Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Reduce pinhole rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Al-Ti-B-rare earth(RE) grain refiner and preparation method thereof

The invention relates to an Al-Ti-B-RE grain refiner and a preparation method thereof. The Al-Ti-B-RE grain refiner is used for Al-Mg-Si alloy, and is characterized by containing the following components in percentage by weight: 6.9 to 7.9 percent of Ti, 1.31 to 1.75 percent of B and 1.5 to 2.0 percent of mixed RE. The mixed RE is cerium-enriched rare earth. The preparation method of the cerium-enriched rare earth comprises: mixing the raw materials according to a weight part ratio, wherein the mixing time is controlled to be 3 to 4 hours; heating an aluminum ingot in a medium frequency induction furnace to an overhigh temperature of 700 to 750 DEG C; filling a mixed pressed block of potassium fluotitanate and potassium fluoborate and cerium-enriched rare earth into a graphite bell jar; clamping the reversed bell jar by using forceps, and pressing the bell jar into the lower middle part of aluminum melt; raising the furnace temperature to 800 to 850 DEG C, and magnetically stirring for 25 to 30 minutes with the induction furnace; after reaction, taking the graphite bell jar out; standing and keeping the temperature for 20 minutes; forcefully stirring the melt once with an artificial graphite rod every 3 minutes, and stirring for more than five times; treating molten alloy; standing and keeping temperature for 15 to 20 minutes; and performing secondary slagging off.

Owner:HUANGGANG HUAER ALUMINUM ALLOY

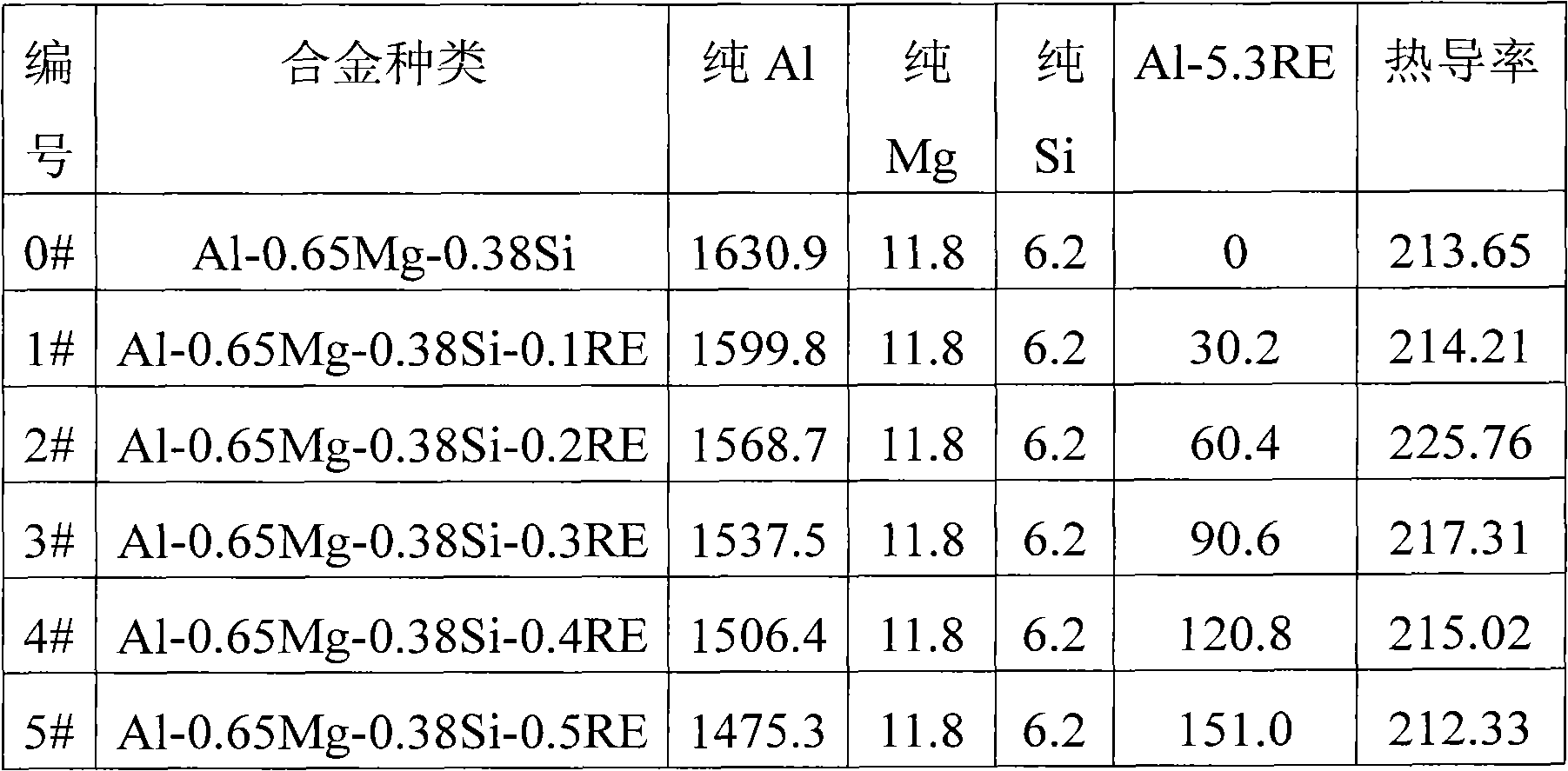

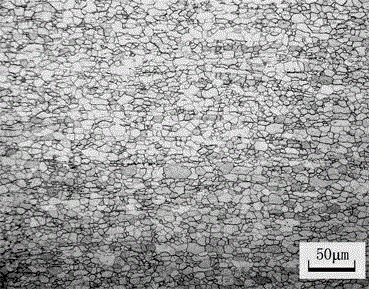

Rare earth aluminum alloy with high thermal conductivity

The invention provides a rare earth aluminum alloy with high thermal conductivity. Mixed rare earth element RE composed of lanthanum and yttrium is added into 6063 aluminum alloy to form the rare earth aluminum alloy, wherein in the 6063 aluminum alloy, Mg accounts for 0.45 to 0.8 weight percent of the total weight of the rare earth aluminum alloy, Si accounts for 0.25 to 0.6 weight percent of the total weight of the rare earth aluminum alloy, Fe accounts for less than 0.35 weight percent of the rare earth aluminum alloy, Cu accounts for less than 0.1 weight percent of the rare earth aluminum alloy, Zn accounts for less than 0.1 weight percent of the rare earth aluminum alloy, and Ti accounts for less than 0.1 weight percent of the rare earth aluminum alloy. Mixed RE accounts for 0.1 to 0.5 weight percent of the total weight of the rare earth aluminum alloy, and comprises 5 to 80 weight percent of lanthanum and 1 to 20 weight percent of yttrium. Besides the above elements, the rest component of the rare earth aluminum alloy is Al. By adding a certain amount of mixed rare earth, the thermal conductivity of the aluminum alloy, the plastic forming property and processing property of the alloy are improved.

Owner:李其真

Formula for casting aluminum alloy hubs

The invention discloses a formula for casting aluminum alloy hubs. The formula is prepared from, by weight, 6.5-7.5% of Si, 0.28-0.45% of Mg, 0-0.12% of Fe, 0-0.02% of Cu, 0.02-0.05% of Mn, 0.04-0.05% of Zn, 0.10-0.20% of Ti, 0.2-0.6% of Sr, 0.01-0.05% of Cr, 0.01-0.02% of Zr, 0.025-0.05% of B, 0.4-0.8% of mixed light rare earth and the balance Al. Due to the fact that Sr and the mixed rare earth metal serve as an alterant together, the surface defects of alloy phases can be overcome, surface tension on a new-phase interface and an old-phase interface is reduced, and the problem that compactness is reduced when only Sr is added is avoided. Zr, Ti, Cr and Al work together, the cast structure is further refined, and the hardness and the toughness of aluminum alloy are improved.

Owner:GUANGDONG DCENTI AUTO PARTS STOCK LTD

Full-ferrite enamel steel for heat exchanger and production method thereof

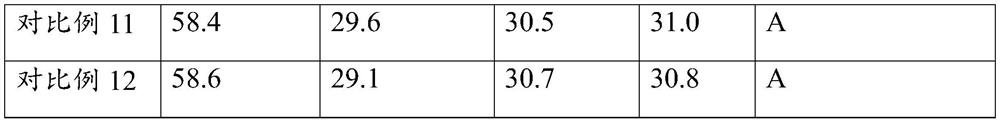

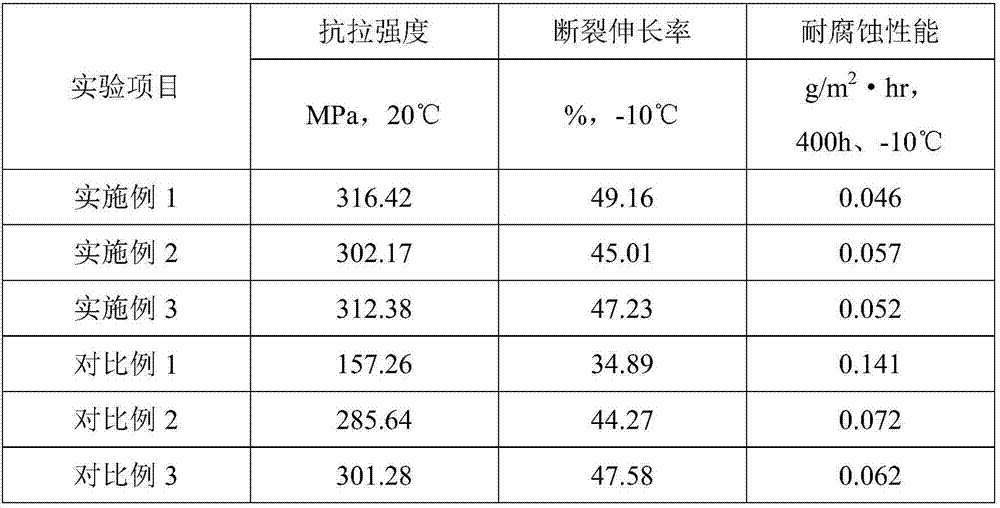

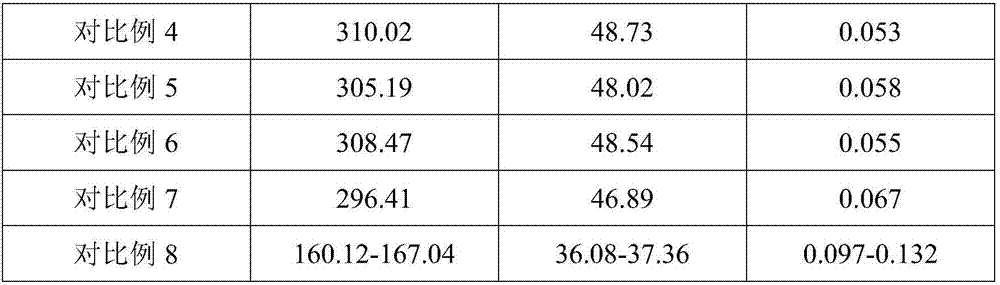

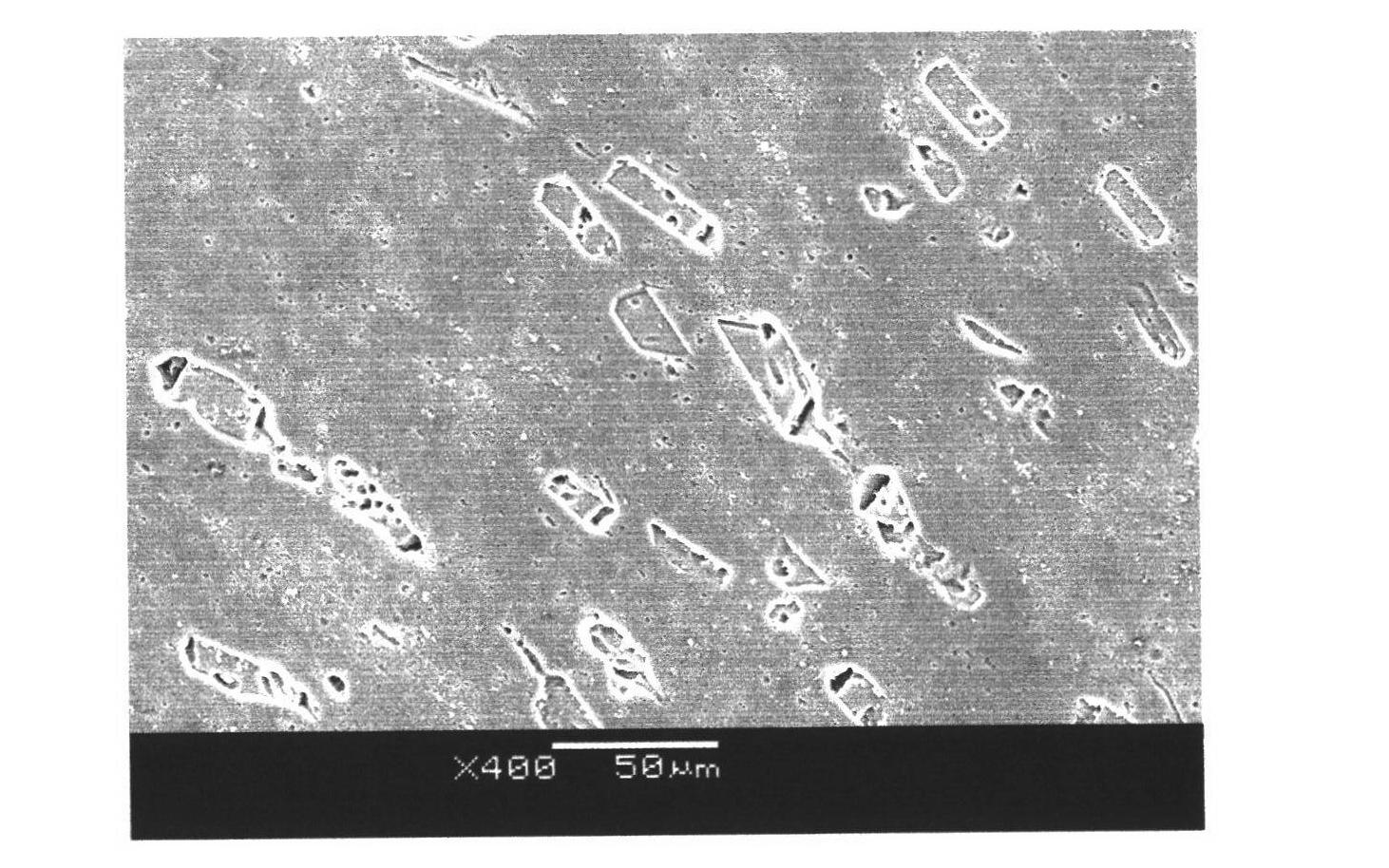

The invention relates to a full-ferrite enamel steel for a heat exchanger. The full-ferrite enamel steel comprises the following chemical components in percentages by weight: less than or equal to 0.0050% of C, 0.10-0.50% of Mn, less than or equal to 0.010% of Si, less than or equal to 0.020% of P, 0.015-0.045% of S, less than or equal to 0.010% of Als, 0.010-0.055% of Nb, less than or equal to 0.0030% of B and 0.010-0.050% of O; the production method comprises the following steps of pretreating molten iron, smelting, refining and continuously casting by virtue of a converter; heating the cast blank; carrying out hot rolling; coiling and acid pickling; carrying out cold rolling; annealing; finishing for later use. The microstructure of the enamel steel disclosed by the invention is full ferrite, the grain size of ferrite reaches Grade 11, the main inclusions are long-wire-shaped MnS and granular Mn / Nb composite oxides, the precipitated phases are fine NbC / N and BN particles, Rel is 180-240MPa, the tensile strength is 280-360MPa, the elongation is 36-46%, the hydrogen permeation time of the steel plate is equal to or greater than 25min / mm<2>, no scute burst is caused after enamelling, enamel adhesion strength is greater than A1 level and the pinhole rate is less than 10 / m<2>.

Owner:武汉钢铁有限公司

Permeable fireproof materials for aluminium refining and process for preparing same

The invention discloses a poromeric fire-proof material and preparing method of refined aluminum, which comprises the following parts: 60-92 percent sintered compact calcium hexaluminate, 8-30 percent auxiliary material and 2.5-5.5 percent binder, wherein the auxiliary material is some or all of board-shaped corundum, electric melting white corundum, mild-clay, quartz, kyanite, chromium hemitrioxide green and zircon. The preparing method comprises the following steps: blending poromeric fire-proof material and binder completely; loading the material in the mould; placing the mould on the vibrating platform; pressurizing on the material at 10-20 ton; vibrating at 3-5 mm amplitude at 5-15 s; sintering at 1400-1700 deg.c.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

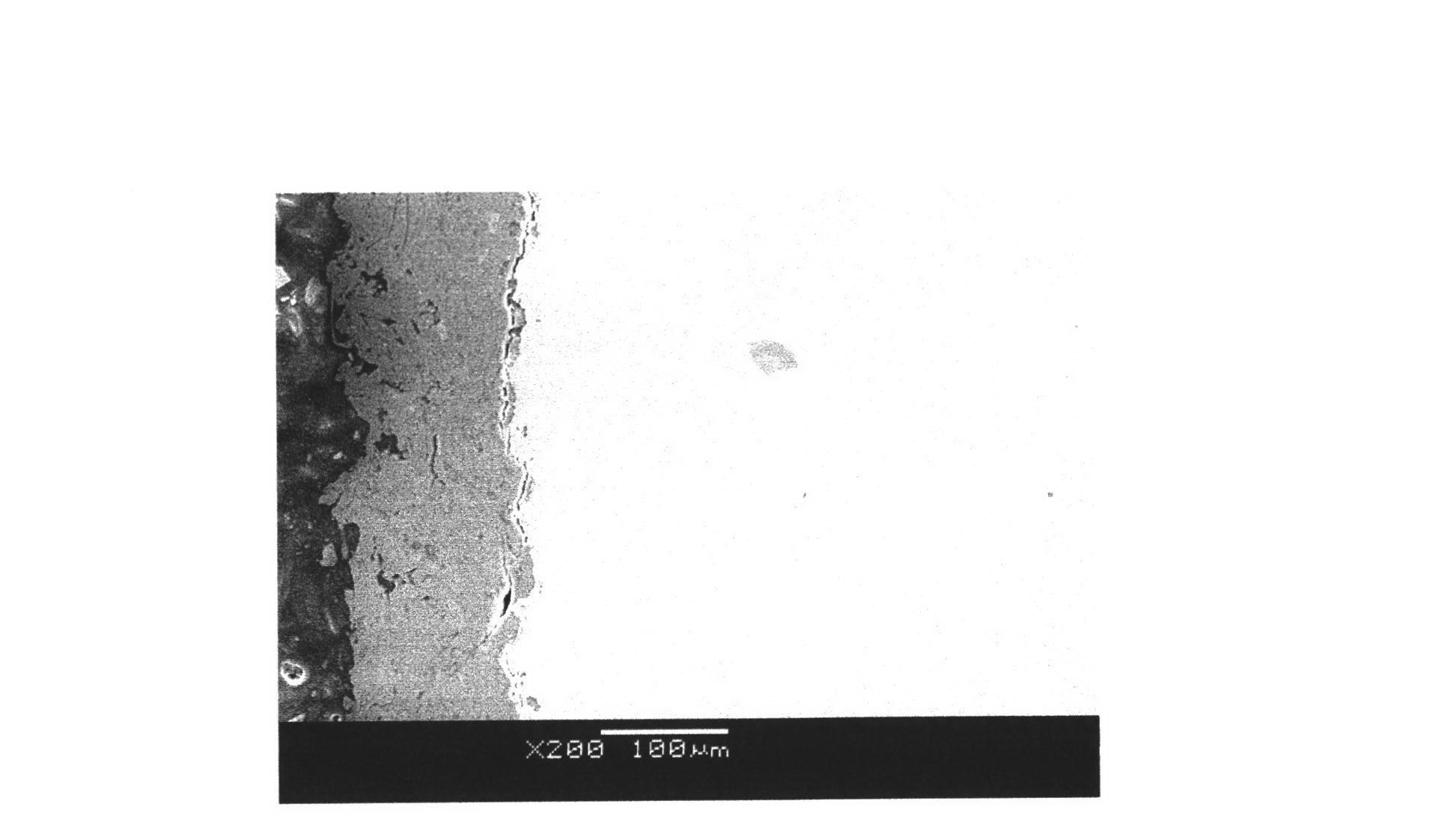

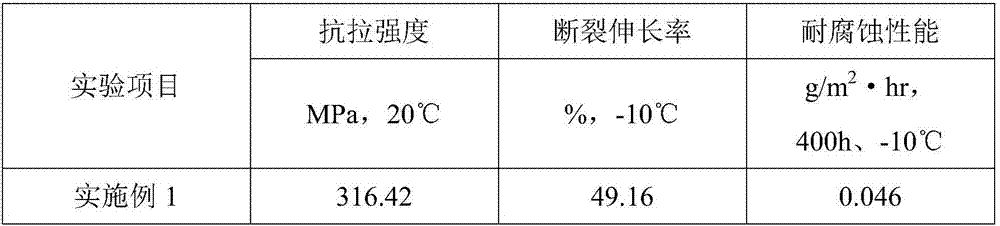

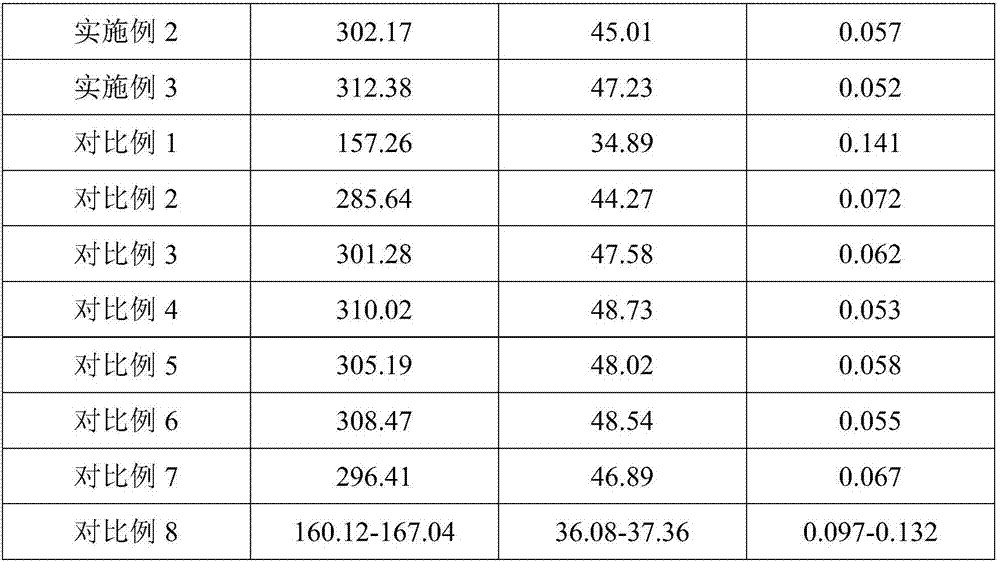

Rare earth-containing aluminium alloy and preparation method thereof

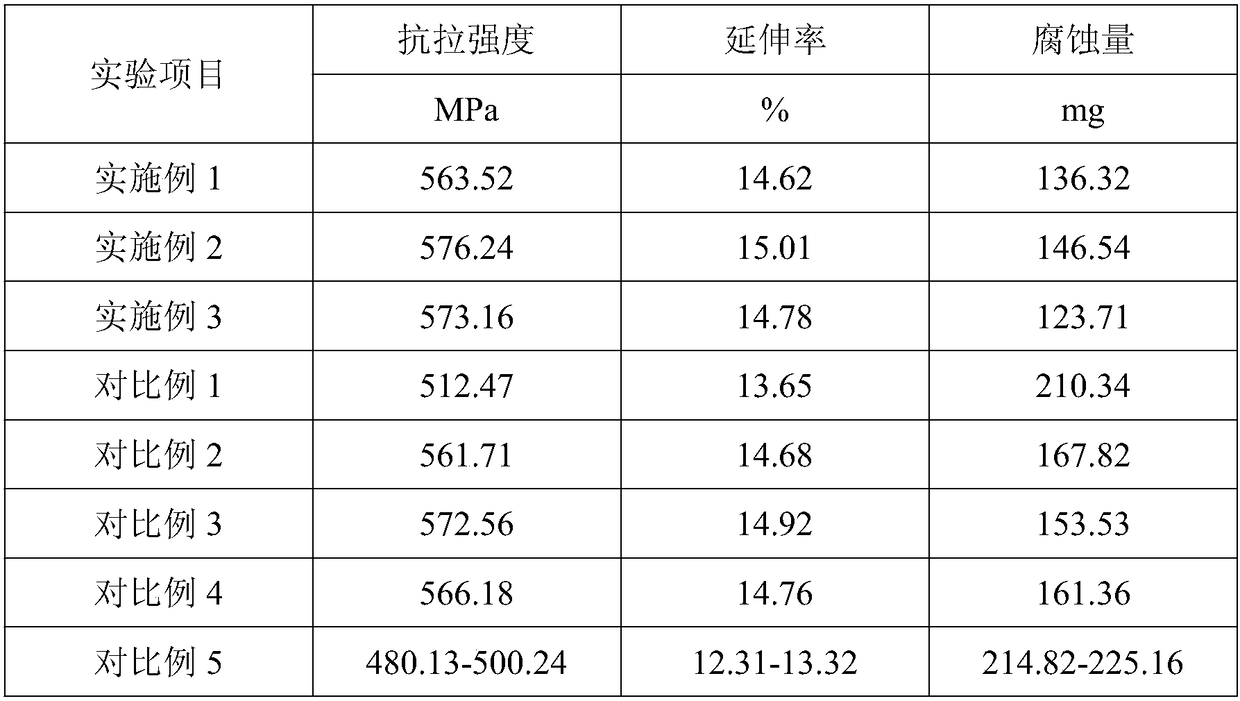

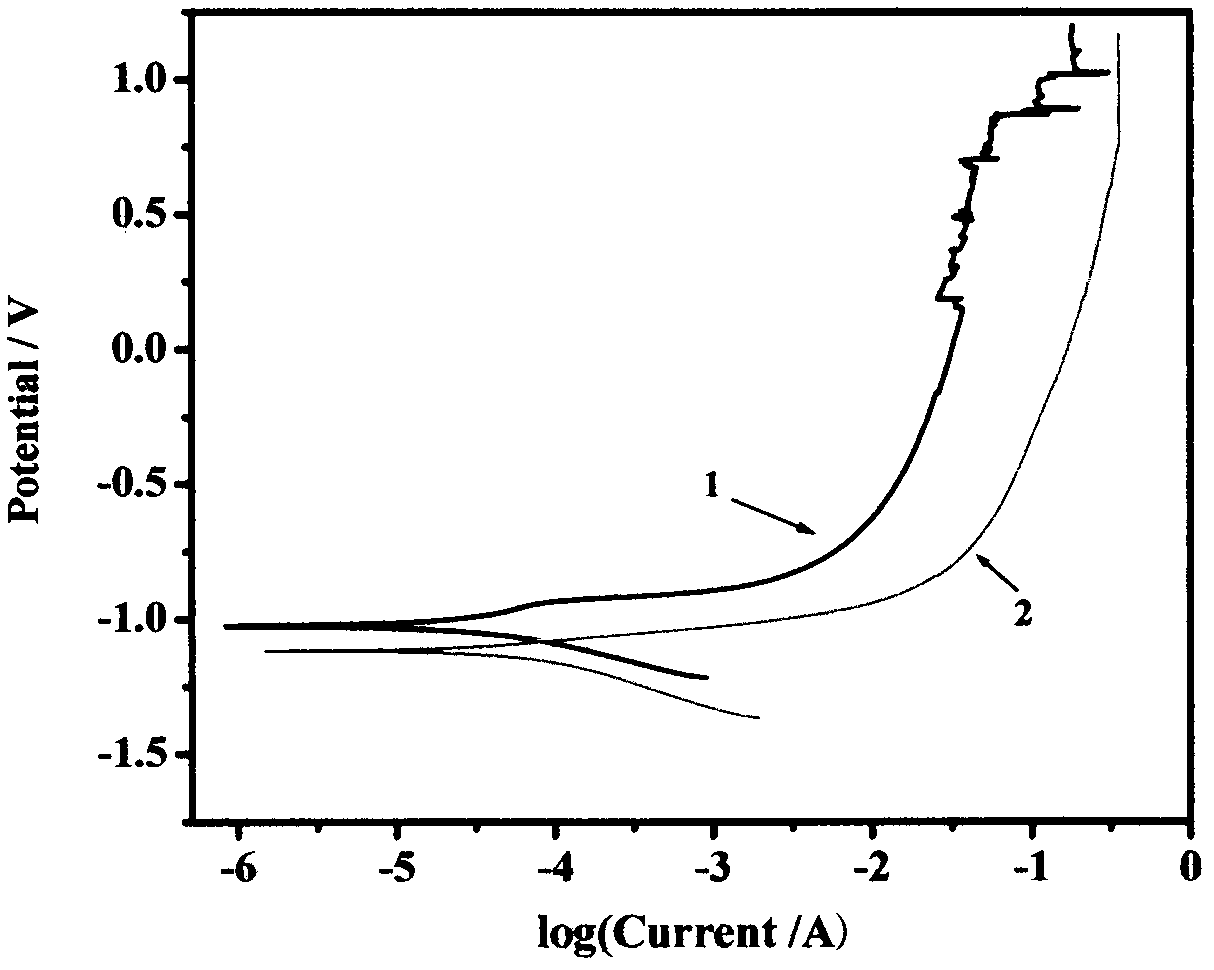

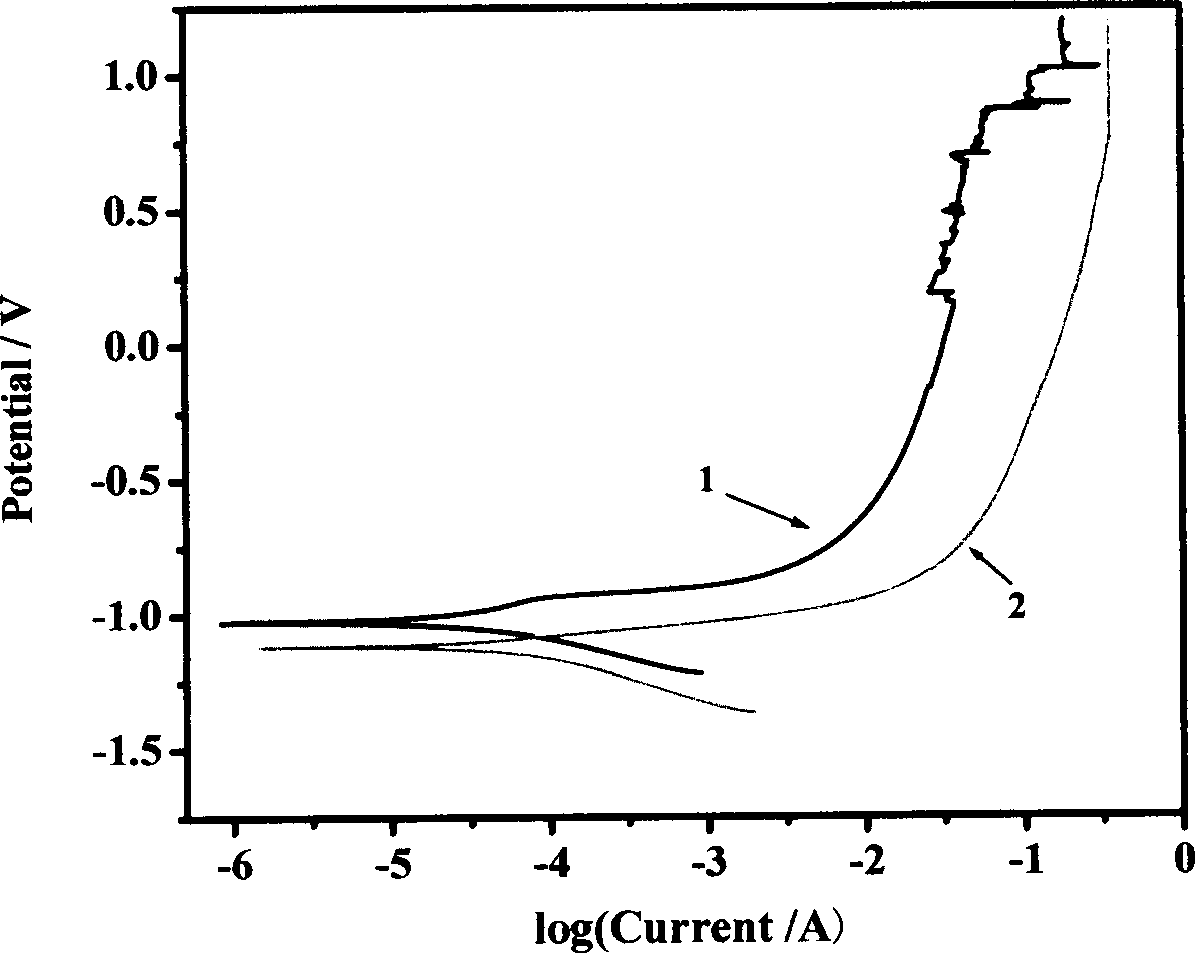

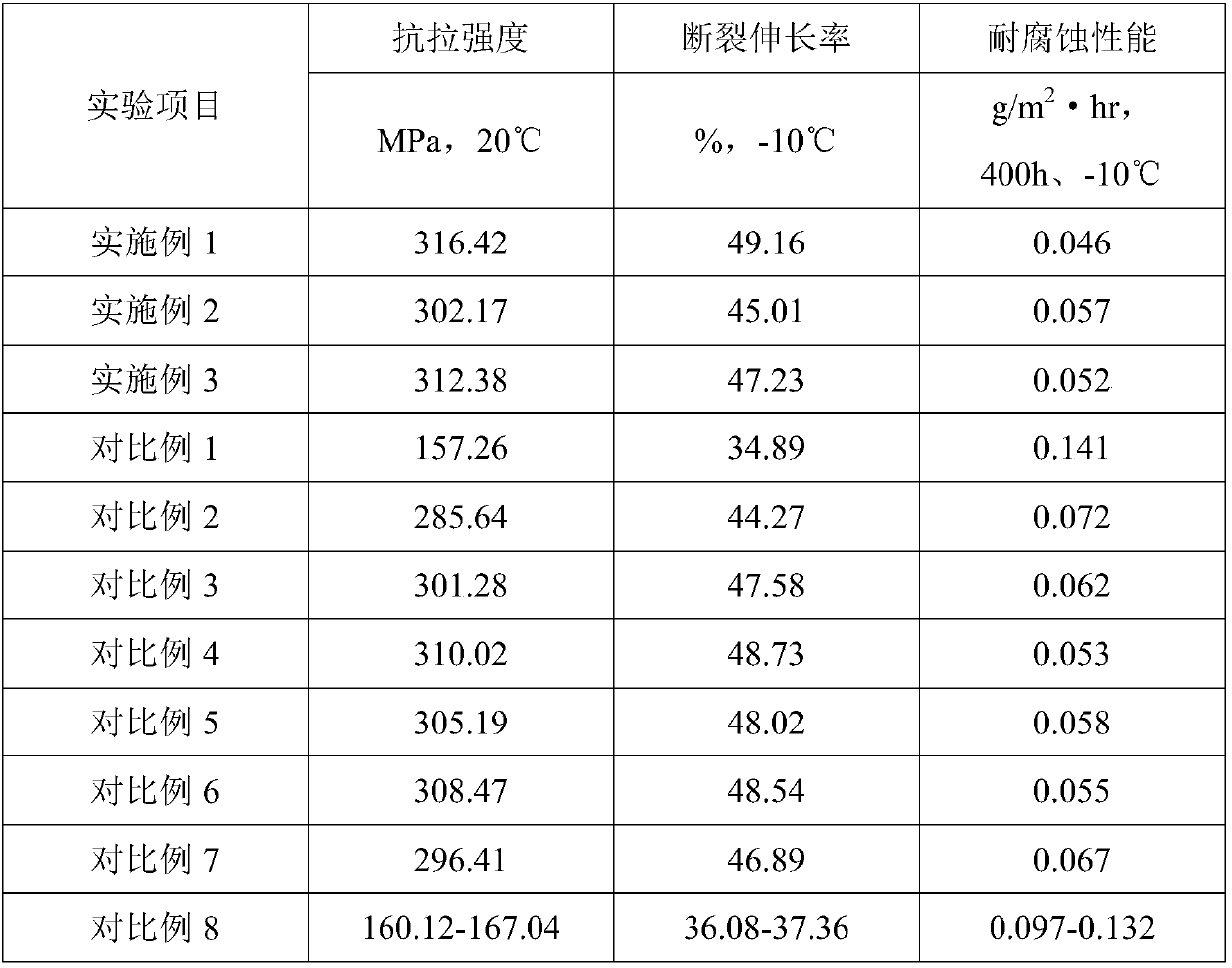

The invention discloses a rare earth-containing aluminium alloy and a preparation method thereof, and belongs to the technical field of aluminium alloy preparation. The rare earth-containing aluminiumalloy is prepared from the following raw materials: titanium, zinc, iron, manganese, copper, carbon, chromium, boron, magnesium, molybdenum, tungsten, vanadium, rare earth elements, a refining agent,sodium pentafluorophenol, a grain refiner and aluminium; the rare earth-containing aluminium alloy is prepared by the steps of melting, refining, slagging-off, casting and the like. By adopting the process of the invention, the tensile strength, the ductility and the corrosion resistance of the aluminium alloy can be remarkably improved.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

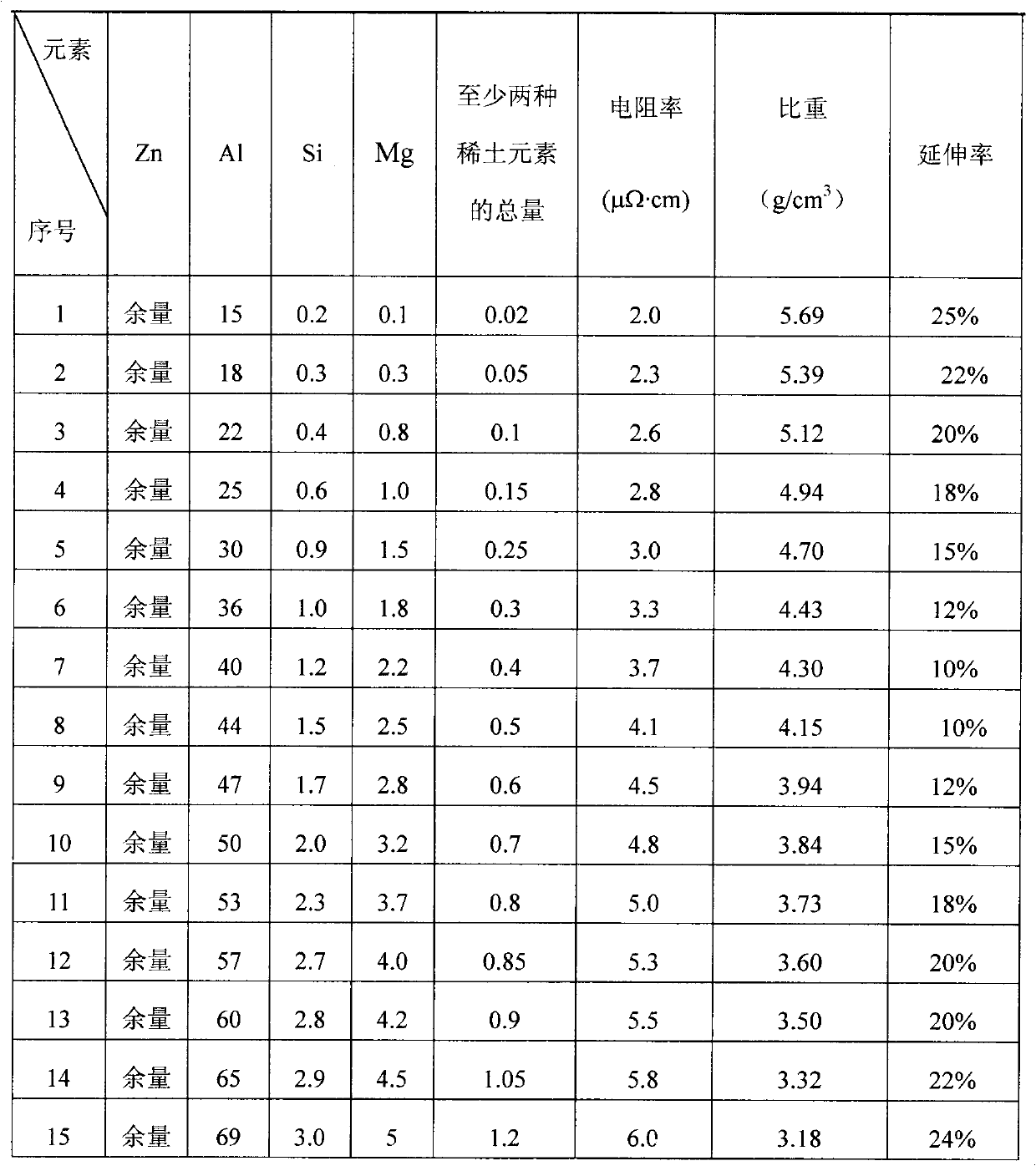

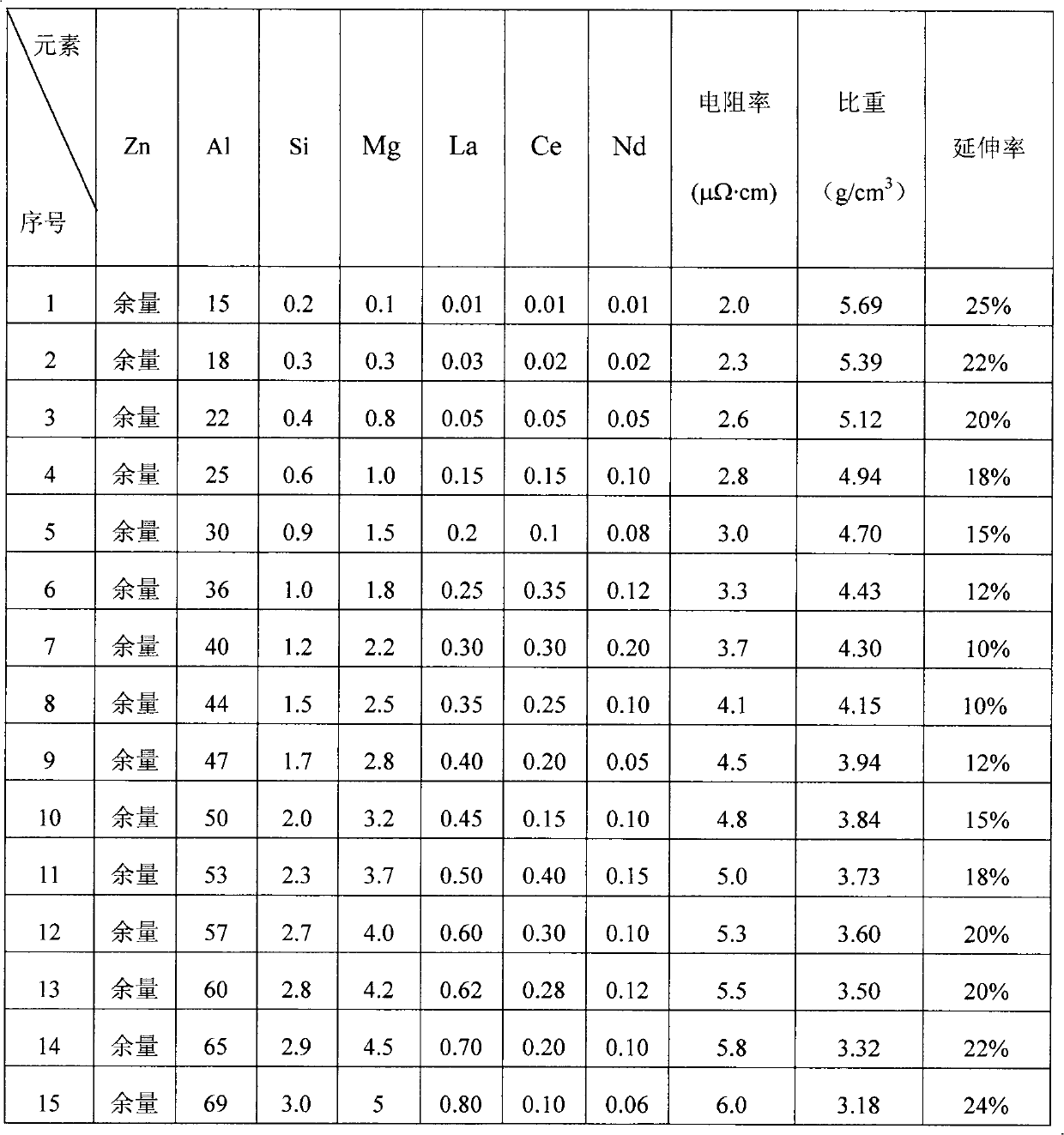

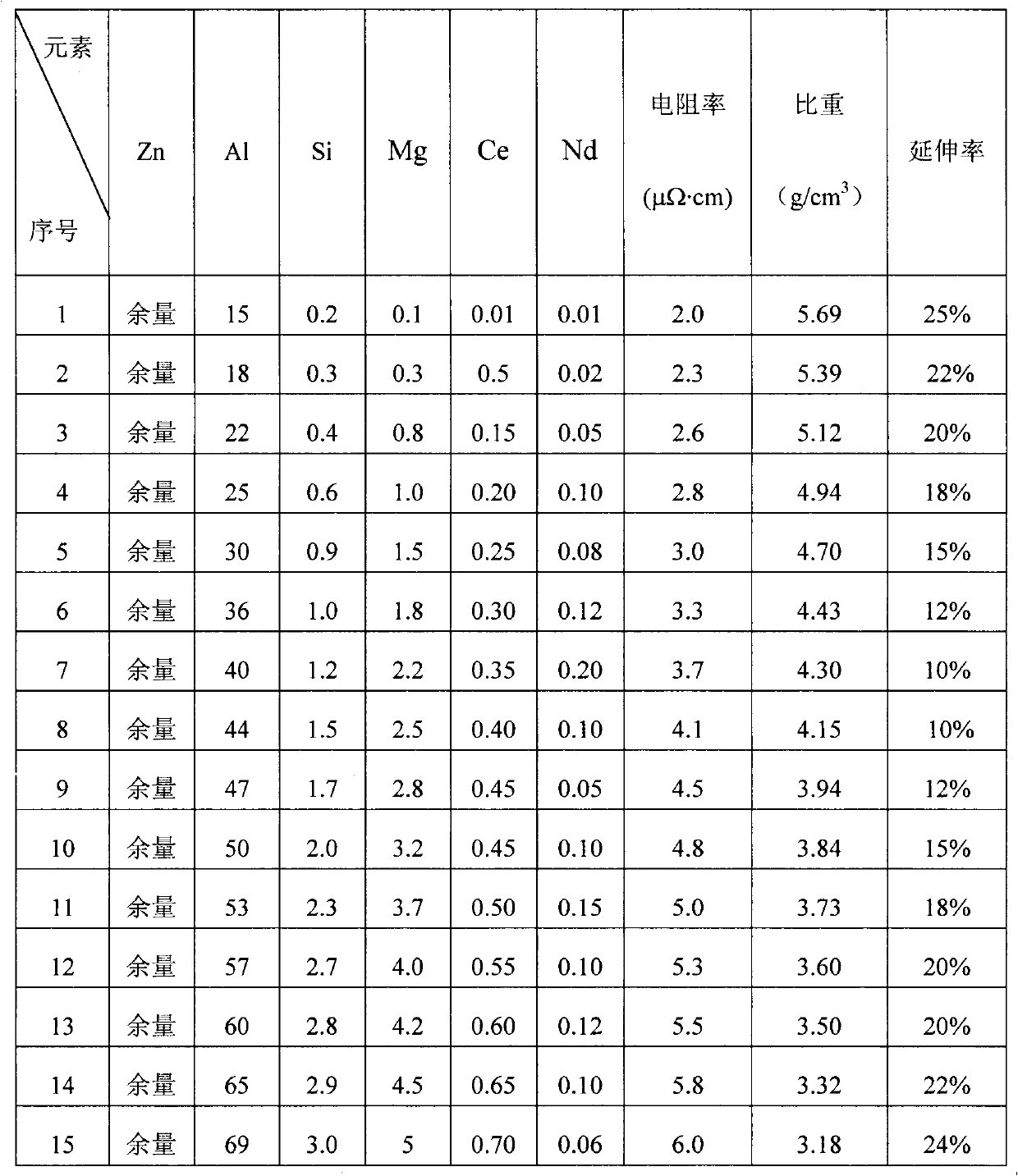

Multielement zinc-aluminum alloy wire and manufacturing method thereof

The invention relates to a multielement zinc-aluminum alloy wire which comprises the following components in percentage by weight: 15-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.02-1.15% of at least two rare-earth elements, at most 1% of microelements and the balance of Zn. The resistivity of the zinc-aluminum alloy wire is 2.0-6.0 mu omega.cm, the specific gravity of the zinc-aluminum alloy wire is 3.18-5.69 is g / cm<3>, and the elongation percentage of the zinc-aluminum alloy wire is 10-25%; and thus, the zinc-aluminum alloy wire can be widely used in ships, power supply towers, large-size storage tanks, underground pipelines, tunnel frames and other facilities, and has very wide application prospects.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Manufacture process of automobile power battery enclosure

The invention provides a manufacture process of an automobile power battery enclosure, which comprises the following main steps of: (1) manufacturing aluminum alloy for the automobile power battery enclosure, wherein the aluminum alloy comprises the following components by weight percent: 0.10%<Si<0.60%, 0.40%<Fe<0.70%, 0.05%<Cu<0.20%, Mg<0.05%, 1.05%<Mn<1.25%, 0.15%<RE<0.40%, and 0.05<Ti<0.1, each of other elements is at most 0.05%, the total content of other elements is at most 0.15%, and the balance is aluminum; and (2) smelting the aluminum alloy proportioned by the step (1), casting the smelted aluminum alloy into a billet, and then sequentially carrying out four processes of homogenization, hot extrusion, heat treatment as well as punching and drawing on the billet to manufacture the automobile power battery enclosure. The automobile power battery enclosure manufactured through the process has excellent corrosion resistance, favorable high temperature creep property, and excellent punching-ironing processability and laser welding property, and is suitable for a square-shaped or box-shaped lithium ion battery case.

Owner:李其真

Spray-formed 7xxx series aluminum alloy containing rare earth element Er and preparation method thereof

The invention discloses a spray-formed 7xxx series aluminum alloy containing a rare earth element Er and a preparation method thereof. The spray-formed 7xxx series aluminum alloy containing the rare earth element Er comprises the following specific components in percent by weight: 0.3-0.8% of Er, 3.0-12.0% of Zn, 1.0-4.0% of Mg, 1.5-3.5% of Cu and the balanced of Al. The preparation method comprises the following steps: preparing all elements according to the proportion of the design components of the alloy, melting, casting to prefabricate ingots, re-melting, refining, spraying forming, performing hot extrusion to prepare aluminum alloy tube materials or bar materials, and performing solid solution and aging treatment to obtain aluminum alloy products with excellent strength and elongation. According to the prepared high-strength spray-formed 7xxx series aluminum alloy, due to the added rare earth element Er, on one hand, a melt body is purified, and impurities of solid solution of the alloy are reduced, so that the structure is optimized; on the other hand, grains can be refined, strengthening phases are separated out, the strength of the alloy is improved, the tensile strength of the alloy is 680MPa, and the elongation can be up to 15%.

Owner:JIANGSU UNIV OF TECH

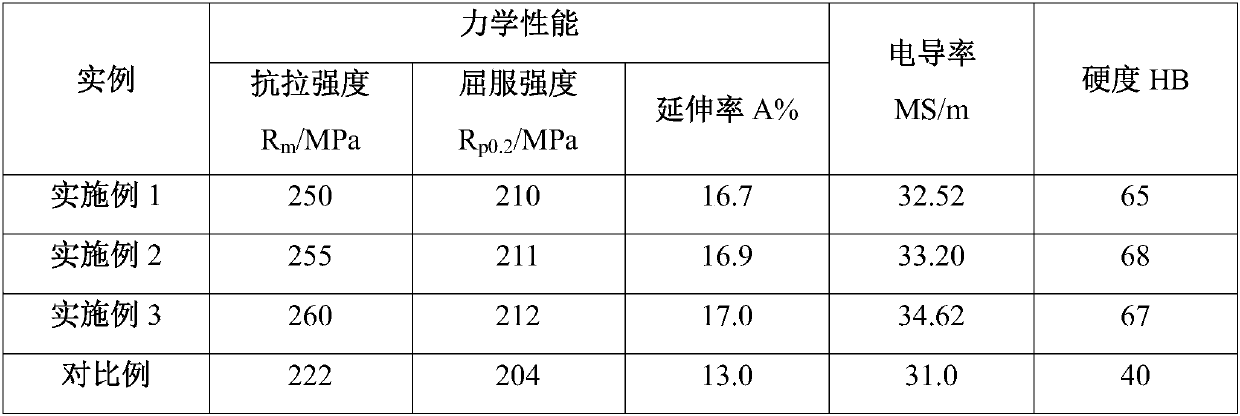

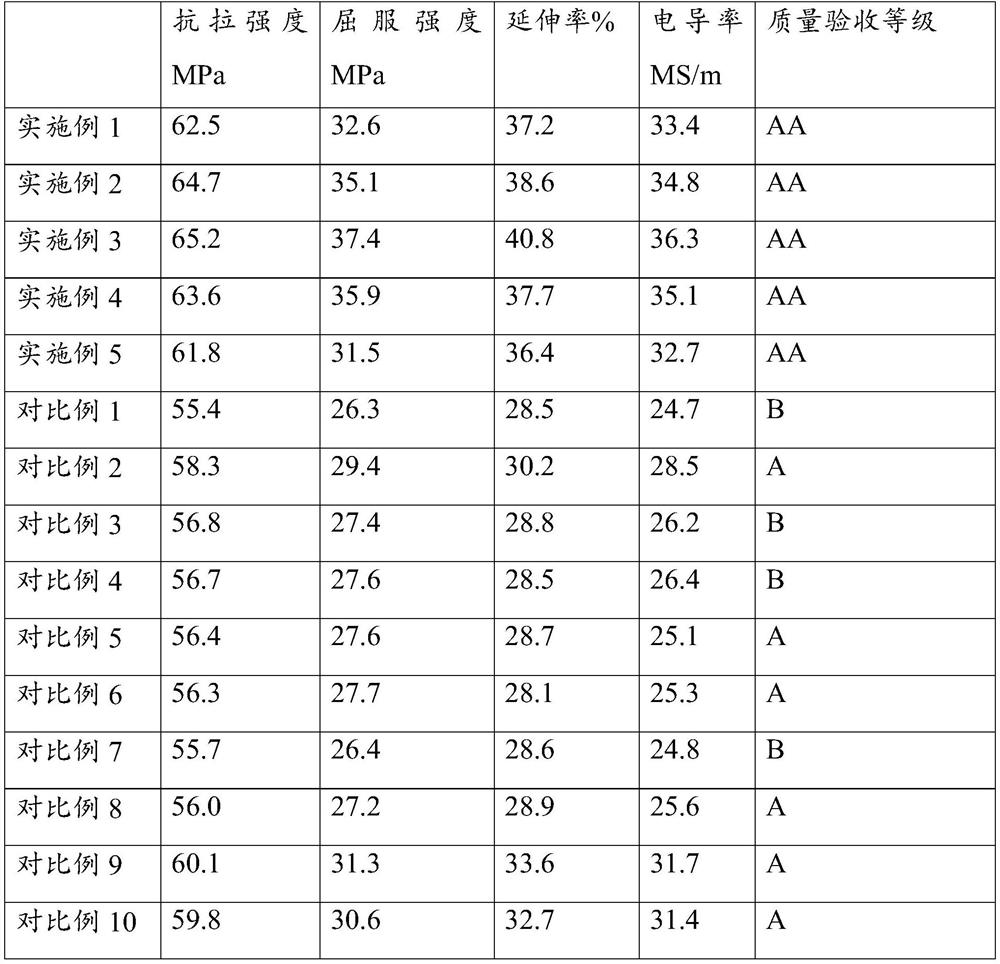

High-conductivity 6 series aluminum alloy and production process therefor

InactiveCN110983124ALow thermal conductivityReduced mechanical propertiesExtrusion control devicesUltimate tensile strengthMechanical property

The invention belongs to the technical field of aluminum alloy production processes, and relates to a high-conductivity 6 series aluminum alloy and a production process therefor. The high-conductivity6 series aluminum alloy is prepared from the following element components in percentage by weight: 0.55%-0.60% of Si, 0.10%-0.15% of Fe, 0.05%-0.08% of Cu, 0.01%-0.02% of Mn, 0.60%-0.65% of Mg, 0.01%-0.02% of Cr, not greater than 0.01% of Ti, 0.05%-0.08% of Zn, not greater than 0.01% of V, 0.15%-0.18% of Gd, 0.015%-0.02% of B, not greater than 0.03% of single impurities, not greater than 0.10% ofimpurities and the balance Al; by improving a formula and the process, the tension strength of the aluminum alloy reaches 250 Mpa, the yield strength reaches 210 Mpa, the percentage elongation afterfracture reaches 16.7%, and the conductivity Gamma is equal to 32.52 MS / m; and the hardness HB is equal to 65, so that the mechanical property and the conductivity of the 6 series aluminum alloy are obviously improved.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

Overhead heat-resistance aluminum alloy conductor material and preparation method thereof

InactiveCN106893899ARaise the recrystallization temperatureAdd lessConductive materialMetal/alloy conductorsCeriumTemperature resistance

The invention discloses an overhead heat-resistance aluminum alloy conductor material and a preparation method thereof, and relates to the technical field of aluminum alloy conductor materials. The overhead heat-resistance aluminum alloy conductor material comprises the following elements in percentage by mass: 0.10-0.45% of zirconium, 0.01-0.10% of yttrium, 0.01-0.10% of scandium, 0.3-1.0% of lanthanum and cerium, 0.05-0.18% of iron, silicon not more than 0.05%, nickel not more than 0.05, magnesium not more than 0.02, zinc not more than 0.04, boron not more than 0.01, and the balance of aluminum and inevitable impurities. The preparation method comprises the following steps: foundry returns, aluminum ingots and Al-Fe intermediate alloy blanks are put in a smelting furnace, are heated for melting, and are transferred into an insulation furnace; then, Al-Zr, Al-Sc, Al-Y and Al-RE intermediate alloys are added for refining and deslagging to prepare fine alloy melts; a continuous casting and continuous rolling process is adopted to firstly pour the fine alloy melts as aluminum alloy castings; and the aluminum alloy castings are leaded into a rolling mill to roll aluminum alloy rods with needed specifications. The aluminum alloy conductor material is high in electric conductivity and excellent in high-temperature resistance; and the preparation method needs no heat treatment, saves the energy consumption, and reduces the production cost.

Owner:河北欣意电缆有限公司

Pr-Nd-containing zinc-aluminum alloy wire and manufacturing method thereof

ActiveCN102703777AReduce harmful effectsHigh strengthMolten spray coatingRare-earth elementLarge size

The invention relates to a multielement zinc-aluminum alloy wire which comprises the following components in percentage by weight: 15-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.2% of Pr, 0.01-0.2% of Nd (the total amount of the two rare-earth elements is 0.02-0.40%), at most 1% of microelements and the balance of Zn. The resistivity of the zinc-aluminum alloy wire is 2.0-6.0 mu omega.cm, the specific gravity of the zinc-aluminum alloy wire is 3.18-5.69 is g / cm<3>, and the elongation percentage of the zinc-aluminum alloy wire is 10-25%; and thus, the zinc-aluminum alloy wire can be widely used in ships, power supply towers, large-size storage tanks, underground pipelines, tunnel frames and other facilities, and has very wide application prospects.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Thermal treatment process of aluminum foil stock

A thermal treatment process of aluminum foil stock comprises the steps of: carrying out high-temperature homogenizing annealing when an original plate blank is rolled into be 2.0-4.0mm in thickness, wherein the high-temperature homogenizing annealing is realized by three steps: adopting segmented time annealing under the condition being 540-560 DEG C, rolling continuously after the high-temperature homogenizing annealing according to annealing time with different specifications; carrying out intermediate annealing by one time when the aluminum foil stock is rolled to be 0.50-0.70mm in thickness, carrying out annealing treatment by five steps, and determining the temperature time according to specification requirements of a product. The pinhole degree of the aluminum foil produced by using the process disclosed by the invention is smaller than 300 / m<2>; the rate of finished products is greater than or equal to 90%; the strength of 0.006mm aluminum foil is 70-90MP, and the surface quality and the metallic luster are uniform.

Owner:CENT SOUTH UNIV

Antibacterial enamel material and preparation method and application thereof

ActiveCN105601113AImprove compactnessReduce pinhole rateDomestic stoves or rangesLighting and heating apparatusMicrowaveTemperature resistance

The invention provides an antibacterial enamel material and a preparation method and application thereof. The antibacterial enamel material is prepared from a matrix agent, an adhesive agent, an auxiliary agent and an antibacterial agent. The antibacterial enamel material has ideal antibacterial performance and low sintering temperature while good high-temperature resistance, acid and alkali resistance, scraping resistance, corrosion resistance and other performance are achieved, no gas is generated when the material is combined with a metal base material, the compactness of enamel is good, the pinhole rate is low, the adherence between the material and the metal base material is good, binding force between the material and the metal base material is high, the enamel material is not prone to falling off, and besides, the enamel material has small wave absorbing performance and is high in microwave outputting rate.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Preparing method for rare earth aluminum alloy material good in corrosion-resisting performance

The invention discloses a preparing method for a rare earth aluminum alloy material good in corrosion-resisting performance and belongs to the technical field of preparing of aluminum alloys. The rareearth aluminum alloy material comprises the following raw materials including aluminum, copper, vanadium, manganese, tin, chromium, rare earth elements, titanium carbide, tungsten carbide, tungsten silicide, tungsten, a refeining agent and a grain refining agent. The rare earth aluminum alloy material is prepared through the steps of melting, refining, drossing, casting and the like. By the adoption of the technology, the corrosion-resisting performance of the rare earth aluminum alloy material can be obviously improved.

Owner:广西丰达三维科技有限公司

La-Nd-containing zinc-aluminum alloy wire and production method thereof

The invention relates to a multi-element zinc-aluminum alloy wire. The multi-element zinc-aluminum alloy wire comprises, by weight percent, 15%-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.7% of La, 0.01-0.2% of Nd, not more than 1% of added microelements, and the balance of Zn, wherein the two rare earth elements have a total amount of 0.02-0.76%. The zinc-aluminum alloy wire has a resistivity of 2.0-6.0 Mu Omega / cm, a specific gravity of 3.18-5.69g / cm<3>, and an elongation of 10-25%. The multi-element zinc-aluminum alloy wire is widely applicable to ships, power supply towers, large storage tanks, underground pipelines and facilities such as tunnel frames, and has broad application prospect.

Owner:JIANGSU LINLONG NEW MATERIALS

Preparation method of low-segregation-degree motor rotor microalloy aluminum of new energy automobile and microalloy aluminum prepared through preparation method

The invention discloses a preparation method of low-segregation-degree motor rotor microalloy aluminum of a new energy automobile, which comprises the following steps: (1) preheating a mixture of titanium, boron, silicon, iron, copper, magnesium, zinc and aluminum, charging into a furnace for smelting, paving a layer of covering agent on the surface, and heating to 670-800 DEG C; (2) adding a refining agent for refining, performing standing and slag removal to obtain refined melt A; (3) heating the refined melt A to 800-900 DEG C, firstly adding lanthanum, preserving heat for 15-30 minutes, then adding ytterbium, stirring, paving a covering agent, preserving heat for 10-60 minutes, and then cooling; (4) when the temperature is reduced to 670-800 DEG C, adding a refining agent for refining, standing, covering and slagging off to obtain refined melt B; and (5) spraying coating on the inner side of a casting mold, pouring the refined melt B into the casting mold, performing centrifugal casting for 20-40 s, and taking the microalloy aluminum out. According to the method, by adding lanthanum and ytterbium, pinholes are eliminated, and the mechanical property of the microalloy aluminum is improved; and through the regulation and control of each preparation step, the cooling time is shortened, migration and aggregation of TiAl3 and TiB2 are reduced, and segregation is reduced.

Owner:SHANDONG BOYUAN PRECISION MASCH CO LTD

Rare earth aluminum alloy

The invention discloses a rare earth aluminum alloy, and belongs to the technical field of aluminum alloy preparing. The rare earth aluminum alloy comprises the following raw materials of aluminum, copper, vanadium, manganese, tin, chromium, a rare earth element, titanium carbide, tungsten carbide, tungsten silicide, tungsten, a refining agent and a grain refiner; and the rare earth aluminum alloyis prepared through the steps of fusion, refining, drossing, casting and the like. By means of the process, the strength of extension, the elongation at break and the corrosion resistance of the rareearth aluminum alloy can be obviously improved.

Owner:广西丰达三维科技有限公司

Aluminum-titanium (Al-Ti) alloy wire containing praseodymium (Pr) and neodymium (Nd) and method for manufacturing same

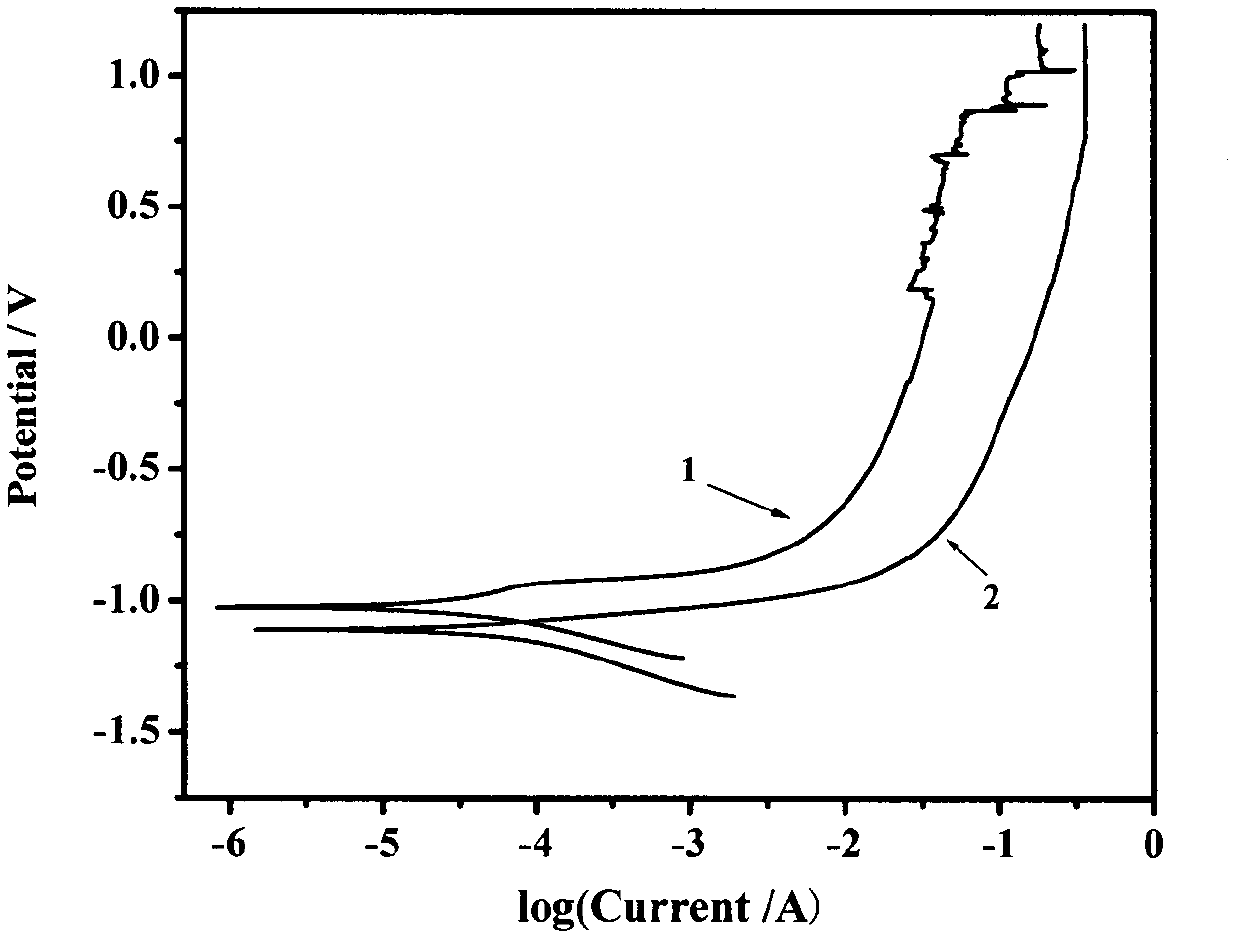

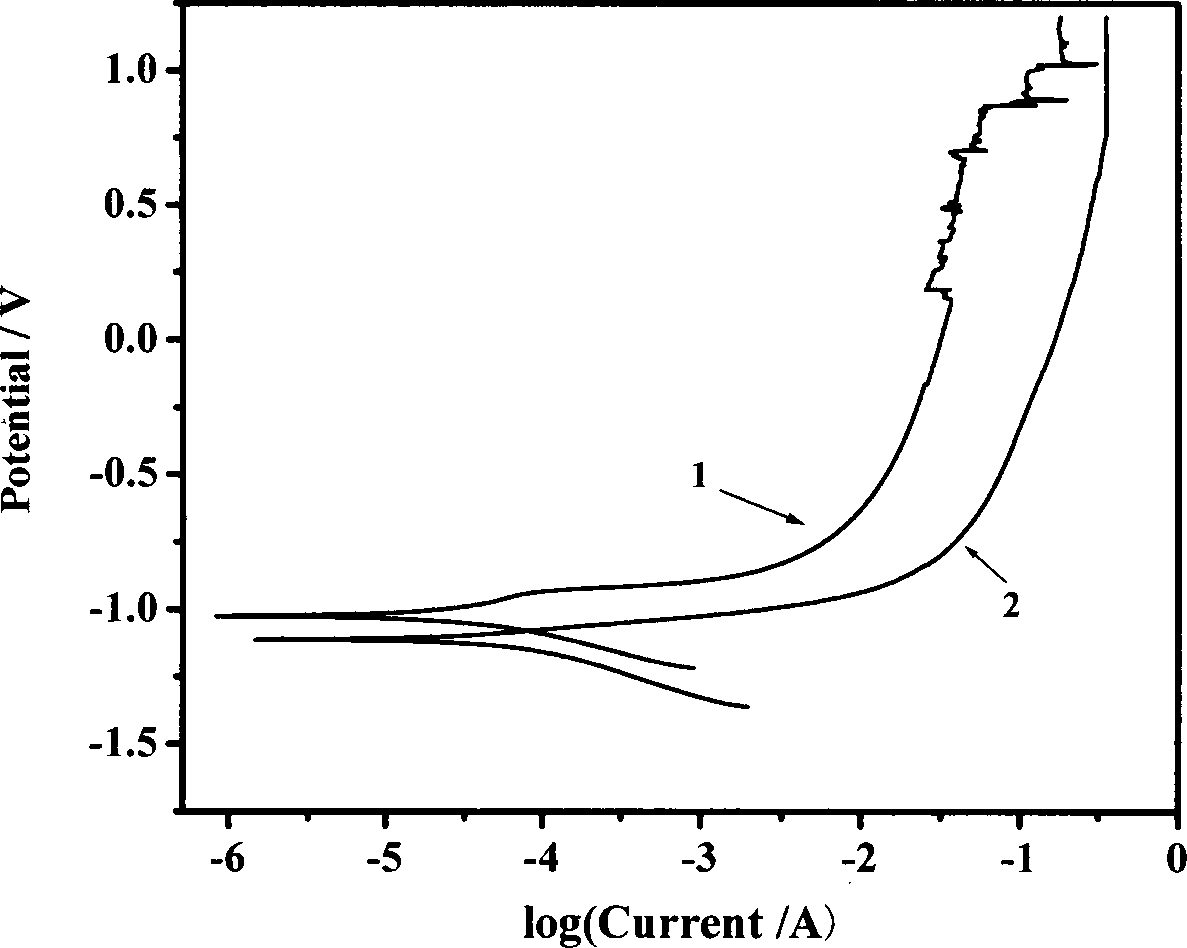

ActiveCN102605215AImprove passivation effectStrong expandabilityMolten spray coatingRare earthTitanium

The invention relates to a multi-component aluminum-titanium (Al-Ti) alloy wire which comprises the following components in percent by weight: 94-97% of Al, 0.05-1% of vanadium (V), 2-5% of Ti, 0.01-0.2% of praseodymium (Pr), 0.01-0.2% of neodymium (Nd). The total percent by weight of the two rear-earth elements which are Pr and Nd is 0.02-0.40%, and the total percent by weight of the added traceelements is 1% or less. The Al-Ti alloy wire has the resistivity of 2.0-6.0 muohm.cm, the specific weight of 2.60-2.75g / cm<3> and the elongation rate of 10-25%.

Owner:JIANGSU LINLONG NEW MATERIALS

Zinc-aluminum-magnesium alloy wire containing rare earth, and preparation method and application thereof

The invention discloses a zinc-aluminum-magnesium alloy wire containing rare earth, and a preparation method and application thereof. The zinc-aluminum-magnesium alloy wire is prepared from the following components: 15 to 40 percent of aluminum, 0.2 to 4.0 percent of magnesium, 0.02 to 0.2 percent of rare earth elements, i.e. cerium and erbium, not larger than 0.025 percent of impurities, and the balance of zinc, wherein the mass ratio of the two rare earth elements i.e. Ce to Er is 3:7 or 7:3. According to the zinc-aluminum-magnesium alloy wire containing the rare earth provided by the invention, the rare earth elements such as the cerium and the erbium are added, so that the corrosion resistance is improved, meanwhile, the zinc-aluminum-magnesium alloy wire has the advantages of high strength, high hardness, low price and the like, and can replace a traditional zinc wire so as to be used for the fields such as spraying anticorrosion engineering, and a zinc-aluminum-magnesium alloy heat coating has an excellent adhesive force, favorable physical and mechanical properties and a corrosion resisting property. The average annual corrosion rate of the zinc-aluminum-magnesium alloy heat coating is larger than the average annual corrosion rates of a heat spraying zinc coating, a zinc aluminum alloy coating, a zinc aluminum pseudo alloy coating and the like, and an anodic protection effect of the zinc-aluminum-magnesium alloy heat coating is remarkably improved compared with the anodic protection effects of aluminum and other aluminum alloy heat spraying metal layers; the whole wire material processing and manufacturing process is simple and convenient, and the cost is lower.

Owner:GUANGZHOU YUEHUI METAL MACHINERY PROTECTION TECH +2

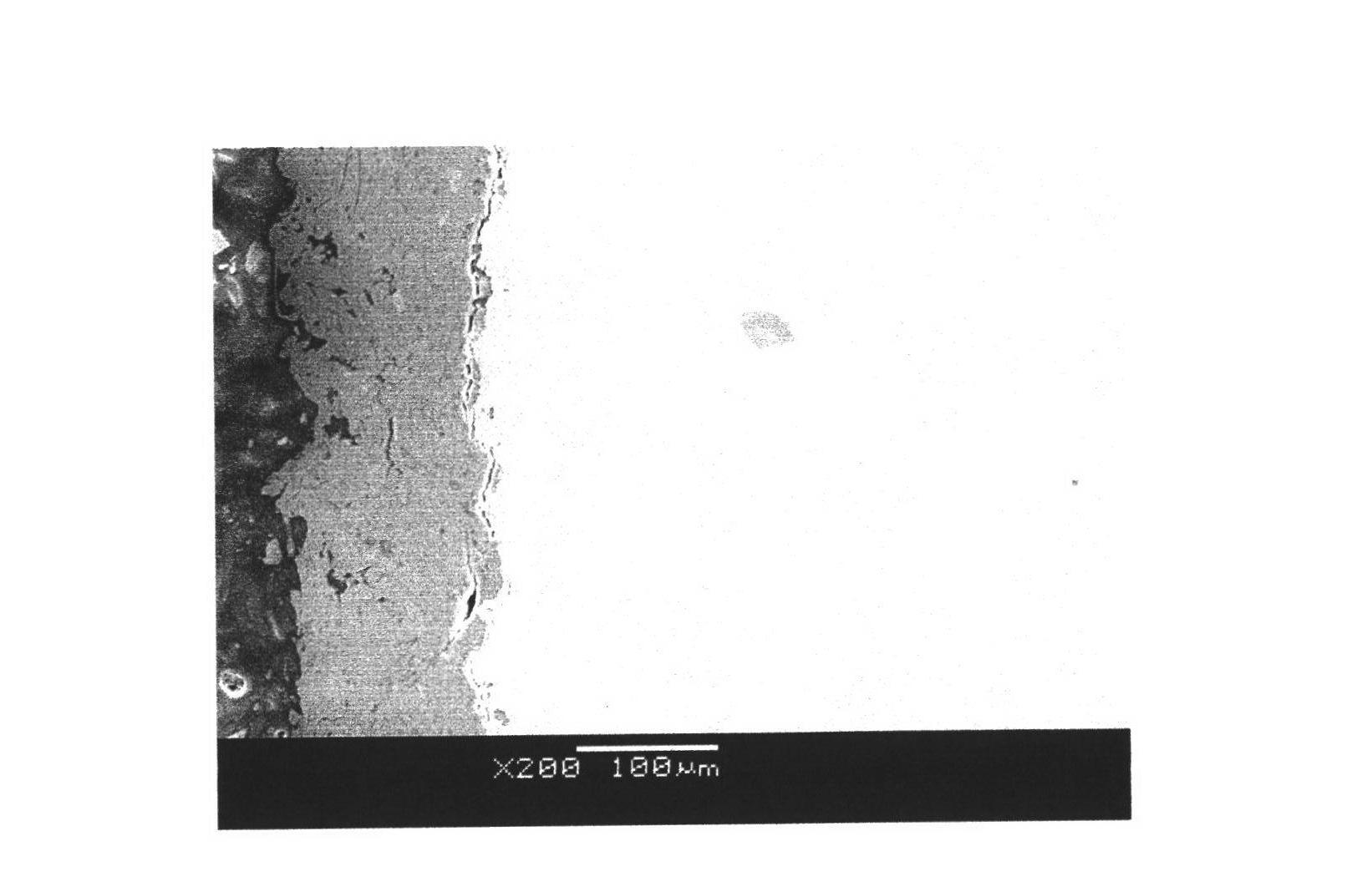

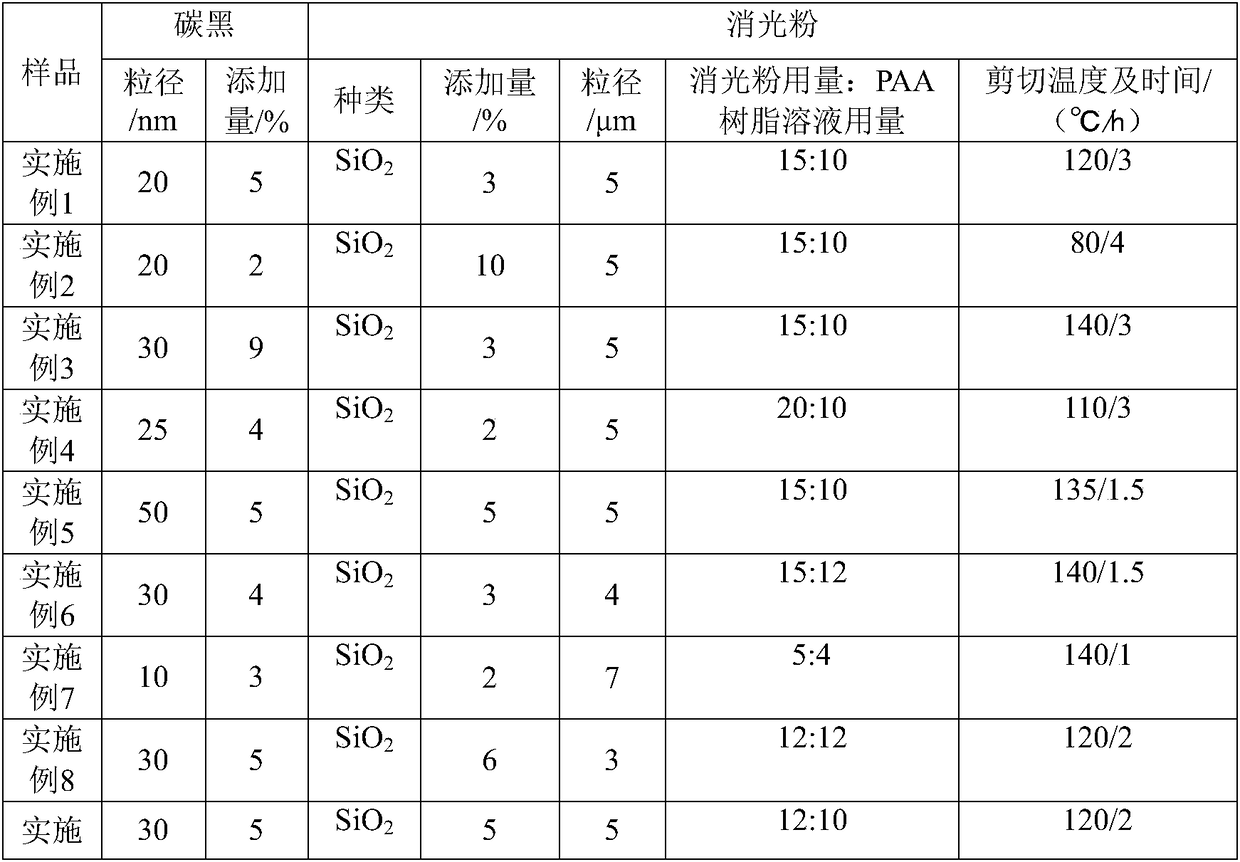

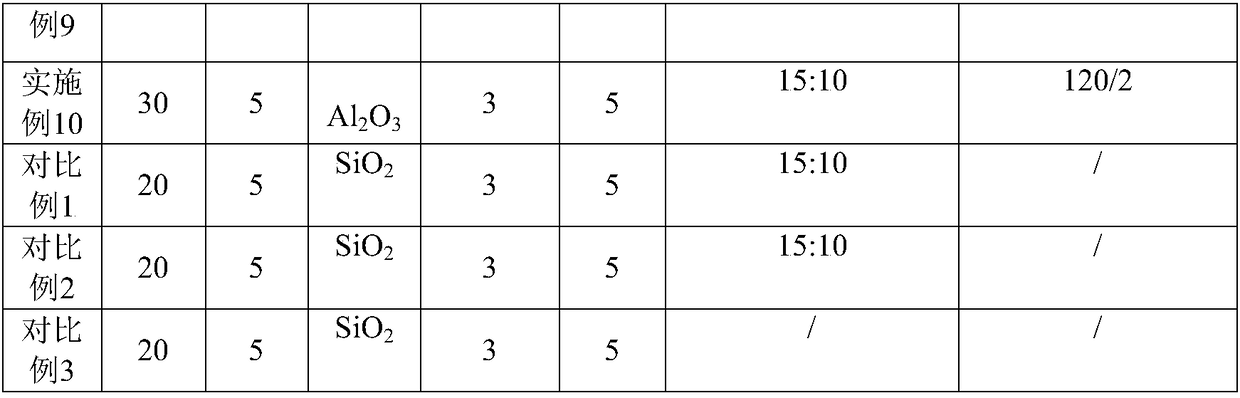

Preparation method for black low-matte polyimide film

The invention discloses a preparation method for a black low-matte polyimide film. The method comprises the following steps: 1) uniformly dispersing matting powder in an aprotic polar solvent, addinga polyamide acid resin solution into the obtained mixed liquid, heating the obtained material to 80-140 DEG C, and then performing shearing dispersion to obtain a dispersion liquid A, wherein the usage amount of the matting powder is 5-10 times the solid content of the polyamide acid resin solution used in the step; 2) uniformly dispersing carbon black in the aprotic polar solvent to obtain a dispersion liquid B; and 3) adding diamine and dianhydride into the aprotic polar solvent for polycondensation so as to obtain a polyamide acid resin solution, adding the dispersion liquid A and the dispersion liquid B into the polyamide acid resin solution, performing uniform mixing, and then successively carrying out defoaming, tape casting, drawing and thermal imidization so as to obtain the blacklow-matte polyimide film. The film prepared by using the method of the invention has excellent tensile strength and electrical strength, low pinhole ratio and gloss, and more ideal overall performance.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Preparation method of chromium-alloy foamed metal

The invention discloses a preparation method of chromium-alloy foamed metal. The preparation method is characterized by the following steps of: selecting materials; chemically degreasing; washing in hot water; washing in cold water; leaching nanometer graphite chromium powder mixed conductive glue; electrically coating a nanometer Al2O3 and nickel composite depositing layer; washing in cold water; drying in air; oxidizing and reducing; leaching ammonium chloride and chromium; and diffusing at high temperature and the like to prepare the chromium-alloy foamed metal product. The preparation method of the chromium-alloy foamed metal has the advantages of being scientific and reasonable, easy to operate, small in raw material consumption, low in cost, free of pollution and the like. The chromium-alloy foamed metal prepared by the preparation method disclosed by the invention is large in thickness and pore diameter range, has a structure the same as that of the polyurethane foam, a large specific surface area, large specific strength, a stable gold-phase structure, good heat resistance and good corrosion resistance and is extensive in application field.

Owner:吉林市卓尔新型金属材料有限公司

Zinc-aluminum alloy wire containing La, Ce and Nd and production method thereof

ActiveCN102703780AReduce harmful effectsHigh strengthMolten spray coatingRare-earth elementPower tower

The invention relates to a multi-element zinc-aluminum alloy wire. The multi-element zinc-aluminum alloy wire comprises, by weight percent, 15%-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.8% of Ce, 0.01-0.2% of Pr, 0.01-0.2% of Nd, not more than 1% of added microelements, and the balance of Zn, wherein the three rare earth elements have a total amount of 0.03-0.92%. The zinc-aluminum alloy wirehas a resistivity of 2.0-6.0 Mu omega / cm, a specific gravity of 3.18-5.69g / cm<3>, and an elongation of 10-25%. The multi-element zinc-aluminum alloy wire is widely applicable to ships, power towers, large storage tanks, underground pipelines and facilities such as tunnel frames, and has broad application prospect.

Owner:JIANGSU LINLONG NEW MATERIALS

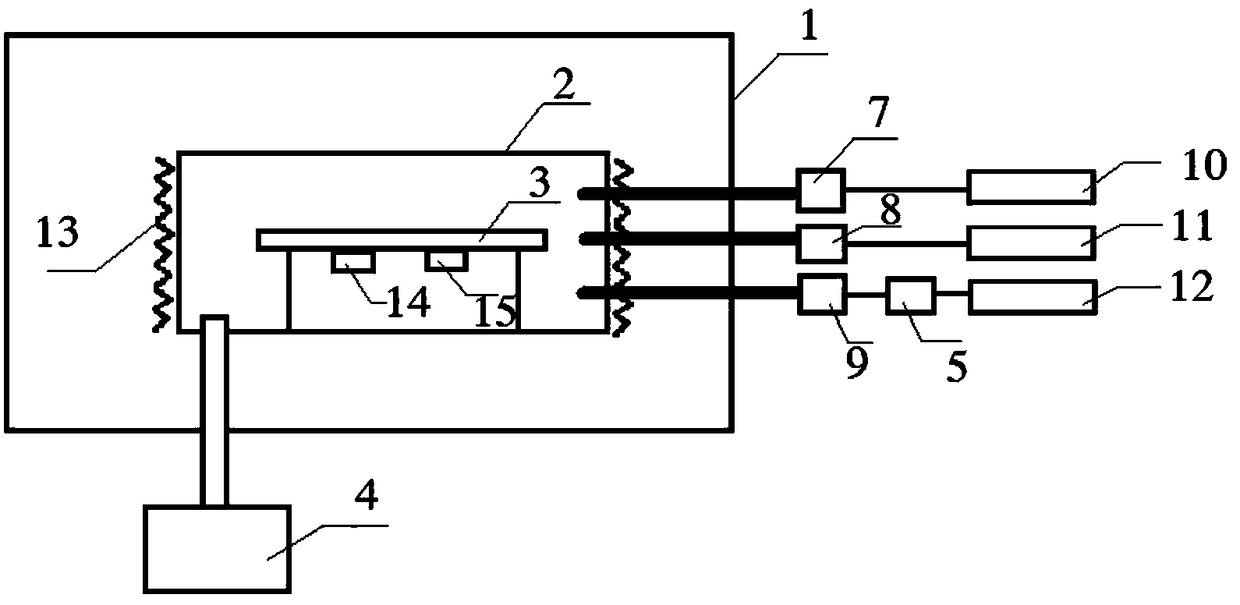

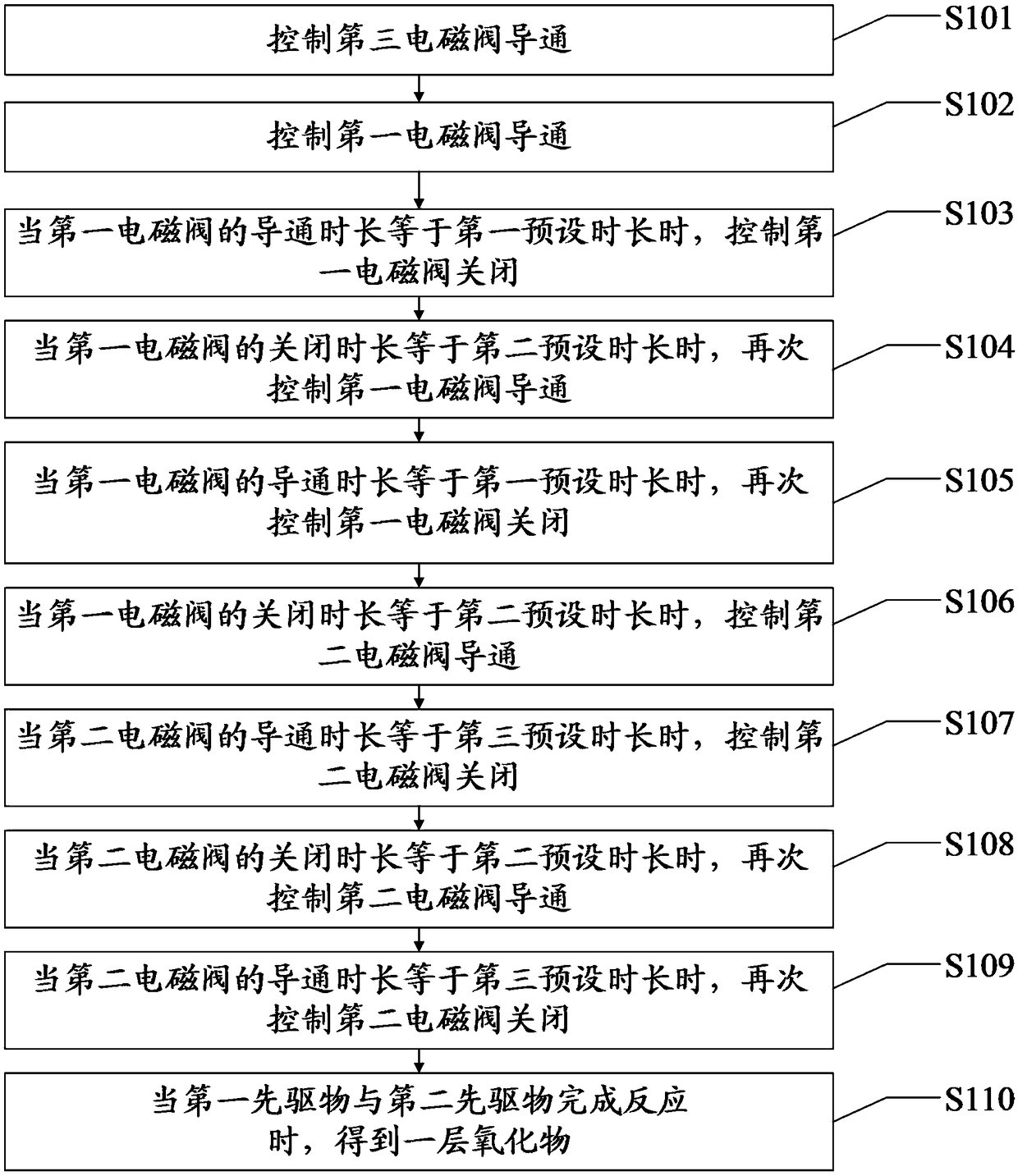

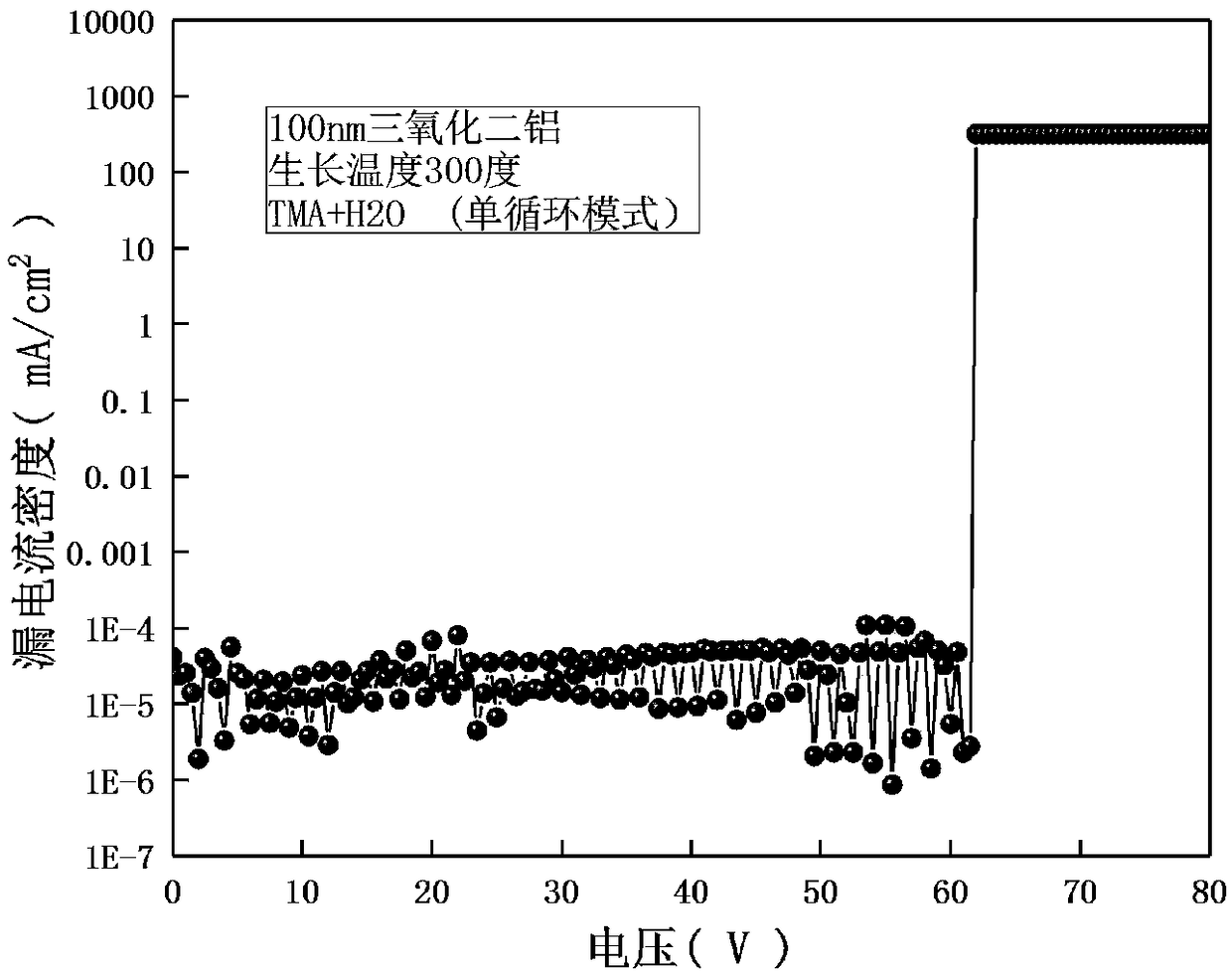

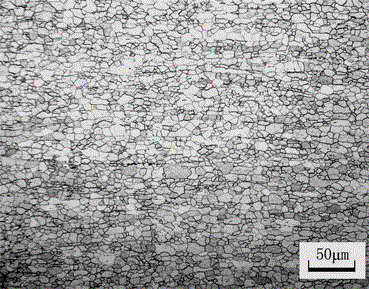

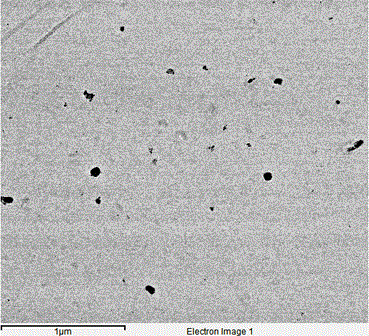

Device and method for depositing oxide film through atom layer deposition technology

The invention discloses a device and a method for depositing an oxide film through an atom layer deposition technology. The method comprises the following steps: controlling a third solenoid valve toconduct, and closing after controlling a first solenoid valve to conduct for first preset time length; conducting after controlling the first solenoid valve to close for second preset time length; closing after controlling the first solenoid valve to conduct for the first preset time length; conducting a second solenoid valve after controlling the first solenoid valve to close for the second preset time length; closing after controlling the second solenoid valve to conduct for third preset time length; conducting after controlling the second solenoid valve to close for the second preset time length; closing after controlling the second solenoid valve to conduct for the third preset time length, thereby completing preparation of one layer of oxides, and repeating the preparation process forone layer of the oxides by many times to obtain the oxide film. The method for depositing the oxide film is used for continuously introducing a first precursor into the device for depositing the oxide film twice, and continuously introducing a second precursor twice after adopting nitrogen gas purging, so that a pinhole rate of the deposited oxide film is reduced.

Owner:SHANGHAI UNIV

A kind of all-ferrite enamel steel for heat exchanger and its production method

InactiveCN104087828BSimple chemical compositionImprove performanceHydrogen permeationUltimate tensile strength

The invention relates to a full-ferrite enamel steel for a heat exchanger. The full-ferrite enamel steel comprises the following chemical components in percentages by weight: less than or equal to 0.0050% of C, 0.10-0.50% of Mn, less than or equal to 0.010% of Si, less than or equal to 0.020% of P, 0.015-0.045% of S, less than or equal to 0.010% of Als, 0.010-0.055% of Nb, less than or equal to 0.0030% of B and 0.010-0.050% of O; the production method comprises the following steps of pretreating molten iron, smelting, refining and continuously casting by virtue of a converter; heating the cast blank; carrying out hot rolling; coiling and acid pickling; carrying out cold rolling; annealing; finishing for later use. The microstructure of the enamel steel disclosed by the invention is full ferrite, the grain size of ferrite reaches Grade 11, the main inclusions are long-wire-shaped MnS and granular Mn / Nb composite oxides, the precipitated phases are fine NbC / N and BN particles, Rel is 180-240MPa, the tensile strength is 280-360MPa, the elongation is 36-46%, the hydrogen permeation time of the steel plate is equal to or greater than 25min / mm<2>, no scute burst is caused after enamelling, enamel adhesion strength is greater than A1 level and the pinhole rate is less than 10 / m<2>.

Owner:武汉钢铁有限公司

Anti-oxidation metal product

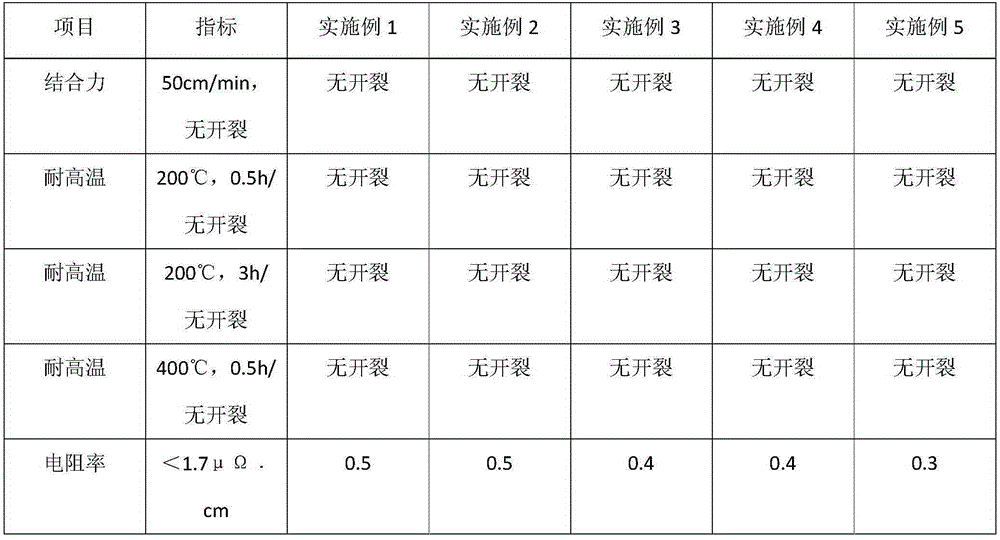

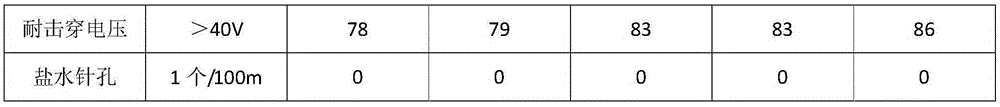

InactiveCN105355616AImprove bindingHigh temperature resistantSemiconductor/solid-state device detailsSolid-state devicesOxidation resistantTemperature resistance

The invention discloses an anti-oxidation metal product. The anti-oxidation metal product is bonding brass wires, purity of the brass wires is greater than or equal to 99.99wt%, the surface of the brass wires is coated with an anti-oxidation layer with thickness of 1-2nm, the anti-oxidation layer is composed of 0.1-0.5 parts of fullerene, 2-8 parts of aluminum, 8-15 parts of polyethylene, 11-16 parts of polyacrylamide and 1-3 parts of carbon disulfide by weight. The anti-oxidation metal product has advantages of high bonding force of a coating layer, low pinhole rate, high temperature resistance capability, great oxidation resistance capability, low resistivity, excellent conductivity and high breakdown resistance voltage, the anti-oxidation metal product can further stand 400 DEG C temperature and can stand 200 DEG C high temperature environments for three hours, and thereby a brass wire oxidation problem can be effectively solved.

Owner:GUANGDONG MEIYAN JIXIANG IND INVESTMENT

Ce-Nd-containing zinc-aluminum alloy wire and production method thereof

The invention relates to a multi-element zinc-aluminum alloy wire. The multi-element zinc-aluminum alloy wire comprises, by weight percent, 15%-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.7% of Ce, 0.01-0.2% of Nd, not more than 1% of added microelements, and the balance of Zn, wherein the two rare earth elements have a total amount of 0.02-0.76%. The zinc-aluminum alloy wire has a resistivity of 2.0-6.0 Mu omega / cm, a specific gravity of 3.18-5.69g / cm<3>, and an elongation of 10-25%. The multi-element zinc-aluminum alloy wire is widely applicable to ships, power towers, large storage tanks, underground pipelines and facilities such as tunnel frames, and has broad application prospect.

Owner:JIANGSU LINLONG NEW MATERIALS

La and Pr-containing aluminum titanium alloy wire and production method thereof

The invention relates to an a multielement aluminum titanium alloy wire, which comprises the following components in weight percentage: 94-97% of Al; 0.05-1% of V; 2-5% of Ti; 0.01-0.7% of La, and 0.01-0.2% of Pr, wherein the total amount of the two rare-earth elements is 0.02-0.76%, the total amount of trace additional elements is not greater than 1%, the resistivity of the aluminum titanium alloy wire is 2.0-6.0 muomega*cm, the specific weight of the aluminum titanium alloy wire is 2.60-2.75g / cm<3>, and the percentage elongation of the aluminum titanium alloy wire is 10-25%.

Owner:JIANGSU LINLONG NEW MATERIALS

Rare-earth modified aluminum alloy materials and application thereof

The invention discloses rare-earth modified aluminum alloy materials and an application thereof, and belongs to the technical field of aluminum alloy preparation. The rare-earth modified aluminum alloy materials comprise, by mass, 1200-1850 parts of aluminum, 12-19 parts of copper, 5-8 parts of vanadium, 2-6 parts of manganese, 4-8 parts of tin, 1-3 parts of chromium, 20-38 parts of rare earth elements, 10-15 parts of titanium carbide, 8-12 parts of tungsten carbide, 7-9 parts of tungsten silicide, 3-5 parts of tungsten, 15-20 parts of refining agents, and 26-35 parts of grain refiners. The rare-earth modified aluminum alloy materials are prepared through the steps of melting, refining, slagging off, casting and the like. The rare-earth modified aluminum alloy materials are applied to aluminum alloy cables so that the tensile strength, the elongation at break and the corrosion resistance can be remarkably improved.

Owner:广西丰达三维科技有限公司

High-strength anti-cracking aluminum alloy welding wire for welding joint

InactiveCN107214432AHigh yield strengthHigh hardnessWelding/cutting media/materialsSoldering mediaUltimate tensile strengthImpurity

The invention discloses a high-strength anti-cracking aluminum alloy welding wire for a welded joint. The high-strength anti-cracking aluminum alloy welding wire comprises, by mass, Mg, B, Li, Cu, Si, Ti, Cr, Mn, Fe, V, Sr, Na, Zr, Nb, Mo, Pr, Ce, Nd, and the balance Al and inevitable impurities. The high-strength anti-cracking aluminum alloy welding wire for the welded joint, provided by the invention, is reasonable in component, little in splash in the welding process, compact in deposited metal structure and free of pores and cracks. The welded joint has the advantages of high strength, good anti-cracking property, large base metal bonding strength and the like. The overall performance of a metal component is improved.

Owner:安徽飞弧焊业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com