Tube wire for overlaying welding and preparation thereof

A tubular electrode and tube technology, applied in the field of surfacing tubular electrodes and their preparation, can solve the problems of limited application scope, less variety, narrow surfacing welding bead, etc. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Select the H08A cold-rolled steel strip with a width of 39mm and a thickness of 0.3mm, and use the existing cored wire production equipment for steelmaking to roll it into a U-shaped cross-section along the length direction (longitudinal direction) of the steel strip ;

[0049] (2) Add medicated powder granules to the above-mentioned U-shaped pit, the filling rate is 48%, wherein: the medicated powder granule size is-50 mesh, and the medicated powder granule components are in parts by weight (kg), including high-carbon ferrochrome 60. Ferrovanadium 8, 75# ferrosilicon 5, high carbon ferromanganese 1, aluminum magnesium alloy 5, ferroboron 4, ferrotitanium 5, ferromolybdenum 6, fluorite 2 and potassium titanate 3;

[0050] The powder is applied after 15 minutes of powder mixing with a conventional powder mixer;

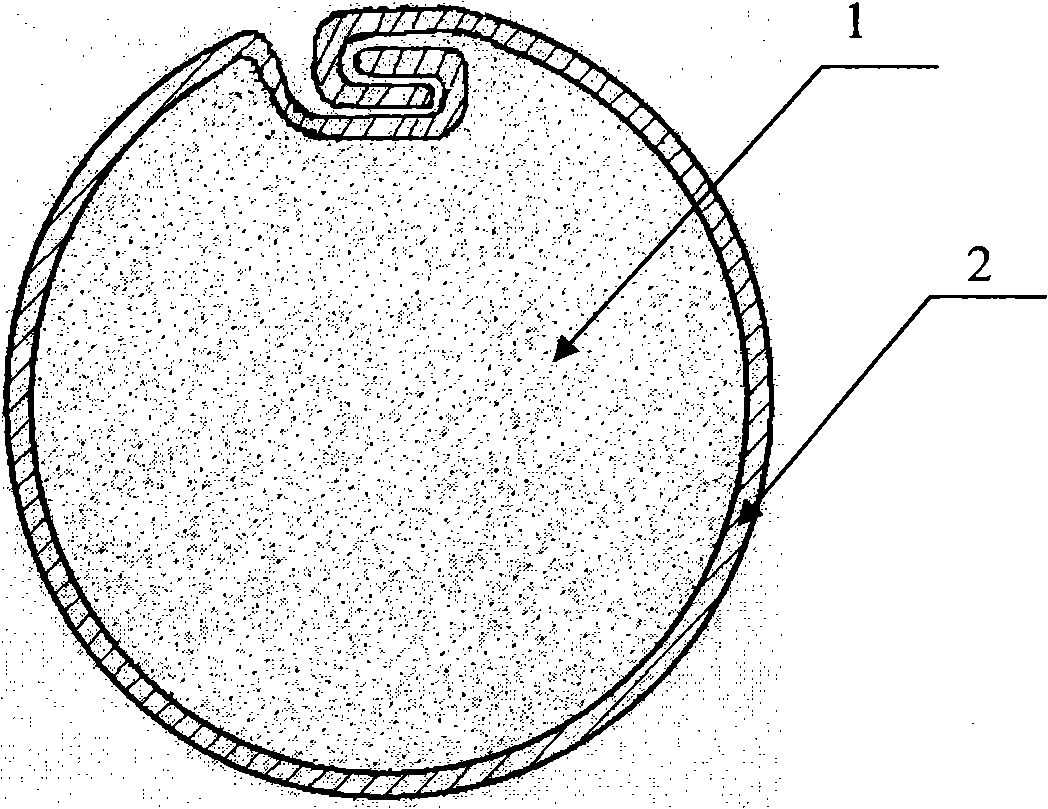

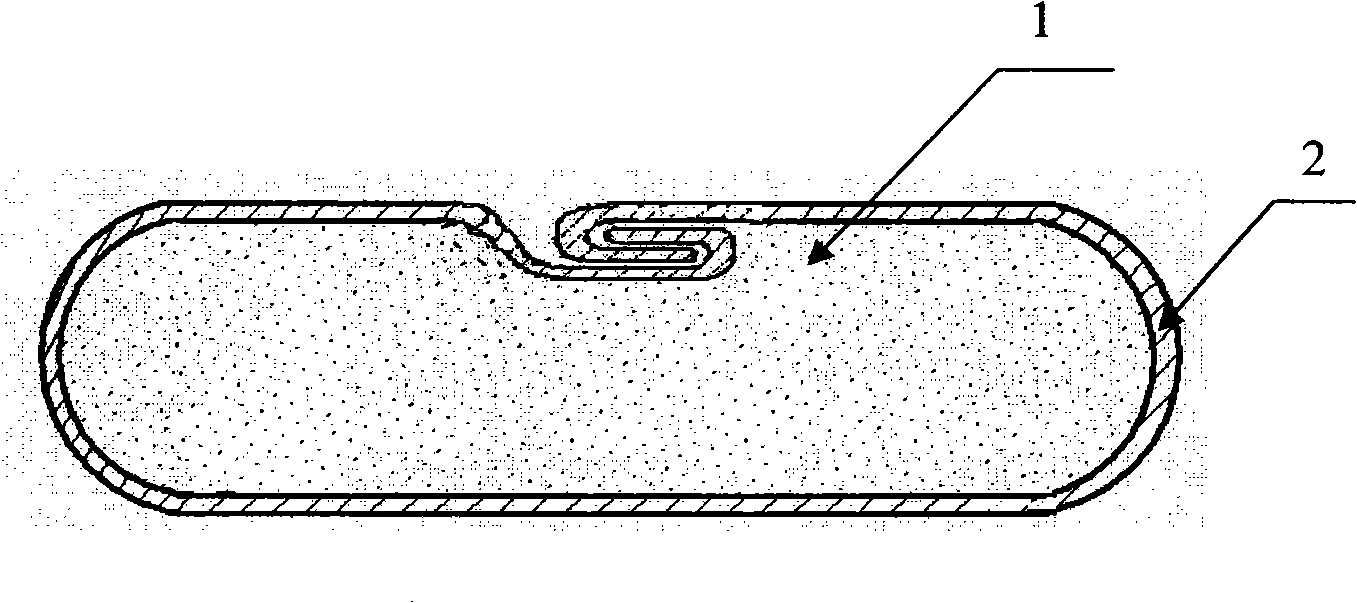

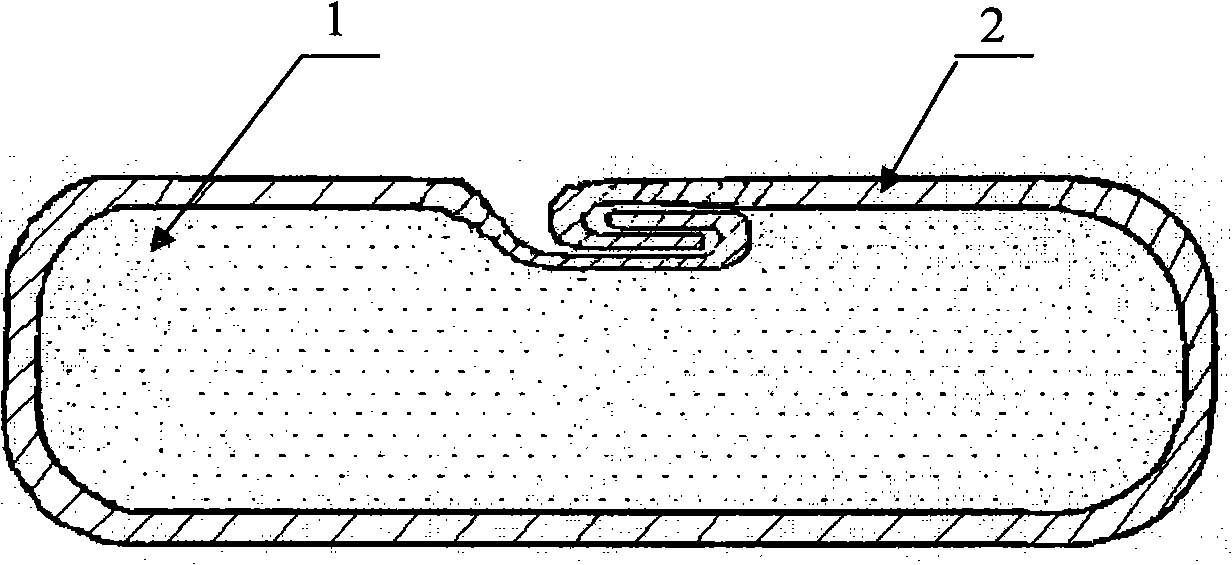

[0051] (3) The cross-section of the U-shaped steel strip after adding the medicine powder is connected in the form of a bite, so that the medicine powder i...

Embodiment 2

[0056] (1) Select the H08A cold-rolled steel strip with a width of 130mm and a thickness of 0.4mm, and use the existing cored wire production equipment for steelmaking to roll it into a U-shaped cross-section along the length direction (longitudinal direction) of the steel strip ;

[0057] (2) Add medicated powder granules to the above-mentioned U-shaped pit, the filling rate is 55%, wherein: the medicated powder particle size is-50 mesh, and the granule components are in parts by weight (kg), including high-carbon ferrochromium 70 , ferro-vanadium 10, high-carbon ferromanganese 1, ferro-boron 12, ferro-titanium 3, ferro-molybdenum 3 and graphite 4;

[0058] The powder is applied after 20 minutes of powder mixing with a conventional powder mixer;

[0059] (3) The cross-section of the U-shaped steel strip after adding the medicine powder is connected in the form of a bite, so that the medicine powder is wrapped in the steel belt to form a steel pipe wrapped with the medicine p...

Embodiment 3

[0064] (1) Select the Q195 cold-rolled steel strip with a width of 45mm and a thickness of 0.3mm, and use the existing steelmaking cored wire production equipment to roll it into a U-shaped cross-section along the length direction (longitudinal direction) of the steel strip ;

[0065] (2) Add medicated powder granules to the above-mentioned U-shaped pit, the filling rate is 50%, wherein: the medicated powder granule size is-50 mesh, and the medicated powder granule components are in parts by weight (kg), including high-carbon ferrochrome 66. Ferrovanadium 6, 75# ferrosilicon 3, high carbon ferromanganese 2, aluminum magnesium alloy 5, ferroboron 7, ferrotitanium 4, ferromolybdenum 4, fluorite 2 and potassium titanate 2;

[0066] The medicated powder is applied after 20 minutes of powder mixing with a conventional powder mixer;

[0067] (3) Connect the U-shaped cross-section of the steel strip with a U-shaped cross-section after adding the powder particles, so that the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com