Room-temperature rapid-curing coating material with high-infrared-radiation coating as cured product, and preparation method thereof

An infrared radiation coating and rapid curing technology, applied in coatings, epoxy resin coatings, etc., can solve the problem that infrared radiation coating man-hours and ergonomics cannot fully meet the needs of actual production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

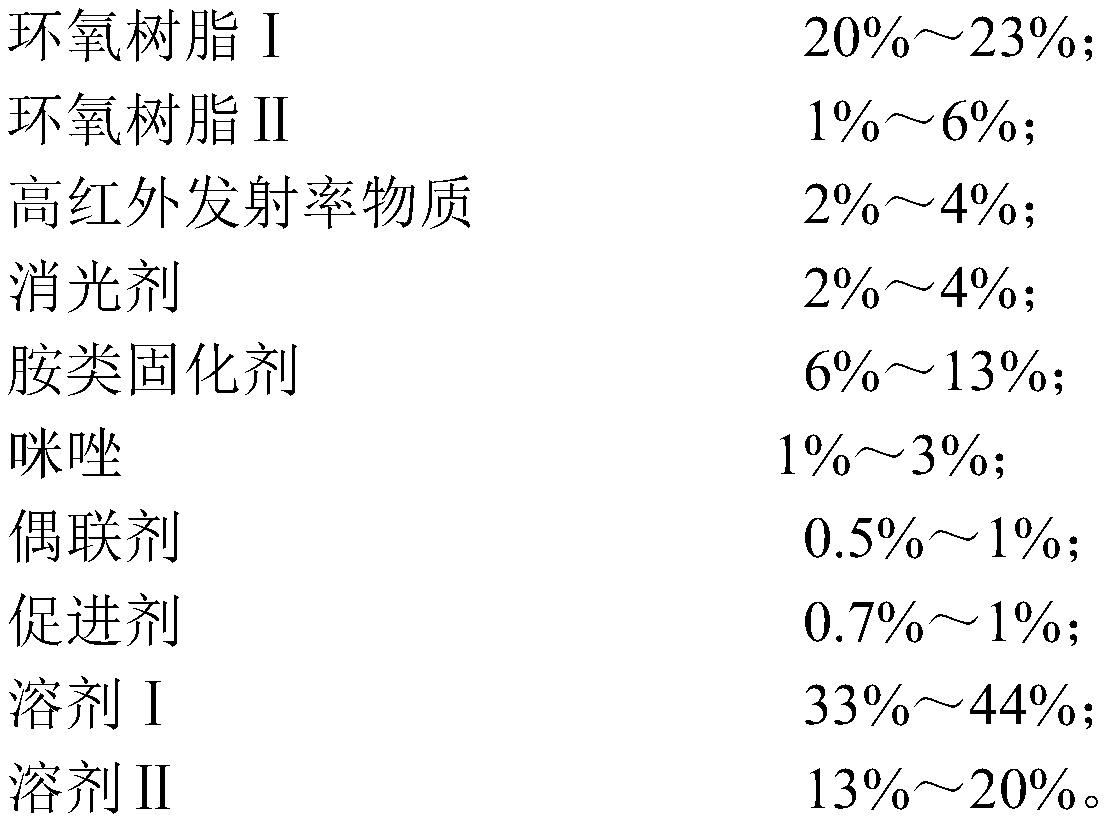

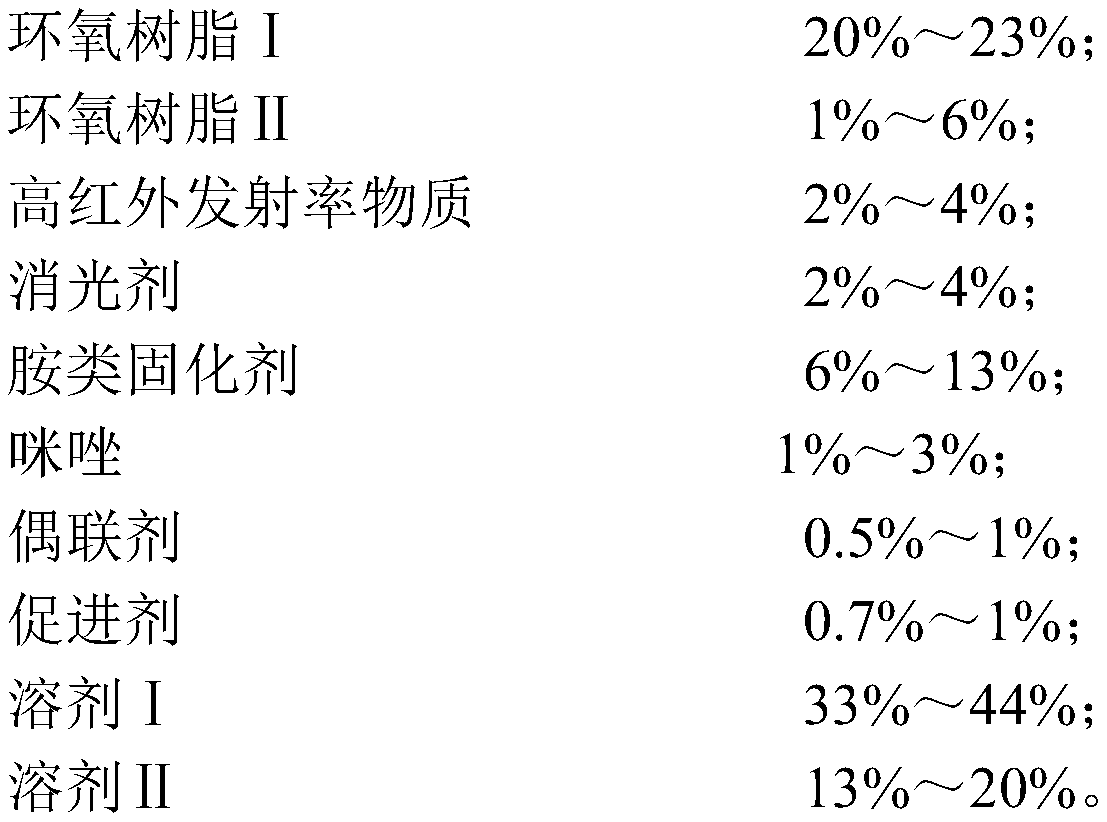

Embodiment 1

[0032] Add epoxy resin II to epoxy resin I according to the components specified in Table 1, and disperse evenly with a disperser to obtain component A.

[0033] Mix the high-infrared emissivity substance, matting agent, amine curing agent, imidazole, coupling agent, accelerator, solvent I and solvent II evenly, grind and disperse, and obtain component B;

[0034] After mixing component A and component B and stirring evenly, spray on the substrate and cure at room temperature to obtain a coating. The pot life of the test coating, the initial curing time of the coating, the tensile shear strength of the coating and the blackness coefficient of the coating are listed in Table 1.

Embodiment 2

[0036] Repeat the method of Example 1 by each component content specified in the following Table 1, but each component ratio is listed in Example 2 in Table 1, and the test results are listed in Table 1.

Embodiment 3

[0038] Repeat the method of Example 1 by each component content specified in the following Table 1, but each component ratio is listed in Example 3 in Table 1, and the test results are listed in Table 1.

[0039] Table 1 A kind of room temperature rapid curing adhesive glue embodiment

[0040]

[0041] The coating composition of the present invention can be coated by conventional coating methods, for example, by manual or automatic methods, the coating can be brushed or sprayed on the surface of high-speed rotating mechanical parts conveniently and uniformly, and then cured at room temperature to form a coating , this coating has good mechanical properties, infrared radiation heat transfer performance, heat resistance, etc., and can be used for infrared radiation heat dissipation of parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com