Inorganic heat-insulating material and preparation method thereof

A thermal insulation and inorganic technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of limited thermal insulation effect, thick thermal insulation layer, etc., and achieve low cost, improved thermal insulation performance, and good adhesion Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

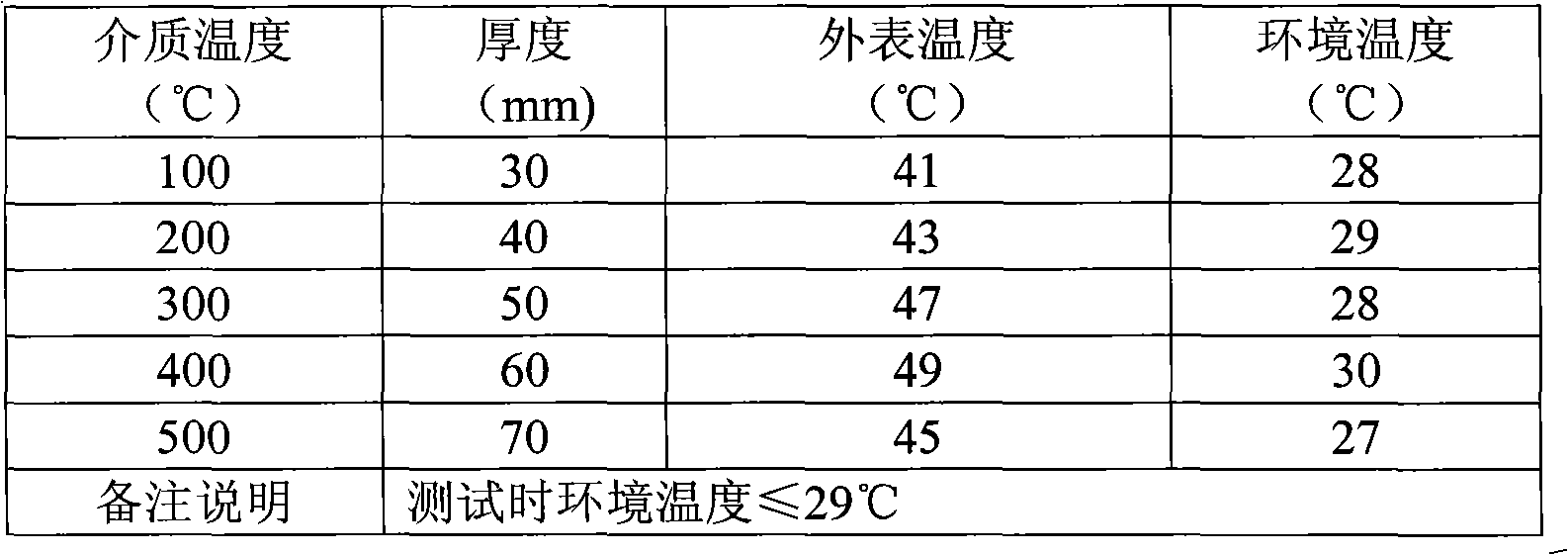

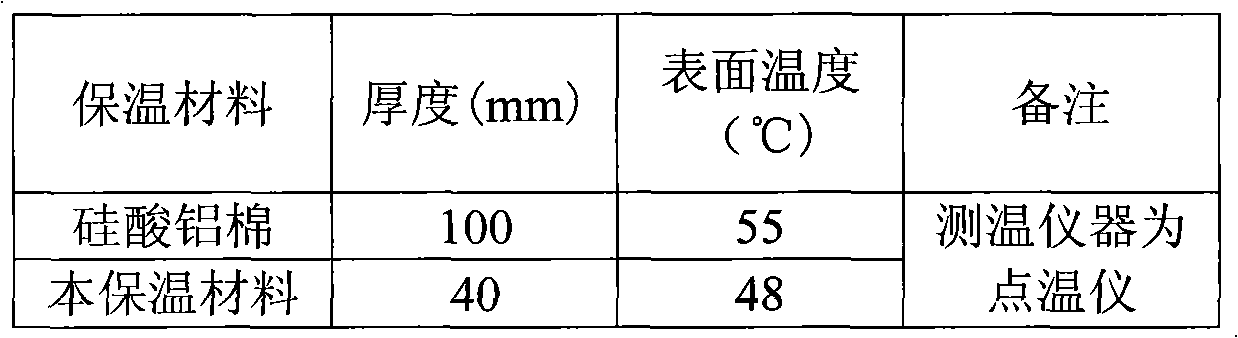

Examples

Embodiment 1

[0020] A kind of inorganic thermal insulation material described in this embodiment is made of raw materials including the following weight (kg): phosphoric acid 20, aluminum hydroxide 5, silicate 5, aluminum silver paste auxiliary agent 7, potassium titanate crystal Whiskers 10, expanded perlite 5, ceramic microspheres 15, 803 thermal insulation powder 3.5, carbon fiber 8, sepiolite 5, magnesium hydroxide 7, boron nitride 1, glass powder 2.4, nano-zirconia 1, carboxymethyl fiber Plain sodium 2, calcium oxide 0.1, calcium-based bentonite 3; among them, potassium titanate whiskers, preferably nano-scale potassium hexatitanate whiskers; expanded perlite is preferably closed-cell expanded perlite, and the particle diameter is 0.1-2mm. 30% of the diameter is 0.1-0.8mm, 40% of the particle diameter is 0.9-1.5, and 30% of the particle diameter is 1.5-2; Pretreated by indium tin oxide, the vacuum pore diameter of the microbeads is between 100-500 nanometers; the carbon fiber diameter...

Embodiment 2

[0028] A kind of inorganic thermal insulation material described in this embodiment is made of raw materials including the following weight (kg): phosphoric acid 15, aluminum hydroxide 7, silicate 2, aluminum silver paste auxiliary agent 5, expanded perlite 12 , ceramic microspheres 9, nano-silica airgel 6, carbon fiber 5, sepiolite 15, wollastonite needle powder 5, boron nitride 3, chromium trioxide 4.5, glass powder 3, boric acid 1.5, carboxylate Sodium methylcellulose 5, calcium-based bentonite 2; among them, the expanded perlite is preferably closed-cell expanded perlite, and the particle diameter is 0.1-2mm, 30% of the particle diameter is 0.1-0.8mm, and 40% of the particle diameter is 0.9-1.5mm. %, the particle diameter is 1.5-2, accounting for 30%; the ceramic microsphere particles are between 2500-12500 mesh, and it is a vacuum structure. Between; the density of nano-silica airgel should be less than 40 kg / m3; the diameter of carbon fiber is less than 325 mesh, the tem...

Embodiment 3

[0031]A kind of inorganic thermal insulation material described in this embodiment is made of raw materials including the following weight (kg): phosphoric acid 10, aluminum hydroxide 3, silicate 0.5, aluminum silver paste additive 2, potassium titanate crystal Whiskers 5.2, expanded perlite 17, nano-silica airgel 2.2, 803 thermal insulation powder 9.1, carbon fiber 13, wollastonite needle powder 9, magnesium hydroxide 5, boron nitride 6, chromium trioxide 2.5, Boric acid 6.5, sodium carboxymethyl cellulose 1, calcium-based bentonite 8; among them, expanded perlite is preferably closed-cell expanded perlite, and the particle diameter is 0.1-2mm, and the particle diameter is 0.1-0.8mm, accounting for 30%, and the particle diameter is 0.9 -1.5 accounts for 40%, particle diameter 1.5-2 accounts for 30%; ceramic microsphere particles are between 2500-12500 mesh, and it is a vacuum structure, the outer surface is pretreated by indium tin oxide, and the vacuum aperture of the microsp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com