Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1421 results about "Potassium titanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium titanate is a titanic acid compound that is particularly renowned for its strength, stiffness, low dielectricity and wear resistance, which makes it absolutely perfect for use in the automotive industry.

Environmental ceramic base friction material free of copper or metal and preparation method of material

InactiveCN103881657AGood mechanical skeleton performanceStable coefficient of frictionOther chemical processesFriction liningSulfurMetallic sulfide

The invention discloses an environmental ceramic base friction material free of copper or metal and a preparation method of the material. The environmental ceramic base friction material is characterized by comprising the following components by weight percent: 6-12% of phenolic resin, 2-10% of ceramic fiber, 2-8% of inorganic fiber, 2-10% of rubber, 4-12% of graphite, 10-25% of potassium titanate lamella, 3-15% of mineral fiber, 4-20% of metal sulfur compound, 6-20% of grinding aid and 5-20% of filler. The prepared friction material has excellent friction and wear properties, high heat-conducting property, excellent high-temperature decline property, stable friction coefficient, and excellent noise performance.

Owner:YANTAI SHENGRUI BRAKE SYST

Ceramic base/NAO composite friction material and preparation method thereof

The invention relates to an oxide ceramic base / NAO composite friction material used in a brake of a medium or high-grade car and a preparation method thereof. In the composite friction material, mixed fibers comprise aramid fibers, potassium titanate fibers and silicon, magnesium and calcium oxide ceramic fibers; aedelforsite or mineral fibers and copper fibers are used as the enhancement and conduction fibers; phenolic resin is used as the organic bonding agent; pure oxide ceramics, such as Al2O3, ZrO2, MgO, CaO and the like, are used as the abrasives; solid lubricant, sulfide, graphite coke and the like are used as the abrasion resistant lubricants; and sodium bicarbonate is used as the blowing agent and pairing antioxidant, and barium sulfate inorganic filler is used as the function and toughening filler. The ceramic base / NAO organic friction material mainly maintains the unique performance of the asbestos friction material, remakably lowers the noise, reduces the abrasion possibility, and is beneficial to prolonging the service life of a brake disc, there by being a novel green (less-dust) low-noise environmentally-friendly friction material.

Owner:HUBEI CHIBI SALFER FRICTION MATERIAL

Thermostable heat-isolating coating and its preparation method

The invention discloses a high-temperature proof insulating paint and making method, which comprises the following parts: 400-500g organic silica resin, 50-100g thermostable dye, 100-200g fill, 80-150 hollow ceramic microball, 30-60g bergmeal, 20-50g potassium titanate whisker, 100-150g solvent and 5-15g adjuvant.

Owner:北京国邦技术发展中心

Potassium titanate, method for manufacturing the same, friction material and resin composition

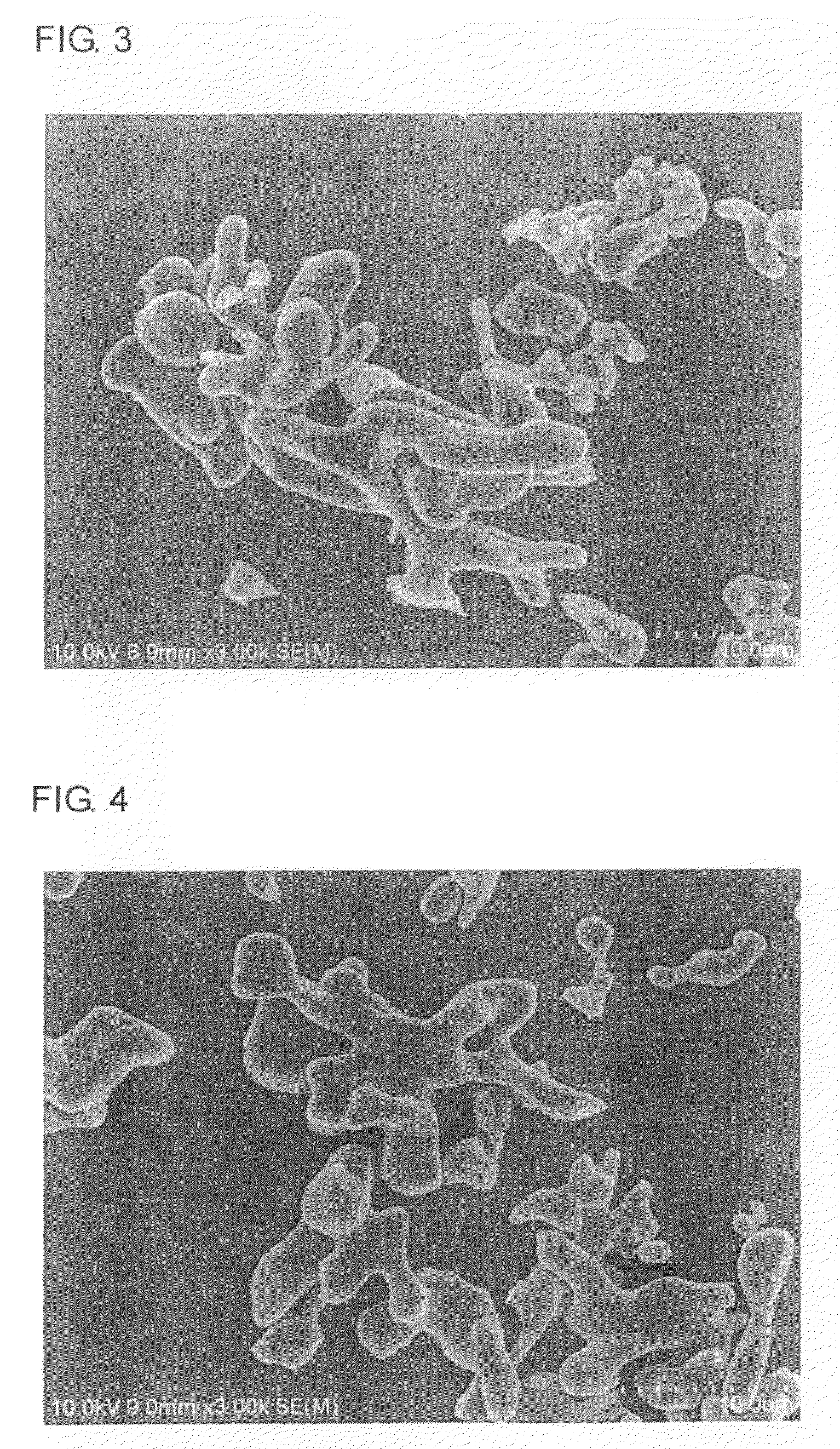

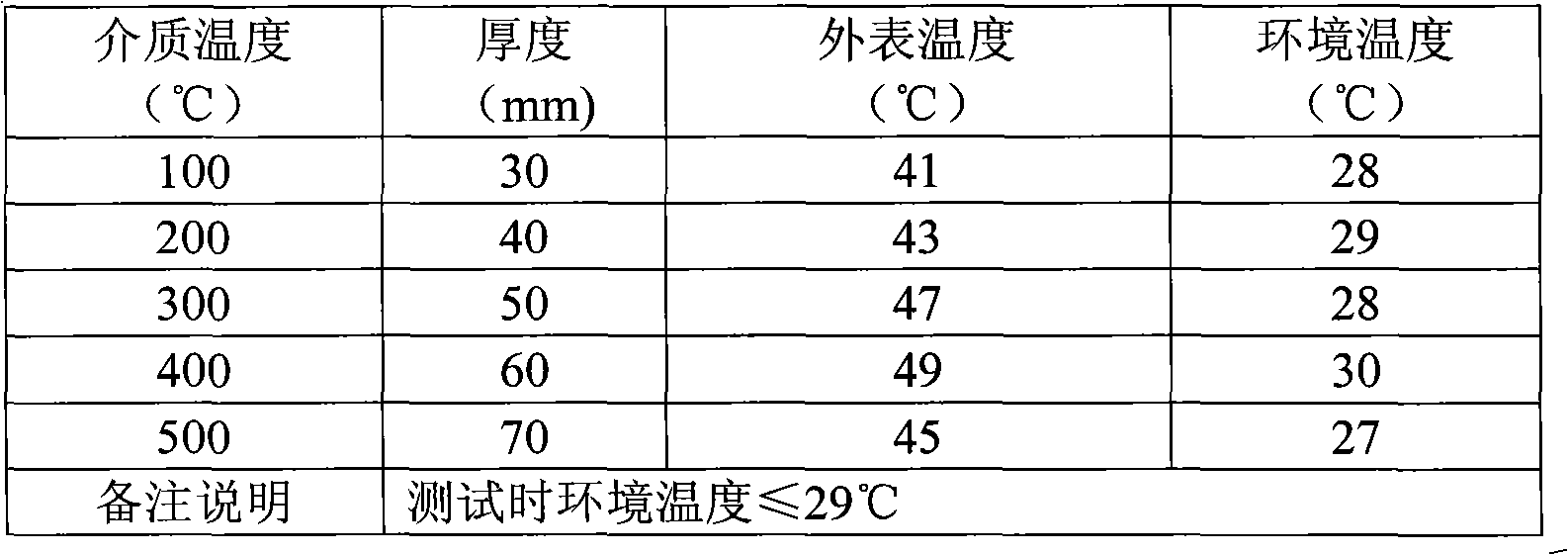

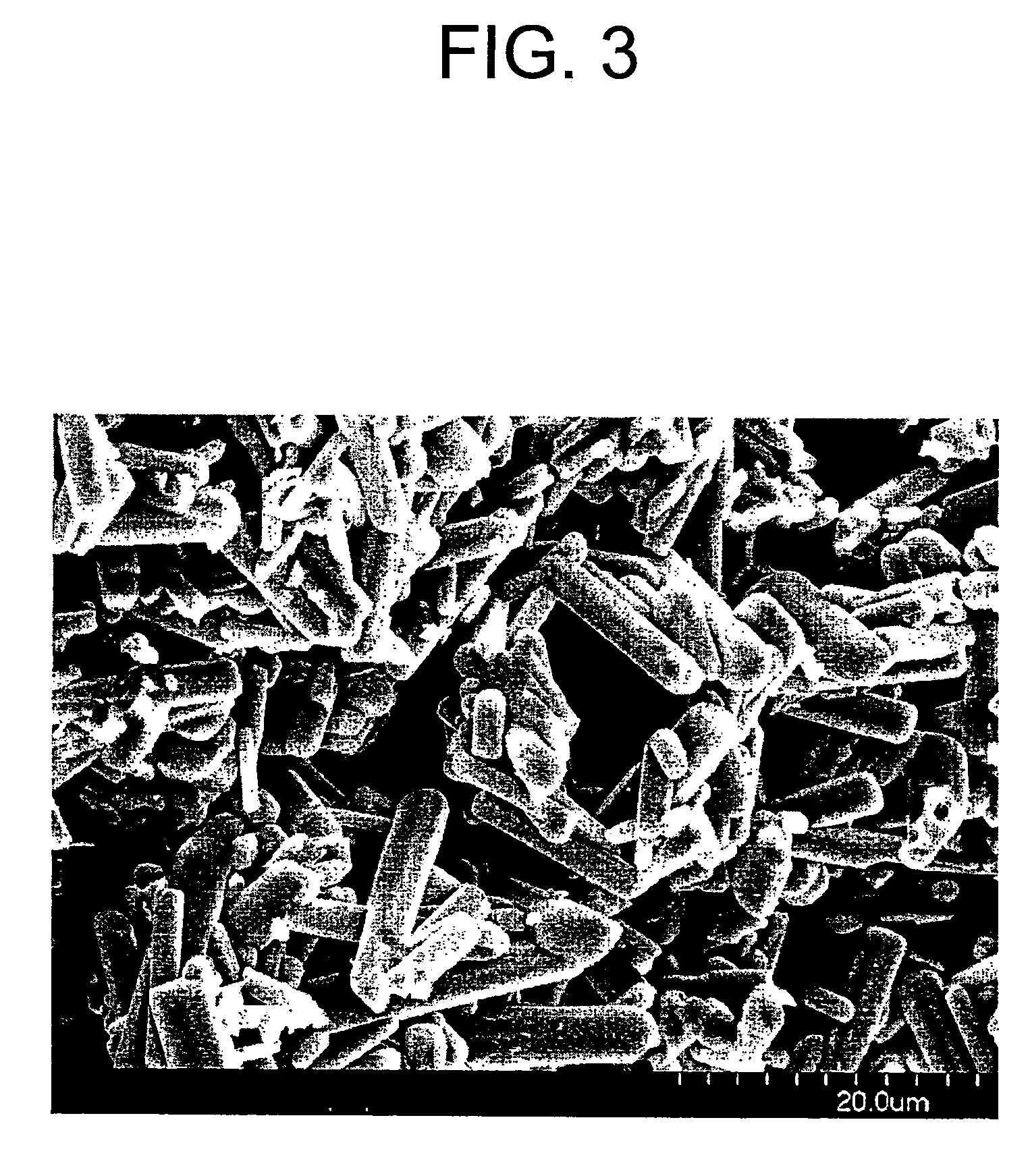

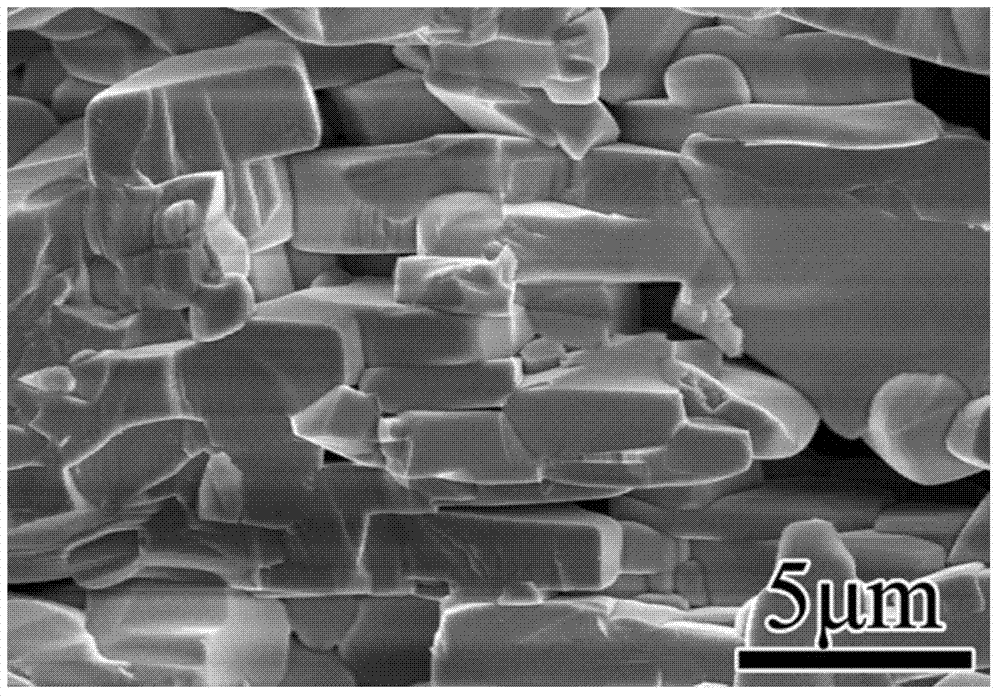

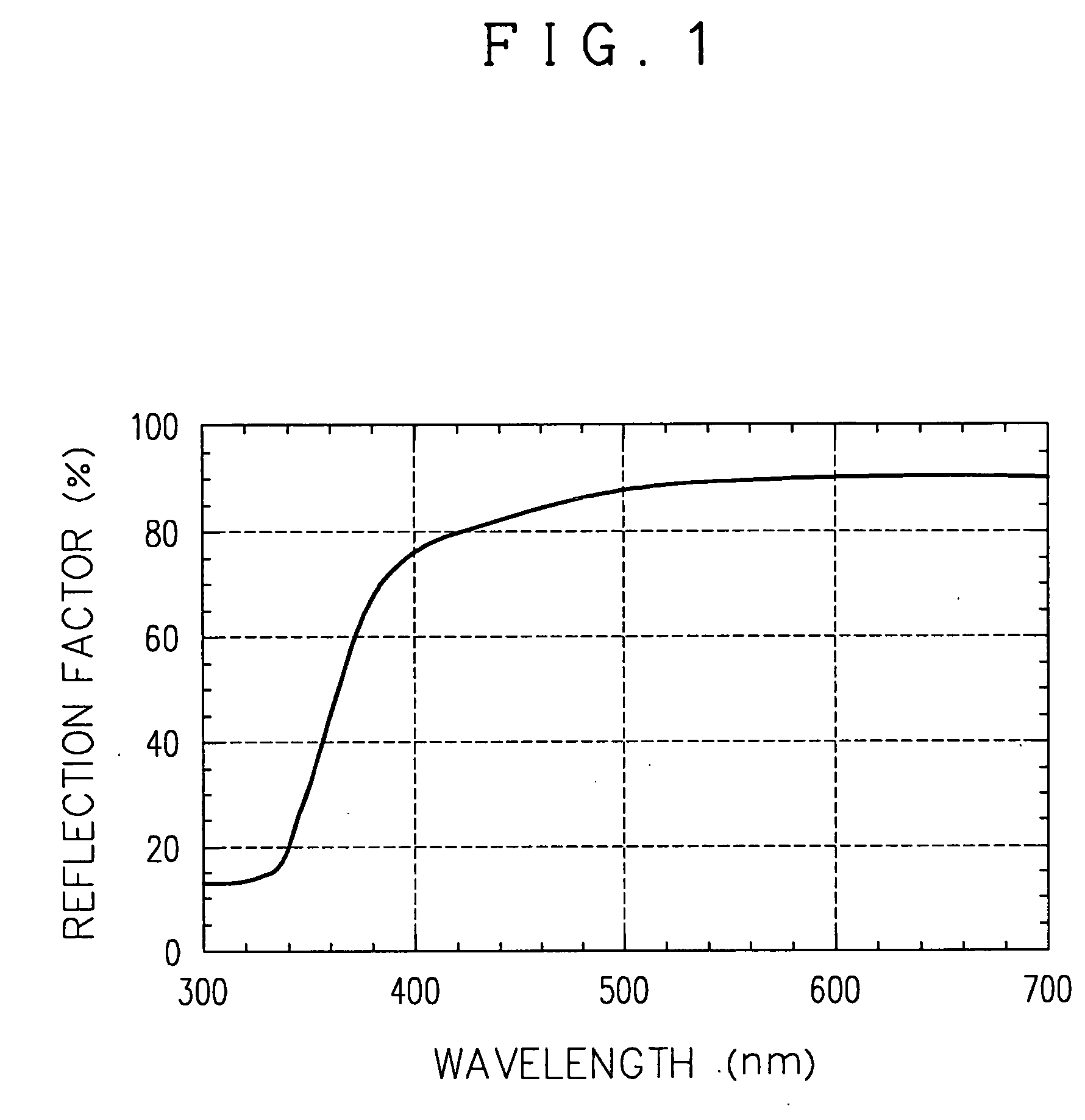

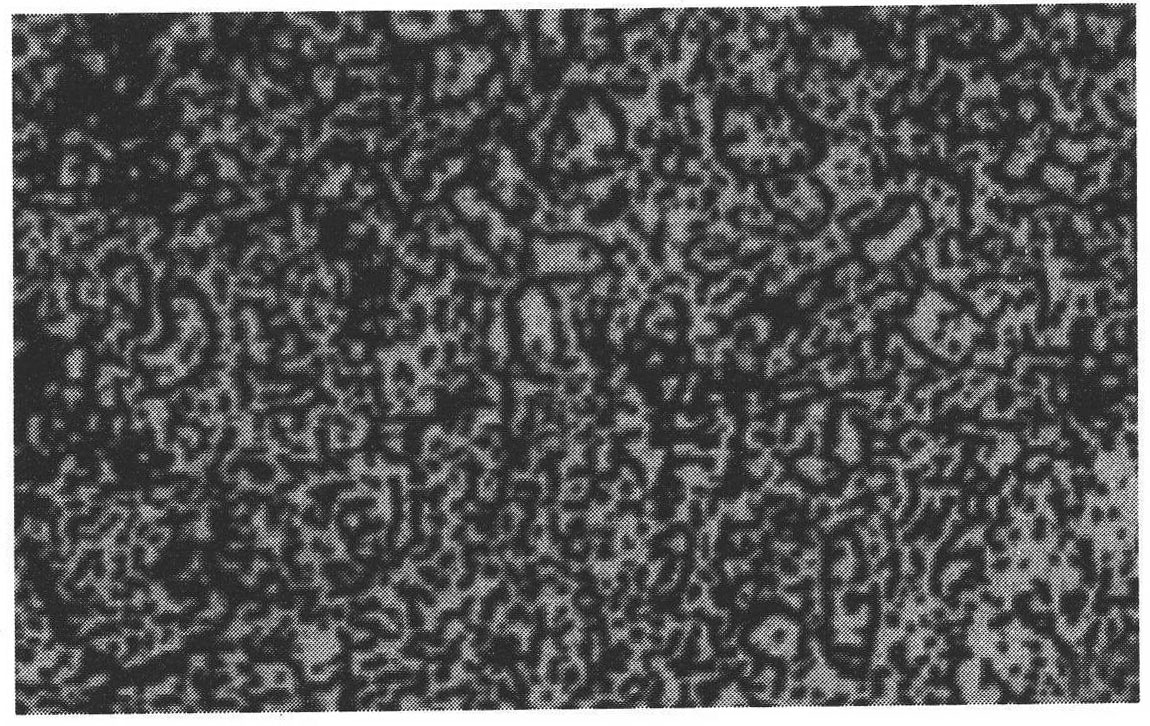

ActiveUS20080249222A1Improve reinforcementNovel shapePigmenting treatmentAlkali titanatesX-rayWear resistance

Potassium titanate is obtained which has a novel configuration, exhibits excellent wear resistance when incorporated in a friction material and shows an excellent reinforcement performance when incorporated in a resin composition. A manufacturing method of the potassium titanate, a friction material using the potassium titanate and a resin composition using the potassium titanate are also obtained. The potassium titanate is represented by K2TinO(2n+1) (n=4.0-11.0) and has the highest X-ray diffraction intensity peak (2θ) in the range of 11.0°-13.5° with its half width being not less than 0.5°.

Owner:OTSUKA CHEM CO LTD

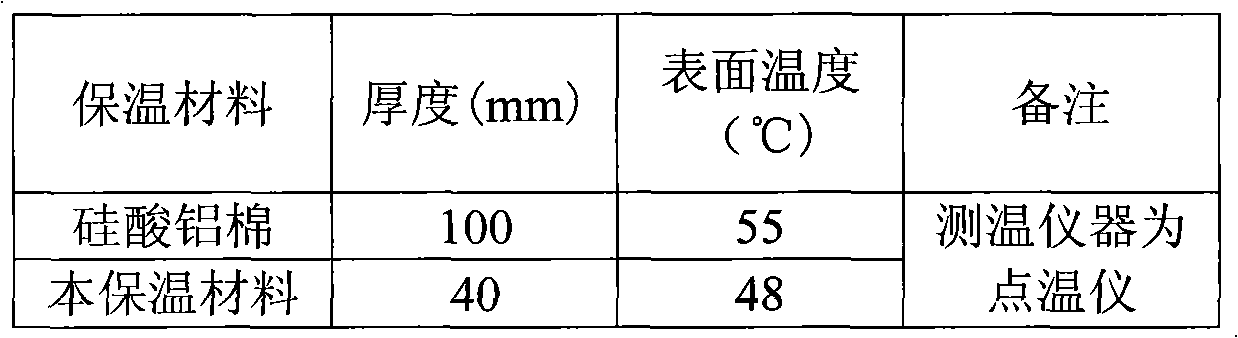

Inorganic heat-insulating material and preparation method thereof

InactiveCN101973750AImprove isolation abilityStrong anti-radiation heat conduction abilitySolid waste managementSodium BentoniteCarbon fibers

The invention relates to an inorganic heat-insulating material and a preparation method thereof. The inorganic heat-insulating material is prepared from the following raw materials in parts by weight: 15-37 parts of basic material, 45-70 percent of pigment and filler and 9-26 parts of auxiliary agent, wherein the basic material comprises the following raw materials in parts by weight: 10-20 partsof phosphoric acid, 3-8 parts of aluminium hydroxide, 2-8 parts of aluminum-silver slurry auxiliary agent, 0.5-5 parts of silicate and 1-5 parts of sodium carboxymethyl cellulose; the pigment and filler is one or a combination of potassium titanate whiskers, expanded perlite, ceramic microspheres, nano-silicon dioxide aerogel, heat-insulating powder, carbon fibers, meerschaum, needle-shaped wollastonite powder and magnesium hydrate; and the auxiliary agent is one or a combination of boron nitride, dichromium trioxide, glass powder, boric acid, nano-zirconia, calcium oxide and calcium-based bentonite. The invention inorganic heat-insulating material has strong insulating capability for solid conductive heat at high temperature (150-500 DEG C) and simultaneously also has strong insulating capability for radiation and flow conductive heat.

Owner:童金荣

Preparation of aluminium titanium carbide intermediate alloy grain refiner in the ultrasonic field

The invention relates to the composition, structure characteristics and preparation method of a new type of aluminum-titanium-carbon master alloy grain refiner and its application to aluminum and aluminum alloy grain refinement methods and effects. The present invention proposes a composition of an aluminum-titanium-carbon master alloy refiner prepared under the action of an ultrasonic field, which is characterized in that the main component of this type of refiner only needs to include aluminum (Al) , Titanium (Ti), carbon (C) without the need for other additional components. The method for preparing an aluminum-titanium-carbon master alloy under the action of an ultrasonic field proposed by the present invention is characterized in that raw materials such as pure aluminum ingot, potassium fluorotitanate, and graphite carbon are prepared according to the pre-designed master alloy composition; The aluminum ingot is melted by internal heating, and then various raw materials are added; ultrasonic waves are added to the melt that starts to react; after the reaction is completed, the temperature is raised, kept warm, left still, and slag is removed, and then cast into ingots or continuously cast and rolled into wire rods, thereby Get the required master alloy refiner with various components and shapes.

Owner:TSINGHUA UNIV

Low-abrasion environment-friendly composite ceramic-based friction material

ActiveCN101619202ANo brake noiseReduce wear rateOther chemical processesFriction liningComposite ceramicBoron nitride

The invention discloses a low-abrasion environment-friendly composite ceramic-based friction material which comprises the following components in percentage by weight: 5 to 7 phenolic resin, 5 to 9 nitrile rubber, 2 to 5 aramid fiber, 2 to 6 silicon carbide, 15 to 20 ceramic fiber, 3 to 5 zirconia, 8 to 10 artificial graphite, 3 to 10 molybdenum disulphide, 5 to 15 zirconium silicate, 1 to 3 aluminum oxide, 8 to 10 potassium titanate whiskers, 5 to 15 precipitated barium sulfate, 1 to 3 magnesium oxide, 1 to 3 petroleum coke, 3 to 5 friction powder, 8 to 10 vermiculite and 4 to 9 boron nitride. The invention has the advantages that the friction material manufactured by using the components and the blending ratio has the advantages of no asbestos and brake noise, low wear rate, stable high-temperature brake performance, stable speed reduction brake, lower cost than the similar imported products, and the like.

Owner:CHONGQING HONGYU FRICTION PROD

Synthesis of titania with high specific surface area

InactiveCN1526474ASimple preparation processLow costCatalyst activation/preparationPotassiumWhiskers

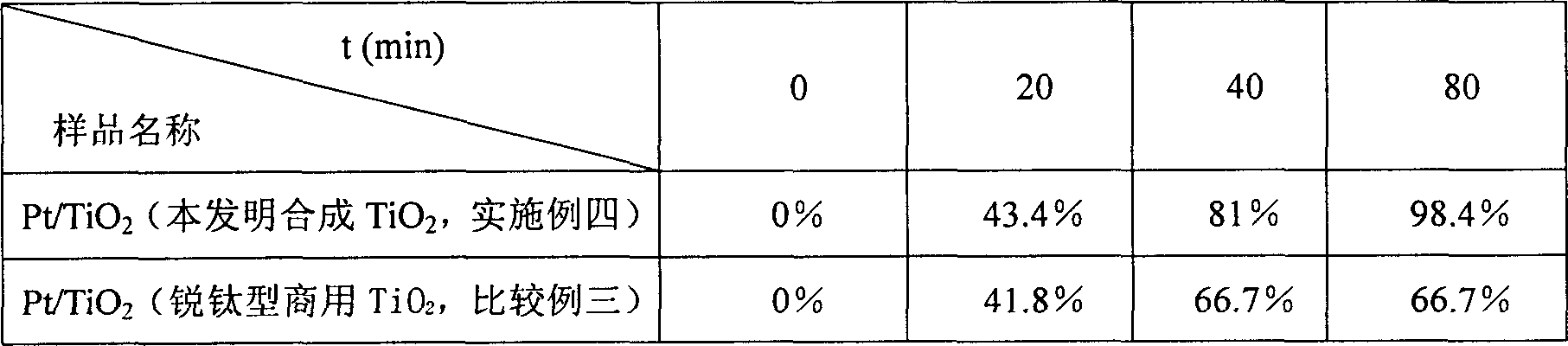

The synthesis of titania with high specific surface area includes sintering titanium compound and potassium compound material to obtain potassium titanate containing potassium dititanate crystal; dispersing the sintering product in water, reactionalkali solution of 1-50 times in pH not less than 8 at 20-100 deg.c for over 4 hr; hydration treatment in acid solution to obtain hydrated product with potassium content less than 5 wt% and specific surface area over 100 sq m / g; heat treatment and crystallization to obtain the titania mixture with excellent photocatalytic activity and specific surface area over 50 sq m / g. The said production process uses no template and is simple and low in cost, and the product is crystal whisker, fiber or grain of diameter or equivalent diameter 0.1-10 micron and may be used as catalyst or catalyst carrier used, especially, in photocatalytic field. It is more easily in separation and recovery than nano level titania.

Owner:NANJING UNIV OF TECH

Efficient composite modifying-refining agent for hypoeutectic cast aluminium-silicon alloy and treatment process

InactiveCN1936044ASimplify the melt handling processImprove performanceStrontium carbonateSilicon alloy

The invention relates to a high efficiency compounded refiner for hypoeutectic aluminum-silicon alloy and the method of application. It contains 10-30wt% NaCl, 10-15wt% KCl, 10-20wt% sodium fluoride, 1-30wt% potassium fluoborate, and 1-20wt% potassium fluotitanate, 1-20wt% strontium carbonate, 1-15wt% cerium fluoride, 5-20wt% granular lanthanum abundant mixed rare earths and 1-5% heachloroethane. After taking the process of heating, dehydrating, mixing according to the ratio to equal, pressing to molding, it could be sealed to use. The technology includes the following steps: after the magnesium alloy melting in crucible, heating to 720-740 degree centigrade and removing the slag, standing for 3-5 minutes, pressing the refiner into alloy liquid to take refining process for 5-10 minutes, standing for 5-10 minutes after process to gain hypoeutectic aluminum-silicon alloy melt. The invention simplifies melt process technology, lowers cost and improves the capability of alloy.

Owner:重庆工学院

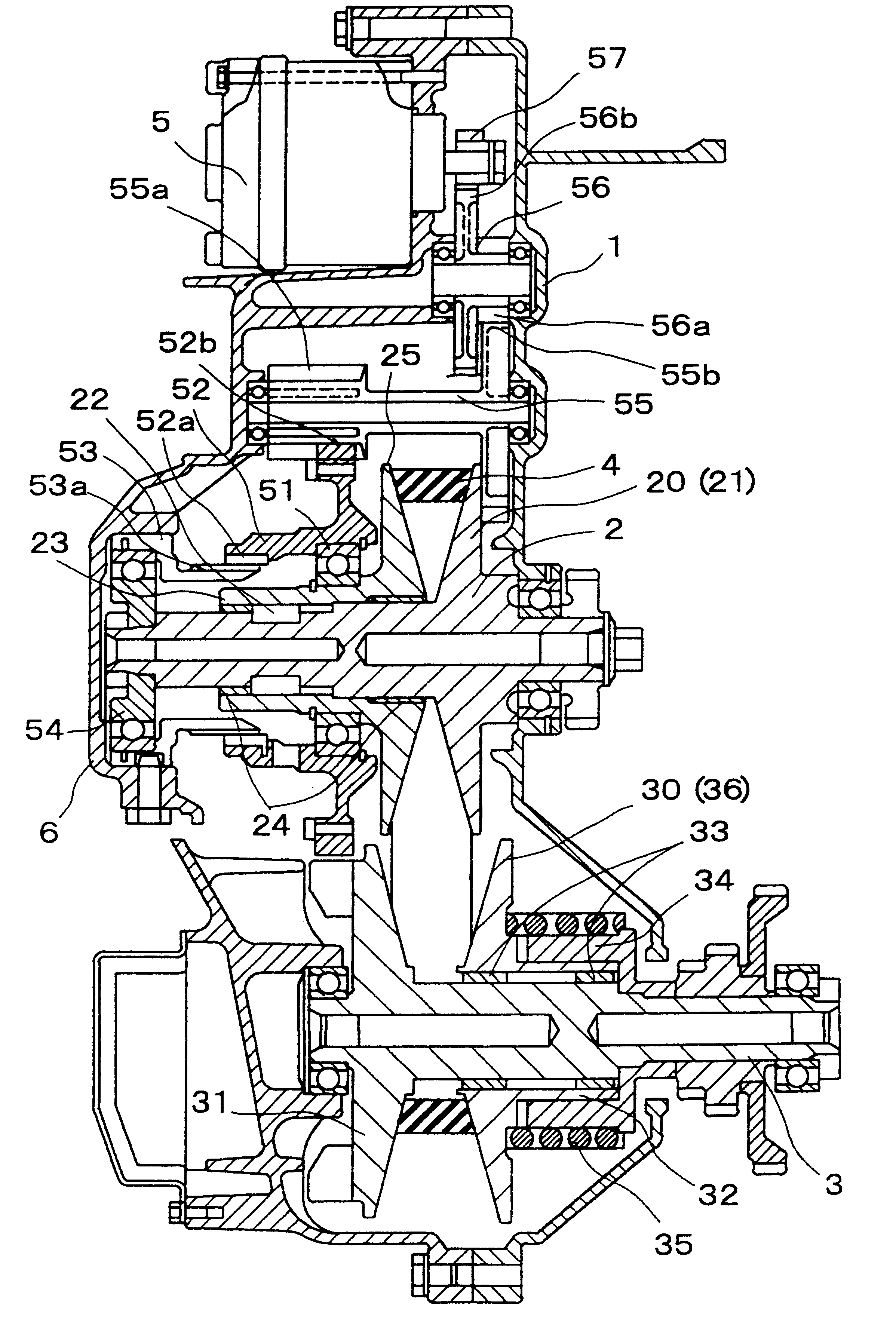

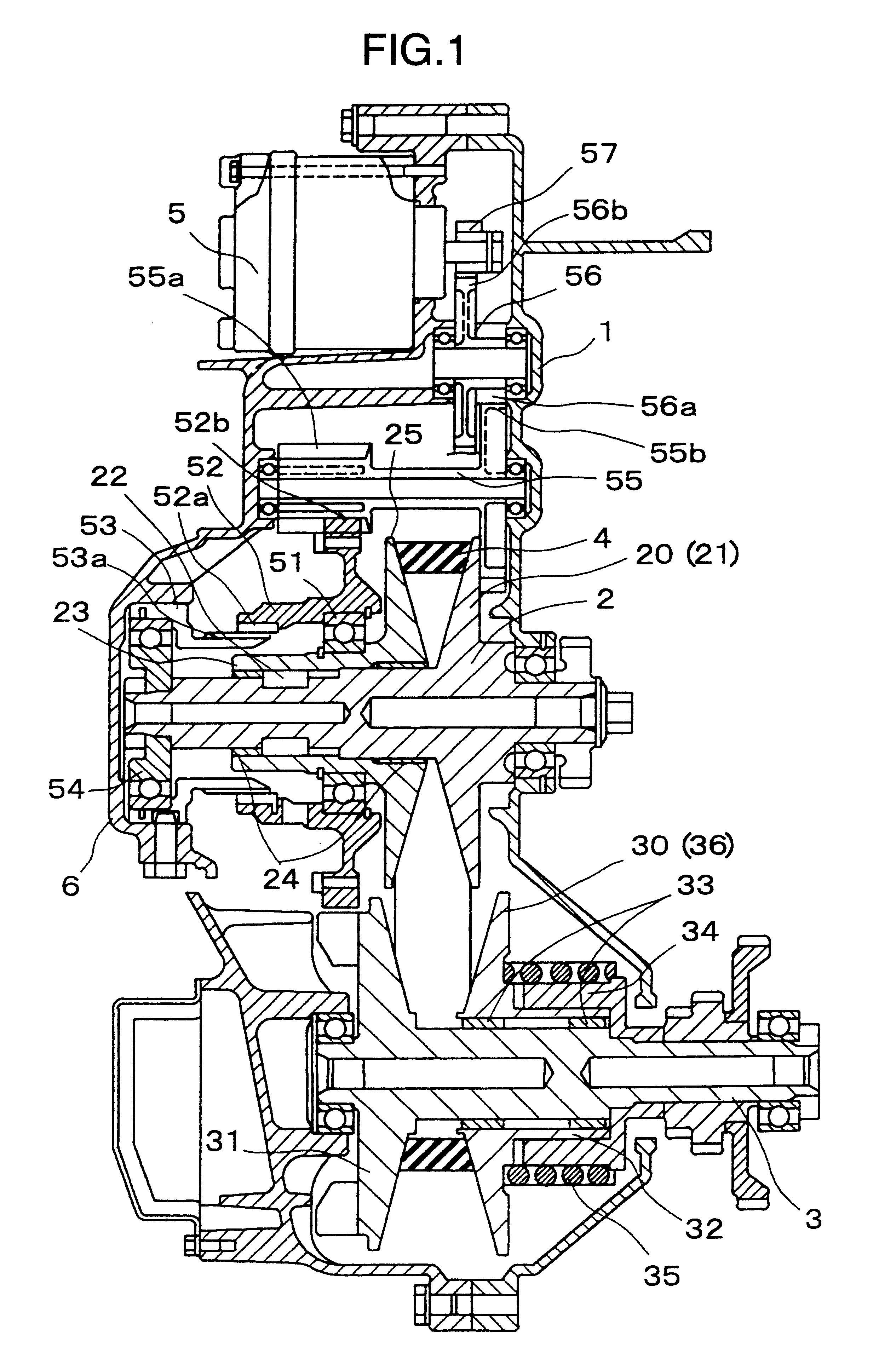

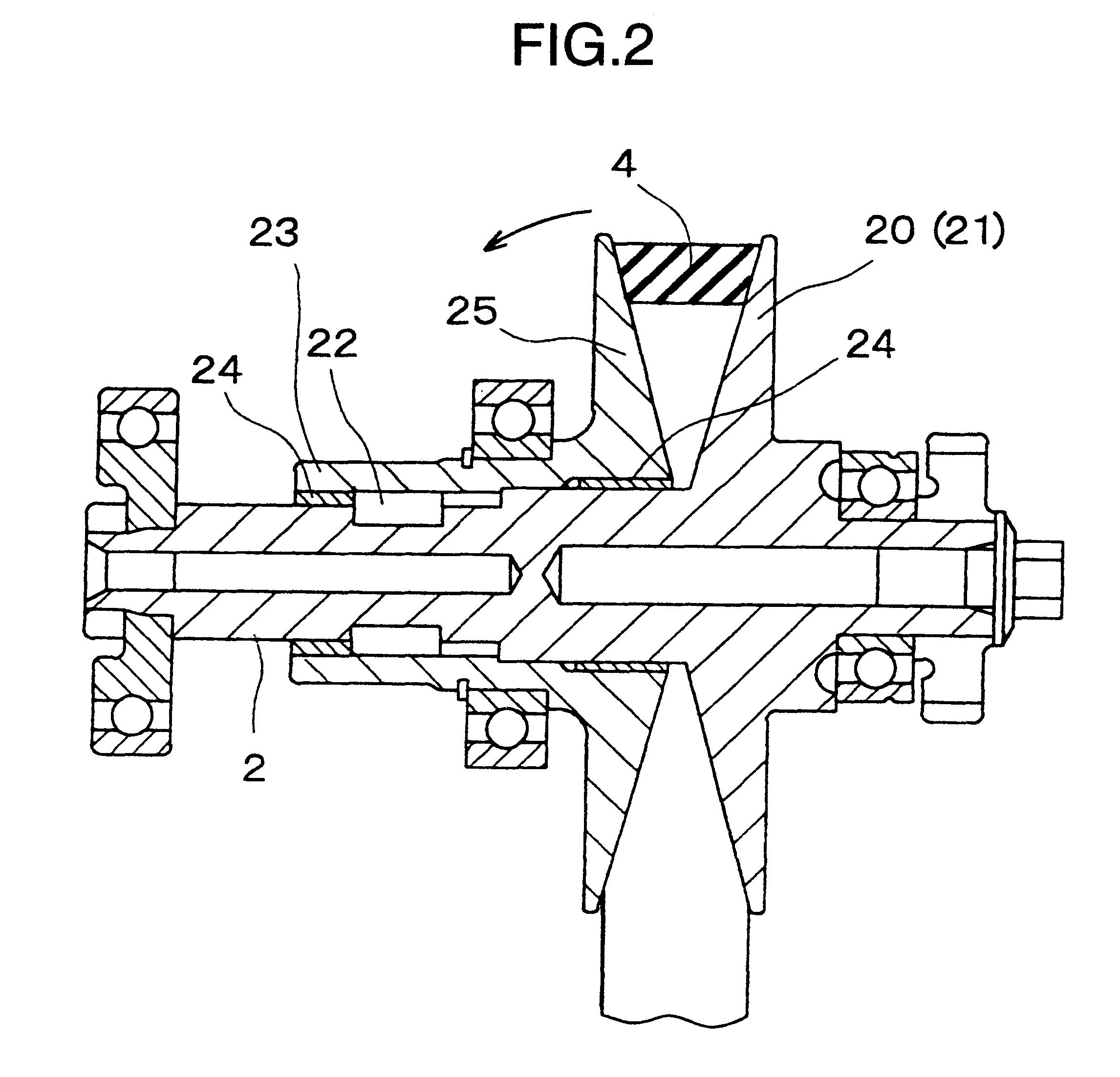

Bearing structure

InactiveUS6183137B1High hardnessImprove wear resistanceGearingPortable liftingPolyether ether ketoneWear resistance

A bearing structure with a low coefficient of friction and a distinguished wear resistance is obtained by coating a shaft with a resin composition comprising PAI and 5 to 50% by weight of PTFE, based on total resin composition and / or coating a bearing with a resin composition comprising PEEK and not more than 50% by weight of PTFE, based on total resin composition. By adding potassium titanate whiskers or a lead compound to the bearing resin composition, more improved coefficient of friction and wear resistance are obtained.

Owner:DAIDO METAL CO LTD +1

Temperature-resistance thermal-insulation heavy-duty anticorrosion coating

InactiveCN102134444AImprove adhesionImprove media resistanceAnti-corrosive paintsEpoxy resin coatingsZinc phosphatePolymer science

The invention relates to the technical field of coating, in particular to temperature-resistance thermal-insulation heavy-duty anticorrosion coating, which comprises the following raw material components in percentage by mass: 10 to 40 percent of epoxy modified organosilicon resin, 5 to 20 percent of novolac epoxy resin, 8 to 20 percent of modified amine curing agent, 2 to 10 percent of flexibilizer, 0.1 to 1 percent of modified polysiloxane flatting agent, 0.01 to 0.1 percent of polysiloxane defoaming agent, 0.1 to 1 percent of polyacrylate dispersant, 4 to 11 percent of zinc phosphate, 4 to 10 percent of barite powder, 3 to 8 percent of titanium white, 0.01 to 0.1 percent of carbon black, 15 to 40 percent of potassium titanate whiskers and 2 to 20 percent of nano porous material. The organosilicon-modified epoxy resin adopted by the invention combines the high performance of epoxy resin and organosilicon resin, and the organosilicon-modified epoxy resin and the novolac epoxy resin compensate for respective defects. The coating has high anticorrosion performance, high high-temperature-resistance performance and high insulating performance, and the adhesion force, medium-resistance performance and thermal-insulation and heat-preservation performance of the coating are improved considerably.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

Friction material

ActiveUS20050014862A1Reduce porosityNot cause deterioration of the fading characteristicsOther chemical processesFriction liningLithiumAlkaline earth metal

In a friction material, columnar or scaly non-whisker-like alkali metal titanate or non-whisker-like alkali metal.alkaline-earth metal titanate having an average particle diameter in the range of 0.1 to 100 μm and an aspect ratio of 3 or less and an inorganic porous filler are compounded, and a friction material in which non-whisker-like lithium.potassium titanate having an average particle diameter in the range of 0.1 to 100 μm and an aspect ratio of 3 or less is compounded.

Owner:AKEBONO BRAKE IND CO LTD

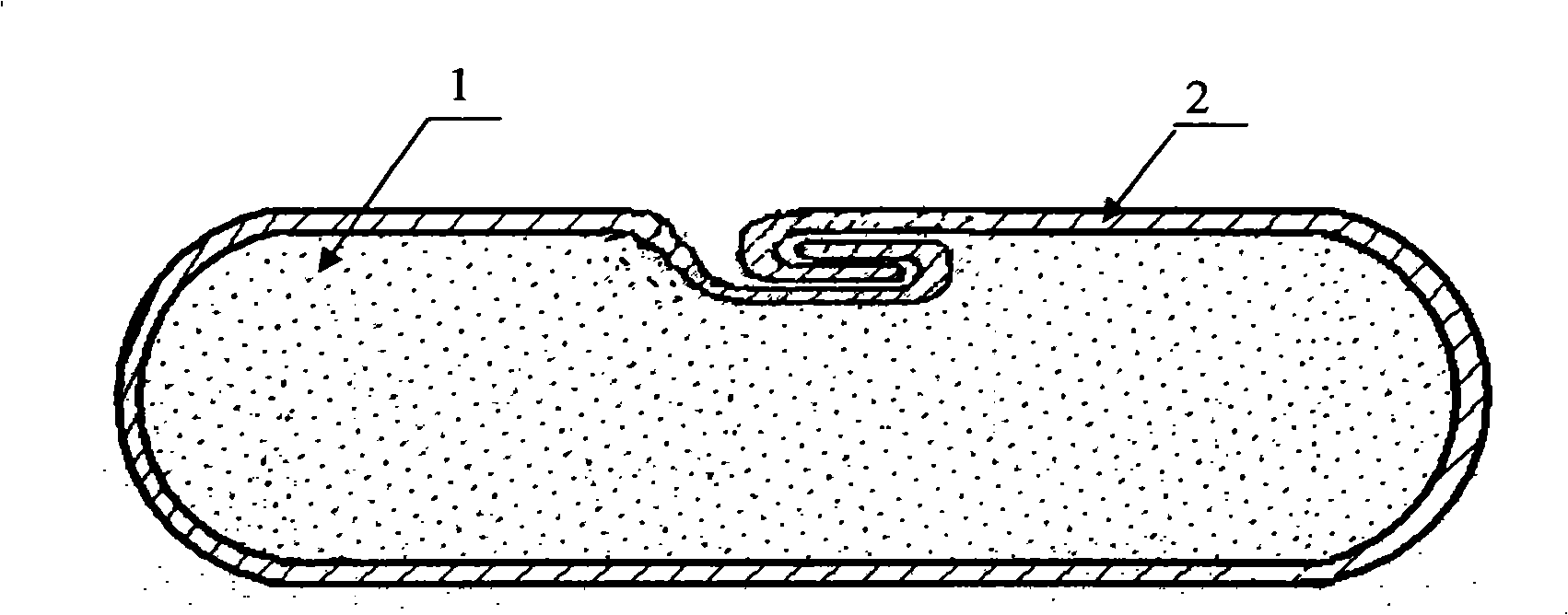

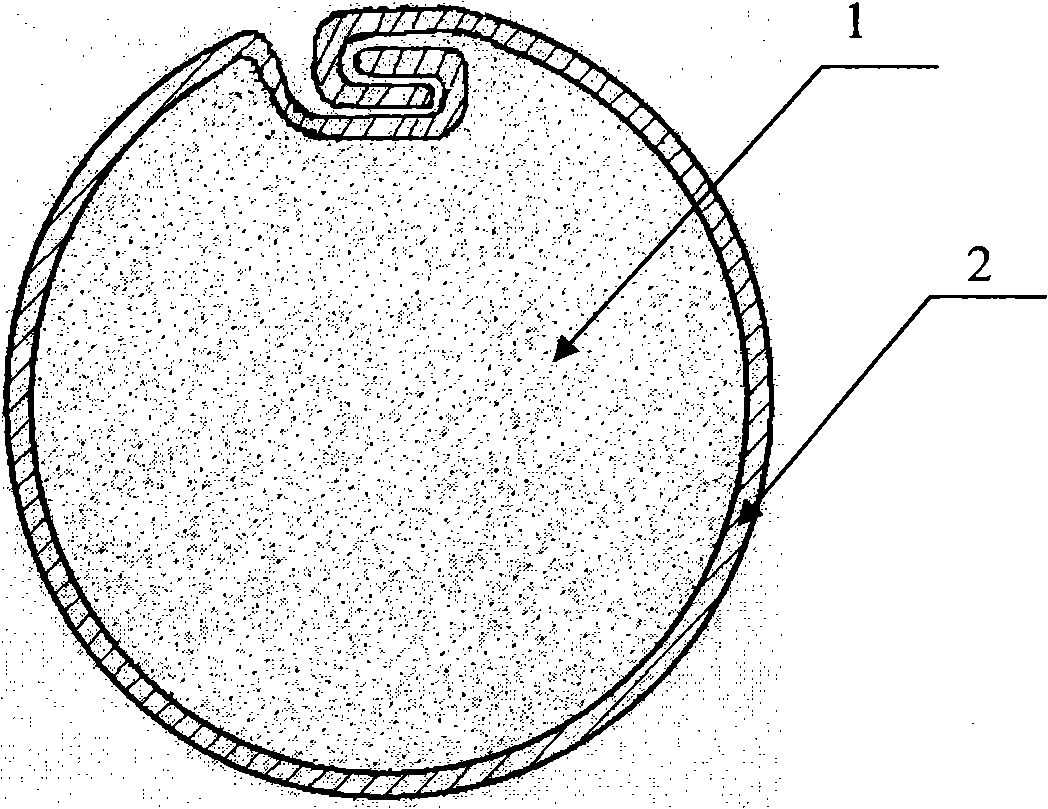

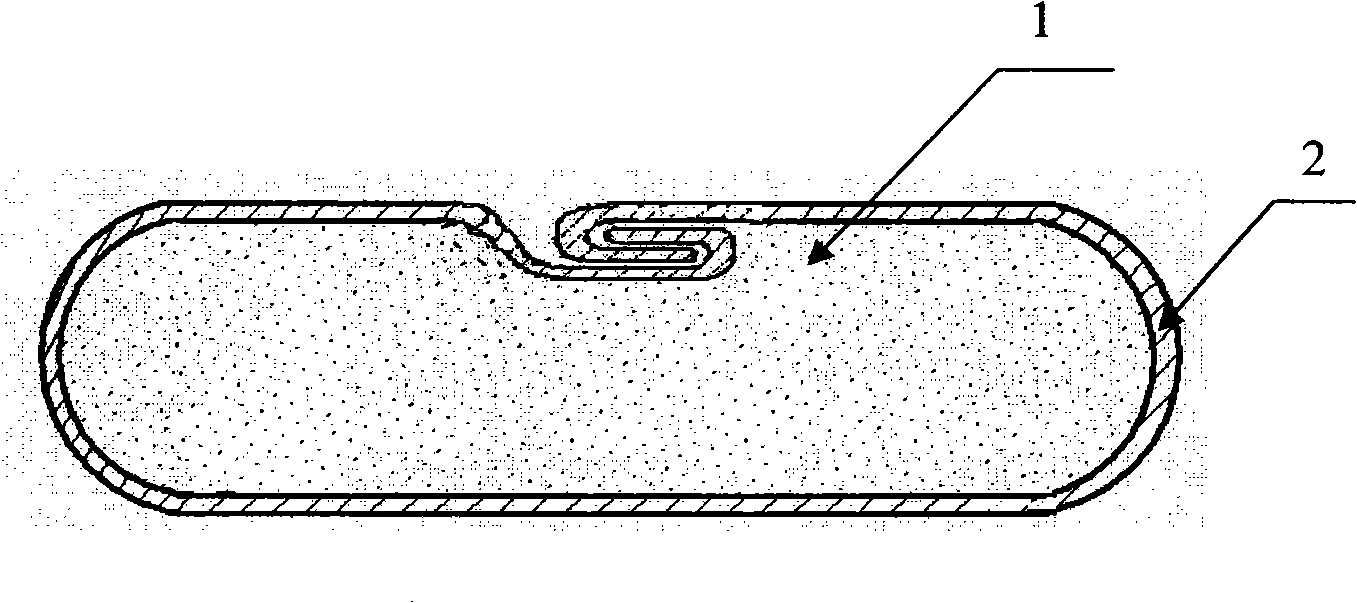

Method of manufacturing alkali metal titanate and hollow body particle thereof, product thereof, and friction material containing the product

ActiveUS20100112350A1Improve braking performanceImproved braking stabilityAlkali titanatesZirconium compoundsPotassiumTitanium

The present invention is to provide a method of manufacturing a potassium titanate adapted for a friction material of a friction slide member. The present invention includes the steps of uniformly mixing an aggregate or a granulation of a titanium compound and a potassium compound with a vibration rod mill to form a mixture and sintering the mixture for reaction one another in order to manufacture a desired potassium titanate with ease and low cost.

Owner:TOHO TITANIUM CO LTD

Method for manufacturing refined high cleanliness Al-Ti-B alloy

The invention relates to a method for manufacturing a refined high cleanliness Al-Ti-B alloy, comprising the following steps of: (1) melting an aluminum ingot, and adding potassium fluotitanate and potassium fluoborate for alloying; (2) pouring a reaction by-product floating on the surface of aluminum liquid, and neutralizing with alumina powder; (3) raising the temperature of the aluminum liquid, and scattering an alumina powder layer; (4) introducing argon or nitrogen with a pipe so that a residue solution coated in the aluminum liquid floats and is neutralized; (5) measuring the hydrogen content after the solution is treated by utilizing a small bubble rotation and degassing refining technology; (6) scattering a special high temperature anti-oxidation covering agent layer in the hot state of more than 800 DEG C; (7) raising the temperature of the aluminum liquid, introducing the aluminum liquid to a filtering box body filled with an alumina ceramic filter, and carrying out online filtering treatment on the alloy aluminum liquid; and (8) finally, reducing the temperature of the aluminum liquid, discarding scruff scum, and molding by casting to produce Al-Ti-B filaments. The method can effectively separate fluoride salt and other impurities in the Al-Ti-B alloy liquid so that the impurities in an Al-Ti-B alloy refining agent are reduced, and the cleanliness is greatly improved.

Owner:HUNAN JINLIANXING SPECIAL MATERIALS CO LTD

Flux-cored steel belt for build-up welding and preparation method thereof

InactiveCN101306493AIncrease varietyIncrease weld widthWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention discloses a resurfacing welding used drug cored steel strap and the preparation method. The steel strap is prepared from a mild steel strap and drug powder enwrapped therein, the shape of the steel strap is a tube with the longitudinal cross-section to be in a long and flat shape or in a similar rectangle shape, the longitudinal length can be determined randomly, and the transverse sides of the steel strap are connected in a seam manner or a related joint manner; the drug powder is uniformly filled in the tube rolled from the steel strap, wherein the particle diameter of the drug powder is smaller than 120 Mum, the components include (by weight) 45-70 parts of high carbon ferrochrome, 5-35 parts of ferrovanadium, 1-8 parts of No.75 ferrosilicon, 1-10 parts of high carbon ferromanganese, 2-16 parts of ferroboron, 1-8 parts of ferrotitanium, 0-5 parts of ferroniobium, 2-8 parts of ferromolybdenum, 0-10 parts of graphite, 0-5 parts of fluorite and 0-6 parts of potassium titanate. The drug cored steel strap adopting the invention can efficiently improve the abrasion resistance of the metal on the resurfacing welding layer and the stability of the electric arc, and can be coiled into coils, thereby being suitable for continuous automatic resurfacing welding.

Owner:SHANDONG UNIV

Tube wire for overlaying welding and preparation thereof

InactiveCN101301709AOvercome the shortcomings of a single ingredientIncrease varietyWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention provides a tubular electrode used for surfacing welding, which is prepared by low-carbon steel band and powder grains wrapped in the low-carbon steel band, wherein, the longitudinal cross-section of the tubular electrode is a long flat shape or rectangle-similar; the powder grains in the pipe have the granularity of 50 meshes; according to the portions by weight, the powder comprises the components as follows: 40-70 portions of high-carbon ferrochrome, 5-30 portions of ferrovanadium, 0-6 portions of 75# ferrosilicon, 1-9 portions of high-carbon ferromanganese, 0-8 portions of aluminium-magnesium alloy, 2-15 portions of ferroboron, 1-6 portions of ferrotitanium, 2-8 portions of ferromolybdenum, 0-8 portions of graphite, 0-5 portions of fluorite and 0-6 portions of potassium titanate; the longitudinal length of the tubular electrode is 300-500mm; one end of the tubular electrode is provided with a flat area with the width of 8-68mm, thickness of 0.5-1.5mm and length of 8-20mm. The tubular electrode of the invention has large surfacing welding seam, beautiful forming and high surfacing welding efficiency, is easier to realize the automatic surfacing welding compared with the conventional electrodes, and can carry out the production of large batches.

Owner:SHANDONG UNIV

Nickel-based welding rod for AC welding

InactiveCN101745758AGood production technologyImprove yieldWelding/cutting media/materialsSoldering mediaSodium BentoniteSlag

The invention relates to the technical field of welding materials, in particular to a nickel-based welding rod for AC welding, the welding rod adopts a high-nickel alloy welding wire which is in line with the requirements of GB / T13814-2008 on ENi1008 ingredients as a welding core, and a drug paper comprises the following components: 40-50% of marble, 2-5% of potassium titanate, 20-28% of fluorite, 2-7% of barium fluoride, 1.5-3% of bentonite, 1-3% of zircon sand, 1-2% of soda ash, 1-3% of metal manganese, 3-7% of ferrosilicon containing 43.0-47.0% of Si, 1-3% of magnesium alloy containing 47-53% of Al and 7-10% of barium carbonate. When in welding, the welding rod can realize stable arc, almost no spatter, good slag detachability and excellent operating performance of the welding rod; and the shape of a weld seam is beautiful, and a wetting angle of the weld seam is moderate.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

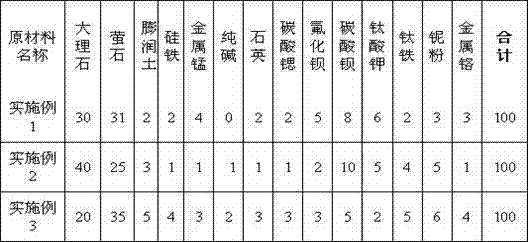

Method for preparing brake block by calcium carbonate crystal whisker

InactiveCN101205456AImprove high temperature resistanceReduce decomposition rateOther chemical processesPorosityDecomposition

The invention relates to a method for preparing a brake sheet through adopting calcium carbonate crystal whisker, belonging to the friction material field, wherein the following raw materials of corresponding part by weight are adopted: 5 to 15 portions of adhesive which adopts phenol formaldehyde resin, 20 to 30 portions of reinforcing material which is obtained through mixing steel fiber or ceramic fiber with one or several of aramid fiber, mineral fiber and glass fiber, 1 to 15 portions of grinding agent which comprises one or combination of several of aluminum sesquioxide, ferric oxide, magnesium oxide and friction powder, 5 to 15 portions of lubricant which comprises one or combination of several of graphite, molybdenum disulfide and mica, 5 to 15 portions of stabilizer calcium carbonate crystal whisker, and 30 to 50 portions of filler which comprises one or combination of several of barium sulfate, potassium titanate and magnesium oxide. The brake sheet, which is made through the method, can effectively increase porosity and improve the high-temperature resistance of material, thereby lowering the decomposition rate of organic material at a high temperature; meanwhile, the brake sheet can slow down the gaseous escape speed on a friction surface during fading, thereby reducing fading rate and the change rate of friction coefficient at high speed to less than 10 percent.

Owner:信义集团公司

Micro slag gas protection flux-cored wire suitable for electric arc additive manufacturing of die

ActiveCN106077992ANo flowWell formedArc welding apparatusWelding/cutting media/materialsLiquid metalMagnesite

The invention relates to a micro slag gas protection flux-cored wire suitable for electric arc additive manufacturing of a die. The flux-cored wire is formed by wrapping a powder core with a steel strip and comprises a component A, a component B and a component C. The component A comprises, by weight, 30-45% of rutile, 4-7% of cryolite, 8-14% of fluorite, 10-20% of marble, 8-14% of magnesite, 8-14% of potassium titanate and 10-22% of albite. The component B comprises, by weight, 5-20% of aluminum magnesium alloy, 5-15% of ferrotitanium, 26-40% of nickel, 8-20% of molybdenum, 12-24% of chrome, 10-18% of 45# silicon iron and 10-28% of manganese. The component C is composed of iron powder and impurities. After the flux-cored wire is welded, a micro amount of molten slag is formed and thinly and uniformly covers the surface of deposited metal, the molten slag cocks and falls off automatically after cooling, and multilayer welding can be achieved without slag removing; and in addition, weld spatter hardly appears, electric arcs are stable, molten metal does not flow, the appearance is attractive, excellent welding technological performance is achieved, and the deposited metal has good comprehensive mechanical performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Double-phase stainless steel electric welding bar

InactiveCN101817123AHigh strengthGood formabilityWelding/cutting media/materialsSoldering mediaArc stabilityElectrolysis

The invention discloses a double-phase stainless steel electric welding bar, and relates to the stainless steel electric welding field of electric arc welding. The invention provides a novel titanium-calcium type double-phase stainless steel electric welding bar, which has good welding performance such as little splash, low cost, good slag removal performance and the like. The electric welding bar is characterized in that: according to the coating formula, the electric welding bar comprises the following components in part by weight: 35 to 38 parts of rutile, 8 to 10 parts of natural mica, 1 to 2 parts of potassium titanate, 5 to 7 parts of marble, 10 to 12 parts of iron powder, 1 to 2 parts of bentonite, 2 to 3 parts of electrolytic manganese, 3 to 5 parts of fluorite, 1 to 2 parts of potassium feldspar, 1 to 2 parts of sodium alginate, 2 to 3 parts of chromium nitride, 20 to 24 parts of chromium metal, 8 to 10 parts of ferromolybdenum, 2 to 4 parts of magnesite, 2 to 4 parts of nickel powder and 1 part of Teflon. The welding process performance of the stainless steel welding bar is improved, and particularly the application range of the stainless steel welding bar is enlarged during welding, so the double-phase stainless steel electric welding bar has good welding performance such as good electric arc stability, little splash, low cost, good slag removal performance and the like.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

Preparation method for potassium titanate crystal whisker

The preparation process of potassium titanate crystal whisker belongs to the field of new material technology. The potassium titanate crystal whisker is prepared with technological pure potassium compound and titanium compound powder material and fluoride as the crystal whisker growth promoter, and through high temperature solid phase reaction in a sealed ceramic crucible. The potassium titanate crystal whisker has low cost and excellent performance, and the preparation process is simple and suitable for industrial production.

Owner:SHANDONG UNIV

Method for preparing brake block by calcium sulfate crystal whisker

InactiveCN101177601AEasy to compressImproved high-temperature heat-fading propertiesOther chemical processesFriction liningAdhesiveAramid

The invention relates to a method of using calcium sulfate whisker in the friction material field to prepare a brake block. The technical proposal of the invention consists of the following materials by weight: 5-18 portions of adhesive which is produced by employing modified phenolic resin; 20-40 portions of strengthening materials which are mixed by one or several of calcium sulfate whisker and one of aramid fiber, steel fiber, ceramic fiber and mineral fiber and glass fiber; 1-15 portions of grinding agent which is compounded by one or several of aluminum oxide , ferric oxide and magnesium oxide; 5-15 portions of lubricant which is compounded by one or several graphite, molybdenum disulfide and mica; and 10-30 portions of fillers which are compounded by one or several barium sulfate, potassium titanate and vermiculite powder. The brake block prepared by the method is able to lower the thermal fading of organics caused by thermal decomposition under high temperature, and has stable friction coefficient; when in use, the brake block has comfortable brake, being quiet, small abrasion and more than 70,000 kilometers of service life.

Owner:信义集团公司

Hard polychloroethylene tube and its prodn. method

InactiveCN1831041AImprove stabilityWith high temperature sound absorptionTubular articlesPolyvinyl chlorideWhiskers

Owner:上海正鸣塑胶管业有限公司

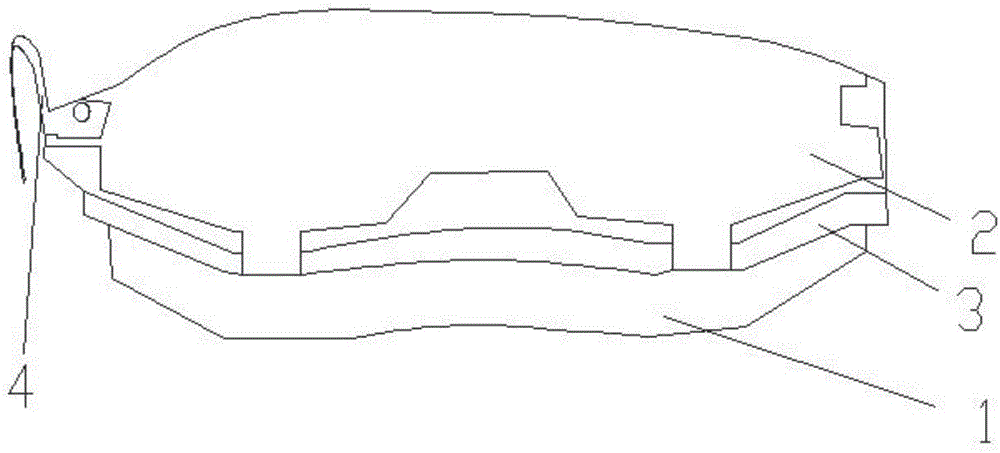

Rice and wheat straw active carbon powder artificial graphite friction material brake pad and manufacturing method thereof

ActiveCN104696399AImprove toughnessStable coefficient of frictionOther chemical processesFriction liningPollutionIron ore

The invention discloses a rice and wheat straw active carbon powder artificial graphite friction material brake pad and a manufacturing method thereof. The brake pad comprises a friction material, a noise elimination sheet, a steel back and an accessory, wherein the friction material comprises the following components: 25 parts of rice straw composite fibers, 6 parts of phenolic modified resin, 10 parts of wollastonite, 5 parts of potassium titanate whiskers, 0.5 parts of iron pyrite, 0.5 parts of carbon black, 1 part of aluminum oxide, 7 parts of 40-mesh brass powder, 15 parts of rice and wheat straw active carbon powder, 5 parts of secondary reduced iron powder and 25 parts of rice and wheat straw active carbon powder artificial graphite; the friction material is adhered on the steel back; the noise elimination sheet is mounted on the surface of the steel back; the accessory is riveted on the steel back. The prepared rice and wheat straw active carbon powder artificial graphite friction material enhances the toughness of the brake pad, improves the performance and the braking effect of the brake pad, guarantees stable friction coefficient of the brake pad, reduces frictional noise, is environment-friendly and pollution-free, and expands the utilization channel of rice and wheat straws.

Owner:JIANGSU JINMAISUI NEW ENERGY TECH

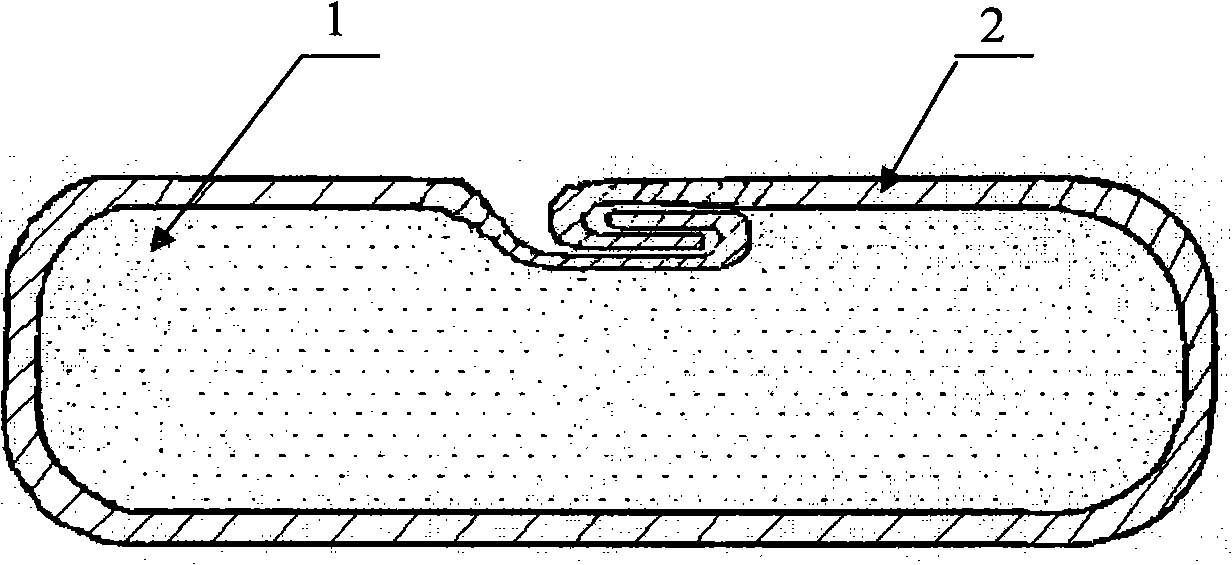

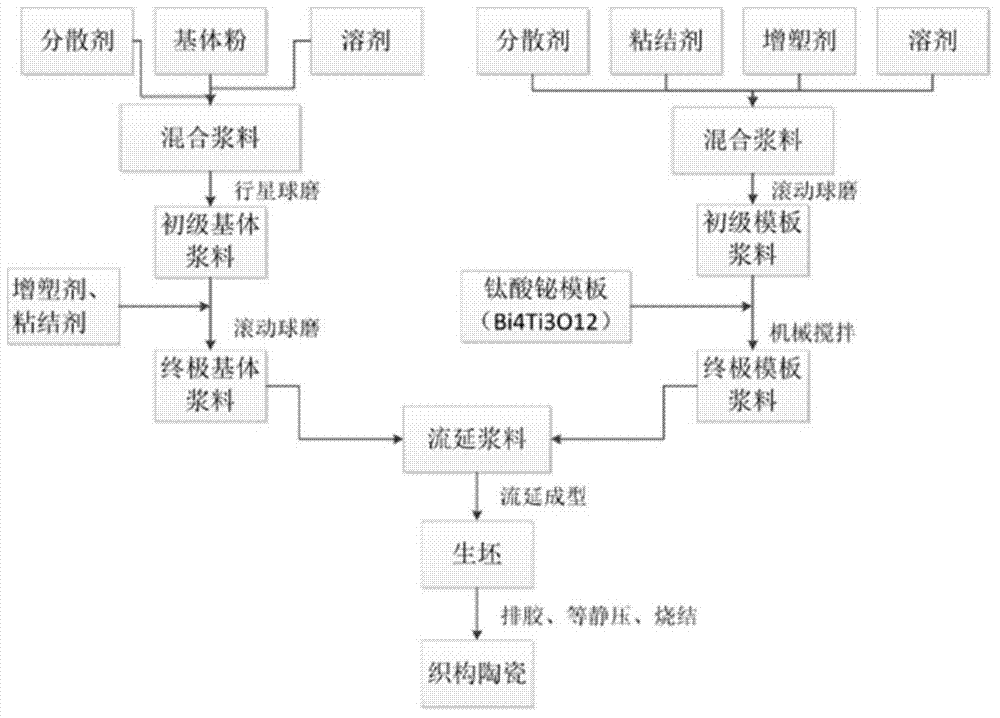

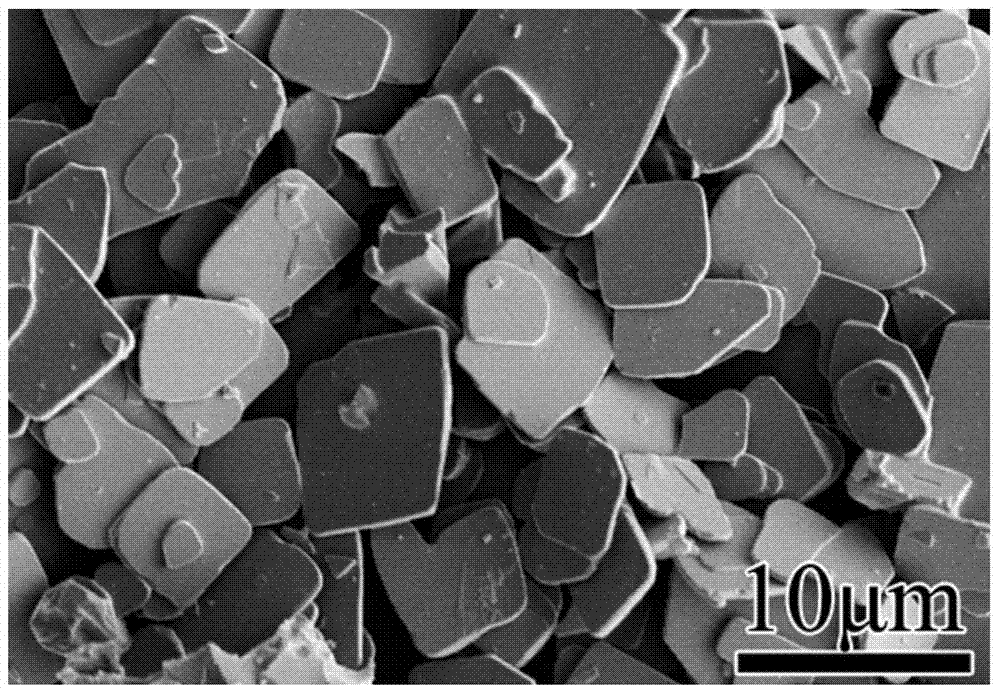

Sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and preparation method thereof

InactiveCN103613382AExcellent piezoelectric propertiesThe original composition does not changeBarium titanatePotassium

The invention provides sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and a preparation method thereof. The preparation method comprises the following steps: mixing a template with organic additives such as matrix powder, an organic solvent and a binder to obtain slurry by taking a Bi4Ti3O12 crystal as the template; preparing the slurry into a film sheet with thickness of 30 mu m-60 mu m through a curtain coating process; and sintering the film sheet after laminating, cutting, rubber exhausting and isostatic cool pressing to prepare a BNBK texture ceramic material with high oriented growth, wherein original components of the materials are not changed due to precise control in the process. The prepared sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic constitutes a (1-x-y)Na0.5Bi0.5TiO3-xBaTiO3-Yk0.5Bi0.5TiO3 ternary system, has good crystalline grain orientation effect, excellent performances in the lead-free piezoelectric field, a piezoelectric constant of over 210 pC / N and a Curie temperature of over 320 DEG C.

Owner:TIANJIN UNIV

Friction material composition for high-performance brake pad

ActiveCN103059807AHigh strengthImprove wear resistanceOther chemical processesFriction liningGas phaseCellulose fiber

The invention relates to a friction material composition for a high-performance brake pad, which is prepared from the following components in percentage by weight: 10-15% of ceramic fiber, 6-8% of aramid fiber pulp, 8-10% of copper powder, 3-5% of wollastonite fiber, 1.2-2.5% of flaky potassium titanate, 6-8% of cellulose fiber, 5-8% of zirconium silicate, 8-10% of vermiculite powder, 1-3% of magnesium hydroxide, 1-3% of aluminum hydroxide, 0.8-1.5% of gas-phase silicon dioxide, 6-10% of barite, 6-8% of titanium white, 5-7% of stannic sulfide, 4-5% of calcined petroleum coke, 6-8% of expanded graphite, 1-2% of nitrile-butadiene rubber and 6-10% of phenolic resin. The brake pad produced according to the formula has favorable strength and excellent wear resistance, and the integral friction factor of the brake pad is enhanced, so that the entire car has better braking performance in the high-speed traveling process and still has favorable heat face resistance after continuous braking; and the brake pad has the advantages of stable high-temperature braking performance and long service life.

Owner:摩擦一号制动科技(仙桃)有限公司

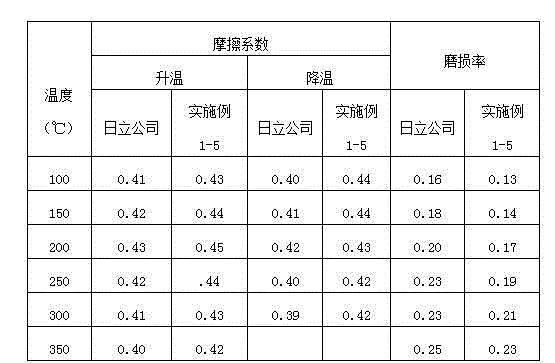

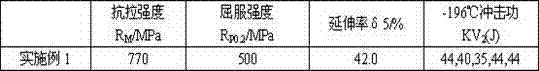

Nickel base welding rod of Ni-Cr-Mo alloy system

InactiveCN102962603AHigh strengthImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaNiobiumFerrosilicon

The invention introduces a nickel base welding rod of a Ni-Cr-Mo alloy system. The nickel base welding rod comprises a core wire and a coating and is characterized in that the core wire is an ERNiCrMo-3 core wire; and the coating comprises 20-40% of marble, 25-35% of fluorite, 2-5% of bentonite, 1-4% of ferrosilicon, 1-4% of manganese metal, 0-2% of sodium carbonate, 1-3% of quartz, 1-3% of strontium carbonate, 2-5% of barium fluoride, 5-10% of barium carbonate, 2-6% of potassium titanate, 2-5% of ferrotitanium, 3-6% of niobium powder and 1-4% of chromium metal. The nickel base welding rod produced by the invention is relatively high in strength, has deposited metal tensile strength which is up to more than 760MPa, is better in low-temperature impact toughness, has an impact powder average value of more than 40J at minus 196 DEG C, and is favorable in welding technological efficiency, stable in arcing during welding, easy in operation, good in formation of welding seams, convenient in deslagging, simple in production process and lower in cost.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

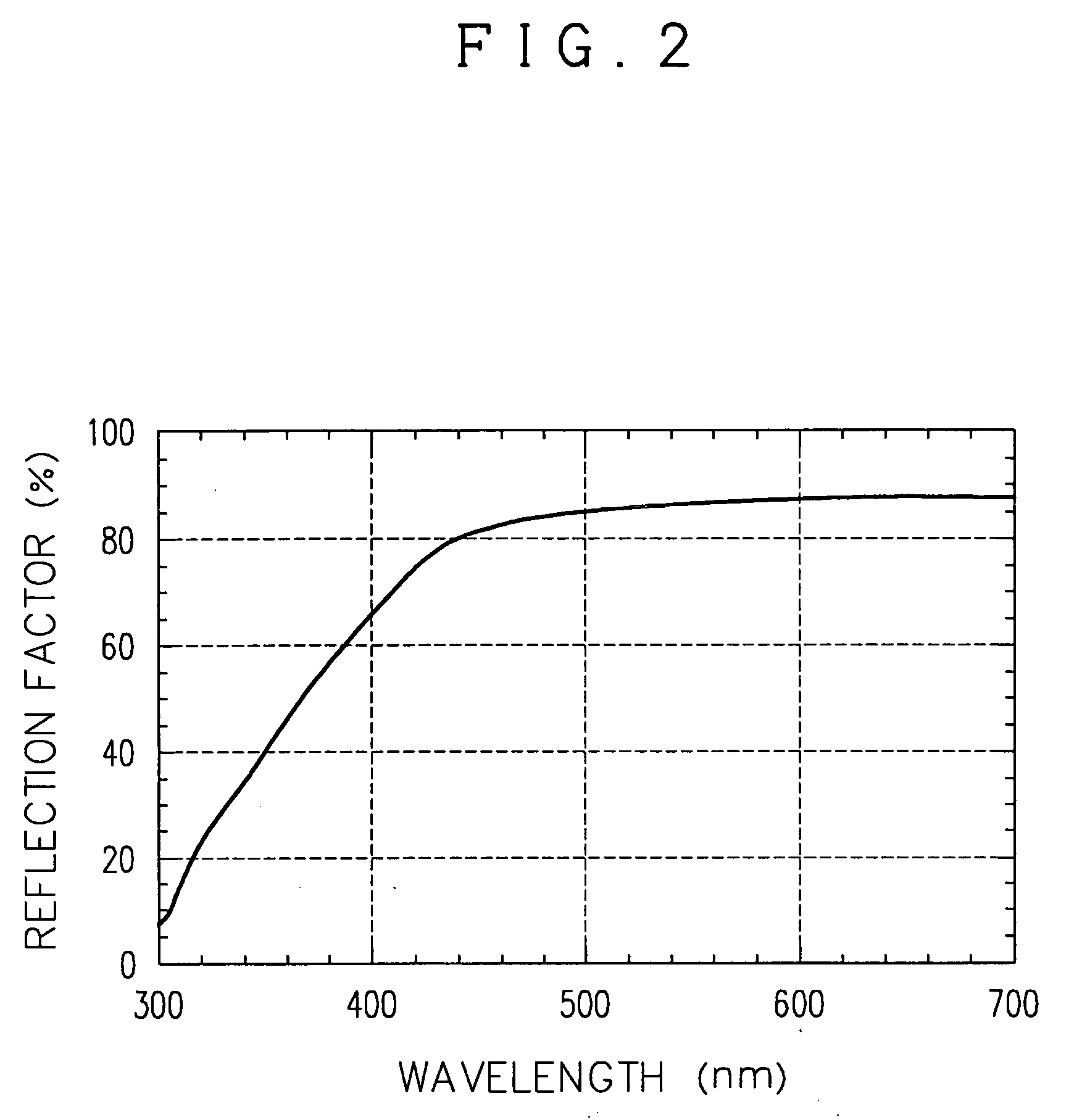

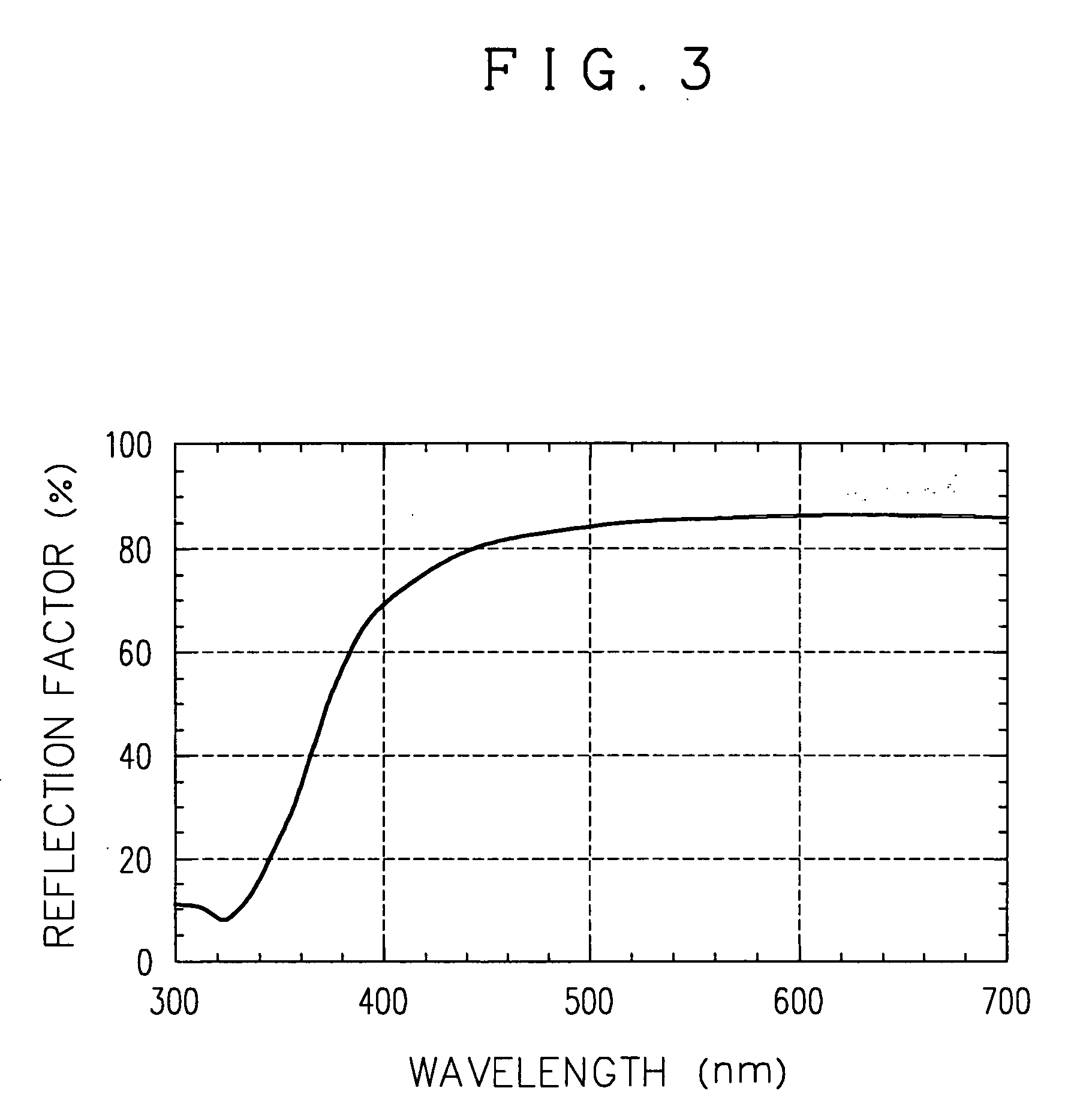

Resin composition for reflecting plate

The present invention relates to a resin composition for reflector plates containing 30 to 95% by weight of a semi-aromatic polyamide having the ratio of aromatic monomers to all the monomer components being 20% by mole or more, and 5 to 70% by weight of potassium titanate fiber and / or wollastonite. Additionally, the present invention relates to a resin composition for reflector plates used for an ultraviolet-ray generating source, comprising a thermoplastic resin and at least one inorganic compound selected from the group consisting of fibrous and flaky inorganic compounds capable of reflecting ultraviolet rays as well as visible light.

Owner:OTSUKA CHEM CO LTD

Al-Ti-B-rare earth(RE) grain refiner and preparation method thereof

The invention relates to an Al-Ti-B-RE grain refiner and a preparation method thereof. The Al-Ti-B-RE grain refiner is used for Al-Mg-Si alloy, and is characterized by containing the following components in percentage by weight: 6.9 to 7.9 percent of Ti, 1.31 to 1.75 percent of B and 1.5 to 2.0 percent of mixed RE. The mixed RE is cerium-enriched rare earth. The preparation method of the cerium-enriched rare earth comprises: mixing the raw materials according to a weight part ratio, wherein the mixing time is controlled to be 3 to 4 hours; heating an aluminum ingot in a medium frequency induction furnace to an overhigh temperature of 700 to 750 DEG C; filling a mixed pressed block of potassium fluotitanate and potassium fluoborate and cerium-enriched rare earth into a graphite bell jar; clamping the reversed bell jar by using forceps, and pressing the bell jar into the lower middle part of aluminum melt; raising the furnace temperature to 800 to 850 DEG C, and magnetically stirring for 25 to 30 minutes with the induction furnace; after reaction, taking the graphite bell jar out; standing and keeping the temperature for 20 minutes; forcefully stirring the melt once with an artificial graphite rod every 3 minutes, and stirring for more than five times; treating molten alloy; standing and keeping temperature for 15 to 20 minutes; and performing secondary slagging off.

Owner:HUANGGANG HUAER ALUMINUM ALLOY

Thin ceramic coating and production method thereof

InactiveCN101445677AWith qualityHigh temperature resistantFireproof paintsHigh densityCeramic coating

The invention provides a thin ceramic coating and a production method thereof, belonging to the field of functional coatings, in particular to the filed of high temperature resistant coatings. The thin ceramic coating is realized mainly through materials such as water dispersive nanometer alumina, pigments, fillers, potassium titanate whisker, methyl trimethoxysilane and the like. The coating produced by the invention has the qualities of an enamel surface, is complete harmless to a human body, and has the advantages of burning resistance, high temperature resistance, high hardness, high density, and good weatherability.

Owner:上海瓷龙贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com