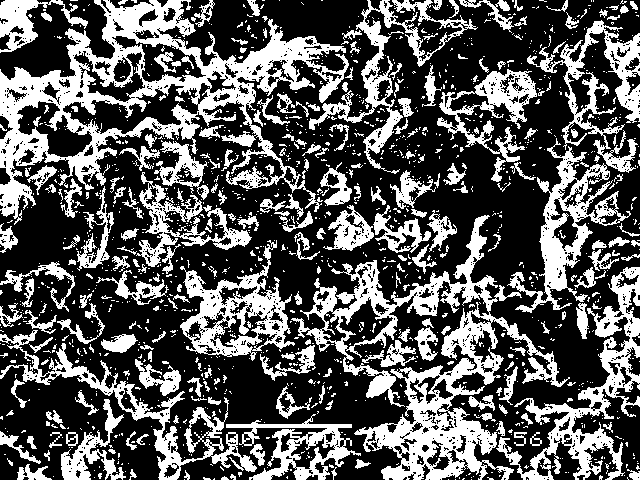

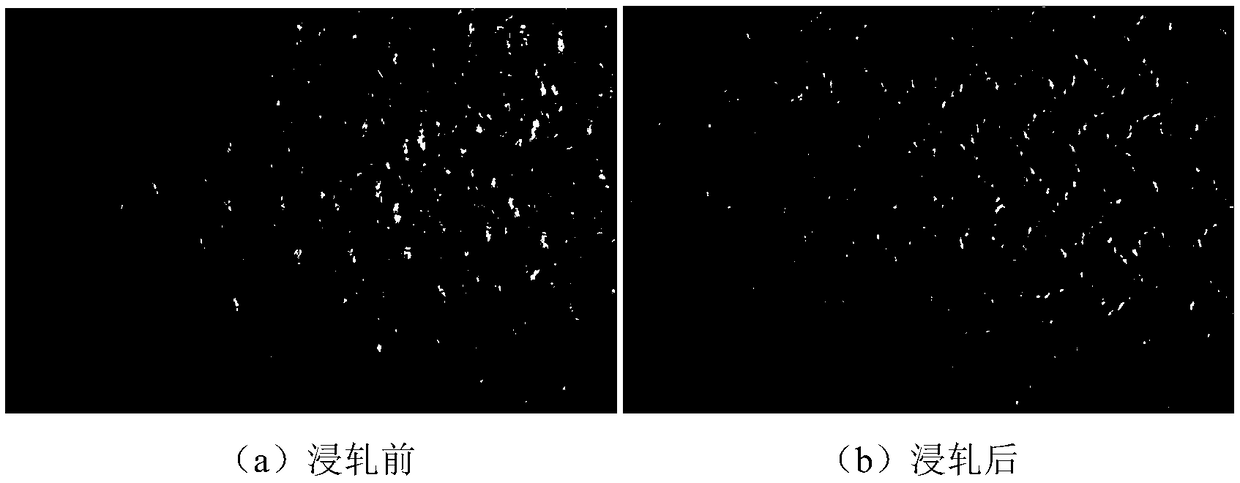

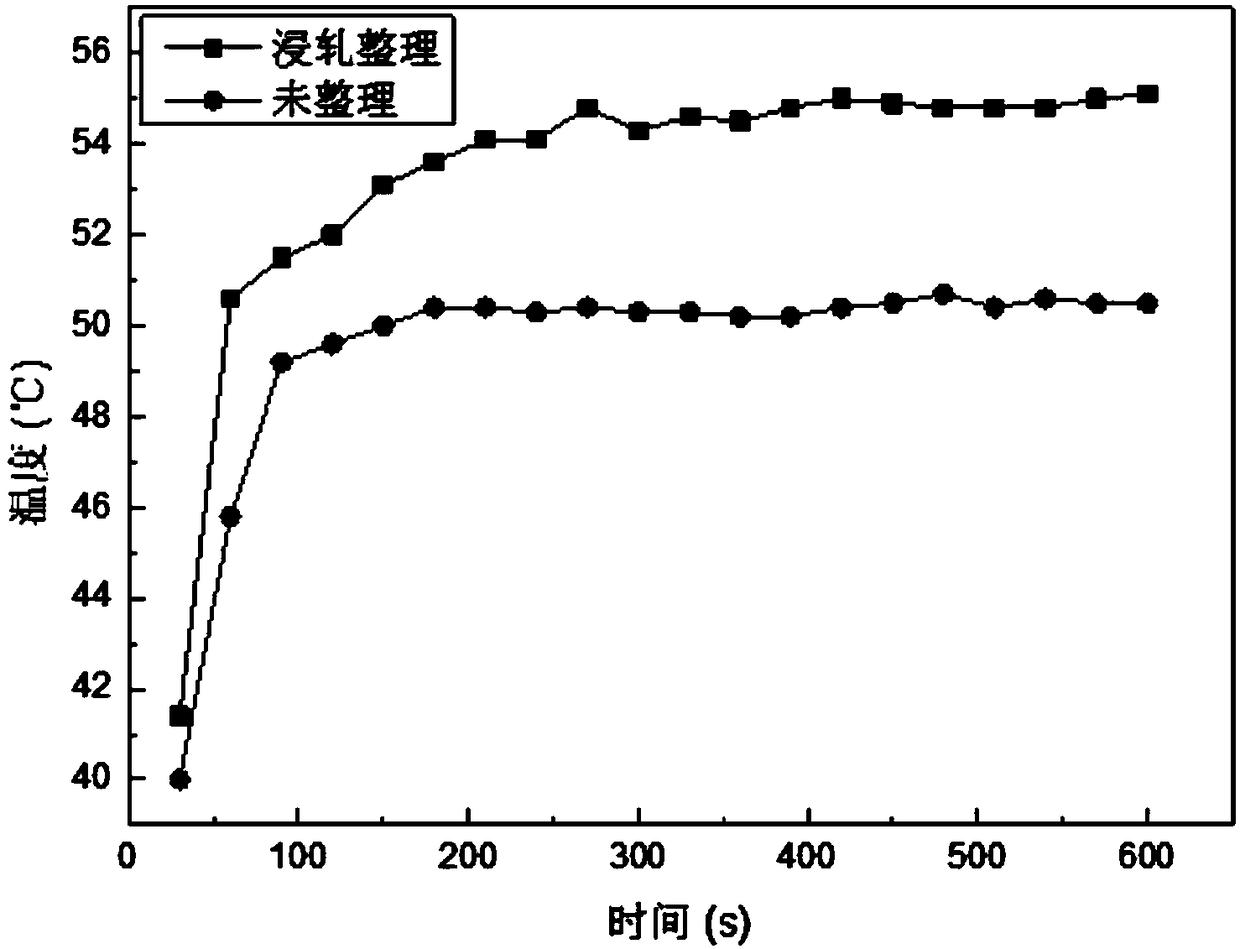

Preparation method of far infrared heating bandage

InactiveCN109505119AImprove infrared radiation performanceExcellent release of negative ionsFibre typesAbsorbent padsIonBandage

The invention relates to a preparation method of a far infrared heating bandage. The preparation method is characterized by comprising the following specific steps: step 1: after washing a bandage with a non-ionic detergent, airing at room temperature; step 2: mixing tourmaline powder and de-ionized water, wherein the mass percent of the tourmaline in a mixture is 2 to 15 percent; stirring at roomtemperature for 5 to 10min; then adding a dispersant, wherein the mass percent of the dispersant in the mixture is 1 to 5 percent; stirring for 1 to 2h to obtain a tourmaline dispersion solution; step 3: adding the tourmaline dispersion solution prepared by step 2 into a mixture of an adhesive and the de-ionized water, wherein the mass percent of the tourmaline dispersion solution is 30 to 80 percent and the mass percent of the adhesive s 5 to 25 percent; stirring for 2 to 3h to prepare a tourmaline after-finishing solution; step 4: carrying out one-padding and one-rolling on the washed and aired bandage in step 1 in the tourmaline after-finishing solution obtained by step 3, wherein the pick-up rate is 30 to 80 percent; drying and then baking at 120 to 140 DEG C for 0.5 to 2min to obtainthe far infrared heating bandage. The far infrared heating bandage prepared by the preparation method has the advantages of excellent temperature-rising performance, high temperature-rising value andsimple preparation method and is applicable to industrial production.

Owner:ZHENDE MEDICAL CO LTD +1

High-temperature-resistant high-radiance anticorrosive paint

ActiveCN111073503AGood high temperature corrosion resistanceAvoid erosionFireproof paintsAnti-corrosive paintsCordieriteGraphite

The invention relates to a high-temperature-resistant high-radiance anticorrosive paint. The paint is prepared from the following raw materials in parts by weight: 5-10 parts of cordierite micro powder, 4-8 parts of ferroferric oxide micro powder, 2-6 parts of chromic oxide micro powder, 6-10 parts of cobalt oxide micro powder, 4-10 parts of ferromanganese spinel micro powder, 15-20 parts of borosilicate glass powder, 3-5 parts of low-melting-point glass powder modified graphene, 30-50 parts of binding agent. 0.1-0.2 part of a dispersing agent, 0.03-0.1 part of a wetting agent, 0.15-0.3 part of a thickening agent and 0.05-0.15 part of a defoaming agent. The anticorrosive paint disclosed by the invention has low-temperature and high-temperature anticorrosive properties and also has relatively high infrared radiance.

Owner:洛阳嘉德节能科技有限公司

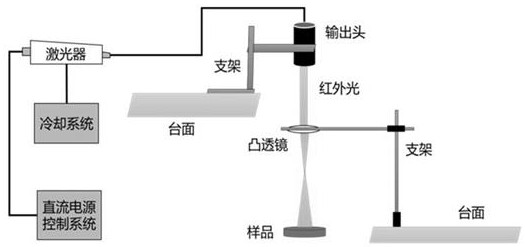

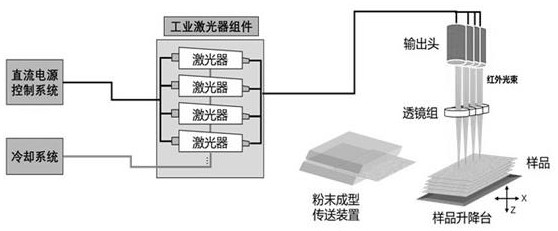

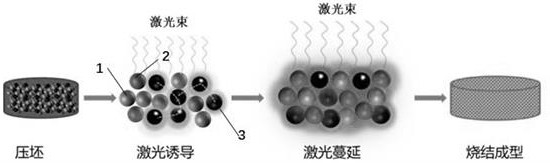

Preparation method of normal-temperature high-radiance infrared radiation ceramic material

The invention discloses a normal-temperature high-radiance infrared ceramic material prepared through rapid laser self-propagating sintering and a preparation method thereof. The preparation method comprises the steps that CuO, Fe2O3, MnO2 and other transition metal oxides are adopted to be subjected to ball milling according to a certain proportion, drying, compacting and tabletting are conducted after ball milling is conducted, then the obtained product is placed in a copper crucible or on other matrixes, laser spot, power, time and other parameters are adjusted to carry out laser irradiation or sintering to enable the raw material mixture to be subjected to high-temperature solid-phase reaction, and thus the AB2O4 type ferrite material is obtained; secondly, the prepared ferrite is crushed, the crushed ferrite is mixed with cordierite according to a certain proportion, a proper amount of a pore-forming agent and a sintering aid are added, long-time ball milling, drying is carried out, and compacting and tabletting are carried out; and high-temperature sintering is carried out by using laser to finally obtain the high-radiance composite ceramic material. The method has the advantages of short sintering time, low energy consumption and the like, and the obtained composite ceramic material has high normal-temperature infrared radiance and wide application prospects.

Owner:YUNNAN HUAPU QUANTUM MATERIAL CO LTD +6

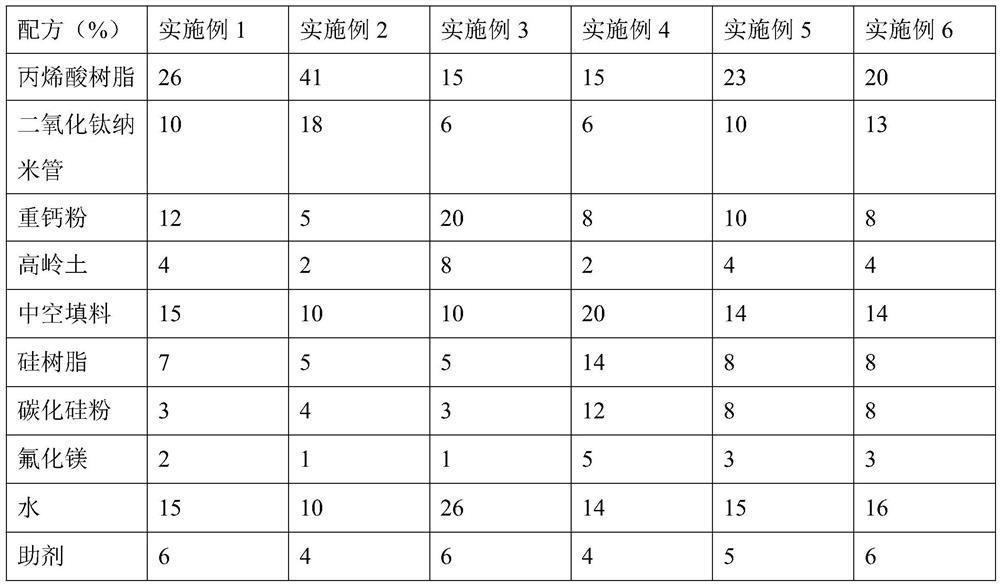

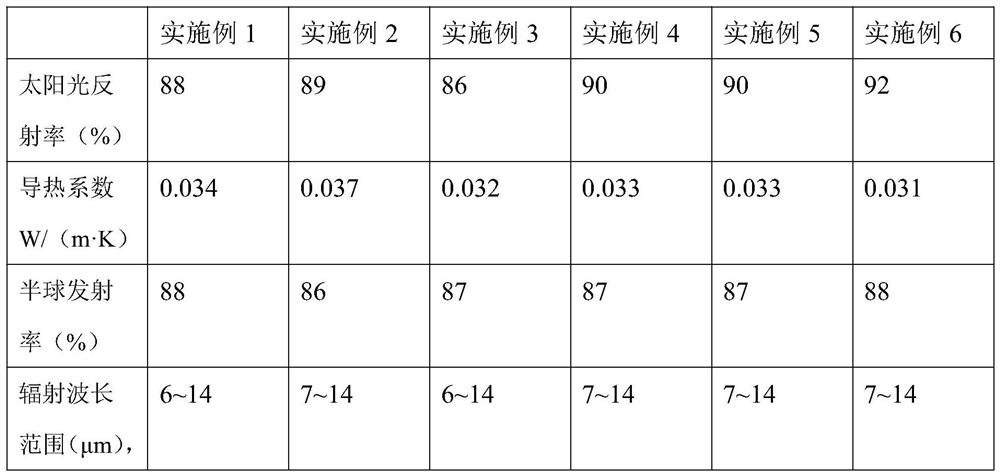

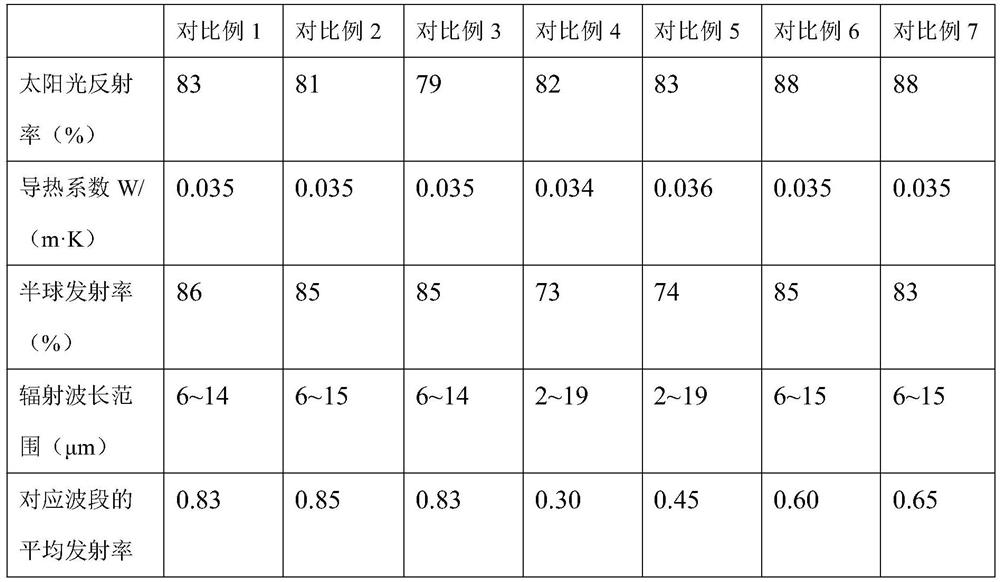

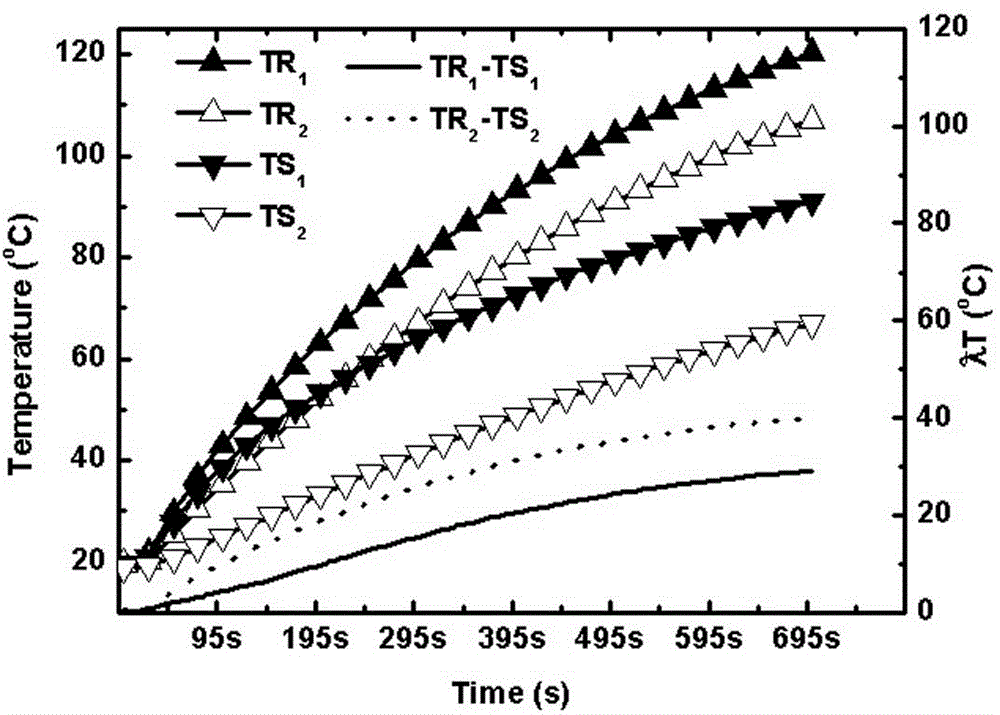

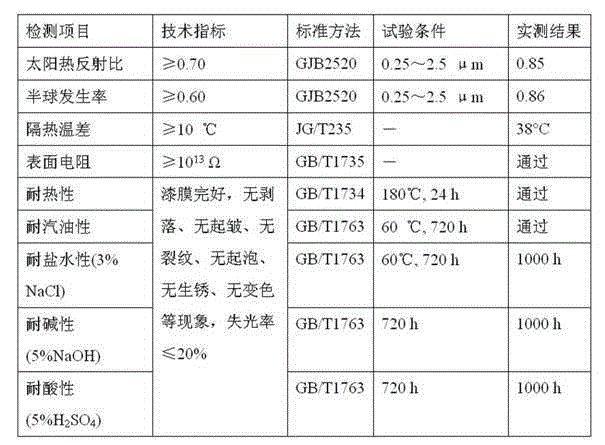

A kind of functional thermal insulation environmental protection coating material and preparation method thereof

ActiveCN110511638BHigh solar reflectanceIncreased hemispherical emissivityAnti-corrosive paintsReflecting/signal paintsCarbide siliconAcrylic resin

The invention discloses a functional heat-insulating and environmentally friendly coating material and a preparation method thereof, belonging to the technical field of coatings. The functional and environmentally friendly coating material includes the following main raw materials: 15% to 45% of acrylic resin, 4% to 4% of titanium dioxide nanotubes 18%, heavy calcium powder 5%~22%, kaolin 2%~8%, hollow filler 10%~20%, silicone resin 5%~14%, silicon carbide powder 3%~12%, magnesium fluoride 1%~ 5%, water 10% ~ 30%, and appropriate amount of dispersant, toughener, thickener, defoamer. The coating preparation method comprises the following steps: adding titanium dioxide nanotubes, heavy calcium powder, and kaolin into water, and stirring uniformly; adding hollow filler and acrylic resin, stirring evenly; adding silicon carbide powder and magnesium fluoride, stirring evenly; adding silicone resin, stirring Obtain heat insulation and environmental protection coating material. The material's thermal insulation is a significant improvement over conventional reflective materials.

Owner:常州蔻庭纳米材料科技有限公司

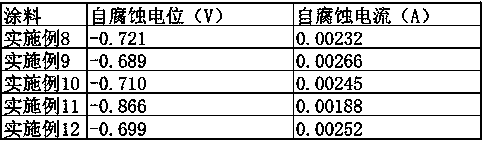

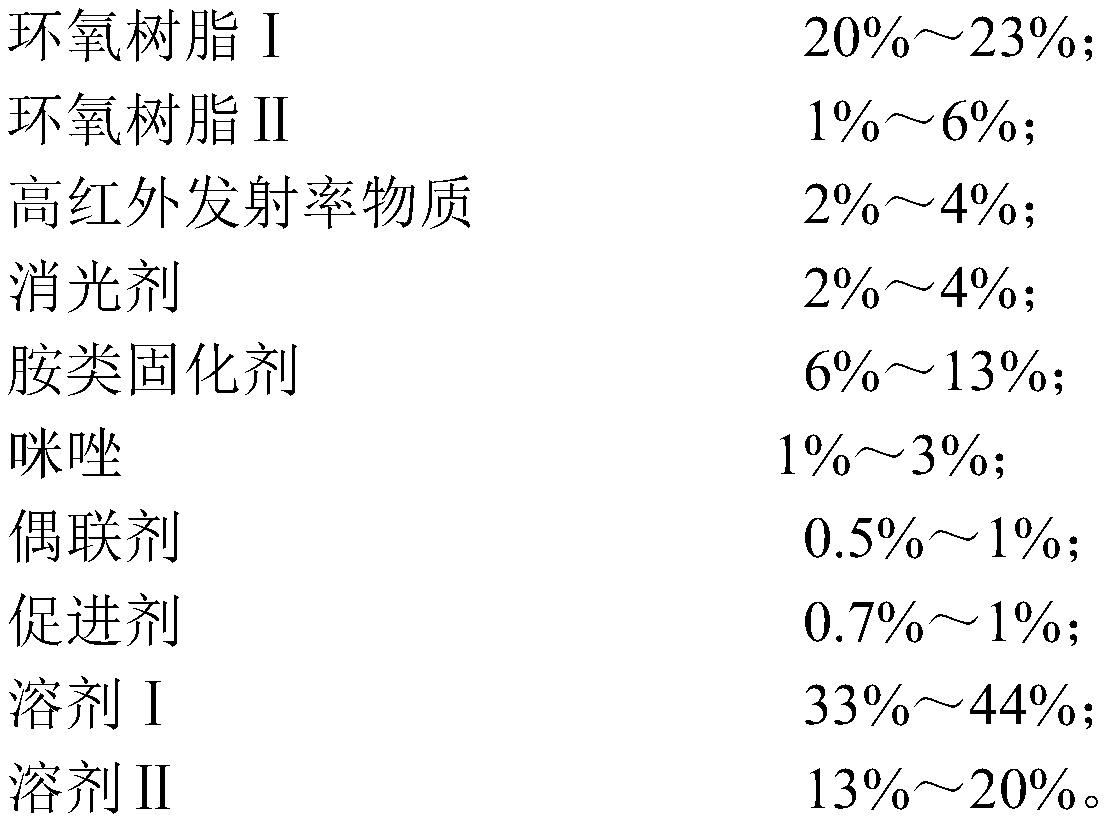

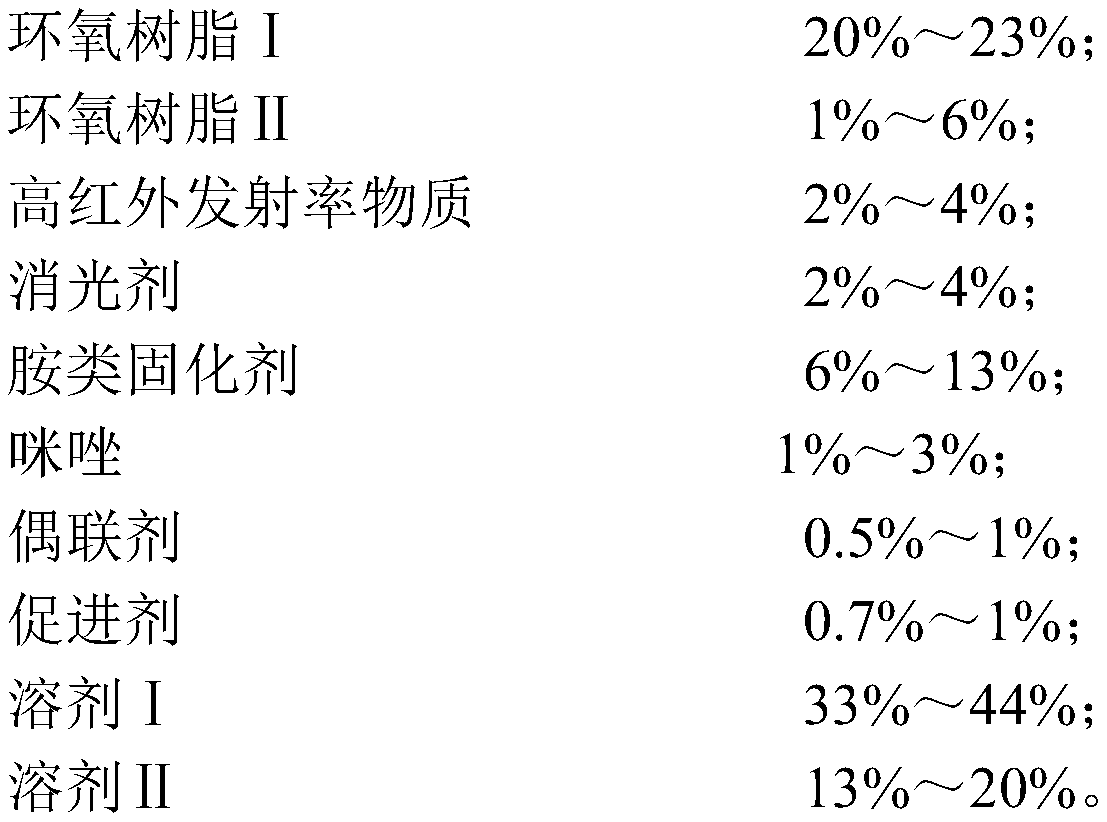

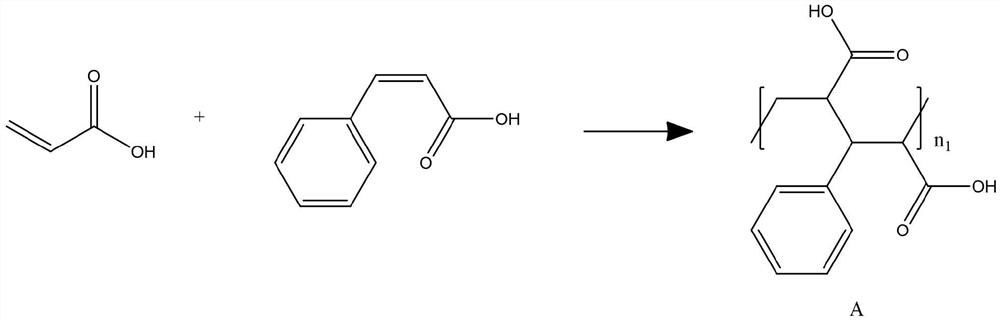

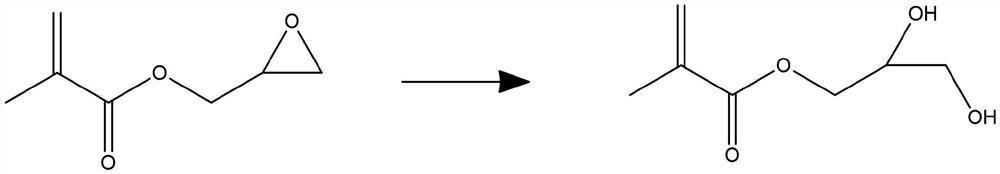

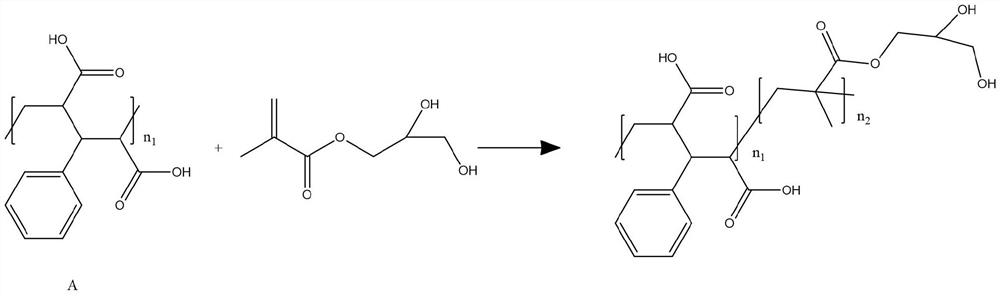

Room-temperature rapid-curing coating material with high-infrared-radiation coating as cured product, and preparation method thereof

ActiveCN110746854AImprove infrared radiation performanceEpoxy resin coatingsPolymer scienceEmissivity

The invention discloses a room-temperature rapid-curing coating material with a high-infrared-radiation coating as a cured product, and a preparation method thereof, wherein the curing coating material is prepared by mixing and stirring an epoxy resin, a high-infrared-emissivity substance, an amine curing agent, imidazole, a coupling agent, an accelerant, a surfactant and a solvent, wherein the mixed solution is good in environmental protection property, has proper working life and paint film initial curing time at a room temperature, and is suitable for rapid curing at a room temperature. According to the invention, with the application of the curing coating material to perform surface treatment on parts, the defects of too long or too short working life and too long or too short initialcuring time of the coating materials in the prior art are overcome.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Reversible dynamic macroporous elastomer polymer material and its preparation method and application

The invention discloses a reversible dynamic macroporous elastomer polymer material, a preparation method and application thereof. The invention mixes and stirs the polymerizable precursor or the crosslinkable polymer precursor and the template liquid insoluble in the precursor evenly, and solidifies the obtained emulsion to prepare a reversible dynamic macroporous elastomer polymer material. The novel elastic body polymer material of the reversible dynamic porous structure of the present invention has a simple and easy synthesis process, is environmentally friendly, has high yield, low preparation cost, and is easy to popularize. The reversible dynamic macroporous elastomeric polymer material of the present invention has an adjustable reversible multi-level pore structure, has good convertible solar light reflection performance and infrared radiation performance, high solution storage capacity, and adjustable surface roughness, It belongs to macroporous polymer material, and has broad application prospects in radiative refrigeration, solar heating, and intelligent interface.

Owner:CHENGDU YUPING TECH CO LTD

Building sunscreen heat insulation coating and preparation method thereof

ActiveCN113372776AImprove dispersion stabilityPromote the development of high-grade green buildingsEpoxy resin coatingsEpoxyNonlinear optical crystal

The invention discloses a building sunscreen heat insulation coating and a preparation method thereof. The preparation method comprises the following steps: mixing waterborne acrylic resin, modified silicon dioxide sol, zinc phosphate, organic fluorine epoxy resin and organic silicon resin to obtain a blended material, adding the blended material into a stirring tank, uniformly stirring, and filtering. Boric acid microparticles and an inorganic filler are doped into a SiO2 sol precursor, so defects in the nonlinear optical crystal are filled, the infrared radiation performance is further regulated and controlled, and the function of enhancing the infrared radiation performance of the atmospheric window wave band is achieved; and a dispersing agent is added the molecular chain of the dispersing agent can be completely expanded in an aqueous solution, and forms a surface adsorption layer with a certain thickness on the surfaces of SiO2 aerogel particles, and a steric hindrance effect is generated, so that the aims of promoting the development of high-grade green buildings and improving the dispersion stability of a SiO2 aerogel system are fulfilled.

Owner:JIANGSU MIRAFUL NANO MATERIAL CO LTD +1

A kind of building sun-proof and heat-insulating coating and preparation method thereof

ActiveCN113372776BImprove dispersion stabilityPromote the development of high-grade green buildingsEpoxy resin coatingsEpoxyNonlinear optical crystal

Owner:JIANGSU MIRAFUL NANO MATERIAL CO LTD +1

Infrared radiation coating capable of forming coating with low conductivity factor

InactiveCN102702808BImprove bindingLow thermal conductivityAlkali metal silicate coatingsPhysical chemistryPotassium titanate

The invention discloses an infrared radiation coating capable of forming a low thermal conductivity coating, which is prepared from the following raw materials in mass percent: spinel-silicate multiphase composite system infrared radiation powder: 30-50 %, pore forming agent: 3~15%, potassium hexatitanate: 0~20%, water glass: 25~50%, water: 5~15%, inorganic bonding agent: 1~10%, anti-settling agent: 0~2%, dispersant: 0~3%, defoamer: 0~1%, leveling agent: 0~1%. After the coating of the present invention is dried and solidified, a coating with a porous structure is formed during use. The coating has excellent infrared radiation performance and low thermal conductivity, and can be firmly combined with the refractory material matrix. No cracking, no shedding, corrosion resistance, excellent thermal shock resistance.

Owner:WUHAN UNIV OF TECH

A kind of high infrared radiation ceramic material and its preparation method and application

The invention provides a high-infrared radiation ceramic material and its preparation method and application. The high-infrared radiation ceramic material is synthesized by a base material and an auxiliary material through a high-temperature solid-phase reaction; the base material includes La 2 o 3 and CeO 2 ; The auxiliary material includes Mn 2 o 3 , SrO, SrCO 3 One or more of them; by mass percentage, in the high infrared radiation ceramic material, the La 2 o 3 45% to 50%, the CeO 2 45% to 50%, and the auxiliary material is 1% to 5%. The high infrared radiation ceramic material of the present invention has simple raw material composition, good uniformity, stable infrared radiation performance and an infrared radiation rate of ≥0.95.

Owner:WUHAN UNIV OF TECH

Ferrite-based high-temperature infrared radiation material and preparation method thereof

The invention relates to a ferrite-based high-temperature infrared radiation material and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps of: evenly mixing Fe2O3 fine powder, MnO2 fine powder, CuO fine powder and Co2O3 fine powder, wherein the mass ratio of Fe2O3 to MnO2 to CuO to Co2O3 is x: (8-x):1:1 (x is larger than or equal to 1 and less than or equal to 7); filling the mixture into a sagger and then putting the sagger into a microwave oven, heating to 900-1180 DEG C, and carrying out heat preservation for 30-60 minutes to prepare a ferrite blackening agent; and evenly mixing one of cordierite fine powder, mullite fine powder and spodumene fine power with the ferrite blackening agent in a mass ratio of (1-4):1, filling evenly mixed prefabricate in the sagger and then putting the sagger into the microwave oven, heating to 1000 DEG C-1200 DEG C, and carrying out heat preservation for 30-60 minutues to obtain the ferrite-based high-temperature infrared radiation material. The method has the characteristics of short production period and low energy consumption; and the prepared ferrite-based high-temperature infrared radiation material is small in expansion coefficient and excellent in infrared radiation performance in middle-short wavebands.

Owner:湖北赛格瑞新能源科技有限公司

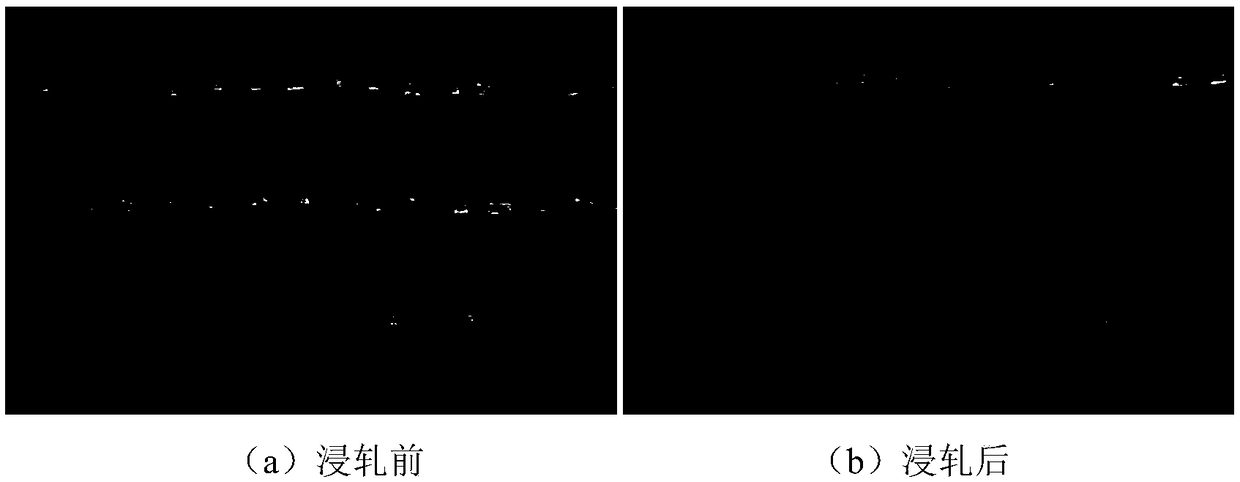

A high-efficiency heat dissipation coating and its application method

ActiveCN105949903BHigh full-band infrared radiation rateImprove infrared radiation performanceCoatingsFull waveRadiance

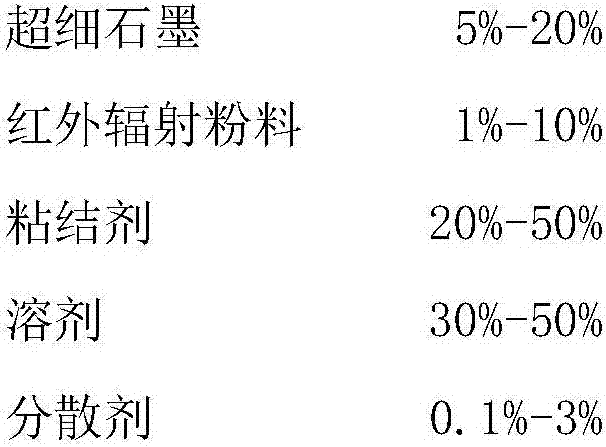

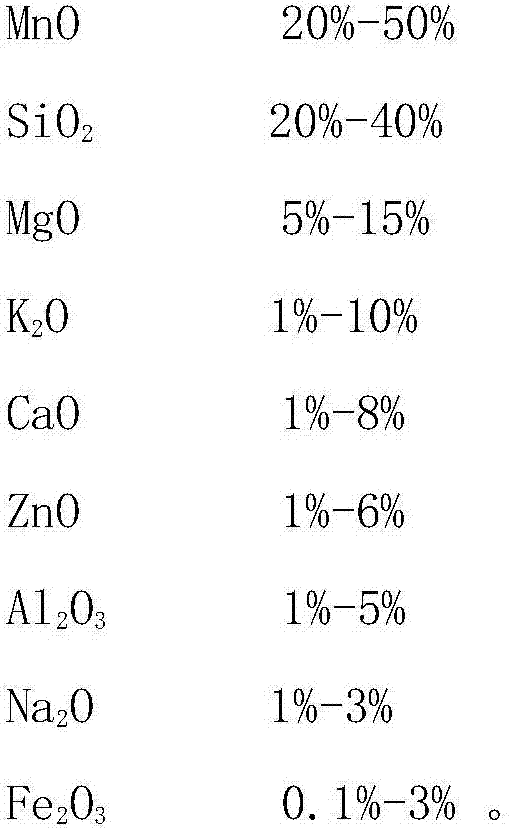

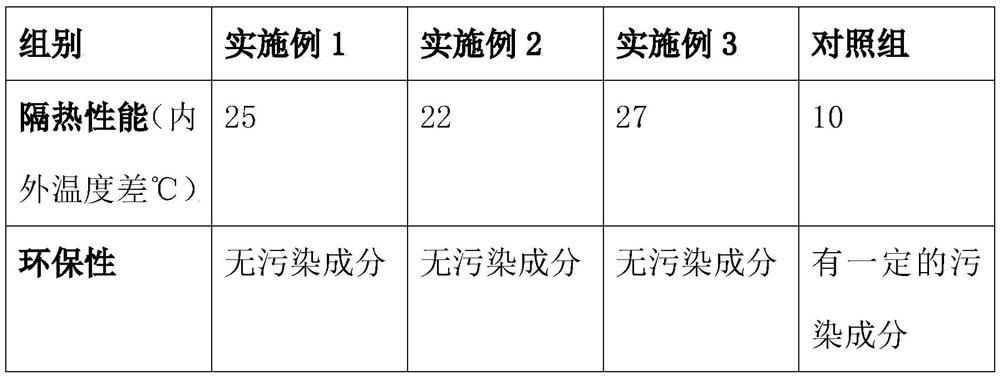

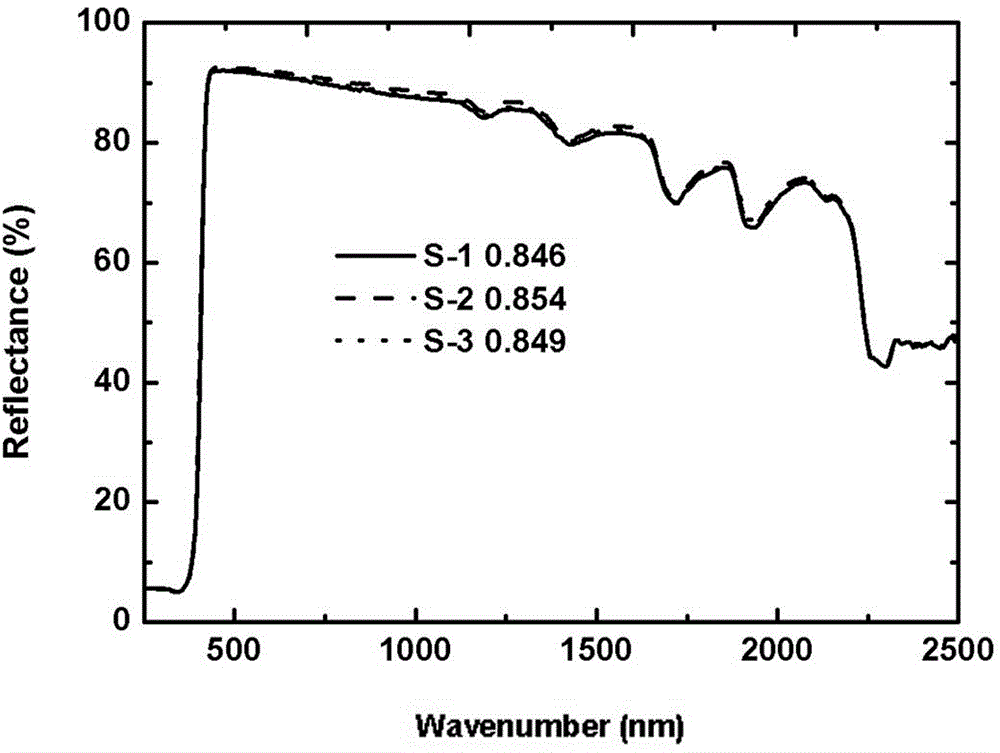

The invention relates to an efficient heat dissipation coating and an application method thereof. The heat dissipation coating is prepared from, by mass, 5%-20% of superfine graphite, 1%-10% of infrared radiation powder, 20%-50% of a bonding agent, 30%-50% of a solvent and 0.1%-3% of a dispersing agent, wherein the proportion sum of all the components is 100%. A preparation method of the efficient heat dissipation coating comprises the steps that the weighted superfine graphite, infrared radiation powder, bonding agent, dispersing agent and solvent are mixed and then stirred to be uniform to obtain slurry; the slurry is uniformly applied to the surfaces of metal heat dissipation fins of electronic equipment through a spraying or immersing method, natural curing is conducted under the room temperature condition, and heat preservation is conducted for 2 h. The efficient heat dissipation coating has the heat conductivity coefficient approaching to that of graphite and can effectively decrease the surface temperature of the electronic equipment, improve the operating reliability of the electronic equipment and prolonging the service life of the electronic equipment; the full-wave band radiance is stable at 0.96 or above for a long term; when the heat dissipation fins of the electronic equipment are in a working state under the temperature of 80 DEG C to 100 DEG C, the surface temperature of the heat dissipation fins coated with the efficient heat dissipation coating is decreased by 8 DEG C-10 DEG C than that of the heat dissipation fins not coated with the efficient heat dissipation coating.

Owner:SHANGHAI UNIV

Heat-insulating coating additive and production method

InactiveCN112322100AWell mixedGood heat insulationAntifouling/underwater paintsPaints with biocidesPolyvinyl alcoholThermal insulation

The invention discloses a thermal insulation coating additive, which comprises the following raw materials in parts by weight: 15-25 parts of polyamide resin, 10-20 parts of nano titanium dioxide, 10-20 parts of nano calcium carbonate, 8-14 parts of polyvinyl alcohol, 15-25 parts of silica sol, 6-12 parts of coupling agent, 20-30 parts of deionized water, 8-14 parts of thickening agent, 6-12 partsof defoaming agent, 10-20 parts of polyvinyl alcohol colloid, 12-18 parts of emulsifying agent, 20-25 parts of sodium bicarbonate and 10-20 parts of film-forming agent. The product and the method belong to the technical field of coating production. According to the heat-insulating coating additive and the production method thereof, by adding nano titanium dioxide, the reflectivity is high, the infrared radiation performance is good, the reflectivity and weather resistance of the coating can be improved, the thermal insulation effect of the coating can be enhanced, the advantages of environmental protection and energy conservation are achieved, the dispersity in the coating is excellent, the cost is low, the service life is long, and various used raw materials are cheap and easy to obtain;the additive is simple in preparation method, good in heat insulation effect, easy to popularize and use and capable of accelerating the energy conservation and emission reduction process, and components of the coating do not contain pollution components.

Owner:安徽嘉年华漆业有限公司

Environment-friendly anticorrosion and temperature-reduction integrated paint for storage tank and preparation method of paint

InactiveCN102963098BImprove cooling effectGood scrub resistanceSynthetic resin layered productsAnti-corrosive paintsFar infraredSilicon dioxide

The invention discloses an environment-friendly anticorrosion and temperature-reduction integrated paint for a storage tank and a preparation method of the paint. The environment-friendly anticorrosion and temperature-reduction integrated paint consists of anticorrosion primer, heat-insulation interlayer paint and temperature-reduction surface layer paint. The anticorrosion primer is prepared by taking acrylic emulsion as a filming base material, iron-titanium powder as an antirust pigment filler and calcium carbonate powder, precipitated barium sulphate powder and talcum powder as body fillers, and supplementing auxiliaries and water. The heat-insulation interlayer paint is prepared by taking acrylic emulsion as a filming base material and hollow glass beads as a heat-insulation filler and supplementing auxiliaries and water. The temperature-reduction surface layer paint is prepared by taking acrylic emulsion as a filming base material and titanium dioxide powder, talcum powder, silicon dioxide, hollow glass beads and far infrared ceramic powder as temperature-reduction pigment fillers and supplementing auxiliaries and water. The environment-friendly anticorrosion and temperature-reduction integrated paint can form a film at normal temperature, is friendly to environment, plays a remarkable protection role to the storage tank due to high anticorrosion and temperature-reduction properties, and can be widely used for various storage tanks of oil gas and chemical materials.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

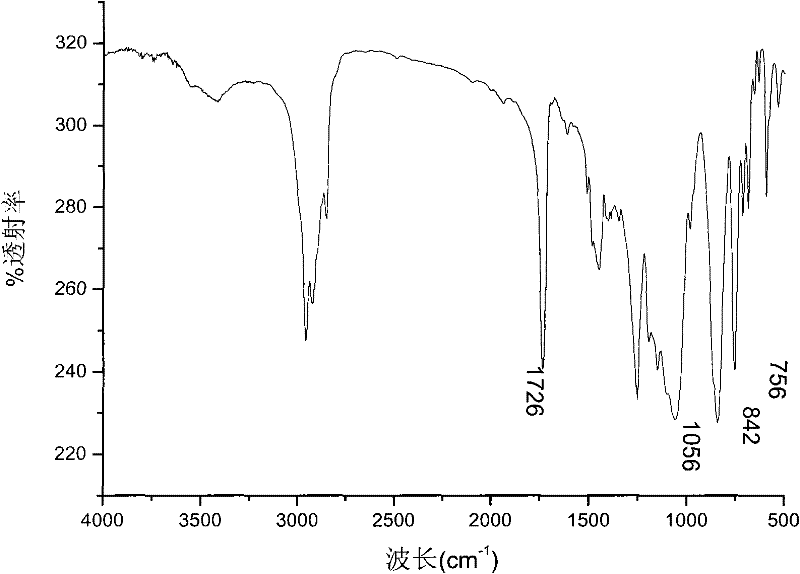

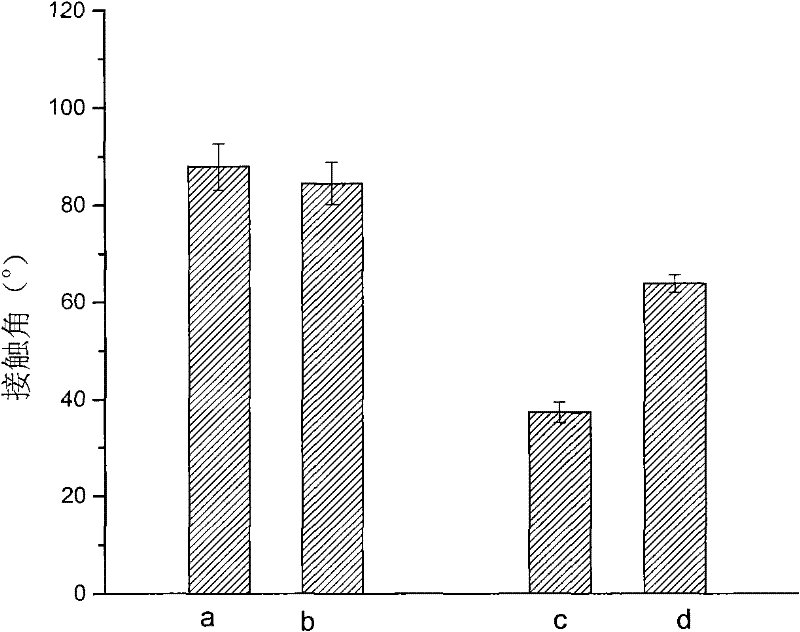

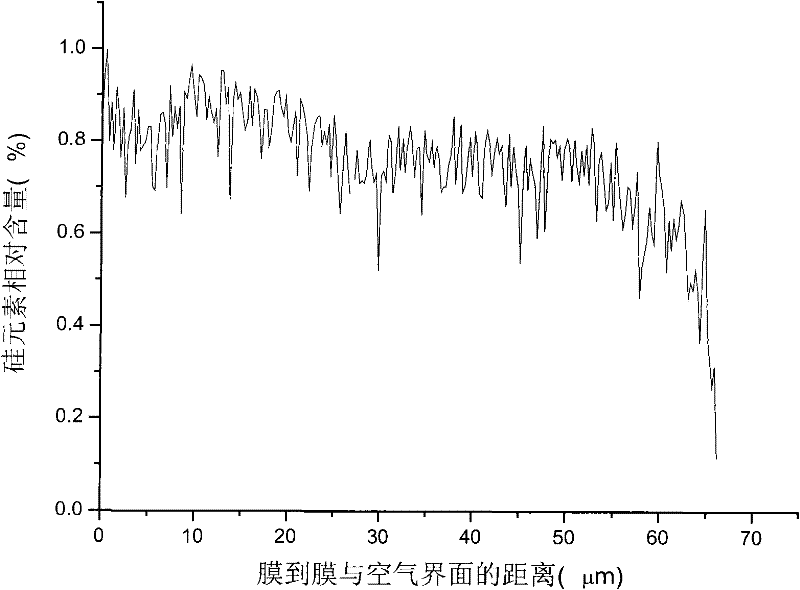

Preparation method of organic silicon acrylic ester self-organizing gradient emulsion film

InactiveCN101712767BReduce energy consumptionAvoid the disadvantages of blendingTemperature resistanceHydrolysis

The invention relates to a preparation method of an organic silicon acrylic ester self-organizing gradient emulsion film, which in particular comprises the following steps: firstly adopting a soap-free emulsion method to prepare organic silicon acrylic ester copolymer soap-free emulsion and methyl methacrylate copolymer soap-free emulsion; blending the two emulsion according to the weight ratio of 1:1; and self-organizing to form the emulsion film of which the content of silicon element is in gradient change from the surface of the base material to the surface of the air by utilizing the difference of surface energy between different emulsion particles and the difference of selected wettability to the base material. The invention solves the hydrolysis problem of multiple organic silicon monomers in the emulsion polymerization process, improves the silicon content and hydrophobic nature of the polymer; the surface on one side of the formed gradient emulsion film possesses excellent film forming property and caking property of acrylic ester polymer, and the surface on the other side possesses the advantages of excellent high temperature resistance, ultraviolet resistance, infrared radiation resistance, oxidation degradability resistance, low surface energy and the like of organic silicon; and the preparation method is simple and easy to control, has no pollution to the environment and is applied widely.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com