Hull structural steel with excellent welding performance and producing method thereof

A technology of welding performance and production method, which is applied in the field of low-carbon low-alloy high-strength steel manufacturing, can solve problems such as poor welding performance and mechanical performance, complicated production process, and high price, and achieve excellent welding performance, excellent mechanical performance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

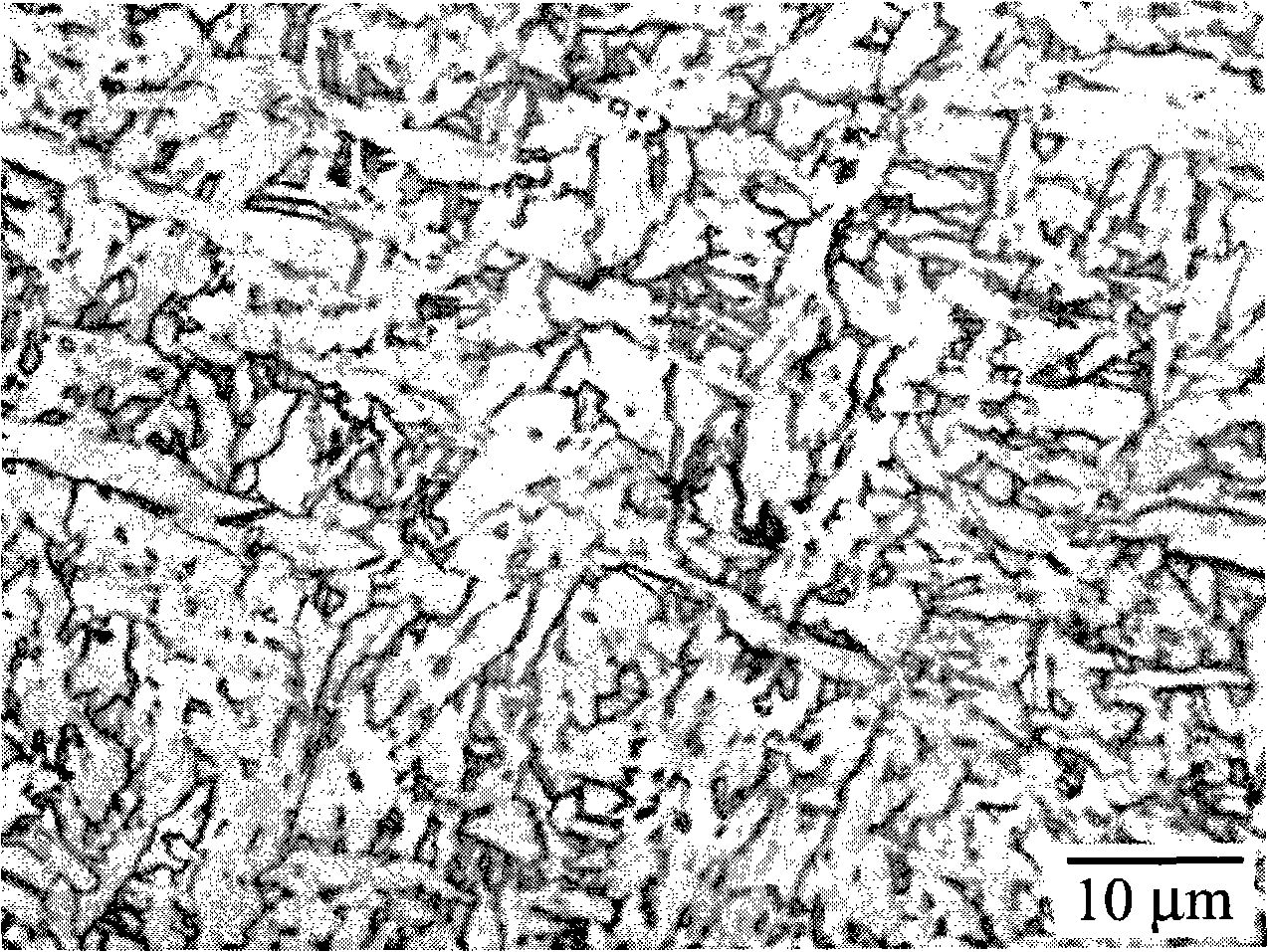

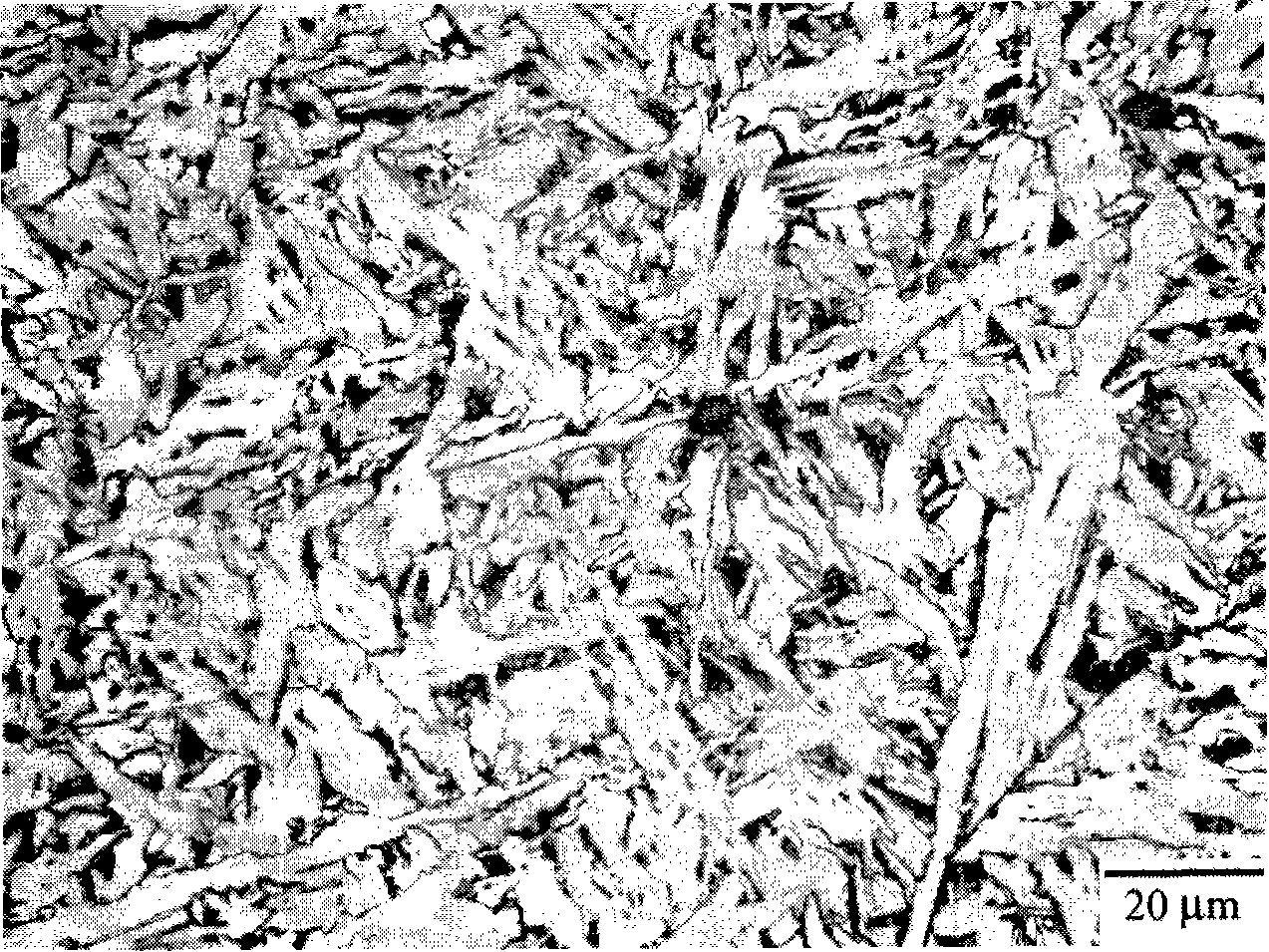

Image

Examples

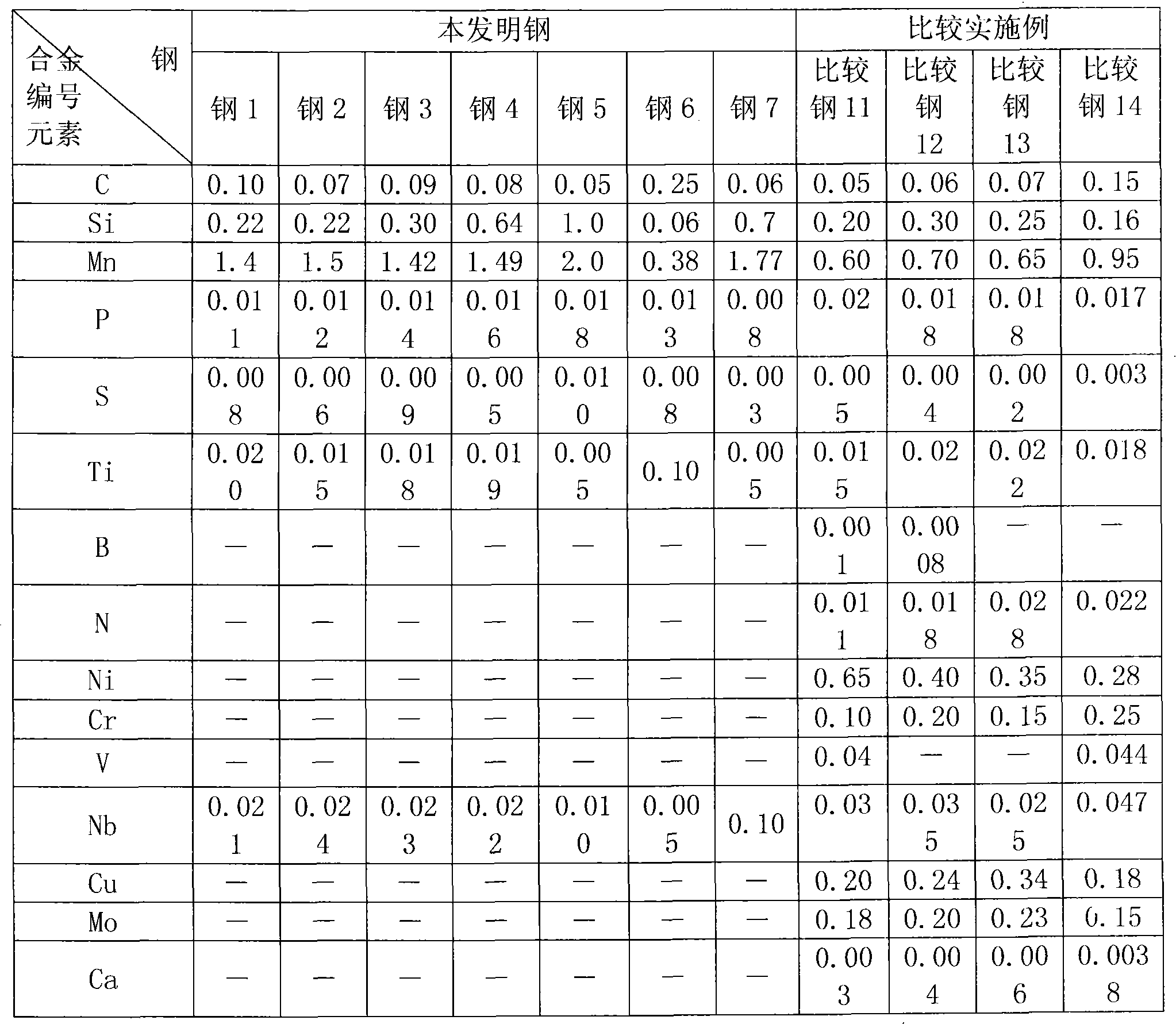

Embodiment 1

[0046] According to the production method of the present invention, steel 1 is produced, and its chemical composition is shown in steel 1 in table 1. The concrete parameter control of the production method is shown in steel 1 in table 2, and its mechanical properties are shown in steel 1 in table 3. See steel 1 in Table 4 for the mechanical properties and fracture locations of the heat-affected zone after electric vertical welding.

Embodiment 2

[0048] According to the production method of the present invention, steel 2 is produced, and its chemical composition is shown in steel 2 in table 1. The concrete parameter control of the production method is shown in steel 2 in table 2, and its mechanical properties are shown in steel 2 in table 3. See steel 2 in Table 4 for the mechanical properties and fracture locations of the heat-affected zone after electric vertical welding.

Embodiment 3

[0050] According to the production method of the present invention, steel 3 is produced, and its chemical composition is shown in steel 3 in table 1. The concrete parameter control of the production method is shown in steel 3 in table 2, and its mechanical properties are shown in steel 3 in table 3. See steel 3 in Table 4 for the mechanical properties and fracture locations of the heat-affected zone after electric vertical welding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com