Infrared radiation coating capable of forming coating with low conductivity factor

A technology of infrared radiation coating and low thermal conductivity, applied in the field of infrared radiation energy-saving materials, can solve problems such as poor high temperature stability and poor infrared radiation performance, achieve excellent low thermal conductivity, excellent infrared radiation performance, and ensure energy-saving effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In terms of mass percentage, it is 40% of spinel-silicate multiphase composite system infrared radiation powder, 5% of pore-forming agent, 10% of potassium hexatitanate, 30% of water glass, 5% of water, and 6.7% of inorganic bonding agent , organic bentonite 1%, sodium phosphate 2%, tributyl phosphate 0.2%, water-based acrylic resin 0.1%, the pore-forming agent is composed of graphite and starch, and the mass ratio of graphite and starch is 50%: 50% , Weigh the above-mentioned components, stir and mix for 4 hours, and then obtain the infrared radiation coating of viscous suspending fluid.

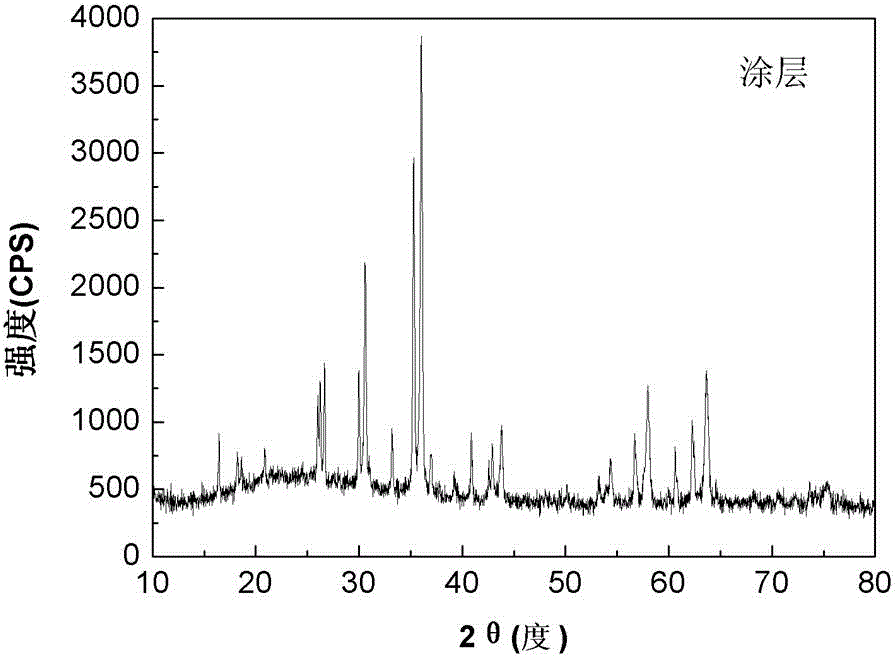

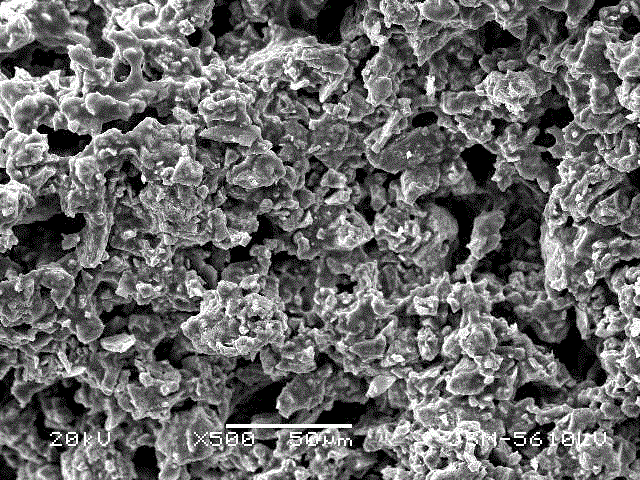

[0023] Among them, the infrared radiation powder of the spinel-silicate multi-phase composite system includes the A component forming the spinel solid solution, the B component forming the silicate mineral and the accelerator C component, wherein the The above-mentioned A component includes Fe 2 o 3 , MnO 2 , CuO and Mo 2 o 3 , the B component includes Al 2 o 3 , SiO 2 , MgO ...

Embodiment 2

[0028] According to the mass ratio, 30% spinel-silicate multiphase composite system infrared radiation powder, 3% pore forming agent, 20% potassium hexatitanate, 25% water glass, 10% water, 8% inorganic bonding agent , 2% organic bentonite, 1% sodium phosphate, 0.5% tributyl phosphate, 0.5% water-based acrylic resin, the above-mentioned various components are weighed according to the proportion, and the described pore-forming agent is composed of graphite and starch. The mass ratio of starch and starch is 50%:50%. Stir and mix for 1 hour to obtain a viscous suspension fluid infrared radiation coating.

[0029] Among them, the mass ratio of each component in the infrared radiation powder of the spinel-silicate multiphase composite system is: 28%MnO 2 , 12%CuO, 6%Mo 2 o 3 , 5%V 2 o 5 、5%WO 3 , 5%Al 2 o 3 , 20%SiO2 2 , 10%MgO, 6%TiO 2 and 3% CaO; the preparation process is as follows: batching various raw materials according to the specified ratio, ball milling, mixing, ...

Embodiment 3

[0033] According to the mass ratio, it is 50% spinel-silicate multiphase composite system infrared radiation powder, 3% pore forming agent, 33% water glass, 10% water, 1% inorganic bonding agent, 1% organic bentonite, 1% % tributyl phosphate, 1% water-based acrylic resin, the above-mentioned various components are weighed according to the proportion, stirred and mixed for 3 hours, and the infrared radiation coating of viscous suspension fluid is obtained.

[0034] Among them, the mass ratio of each component in the infrared radiation powder of the spinel-silicate multiphase composite system is: 10% Fe 2 o 3 , 60%MnO 2 , 3%CuO, 4%Co 2 o 3 , 3%NiO, 2%WO 3 , 8%Al 2 o 3 , 5%SiO2 2 , 3% BaO and 2% CaO; the preparation process is as follows: batching various raw materials according to the specified ratio, ball milling, mixing, drying and pressing the ingredients into a block green body; During the process, first heat to 800°C for 6 hours to form a spinel solid solution, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com