Tensile strength-700MPa level easy-to-weld low-internal-stress structural steel plate and manufacturing method thereof

A technology of tensile strength and structural steel plate, applied in the field of low-alloy high-strength steel production, can solve the problems of steel plate size out of tolerance, damage to cutting equipment, and affect use, and achieve the effect of excellent low-temperature toughness and simple chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

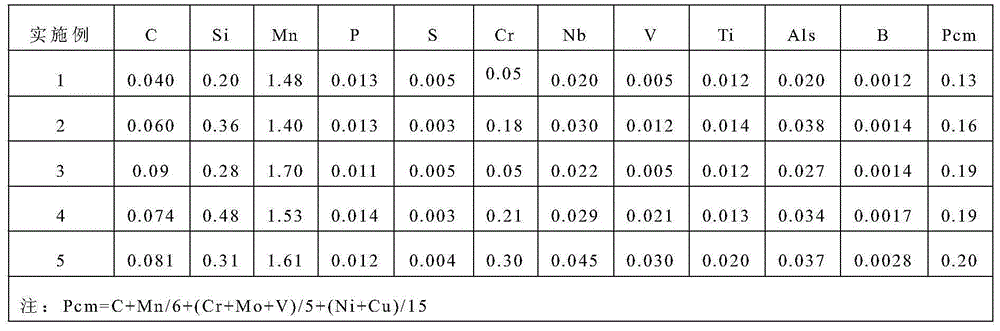

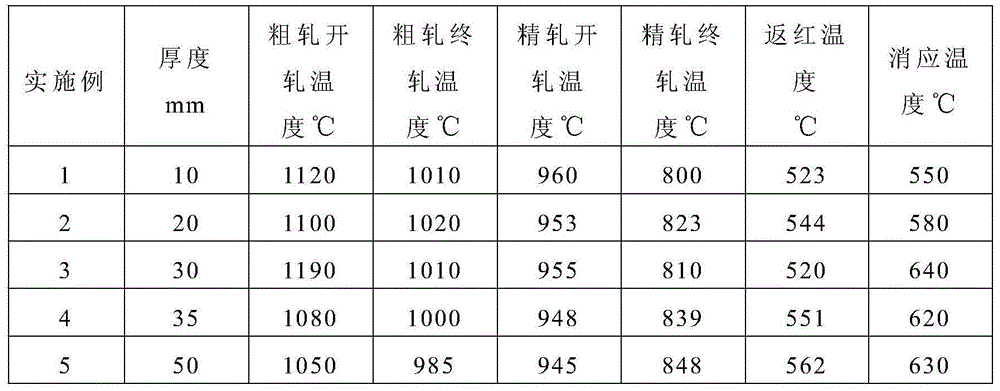

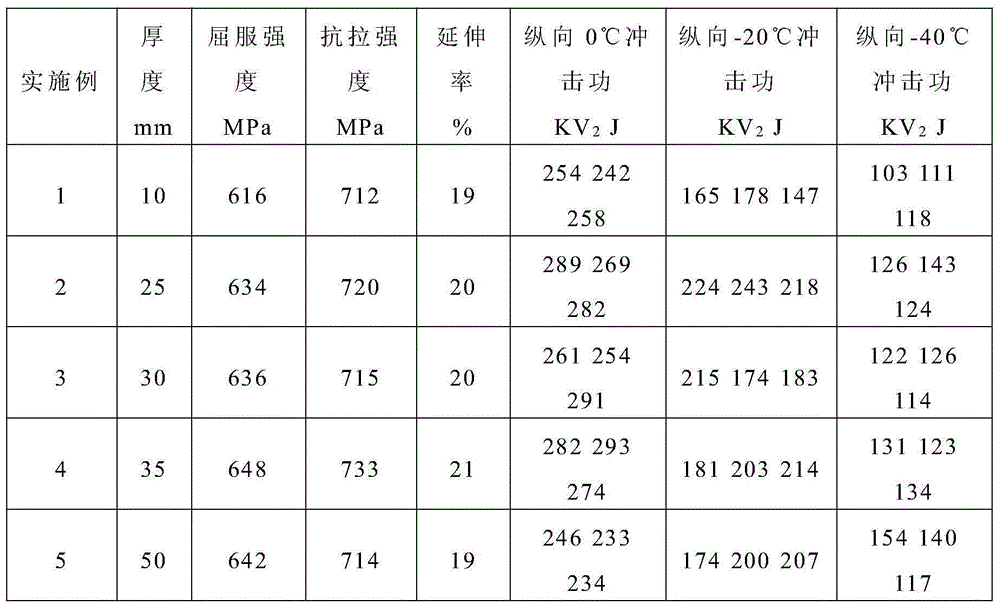

[0035] According to the chemical composition and production process of the present invention, the actual chemical composition of the smelted steel of the present invention is shown in Table 1, the actual process parameters of the present invention to produce steel plates of various specifications are shown in Table 2, and the performance results of the steel plates are shown in Table 3.

[0036] The smelting composition (wt %) of steel grade of the present invention of table 1

[0037]

[0038] The actual technological parameter of table 2 steel example of the present invention

[0039]

[0040] The mechanical property of table 3 steel plate of the present invention

[0041]

[0042] The mechanical property of table 4 steel plate of the present invention

[0043]

[0044] As can be seen from Table 3, the indicators of the steel plates of various specifications produced by the present invention reach: yield strength ≥ 550MPa, tensile strength ≥ 700MPa, elongation ≥...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com