Rice and wheat straw active carbon powder artificial graphite friction material brake pad and manufacturing method thereof

A technology of activated carbon powder, rice and wheat straw, applied in friction linings, chemical instruments and methods, other chemical processes, etc., can solve problems such as pollution, waste of resources and the environment, and achieve noise reduction, friction coefficient stability, performance improvement and manufacturing. effect of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] A method for manufacturing a brake pad made of rice and wheat straw activated carbon powder artificial graphite friction material, comprising the following steps:

[0041] Step 1. Mixing: Stir the material for friction material 1 in a high-speed mixer for 30 minutes. The mixed material contains the following ingredients: 25 parts of rice straw composite fiber, 6 parts of phenolic modified resin, 10 parts of silica fume cotton 5 parts of potassium titanate whiskers, 0.5 parts of pyrite, 0.5 parts of carbon black, 1 part of alumina, 7 parts of 40 mesh brass powder, 15 parts of rice straw activated carbon powder, 5 parts of secondary reduced iron powder, Rice and wheat straw activated carbon powder 25 parts of artificial graphite; all materials are fully fused and released into barrels;

[0042] Step 2. Degreasing the steel back: remove the oil and rust on the steel back of the brake pad;

[0043] Step 3. Glue compounding: Dilute the special glue for steel back with alcoh...

Embodiment 3

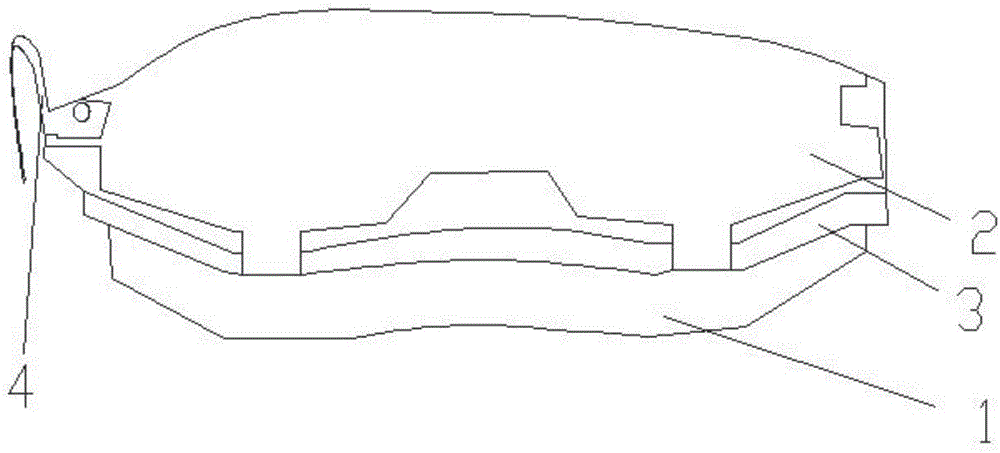

[0055] The prepared brake pads include a friction material 1, a sound-absorbing sheet 2, a steel back 3 and an accessory 4, the friction material 1 is pasted on the steel back 3, the sound-absorbing sheet 2 is installed on the back of the steel back 3, and the steel back Attachment 4 is riveted on the 3, powder spraying or paint is sprayed on the steel back 3, and code spraying is also sprayed on the steel back 3.

[0056] The main technical and performance indicators of the prepared brake pads are as follows:

[0057] Friction coefficient 0.25-0.45;

[0058] Wear rate 0.2-0.4;

[0059] Lifespan of more than 60,000 kilometers;

[0060] No noise;

[0061] Thermal recession ≤ 20%;

[0062] Impact strength not less than 0.3J / cm2;

[0063] Wear rate≤0.2;

[0064] The thermal expansion rate (400℃±10℃) is not more than 2.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com