A kind of functional thermal insulation environmental protection coating material and preparation method thereof

A coating material and functional technology, which is applied in the field of functional heat-insulation and environmental-friendly coating materials and their preparation, can solve the problems of high formula and raw material requirements of radiation heat-insulation coating materials, and achieve the purpose of improving infrared radiation capability and reducing heat dissipation. The effect of high conductivity and radiation emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

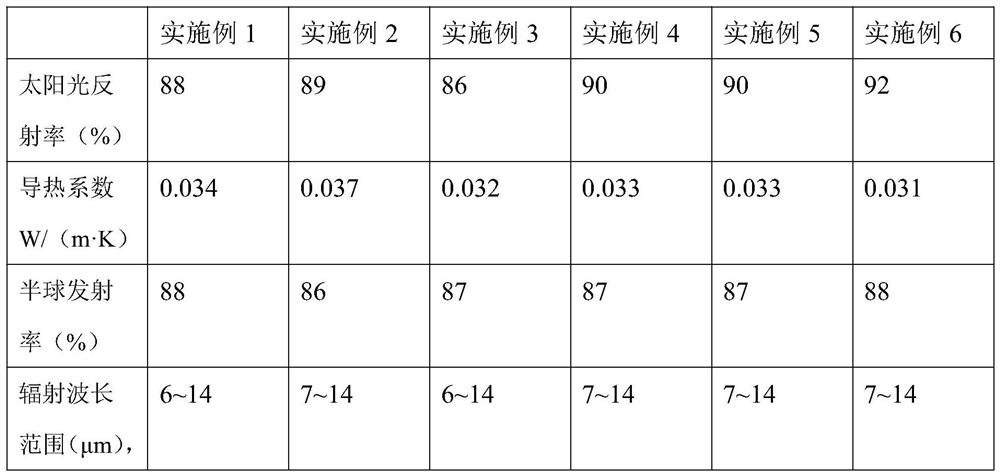

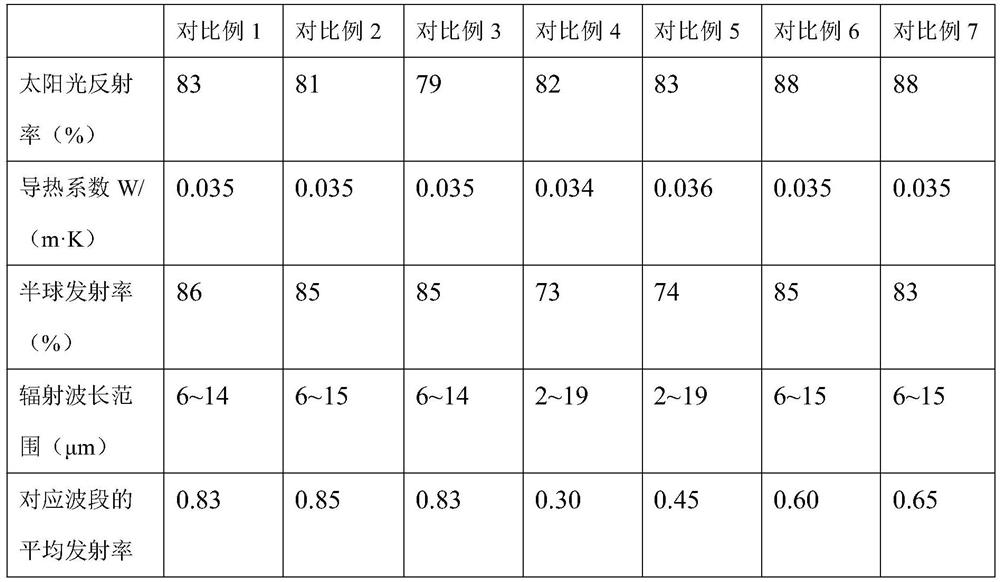

Examples

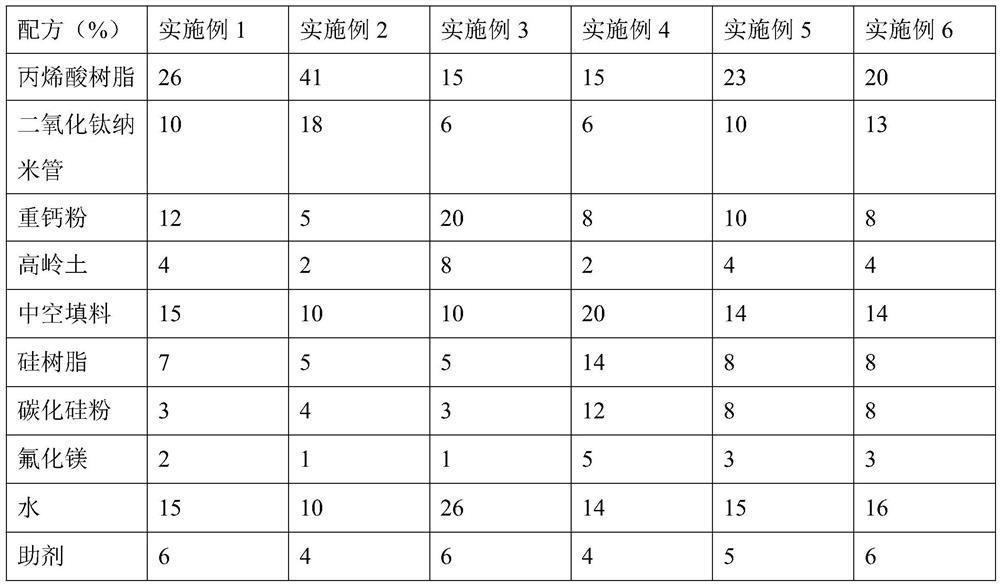

Embodiment 1

[0050] Functional insulation and environmentally friendly coating material, by mass percentage, including the following components:

[0051] After mixing the appropriate amount of dispersing agent, toughening agent, the antifoaming agent (6%), add 15% of deionized water, stirring at a constant temperature at a constant temperature of 1400 r / min to a uniform uniform, and the rotation speed is reduced to 200R / min and added. 10% titanium dioxide nanotubes, 12% heavy calcium powder and 4% kaolin, fully stirred, add 15% hollow filler and 26% acrylic resin, to be mixed, supplemented with 3% silicon carbide powder, 2% magnesium fluoride mixture, 600R / min was stirred for 40 minutes; finally added silicone, stirring at 500 r / min for 30 minutes to get the final product.

Embodiment 2

[0053] Functional insulation and environmentally friendly coating material, by mass percentage, including the following components:

[0054]After mixing the appropriate amount of dispersing agent, toughening agent, the antifoaming agent (3%), add 10% of deionized water, stirring at a constant temperature at a constant temperature of 1400 r / min to uniformly dispersion, reduce the speed to 200R / min and add 18% titanium dioxide nanotubes, 5% heavycalcium powder and 2% kaolin, 10% hollow filler and 41% acrylic resin were added, and the mixture was mixed, and 1% magnesium carbide powder was supplemented. 600R / min was stirred for 40 minutes; silicone resin was added, and stirred for 30 min, 1% thickener was added and stirred for 30 min, and prepared was completed.

Embodiment 3

[0056] Functional insulation and environmentally friendly coating material, by mass percentage, including the following components:

[0057] After mixing the appropriate amount of dispersing agent, toughening agent, the antifoam agent (5%), 26% of deionized water, stirred at a constant temperature at a constant temperature of 1400 r / min to uniformly dispersion, reduce the speed to 200R / min and add 6% titanium dioxide nanotubes, 20% heavy calcium powder, and 8% kaolin, 10% hollow filler and 15% acrylic resin were added, and 3% silicon carbide powder, 1% magnesium carbide powder were supplemented, and 1% magnesium carbide powder was supplemented. 600R / min was stirred for 40 minutes; silicone resin was added, and stirred for 30 min, 1% thickener was added and stirred for 30 min, and prepared was completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com