Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155results about How to "Simple chemical composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diphasic steel plate by continuous casting and rolling middle bar strip and manufacturing method thereof

ActiveCN101130847ASimple chemical compositionHigh tensile strengthMetal rolling arrangementsChemical compositionSheet steel

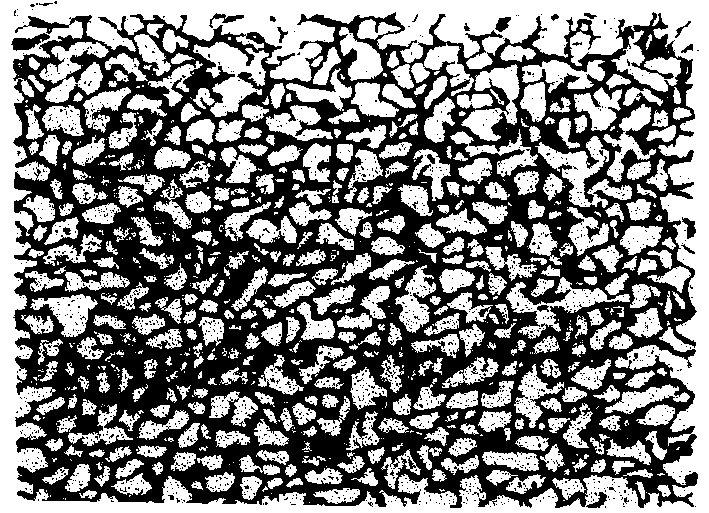

The present invention provides a dual phase steel sheet made up by using medium-thin sheet billet through a certain continuous-casting and continuous-rolling process. The component composition of said steel sheet includes (by wt%) 0.04%-0.11% of C, 0.02%-1.5% of Si, 0.6%-2.50% of Mn, 0.02%-2.0% of Cr, also can contain Mo or Ti, the rest is Fe and unavoidable impurity. The microscopic structure of said steel sheet includes: matrix phase is ferrite and second phase mainly is martensite. Besides, said invention also provides the concrete operation steps of its production method.

Owner:ANGANG STEEL CO LTD

Biodegradable plastic composition and producing method thereof

InactiveUS20050288399A1Simple chemical compositionEasy to makePaper coatingCoatingsSynthetic resinAlkene

A biodegradable plastic composition is provided. The biodegradable plastic composition includes a starch in a range from about 25% to about 50% by weight of the composition, a synthetic biodegradable resin in a range from about 10% to about 40% by weight of the composition, a synthetic resin with linear alkenes in a range from about 5% to about 15% by weight of the composition, an affinity agent in a range from about 8% to about 20% by weight of the composition, a coupling agent in a range from about 1% to about 3% by weight of the composition, and an additives in a range from about 1% to about 15% by weight of the composition. Further, a producing method of the biodegradable plastic also is provided.

Owner:CHEN MING TUNG

High-performance building structure refractory steel plates and manufacturing method thereof

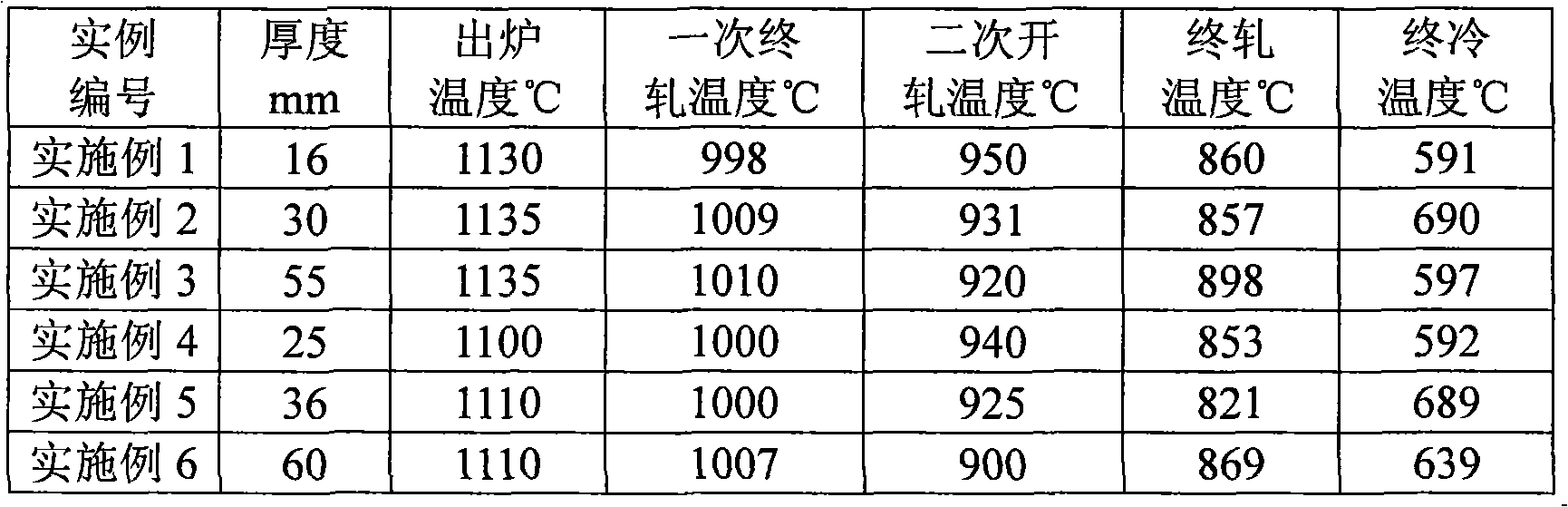

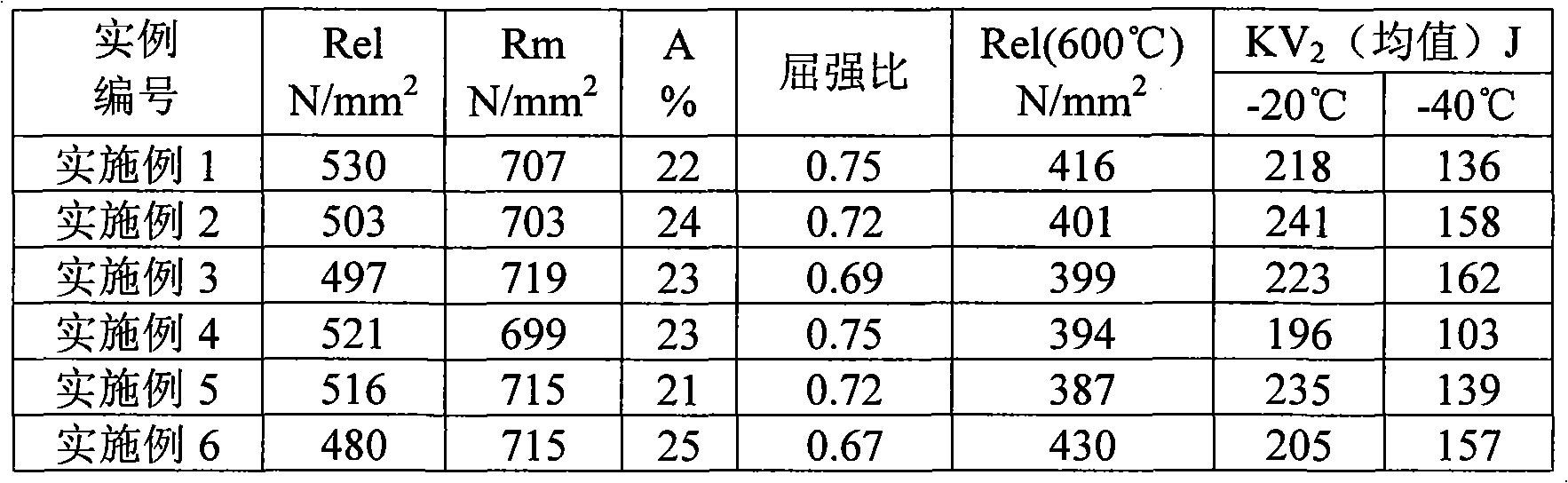

ActiveCN101906585AMeet design needsMeet construction needsTemperature control deviceChemical compositionHeating time

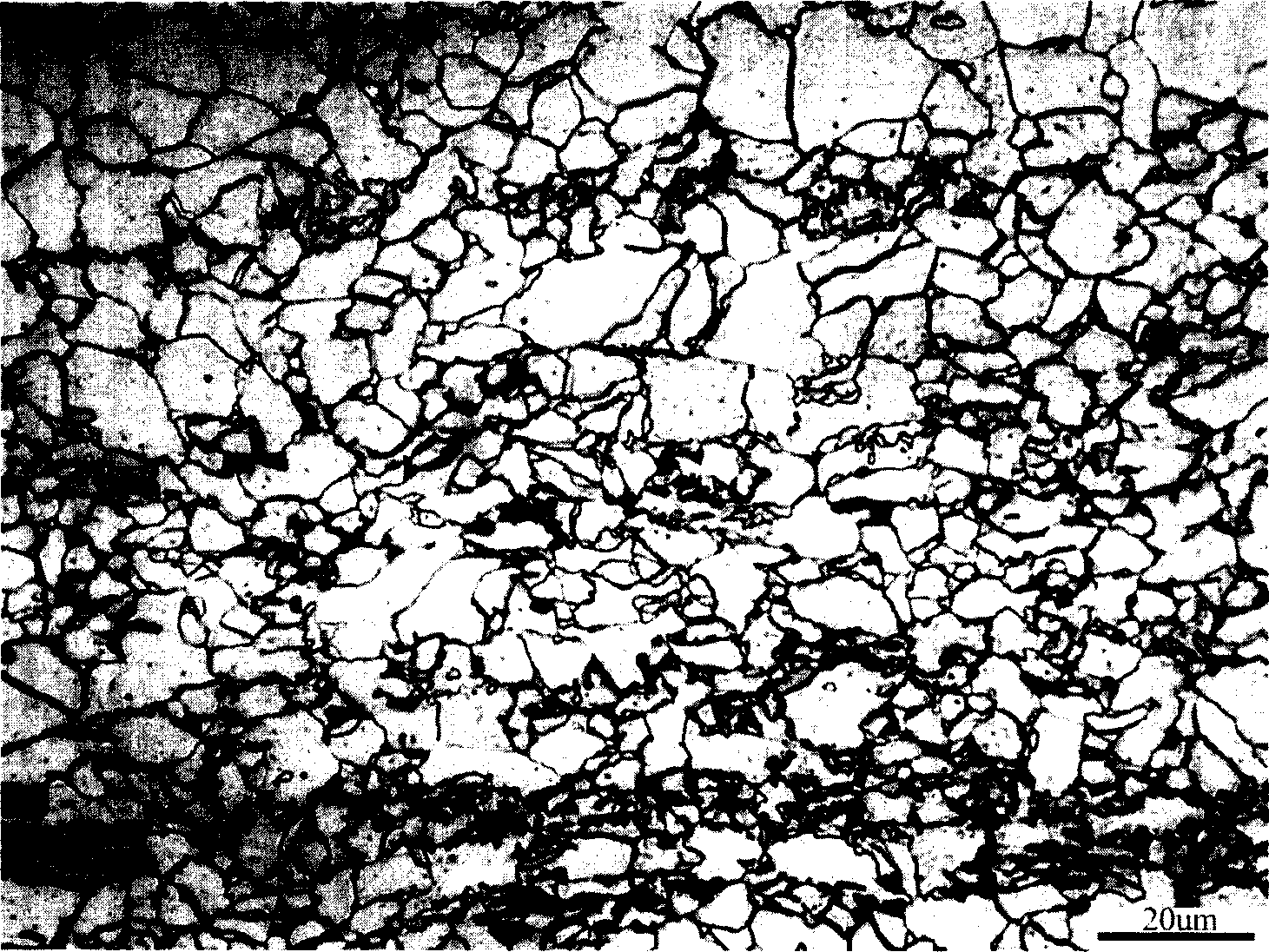

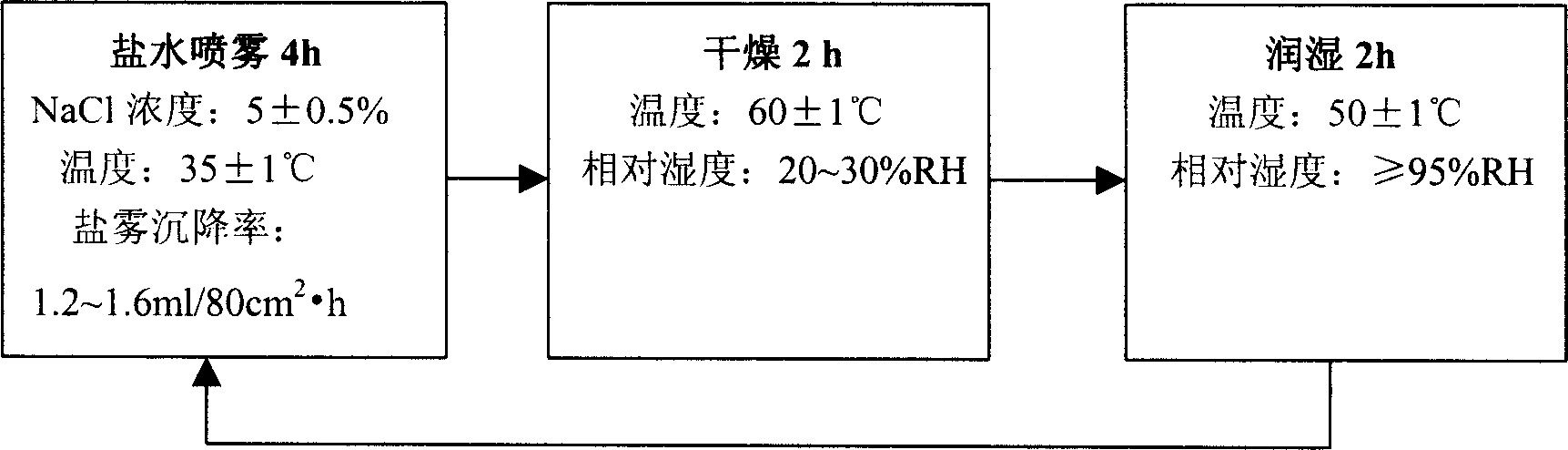

The invention discloses high-performance building structure refractory steel plates and a manufacturing method thereof. The high-performance building structure refractory steel plate comprises the following chemical components in percentage by weight: 0.02 to 0.12 percent of C, 0.05 to 0.50 percent of Si, 0.08 to 1.50 percent of Mn, 0.010 to 0.050 percent of Nb, 0.010 to 0.040 percent of Ti, 0.010 to 0.050 percent of Als, 0.20 to 0.60 percent of Cr, 0.20 to 0.40 percent of Mo, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.0040 percent of N, less than or equal to 0.0020 percent of O and the balance of Fe and inevitable impurities. The production process of the high-performance building structure refractory steel plates is characterized in that: the steel blank heating temperature is 1,100 to 1,250 DEG C; the heating time is 60 to 110s / cm; two-stage controlled rolling is adopted; the final rolling temperature is kept between 800 and 900 DEG C; cooling is started 30 to 120 seconds later after final rolling; the final cooling temperature is kept between 500 and 750 DEG C; the steel plates are stacked quickly, cooled slowly and kept at a constant temperature; the stacking temperature is kept between 650 and 300 DEG C; and the temperature is kept for 10 to 24 hours. The plates have the characteristics of simple chemical components, low cost, and high refractability.

Owner:ANGANG STEEL CO LTD

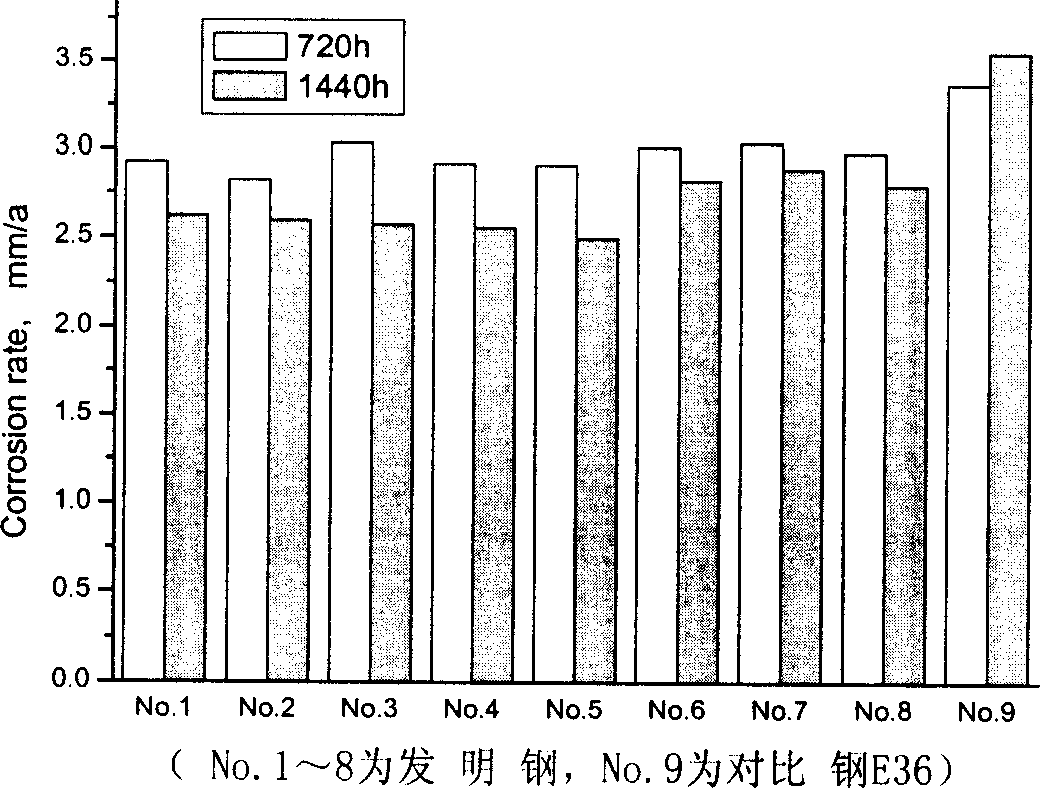

Sea water corrosion resistant steel for ocean drilling/production platform and preparation method thereof

InactiveCN1908217AReduce unevennessAvoid corrosionRoll mill control devicesWelding/cutting media/materialsChemical compositionImpurity

the invention discloses a marine exploiting platform steel of erosion property of sea water resistance, which comprises the following parts: 0.03-0.09% C, 0.90-1.60% Mn, 0.10-0.50% Si, 0.006-0.020% P, 0.004-0.100% Cr, 0.02-0.40% Cu, 0.010-0.060% Als, 0.005-0.060% Nb, 0.005-0.030% Ti, Fe and impurity. the manufacturing method comprises the following steps: desulfurizing; blowing; disposing through vacuum; casting continually; rolling.

Owner:武钢集团有限公司

Method for producing steel plate of petroleum storage tank by using direct quenching process

The invention discloses a method for producing a steel plate of a petroleum storage tank by using a direct quenching process. The invention provides a chemical composition of special petroleum storage tank steel and adopts a direct quenching process. The method comprises the following steps of: heating a steel blank to 1100 to 1280 DEG C, rolling into a steel plate in re-crystallization and non-recrystallization stages; carrying out on-line quenching operation under the conditions that the temperature of the steel plate is between 780 DEG C and 900 DEG C, the average cooling rate ranges from 25 DEG C / s to 60 DEG C / s, the cooling terminal temperature is less than or equal to 350 DEG C, and performing off-line tempering on the steel plate subjected to quenching. Compared with the conventional high-energy-consumption hardening process based on the combination of off-line tempering and tempering, the method provided by the invention has the advantages of short production flow and low energy consumption and the prepared steel plate has good general mechanical properties and high heat input welding property. The yield strength of the steel plate is more than 490 MPa and the tensile strength of the steel plate is more than 610 MPa. In case of high heat input welding (less than or equal to 400 KJ / cm), a welding heat affected zone maintains excellent low-temperature toughness, and the mean value of work done by impact at -20 DEG C is more than 50 J.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

Martensite abrasion-resistant steel with high strength and production produce thereof

The invention relates to a ferrous alloy and a production process thereof, especially a martensite abrasion resistant steel and a production process thereof. The martensite abrasion-resistant steel with high strength is prepared from raw chemical components by weight percentage as follows: 0.1%<=C<=0.2%, 0.5%<=Si<=1.0%, 1.0%<=Mn<=2.0%, P<=0.009%, S<=0.004%, Al<=0.03%, 0.02%<=Nb<=0.04%, 0.02%<=Ti<=0.03%, 0.015%<=V<=0.060%, 0.0015%<=B<=0.0020%, the residual is Fe and other unavoidable impurity. The production produce of the martensite abrasion-resistant steel with high strength is that: smeltingin converter or electric furnace - secondary refining in vacuum furnace - casting billet or casting ingot - reheating billet or steel ingot - TMCP + rapidly cooling process - steel plate. The martensite abrasion-resistant steel with high strength has higher strength, hardness, toughness and abrasion-resistance, which can ensure weldability and reduce cost.

Owner:BAOSHAN IRON & STEEL CO LTD

600MPa grade high-strength weathering steel and preparation method thereof

InactiveCN101225498ASimple chemical compositionThe production process is easy to controlMetal rolling arrangementsChemical compositionThin slab

The invention discloses a 600MPa high strength weathering steel and the manufacturing method, which is characterized in that: the 600MPa high strength weathering steel adopts electric stove-thin slab continuous casting and rolling process for preparation; the main chemical components of the refined molten steel for preparing the high strength weathering steel are: C: 0.045 wt % to 0.07wt%, Si: 0.10 wt % to 0.29wt%, Mn: 0.8 wt % to 1.5wt%, P: 0.005 wt% to 0.030wt%, S: 0.002 wt% to 0.008 wt%, Cu: 0.20 wt% to 0.5wt%, Cr: 0.3 wt% to 0.7wt%,Ni: 0.15 wt % to 0.35wt%, Ti: 0.06 wt% to 0.079wt%, Nb: 0.035 wt% to 0.050wt%, Alt: 0.025 wt% to 0.050wt%. The 600MPa high strength weathering steel has the advantages of low cost, strong competitiveness, cold formability, good welding performance and application to tower frame, heavy duty automobile, bridge, container, railway vehicle manufacture.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Soldering boat deck steel in high intensity by large line energy, and manufacturing method

InactiveCN101050502ASimple chemical compositionThe process is simpleRoll mill control devicesMetal rolling arrangementsChemical compositionHigh intensity

This invention relates to a method for producing high-strength ship plate steel suitable for high heat input welding. The chemical compositions of the ship plate steel are: C 0.01-0.18 wt.%, Si 0.05-0.4 wt.%, Mn 1.0-1.8 wt.%, Als 0.001-0.06 wt.%, Nb 0.01-0.08 wt.%, Ti 0.01-0.08 wt.%, N 0.002-0.012 wt.%, B 0.0001-0.0030 wt.%, one or more of Ca, Mg and Zr 0.0001-0.030 wt.%, P less than 0.015 wt.%, S less than 0.010 wt.%, Fe and impurities. The method comprises: keeping the oxygen content in the molten steel at 10-600 ppm, performing deoxidation with Fe-Ti alloy or metal Ti after steelmaking, adding one or more of Ca, Mg and Zr, performing final deoxidation with Al wire, adding B, casting, homogenizing, rolling, relaxing, and cooling online. The obtained ship plate steel has such advantages as simple chemical compositions, simple process, and high heat input welding, and is suitable for producing ships.

Owner:WUHAN UNIV OF SCI & TECH

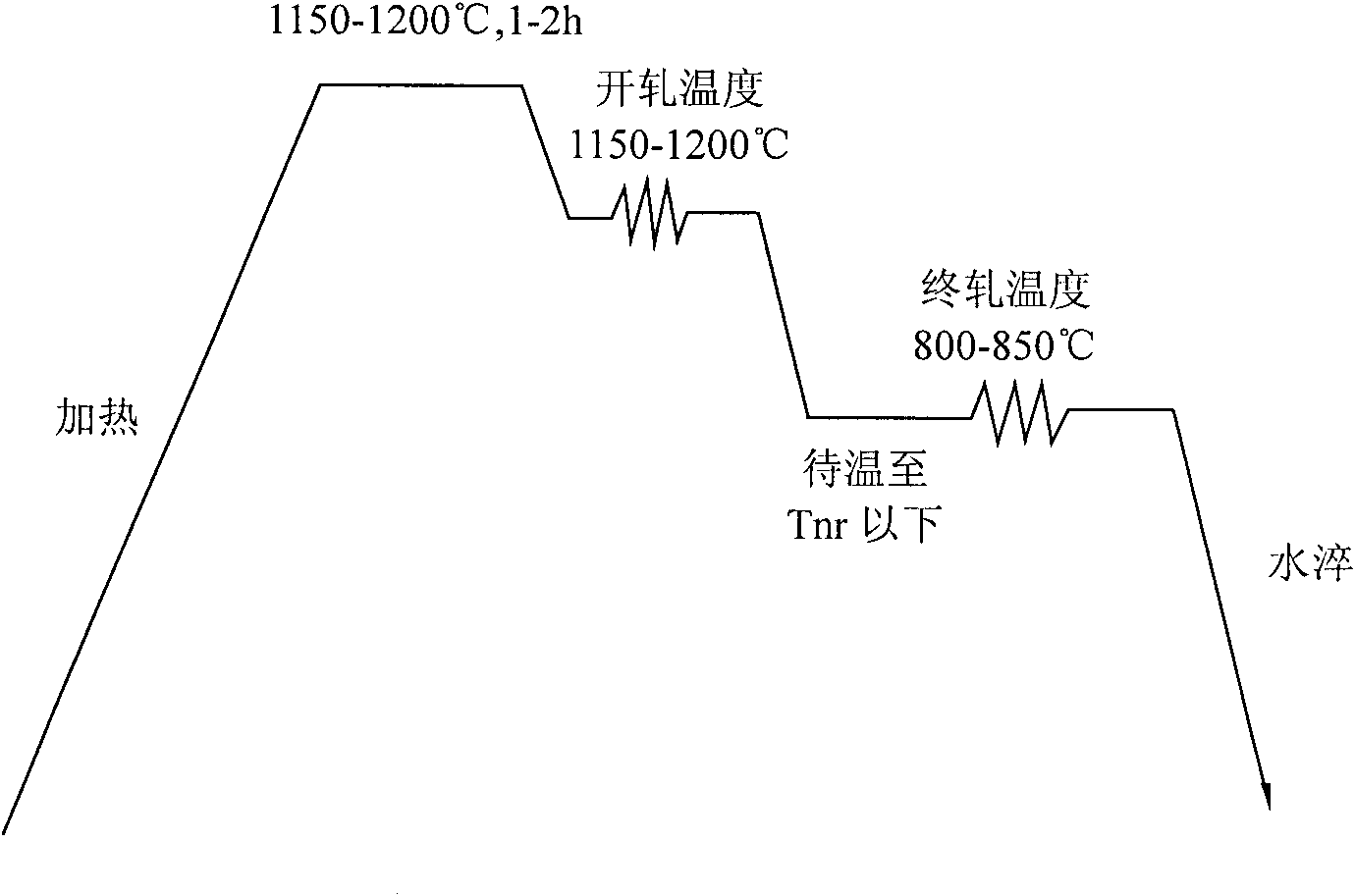

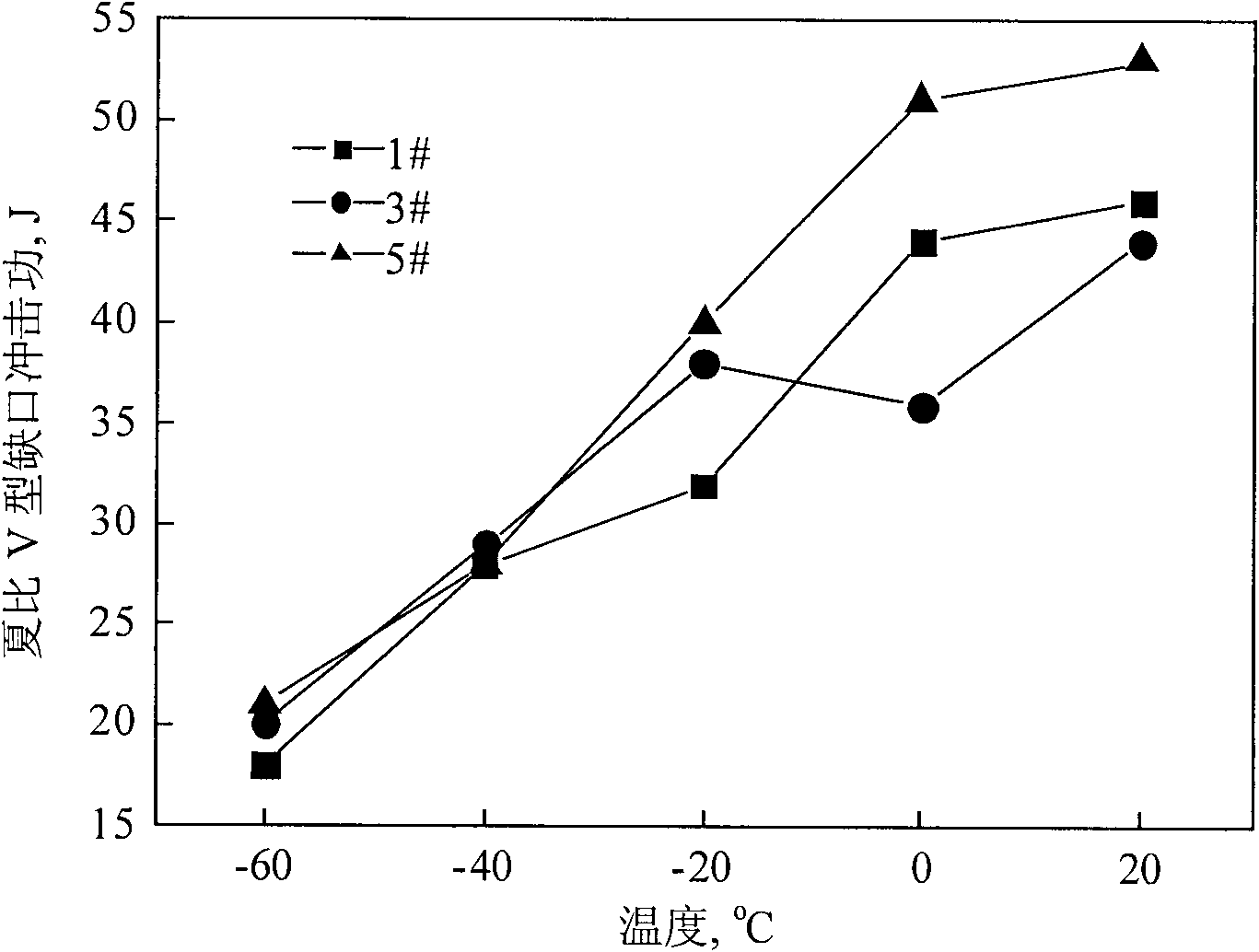

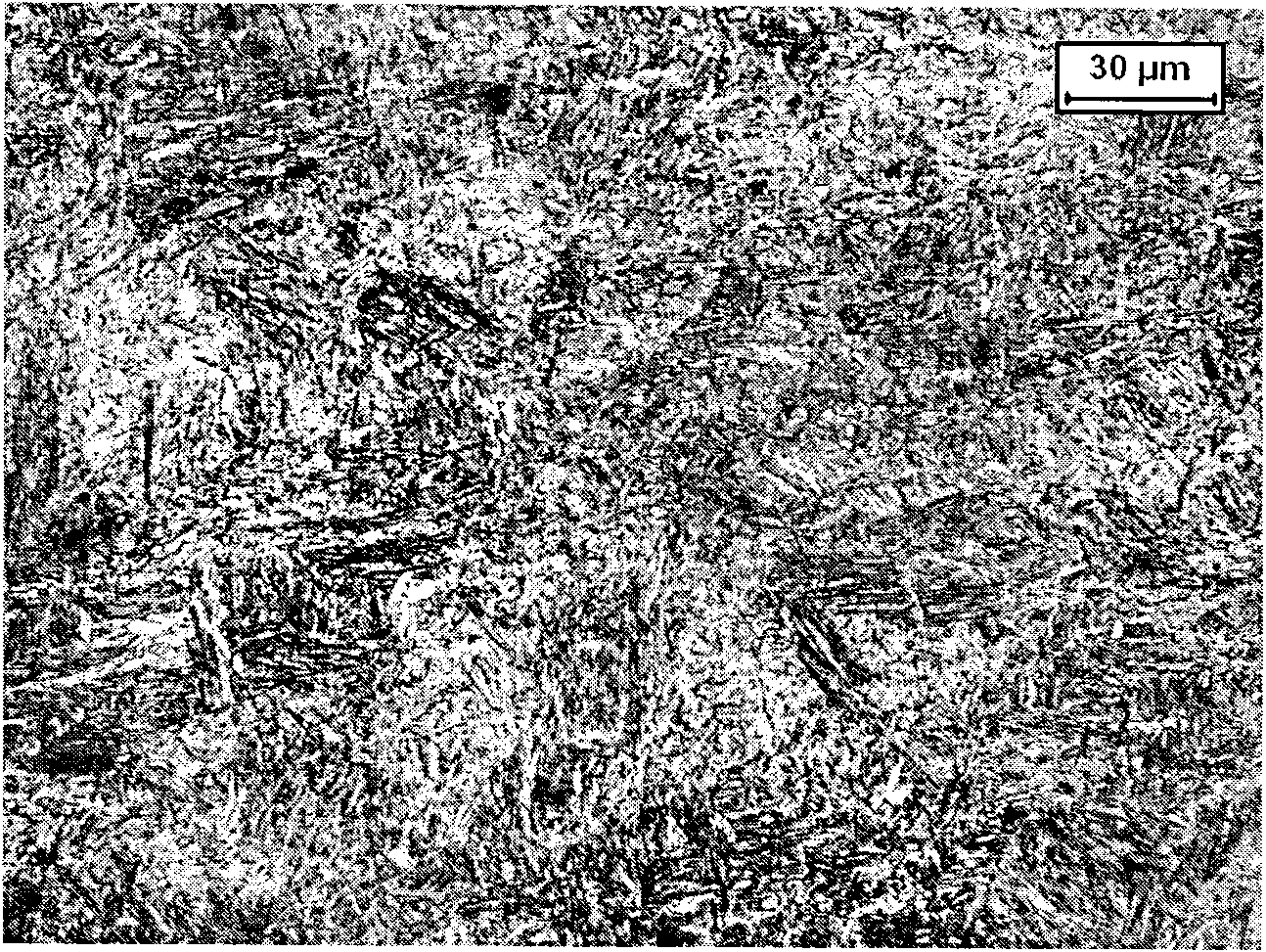

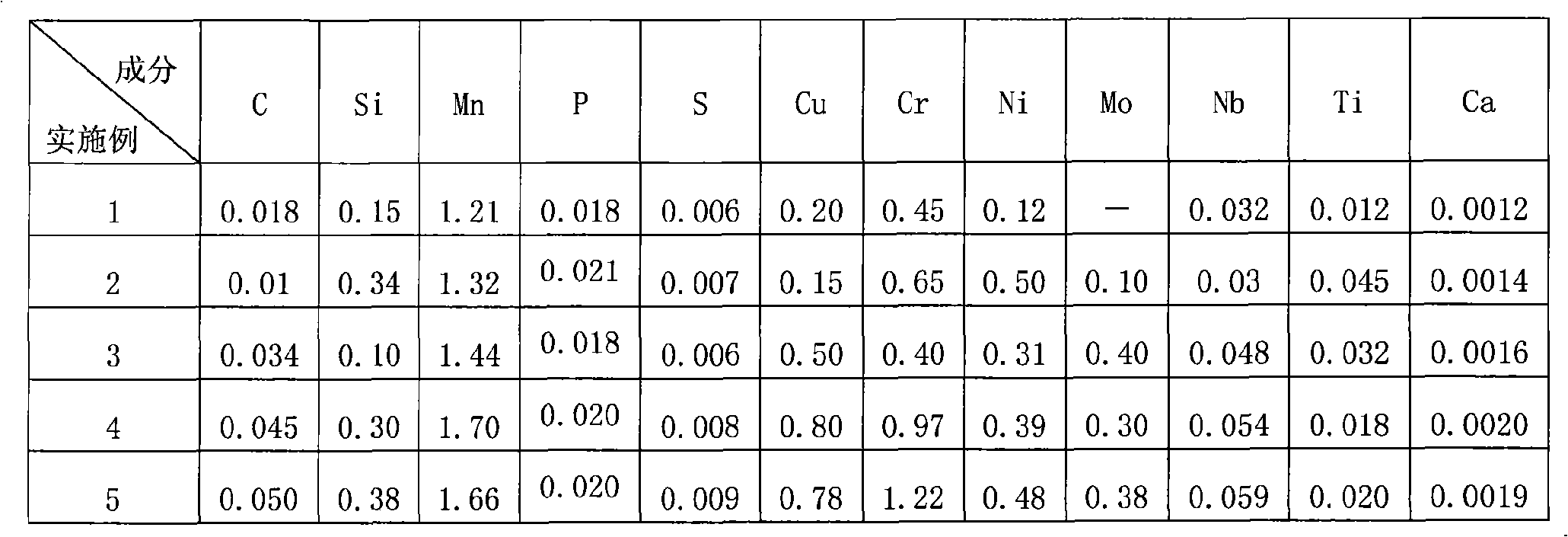

Ultra-low carbon hot rolling weathering steel with yield strength larger than 550MPa

InactiveCN101407892AGood mechanical propertiesSimple chemical compositionMechanical propertyWeathering steel

The invention discloses an ultra low carbon hot rolling weathering steel with the yield strength of more than the grade of 550MPa and belongs to the manufacturing field of low alloy steel. The steel consists of the compositions with the following weight percentages: 0.01 to 0.05 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, equal to or less than 0.02 percent of P, equal to or less than 0.010 percent of S, 0.15 to 0.80 percent of Cu, 0.40 to 1.25 percent of Cr, 0.10 to 0.50 percent of Ni, equal to or less than 0.40 percent of Mo, 0.03 to 0.06 percent of Nb, equal to or less than 0.050 percent of Ti, 0.0010 to 0.0020 percent of Ca and the residual quantity of Fe and unavoidable impurities. The steel has good mechanical properties, the yield strength of equal to or more than 550MPa and the tensile strength of equal to or more than 650MPa which are both higher than that of traditional weathering steel. Besides, Ti is included in the compositions of the steel.

Owner:武钢集团有限公司

Superfine crystal particle hot-rolling steel plate with thick specification and production thereof

InactiveCN1614067ASimple chemical compositionEasy to controlMetal rolling arrangementsSteel platesInlet temperature

The invention was involved in the preparation method of thick hot rolled steel plate with ultra-fine grain. The alloy consist of 0.13-0.18%C, 0.12-0.30% Si, 0.50-0.70%Mn, is less than or equal to 0.020% P and is less than or equal to 0.015%S. The technology included the following steps: a) the heating-up temperature of continuous cast ingot was 1150-1200deg.C. b) The temperature of coarse crushing was 950-1000deg.C. c) The thickness of intermediate ingot after coarse crushing was 30-35mm. d) Inlet temperature of fine rolling was 880-920deg.C. e) Five or six groups frameworks were used in the rolling process of fine rolling. f) Three or four groups cooling water were input among the frameworks. g) Outlet temperature of fine rolling was 800-830deg.C. h) The reel temperature was 500-560deg.C. Chemical constitution of the hot rolling steel plate was simple and the cost was low. Ultra-fine grain hot rolling steel plate with 6.5-8.0mm thick was formed by controlling heating, coarse rolling and cooling. The steel plate had fine strength of extension, yield strength, extensibility and cold bending performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

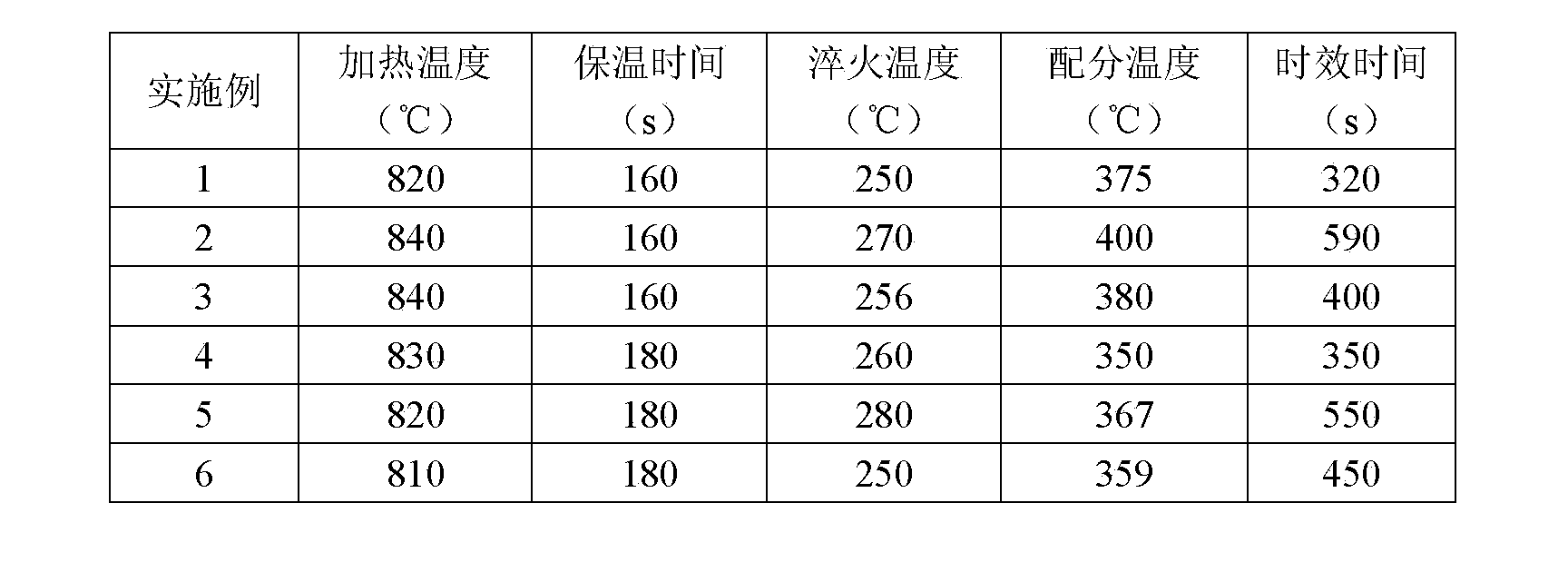

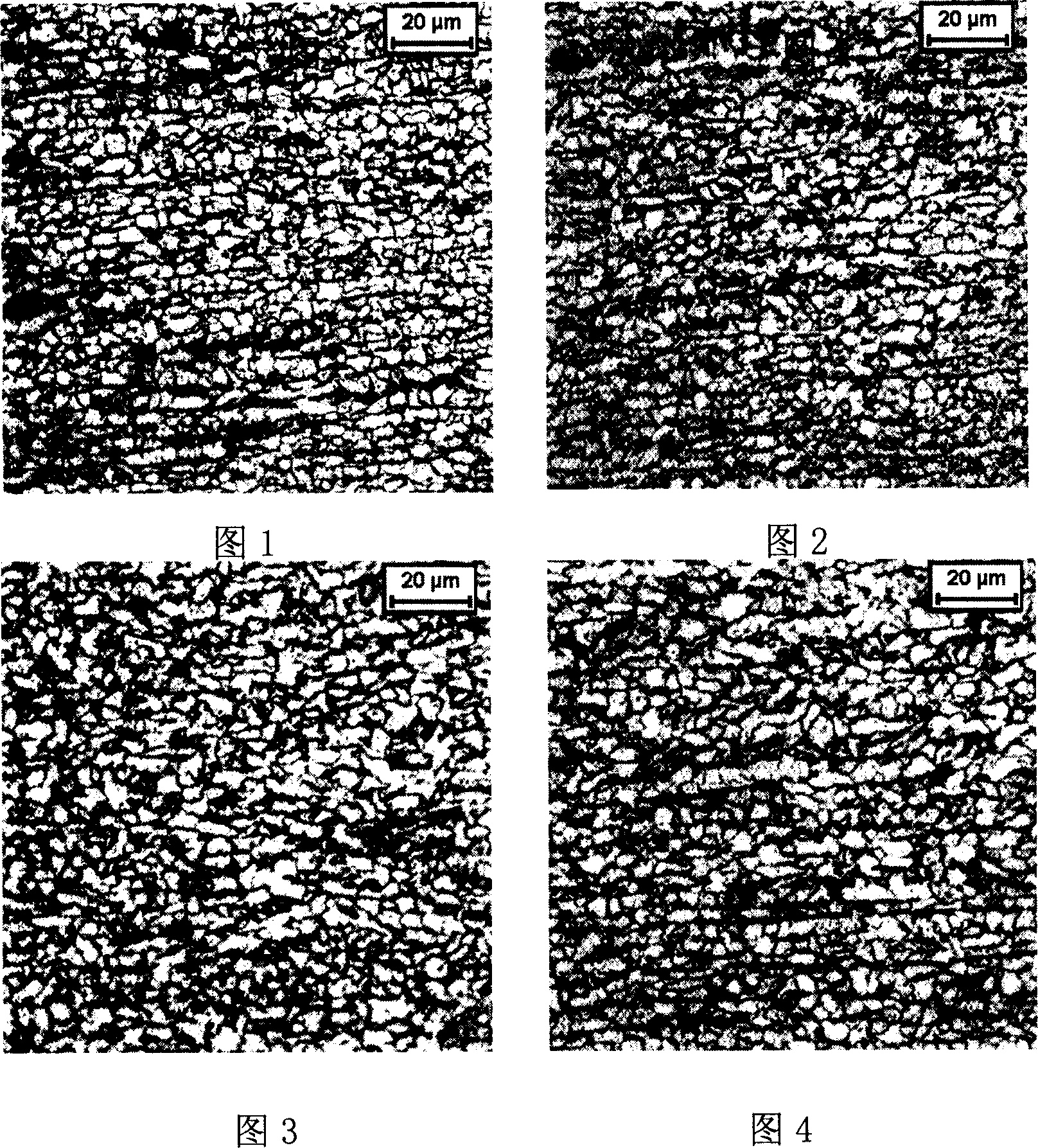

High-strength high-plasticity cold-rolled steel plate for automobiles and production method thereof

ActiveCN104278194AReduce equipment performance requirementsComply with reduction requirementsThermal insulationRoom temperature

The invention discloses a high-strength high-plasticity cold-rolled steel plate for automobiles and a production method thereof. The high-strength high-plasticity cold-rolled steel plate comprises, by weight, 0.25-0.35% of C, 0.8-1.2% of Si, 2.0-2.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, 0.5-1.0% of Al, 0.001-0.002% of B and the balance Fe and unavoidable impurities. The production method comprises smelting, continuous casting, hot rolling, pickling, cold rolling and continuous annealing. A continuous annealing heating temperature is in a range of 800-850 DEG C, thermal insulation time is in a range of 150-180s, a cooling rate is greater than or equal to 50 DEG C / s, a quenching temperature is in a range of 250-280 DEG C, a partition temperature is in a range of 350-400 DEG C, partition time is in a range of 300-600s and after partition, the product is cooled to a room temperature at a cooling rate greater than or equal to 50 DEG C / s.

Owner:ANGANG STEEL CO LTD

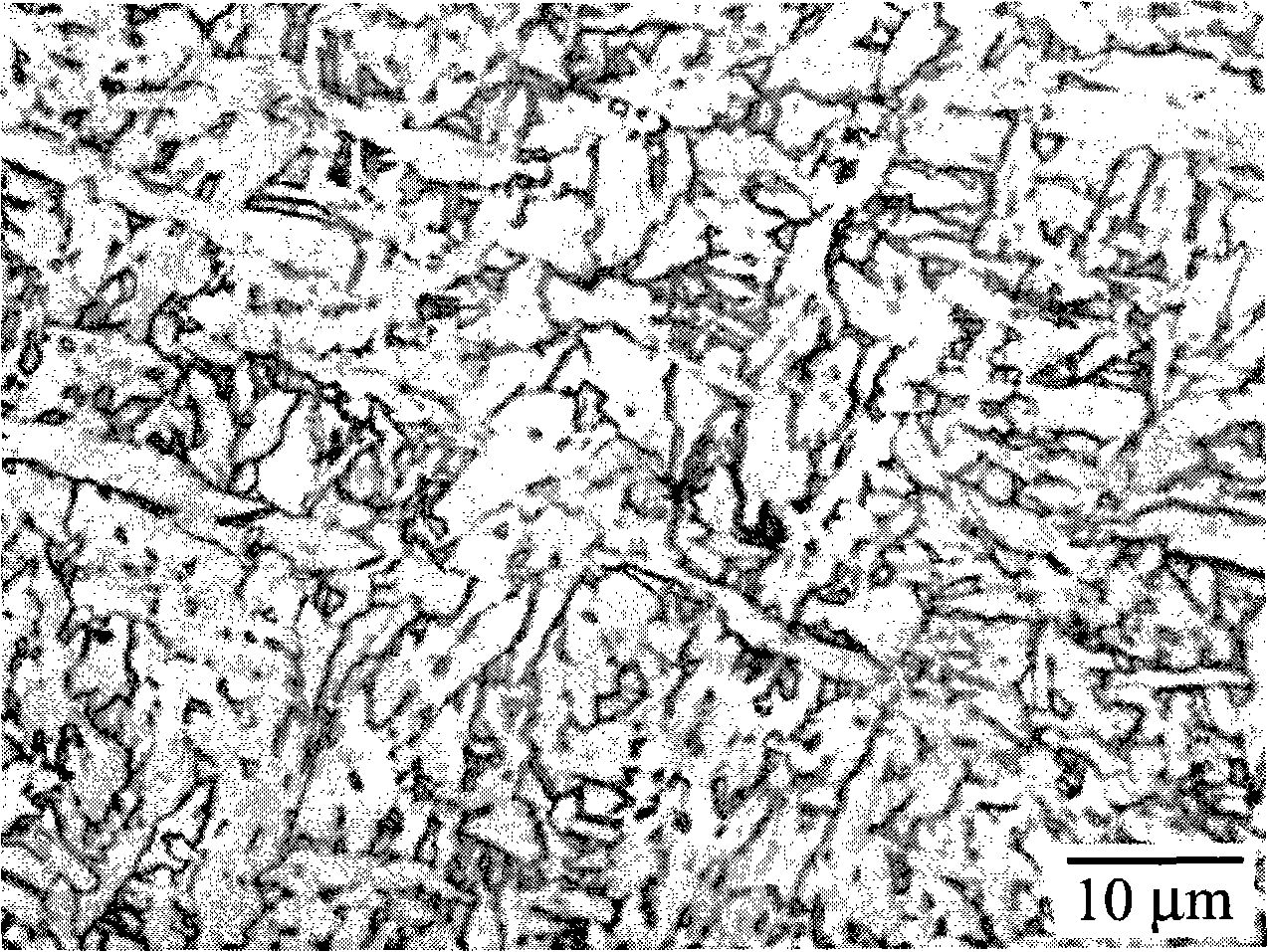

Method for medium sized or thin plate blank continuous casting and continuous rolling for producing superfine crystal grain steel plate and the steel plate

InactiveCN1995431ASimple chemical compositionImprove plastic toughnessTemperature control deviceFurnace typesSheet steelChemical composition

The invention discloses a manufacturing method of hyperfine crystal steel board through continuous rolling thin board, which comprises the following steps: allocating raw material with 0.12-0.18% C, 0.15- 0.35% Si, 0.65-1. 20% Mn, not more than 0.02% P, not more than 0.015% S and Fe; casting in the 100-200mm*1000-2000mm blank; setting the loading temperature over 800 deg. c; heating to 1100-1280 deg. c; reducing rough rolling of blank to 30-60 mm; setting refining rolling temperature between 920 and 1050 deg. c; exerting multi-channel and large-deforming strain accumulation with even deforming velocity at 1-10 / s; setting the refining rolling outlet temperature at 750-900 deg. c; setting cooling speed of laminar flow at 10-45 deg. c / s; coiling at 400-620 deg. c; setting the norm of continuous heat rolling steel at 2-18mm with even crystal size at 3-7um and yielding strength over 400Mpa; making the extending proof strength between 510 and 580 Mpa and extending rate over 26%.

Owner:ANGANG STEEL CO LTD

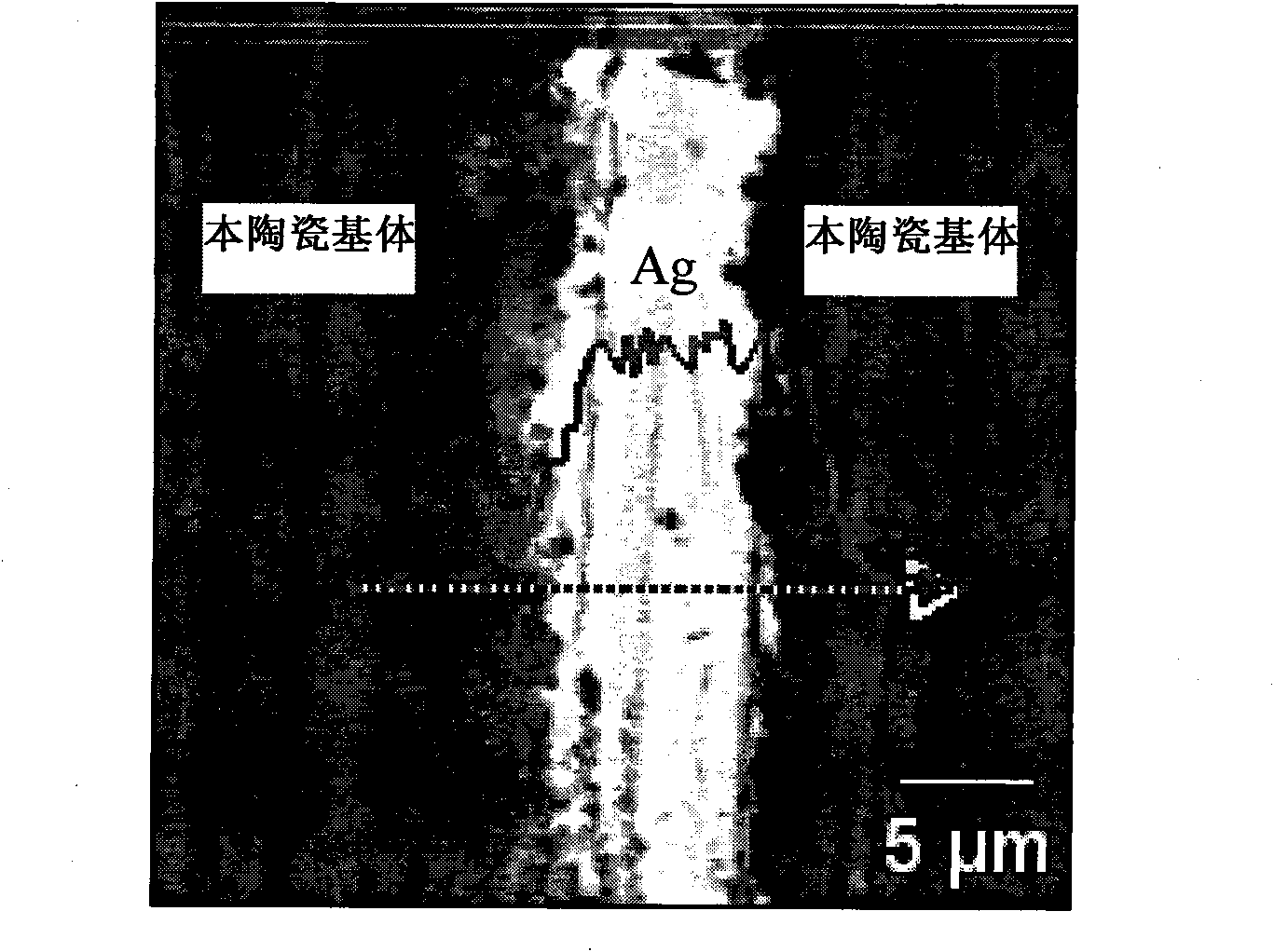

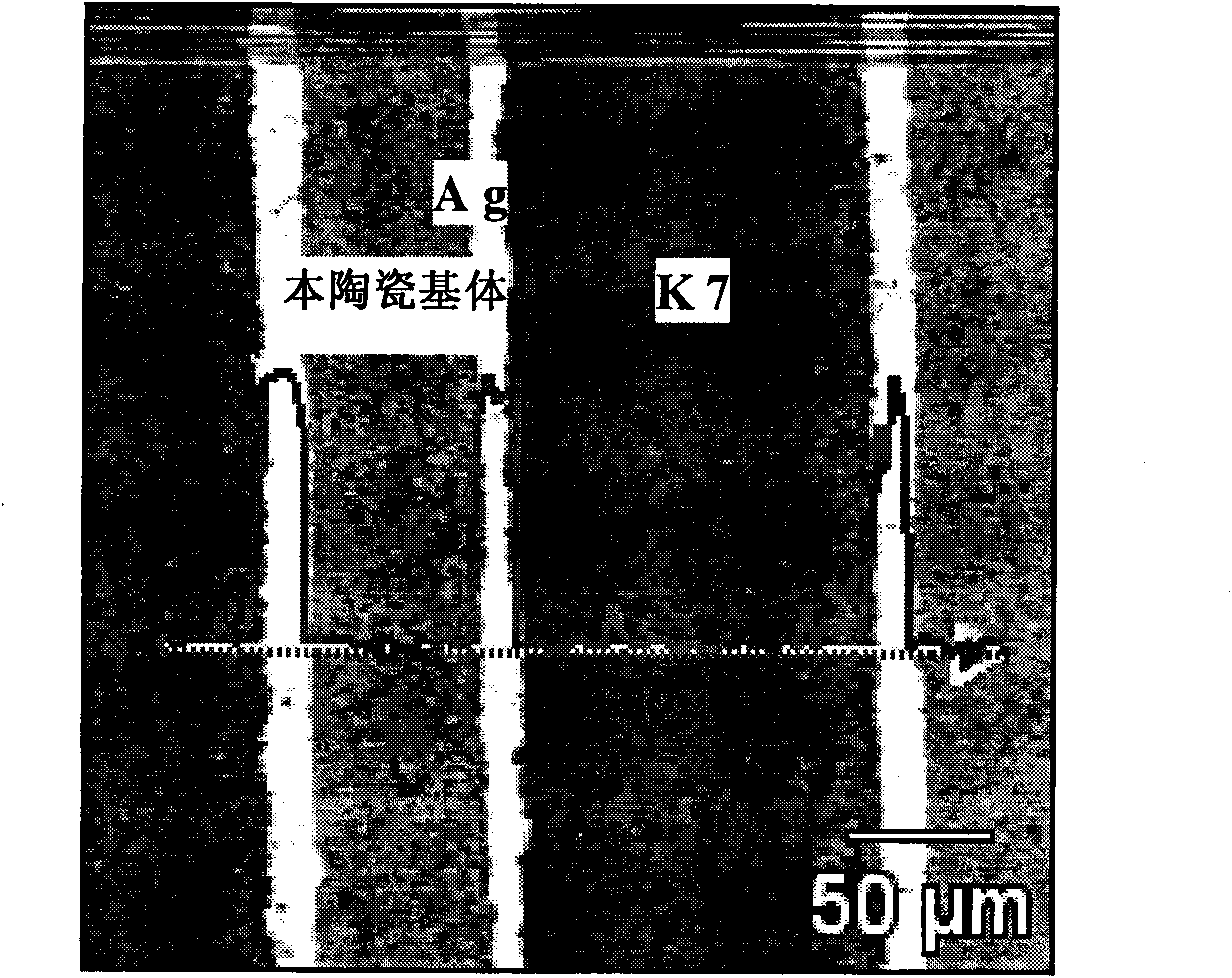

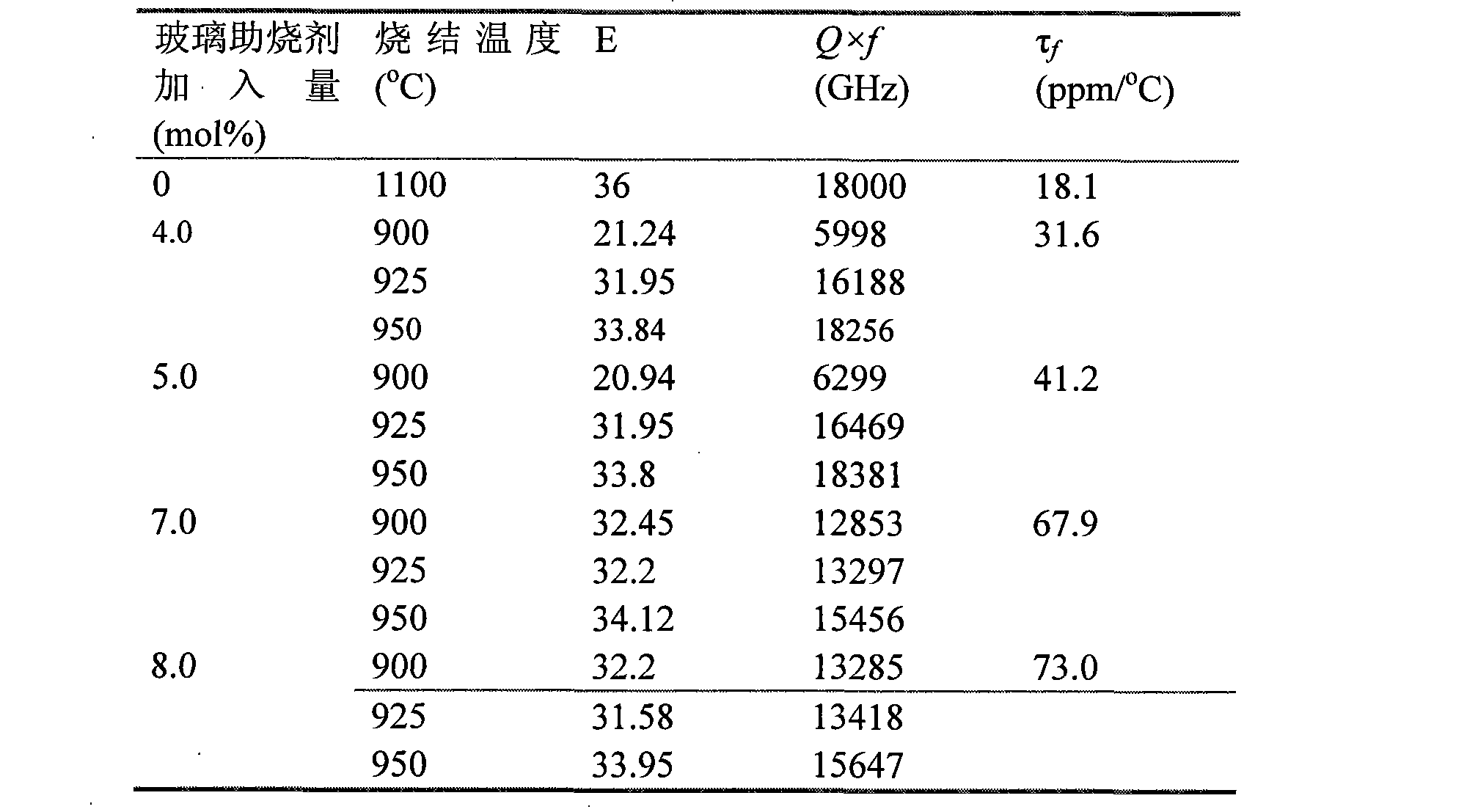

Low-temperature sintered microwave medium ceramic material and preparation method thereof

ActiveCN101613200AImprove performanceExcellent microwave dielectric propertiesCeramicsCombustionSilver electrode

The invention discloses a low-temperature sintered microwave medium ceramic material and a preparation method thereof. The material comprises the raw materials with the mol ratio: BaCO3:ZnO:TiO2:Q=1:x:(4+y):z, wherein x=0.01-0.5, y=0.01-0.5, z=0.01-0.1, and Q is glass combustion-supporting agent or BaCu (B2O5); the glass combustion-supporting agent comprises the raw materials with the mol ratio being Li2O:ZnO:B2O3=1:2:7 or Li2O: B2O3-1:2:7=3:2:5. The material can be obtained through traditional solid phase reaction synthesis. The material has lower sintering temperature (is capable of being fired at the temperature below 900 DEG C to form ceramics), is capable of being fired at the temperature of 900 DEG C to form ceramics and has better microwave dielectric property, wherein Epsilon r is equal to 25-35, Q*F is larger than 12,000, and Pi f is equal to -10ppm / DEG C to +30ppm / DEG C; in addition, the material has stable process and good repeatability and can be better co-fired and matched with a silver electrode. The low-temperature sintered microwave medium ceramic material can be used for manufacturing microwave devices, such as lower temperature co-fired ceramic (LLCC) systems, multilayer medium resonators, microwave antennae, wave filters, and the like.

Owner:XI AN JIAOTONG UNIV

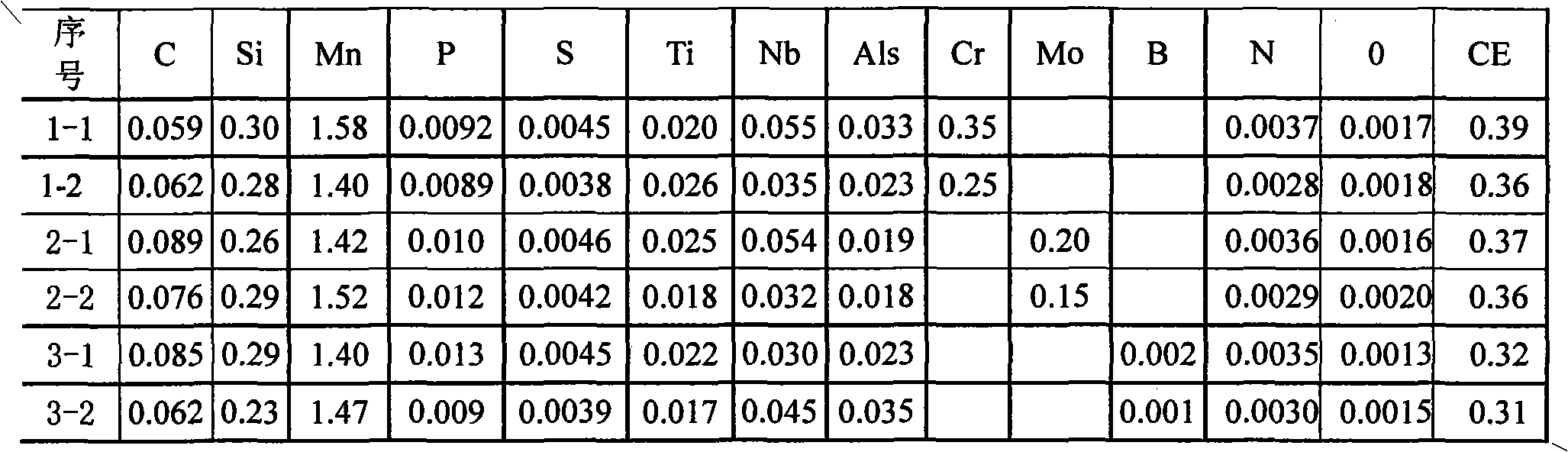

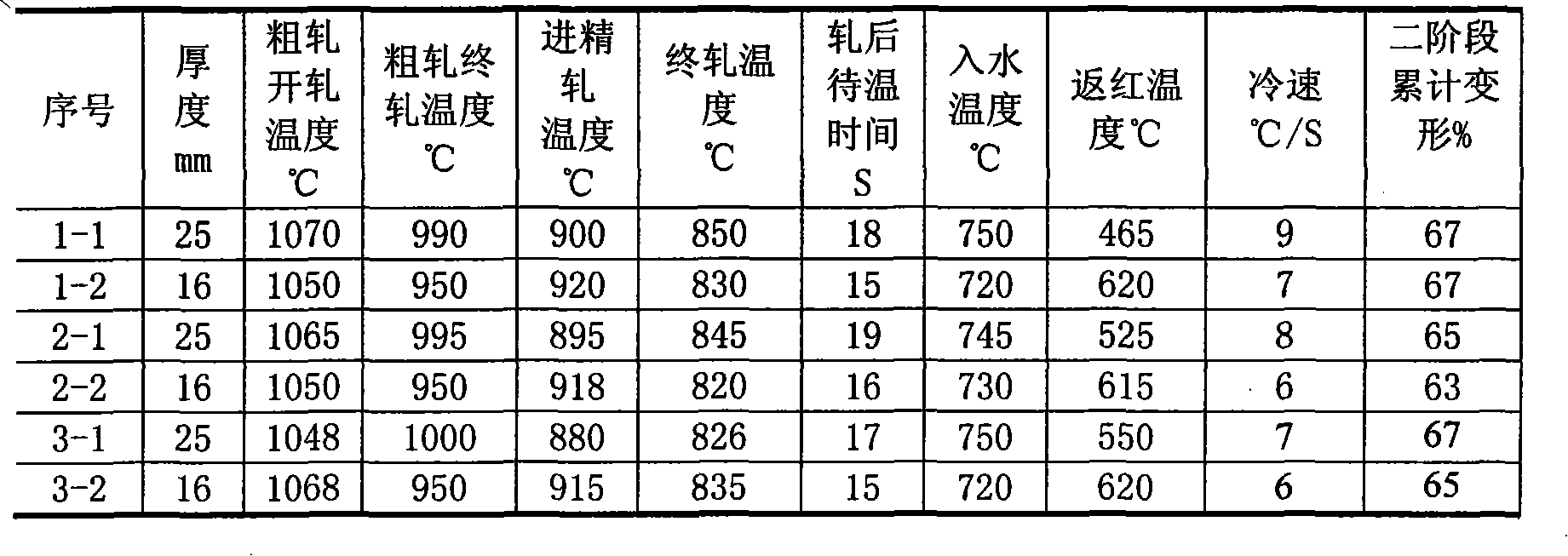

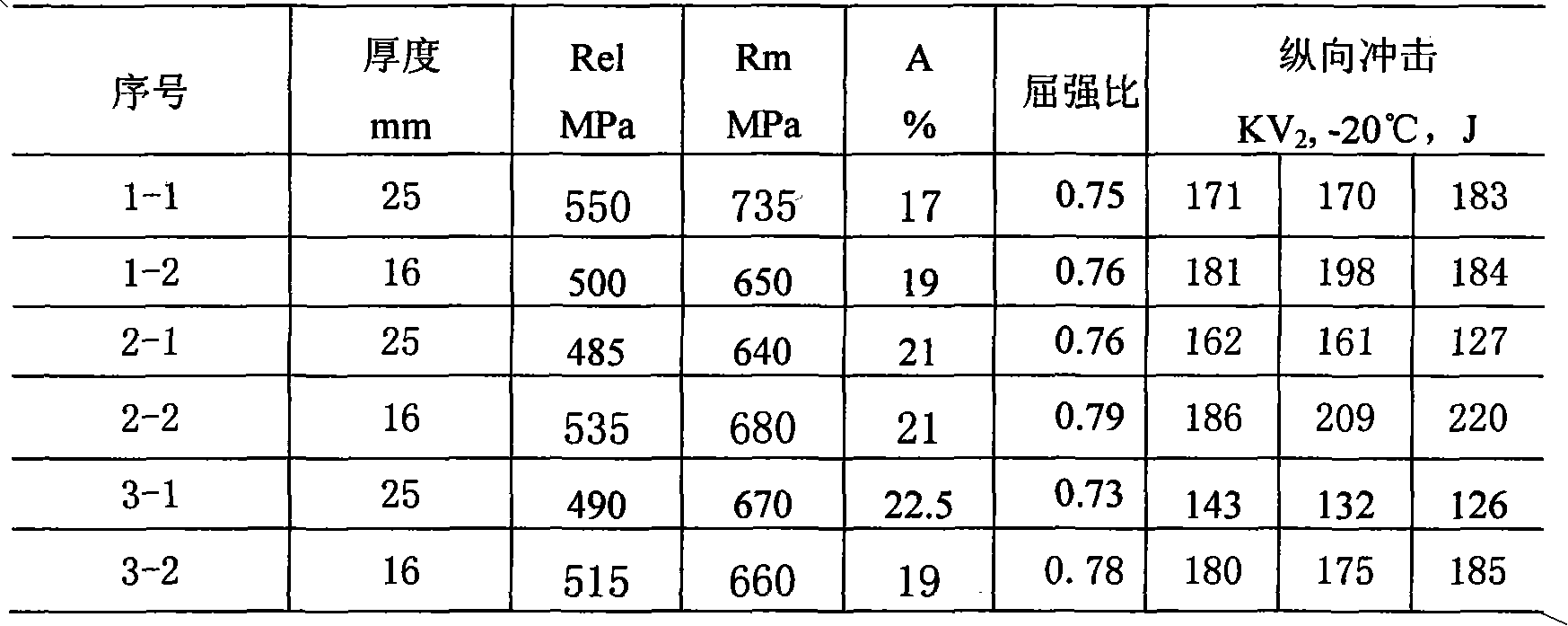

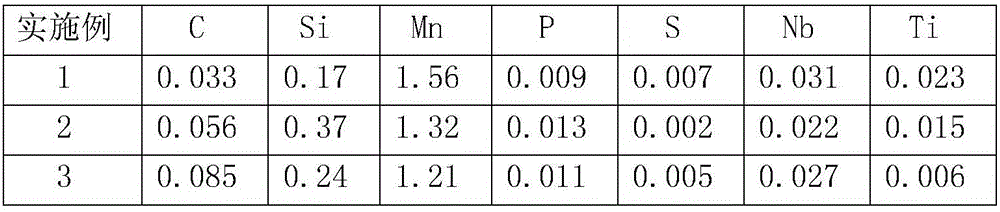

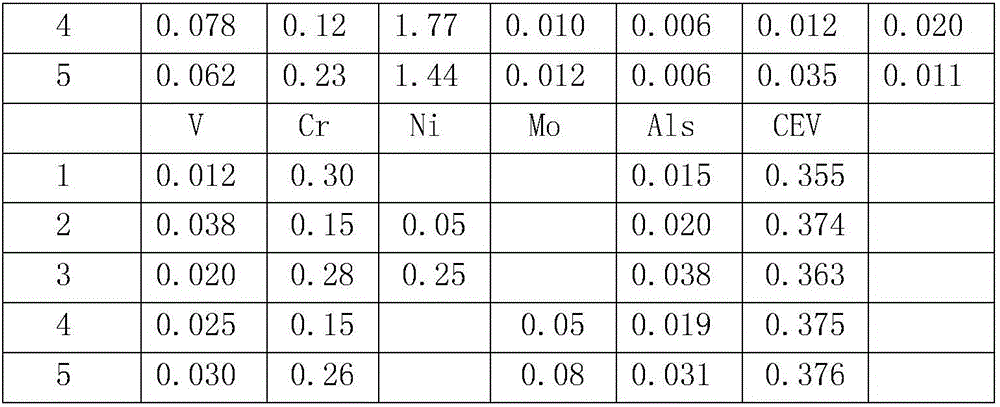

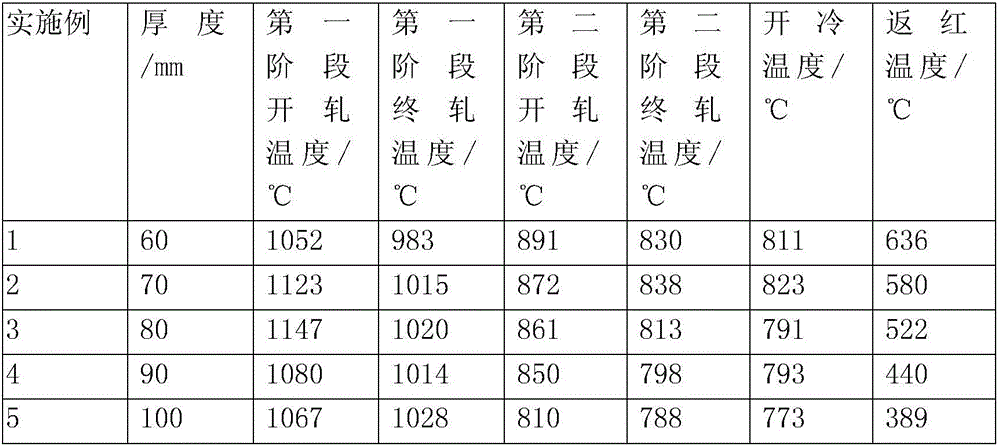

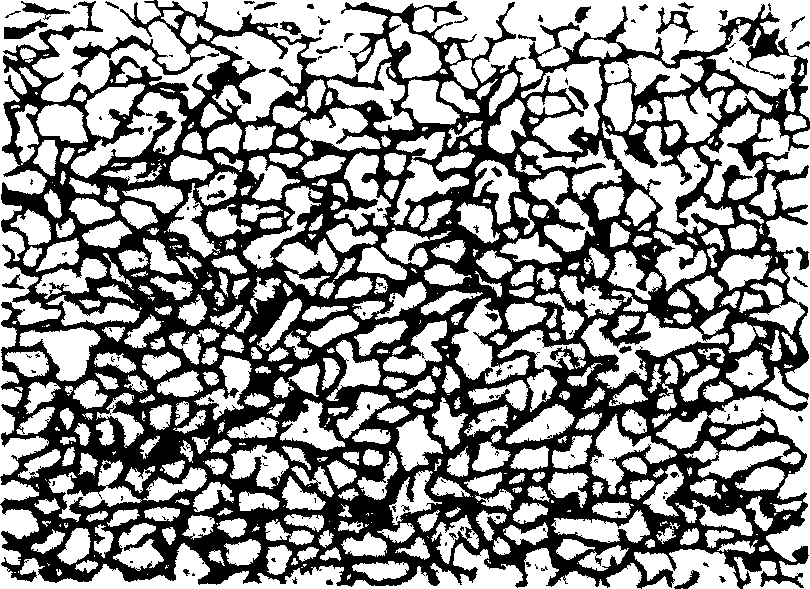

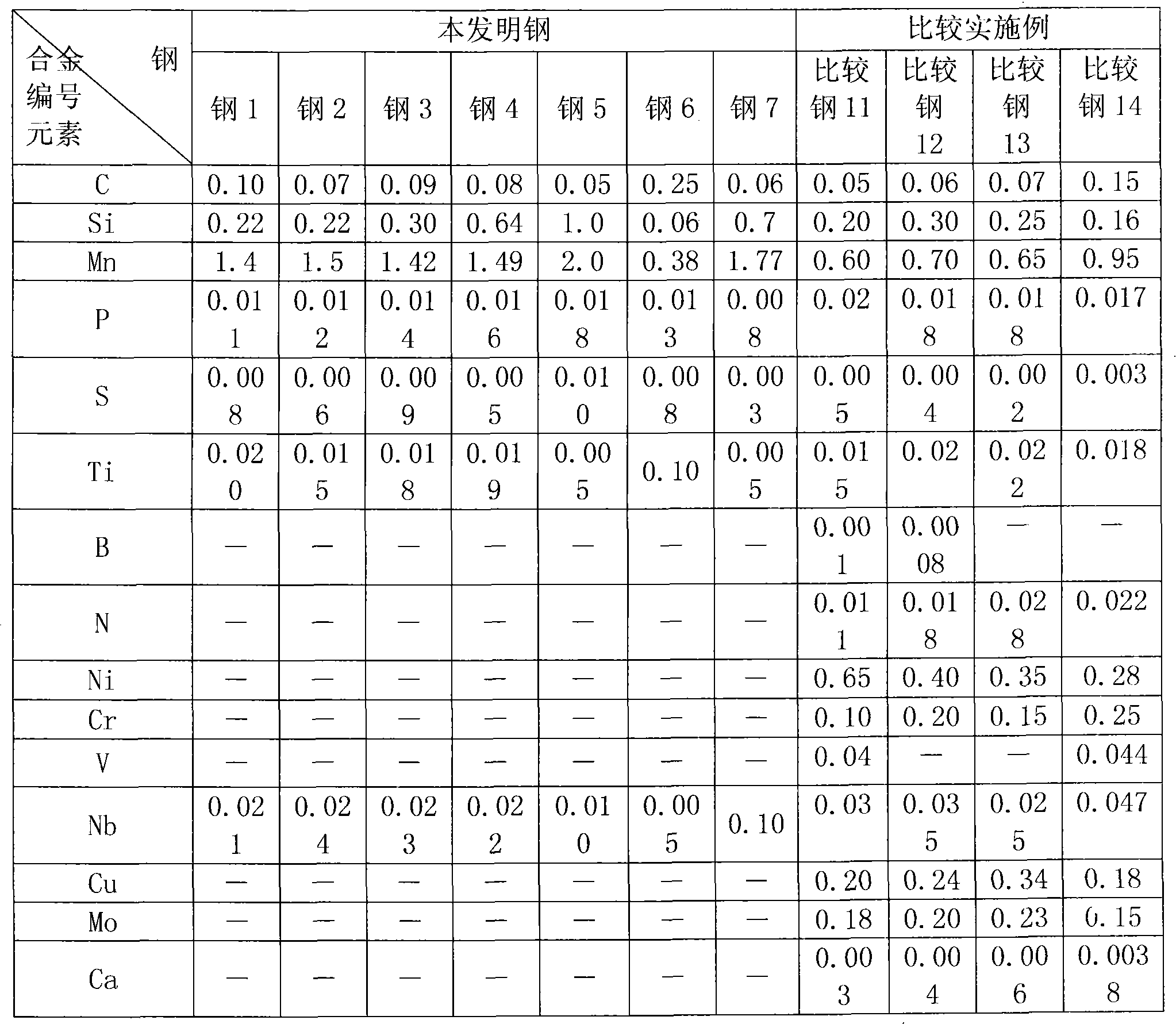

Steel plate for building structure with yield strength of 460 MPa, and manufacturing method thereof

ActiveCN102400053ALow yield ratioSimple production processTemperature control deviceChemical compositionSheet steel

The present invention discloses a steel plate for a building structure with yield strength of 460 MPa, and a manufacturing method thereof. Chemical components of the steel plate comprise, by weight, 0.05-0.10% of C, 0.2-0.3% of Si, 1.40-1.60% of Mn, 0.025-0.060% of Nb, 0.015-0.030% of Ti, 0.015-0.045% of Als, one selected from 0.2-0.4% of Cr, 0.10-0.30% of Mo and 0.0010-0.0020% of B, and the balance of Fe and other inevitable impurities, wherein the impurity elements are controlled, and comprise, by weight, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.0040% of [N], and less than or equal to 0.0020% of [O]. The manufacturing method comprises that: the steel billet heating temperature is 1180-1220 DEG C; at the first phase, the rolling starting temperature is 1040-1080 DEG C, and the rolling finishing temperature is 950-1000 DEG C; at the second phase, the rolling starting temperature is 920-870 DEG C, the rolling finishing temperature is controlled to 800-850 DEG C, the amount of the rolling accumulation and deformation in the recrystallization area is more than 60%; after hot rolling, a temperature waiting treatment is performed, and then a water cooling treatment is performed, wherein the temperature waiting time is more than 15 seconds, the water cooling starting temperature is 680-750 DEG C, the cooling rate is 5-9 DEG C per second, and the self-tempering temperature is 450-620 DEG C. The steel plate of the present invention has characteristics of simple chemical components, carbon equivalent less than 0.40, yield ratio less than 0.80 and simple production process.

Owner:ANGANG STEEL CO LTD

460MPa-grade high-toughness low-alloy high-strength structural steel plate and production method thereof

The invention discloses a 460MPa-grade high-toughness low-alloy high-strength structural super-thick steel plate. The chemical ingredients of the steel plate comprise 0.03-0.09% of C, 0.10-0.40% of Si, 1.20-1.60% of Mn, 0.01-0.05% of Nb, 0.005-0.030% of Ti, 0.01-0.04% of V, 0.015-0.045% of Als, 0.015% or smaller of P and 0.008% or smaller of S, and further comprise one or two kinds of 0.01-0.30% of Cr, 0.01-0.08% of Mo and 0.05-0.25% of Ni, and the balance Fe. A production method comprises the steps of smelting, refining, continuous casting, steel billet heating, controlled rolling, controlled cooling, slow cooling and obtaining of the finished product. The super-thick steel plate is good in performance, the impact energy KV2 at -60 DEG C of the 100 mm thick plate is larger than or equal to 200 J, the carbon equivalent is not larger than 0.38, the yield ratio is smaller than or equal to 0.85, the cost is low, the production process is simple, and operation is easy.

Owner:NANJING IRON & STEEL CO LTD

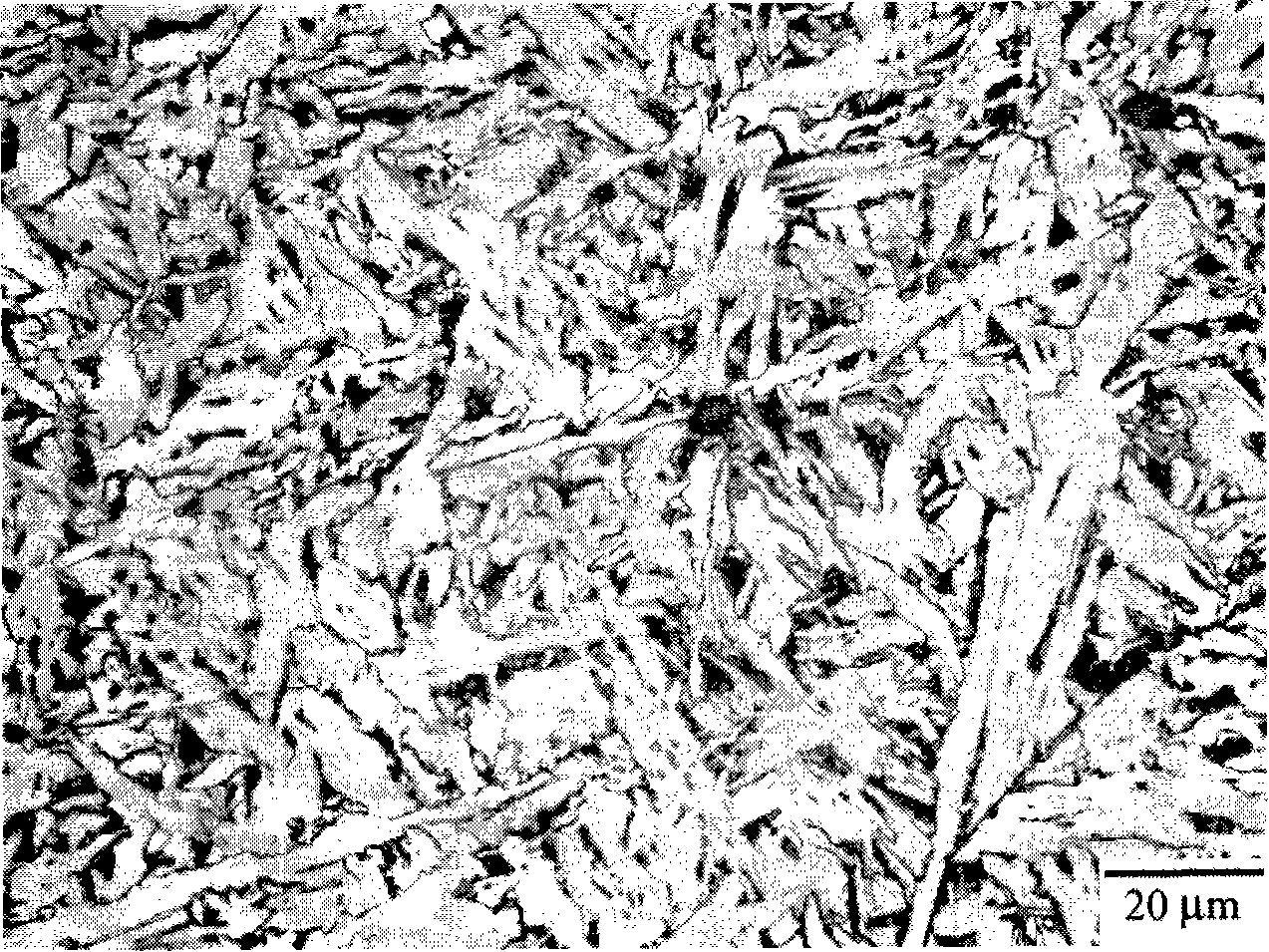

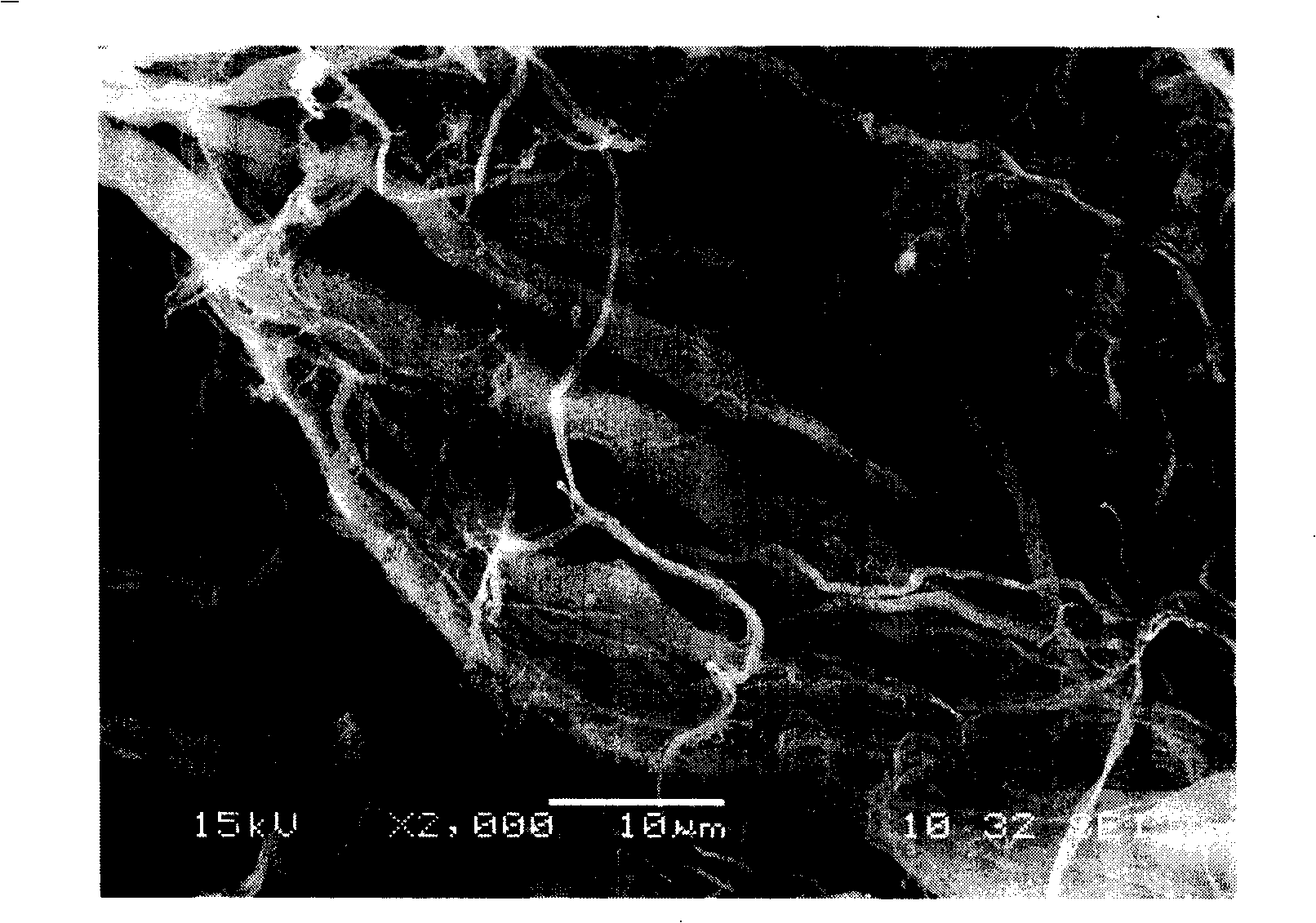

Method for mfg. hot rolled steel plate possessing superfine crystal grains and hot rolled steel plate produced

A technology for manufacturing hot-rolled steel plate with superfine grains is disclosed. The said steel plate contains C (0.1-0.16 wt.%), Si (0.12-0.3 wt.%), Mn (0.45-0.65 wt.%), P (0-0.020 wt.%) and S (0-0.015 wt.%). Its technological steps include casing, heating to 1200-1230 deg.c, coarse rolling, and three-pass fine rolling. Its advantages are superfine crystal grain (3-6 microns), excellentproperties and simple chemical components.

Owner:攀枝花钢铁有限责任公司钢铁研究院 +1

Method for rolling thick specification low-alloy structure steel plate by using middle and thin plate blank

InactiveCN101148735AIncreasing the thicknessIncrease reduction rateRoll mill control devicesMetal rolling arrangementsChemical compositionMaterials science

The present invention relates to production of structural low alloy steel plate, and is especially process of producing high strength hot rolled coiled sheet of 16-20 mm thickness with continuous cast billet of 150-170 mm thickness. The steel has chemical composition comprising C 0.15-0.20 wt%, Si 0.20-0.40 wt%, Mn 1.40-1.60 wt%, S not more than 0.030 wt%, P not more than 0.030 wt%, and Fe and impurity for the rest. The production process includes the steps of controlled heating, rough rolling, finish rolling, cooling, etc. and the produced hot rolled coiled sheet has simple composition, low cost, high tensile strength, high yield strength, high elongation, high impact toughness, high cold bending performance, good welding performance and other features.

Owner:LAIWU IRON & STEEL GRP

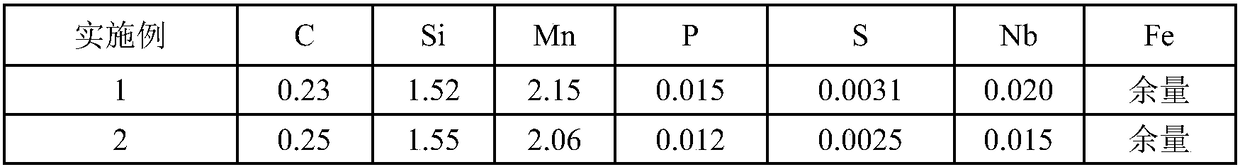

Quenched partitioned cold-rolled steel sheet with tensile strength of greater than 1180 MPa, and production method thereof

The invention relates to a quenched partitioned cold-rolled steel sheet with tensile strength of greater than 1180 MPa, and a production method thereof. During annealing heating, a steel plate is partially austenitized, so the enrichment of carbon in an austenite structure is realized; the two-phase-region slow cooling is employed for adjusting the volume fractions of an austenite phase and a ferrite phase, carbon is further enriched in the austenite; then rapid cooling at a cooling rate of 30-40 DEG C / s is carried out to partially convert the austenite into martensite; then heating and heat preservation are carried out; and finally, air-cooling to room temperature is carried out to obtain a multi-phase structure of ferrite, martensite and metastable austenite. The invention has the advantages that the production method is used for batch production of the quenched partitioned cold-rolled steel sheet with the tensile strength of greater than 1180 MPa; the quenched partitioned cold-rolled steel sheet has simple chemical components, no elemental Nb or only a small amount of elemental Nb is added except C, Si and Mn, so smelting cost is low, and process control is simple; two-phase-region heating is employed for continuous annealing; rapid cooling requires a low cooling speed and has low requirements on the equipment capacity of a continuous-annealing unit is low; and the production method is simple.

Owner:ANGANG STEEL CO LTD

Soldering not quenching and tempering steel plate in high intensity by large line energy, and manufacturing method

InactiveCN101050504AImprove welding qualityImprove toughnessRoll mill control devicesProcess efficiency improvementSteelmakingElectric arc furnace

This invention relates to a method for producing non-quenched and tempered high-strength steel plate suitable for high heat input welding. The chemical compositions are: C 0.01-0.25 wt.%, Si 0.05-0.5 wt.%, Mn 0.5-1.8 wt.%, Als 0.001-0.06 wt.%, Nb 0.01-0.08 wt.%, Ti 0.01-0.08 wt.%, N 0.002-0.012 wt.%, B 0.0001-0.003 wt.%, P less than 0.015 wt.%, S less than 0.015 wt.%, Fe and impurities. The method comprises: steelmaking and refining molten iron, waste steel or their mixture in a converter or electric arc furnace so that the oxygen content is 10-600 ppm, performing deoxidation with Fe-Ti alloy or metal Ti, performing final deoxidation with Al wire, adding B, continuously casting, and hot-rolling. The obtained steel plate is suitable for 150-600 kJ / cm high heat input welding, and has such advantages as high welding quality, high production efficiency, and saved energy.

Owner:WUHAN UNIV OF SCI & TECH

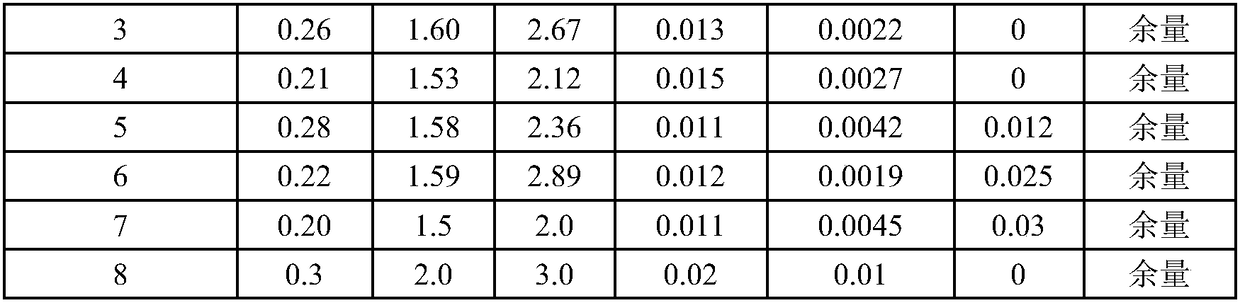

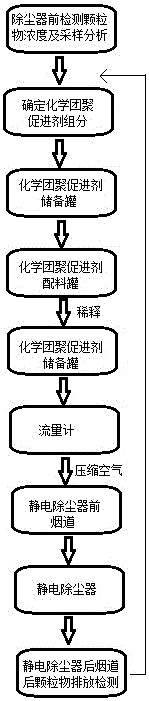

Chemical agglomeration promoter for removing fire coal fine particulate matters and application method of chemical agglomeration promoter

ActiveCN104474830APromote agglomeration and flocculationAgglomeration and flocculation are beneficialAuxillary pretreatmentElectrostatic separationFlue gasFine particulate

The invention discloses a chemical agglomeration promoter for removing fire coal fine particulate matters. The chemical agglomeration promoter is prepared from poly-dimethyl-diallyl-ammonium chloride, sorbitan fatty acid ester and water, wherein the mass percent of poly-dimethyl-diallyl-ammonium chloride is 0.001%-0.01%; and the mass percentage of the sorbitan fatty acid ester is 0.001%-0.1%. The invention also discloses an application method of the chemical agglomeration promoter. The chemical agglomeration promoter is capable of effectively promoting fine particles in a gas flue to agglomerate and flocculate to form large particles, and carrying out integral removal on heavy metals in a flue gas; the efficiency of a dust remover for removing fine particulate matters is improved; and the environment problem is effectively relieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

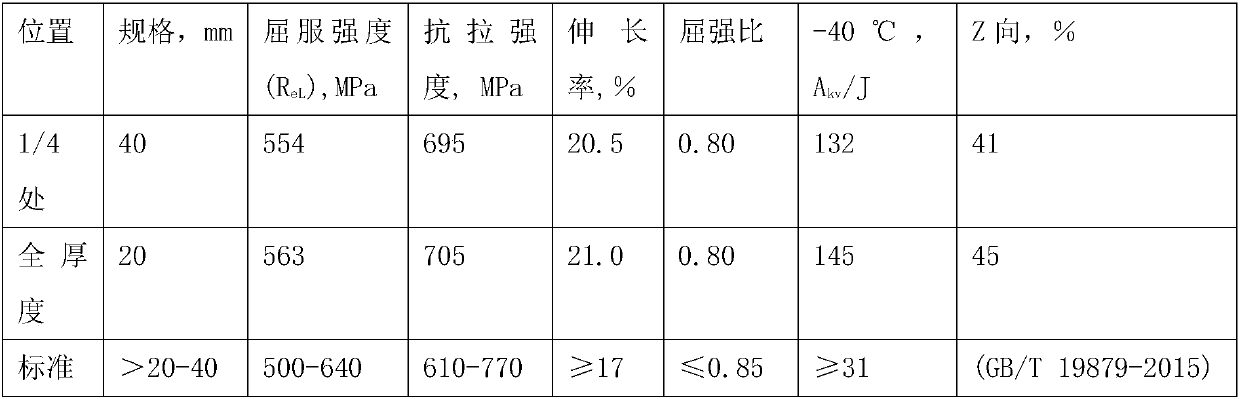

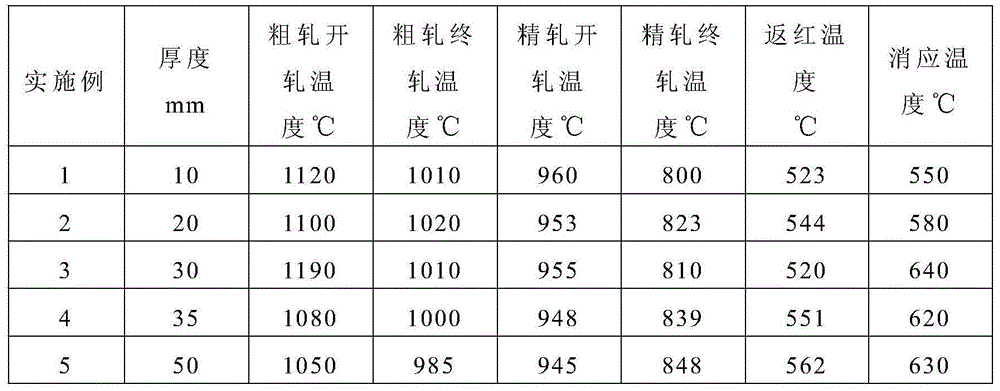

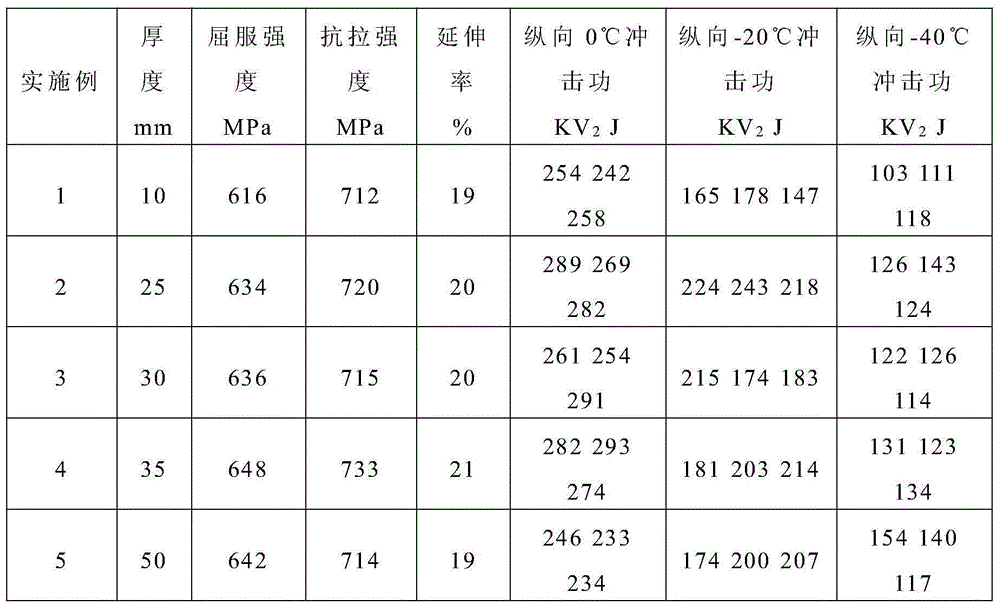

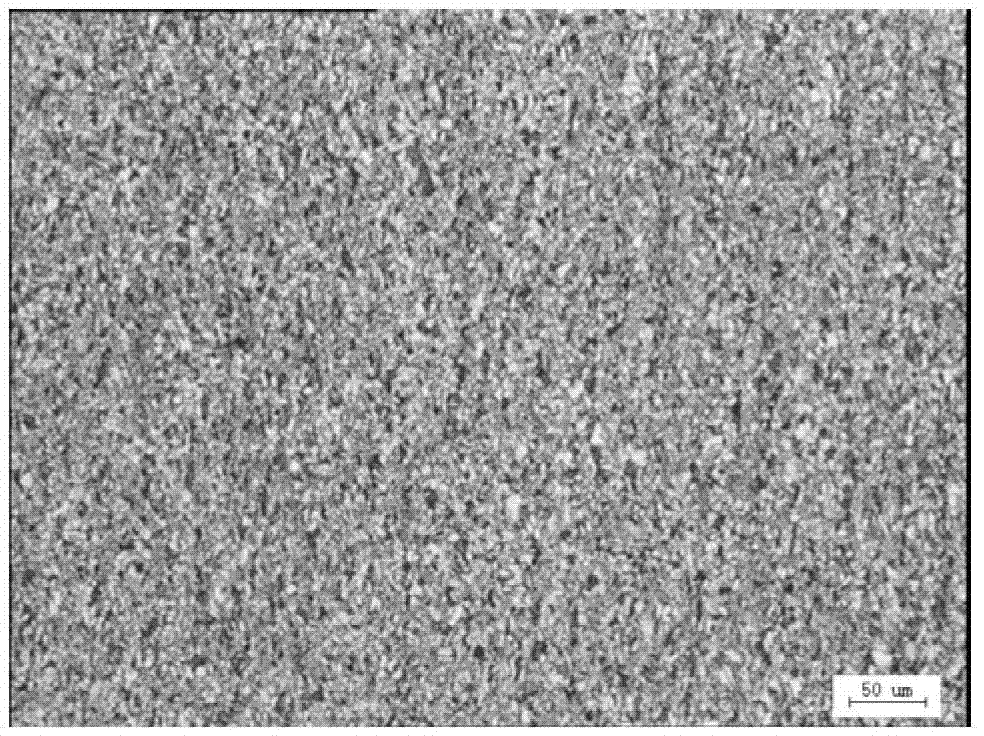

High-strength steel plate for Q500GJE quenched and tempered building structure and manufacturing method of high-strength steel plate

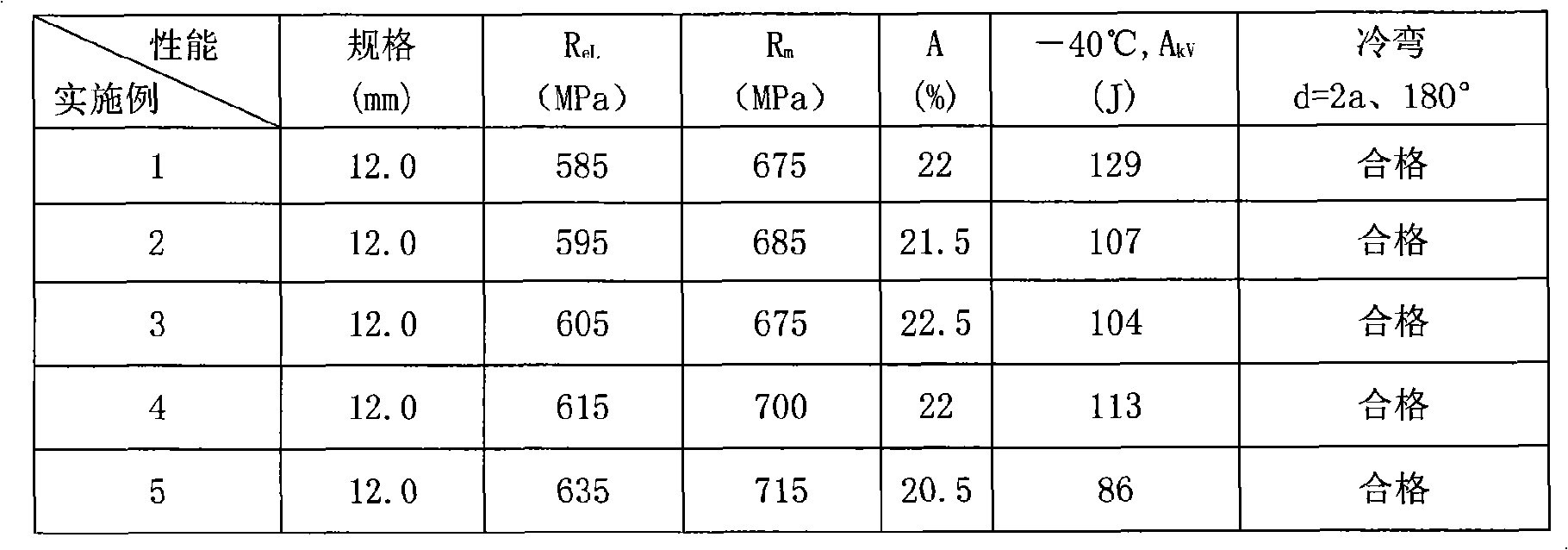

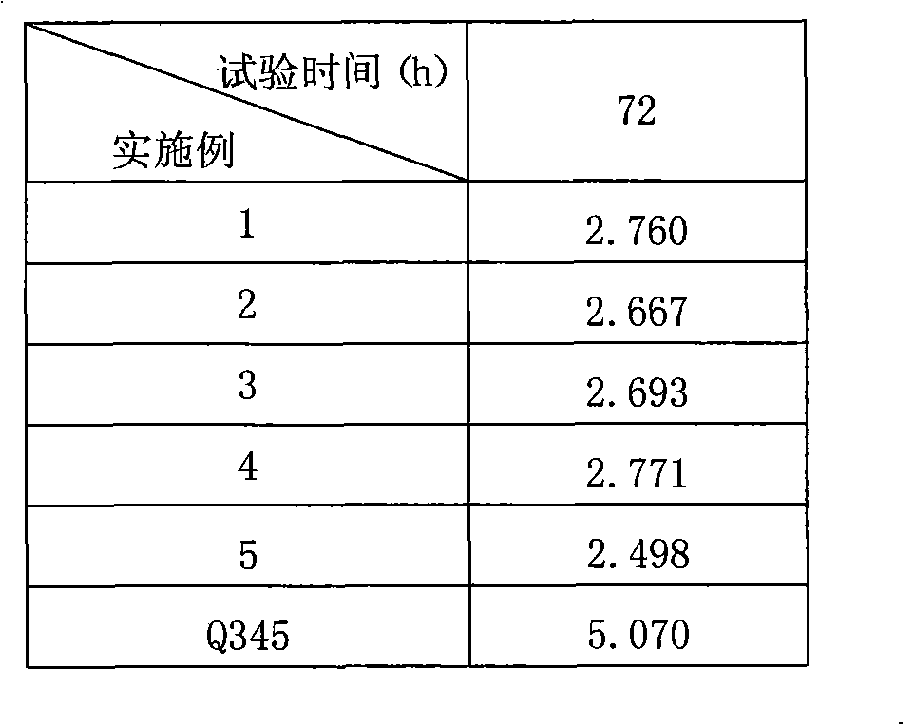

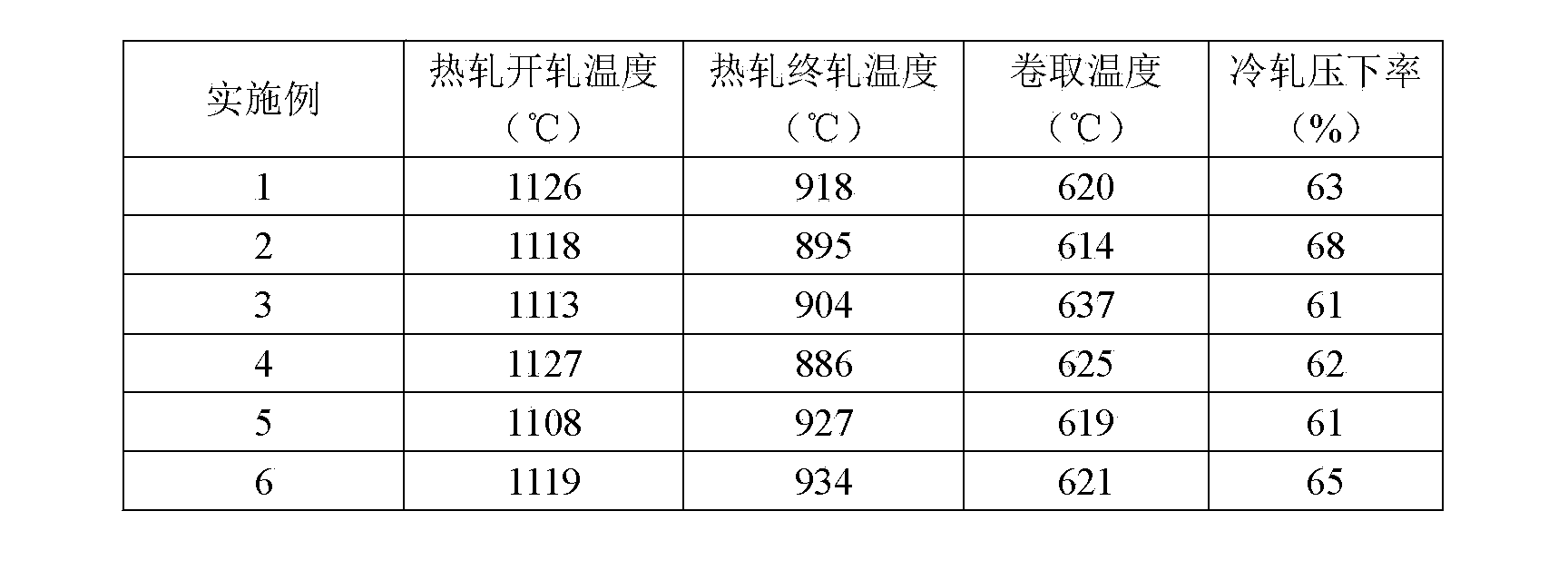

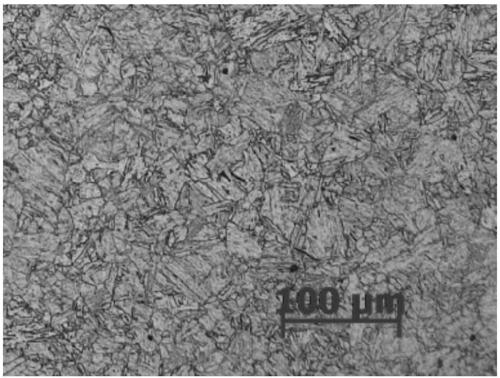

ActiveCN110184525AGood brittle transition temperatureLower brittle transition temperatureImpact energyBainite

The invention relates to a high-strength steel plate for a Q500GJE quenched and tempered building structure. The high-strength steel plate comprises the following chemical components: less than or equal to 0.14% of C, 0.20%-0.50% of Si, 1.10%-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.20% of Cr, less than or equal to 0.30% of Mo, lessthan or equal to 0.90% of Ni+Mo, less than or equal to 0.30% of Cu, 0.02%-0.04% of Al, less than or equal to 0.20% of V+Nb+Ti, less than or equal to 0.006% of N, and the balance of Fe and inevitableimpurity elements, wherein the carbon equivalent is less than or equal to 0.52%. The yield strength is 545-585 MPa, the tensile strength is 670-715 MPa, and the elongation is larger than or equal to 18.5%. A high-strength steel product for a building, with the yielding-to-tensile ratio less than or equal to 0.84, and the V-type impact energy higher than or equal to 110 J at -40 DEG C, is of a ferrite+pearlite+bainite structure, and the grain size is 8.5 levels or above. The comprehensive performance can completely meet GB / T 19879-2015 and the clients' requirements of steel plates for high-risebuildings.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

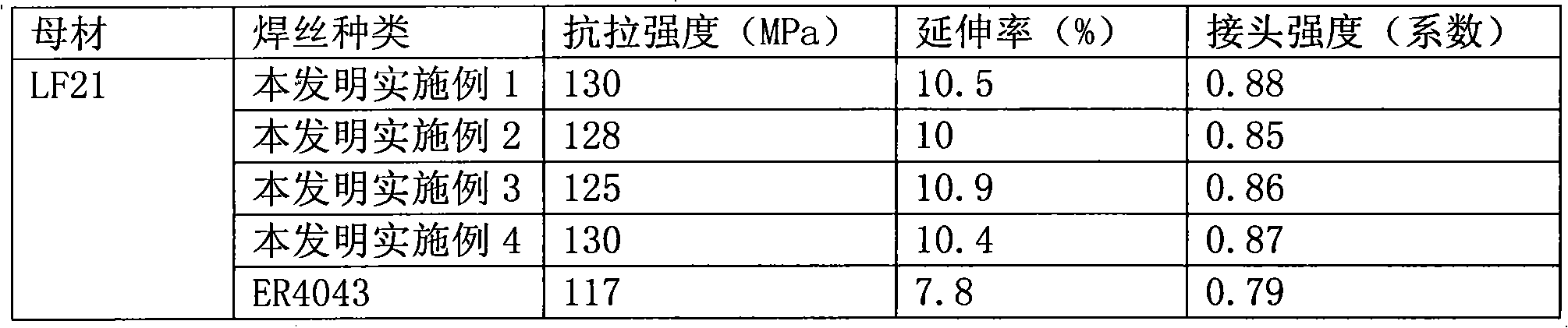

Aluminium-silicon alloy welding wire and preparation method thereof

InactiveCN101823190ASimple chemical compositionEasy to processWelding/cutting media/materialsSoldering mediaSilicon alloySmelting process

The invention discloses an aluminium-silicon alloy welding wire and a preparation method thereof. According to the weight percent, the welding wire comprises 4.5-6.0% of silicon, 0.05-0.20% of titanium, 0.0001-0.0003% of beryllium, 0.01-0.06% of strontium and the balance aluminium. The preparation method comprises the steps of: adding the aluminium in a way of pure metal, and then adding other elements in a way of aluminium-based intermediate alloy; adding aluminium ingot and AeSi30 into a gas reflecting furnace, smelting and then adding slag beating agent for stirring and deslagging; then, adding AlTi10 and AlSr10; after 35-35min, adding refining agent for refining under the protection of argon; after refining, horizontally and continuously casting, and forming an aluminium alloy coil rod; and drawing the aluminium alloy coil rod for a plurality of times, and processing continuous disc-shaped welding wires with different specifications. Compared with the prior art, the invention has simple preparation method and easily controlled operation, and obviously reduces the phenomena of volatilization, oxidation and burning loss in the smelting process; and the obtained welding wire has excellent plastic processing performance and mechanical property.

Owner:桂林南箭焊接材料有限公司

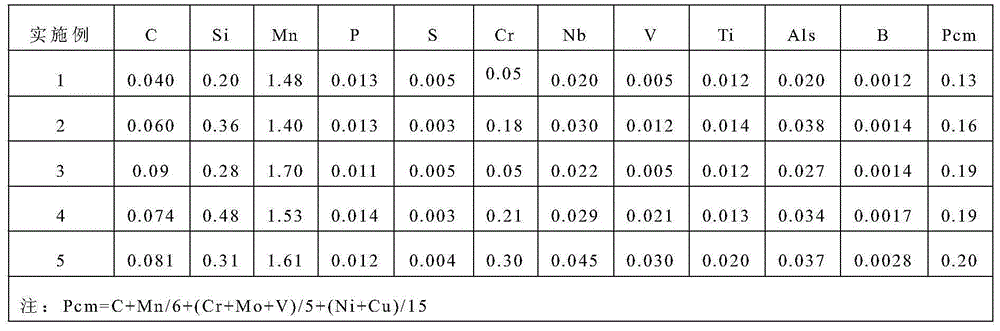

Tensile strength-700MPa level easy-to-weld low-internal-stress structural steel plate and manufacturing method thereof

InactiveCN105200329ASimple chemical compositionImprove low temperature toughnessSheet steelChemical composition

The invention discloses a tensile strength-700MPa level easy-to-weld and low-internal-stress structural steel plate, prepared from the following chemical components according to mass percent: 0.04 to 0.09 percent of C, 0.20 to 0.48 percent of Si, 1.40 to 1.70 percent of Mn, not more than 0.30 percent of Cr, 0.020 to 0.045 percent of Nb, 0.012 to 0.020 percent of Ti, 0.005 to 0.030 percent of V, 0.020 to 0.038 percent of Als, 0.0012 to 0.0028 percent of B, less than 0.015 percent of P, less than 0.006 percent of S, not more than 0.0060 percent of [N], and the balance of Fe and inevitable impurities. The invention also provides a manufacturing method of the tensile strength-700MPa level easy-to-weld and low-internal-stress structural steel plate. The steel plate is simple in chemical component, and has excellent low-temperature toughness and a Pcm not more than 0.20 percent; the expensive alloying elements such as Mo, Cu and Ni are not added, and adding new equipment is also not needed, and the performance of the steel plate produced by controlled rolling and controlled cooling as well as stress removal processing can completely meet the relevant requirements of national standards.

Owner:武钢集团有限公司

Chemical agglomeration promoter

ActiveCN105771531APromote agglomeration and flocculationReduce surface tensionAuxillary pretreatmentDifferential sedimentationChemical compositionCompound (substance)

The invention provides a chemical agglomeration promoter.The chemical agglomeration promoter is prepared from, by mass, 0.001%-0.01% of polyethyleneimine, 0.001%-0.1% of tween-80 and the balance water.The chemical agglomeration promoter is wide in raw material source, low in price, environmentally friendly, simple in chemical composition, simple and fast in synthesis process and free of harm to the environment; the agglomeration effect on fine particulate matter is significant, and the fine particulate matter emission of a coal-fired power plant can be reduced by 60% or above; besides, the chemical agglomeration promoter does not contain acid matter, and thus corrosion to flue equipment can be avoided; moreover, as most toxic heavy metals are gathered on fine particulate matter, heavy metals can be integrally removed with the chemical agglomeration promoter.

Owner:武汉天空蓝环保科技有限公司

Regeneration method for alkali metal poisoned denitration catalyst

InactiveCN106179528AEfficient removalAvoid churnCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsRegenerative processActive component

The invention discloses a regeneration method for an alkali metal poisoned denitration catalyst. After ash removal is carried out, the alkali metal poisoned denitration catalyst is dipped in an ammonium salt aqueous solution; and then a mixed solution is transferred to a microwave reactor to carry out microwave treatment, and filtered, dried and roasted to obtain a regenerated denitration catalyst. The regeneration method for the alkali metal poisoned denitration catalyst disclosed by the invention is simple to operate, short in processing time and better in removal effect for alkali metals on the surface of an inactivated denitration catalyst, and further can remove most of calcium compounds on the catalyst. Furthermore, active components of the denitration catalyst are not lost greatly in the regenerative process.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

High-toughness gas protective welding wire for large-linear energy welding low-alloy steel

InactiveCN101658983APromote formationImprove purification effectWelding/cutting media/materialsSoldering mediaElectric arc furnaceChemical composition

The invention relates to a high-toughness gas protective welding wire for large-linear energy welding low-alloy steel. The technical scheme is that the welding wire comprises the following chemical components in percentage by weight: 0.02-0.12 percent by weight of C, 1.00-2.50 percent by weight of Mn, 0.05-0.50 percent by weight of Si, 0.03-0.30 percent by weight of Ti, 0.001-0.004 percent by weight of B, less than or equal to 0.50 percent by weight of Cr, less than or equal to 0.5 percent by weight of Mo, less than or equal to 0.025 percent by weight of S, less than or equal to 0.025 percentby weight of P, 0.03-0.3 percent by weight of two or three kinds of Ca, Mg and Ba and the balance of Fe and inevitable impurities. The high-toughness gas protective welding wire is manufactured by thefollowing steps: carry out steel making on molten iron or scrap steel or the molten iron and the scrap steel by adopting a converter or an electric arc furnace, and then refining and adjusting molteniron components, casting into square billets, and then rolling into coil rods and cold-drawing into welding wires by conventional processes. The prepared welding material has good metal welding toughness and high tensile strength and is suitable for the welding of low-alloy high-strength steel under the condition of large-linear energy welding condition of 100-800kj / cm.

Owner:WUHAN UNIV OF SCI & TECH

Five hundred and ninety Mpa-grade dual-phase steel and production method thereof

InactiveCN103088258AImprove toughnessReduce strength differenceTemperature control deviceAlloyContinuous rolling

The invention discloses 590Mpa-grade dual-phase steel and a production method thereof. The 590Mpa-grade dual-phase steel comprises the following components in percentage by mass: less than or equal to 0.20% of C, less than or equal to 1.80% of Si, less than or equal to 2.00% of Mn, less than or equal to 0.050% of P, less than or equal to 0.015% of S, less than or equal to 0.10% of Nb, and less than or equal to 0.10% of Ti; and the production method comprises the steps of pretreatment of hot metal, smelting in a converter, fine adjustment of alloy, smelting in a refined-smelting ladle furnace, continuous casting and hot continuous rolling, wherein according to the hot continuous rolling, heating temperature is 1150-1250 DEG C, finish rolling temperature is 800-900 DEG C, the rolled steel is rapidly cooled to 650-750 DEG C, and air cooling is carried out for 6-11 seconds, the steel is rapidly cooled to a target coiling temperature, and the coiling temperature is 400-500 DEG C. According to the production method, the accuracy control and proportioning of ferrite and bainite are realized through appropriate components and process control, the strength difference of soft and hard of the material can be reduced, a soft and hard two-phase interface is eliminated, and the product has excellent strength-ductility and toughness matching property and good stretching and flanging property.

Owner:MAANSHAN IRON & STEEL CO LTD

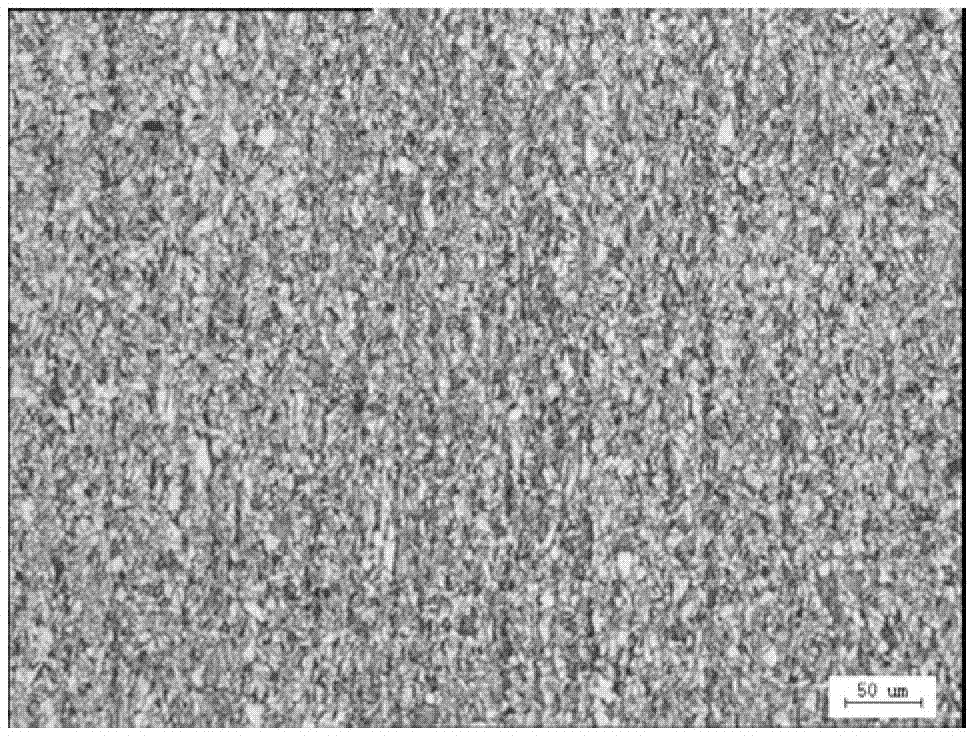

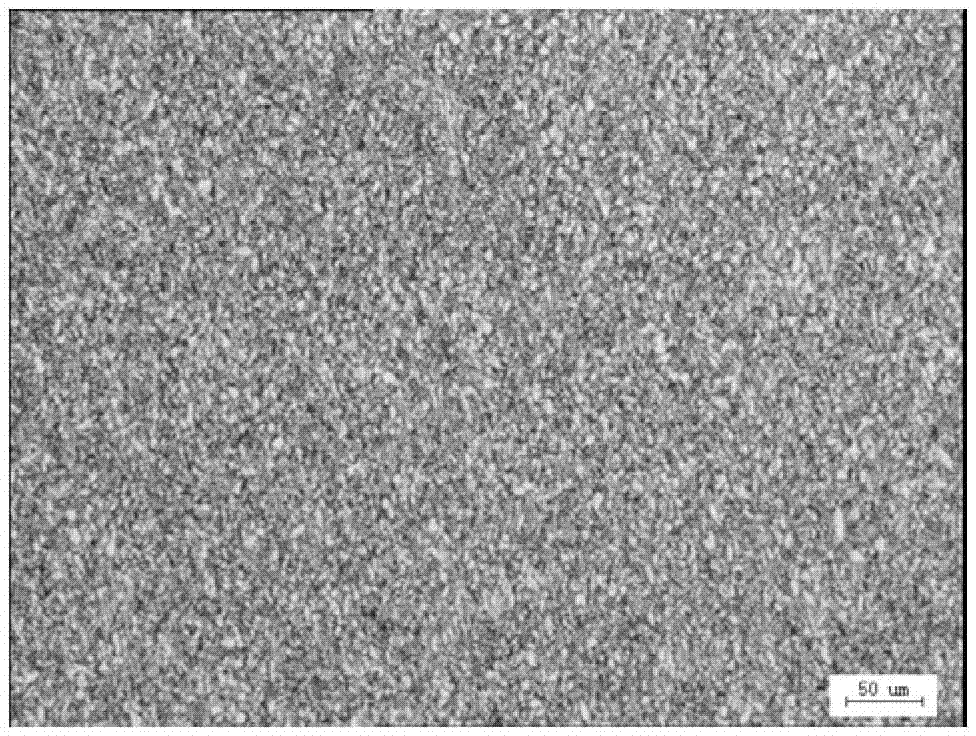

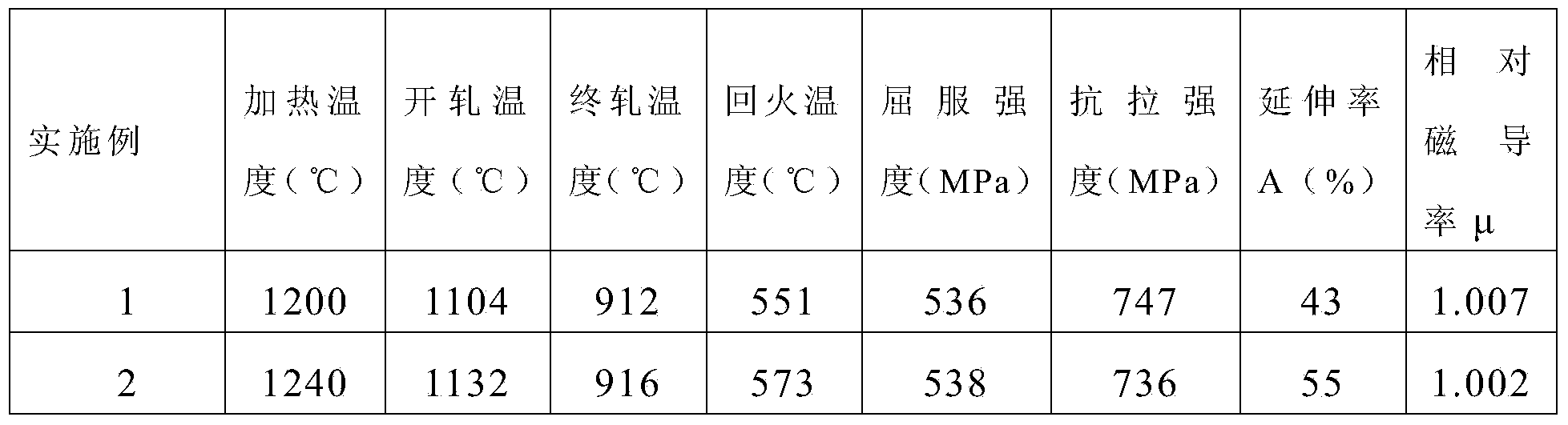

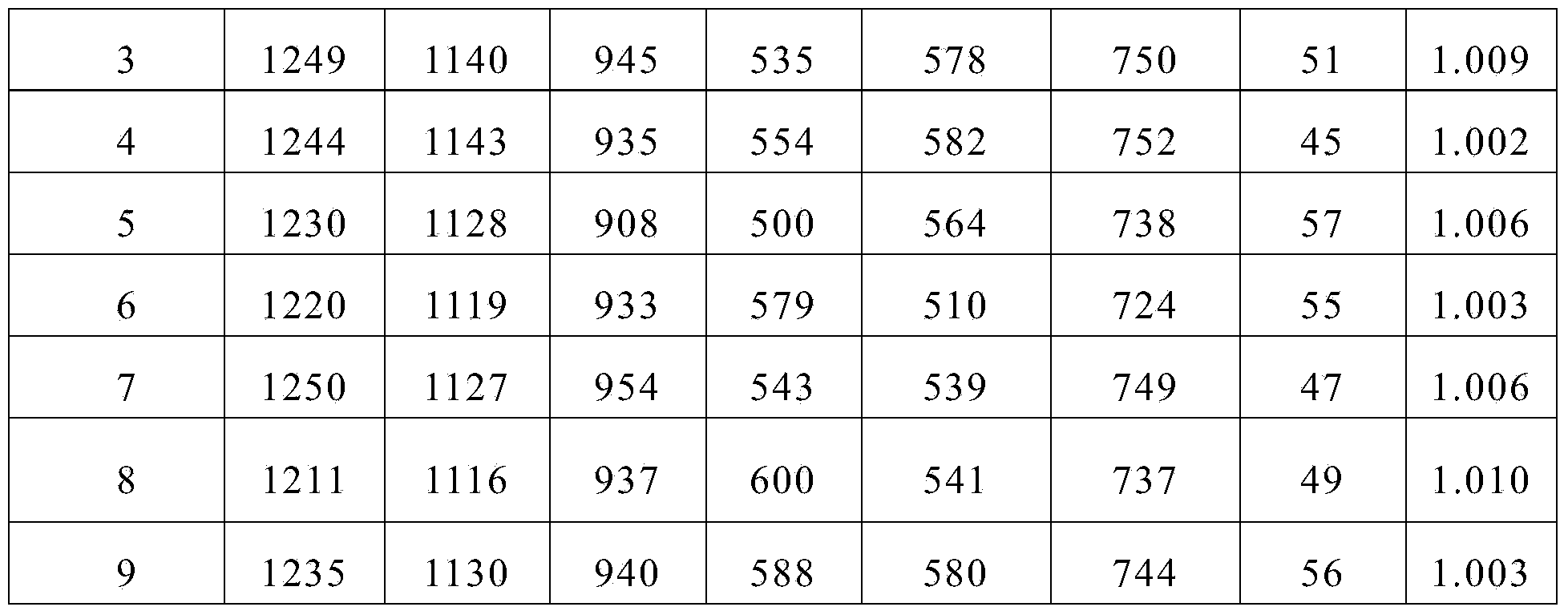

High-strength vanadium-containing high-manganese non-magnetic steel and production method thereof

The invention discloses high-strength vanadium-containing high-manganese non-magnetic steel and a production method thereof. The steel comprises the following chemical components by weight: 0.15 to 0.25% of C, 0.2 to 0.4% of Si, 18 to 20% of Mn, no more than 0.015% of P, no more than 0.010% of S, 0.5 to 1.0% of V, with the balance being Fe and unavoidable impurities. The production method is carried out according to common technology for clean steel and comprises the following steps: electric furnace smelting; ladle furnace refining; vacuum treatment; bottom-pouring die casting; casting blank heating; rolling; tempering; and air cooling. The steel has yield strength of no less than 500 MPa, tensile strength of no less than 700 MPa, elongation percentage A of no less than 40% and relative permeability mu of no more than 1.05 and is applicable to manufacturing of equipment like transformers and generators. Meanwhile, the steel has the advantages of simple chemical components, low cost, easy production and operation, high production efficiency and substantial economic benefits and social benefits.

Owner:武汉钢铁有限公司

Hull structural steel with excellent welding performance and producing method thereof

InactiveCN101250664ASimple chemical compositionEasy to operateTemperature control deviceHull structureChemical composition

The invention discloses a hull structure steel with excellent welding performance and the manufacturing method thereof, which belongs to the manufacturing field of low-carbon low-alloy high strength steel, and hull structure steel with excellent welding performance can be manufactured through utilizing the invention. According to the percentage by weight, the chemical components of the steel comprise C 0.05-0.25%, Si 0.01-1.0%, Mn 0.50-2.0%, P<=0.020%, S<=0.010%, Ti 0.005-0.10%, Nb 0.005-0.10%, and others are Fe and unavoidable impurities, and the chemical components satisfy the following relationship: firstly, 0.015%<=C*Si<=0.075%, secondly, 0.095%<=C*Mn<=0.15%, thirdly, 0.0003%<=Nb*Ti<=0.0005%. The specific manufacturing method comprises the following steps: heating bar plates, roughly rolling, finish rolling, water cooling and air cooling. The steel has high welding performance and mechanical property, and does not contain alloy elements such as Ni, Mo and the like, the manufacturing process is easy to control, and the operation is simple.

Owner:武钢集团有限公司

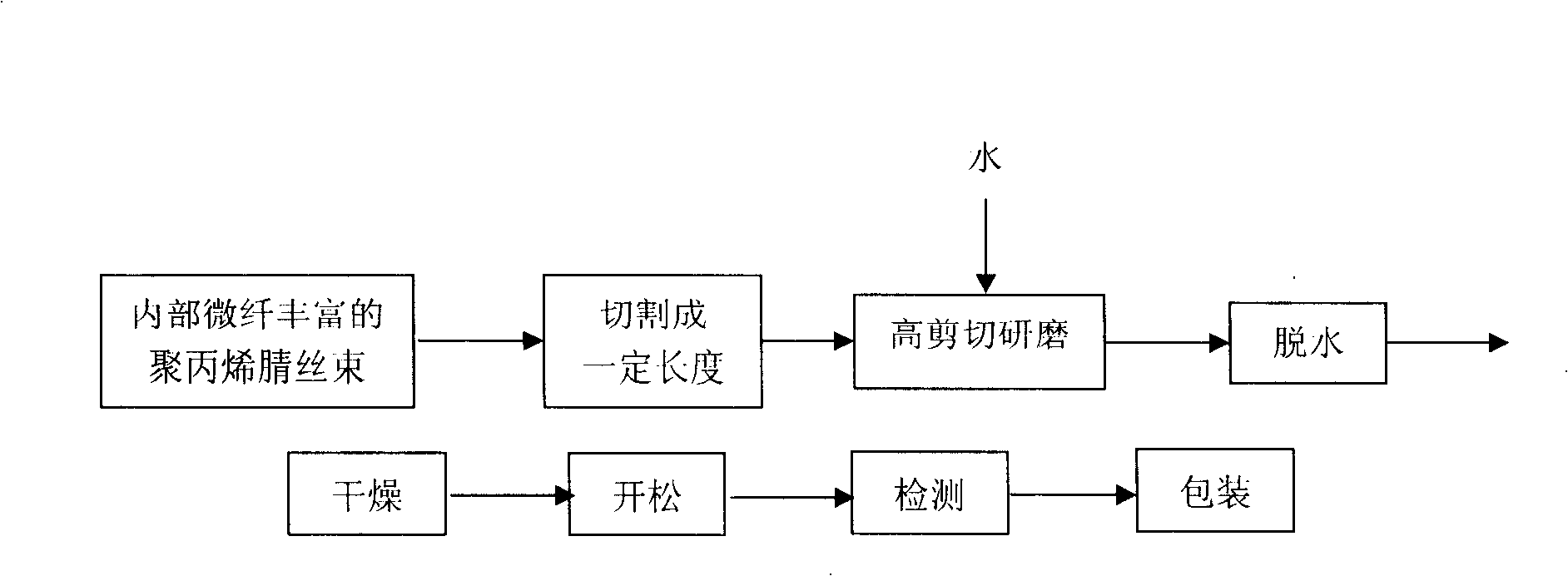

Method for consciously producing polyacryl-nitrile dissolving pulp-like fibre

InactiveCN101280470AEliminate separate processesEfficient productionFilament manufactureWet spinning methodsPapermakingSlurry

The invention relates to a continuous manufacturing method of polypropylene fiber pulp (hereafter referred to as acrylic pulp). Apart from the excellent environment adaptability and the chemical reagents corrosion resistance of acrylic, the acrylic pulp also has the characteristics of a high degree of fibrillation and easy dispersion in aqueous phase, which can replace asbestos and used in friction, sealing materials, papermaking and other filed with a wide range of applications. The invention is in the use of two polyacrylonitrile polymers comprising the same monomer structure with different proportions for the blending wet spinning. In the solidification process, the micro-phase separation of the mixed slurry of the polymers occurs, thus the polypropylene fiber pulp, in which the appearance is the same as the general fiber bundles while the internal micro-fiber is very rich, is formed. After the bundle is cut off, the short chopped fibers and water are transmitted and pumped into a grinding equipment at the same time, which are in the continuous dispersion and grinding under a high shear rate to be in the formation of the polypropylene fiber pulp with a uniform structure, rich hairiness on the appearance and a high degree of fibrillation. The whole process is continuous and simple with low energy consumption.

Owner:SHANGHAI LABON TECHNICAL FIBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com