Chemical agglomeration promoter for removing fire coal fine particulate matters and application method of chemical agglomeration promoter

A technology of fine particles and chemical agglomeration, applied in chemical instruments and methods, separation methods, dispersion particle separation, etc., can solve problems such as unsuitable for large-scale industrial production, complex composition of agglomerating agent solution, limited agglomeration efficiency, etc., to achieve agglomeration Significant, inexpensive, solubility-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of the agglomeration accelerator: add industrial water into the mixing container, and then add polydimethyldiallylammonium chloride under constant stirring. After the polydimethyldiallylammonium chloride is completely dissolved, then Add sorbitan fatty acid ester, and then stir until completely dissolved.

[0015] The agglomeration promoter is stored separately according to different components before mixing, or it can be prepared as a high-concentration solution according to the proportion (diluted with industrial water according to the proportion when used). But the time should not be too long, one week is appropriate.

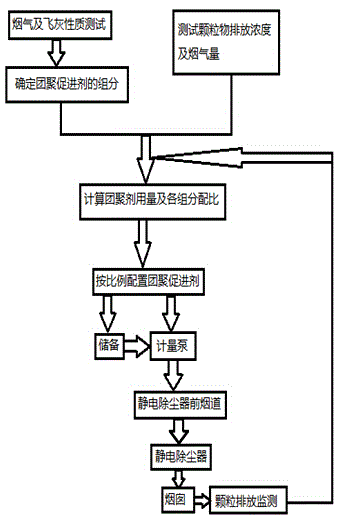

[0016] Carry out chemical agglomeration technical transformation for dust removal equipment in power plants, steel plants, and cement plants, adjust the ratio of different components of the agglomeration accelerator according to different flue gas conditions and characteristics of coal-fired fly ash, determine the amount of agglomera...

Embodiment 1

[0019] Polydimethyldiallylammonium chloride: 0.001%

[0020] Sorbitan fatty acid ester: 0.001%

[0021] The rest is water.

Embodiment 2

[0023] Polydimethyldiallylammonium chloride: 0.005%

[0024] Sorbitan fatty acid ester: 0.01%

[0025] The rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com