Preparation method of normal-temperature high-radiance infrared radiation ceramic material

A technology of infrared radiation and ceramic materials, which is applied in the field of infrared luminescent ceramic materials, can solve the problems of weak infrared emission performance, low preparation efficiency, and large product particles, and achieve the effects of small thermal expansion coefficient, low cost, and high infrared radiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

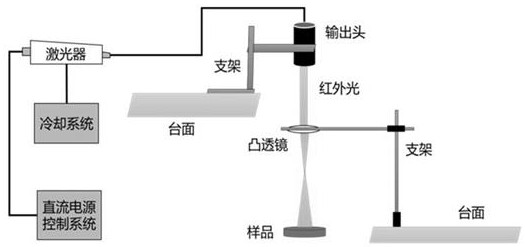

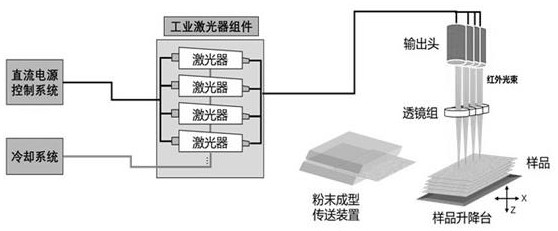

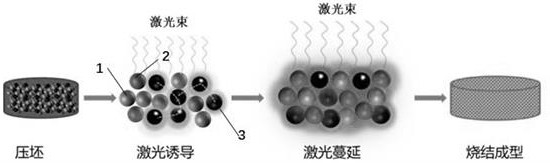

[0026] with Fe 2 o 3 , MnO2, and CuO as raw materials, mixed according to the mass ratio of 6:6:3, using deionized water as the ball milling medium, the ball milling speed is 400r / min, and the ball milling is more than 5 hours, preferably 6~10 hours. The powder was taken out and dried in a drying oven at 80°C for 10 h. The dried mixture powder is compacted by a hydraulic press, the pressure is 15MPa, the holding time is 10s, and then placed in a copper crucible, using a fiber laser, the laser wavelength is 980nm, and the laser sintering power is 30W~1500W, preferably 60W~200W, The laser sintering time is 5s~10min, preferably 30s~3min, so that the mixture undergoes a high-temperature solid-state reaction to obtain AB 2 o 4 type ferrite powder.

[0027] Prepared AB 2 o 4 Type ferrite powder and cordierite fine powder are mixed according to the mass ratio of 10:90, and at the same time, 0~5% (preferably 2~3%) of the total mass percentage is added to the sintering aid and nu...

example 2

[0029] with Fe 2 o 3 , MnO 2 , CuO as raw materials, mixed according to the mass ratio of 6:6:3, using deionized water as the ball milling medium, the ball milling speed is 400r / min, and the ball milling is more than 5 hours, preferably 6~10 hours. The powder was taken out and dried in a drying oven at 80°C for 10 h. The dried mixture powder is compacted by a hydraulic press, the pressure is 15MPa, the holding time is 10s, and then placed in a copper crucible, using a fiber laser, the laser wavelength is 980nm, and the laser sintering power is 30W~1500W, preferably 60W~200W, The laser sintering time is 5s~10min, preferably 30s~3min, so that the mixture undergoes a high-temperature solid-state reaction to obtain AB2O4 type ferrite powder.

[0030] Prepared AB 2 o 4 Type ferrite powder and cordierite fine powder are mixed according to the mass ratio of 20:80, and at the same time, 0~5% (preferably 2~3%) of the total mass percentage is added to the sintering aid and nucleati...

example 3

[0032] with Fe 2 o 3 , MnO 2 , CuO as raw materials, mixed according to the mass ratio of 6:6:3, using deionized water as the ball milling medium, the ball milling speed is 400r / min, and the ball milling is more than 5 hours, preferably 6~10 hours. The powder was taken out and dried in a drying oven at 80°C for 10 h. The dried mixture powder is compacted by a hydraulic press, the pressure is 15MPa, the holding time is 10s, and then placed in a copper crucible, using a fiber laser, the laser wavelength is 980nm, and the laser sintering power is 30W~1500W, preferably 60W~200W, The laser sintering time is 5s~10min, preferably 30s~3min, so that the mixture undergoes a high-temperature solid-state reaction to obtain AB2O4 type ferrite powder.

[0033] Prepared AB 2 o 4 Type ferrite powder and cordierite fine powder are mixed according to the mass ratio of 25:75, and at the same time, 0~5% (preferably 2~3%) of the total mass percentage is added to the sintering aid and nucleati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com